Axial Load Transfer Mechanisms in Fully Grouted Fibreglass Rock Bolts: Experimental and Numerical Investigations

Abstract

1. Introduction

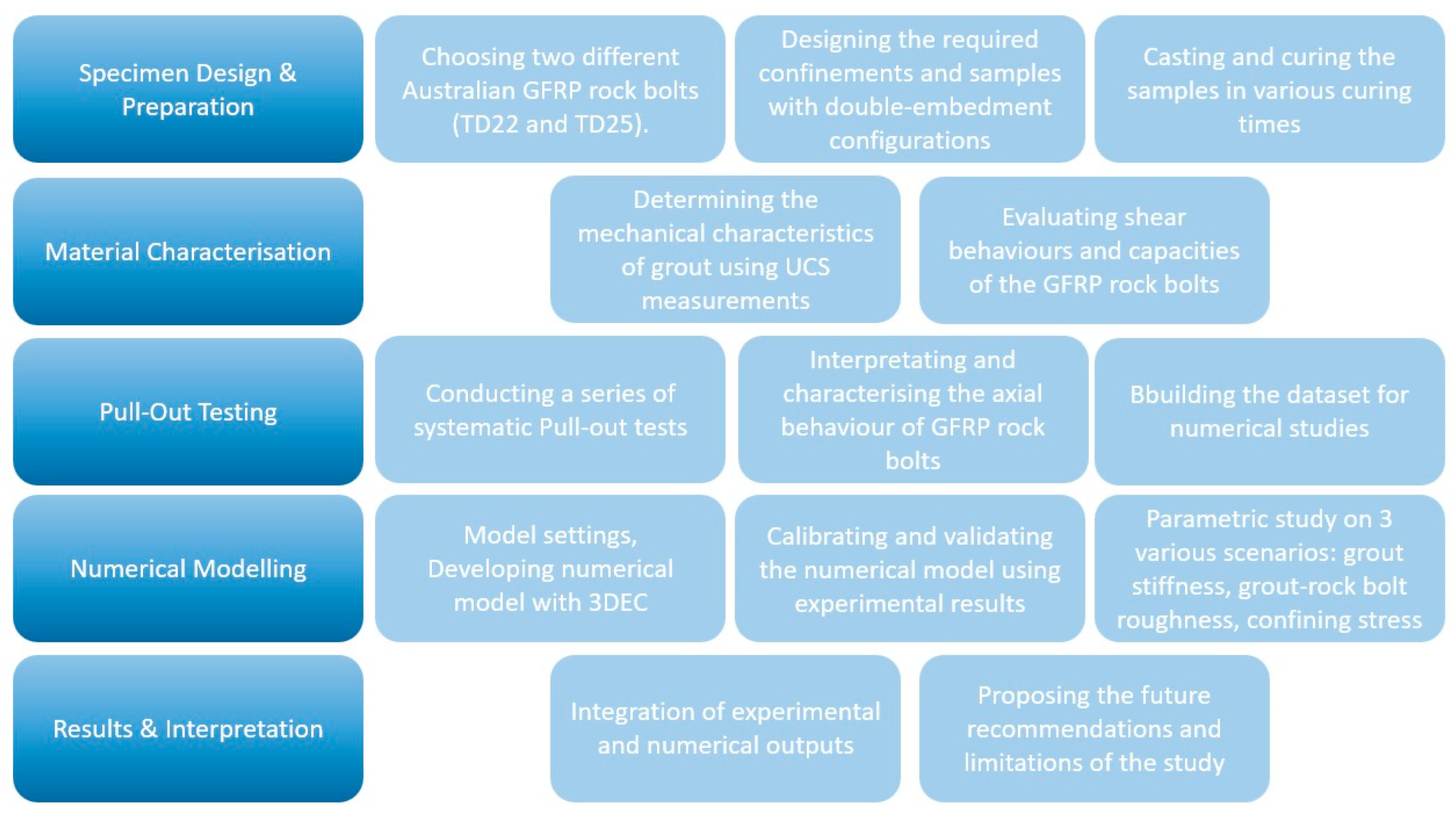

2. Materials and Methods

2.1. Experimental Design

2.2. Materials

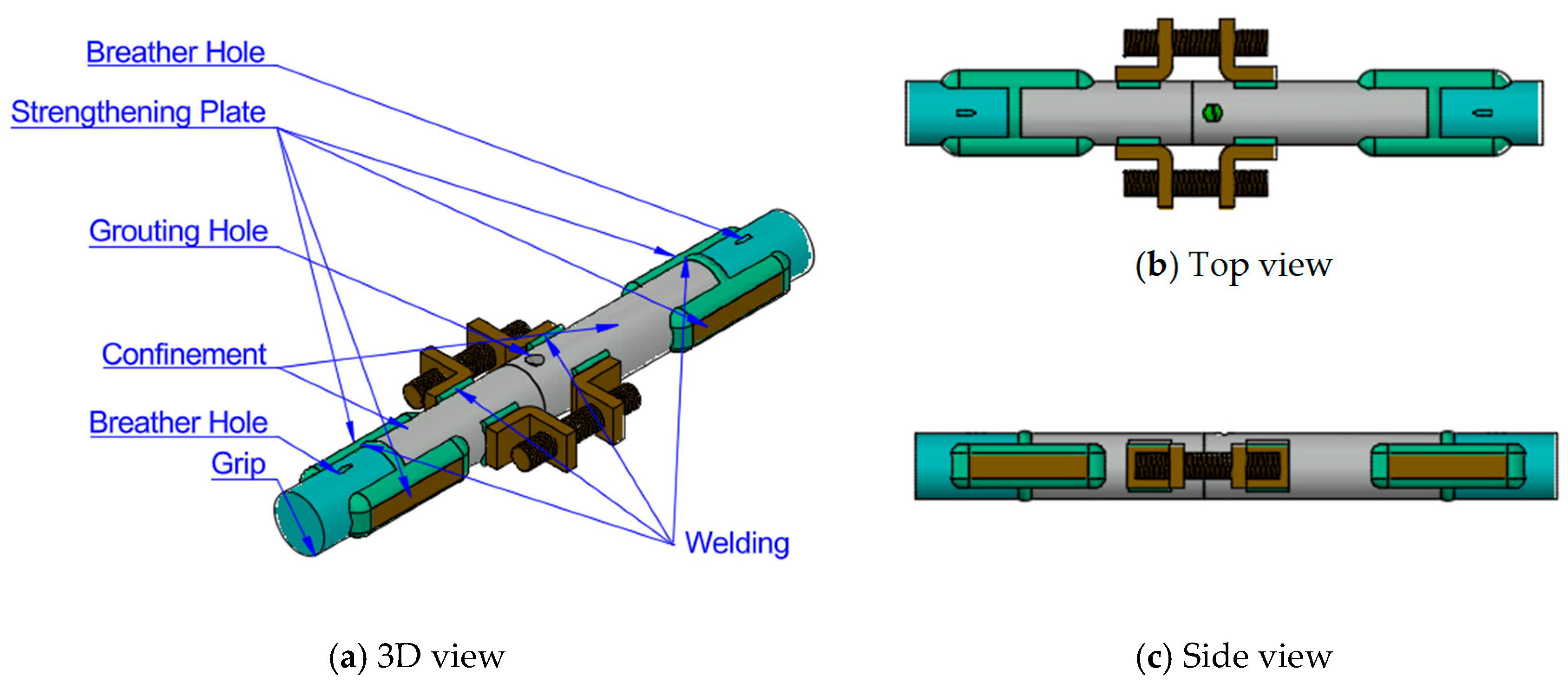

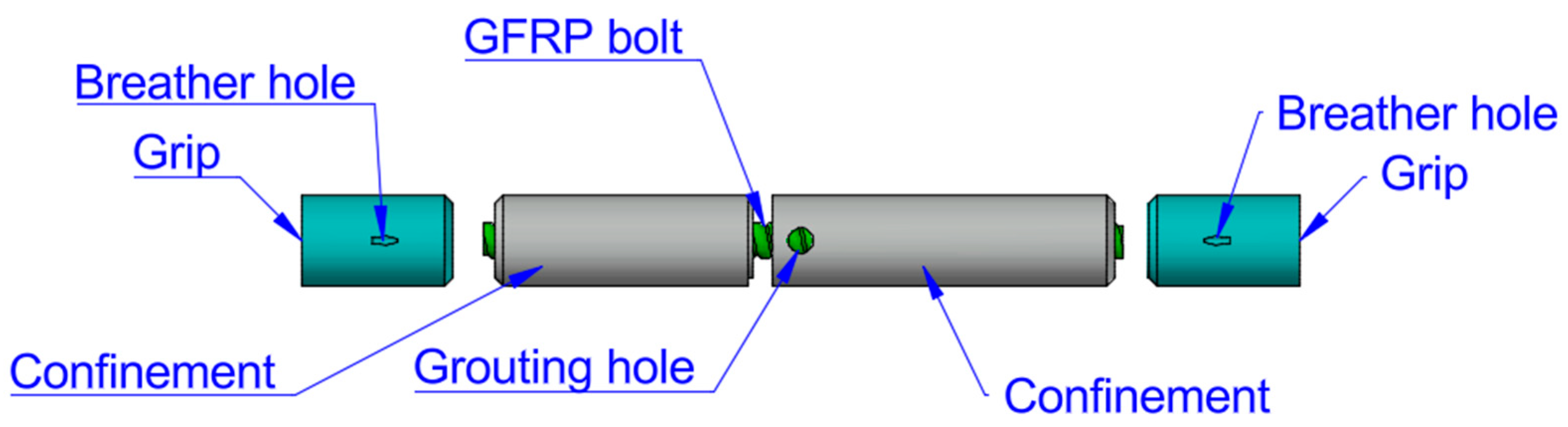

