Condition-Based Maintenance Plus (CBM+) for Single-Board Computers: Accelerated Testing and Precursor Signal Identification

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Acquisition Strategy and Research Overview

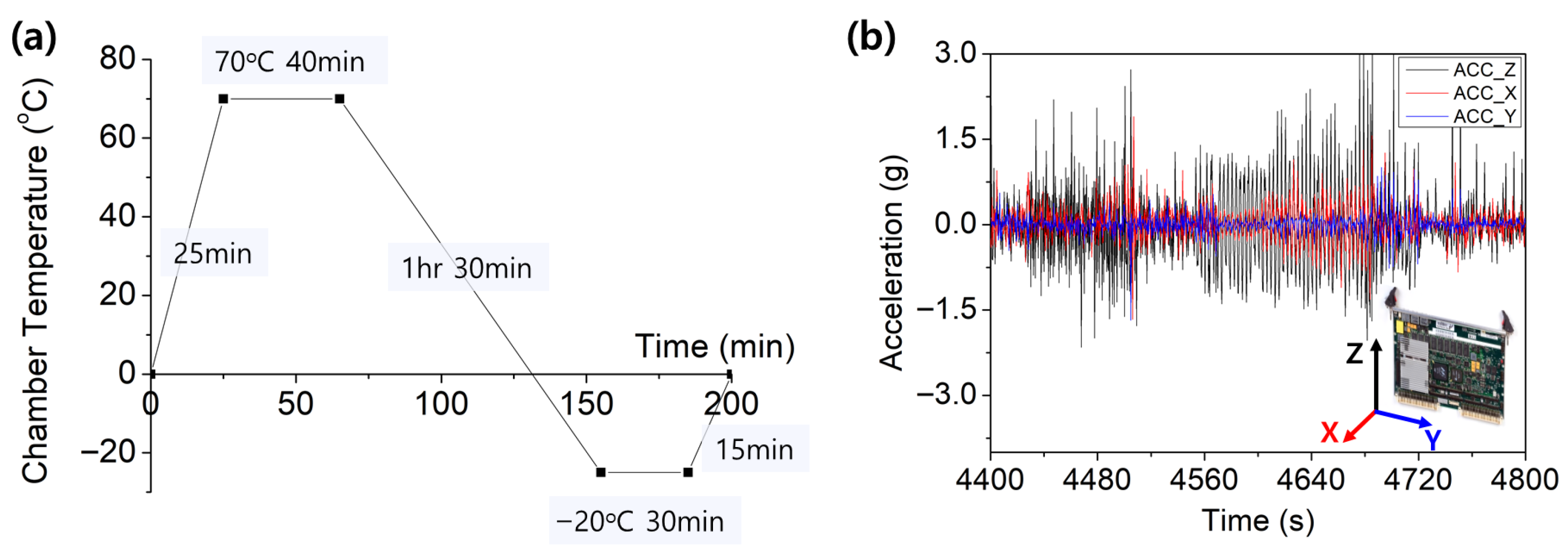

2.2. Temperature–Humidity Accelerated Testing Conditions

- Temperature range: Temperature ranged from −20 °C to 65 °C, with a cycle duration of approximately 5 h.

- Humidity: This was maintained up to 60% RH.

- Procedure: Samples were alternately exposed to high-temperature/high-humidity and low-temperature conditions in repeated cycles. Over the longest run (∼16 months), this corresponds to ∼1900 chamber cycles.

2.3. Vibration Accelerated Testing Conditions

- Frequency range: The range was 5–20 Hz.

- Acceleration: A 0.707 g average RMS sinusoidal vibration was applied sequentially to the Z axis with controlled amplitude, without synthesizing frequency components. The actual acceleration measured on the SBC using an external accelerometer is shown in Figure 2b.

- Duration: The test continued until failure occurred.

