A Preliminary Study on the Comparative Schedule Analysis of Traditional and Advanced Work Packaging Plans for Nuclear Power Plant Construction

Abstract

1. Introduction

2. Background: AWP Application for NPP Construction

2.1. Previous AWP Application Research

2.2. Considerations for AWP Application in NPP Construction

- (1)

- Alignment with licensing hold points and regulatory milestones.

- (2)

- Mapping to QA/QC and document/procedure control.

- (3)

- Bridging phase-driven WBS and CWA-driven AWP.

- (4)

- Engineering–construction data/model consistency.

- (5)

- Commissioning interface (system-based turnover).

3. Methods: Research Framework and Model Set Up

3.1. Model Configuration

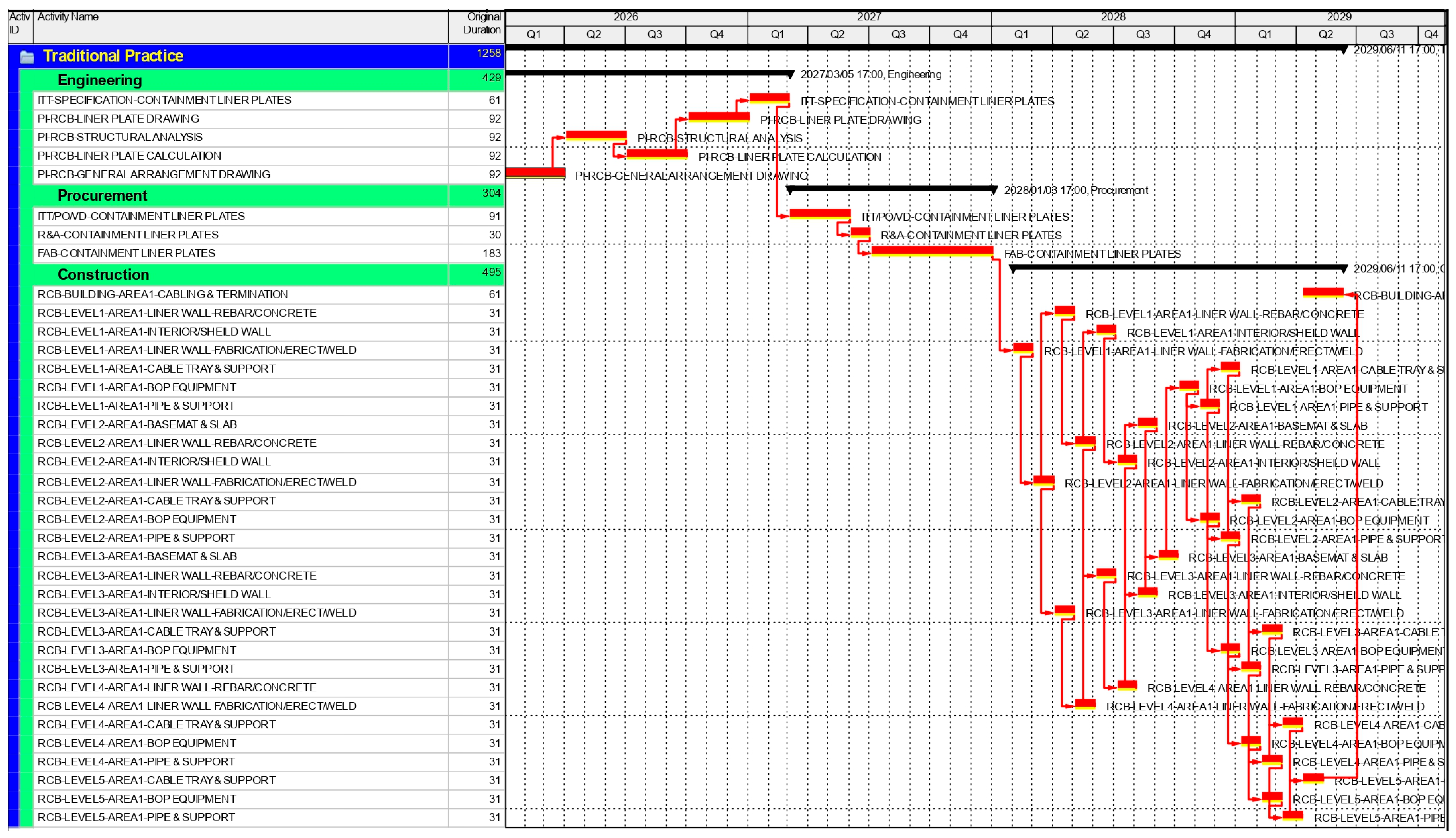

3.2. Traditional Schedule Development

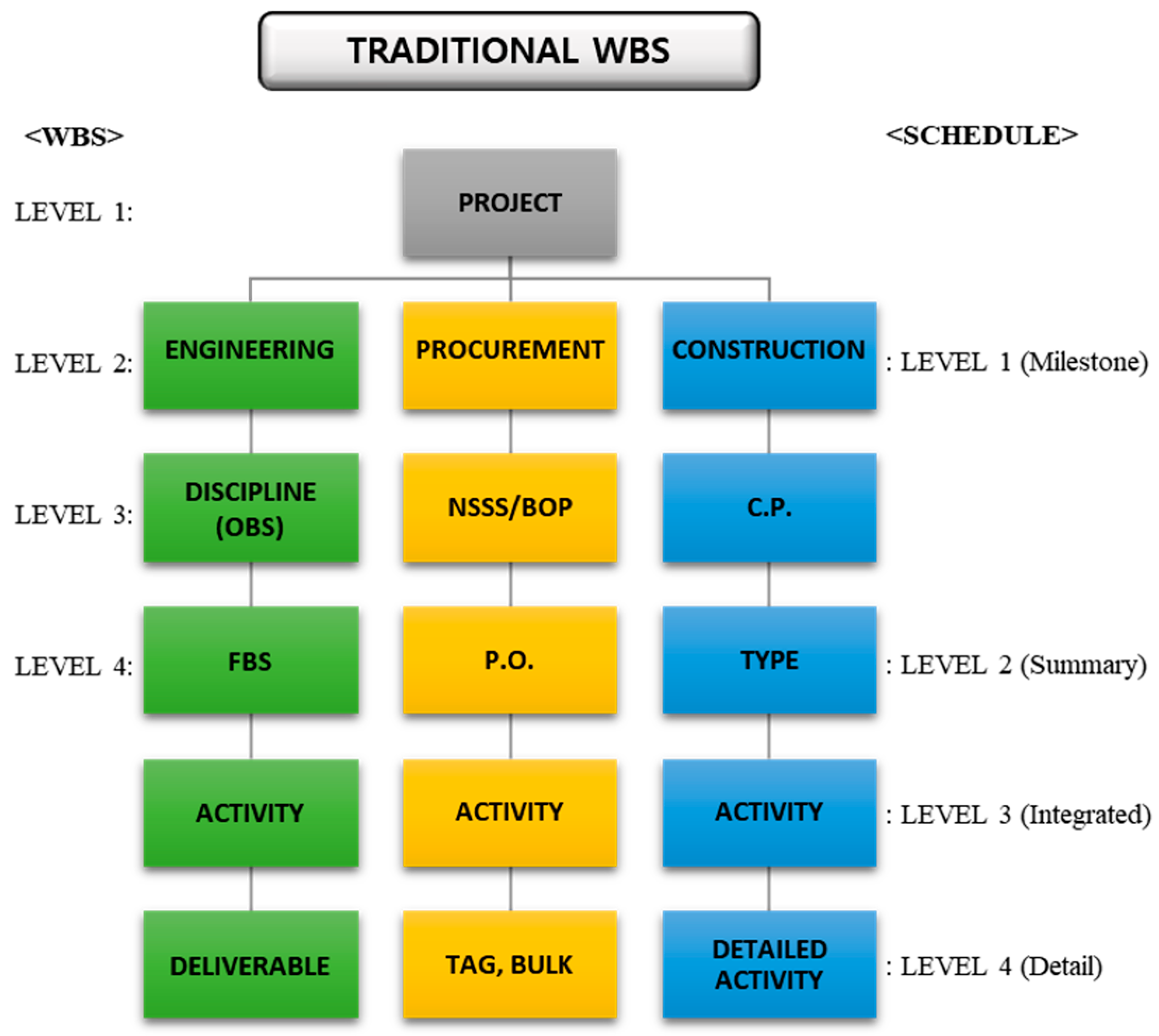

3.2.1. WBS Creation

- Engineering Functional Breakdown Structure (FBS) items representing discipline-specific drawings, specifications, and calculations.

- Procurement packages (PO, Purchase order) representing major material and equipment supply.

- Construction package (CP) activity types representing grouped site work activities. The selected Level 4 items used for modeling are listed in Appendix A.4 Scheduling Assumptions.