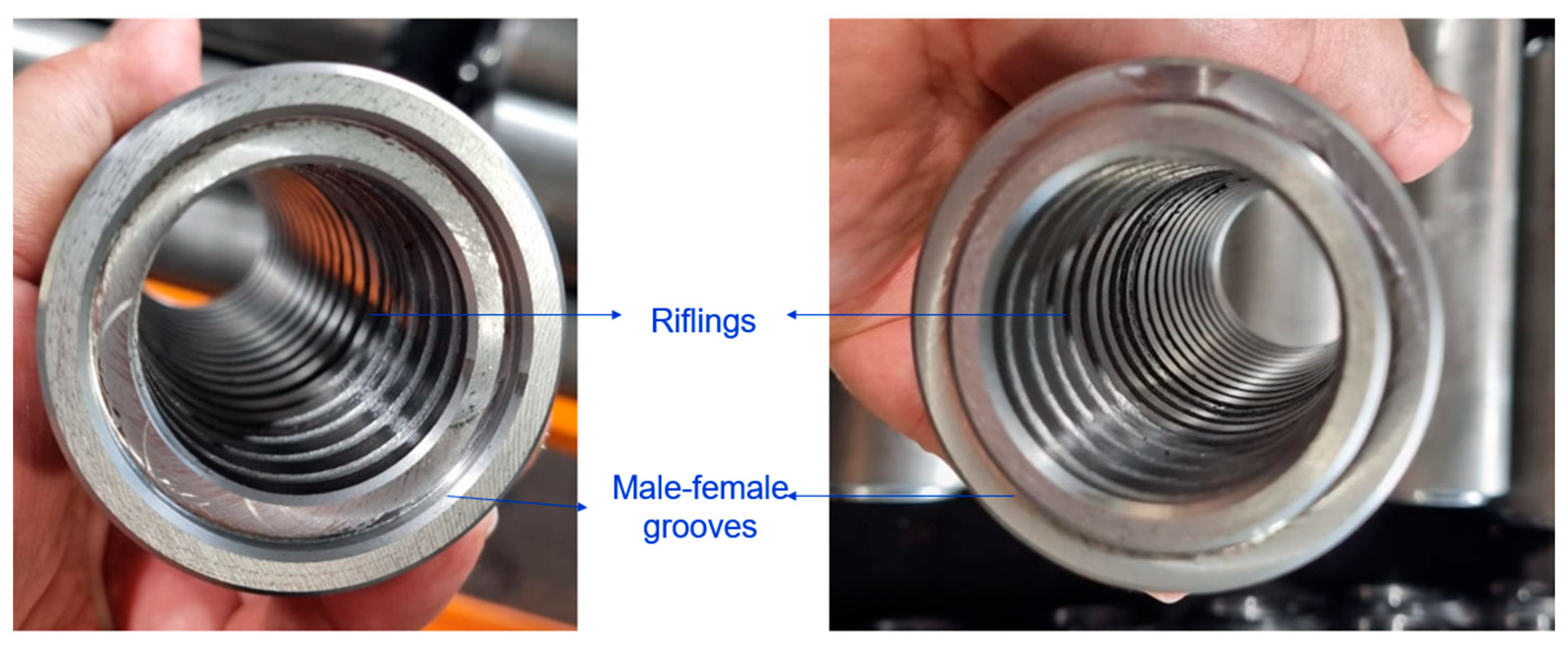

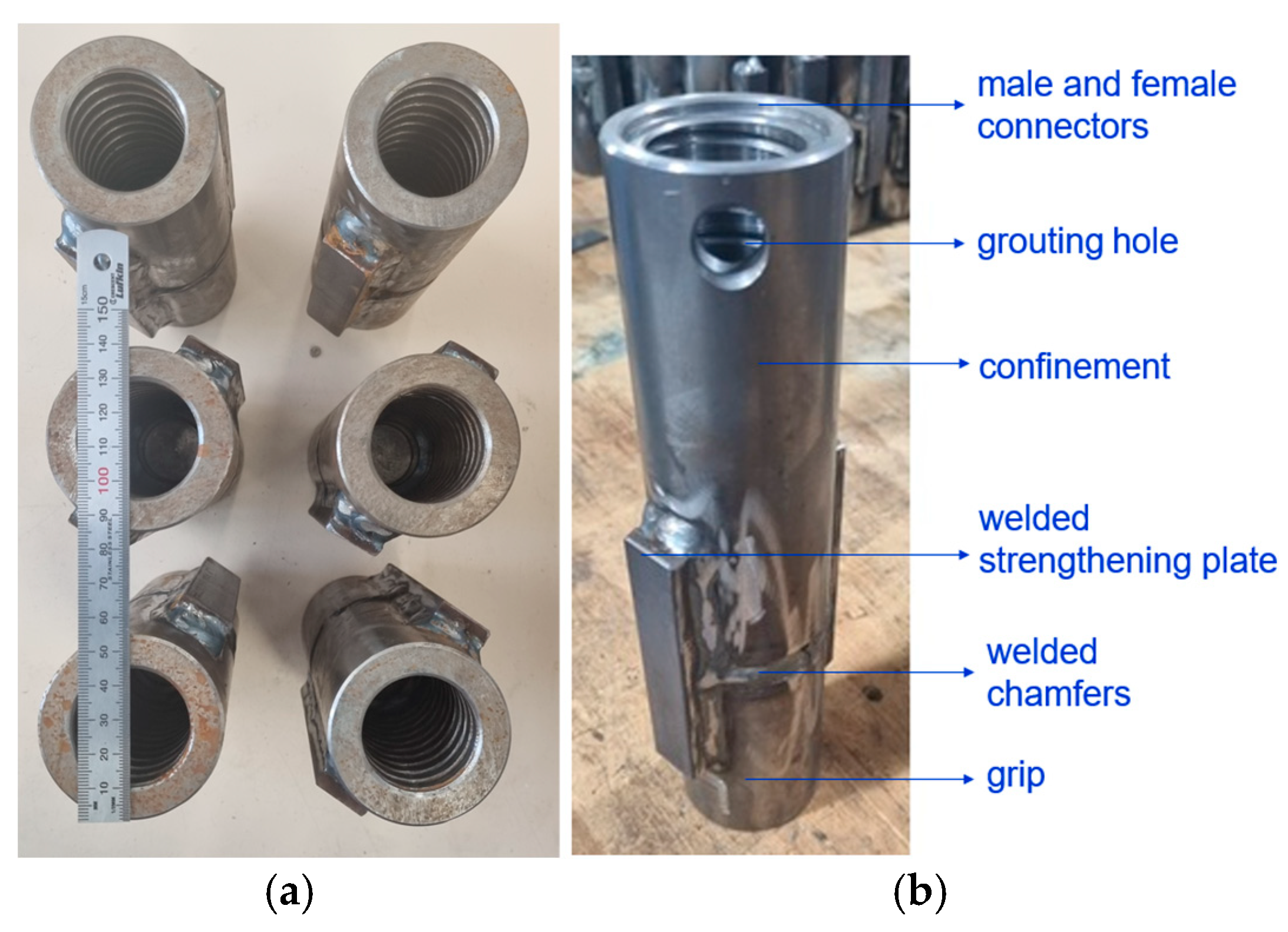

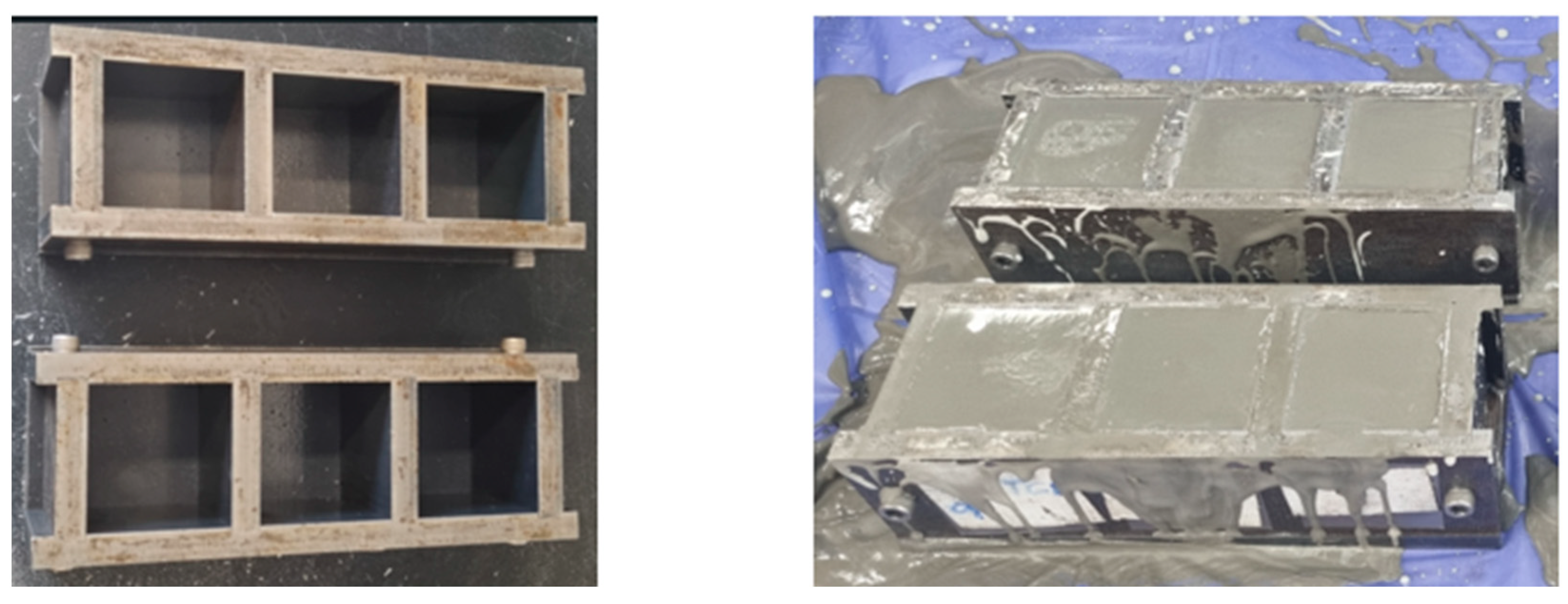

2.2.1. Designing and Manufacturing the Required Confinements

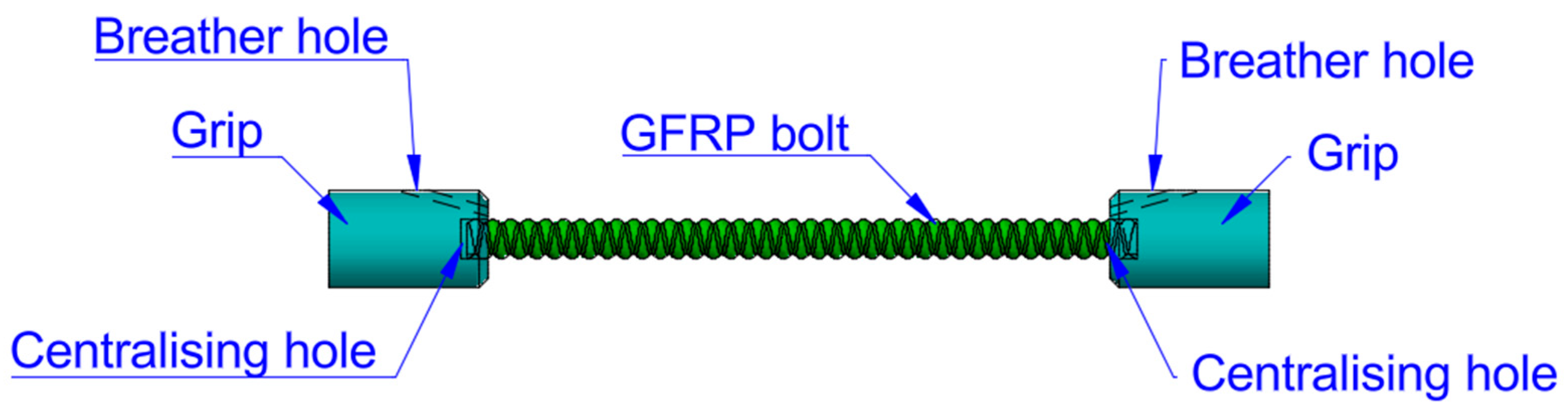

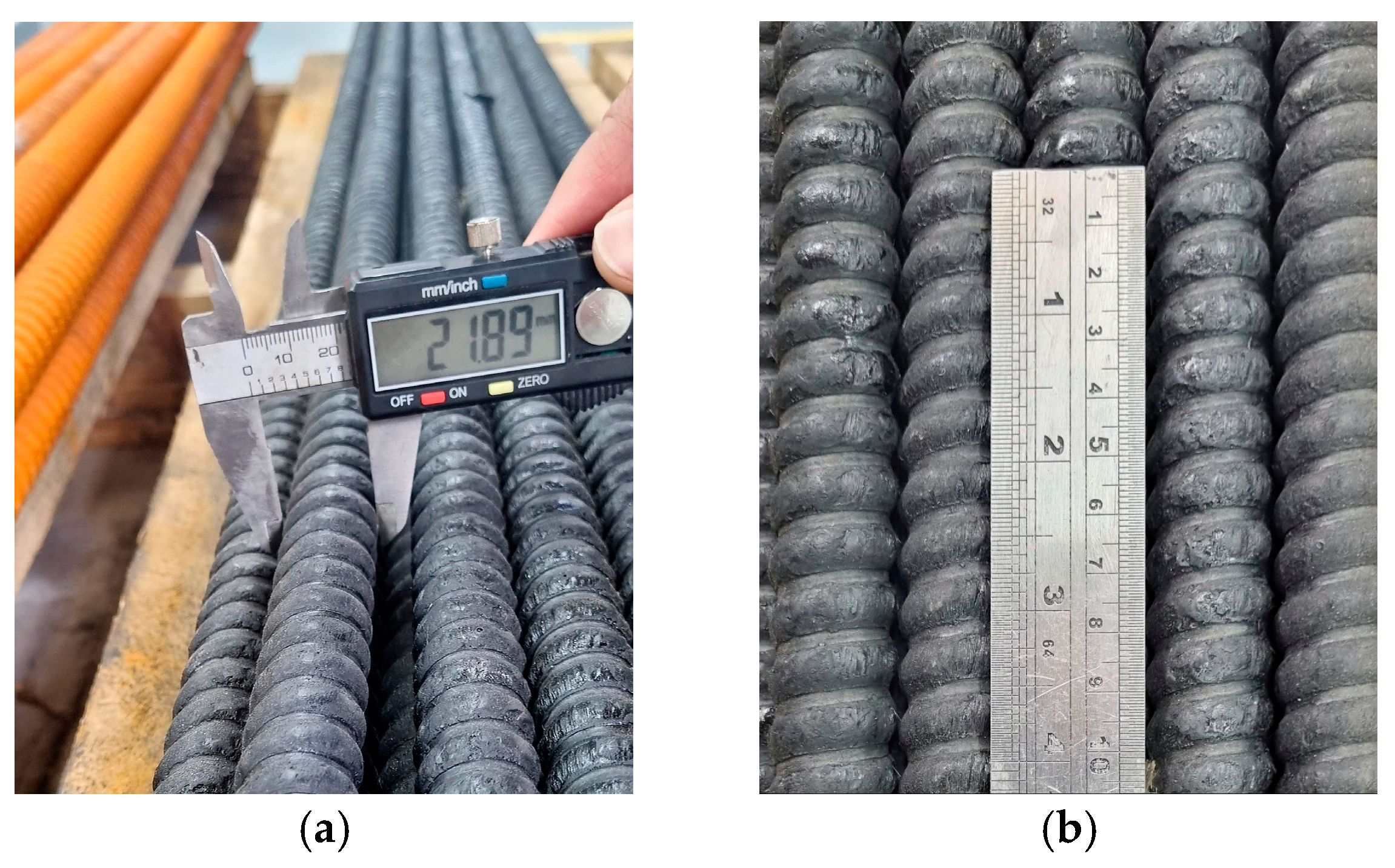

2.2.2. Fibreglass Bars

2.2.3. Bonding Medium

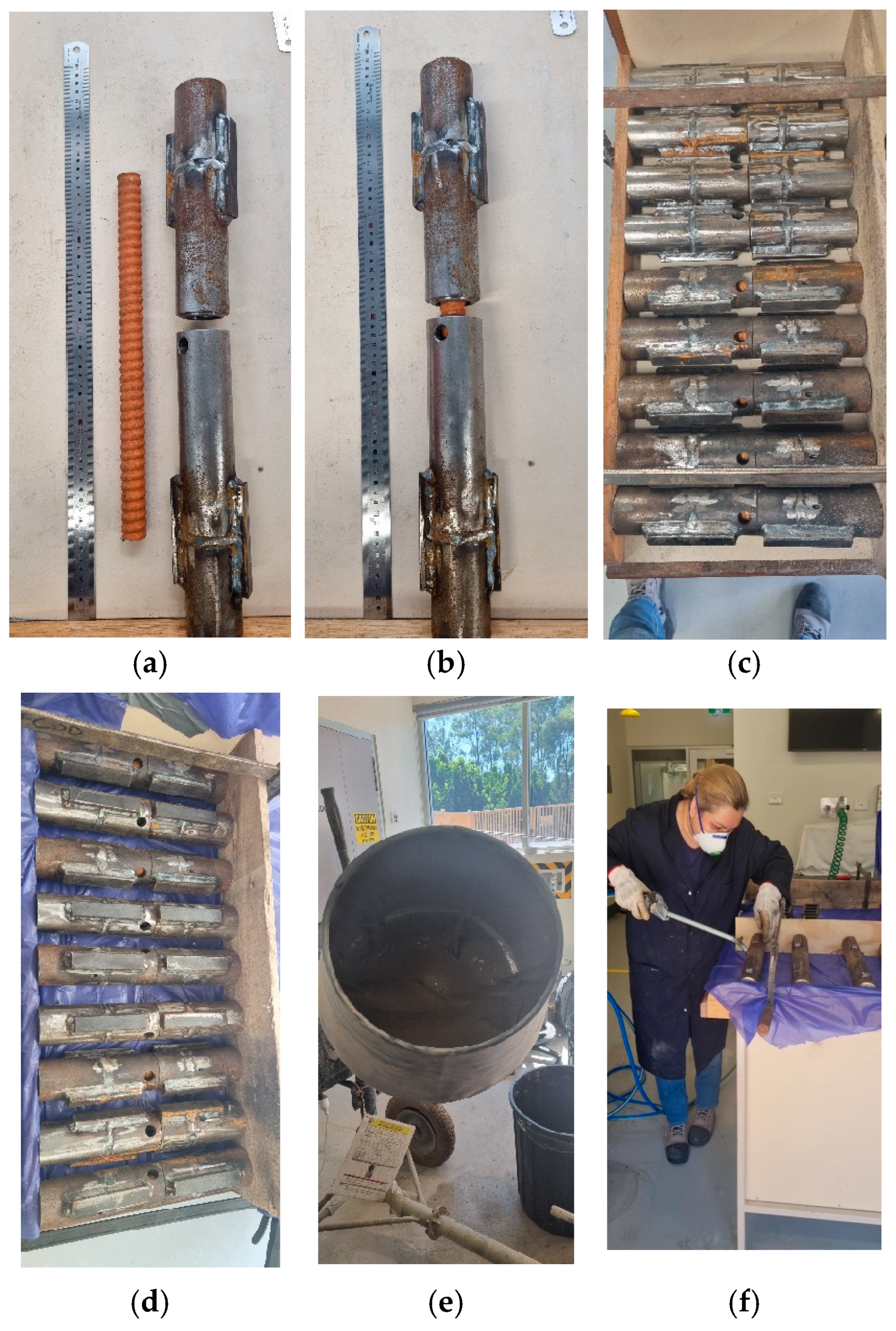

