2.1. Basic Principle Framework

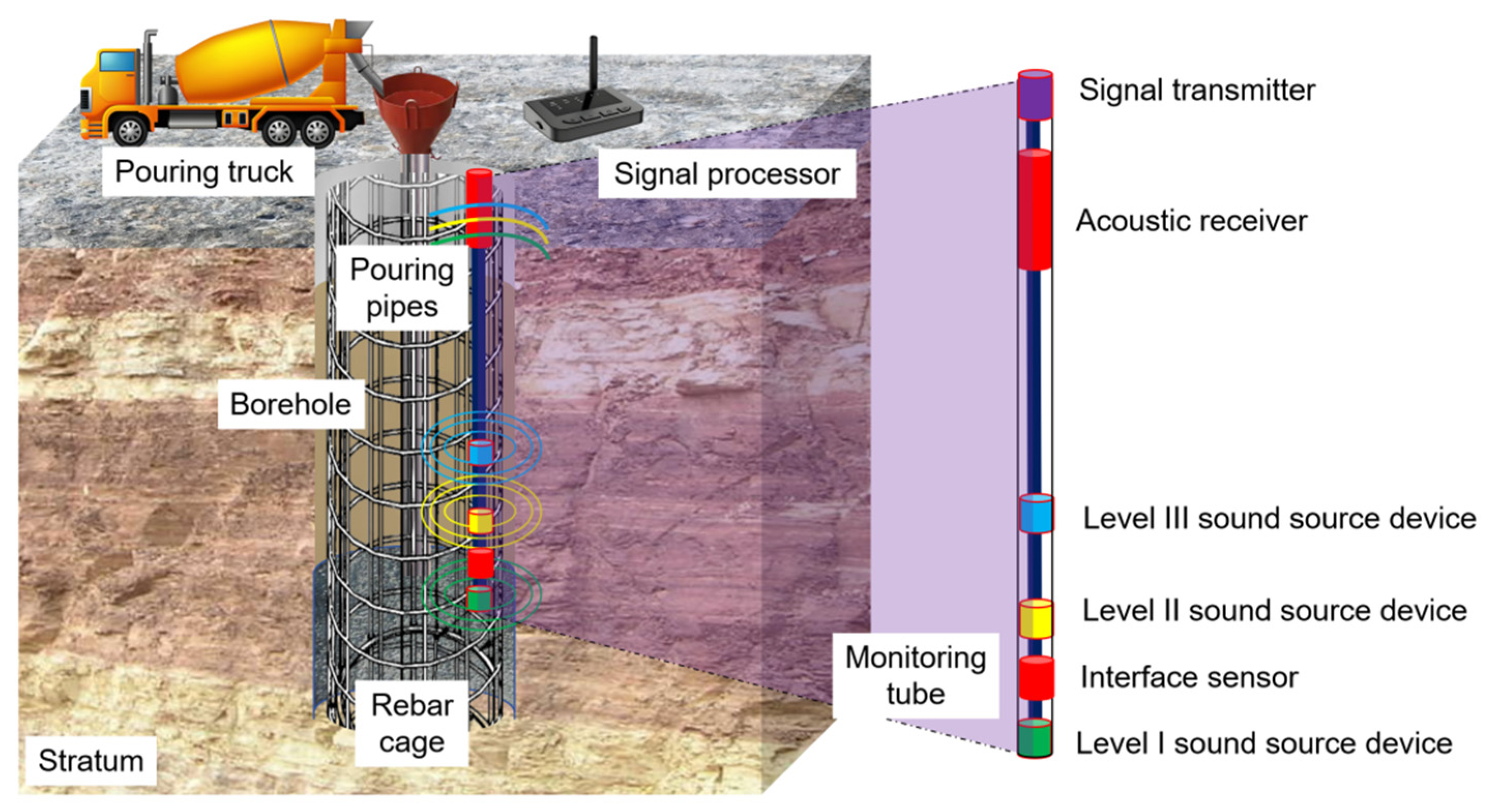

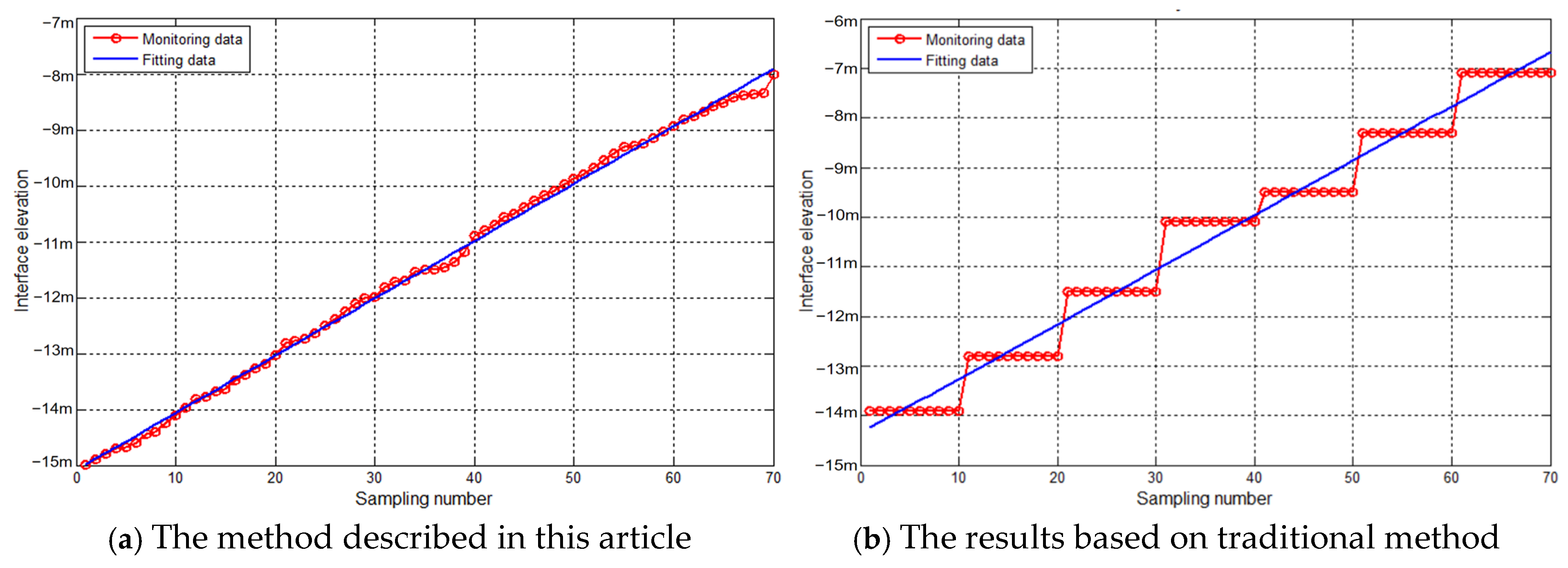

The basic principle of this method is to install sound source devices at different depths within the borehole and capture these sound source signals at the borehole opening. This method leverages the differential characteristics of acoustic wave signal propagation time in different media at various positions to detect the positional information of the concrete pouring interface. For extracting signal differences, full pulse inversion technology is primarily used to identify the propagation characteristics within concrete and the dynamic changes during the cast-in-place pile pouring process. The basic principle of this monitoring method is illustrated in

Figure 1. The implementation of this method requires two types of equipment: a downhole monitoring tube and a ground-mounted signal processor. The downhole monitoring tube mainly comprises the Level I sound source, interface acoustic wave sensor, Level II sound source, Level III sound source, acoustic wave receiver, and signal transmitter. The assembly, consisting of the Level I sound source, interface acoustic wave sensor, Level II sound source, and Level III sound source, is installed in the required monitoring area for the pouring interface. In contrast, the assembly of the acoustic wave receiver and signal transmitter is placed at the borehole opening. The primary function of the Level I, Level II, and Level III sound sources is to generate acoustic signals of different frequencies. The acoustic wave receiver is responsible for receiving the acoustic signals emitted by the Level I, Level II, and Level III sound sources. The interface acoustic wave sensor both emits and receives acoustic signals, capturing the round-trip time of acoustic waves between its transducer and the concrete pouring interface. The signal transmitter’s main role is to transmit the collected signals to the ground-based signal processor, while signal storage, analysis, and display are performed by the signal processor.