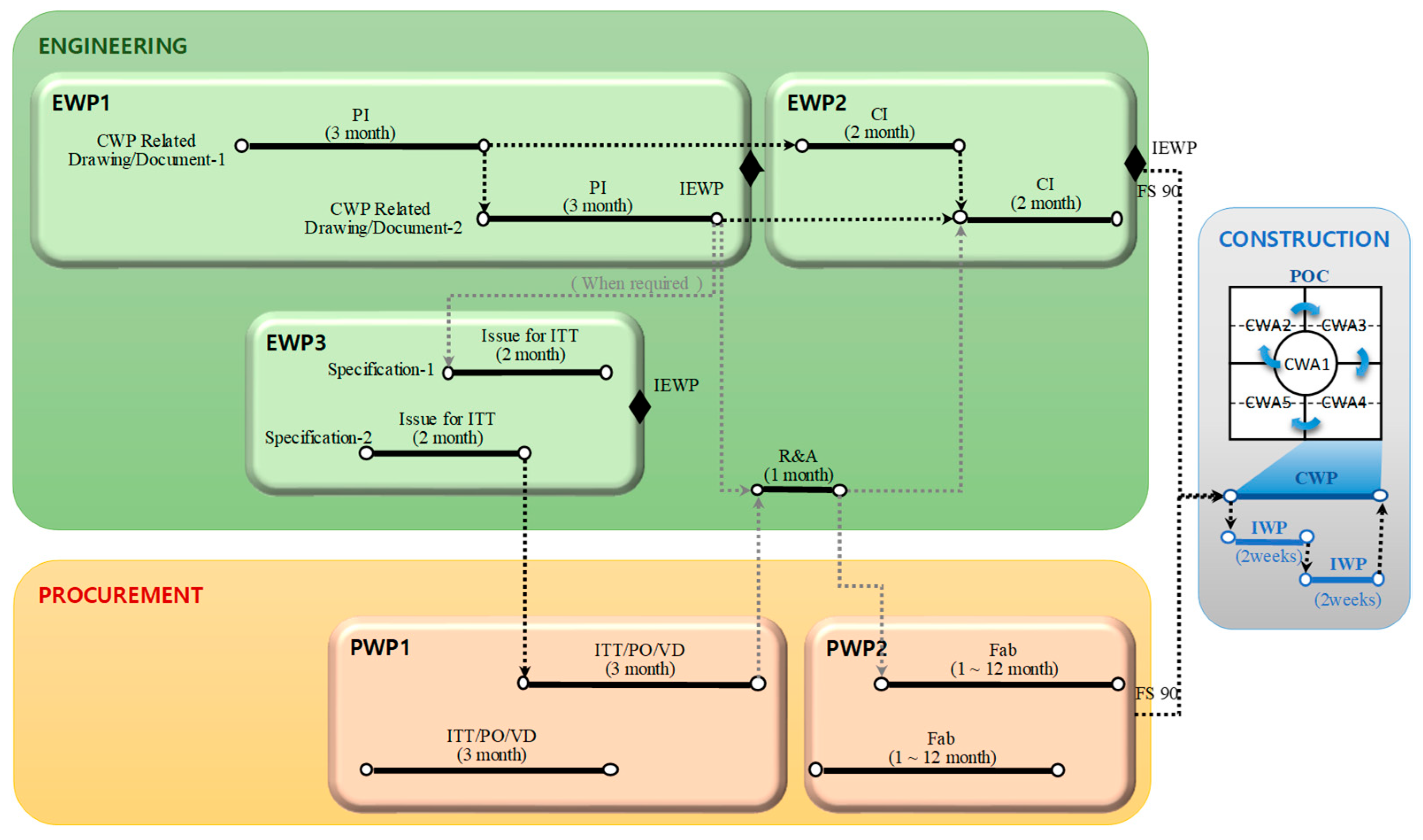

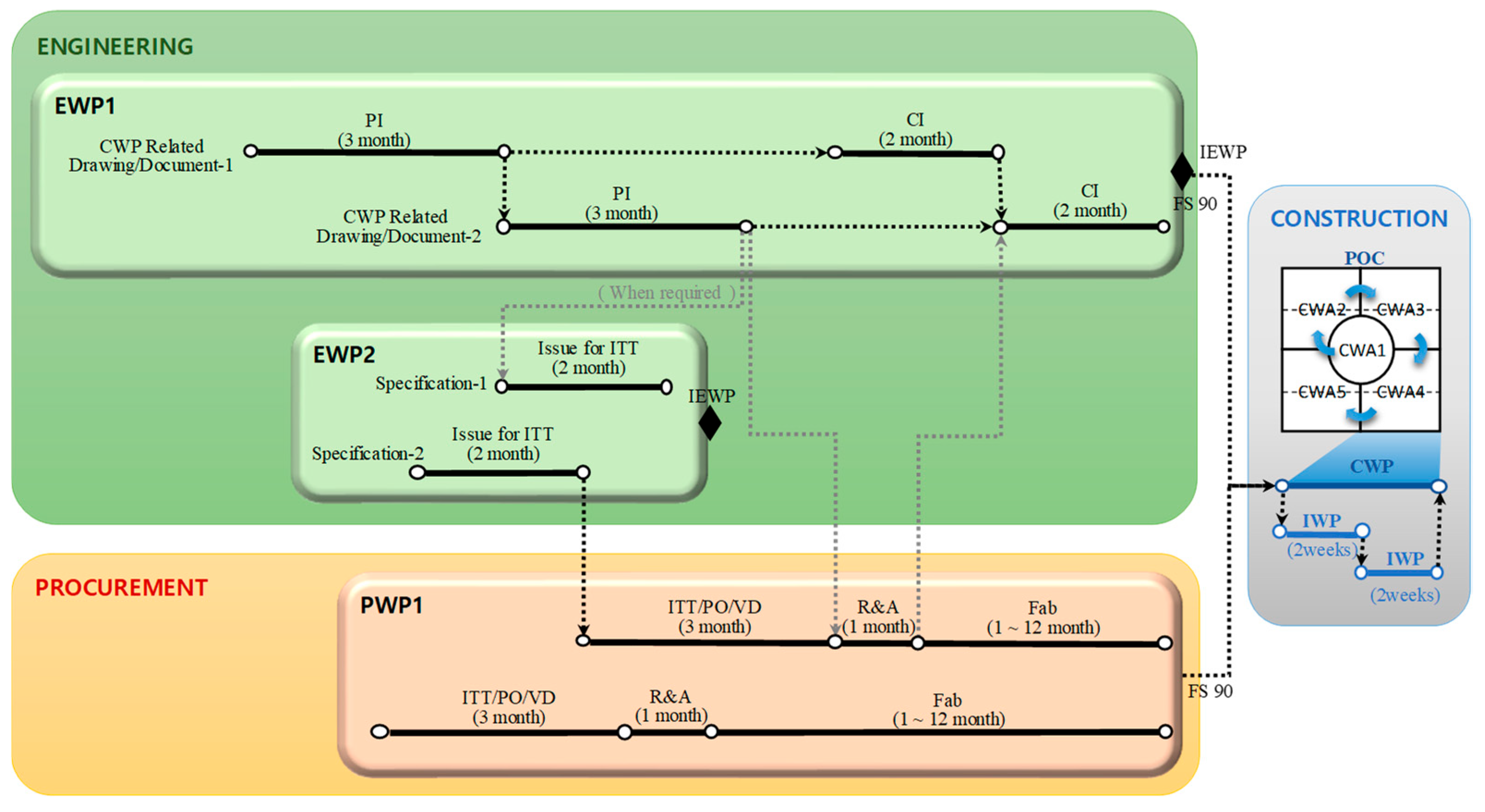

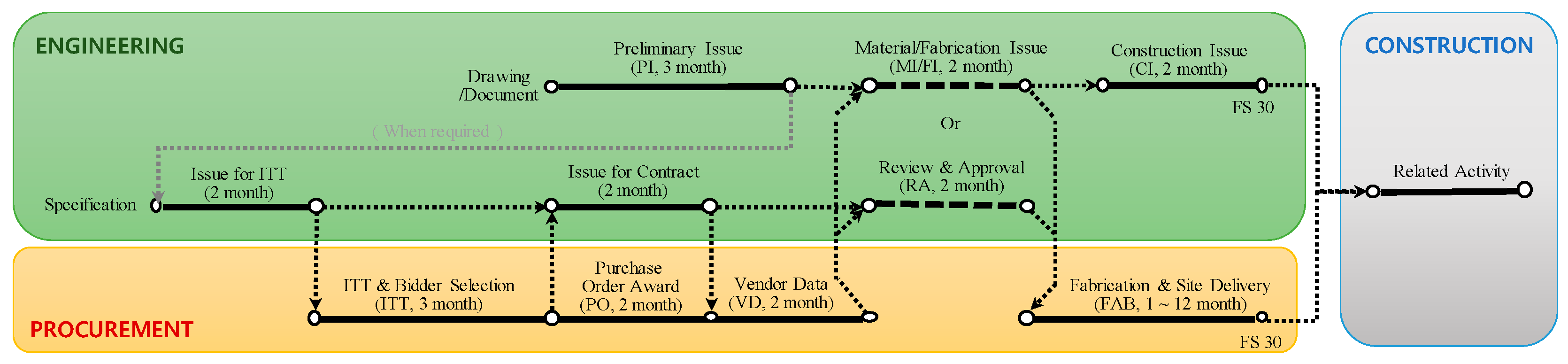

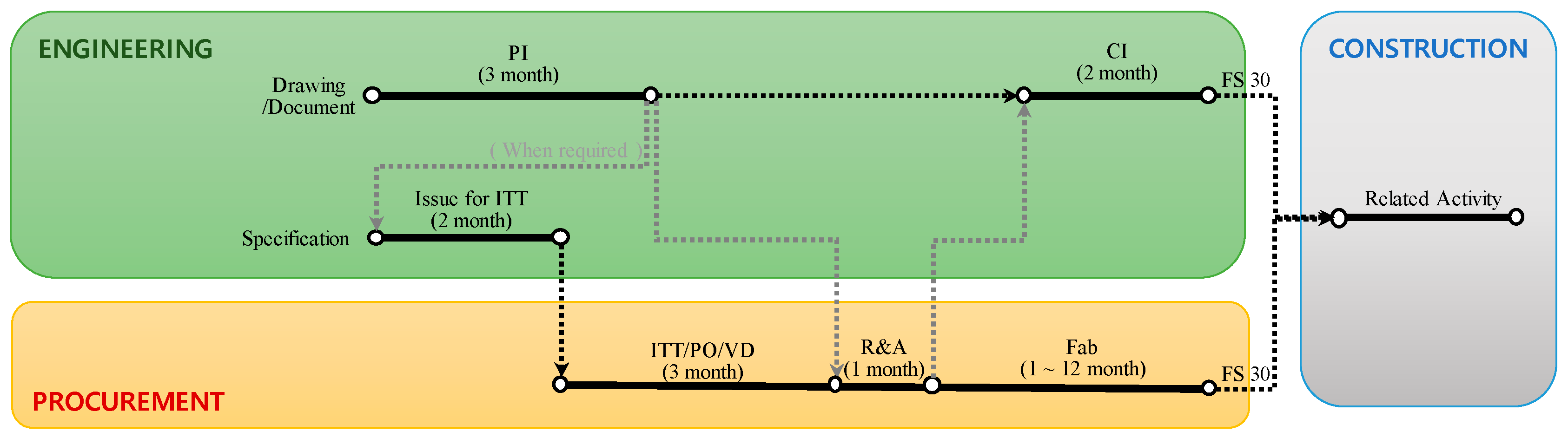

3.2.2. Schedule Development

Define Activities

Sequence Activities

Estimate Activity Durations

- Engineering activities: PI (3 months), CI (2 months), and specification issue for ITT (2 months).