2.3. Casting Procedure

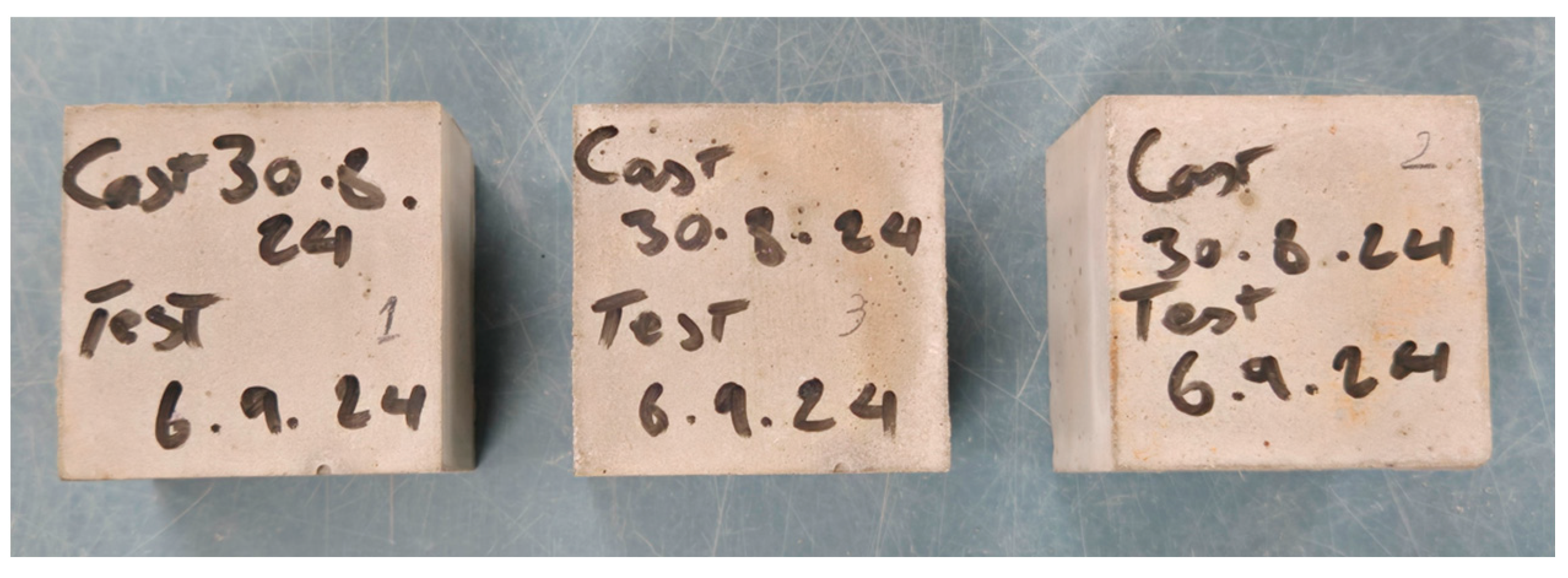

2.4. Material Property Tests

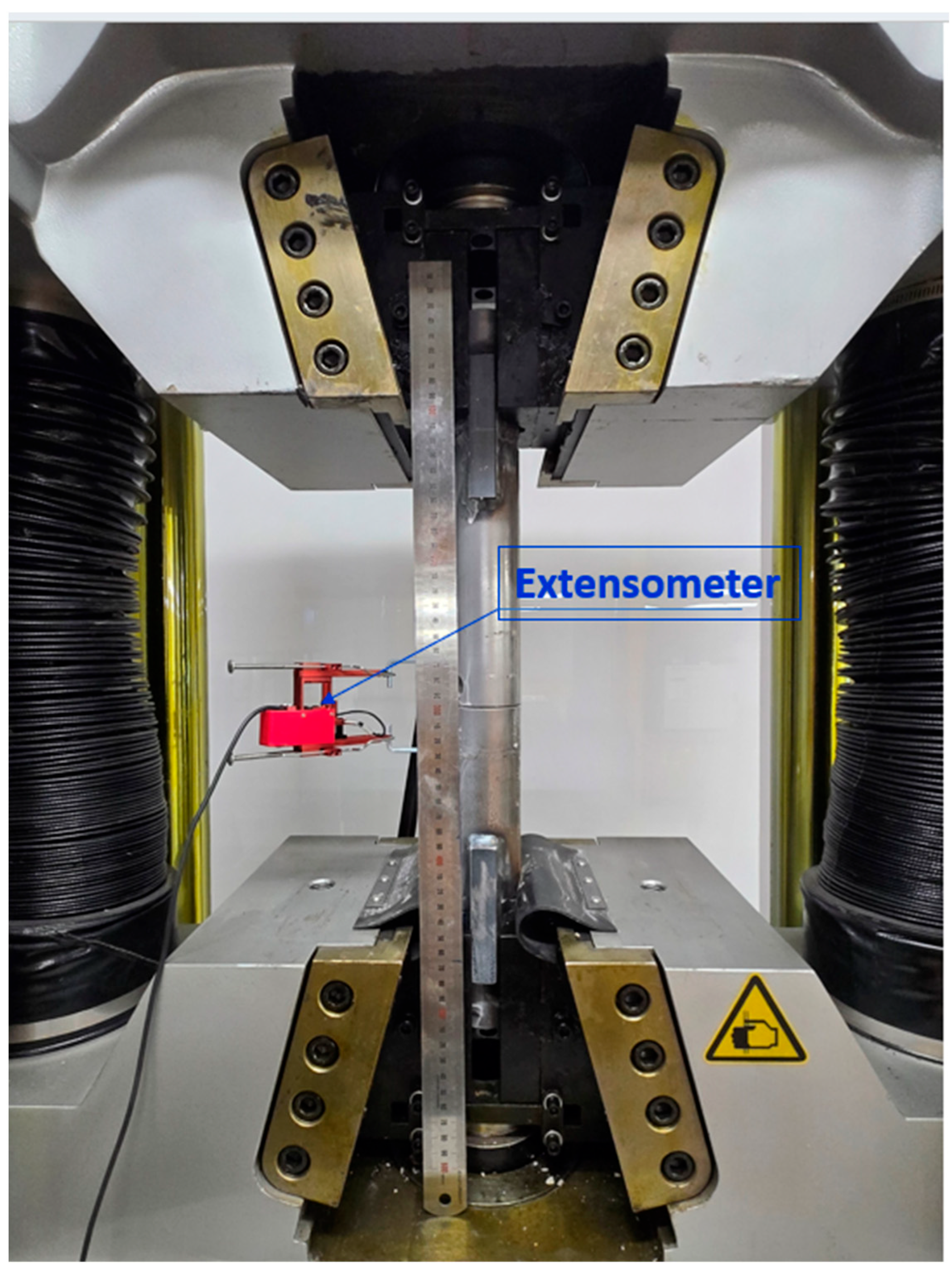

2.4.1. Shear Tests

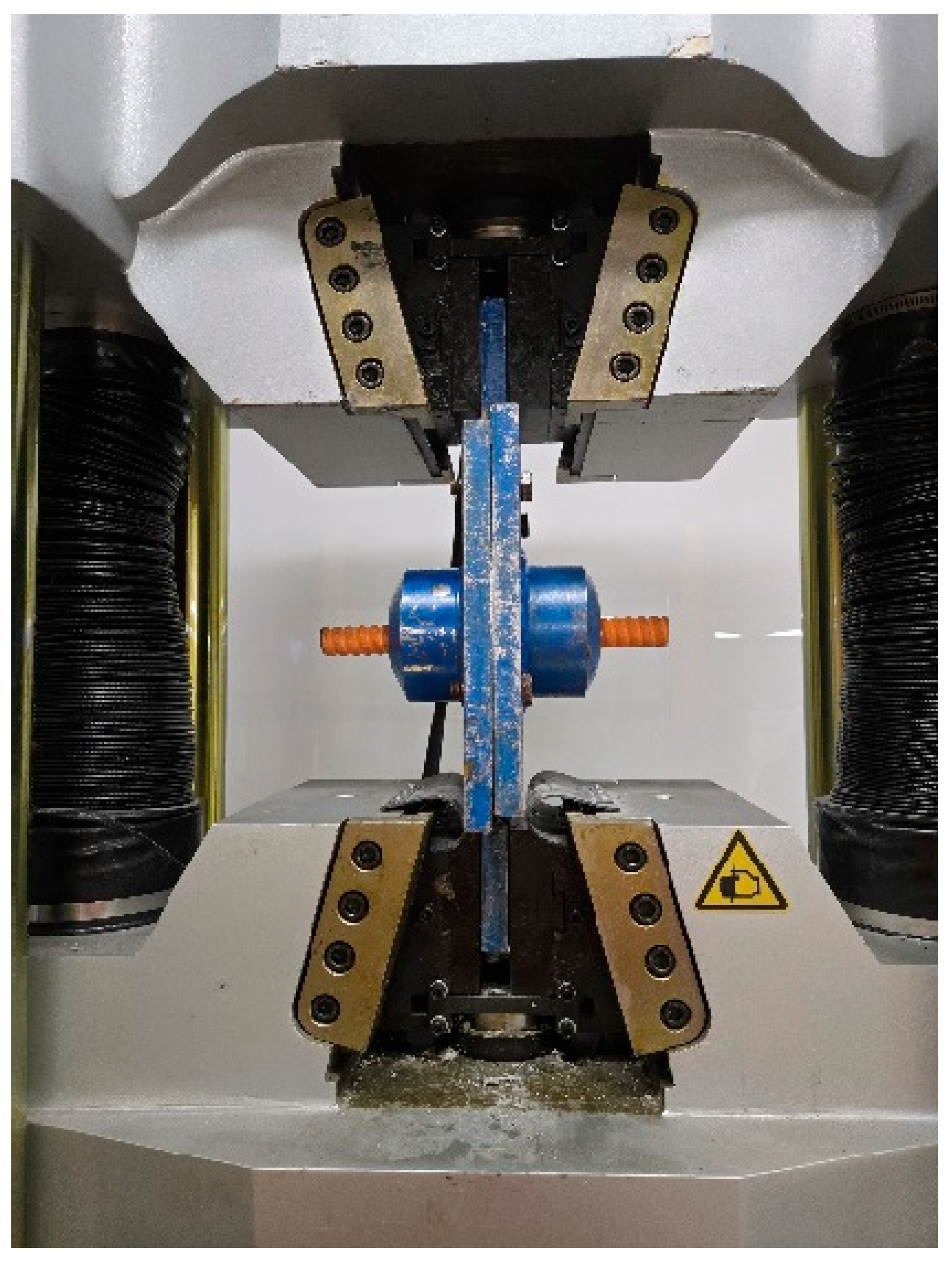

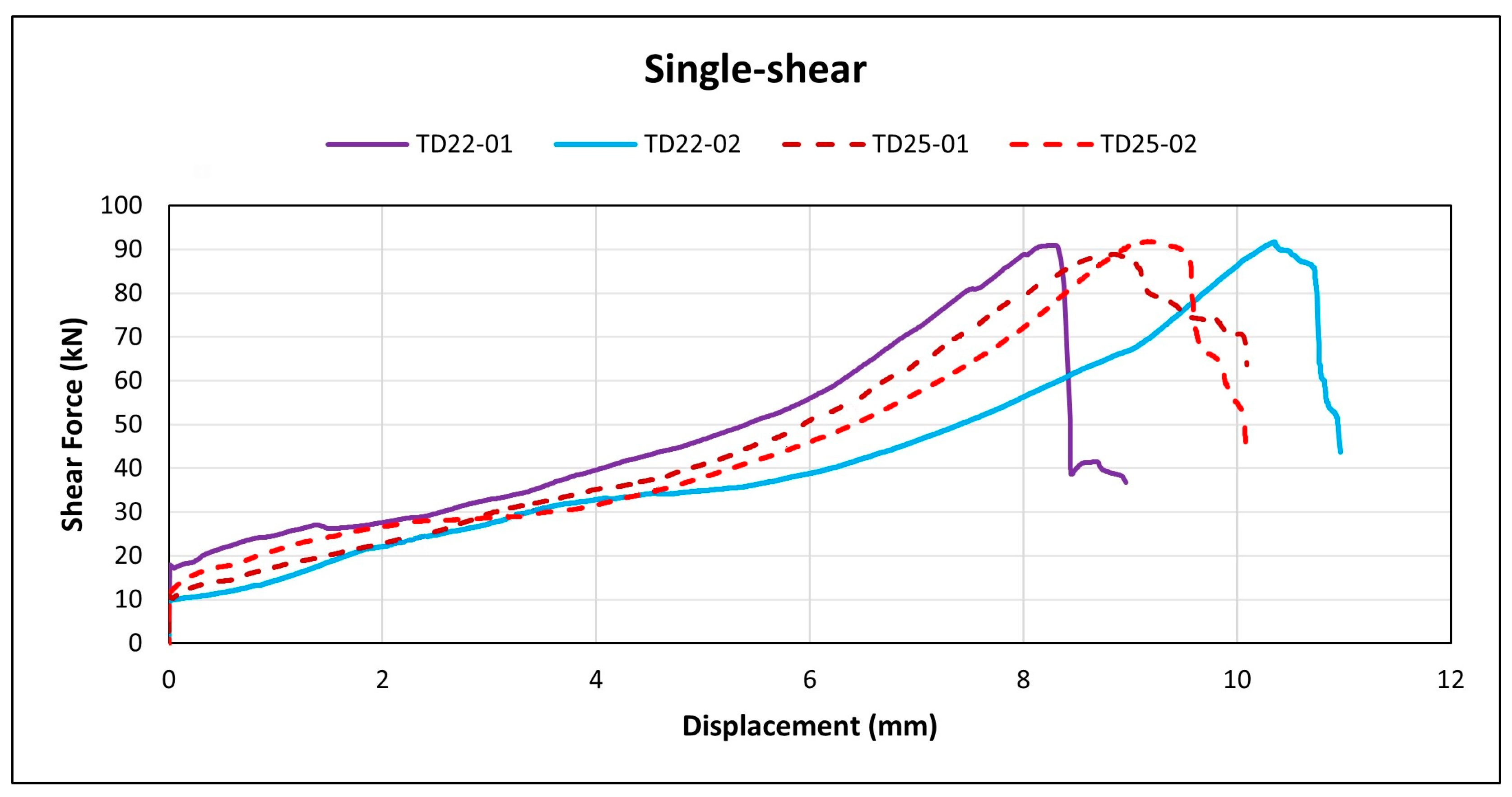

Single Shear Tests

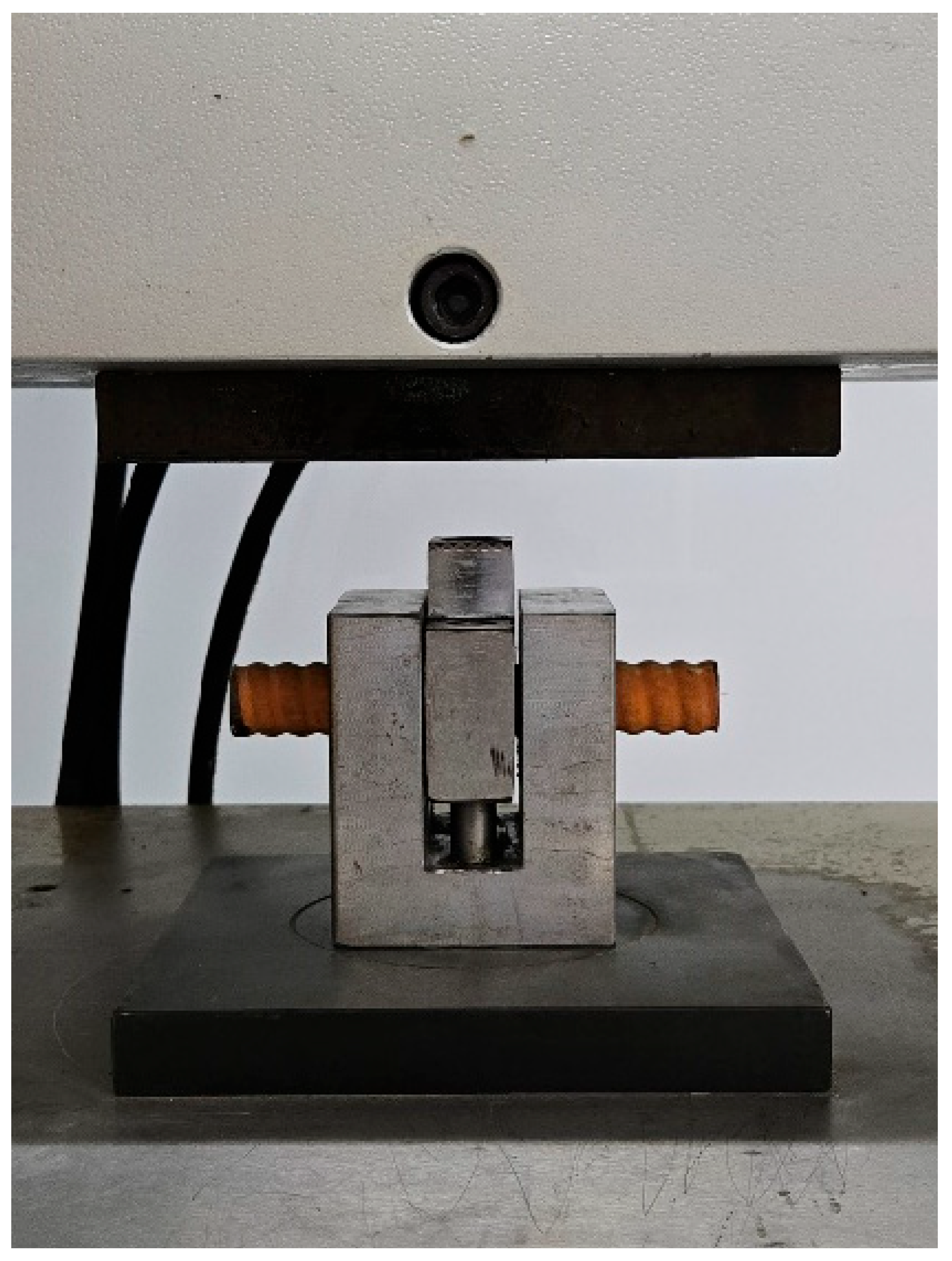

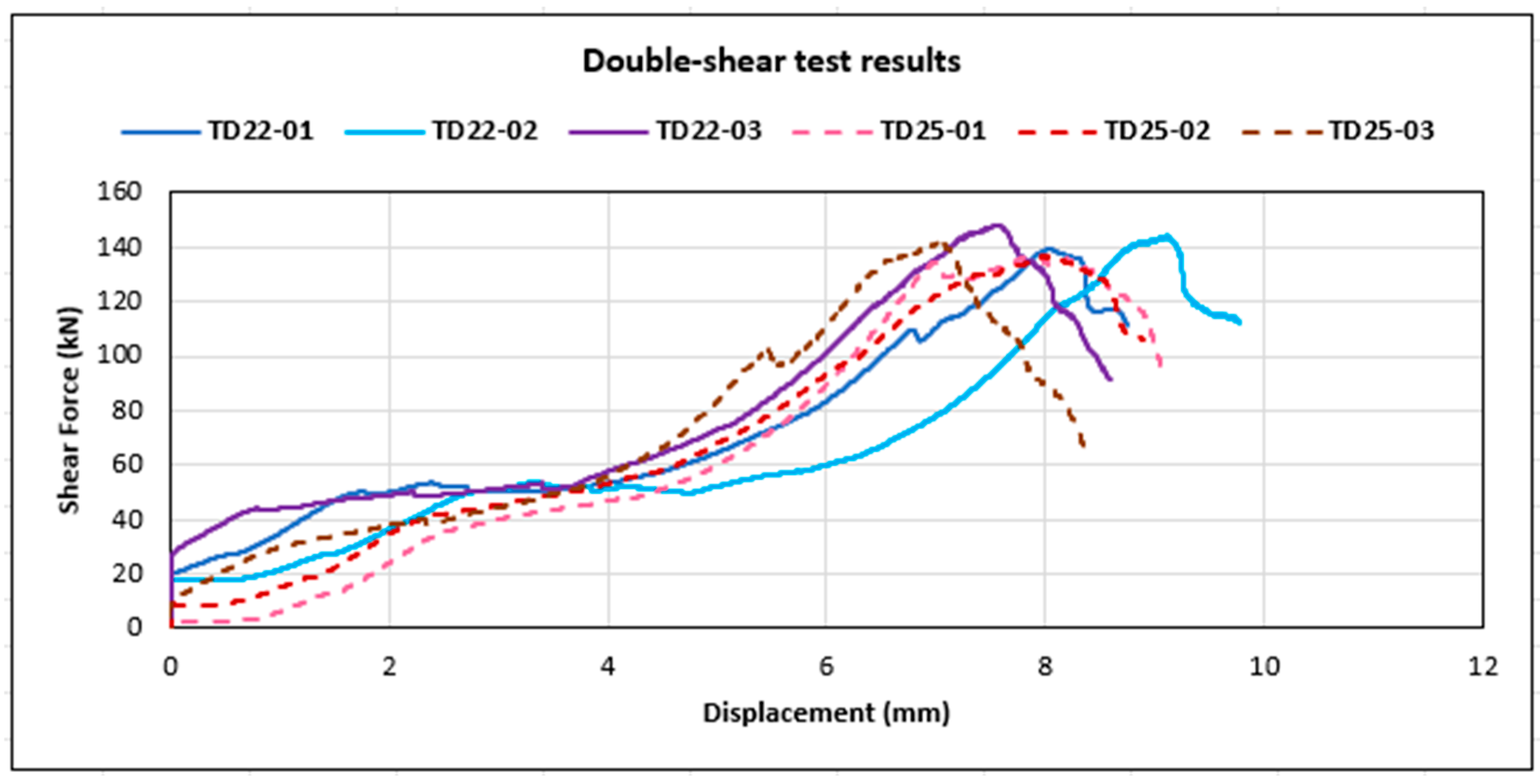