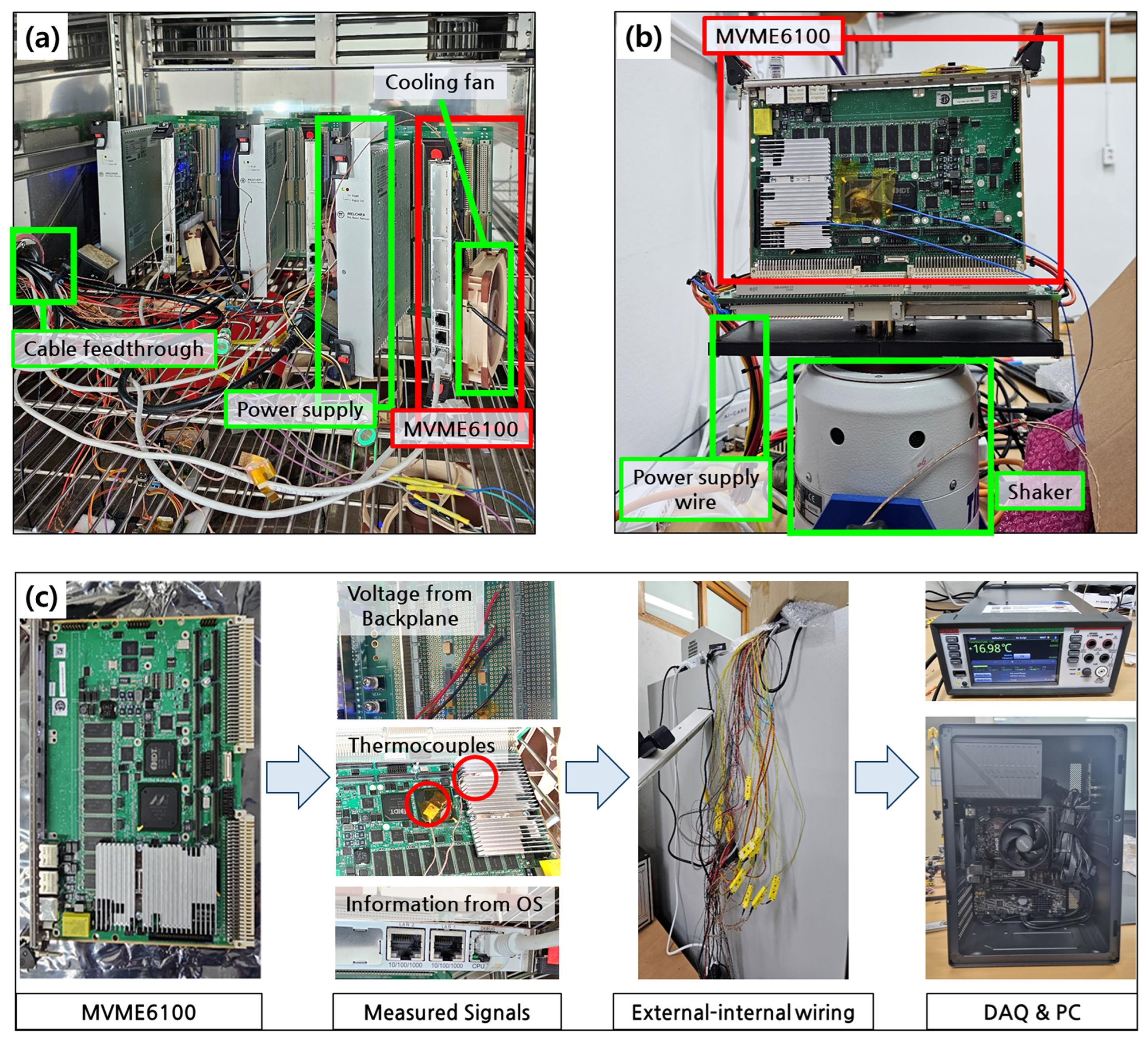

2.4. Experimental Setup and Data Acquisition

- Thermocouples: Attached to the CPU heatsink and the memory chips to measure localized temperature rise.

- Electrical monitoring: Output voltage measured using precision DAQ channels.

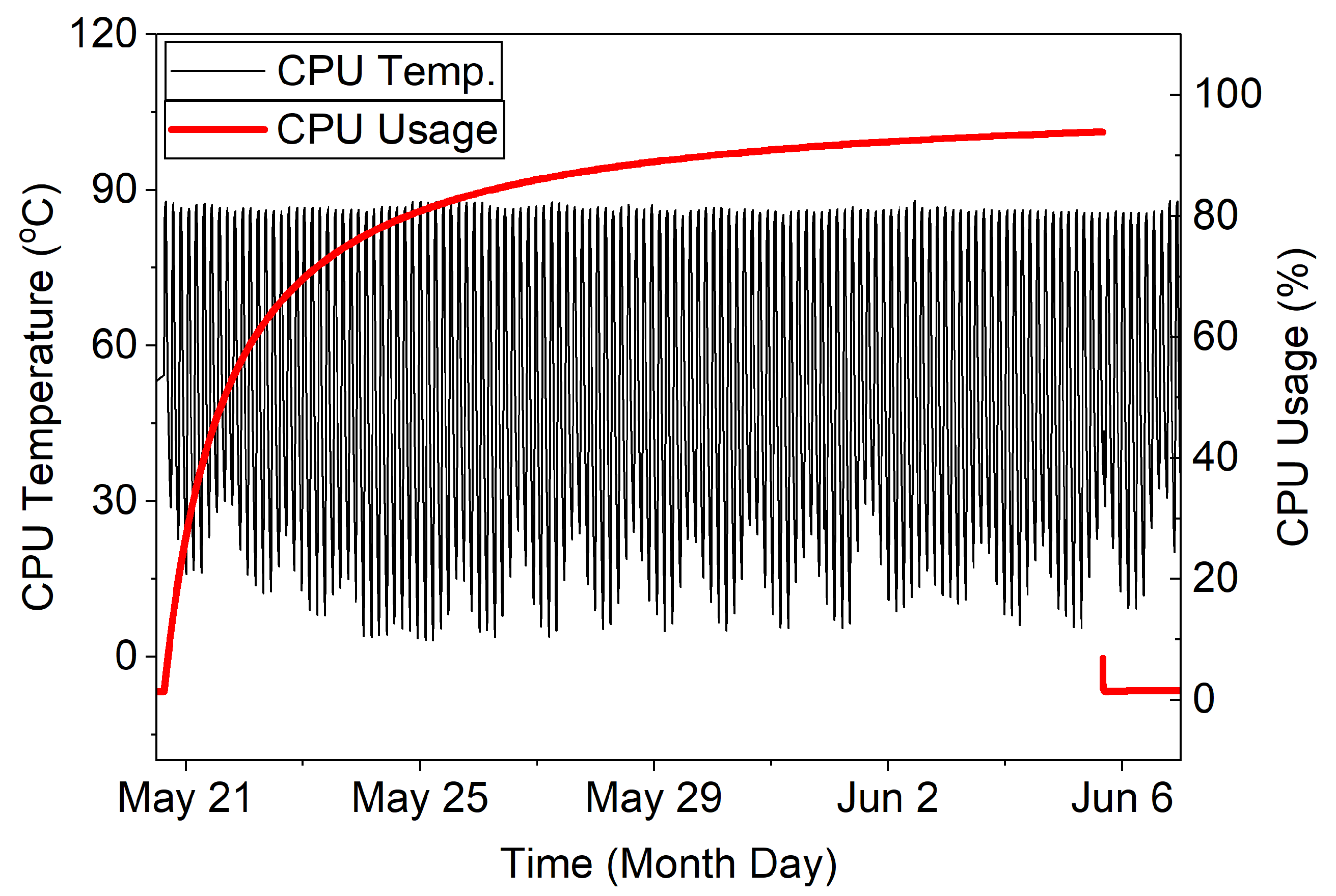

- Performance monitoring: CPU usage and memory usage measured by bash code on Linux.