- Procurement activities: ITT/PO/VD (2 months), R&A (1 month), and fabrication & site delivery (1–12 months depending on material or equipment type).

- Construction activities: durations were assigned according to area, level, or type of work, and adjusted for scaling ratios, reflecting typical field productivity in Korean NPP projects.

Development Schedule

3.3. AWP-Based Schedule Development

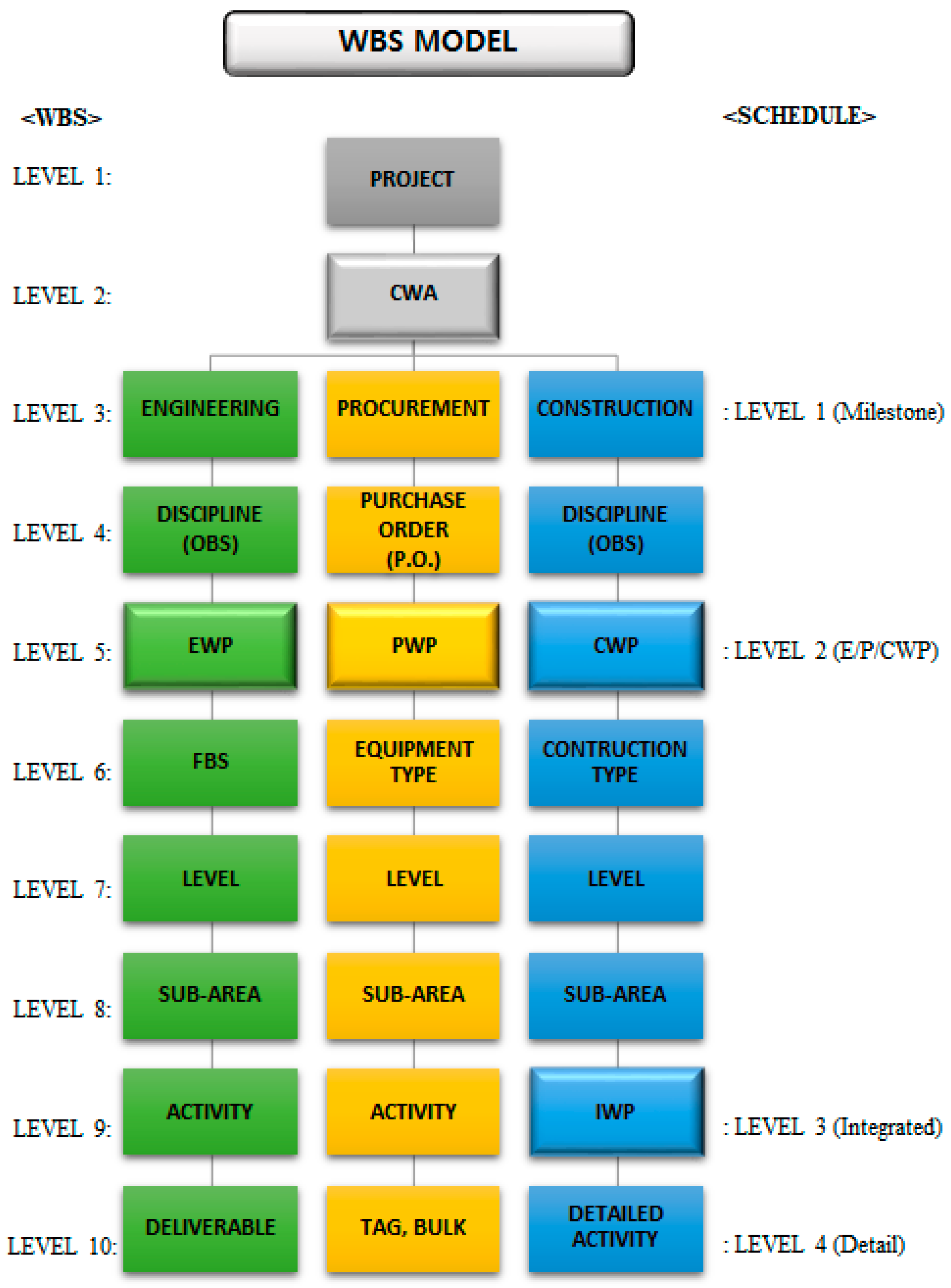

3.3.1. WBS Creation

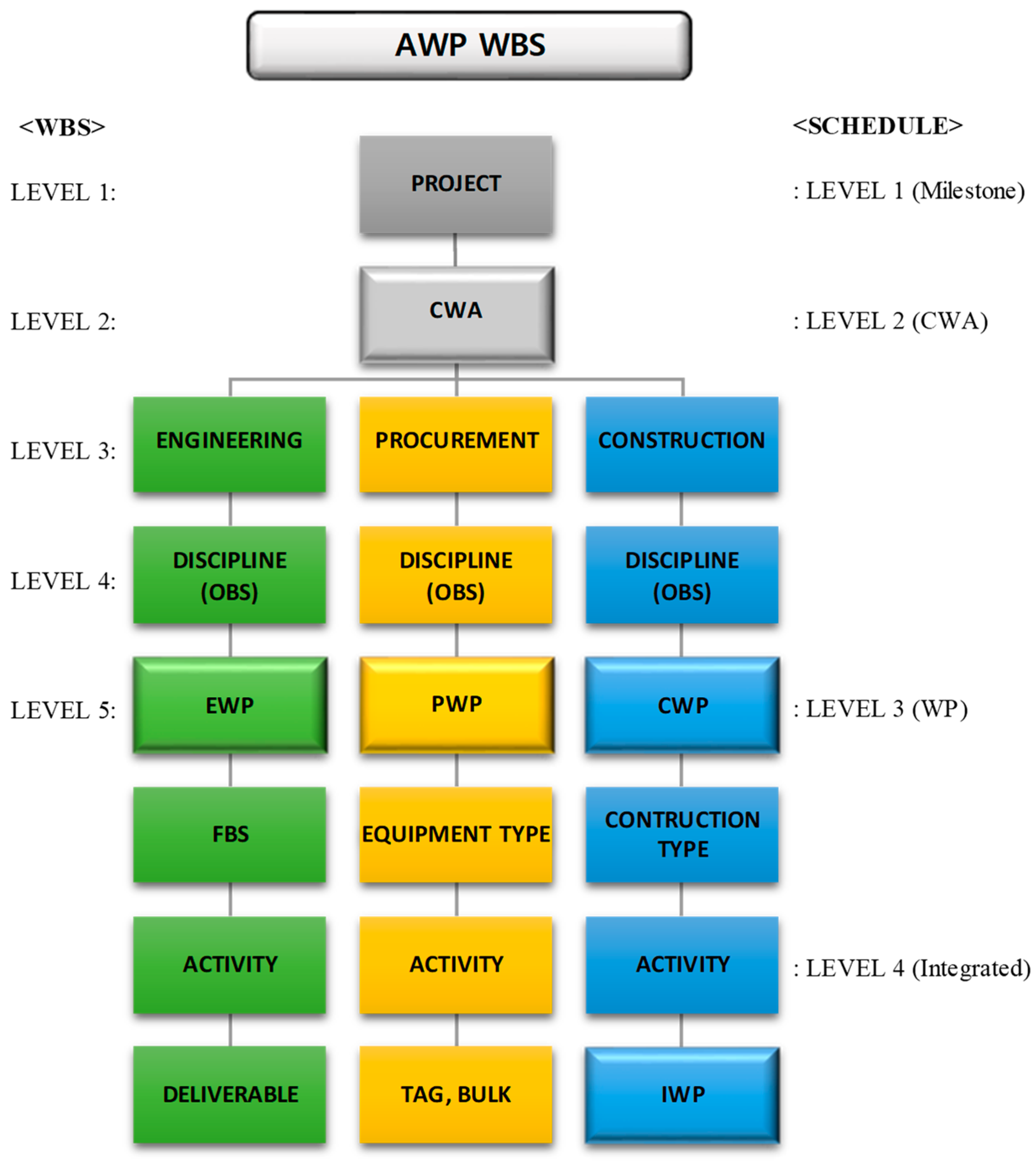

WBS Structure

Define Work Packages

- Method 1 (AWP-M1): Engineering by functional deliverable (FBS); procurement by equipment type.

- Method 2 (AWP-M2): Engineering by discipline; procurement by equipment type.

- Method 3 (AWP-M3): Engineering by discipline and by issue phase (PI/CI); procurement by discipline and by procurement phase.

- Method 4 (AWP-M4): Engineering and procurement by discipline.