Double Shear Tests

2.4.2. Uniaxial Compressive Strength Test

2.5. Rock Bolt Mechanical Tests

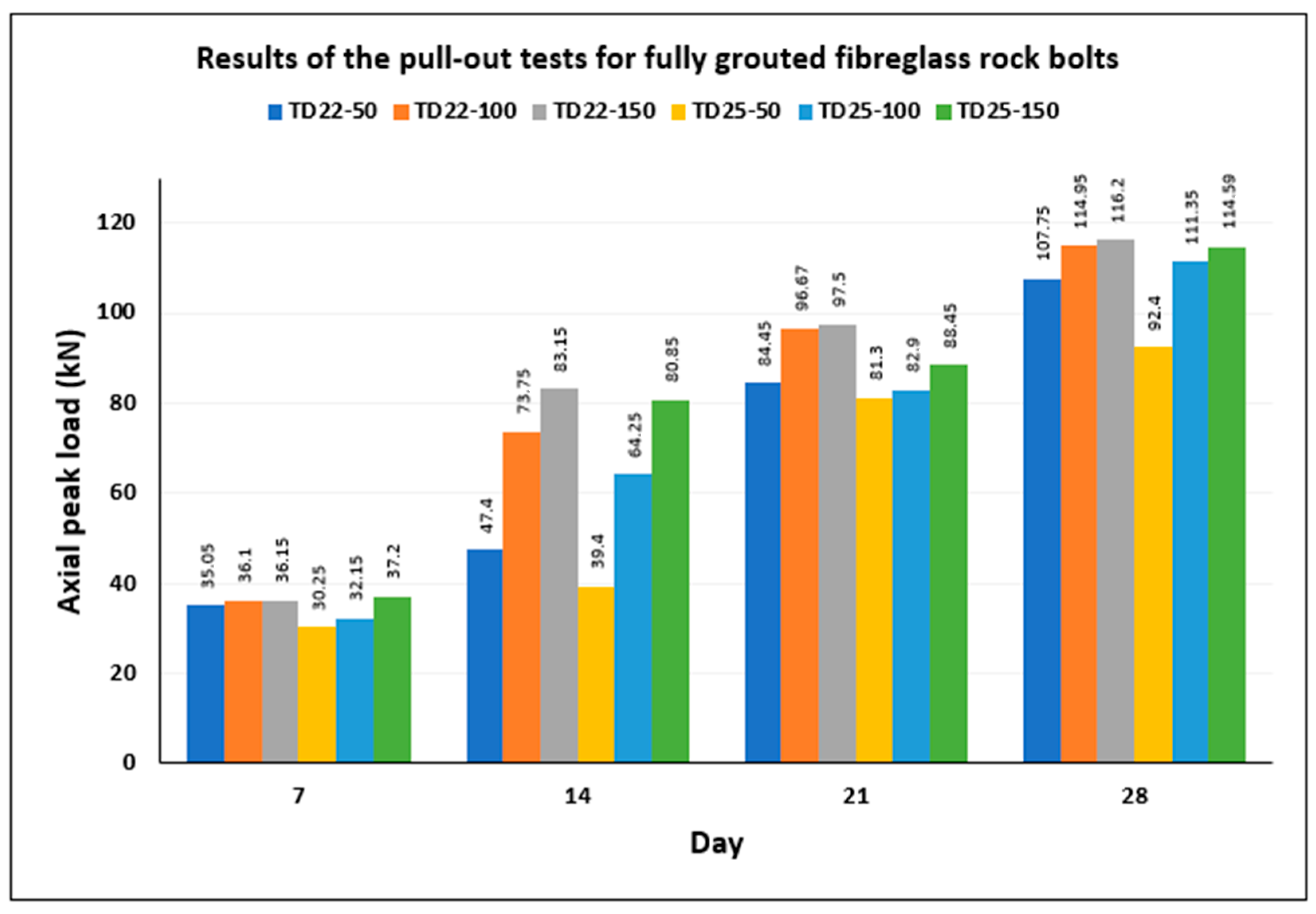

Pull-Out Tests

3. Results and Discussions

3.1. Shear Test Results

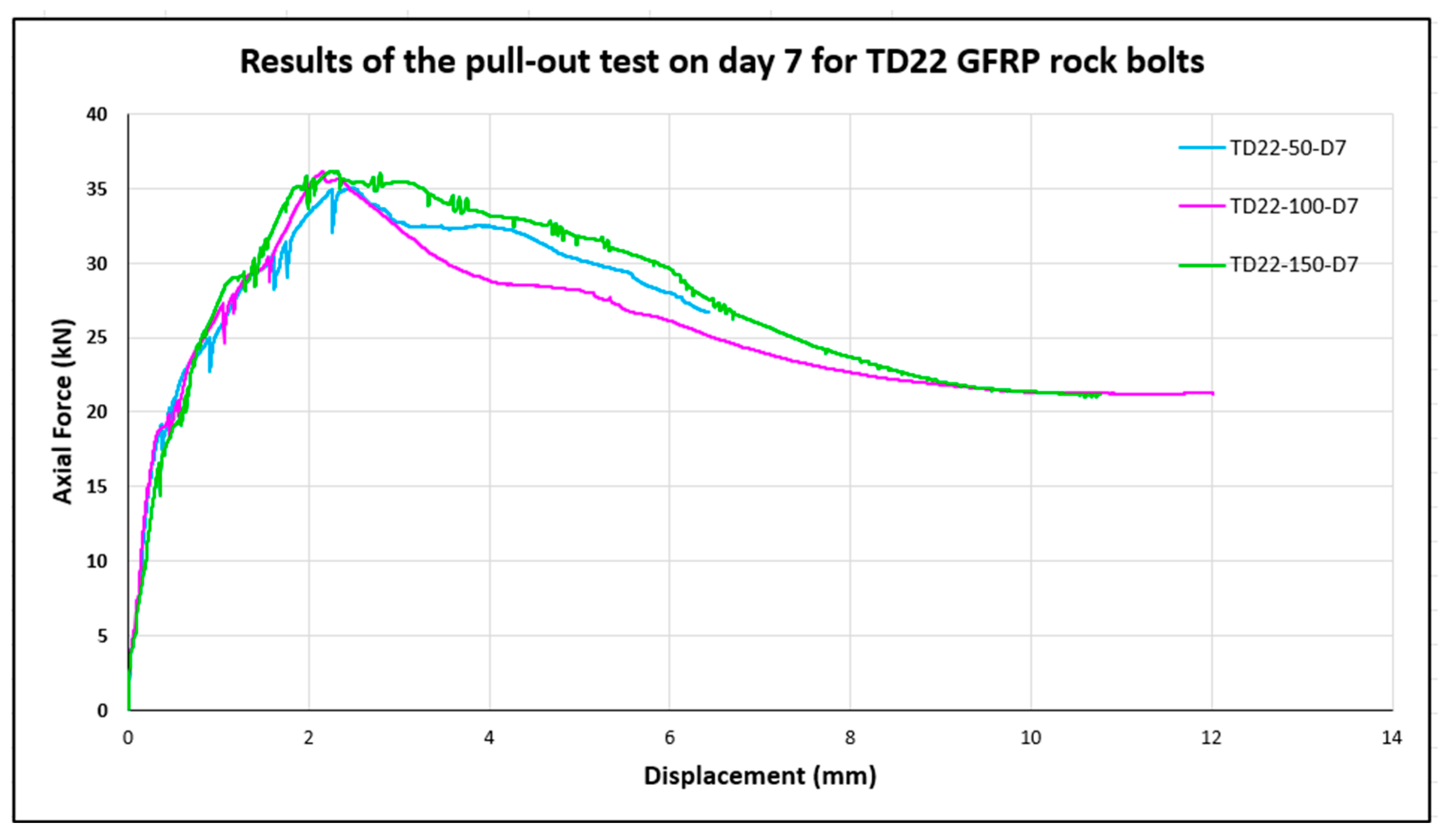

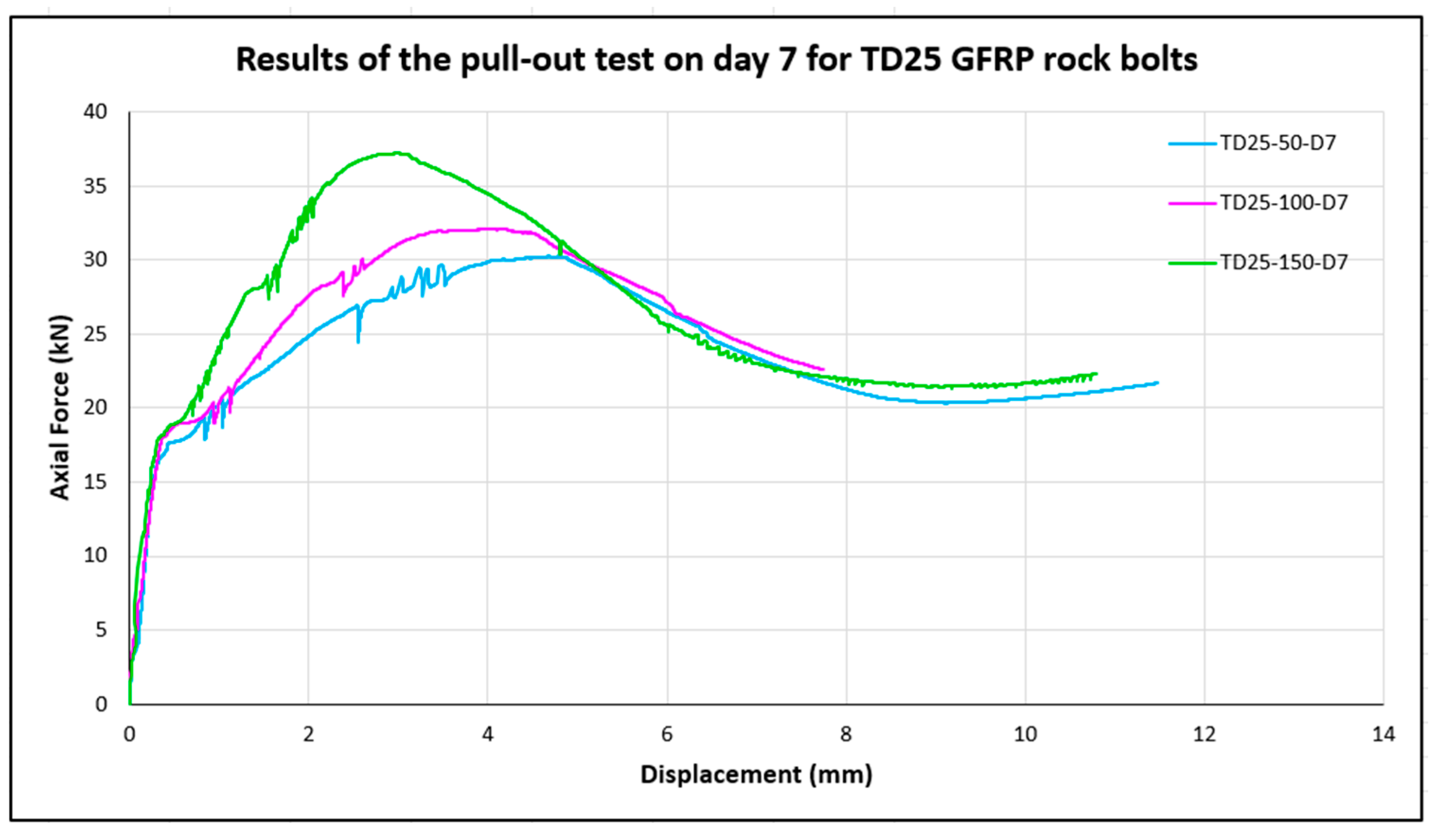

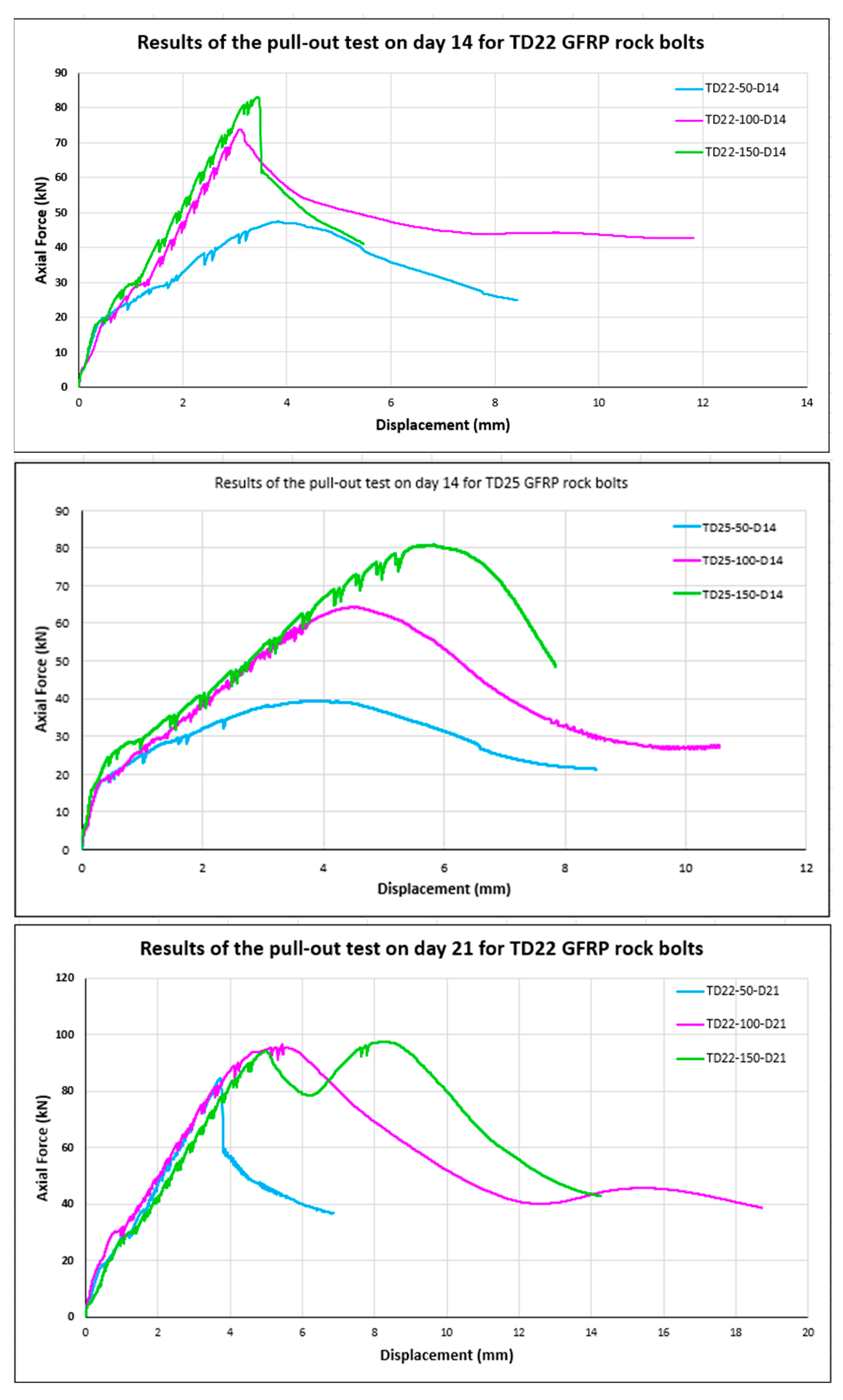