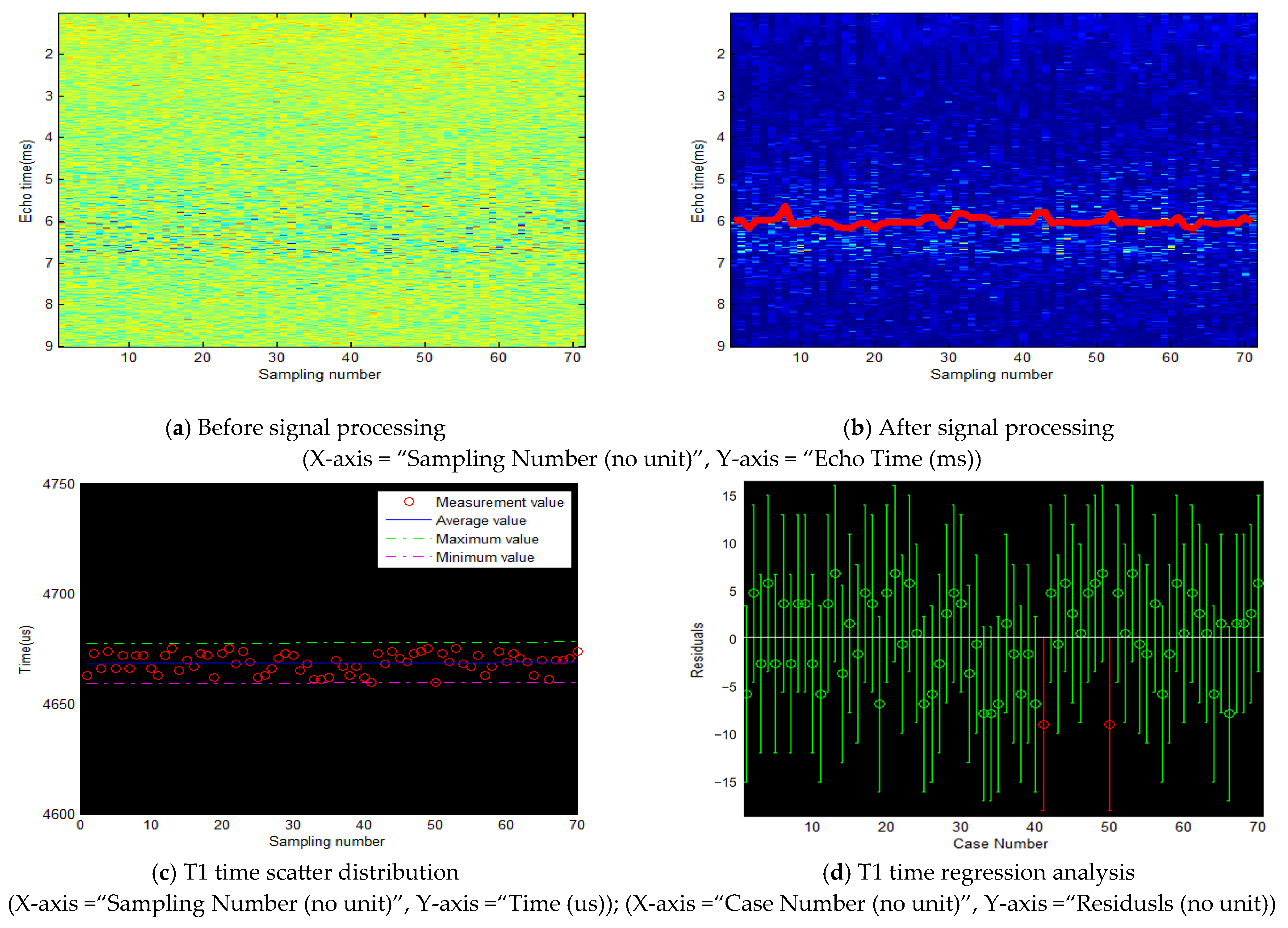

The basic principle of the device is to lower the monitoring tube above the position that needs to be monitored on the pouring interface during the concrete pouring process of the borehole pile, and activate the monitoring tube and signal processor. During the operation of the device, the circuit in the monitoring tube drives the Level I sound source device, Level II sound source device, and Level III sound source device to simultaneously excite acoustic wave signals with different frequency characteristics. These acoustic wave signals propagate in the concrete and undergo reflection and refraction when encountering different medium interfaces (such as concrete pouring interfaces). Meanwhile, the interface acoustic wave sensor is a directional transducer. When the emitted acoustic wave signal encounters the concrete pouring interface in the propagation direction, its reflected echo signal is received by the interface acoustic wave sensor, which records the time it takes for the acoustic wave signal to travel back and forth in the medium. The orifice full pulse receiver captures all in borehole acoustic signals in real time. These signals are transmitted through signal transmitters to signal processors on the ground for further processing and analysis. The signal processor utilizes full pulse inversion technology to analyze these acoustic signals, thereby extracting the propagation characteristics in concrete and the dynamic changes during the pouring process of the cast-in-place pile. By comparing the propagation time differences in acoustic wave signals at different locations, the position of the concrete pouring interface can be accurately located. The core steps of this method mainly consist of waveform data processing, target feature recognition, and interface position calculation.