2.5. Data Labeling Criteria

- Normal: Periods during which the SBC operated without any observable malfunction. In this state, power remained stable, communication signals were consistently received, and CPU/memory temperatures followed ambient chamber variations without irregularities.

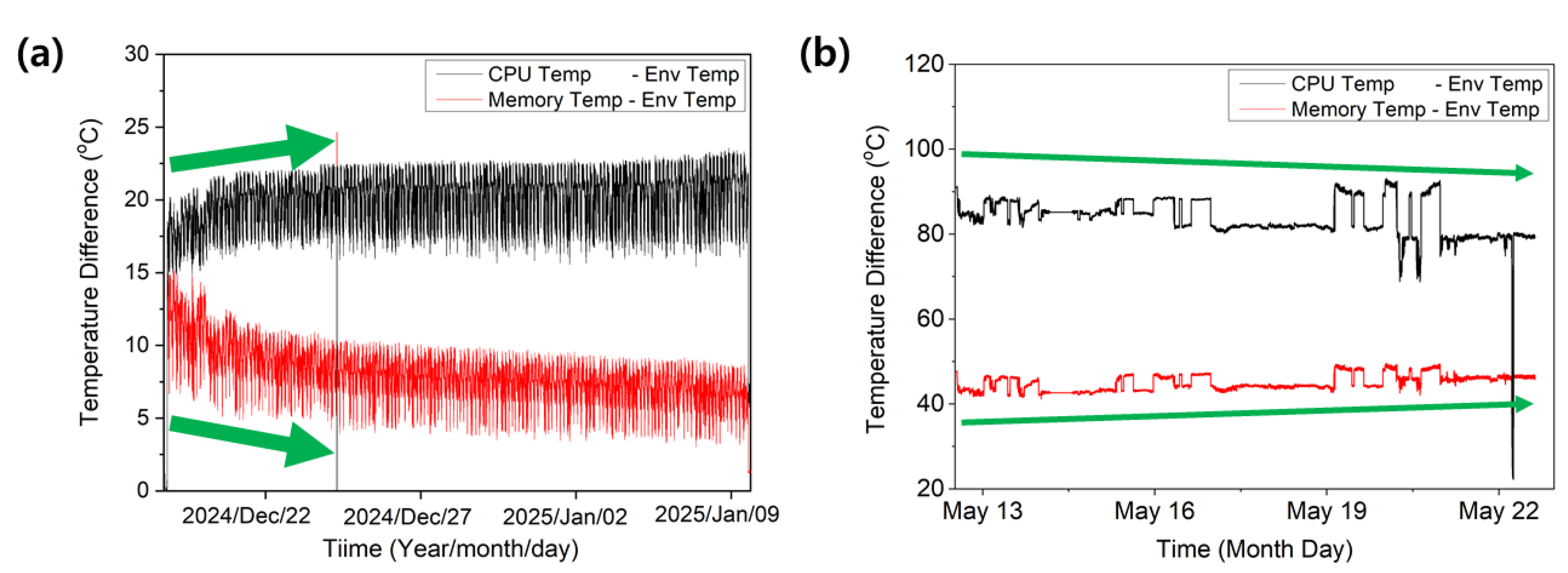

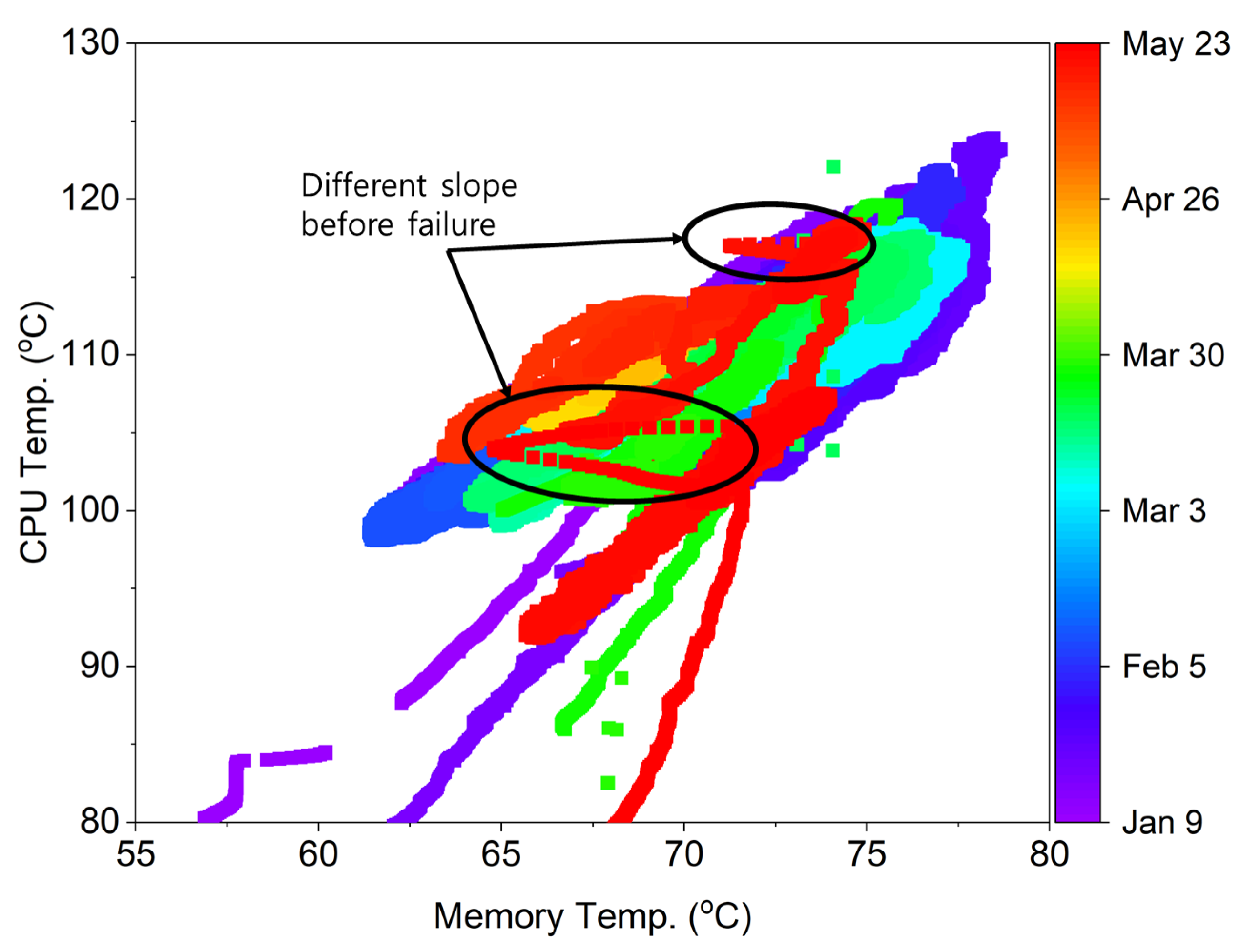

- Abnormal (Precursor): Intervals preceding failure where noticeable deviations appeared in the signals, such as divergence between CPU and memory temperature trends, increasing communication noise, or irregular fluctuations. These periods were identified as precursor