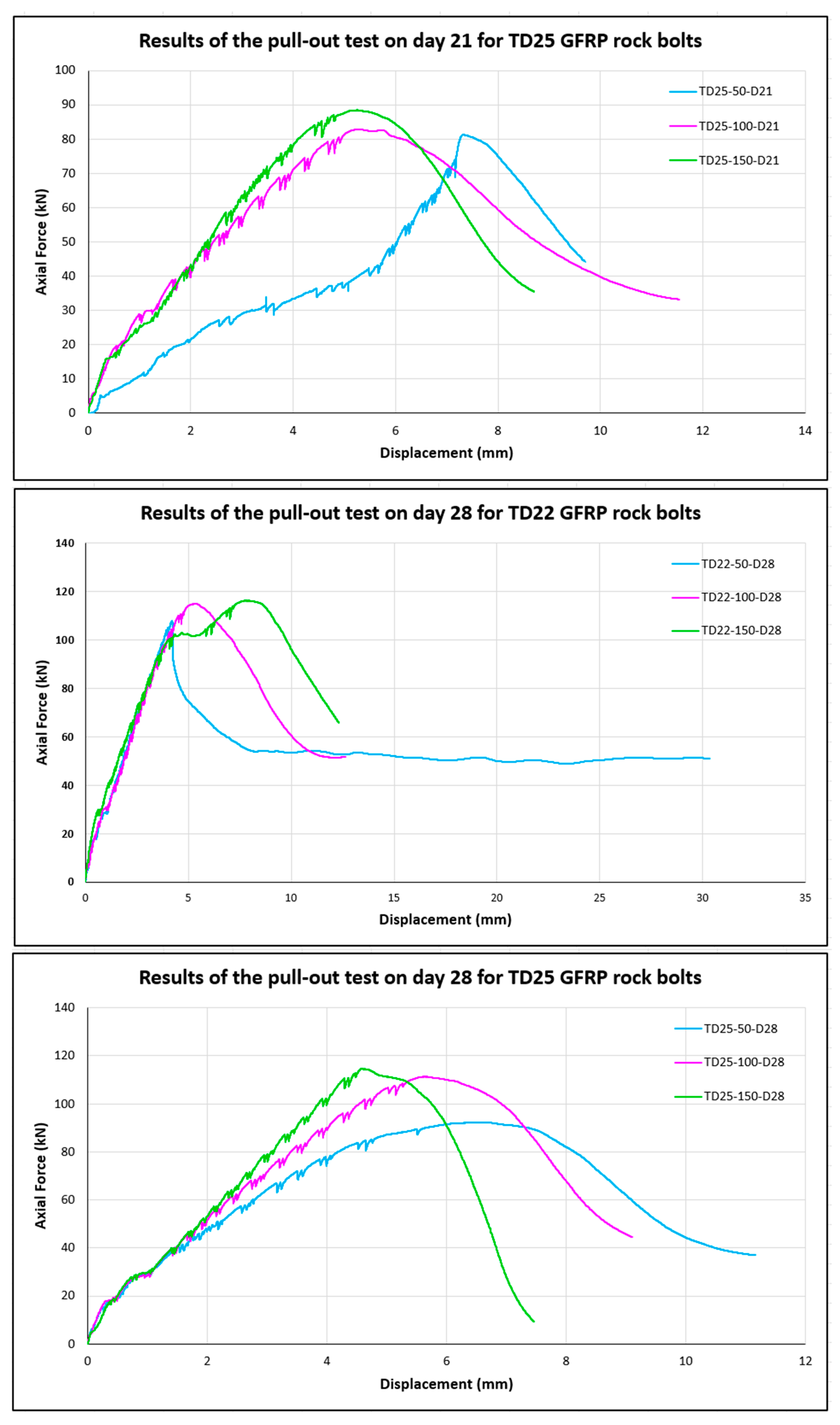

3.2. Pull-Out Test Results

3.3. Numerical Simulation

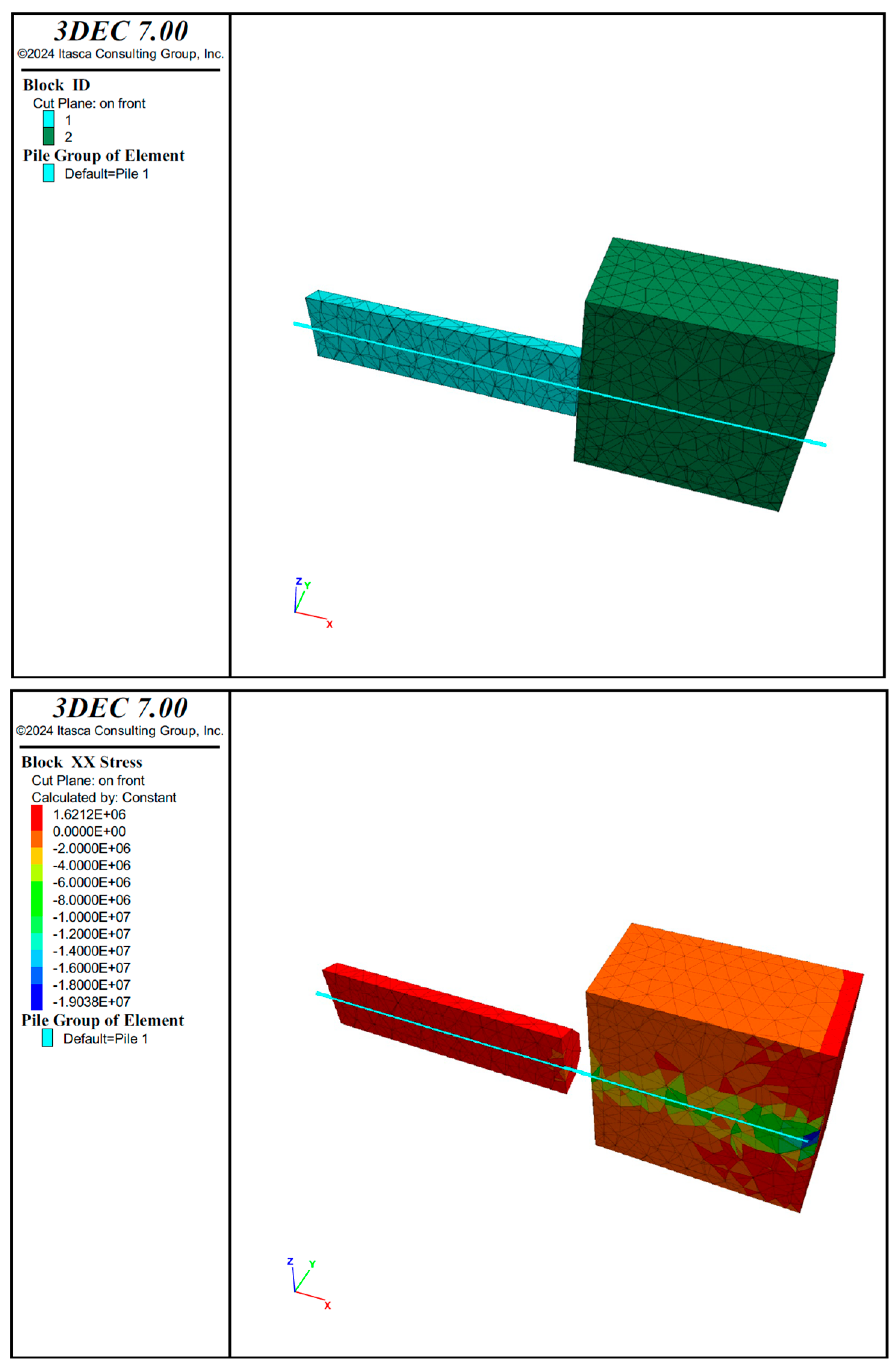

3.3.1. Developing the Fully Grouted Fibreglass Rock Bolt Model

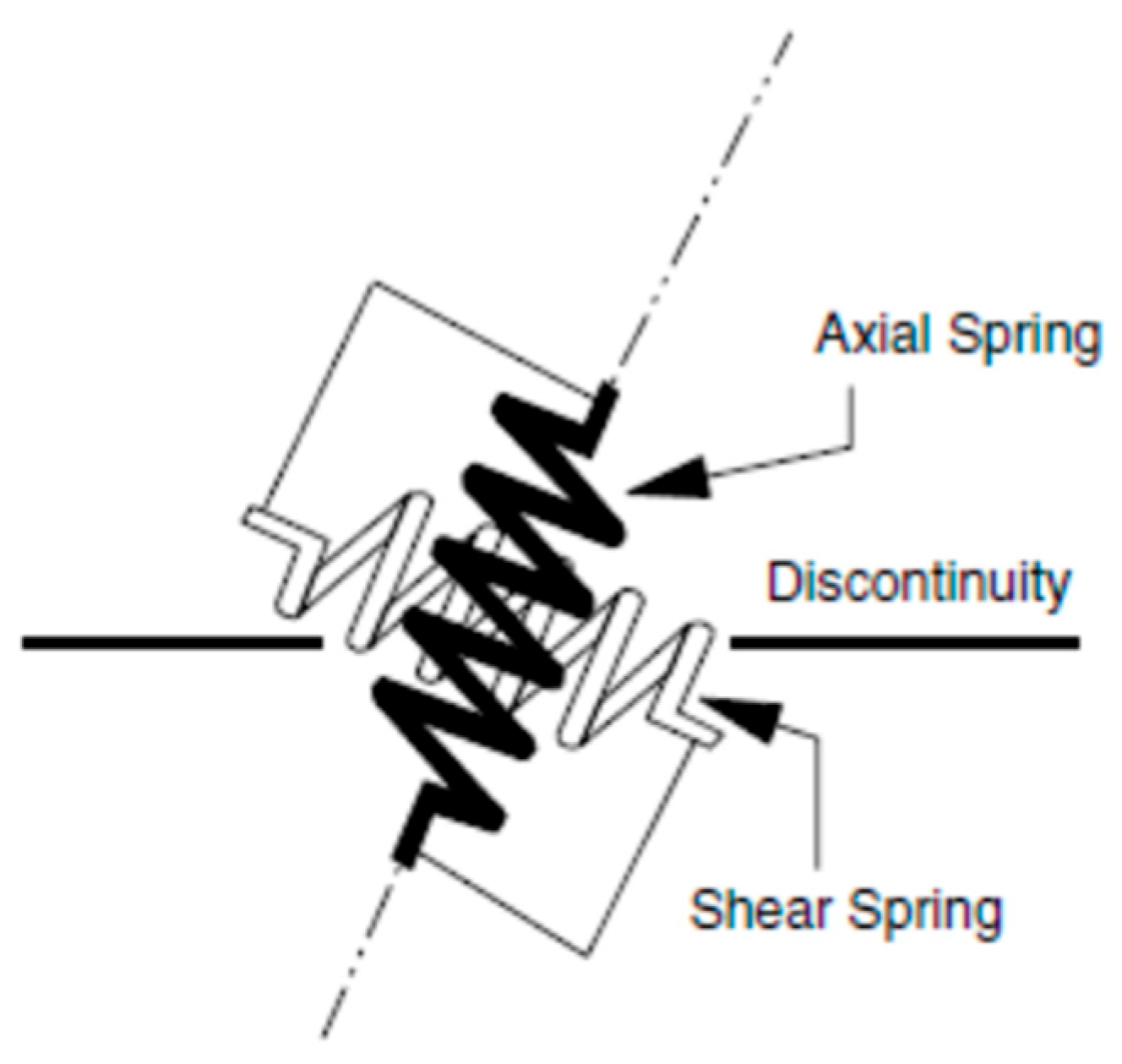

- Axial springs, which deform along the bolt’s longitudinal axis, capture the transfer of tensile loads.