3.3.2. Schedule Development

Define Activities

Sequence Activities

Estimate Activity Durations

Development Schedule

3.4. Schedule Impact Adoption

3.4.1. Construction Productivity Effect

3.4.2. Workface Planning Effect

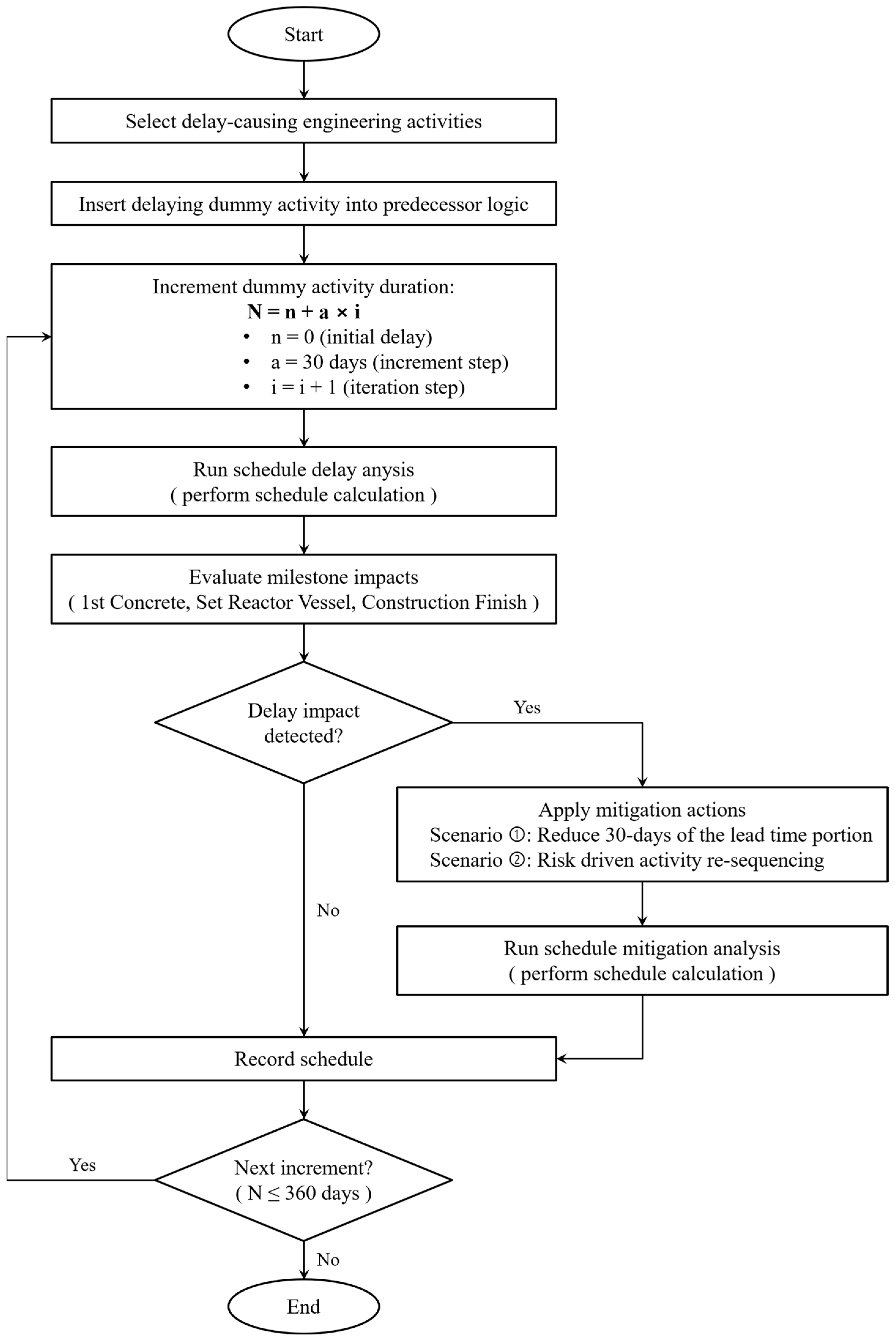

- Selection of delay-causing engineering activities. As summarized in Table A9, delay drivers were selected from the Traditional, AWP-M1, and AWP-M2 schedules by choosing, for each discipline, the earliest drawing-related engineering activity that could affect downstream construction. Multi-discipline deliverables with broad successor impacts were excluded to enable clear attribution of WFP effects. Target structures were grouped as RCB and AB; for the AB, a conservative choice selected the earliest engineering activity in CWA2 to ensure a direct, measurable impact on subsequent construction.