states that reflect incipient degradation. Ambient compensation used and at identical timestamps t; divergence was evaluated on .

- Failure: Defined as the point at which the SBC ceased to function normally, including cases where the board could not be powered on or when system-level communication stopped due to kernel panic, shutdown, or other fatal errors.

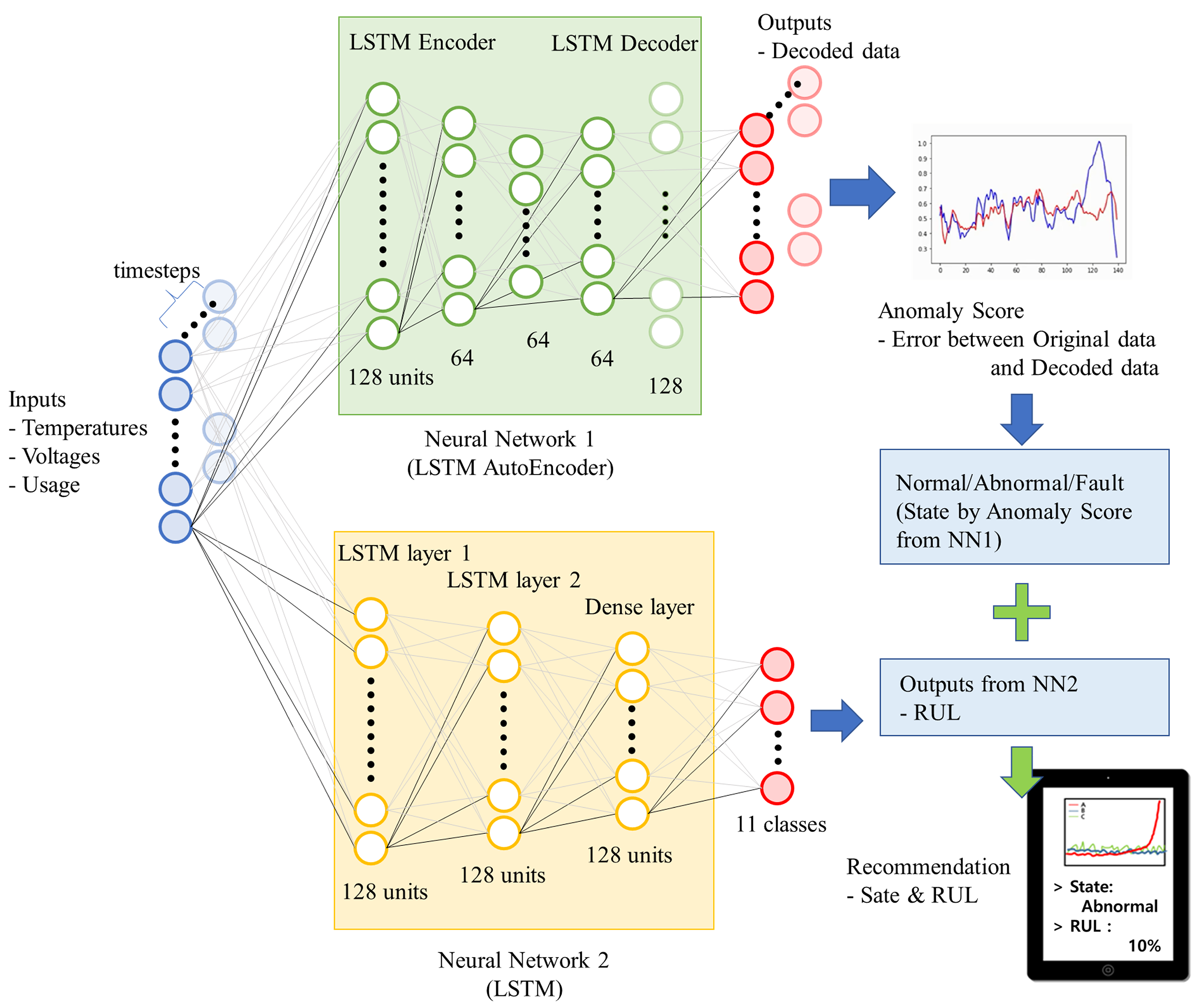

2.6. Artificial Neural Network Modeling Approaches

2.6.1. Challenges with Limited Failure Data

- Data augmentation techniques, which synthetically expand available datasets by injecting noise, scaling, or simulating degradation trends [30].