- Shear springs, which deform perpendicular to the bolt, represent shear interaction and bond behaviour at the interface (Figure 29).

3.3.2. Model Calibration for Fully Grouted Fibreglass Rock Bolt

3.3.3. Sensitivity Analysis

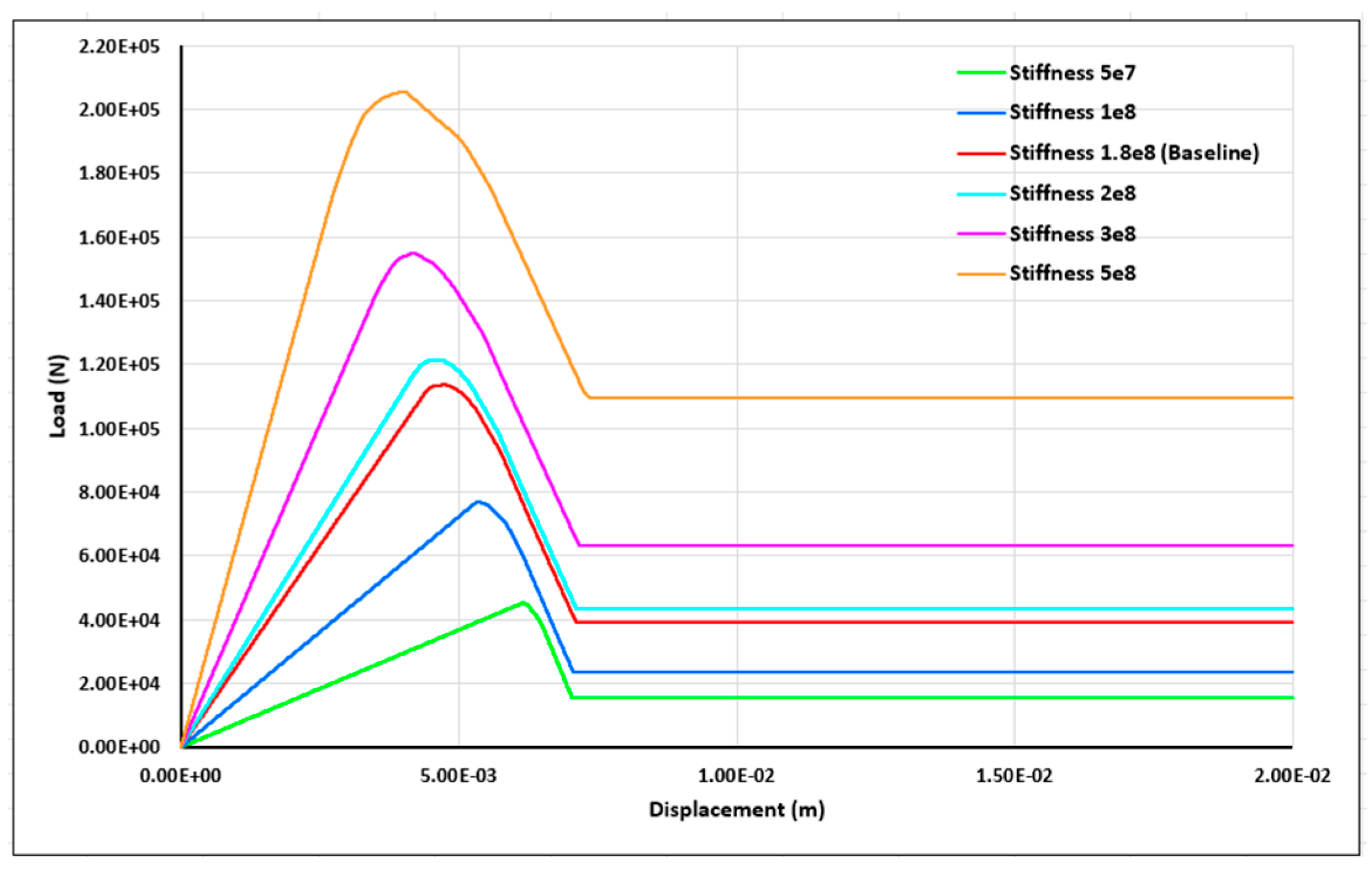

Scenario 1: Grout Stiffness

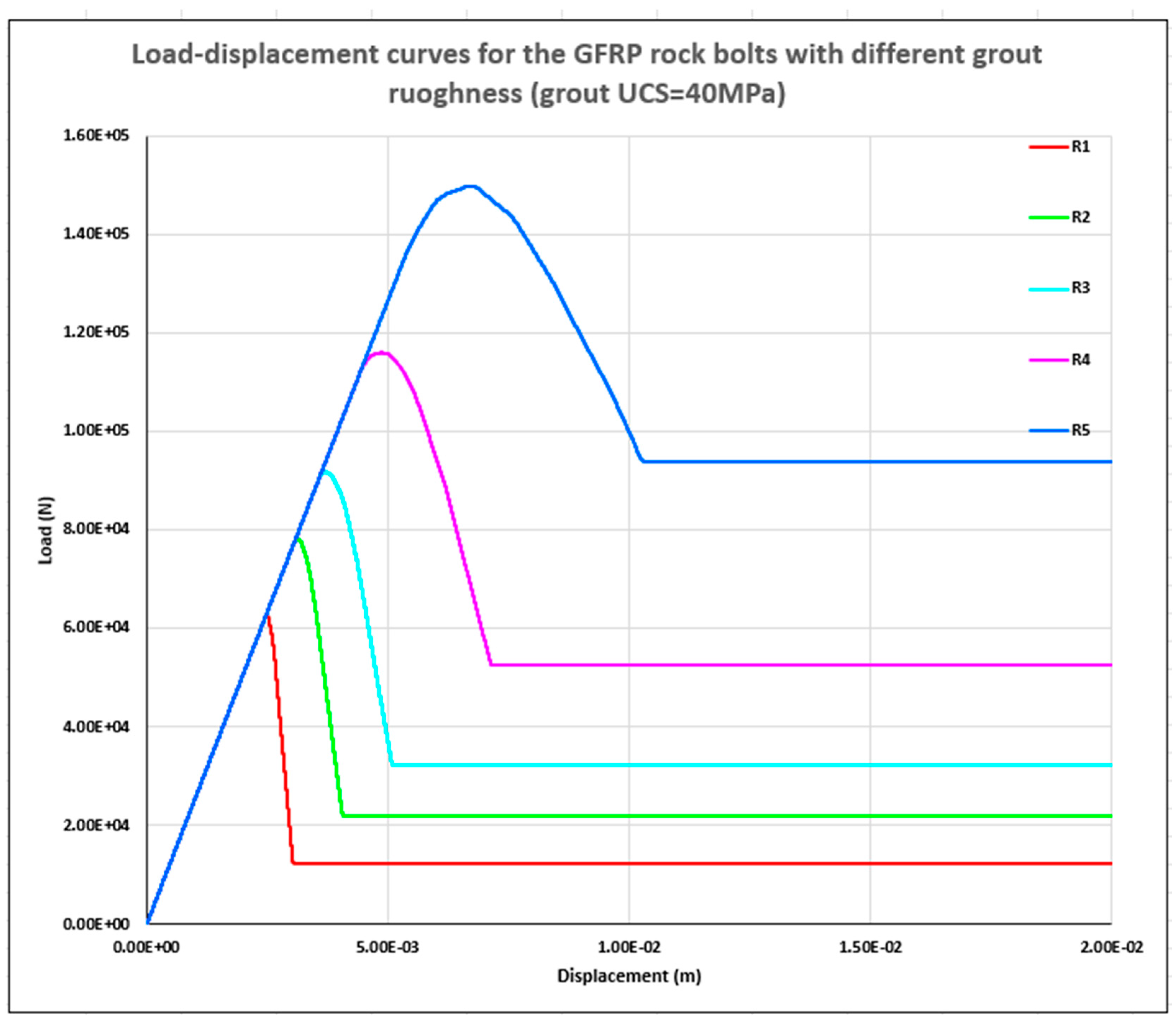

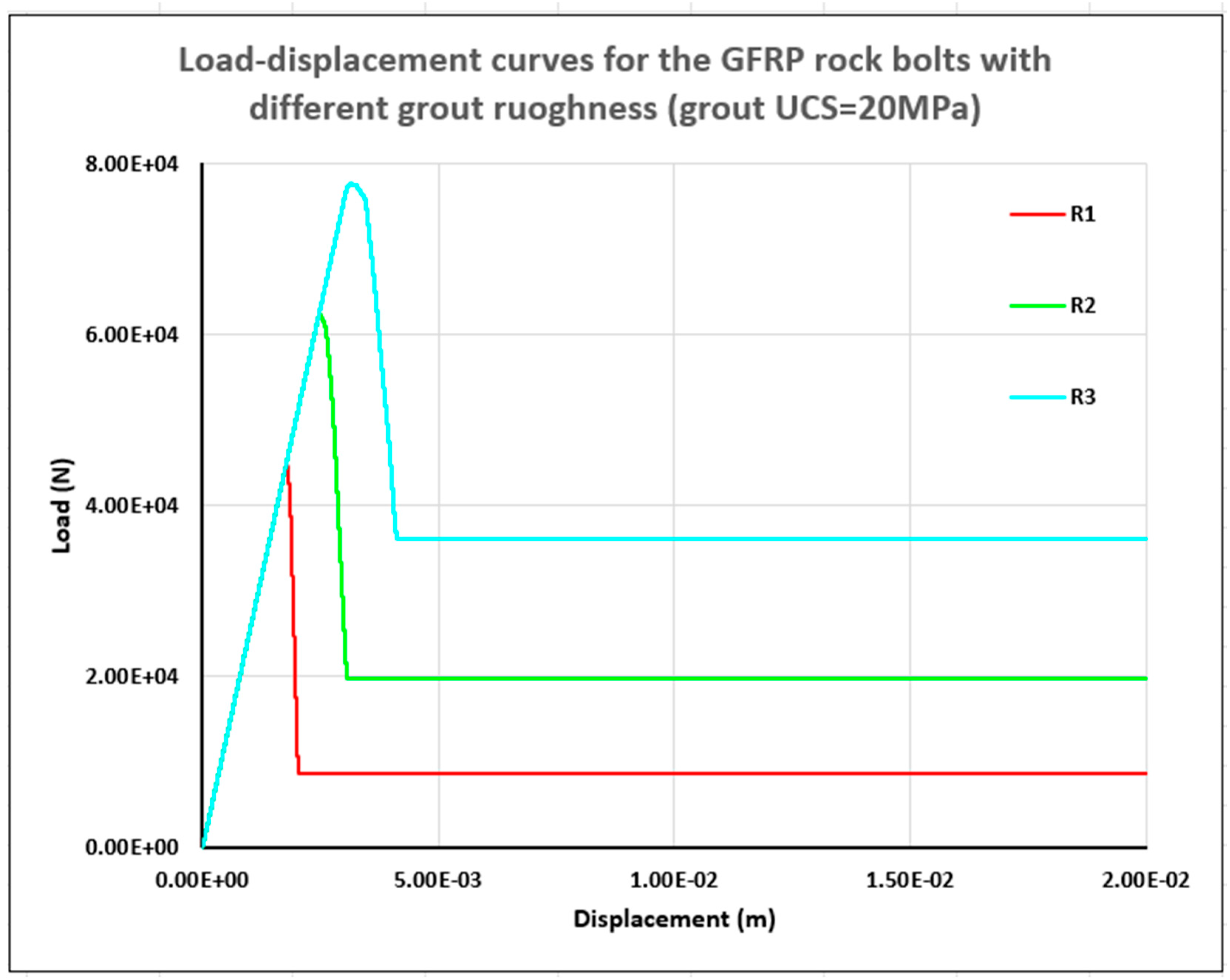

Scenario 2: Grout-Rock Bolt Roughness

- (i)

- The slip displacement required to mobilise peak shear strength,

- (ii)

- The residual shear strength after peak failure, and

- (iii)

- The interface friction angle.