- Insertion of delaying dummy activity. A Delaying Dummy Activity was inserted as a predecessor to the selected construction tasks to represent upstream engineering delay.

- Increment of dummy duration. The dummy duration was increased in monthly steps using.

- Initial delay: n = 0;

- Increment step: a = 30 days;

- Iteration step: i = i + 1;

- Maximum delay duration: N ≤ 360 days.

- 4.

- Schedule delay analysis. For each increment, the schedule was recalculated in Primavera P6, reflecting resulting changes in milestone dates.

- 5.

- Evaluation of milestone impacts. Shifts were confirmed for First Concrete, Set Reactor Vessel (RV), and Construction Finish.

- 6.

- WFP mitigation scenarios. Two scenarios were applied independently to isolate individual effects:

- Scenario ①—Lead-time reduction by construction readiness. Consistent with CII IR 272-2 guidance [7], IWPs were assumed to be prepared 3 months (2 months development and 1 month of lead time) in advance. Upon detecting delay, up to 30 days of this 3-month window were repurposed as schedule float without compromising readiness.

- Scenario ②—Risk-driven re-sequencing via backlog utilization. Successor activities were re-sequenced to maintain workflow continuity, allowing non-impacted areas to proceed in parallel using pre-issued backlogs; the logic is summarized in Table A10.

- Initially, Scenario ① was intended to run with concurrent re-sequencing; however, extensive successor dependencies around the delayed engineering tasks made practical re-sequencing infeasible. Consequently, Scenario ② was executed separately by substituting the delayed engineering activity with its IEWP counterpart, enabling a distinct assessment of the re-sequencing strategy and clearer attribution of milestone recovery.

- 7.

- Schedule update and recording. After each schedule delay/mitigation analysis, the schedule was updated and milestone impacts were recorded.

- 8.

- Iteration and termination. Steps 3–7 were repeated for all increments until N = 360 days, at which point the simulation terminated.

3.5. Comparative Analysis

4. Results: Illustrative Application and Discussion

4.1. Traditional Schedule Development

4.1.1. WBS Creation

4.1.2. Schedule Development

4.2. AWP-Based Schedule Development

4.2.1. WBS Creation

WBS Structure

- Level 1: Project;

- Level 2: CWA;

- Level 3: Phase (Engineering, Procurement, Construction);

- Level 4: Discipline (OBS);

- Level 5: Work Package;

- Level 6: FBS, Equipment type, Construction type.

Define Work Packages

- Method 1 (AWP-M1). Scored 4–5 across all criteria and was the only scheme to receive a 5 for both “EWP as a Schedule Unit” and “Progress Measurement by EWP.” The FBS-based EWP boundary forms self-contained schedule units with minimal cross-coupling, and its deliverable register enables direct, auditable progress measurement. Equipment-type PWPs nest cleanly under CWA/CWP and align with procurement/fabrication streams, sustaining constructability with routine materials planning and measurable progress.

- Method 2 (AWP-M2). Also scored 4–5 across all criteria and was the only scheme to receive a 5 for “EWP Compatibility with Schedule Hierarchy.” Discipline-based EWPs map directly to the OBS layer within the WBS, slotting into the schedule hierarchy with supplemental links. PWPs are defined the same as in Method 1.

- Method 3 (AWP-M3). Predominantly 3–4. The EWP scored 3 on “Scope Definition, Schedule Unit, and Compatibility with Schedule Hierarchy” because splitting by issue phase (PI/CI) divides a single discipline’s scope over time, creating relationship logics for overlapping activities of phase functions of work, and an expanding number of packages as phases increase. The PWP likewise scored 3 on the same items (and associated constructability/progress implications) since discipline-plus-procurement-phase coupling conflicts with PO lifecycles (composition and process), demands supplementary activity relationships and field-requested-date plans, and require management plans per equipment-level traceability.

- Method 4 (AWP-M4). Ranged 3–5. The EWP have same scores with method 2, but the PWP scored 3 on “Schedule Unit, Constructability, and Progress Measurement” because discipline-based PWPs conflicts with PO lifecycles (composition), demands supplementary activity relationships and field-requested-date plans, and require management plans per equipment-level traceability.

AWP Method 1 (AWP-M1)

| WBS Level | Quantity (Activities/IEWP/ENG-IF) | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 CWA | Lev.3 Phase | Lev.4 OBS | Lev.5 WP | AE/BOP | NSSS/RCB | Common | Total | |

| Milestone/Dummy | - | - | 3 | 3 | - | |||

| 0 | ENG | 4 | 6 | 8 (7/1/0) | 11 (7/4/0) | 3 (2/1/0) | 22 (16/6/0) | 16 |

| PRO | 2 | 2 | 3 | 3 | - | 6 | - | |

| CON | 1 | 1 | 1 | - | - | 1 | - | |

| Sum | 9 | 12 | 14 | 3 | 29 | 16 | ||

| 1 | ENG | 5 | 31 | - | 93 (48/31/14) | - | 93 (48/31/14) | 276 |

| PRO | 5 | 10 | - | 30 | - | 30 | - | |

| CON | 5 | 8 | - | 46 | - | 46 | - | |

| Sum | 49 | - | 169 | - | 169 | 276 | ||

| 2, 3, 4, 5 each | ENG | 5 | 24 | 76 (38/24/14) | - | - | 76 (38/24/14) | 162 |

| PRO | 5 | 7 | 21 | - | - | 21 | - | |

| CON | 5 | 5 | 25 | - | - | 25 | - | |

| Sum | 36 | 122 | - | - | 122 | 162 | ||

| Total | 202 | 500 | 183 | 6 | 689 | 940 | ||

AWP Method 2 (AWP-M2)

| WBS Level | Quantity (Activities/IEWP/ENG-IF) | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 CWA | Lev.3 Phase | Lev.4 OBS | Lev.5 WP | AE/BOP | NSSS/RCB | Common | Total | |