Section 2.2 and

Section 2.3 will provide a detailed description of these three parts.

To clarify the implementation process, a simplified process flow diagram (

Figure 2) is first provided, covering four key stages: signal generation, capture, analysis, and interface estimation.

Signal Generation (Multi-level Sound Sources): Three levels of sound sources are pre-installed at fixed depths in the borehole monitoring tube. Each sound source emits continuous, stable pulse signals—high-frequency signals are sensitive to thin mud layers at the interface, medium-frequency signals balance penetration and resolution, and low-frequency signals reduce attenuation in deep concrete. This multi-frequency design directly addresses the limitation of traditional single-frequency methods (unable to distinguish different media).

Signal Capture (Sensors + Receiver): The interface acoustic wave sensor emits directional acoustic waves and captures their round-trip time to the pouring interface. The orifice full pulse receiver (mounted at the borehole opening) collects all acoustic signals propagated from the borehole (including direct signals from sound sources and reflected signals from the interface) in real time, ensuring no loss of effective information.

Signal Analysis (Data Processing + Feature Recognition): The ground processor first performs preprocessing (denoising, enhancement) on the captured signals, then uses wavelet analysis to separate multi-frequency signals, and finally identifies target features via cross-correlation and signal similarity analysis.

Interface Estimation (Dual-mode Calculation): Based on the interface position relative to the sensors, two calculation modes are activated: (1) Near-field mode (interface between sensor and Level II sound source): Uses the sensor’s round-trip time data for direct calculation (high precision). (2) Far-field mode (interface between Level II and Level III sound sources): Uses the propagation time difference between multi-level sound sources for indirect calculation (reduces sensor dependence).

2.2. Waveform Data Processing

After the acoustic wave receiver at the borehole orifice captures all acoustic signals in real-time with full pulses, the waveform data of these captured acoustic signals must first undergo pre-processing to handle complex signals within the borehole. This pre-processing step is critical for improving the accuracy and efficiency of subsequent feature recognition. Waveform data processing primarily includes three key steps: signal denoising, enhancement, and standardization. Specifically, signal denoising involves using filtering algorithms to remove background noise and interference components from acoustic signals, thereby ensuring signal quality. Signal enhancement focuses on amplifying weak components within the signal, which guarantees that all key information can be effectively captured. Signal standardization involves unifying processed acoustic signals to a consistent level, facilitating subsequent data analysis and comparison. Through this series of waveform data processing steps, the signal-to-noise ratio (SNR) of acoustic signals is significantly improved, laying a solid foundation for subsequent target feature recognition.

Wavelet analysis is a time-frequency analysis method in which the width of the window function can vary with the frequency of the signal. It decomposes the signal into a time scale phase space, with each scale corresponding to a certain frequency range. Wavelet transform has the characteristics of multi-resolution analysis and can effectively extract useful information from the signal. It is an ideal tool for processing nonlinear and non-stationary signals. Due to the use of Level I, Level II, and Level III sound sources in this method, which can excite acoustic signals with different frequency characteristics, the acoustic receiver needs to capture all acoustic signals in the borehole in full pulse real-time. Therefore, wavelet analysis method can be used to distinguish signals in different frequency ranges. Let

be a square integrable function, i.e.,

. If its Fourier transform satisfies the condition:

Then

is called a fundamental wavelet or mother wave, and the above equation is the wavelet tolerance condition, which implies that if

, the mean of the analyzed signal is zero. The wavelet mother function

is scaled

and time shifted

to obtain the wavelet function family

, which takes the form of:

is a wavelet mother function that depends on parameters

and

. Changing the size of scale can transform the shape of the window, thereby adjusting the frequency range covered by the wavelet and achieving the translation of the wavelet window in the frequency domain. By changing the size of the time factor b, the position of the wavelet in the time domain window can be adjusted to achieve translation in the time domain. The continuous wavelet transform of signal s(t) is defined as:

In the equation,

is the conjugate function of

. For permissible wavelets, the inverse wavelet transform or reconstruction relationship is:

Wavelet transform has the property of “zoom”. When analyzing low-frequency signals, corresponding to large scales, its time window is large. When analyzing high-frequency signals, corresponding to small scales, its time window decreases. By using wavelet transform, it is possible to effectively distinguish and process acoustic signals with different frequency characteristics captured inside the borehole. By analyzing the wavelet coefficients at each scale, feature information corresponding to different frequency acoustic signals can be extracted. After completing wavelet analysis, other signal processing techniques such as Fourier transform, Hilbert transform, etc., can be further utilized to refine the analysis of acoustic signals, in order to extract more detailed information about the internal structure and pouring process of concrete. These processing results will provide strong support for subsequent target feature recognition and interface position calculation.