2.6.2. Autoencoder Approach

2.6.3. LSTM Approach

2.6.4. Complementary Framework

- Autoencoder: Provides reliable anomaly detection when only normal operation data are available, making it suitable for data-scarce conditions.

- LSTM: Captures temporal dependencies and directly models degradation trajectories when both normal and fault data are accessible.

3. Results

3.1. DAQ Signal Analysis

3.1.1. Overall Experimental Progress

- One temperature–humidity sample failed after 181 days.

- One vibration sample failed after 134 days.

- The remaining four samples are still under test:

- –

- Three temperature–humidity samples have been running for up to 16 months.

- –

- One vibration sample has been running for 5 months.

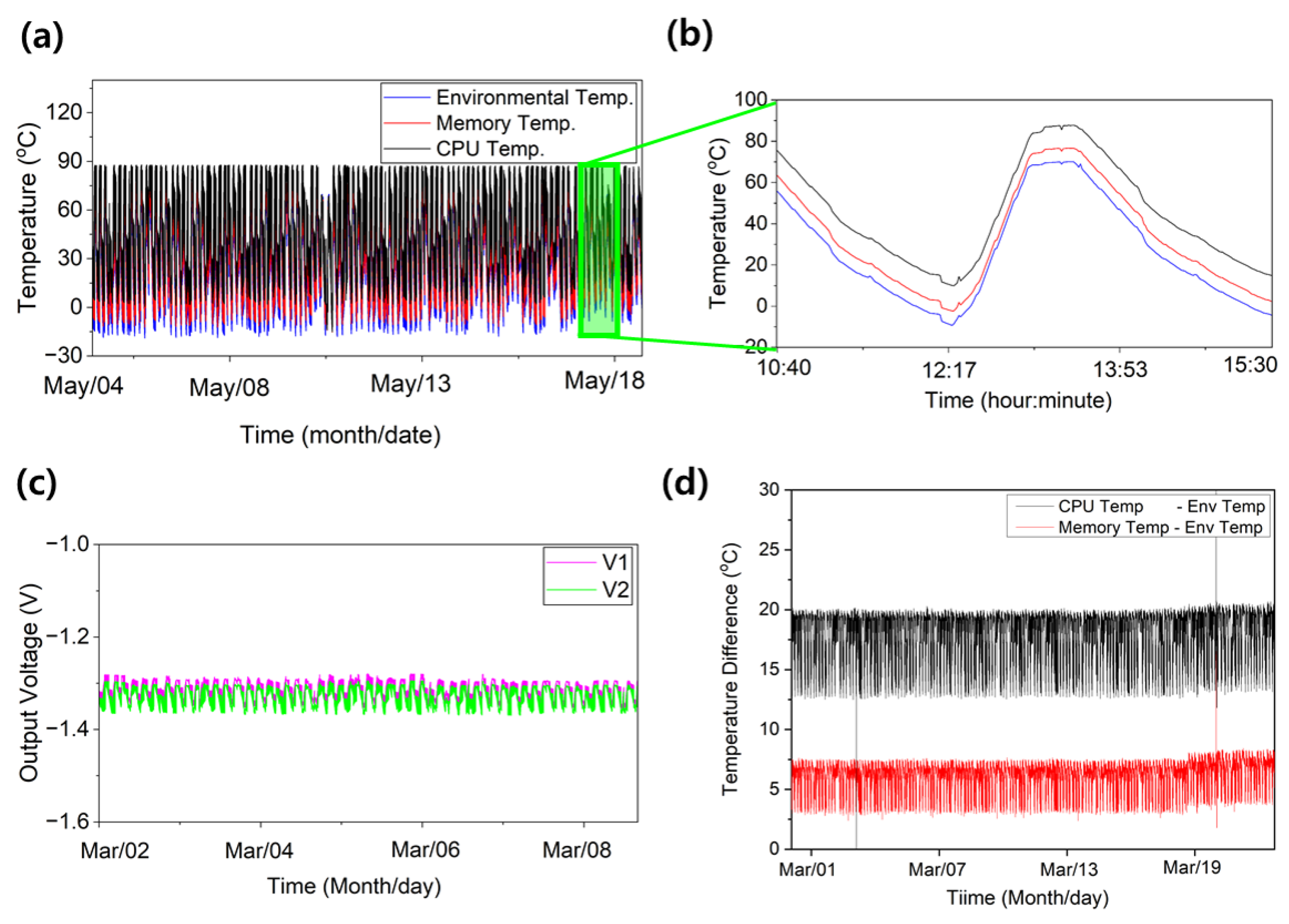

3.1.2. Normal-State Behavior

3.1.3. Precursor Trends Before Failures

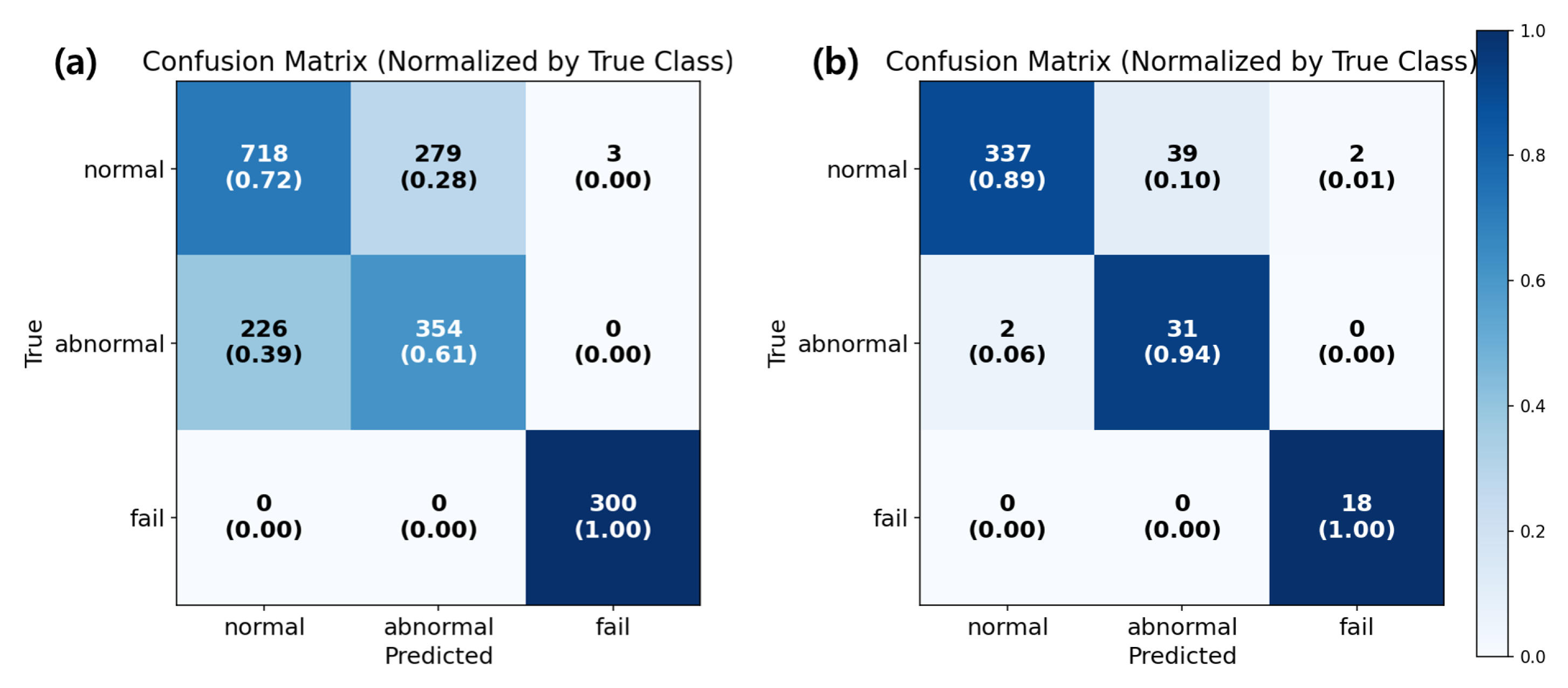

3.2. Autoencoder Results

- One-hour window: 1 min sampling × 60 samples.

- One-day window: 30 min sampling × 48 samples.