| Milestone/Dummy | - | - | 3 | 3 | - | |||

| 0 | ENG | 4 | 6 | 8 (1/1/0) | 11 (7/4/0) | 3 (2/1/0) | 22 (16/6/0) | 16 |

| PRO | 2 | 2 | 3 | 3 | - | 6 | - | |

| CON | 1 | 1 | 1 | - | - | 1 | - | |

| Sum | 9 | 12 | 14 | 3 | 29 | 16 | ||

| 1 | ENG | 5 | 24 | - | 86 (48/24/14) | - | 86 (48/24/14) | 276 |

| PRO | 5 | 10 | - | 30 | - | 30 | - | |

| CON | 5 | 8 | - | 46 | - | 46 | - | |

| Sum | 42 | - | 162 | - | 162 | 276 | ||

| 2, 3, 4, 5 each | ENG | 5 | 16 | 68 (38/16/14) | - | - | 68 (38/16/14) | 162 |

| PRO | 5 | 7 | 21 | - | - | 21 | - | |

| CON | 5 | 5 | 25 | - | - | 25 | - | |

| Sum | 28 | 114 | - | - | 114 | 162 | ||

| Total | 163 | 468 | 176 | 6 | 650 | 940 | ||

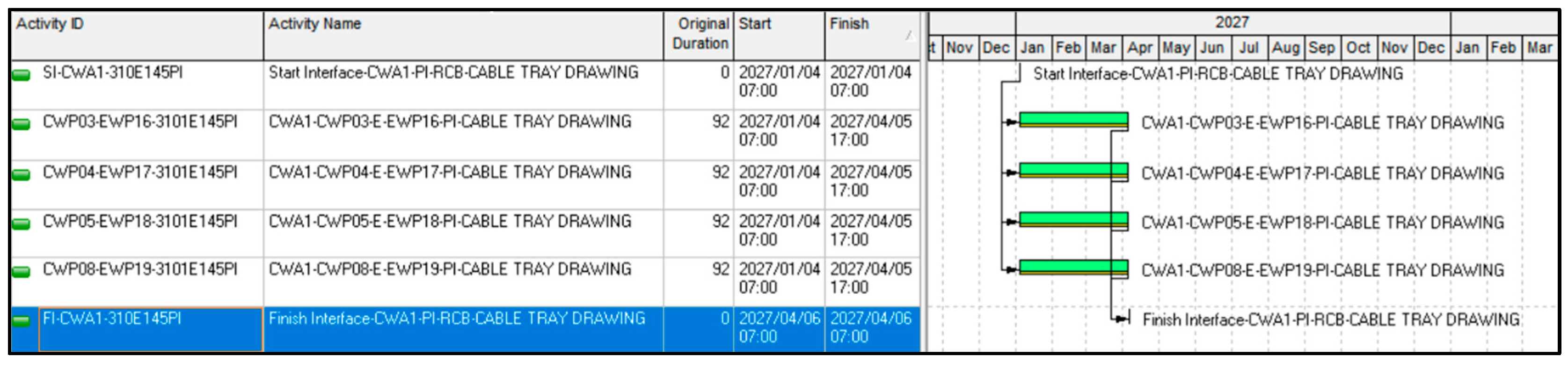

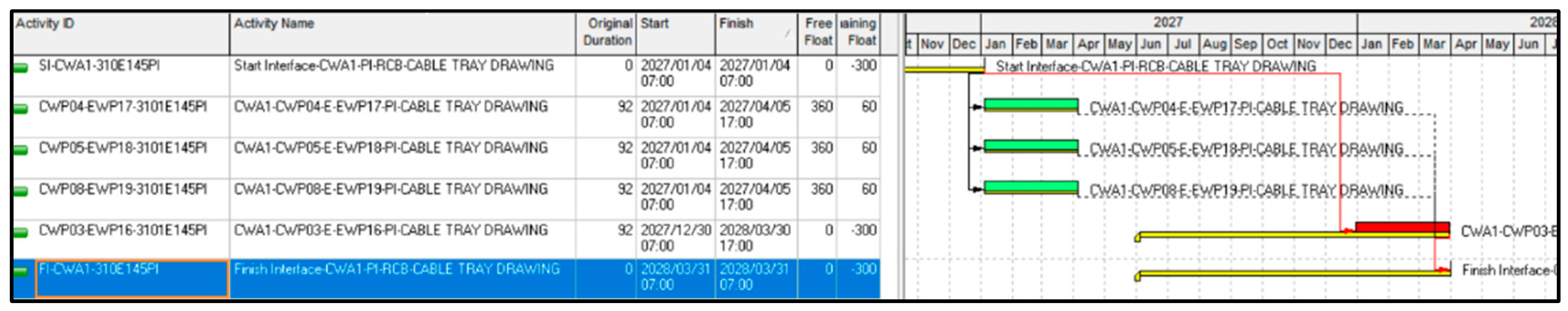

4.2.2. Schedule Development

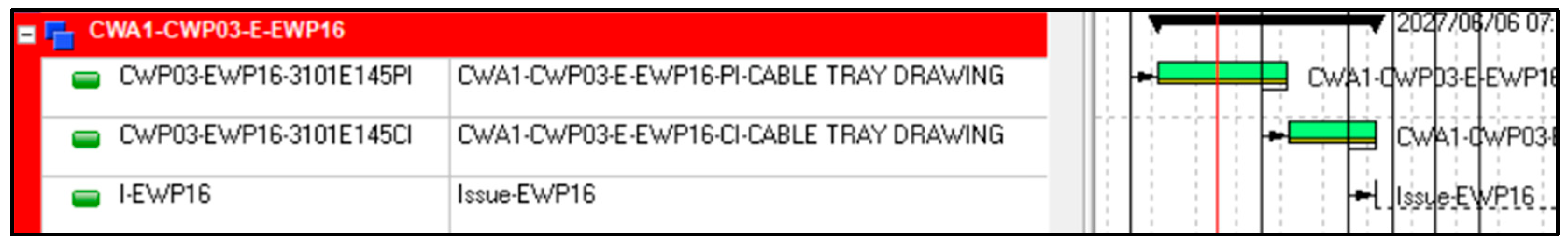

Management of Duplicate Engineering Deliverables

- SI captures the earliest start among all referencing activities.

- FI captures the latest finish among them.

Issuance of Engineering Work Packages (IEWP)

Developed Schedule

4.3. Schedule Impact Adoption

4.3.1. Construction Productivity Effect

4.3.2. Workface Planning Effect

Delay Impact Results in Traditional Schedule

Scenario ①: Schedule Recovery by Backlog Float Utilization (AWP-M1, M2)

Scenario ②: Schedule Recovery by Re-Sequencing of IEWPs Successor Activities (AWP-M1, M2)

4.4. Comparative Analysis

4.4.1. WBS Structure and Work Package Configuration

4.4.2. Schedule Composition and Activity Volume

- The segmentation of engineering deliverables by CWA;

- The replication of identical design activities across multiple CWPs;

- The introduction of Issuance Engineering Work Package (IEWP) and ENG-IF nodes to coordinate shared deliverables across CWPs.

4.4.3. Schedule Logic and Relationship Density

- Engineering-to-Engineering Relationships:

- Segmentation of engineering deliverables by CWA;

- Introduction of ENG-IF (Engineering Interface) activities to coordinate replicated deliverables across CWPs;

- Addition of IEWP (Issuance of Engineering Work Package) activities that structure the design completion status per EWP.