2.3. Target Feature Recognition and Interface Position Calculation

Once waveform data processing is completed, the workflow proceeds to the target feature recognition stage. The primary task of this stage is to extract key feature information related to the concrete pouring interface of cast-in-place piles from the processed acoustic signals. The excitation signals consist of Level III, Level II, and Level I signals, which are emitted by the corresponding Level III, Level II, and Level I sound sources, respectively. The received signals, which serve as the focus of target feature recognition, mainly include the Level III, Level II, and Level I signals—each corresponding to the excitation signal emitted by its namesake sound source. A schematic diagram of the target feature region is presented in

Figure 3. Specifically, the target recognition region encompasses three types of acoustic information: (1) the acoustic information carried by the excitation signal from the Level III sound source as it propagates between the Level III sound source and the acoustic receiver; (2) the acoustic information carried by the excitation signal from the Level II sound source during its propagation between the Level II sound source and the acoustic receiver; and (3) the acoustic information carried by the excitation signal from the Level I sound source as it travels between the Level I sound source and the acoustic receiver. This feature information includes, but is not limited to, the reflection intensity, refraction angle, attenuation characteristics, and propagation time of the acoustic signal. For instance, reflection intensity reflects the energy loss of acoustic waves when they encounter the pouring interface; refraction angle reveals changes in the propagation direction of acoustic waves across different media; attenuation characteristics provide indirect insights into the internal structure and compactness of concrete; and propagation time is a key parameter for locating the position of the pouring interface. To accurately identify these target features, advanced signal processing algorithms are employed.

To identify and distinguish the Level III, Level II, and Level I signals within the target feature region, the cross-correlation function between the excitation signals and received signals should be calculated. This cross-correlation function contains information about the Green’s function between sound source A and receiving point B. The impulse response function of these two points (sound source A and receiving point B) can be derived, and theoretically, this Green’s function is consistent with the impulse response function obtained under active excitation-reception conditions. By analyzing the cross-correlation function, the propagation characteristics of acoustic signals emitted by different levels of sound sources in concrete can be identified, thereby enabling the determination of the target feature region. During the target feature recognition process, attention must also be paid to the frequency components of acoustic wave signals. Since different levels of sound sources excite acoustic signals of different frequencies, the propagation characteristics of these signals in concrete also differ. By analyzing the frequency components of acoustic signals, we can gain further insights into the internal structural characteristics and defect status of concrete.

In the time domain, three types of signals can be predicted based on the order of arrival time and the strength of energy of the acoustic wave signal. Specifically, the third-level signal takes the shortest time and receives the strongest amplitude of the acoustic wave. The duration of the second-level signal is followed by the strength of the received acoustic wave amplitude. Level I signals take the longest time and receive the weakest amplitude of acoustic waves. In addition, combining the similarity of signals to further distinguish acoustic wave signals. Assuming that the initial excitation signal and the received signal are T {m

1, m

2, m

3, …} and R {n

1, n

2, n

3, …}, respectively, the similarity between the signals is defined as:

In the above equation, the description of is the degree of similarity between the initial excitation signal and the reconstructed signal. If the two are completely identical after normalization, the correlation coefficient , indicating that the received signal has the highest probability of being the target signal. If , then the two are not correlated, indicating that the probability of the received signal being the target signal is the smallest.