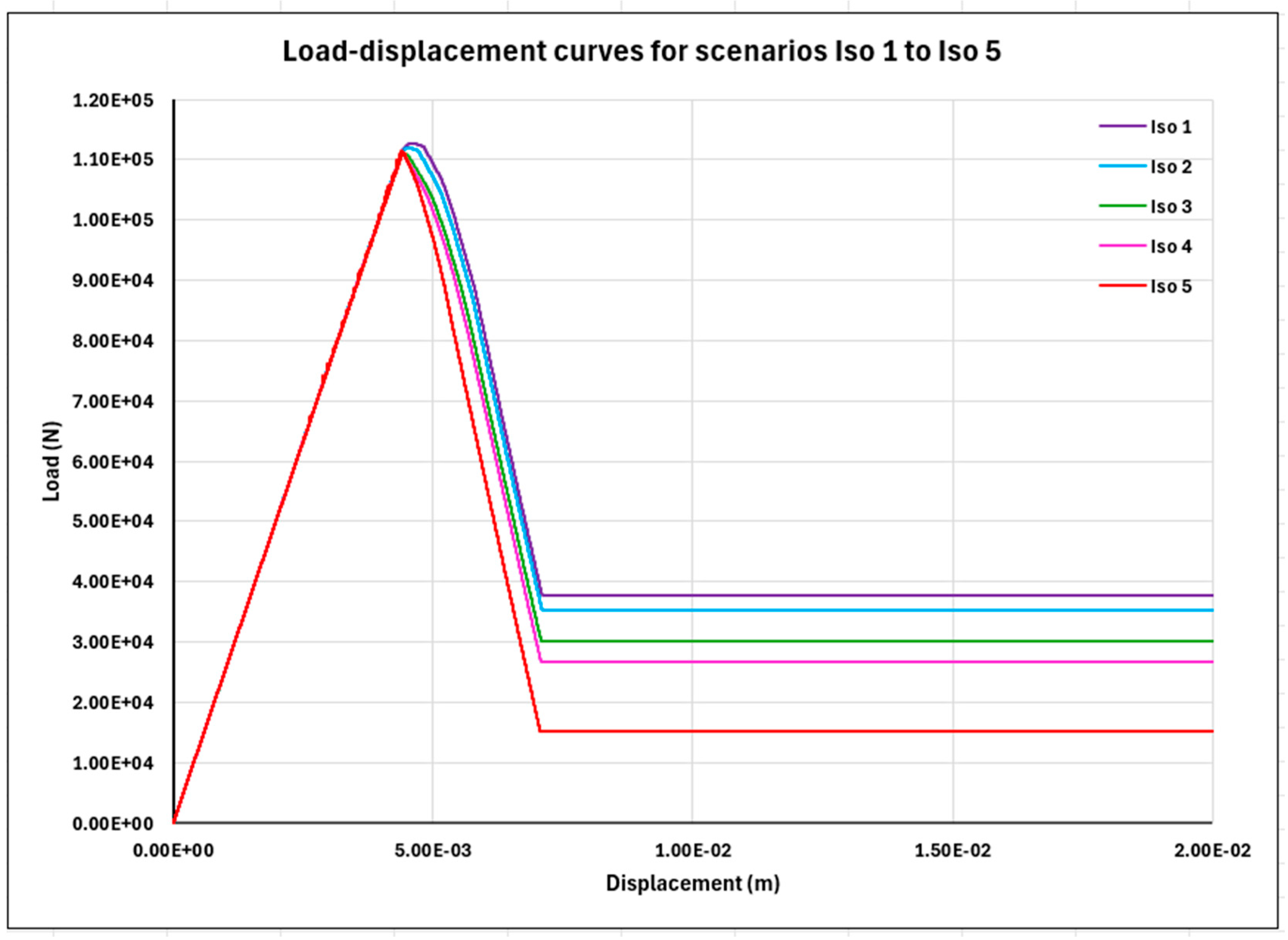

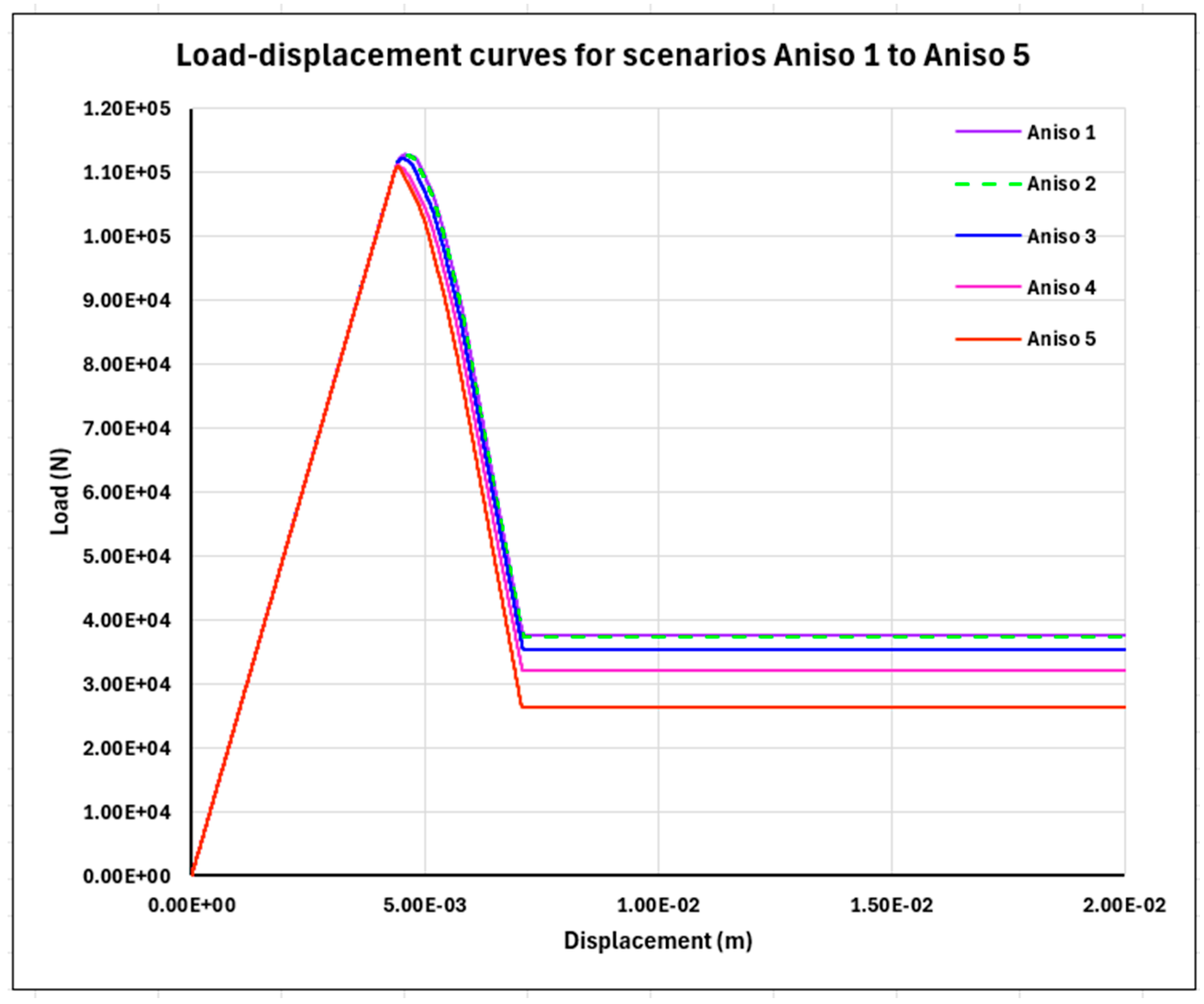

Scenario 3: Confining Stress

- σYY, acting perpendicular to the rock bolt in the Y-direction;

- σZZ, acting perpendicular to the rock bolt in the Z-direction;

- Isotropic Confining Stress

- Anisotropic Confining Stress:

4. Conclusions

- Single and double-shear behaviour: The results revealed that TD-22 rock bolts achieved higher shear capacity (up to approximately 92 kN in single shear and 148 kN in double shear) and exhibited a more gradual post-peak softening response than the TD-25 bolts (up to approximately 92 kN in single shear and 142 kN in double shear), indicating improved ductility and energy absorption. The smaller-diameter TD-22 bolts also exhibited smoother fracture surfaces and more progressive damage evolution, suggesting a more uniform fibre alignment and lower stress concentrations within the shear zone, likely due to differences in manufacturing quality and material composition.

- Axial response and calibration. Pull-out tests revealed a distinct linear elastic stage, followed by a peak and post-peak softening stage due to interface debonding and slip. The calibrated 3DEC model (pile/rock bolt element) accurately captured this behaviour, reproducing approximately 97% of the experimental peak load, thereby validating its suitability for parametric analyses [45].

- Increasing the ELs from 50 mm to 150 mm resulted in a substantial rise in axial peak load for both GFRP rock bolt types, with TD22 increasing from 47.4 kN to 83.15 kN and TD25 from 39.4 kN to 80.85 kN at 14 days of curing—equivalent to gains of 75% and 105%, respectively. At 28 days, when grout strength was fully cured, the effect of EL remained evident, with TD25-150 and TD22-150 achieving peak loads of 114.59 kN and 116.2 kN, representing improvements of up to 25% over the shortest embedments. These results confirmed that both EL and curing time play decisive roles in enhancing bond mobilisation and overall axial performance of fully grouted GFRP rock bolts.

- Influence of grout stiffness. Increasing grout stiffness elevated the peak load yet resulted in a sharper post-peak decline and lower residual load, reflecting a more brittle load-transfer mechanism. This agrees with previous finite discrete coupling studies on interface damage localisation [27].

- Confining stress conditions. Both isotropic and anisotropic confining stress increased initial stiffness but reduced ductility. The residual load decreased by approximately 59.6% under the highest isotropic confinement and by 29.9% under the highest anisotropic confinement.

5. Prospects and Future Work

- Extended confinement mapping: Conduct a broader range of axial loading tests on various GFRP rock bolt types and sizes to develop EL design maps and identify the optimum embedment length for different GFRP rock bolting systems.

- Cyclic and rate-dependent loading. Assess the dynamic response of GFRP rock bolts to cyclical or rapid loading, replicating seismic and blasting conditions.

- Surface geometry optimisation. Investigate parametric effects of rib height, spacing, and angle to refine the GFRP rock bolt’s surface design using DEM/FDM simulations.

- In the present study, roughness effects were represented indirectly through equivalent cohesion and stiffness values back-calculated from pull-out tests. This approach captures the combined influence of surface texture, adhesion, and micro-interlocking without requiring direct measurement. Future work should include the direct characterisation of the bolt–grout and grout–rock interfaces. Measured roughness indices could then be incorporated into numerical models to link surface morphology with bond strength.

- Further studies are also recommended using the Finite Element Method (FEM) (e.g., ABAQUS, ANSYS) to complement the DEM analysis. FEM can provide detailed stress and deformation fields within the grout and bolt, allowing a more complete evaluation of how interface geometry and material behaviour interact during load transfer.

- Combining direct roughness measurements with FEM modelling would enhance the predictive accuracy of interface behaviour in fully grouted GFRP bolt systems.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jodeiri Shokri, B. A Step Toward Better Understanding Rock Bolt Technology, in School of Engineering; University of Southern Queensland: Springfield, Australia, 2025; p. 222. [Google Scholar]

- Jodeiri Shokri, B.; Mirzaghorbanali, A.; Nourizadeh, H.; McDougall, K.; Karunasena, W.; Aziz, N.; Entezam, S.; Entezam, A. Axial Load Transfer Mechanism in Fully Grouted Rock Bolting System: A Systematic Review. Appl. Sci. 2024, 14, 5232. [Google Scholar] [CrossRef]

- Ma, S. Load Transfer Mechanism of Fully Encapsulated Rockbolts, in School of Civil, Mining, and Environmental Engineering; University of Wollongong: Wollongong, Australia, 2014; p. 264. [Google Scholar]

- Thompson, A.G.; Villaescusa, E.; Windsor, C.R. Ground Support Terminology and Classification: An Update. Geotech. Geol. Eng. 2012, 30, 553–580. [Google Scholar] [CrossRef]

- Kim, H.; Rehman, H.; Ali, W.; Naji, A.M.; Kim, J.-J.; Kim, J.; Yoo, H. Classification of Factors Affecting the Performance of Fully Grouted Rock Bolts with Empirical Classification Systems. Appl. Sci. 2019, 9, 4781. [Google Scholar] [CrossRef]

- Farmer, I.W. Stress distribution along a resin grouted rock anchor. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1975, 12, 347–351. [Google Scholar] [CrossRef]

- Li, C.; Stillborg, B. Analytical models for rock bolts. Int. J. Rock Mech. Min. Sci. 1999, 36, 1013–1029. [Google Scholar] [CrossRef]

- Thenevin, I.; Blanco-Martín, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Aziz, N.; Webb, B. Study of Load Transfer Capacity of Bolts Using Short Encapsulation Push Test. In Proceedings of the 2003 Coal Operators’ Conference, Mining Engineering; University of Wollongong: Wollongong, Australia, 2003; pp. 72–80. [Google Scholar]

- Bobet, A.; Einstein, H.H. Tunnel reinforcement with rockbolts. Tunn. Undergr. Space Technol. 2011, 26, 100–123. [Google Scholar] [CrossRef]

- Gregor, P. Shear Behaviour of Fibreglass Rock Bolts for Ground Reinforcement, in School of Engineering. Ph.D. Thesis, University of Southern Queensland, Springfield, Australia, 2022. [Google Scholar]

- Cao, C.; Jan, N.; Ren, T.; Naj, A. A study of rock bolting failure modes. Int. J. Min. Sci. Technol. 2013, 23, 79–88. [Google Scholar] [CrossRef]

- Li, C.C. Principles of rockbolting design. J. Rock Mech. Geotech. Eng. 2017, 9, 396–414. [Google Scholar] [CrossRef]

- Cui, G.; Zhang, C.; Pan, Y.; Deng, L.; Zhou, H. Laboratory investigation into effect of bolt profiles on shear behaviors of bolt-grout interface under constant normal stiffness (CNS) conditions. J. Rock Mech. Geotech. Eng. 2020, 12, 1234–1248. [Google Scholar] [CrossRef]

- Shi, H.; Song, L.; Zhang, H.; Chen, W.; Lin, H.; Li, D.; Wang, G.; Zhao, H. Experimental and numerical studies on progressive debonding of grouted rock bolts. Int. J. Min. Sci. Technol. 2022, 32, 63–74. [Google Scholar] [CrossRef]

- Guan, K.; Jiang, X.; Zhu, W.; Luo, W.; Li, H.; Li, B. Micromechanical model for simulating load transfer behavior and damage evolution for fully grouted rockbolt under axial loads. Int. J. Rock Mech. Min. Sci. 2025, 185, 105971. [Google Scholar] [CrossRef]

- Li, Y.; Tan, Y.; Ahmed, A.; Cheng, H. Experimental study on the pullout behaviour of rockbolts with steel fiber-reinforced grout under constant confining pressures. Constr. Build. Mater. 2023, 397, 132350. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, G.; Chen, X.; Zhou, H.; Deng, L. Effects of bolt profile and grout mixture on shearing behaviors of bolt-grout interface. J. Rock Mech. Geotech. Eng. 2020, 12, 242–255. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, Y.; Wang, G.; Luan, H.; Zhang, Y.; Zhang, S. Experimental investigation on the shear behavior of the bolt-grout interface under CNL and CNS conditions considering realistic bolt profiles. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 111. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Luan, H.; Wang, Y.; Jiang, Y.; Shi, Q.; Wang, C.; Zhang, S. Shear Mechanical Properties of Bolt-Grout Interface under Different Bolt Surface Profiles. Appl. Sci. 2024, 14, 1770. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, Y.; Chen, H.; Luan, H.; Zhang, J.; Shang, D.; Zheng, H. Bolt profile and grout strength influence on shear characteristics of the bolt–grout interface. Phys. Fluids 2025, 37, 043353. [Google Scholar] [CrossRef]

- Høien, A.H.; Li, C.C.; Zhang, N. Pull-out and Critical Embedment Length of Grouted Rebar Rock Bolts-Mechanisms When Approaching and Reaching the Ultimate Load. Rock Mech. Rock Eng. 2021, 54, 1431–1447. [Google Scholar] [CrossRef]

- Li, C.; Kristjansson, G.; Høien, A. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef]

- Yu, S.; Zhu, W.; Niu, L. Experimental and numerical evaluation on debonding of fully grouted rockbolt under pull-out loading. Int. J. Coal Sci. Technol. 2022, 9, 8. [Google Scholar] [CrossRef]