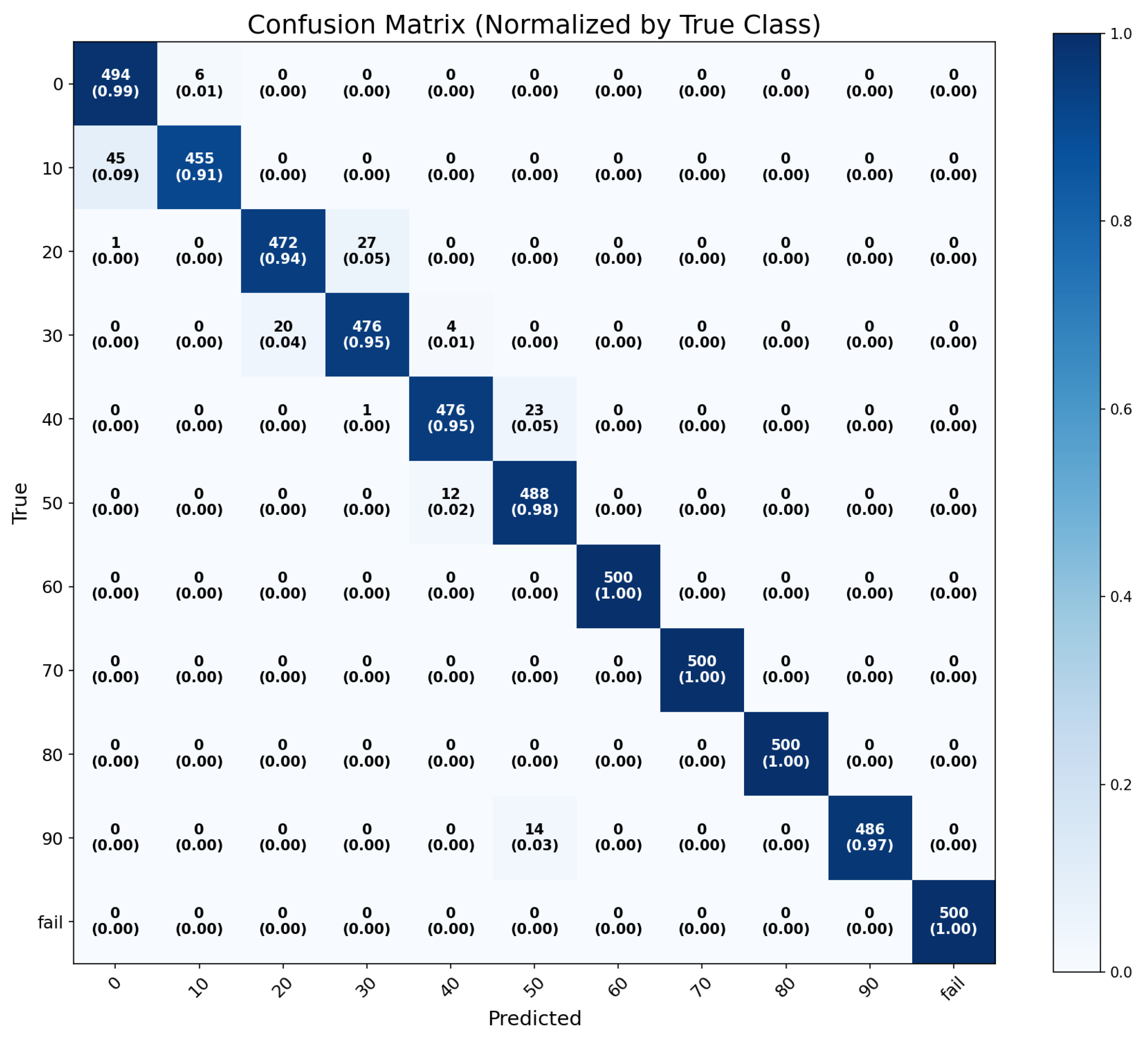

3.3. LSTM Results

3.4. Comparison of LSTM-AE and LSTM Approaches

4. Discussion and Conclusions

4.1. Discussion

- Normal-state stability: Signals track ambient; raw trends make visual prognosis difficult.

- Precursors: After ambient compensation, CPU–memory temperatures diverged ∼10 days before failure; under acceleration, this implies an even earlier lead time under field conditions, enabling proactive maintenance.

- Model performance: LSTM-AE improves with longer horizons; LSTM attains 97.2% with lifecycle labels but may not generalize to novel faults.

- Comparative implications: Hybrid use (Autoencoder for anomaly sensitivity under scarce labels; LSTM for trajectory staging with labels).

- CBM+ translation: In practice, Autoencoder-based anomaly scores can trigger early-warning alerts; LSTM-based lifecycle estimates can drive maintenance scheduling (e.g., inspection windows, spares staging) and mission derating policies. Combining both yields graded responses: warn → inspect → replace.

4.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO 13372:2012; Condition Monitoring and Diagnostics of Machine —Vocabulary. ISO: Geneva, Switzerland, 2012.

- Shin, J.H.; Jun, H.B. On Condition Based Maintenance Policy. J. Comput. Des. Eng. 2015, 2, 119–127. [Google Scholar] [CrossRef]

- Nowlan, F.S.; Heap, H.F. Reliability-Centered Maintenance; United States Department of Defense: Arlington, VA, USA, 1978. [Google Scholar]

- Prajapati, A.; Bechtel, J.; Ganesan, S. Condition Based Maintenance: A Survey. J. Qual. Maint. Eng. 2012, 18, 384–400. [Google Scholar] [CrossRef]

- U.S. Department of Defense. Condition Based Maintenance Plus (CBM+) Guidebook; U.S. Department of Defense: Washington, DC, USA, 2008.

- Byington, C.S.; Roemer, M.J.; Galie, T. Prognostic Enhancements to Diagnostic Systems for Improved Condition-Based Maintenance. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; pp. 2951–2957. [Google Scholar] [CrossRef]

- Crooks, K.; Plawecki, N. Novel Approach to CBM+ Implementation on Aviation Systems. In Proceedings of the 2021 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 24–27 May 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Fox, H.; Pillai, A.C.; Friedrich, D.; Collu, M.; Dawood, T.; Johanning, L. A Review of Predictive and Prescriptive Offshore Wind Farm Operation and Maintenance. Energies 2022, 15, 504. [Google Scholar] [CrossRef]

- Chitteth Ramachandran, R.; Desmond, C.; Judge, F.; Serraris, J.J.; Murphy, J. Floating wind turbines: Marine operations challenges and opportunities. Wind. Energy Sci. 2022, 7, 903–924. [Google Scholar] [CrossRef]

- Fernandes, J.; Reis, J.; Melão, N.; Teixeira, L.; Amorim, M. The role of Industry 4.0 and BPMN in the arise of condition-based and predictive maintenance: A case study in the automotive industry. Appl. Sci. 2021, 11, 3438. [Google Scholar] [CrossRef]

- Jang, D.W.; Kang, J.S.; Lim, J.Y. A feasible strain-history extraction method using machine learning for the durability evaluation of automotive parts. J. Mech. Sci. Technol. 2021, 35, 5117–5125. [Google Scholar] [CrossRef]

- Molęda, M.; Małysiak-Mrozek, B.; Ding, W.; Sunderam, V.; Mrozek, D. From Corrective to Predictive Maintenance—A Review of Maintenance Approaches for the Power Industry. Sensors 2023, 23, 5970. [Google Scholar] [CrossRef]

- Hector, I.; Panjanathan, R. Predictive maintenance in Industry 4.0: A survey of planning models and machine learning techniques. PeerJ Comput. Sci. 2024, 10, e2016. [Google Scholar] [CrossRef]

- Vichare, N.; Pecht, M. Prognostics and health management of electronics. IEEE Trans. Components Packag. Technol. 2006, 29, 222–229. [Google Scholar] [CrossRef]

- Butler, K.M.; Carulli, J.M.; Saxena, J. Modeling Test Escape Rate as a Function of Multiple Coverages. In Proceedings of the 2008 IEEE International Test Conference, Santa Clara, CA, USA, 28–30 October 2008; pp. 1–9. [Google Scholar] [CrossRef]