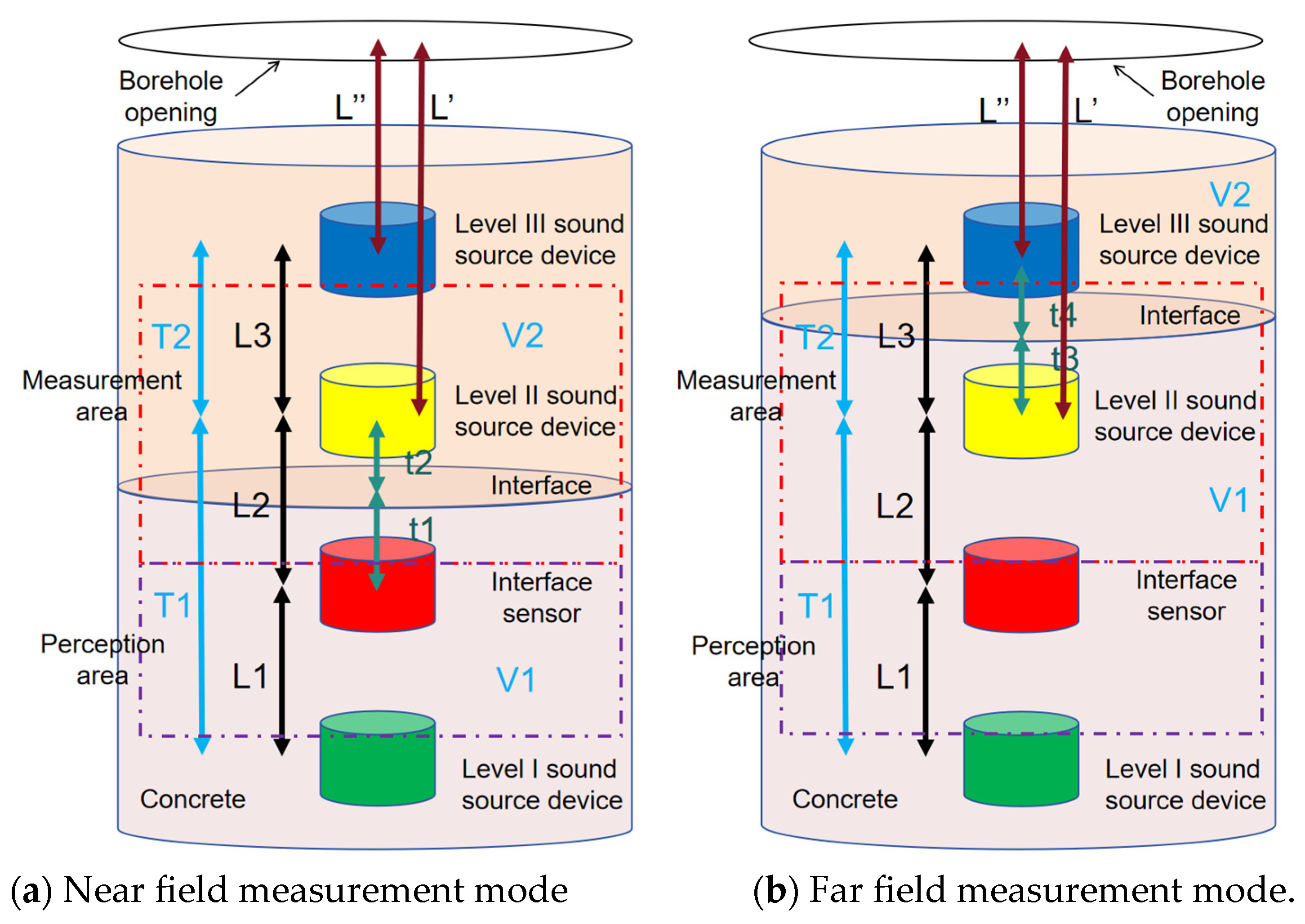

The extracted target features (e.g., T1, T2, V1) directly inform the interface position calculation, which relies on dividing the monitoring tube into ‘perception-measurement’ zones and ‘near-field-far-field’ modes to optimize accuracy. After completing waveform data processing and target feature recognition, calculating the position of the pouring interface becomes necessary. Based on the layout of the Level I sound source, interface acoustic wave sensor, Level II sound source, Level III sound source, and acoustic wave receiver inside the monitoring tube, the tube is divided into a sensing area and a measurement area. Specifically:

When the pouring interface is in the sensing area, the signal processor detects its entry and prepares for real-time measurement of the interface. This method defines the sensing area as the region between the Level I sound source and the interface acoustic wave sensor.

When the pouring interface is in the measurement area, the signal processor detects its entry and calculates the interface’s accurate real-time position. This method defines the measurement area as the region between the interface acoustic wave sensor and the Level III sound source.

When the pouring interface is at different positions within the measurement area, variations in the measurement accuracy of the interface acoustic wave sensor may occur. To achieve higher measurement accuracy, the measurement area is further divided into two modes:

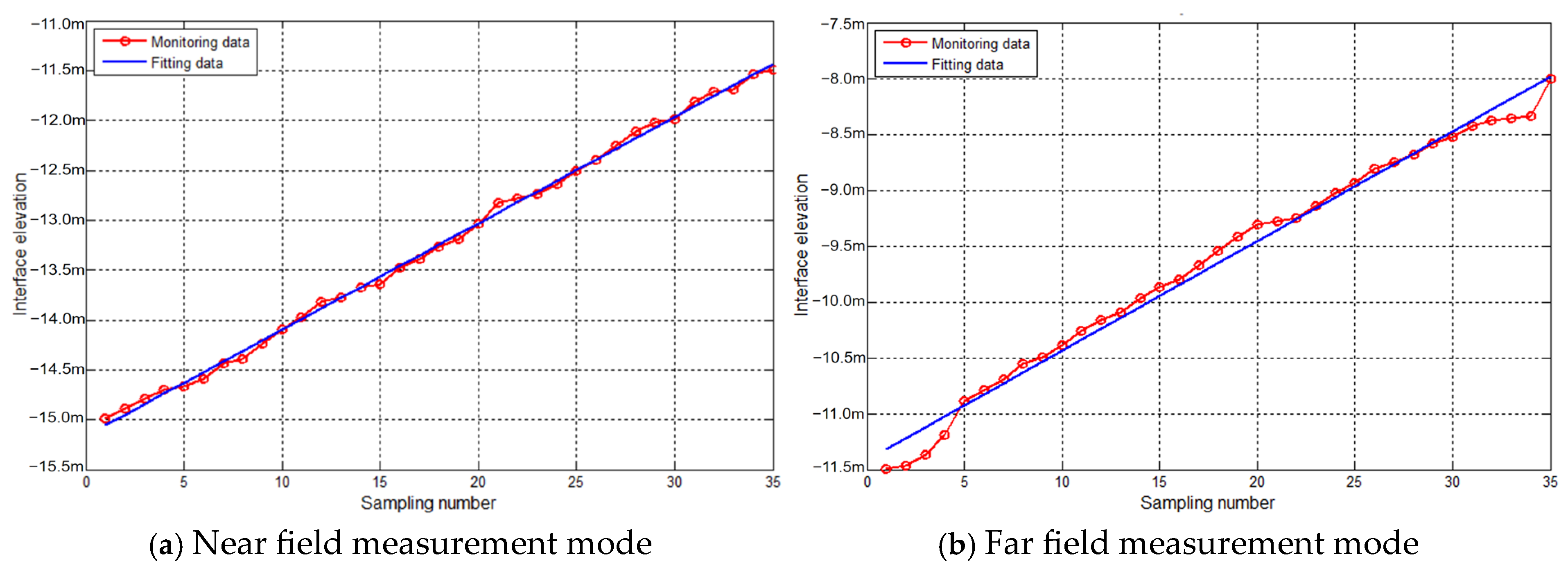

Near-field measurement mode: Activated when the pouring interface is between the interface acoustic wave sensor and the Level II sound source. This mode relies heavily on data from the interface acoustic wave sensor (see

Figure 4a).

Far-field measurement mode: Activated when the pouring interface is between the Level II and Level III sound sources. This mode relies minimally on data from the interface acoustic wave sensor (see

Figure 4b).