- Kang, H.; Li, W.; Gao, F.; Yang, J. Grouting theories and technologies for the reinforcement of fractured rocks surrounding deep roadways. Deep Undergr. Sci. Eng. 2022, 2, 2–19. [Google Scholar] [CrossRef]

- Hu, Y.; Zheng, M.; Feng, W.; Tong, J.; Wang, Y.; Wang, Q.; Liu, K.; Ye, L. Interface bond degradation and damage characteristics of full-length grouted rock bolt in tunnels with high temperature. J. Rock Mech. Geotech. Eng. 2023, 15, 2639–2657. [Google Scholar] [CrossRef]

- Zhang, S.; Luan, H.; Jiang, Y.; Wang, Y.; Li, B.; Liu, Z.; Jiang, T.; Li, X. Study on the Load Transfer and Damage Evolution Characteristics of the Bolt-Grout Interface concerning Bolt Rib Parameters: Based on a Finite-Discrete Numerical Method. Comput. Geotech. 2025, 179, 107010. [Google Scholar] [CrossRef]

- Thirukumaran, S.; Oliveira, D.; Ariza, L. Assessing the Relative Quality of Rock Bolt Grouting in Weak Rock Mass Based on In Situ and Numerical Pull-Out Tests. Rock Mech. Rock Eng. 2025, 58, 10497–10522. [Google Scholar] [CrossRef]

- Wu, S.; Cao, X.; Zhu, Y.; Skrzypkowski, K.; Zagorski, K. Examination of Stress Corrosion Cracking of Rock Bolts in Simulated Underground Environments. Materials 2025, 18, 1275. [Google Scholar] [CrossRef]

- Gregor, P.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Jodeiri Shokri, B. Shear Behaviour of Fibreglass Rock Bolts for Various Pretension Loads. Rock Mech. Rock Eng. 2023, 56, 8083–8113. [Google Scholar] [CrossRef]

- Nourizadeh, H. Axial Load Transfer Mechanism of Rock Bolts; University of Southern Queensland: Springfield, Australia, 2024; p. 227. [Google Scholar]

- Bédard, C. Composite Reinforcing Bars: Assessing Their Use in Construction. Concr. Int. 1992, 14, 55–59. [Google Scholar]

- Aziz, N.; Craig, P.; Nemcik, J.; FI, H. Rock bolt corrosion-an experimental study. In Proceedings of the Coal Operators’ Conference; University of Wollongong: Wollongong, Australia, 2013; pp. 144–151. [Google Scholar]

- Li, H.; Fu, J.; Chen, B.; Zhang, X.; Zhang, Z.; Lang, L. Mechanical Properties of GFRP Bolts and Its Application in Tunnel Face Reinforcement. Materials 2023, 16, 2193. [Google Scholar] [CrossRef]

- Nkurunziza, G.; Debaiky, A.; Cousin, P.; Benmokrane, B. Durability of GFRP bars: A critical review of the literature. Prog. Struct. Eng. Mater. 2005, 7, 194–209. [Google Scholar] [CrossRef]

- GangaRao, H.V.S.; Taly, N.; Vijay, P.V. Reinforced Concrete Design with FRP Composites; CRC Press: Boca Raton, FL, USA, 2006; p. 400. [Google Scholar]

- Thomas, A.H. Glass Fibre Reinforced Plastic (GFRP) permanent rockbolts. In Tunnels and Underground Cities: Engineering and Innovation Meet Archaeology, Architecture and Art; CRC Press: Boca Raton, FL, USA, 2019; pp. 3200–3209. [Google Scholar]

- Phillips, M.G. Prediction of long-term stress-rupture life for glass fibre-reinforced polyester composites in air and in aqueous environments. Composites 1983, 14, 270–275. [Google Scholar] [CrossRef]

- Benmokrane, B.; Xu, H.; Bellavance, E. Bond strength of cement grouted glass fibre reinforced plastic (GFRP) anchor bolts. Int. J. Rock Mech. Min. Sci. 1996, 33, 455–465. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, D.; Sun, Z.; Chen, W. Extrusion prediction of tunnel face reinforced with fiberglass bolts considering interface debonding. Phys. Fluids 2025, 37, 036611. [Google Scholar] [CrossRef]

- Al Omar, S.; Abdelhadi, A. Comparative Life-Cycle Assessment of Steel and GFRP Rebars for Procurement Sustainability in the Construction Industry. Sustainability 2024, 16, 3899. [Google Scholar] [CrossRef]

- Sbahieh, S.; Tahir, F.; Al-Ghamdi, S.G. Environmental and mechanical performance of different fiber reinforced polymers in beams. Mater. Today Proc. 2022, 62, 3548–3552. [Google Scholar] [CrossRef]

- Gregor, P.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Jodeiri Shokri, B. Investigating shear behaviour of fibreglass rock bolts reinforcing infilled discontinuities for various pretension loads. Can. Geotech. J. 2024, 61, 414–446. [Google Scholar] [CrossRef]

- Gregor, P.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Jodeiri Shokri, B.; Nourizadeh, H.; Taheri, A. Analysing Double Shearing Mechanism in Fiberglass Rock Bolting Systems: A Comprehensive Analytical Model and Numerical Simulation Approach. Geotech. Geol. Eng. 2024, 42, 7339–7370. [Google Scholar] [CrossRef]

- Itasca Consulting Group, Inc. Itasca, version 7.0. 3DEC—Three-Dimensional Distinct Element Code. Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2024.

- Entezam, S.; Jodeiri Shokri, B.; Nourizadeh, H.; Gregor, P.; Entezam, A.; Mirzaghorbanali, A.; McDougall, K.; Karunasena, W.; Aziz, N. Investigating the axial and shear performance of fiberglass rock bolts. In Proceedings of the Resource Operators Conference; University of Wollongong: Wollongong, Australia, 2024. [Google Scholar]

- Zheng, H.; Jiang, Y.; Zhang, S.; Wu, X.; Chen, H. Comparative study of shear performance of fully-grouted and energy-absorbing bolts under varying normal stress during cyclic shear tests. Bull. Eng. Geol. Environ. 2025, 84, 1–14. [Google Scholar] [CrossRef]

- Khaleghparast, S.; Aziz, N.; Remennikov, A.; Anzanpour, S. An experimental study on shear behaviour of fully grouted rock bolt under static and dynamic loading conditions. Tunn. Undergr. Space Technol. 2023, 132, 104915. [Google Scholar] [CrossRef]

- Aziz, N.; Nemcik, J.; Mirzaghorbanali, A.; Foldi, S.; Joyce, D.; Moslemi, A.; Ghojavand, H.; Ma, S.; Li, X.; Rasekh, H. Suggested methods for the preparation and testing of various properties of resins and grouts. In Proceedings of the Coal Operators’ Conference; University of Wollongong: Wollongong, Australia, 2014. [Google Scholar]

- Yu, J.-D.; Lee, J.-S.; Tamang, B.; Park, S.; Chang, S.; Kim, J.; Kim, Y. Performance Evaluation of GFRP Rock Bolt Sensor for Rock Slope Monitoring by Double Shear Test. Adv. Civ. Eng. 2020, 2020, 1–14. [Google Scholar] [CrossRef]

- Hosseini, S.; Entezam, S.; Jodeiri Shokri, B.; Mirzaghorbanali, A.; Nourizadeh, H.; Motallebiyan, A.; Entezam, A.; McDougall, K.; Karunasena, W.; Aziz, N. Predicting grout’s uniaxial compressive strength (UCS) for fully grouted rock bolting system by applying ensemble machine learning techniques. Neural Comput. Appl. 2024, 36, 18387–18412. [Google Scholar] [CrossRef]

- Gao, H.; Wang, Q.; Jiang, B.; Zhang, P.; Jiang, Z.; Wang, Y. Relationship between rock uniaxial compressive strength and digital core drilling parameters and its forecast method. Int. J. Coal Sci. Technol. 2021, 8, 605–613. [Google Scholar] [CrossRef]

- Beiki, M.; Majdi, A.; Givshad, A.D. Application of genetic programming to predict the uniaxial compressive strength and elastic modulus of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2013, 63, 159–169. [Google Scholar] [CrossRef]

- Hong, S.; Park, S.-K. Uniaxial Bond Stress-Slip Relationship of Reinforcing Bars in Concrete. Adv. Mater. Sci. Eng. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Hyett, A.J.; Bawden, W.F.; Reichert, R.D. The effect of rock mass confinement on the bond strength of fully grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 503–524. [Google Scholar] [CrossRef]

- Yazici, S.; Kaiser, P.K. Bond strength of grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 279–292. [Google Scholar] [CrossRef]

- Zhao, T.-b.; Guo, W.-y.; Yin, Y.-c.; Tan, Y.-l. Bolt Pull-Out Tests of Anchorage Body under Different Loading Rates. Shock Vib. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Chen, J.; Wang, S.; Sun, G.; Zhang, H.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Investigating the Influence of Embedment Length on the Anchorage Force of Rock Bolts with Modified Pile Elements. Appl. Sci. 2022, 13, 52. [Google Scholar] [CrossRef]

- Chang, L.; Konietzky, H. Application of the Mohr-Coulomb Yield Criterion for Rocks with Multiple Joint Sets Using Fast Lagrangian Analysis of Continua 2D (FLAC2D) Software. Energies 2018, 11, 614. [Google Scholar] [CrossRef]

| Bolt Type | Bolt Diameter (mm) | Hole Diameter (mm) | Rock Diameter (mm) | Shorter EL (mm) | Longer EL (mm) | Bolt Length (mm) | Curing Time (Days) |

|---|---|---|---|---|---|---|---|

| TD22 | 22 | 35 | 55 | 50 | 75 | 155 | 7, 14, 21, 28 |

| 100 | 150 | 280 | |||||

| 150 | 200 | 380 | |||||

| TD25 | 25 | 35 | 55 | 50 | 75 | 155 | 7, 14, 21, 28 |

| 100 | 150 | 280 | |||||

| 150 | 200 | 380 |

| Bolt Name | Bolt Diameter (mm) | Cross-Sectional Area (mm2) | Ultimate Tensile Strength (kN) | Elongation (%) | Mass/Meter (kg/m) |

|---|---|---|---|---|---|

| TD22 | 22 | 340 | 230 | 2 | 0.61 |

| TD25 | 25 | 434 | 300 | 2 | 0.95 |

| Test Type | Specimen | Length (mm) | Peak Load (kN) | Displacement at Peak Load (mm) |

|---|---|---|---|---|

| Single Shear Test | TD22-01 | 200 | 91 | 8.28 |

| TD22-02 | 200 | 91.7 | 10.348 | |

| TD25-01 | 200 | 88.95 | 8.835 | |

| TD25-02 | 200 | 91.8 | 9.16 | |

| Double Shear Test | TD22-01 | 170 | 139.7 | 8.042 |

| TD22-02 | 170 | 144.3 | 9.11 | |

| TD22-03 | 170 | 148.26 | 7.597 | |

| TD25-01 | 170 | 136 | 7.799 | |

| TD25-02 | 170 | 136.65 | 7.977 | |

| TD25-03 | 170 | 141.8 | 7.047 |

| Category | Parameter Name | Value | Unit | Description |

|---|---|---|---|---|

| Geometry—Domain | ConL1 | 0.2 | m | Length of first confinement |

| ConL2 | 0.15 | m | Length of second confinement | |

| ConR | 0.0275 | m | Radius of confinement | |

| ConRConcrete | 0.125 | m | Radius of the concrete block | |

| Material—Rock | (assigned directly) | 2.9 × 1010 | Pa | Bulk modulus of rock |

| 1.5 × 1010 | Pa | Shear modulus of rock | ||

| 2400 | kg/m3 | Density of rock | ||

| 10 × 106 | Pa | Mohr-Coulomb cohesion | ||

| 40 | degrees | Mohr-Coulomb friction angle | ||

| Joint Properties | jkn_ | 3 × 1011 | Pa/m | Normal stiffness of joints |

| jks_ | 3 × 1011 | Pa/m | Shear stiffness of joints | |

| jfric_ | 35 | degrees | Friction angle of joints | |

| Pull-Out Loading | xvel_ | 0.1 | m/s | Applied pull-out velocity |

| Displacement Target | gp_monitor | 0.02 | m | Monitoring the grid point for a 20 mm displacement limit |

| Angle Test | dincl_ | 90 | degrees | Inclination of rock bolt (for orientation testing) |

| Case | Slip at Peak (m) | Residual Shear Strength (Pa) | Interface Friction Angle (°) |

|---|---|---|---|

| R1 | 0.003 | 0.5 × 105 | 35 |

| R2 | 0.004 | 0.8 × 105 | 40 |

| R3 | 0.005 | 1.0 × 105 | 45 |

| R4 | 0.007 | 1.2 × 105 | 50 |

| R5 | 0.010 | 1.5 × 105 | 55 |

| Case | Slip at Peak (m) | Residual Shear Strength (Pa) | Interface Friction Angle (°) |

|---|---|---|---|

| R1 | 0.002 | 25,000 | 35 |

| R2 | 0.003 | 40,000 | 40 |

| R3 | 0.004 | 50,000 | 45 |

| Case | σZZ | σYY |

|---|---|---|

| Iso1 | 1 | 1 |

| Iso2 | 2 | 2 |

| Iso3 | 3 | 3 |

| Iso4 | 4 | 4 |

| Iso5 | 5 | 5 |

| Case | σZZ | σYY |

|---|---|---|

| Aniso1 | 1 | 1 |

| Aniso2 | 2 | 1 |

| Aniso3 | 3 | 1 |

| Aniso4 | 4 | 1 |

| Aniso5 | 5 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Entezam, S.; Mirzaghorbanali, A.; Jodeiri Shokri, B.; Entezam, A.; Nourizadeh, H.; Craig, P.; McDougall, K.; Karunasena, W.; Aziz, N. Axial Load Transfer Mechanisms in Fully Grouted Fibreglass Rock Bolts: Experimental and Numerical Investigations. Appl. Sci. 2025, 15, 11293. https://doi.org/10.3390/app152011293

Entezam S, Mirzaghorbanali A, Jodeiri Shokri B, Entezam A, Nourizadeh H, Craig P, McDougall K, Karunasena W, Aziz N. Axial Load Transfer Mechanisms in Fully Grouted Fibreglass Rock Bolts: Experimental and Numerical Investigations. Applied Sciences. 2025; 15(20):11293. https://doi.org/10.3390/app152011293

Chicago/Turabian StyleEntezam, Shima, Ali Mirzaghorbanali, Behshad Jodeiri Shokri, Alireza Entezam, Hadi Nourizadeh, Peter Craig, Kevin McDougall, Warna Karunasena, and Naj Aziz. 2025. "Axial Load Transfer Mechanisms in Fully Grouted Fibreglass Rock Bolts: Experimental and Numerical Investigations" Applied Sciences 15, no. 20: 11293. https://doi.org/10.3390/app152011293

APA StyleEntezam, S., Mirzaghorbanali, A., Jodeiri Shokri, B., Entezam, A., Nourizadeh, H., Craig, P., McDougall, K., Karunasena, W., & Aziz, N. (2025). Axial Load Transfer Mechanisms in Fully Grouted Fibreglass Rock Bolts: Experimental and Numerical Investigations. Applied Sciences, 15(20), 11293. https://doi.org/10.3390/app152011293