- Shin, I.; Koo, K.; Kwon, D. Development of a Non-Invasive On-Chip Interconnect Health Sensing Method Based on Bit Error Rates. Sensors 2018, 18, 3234. [Google Scholar] [CrossRef]

- Depiver, J.A.; Mallik, S.; Harmanto, D. Solder joint failures under thermo-mechanical loading conditions—A review. Adv. Mater. Process. Technol. 2021, 7, 1–26. [Google Scholar] [CrossRef]

- Li, L.; Du, X.; Chen, J.; Wu, Y. Thermal fatigue failure of micro-solder joints in electronic packaging devices: A review. Materials 2024, 17, 2365. [Google Scholar] [CrossRef]

- Gabbay, F.; Mendelson, A. Asymmetric aging effect on modern microprocessors. Microelectron. Reliab. 2021, 119, 114090. [Google Scholar] [CrossRef]

- Escobar, L.A.; Meeker, W.Q. A review of accelerated test models. Stat. Sci. 2006, 21, 552–577. [Google Scholar] [CrossRef]

- Indmeskine, F.E.; Othman, M.; Gziri, A. Review on accelerated life testing plan to develop reliability model. Qual. Reliab. Eng. Int. 2023, 39, 4303–4327. [Google Scholar] [CrossRef]

- Lee, S.; Kareem, A.B.; Hur, J.W. A Comparative Study of Deep-Learning Autoencoders (DLAEs) for Vibration Anomaly Detection in Manufacturing Equipment. Electronics 2024, 13, 1700. [Google Scholar] [CrossRef]

- Del Buono, F.; Calabrese, F.; Baraldi, A.; Paganelli, M.; Guerra, F. Novelty Detection with Autoencoders for System Health Monitoring in Industrial Environments. Appl. Sci. 2022, 12, 4931. [Google Scholar] [CrossRef]

- Ahn, S.; Yoo, J.; Lee, K.W.; Youn, B.D.; Ahn, S.H. Frequency-focused sound data generator for fault diagnosis in industrial robots. J. Comput. Des. Eng. 2024, 11, 234–248. [Google Scholar] [CrossRef]

- Gómez, A.; Cuiñas, D.; Catalá, P.; Xin, L.; Li, W.; Conway, S.; Lack, D. Use of Single Board Computers as Smart Sensors in the Manufacturing Industry. Procedia Eng. 2015, 132, 153–159. [Google Scholar] [CrossRef]

- Matthews, S.J. Harnessing single board computers for military data analytics. In Military Applications of Data Analytics; Auerbach Publications: Boca Raton, FL, USA, 2018; pp. 63–77. [Google Scholar]

- MIL-STD-883; Test Methods for Microelectronics—Temperature Cycling/Environmental Tests. U.S. Department of Defense: Arlington, VA, USA, 2004.

- IEC 60068-2-30:2025; Environmental Testing—Part 2–30: Tests — Test Db: Damp Heat, Cyclic (12 h + 12 h Cycle). International Electrotechnical Commission: Geneva, Switzerland, 2025.

- MIL-STD-810; Method 514: Vibration. Sinusoidal and Transport/General Vibration Procedures. U.S. Department of Defense: Arlington, VA, USA, 2019.

- Tian, J.; Jiang, Y.; Zhang, J.; Luo, H.; Yin, S. A novel data augmentation approach to fault diagnosis with class-imbalance problem. Reliab. Eng. Syst. Saf. 2024, 243, 109832. [Google Scholar] [CrossRef]

- Binbusayyis, A.; Vaiyapuri, T. Unsupervised deep learning approach for network intrusion detection combining convolutional autoencoder and one-class SVM. Appl. Intell. 2021, 51, 7094–7108. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Y.; Jian, S.; Liao, Q.; Wang, Y.; Pang, G. Calibrated one-class classification for unsupervised time series anomaly detection. IEEE Trans. Knowl. Data Eng. 2024, 36, 5723–5736. [Google Scholar] [CrossRef]

| Model | Accuracy (%) | Robustness to Novel Faults |

|---|---|---|

| LSTM-AE (1 h window) | 72.9 | Limited discrimination, sensitive to short horizons |

| LSTM-AE (1-day window) | 90.0 | Higher robustness; potential to capture unseen faults |

| Supervised LSTM | 97.2 | High accuracy on trained fault modes; poor generalization to novel faults |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mun, G.-H.; Kim, Y.; Park, Y.; Jang, D.-W. Condition-Based Maintenance Plus (CBM+) for Single-Board Computers: Accelerated Testing and Precursor Signal Identification. Appl. Sci. 2025, 15, 11203. https://doi.org/10.3390/app152011203

Mun G-H, Kim Y, Park Y, Jang D-W. Condition-Based Maintenance Plus (CBM+) for Single-Board Computers: Accelerated Testing and Precursor Signal Identification. Applied Sciences. 2025; 15(20):11203. https://doi.org/10.3390/app152011203

Chicago/Turabian StyleMun, Gwang-Hyeon, Youngchul Kim, Youngmin Park, and Dong-Won Jang. 2025. "Condition-Based Maintenance Plus (CBM+) for Single-Board Computers: Accelerated Testing and Precursor Signal Identification" Applied Sciences 15, no. 20: 11203. https://doi.org/10.3390/app152011203

APA StyleMun, G.-H., Kim, Y., Park, Y., & Jang, D.-W. (2025). Condition-Based Maintenance Plus (CBM+) for Single-Board Computers: Accelerated Testing and Precursor Signal Identification. Applied Sciences, 15(20), 11203. https://doi.org/10.3390/app152011203