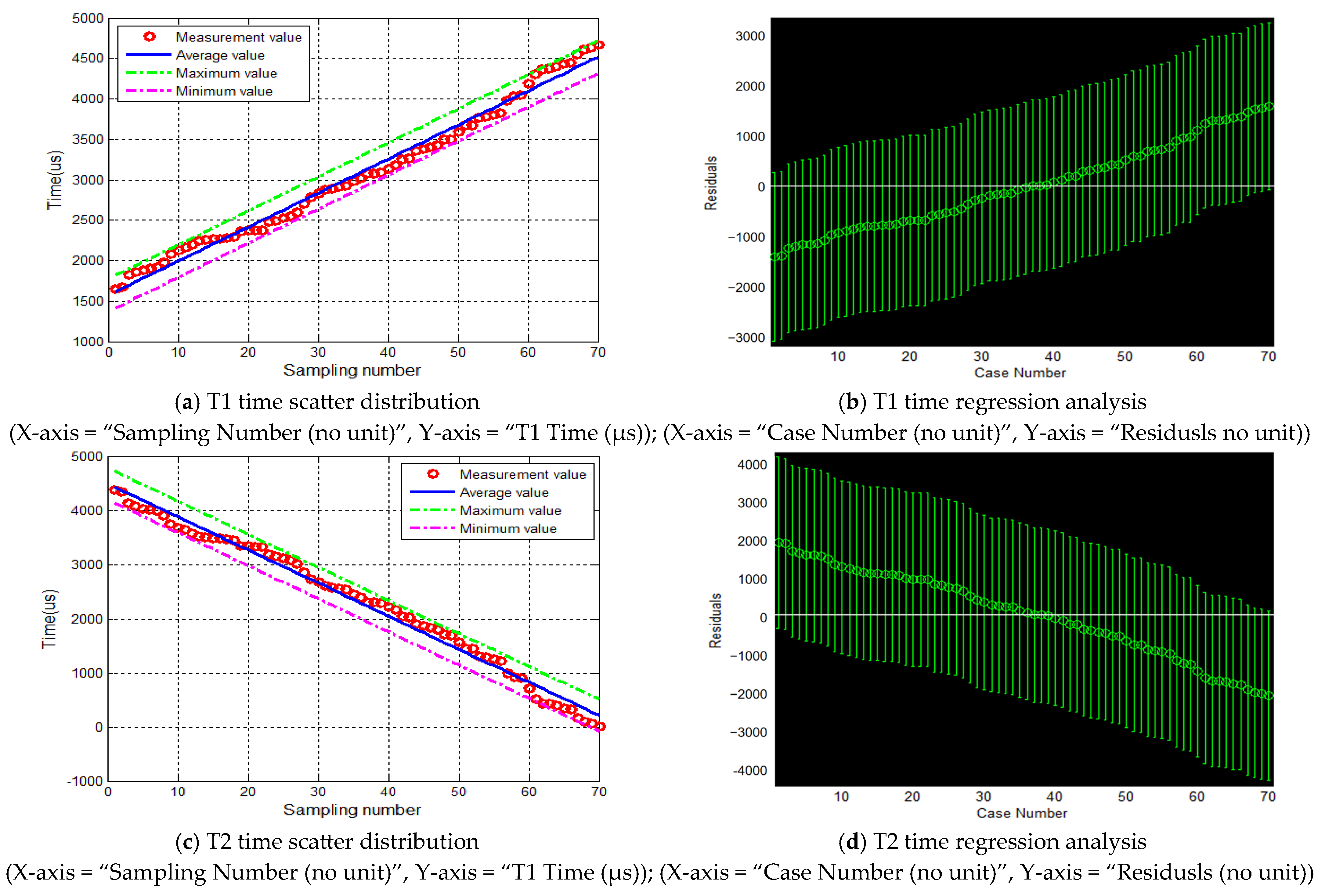

In the pouring interface position measurement model, it is assumed that the acoustic wave transmission time between the first level sound source and the second level sound source is T1, and the acoustic wave transmission time between the second level sound source and the Level III sound source device is T2. T1 corresponds to the time difference between the first-level signal and the second-level signal. T2 corresponds to the time difference between the level II signal and the level III signal. The distance between the Level I sound source and the interface acoustic wave sensor is L1. The distance between the interface acoustic wave sensor and the Level II sound source is L2. The distance between the Level II sound source and the Level III sound source is L3. The acoustic wave velocity below the pouring interface is V1. The acoustic wave velocity above the pouring interface is V2. Therefore, in near-field measurement mode, the following relationship exists:

Among them, t1: One-way sound propagation time from the interface acoustic sensor to the pouring interface (μs). L3: Distance between Level II and Level III sound sources (m). T2: Sound propagation time between Level II and Level III sound sources (μs). L2: Distance between the interface acoustic sensor and Level II sound source (m). L1: Distance between Level I sound source and the interface acoustic sensor (m). T1: Sound propagation time between Level I and Level II sound sources (μs). V1: Sound velocity in concrete below the pouring interface (m/s). V2: Sound velocity in slurry/concrete above the pouring interface (m/s). t2: One-way sound propagation time from Level III sound source to the pouring interface (μs). t1, L3, T2, L2, L1, and T1 are known quantities. T1 is the propagation speed between the interface sensing sensor and the interface, which can be determined by analyzing the first echo signal collected by the interface sensing sensor. T2 and V1 are unknown variables. The values of t2 and V1 can be obtained based on Equation (6).

In practical calculations, there are corresponding constraints for selecting the specific values of t2 and V1. The specific constraints are as follows:

In the far-field measurement mode, since the pouring interface passes the Level II sound source and the distance between the interface acoustic wave sensor and the Level II sound source is relatively large, direct sensing of the pouring interface via the interface acoustic wave sensor tends to introduce substantial errors. To reduce reliance on data from the interface acoustic wave sensor, a calculation method for the interface position in the far-field measurement mode is established, with the corresponding expression given as follows:

Among them, V1, V2, T2, and L3 are known quantities, while t3 and t4 are unknown quantities. The values of t3 and t4 can be obtained based on Equation (13). We can obtain:

The calculation formula for the distance L between the location of the concrete pouring interface and the borehole opening is:

Among them, L′ denotes the vertical distance between the Level II sound source (located inside the monitoring tube) and the borehole opening. L″ denotes the vertical distance between the Level III sound source (located inside the monitoring tube) and the borehole opening.