- Engineering-to-Procurement Relationships:

- Engineering-to-Construction Relationships:

- Procurement-to-Procurement Relationships:

- Procurement-to-Construction Relationships:

- Construction-to-Construction Relationships:

4.4.4. Delay Simulation and Mitigation Effectiveness

- 320C118PI, 320E145PI, and 320P193PI: The delays caused the critical path to move from RCB-related construction to activities in CWA2.

- In the case of 310E145PI, while the traditional schedule had a direct link from engineering to overall construction, the AWP schedules restructured the sequence such that engineering delay propagated through procurement and construction, particularly through the cable tray activity chain in CWA2.

- RCB-zone delays (I-EWP10, I-EWP27):

- ✓

- These elements, associated with single-zone execution in the RCB, showed no recovery after re-sequencing, as there were no alternative packages or CWAs with the same work types scheduled earlier or in parallel. The lack of flexibility in spatial and temporal overlap restricted mitigation.

- CWA2-zone delays (I-EWP41, I-EWP57 in M1; I-EWP31, I-EWP44 in M2):

- ✓

- These were able to make significant delay mitigation through re-sequencing.

- ✓

- For instance, 23 days to 74 days reduction after re-sequencing.

- ✓

- This was possible due to the availability of follow-up CWAs (e.g., CWA3, CWA4, CWA5) with similar work scopes that allowed flexible scheduling.

- Non-impacted or high-float activities (I-EWP16, 24, 46, 52 for M1; I-EWP13, 21, 35, 40 for M2):

- ✓

- These showed no schedule impact due to adequate float or already being outside the critical path.

5. Discussion

- The assumption of a 25% construction-productivity uplift is a simplification. It was adopted as a literature-based scenario value to enable transparent comparison and does not represent trade- or site-specific measurements. Future studies should calibrate differentiated uplifts (e.g., concrete, rebar, MEI) using validated field data or formal meta-analysis.

- Procurement effects were represented deterministically through their intermediate placement between engineering and construction, rather than through stochastic risk distributions. This simplification may understate uncertainty, and probabilistic procurement-risk modeling should be considered in future work.

- The hypothetical model represents 22–28% of referenced plant volume. While the structure was derived from standardized FSAR data to preserve plausibility, no sensitivity runs were performed. As the study’s purpose was comparative, not predictive, results should be interpreted as relative responses. The model was physically simplified and scaled down to serve the needs of a preliminary study, which included treating the RCB as a single construction zone. Accordingly, future research should validate zone-level segmentation against complete, real NPP project schedules where data are accessible.

- The reported 60-day net improvement is a deterministic result derived from fixed scenario logic. Because no probabilistic sampling was conducted, no confidence interval or p-value can be provided. This value should therefore be interpreted as illustrative of structural schedule effects, not as a statistically validated result. Future research should apply stochastic risk analysis to test the statistical robustness of such improvements.

- Commissioning and regulatory gates were not included due to scope and confidentiality. However, research is emerging on how AWP may be applied in commissioning, particularly on reconciling physical packages used in construction with system-level packages required for system turnover. This represents a future extension of the current study.

- While this study concentrated on schedule-level impacts, the adoption of AWP also requires procedural, administrative, and system changes across design, procurement, and project management processes. These adjustments inevitably involve additional time and cost, which were not analyzed here. ROI should therefore not be inferred from schedule benefits alone. Future research should extend the analysis to include these broader dimensions, so that cost–benefit trade-offs are evaluated in a comprehensive manner.

- The weighting applied in Table A2 was developed by the first and corresponding author, both with 10–20 years of project management experience, and then informally cross-checked with a small group of senior practitioners. Because direct AWP implementation experience in nuclear projects is not yet available, no inter-rater reliability testing was possible. This is recognized as a limitation, and future work should validate such weighting through structured expert panels and reliability methods.

- This study applied deterministic, step-wise delays in order to compare schedule-structure responses under controlled conditions. The use of standardized nuclear project schedule data made deterministic testing more suitable than probabilistic sampling. While this approach was appropriate for a preliminary comparison, it does not provide delay distributions or confidence intervals. Future studies should apply stochastic methods such as Monte Carlo or PERT to complement the findings and validate statistical robustness.

- NPP schedules are highly sensitive to external uncertainties, including policy changes, regulatory approval processes, and supply chain disruptions. These factors were not quantified in this study, as the analysis focused on deterministic, comparative scenarios to illustrate AWP-specific effects. Nonetheless, such uncertainties exert significant influence on actual project performance. Future studies should extend the analysis to incorporate probabilistic schedule risk assessments (e.g., Monte Carlo approaches), so that the impact of policy, regulatory, and supply chain risks can be evaluated in a more comprehensive manner.

- As authors’ best knowledge, no published nuclear power project has reported full-scale application of AWP. International references remain at the level of conceptual proposals or emerging contractual requirements rather than validated case studies. In several recent projects, owners have signaled an interest in incorporating AWP principles into execution planning. Against this backdrop, the present work is positioned as a preliminary study to provide a first step toward evaluating the potential of AWP in nuclear construction.

6. Conclusions, Limitations, and Recommendations

6.1. Conclusions

- In evaluating four packaging schemes against six criteria (scope definition, WBS compatibility, schedule-unit suitability, fit with schedule hierarchy, constructability, and progress measurement), Methods 1 and 2 consistently scored 4–5 and were advanced. Method 1 uniquely earned top marks for “EWP as a Schedule Unit” and “Progress Measurement by EWP,” because FBS-based EWPs are self-contained and auditable and pair cleanly with equipment-type PWPs. Method 2 uniquely earned top marks for “EWP Compatibility with Schedule Hierarchy,” as discipline-based EWPs map directly to the OBS within the WBS. By contrast, Methods 3–4 were not advanced: both exhibit PWP configurations that conflict with PO lifecycles (composition and process), demand supplementary activity relationships and field-requested-date plans, and require management plans at equipment-level traceability; in addition, Method 3’s procurement-phase split introduces temporal overlap that further fragments schedule units and progress measurement.

- WBS Structure and Work Packaging: Traditional WBS structures varied by EPC phase (contract-based, discipline-based, package-based, etc.), creating challenges for integrated management and reporting. By contrast, the AWP-based WBS consistently followed: Project → CWA → Phase (E/P/C) → Discipline (OBS) → WP. This structure expanded work packages from 48 (traditional) to 202 (AWP-M1) and 163 (AWP-M2), with engineering deliverables standardized at 940. The increase is explained by CWA-level scoping that replicates discipline deliverables by area; this improves area-based traceability and reporting but raises management complexity due to package proliferation.

- Schedule Activities and Relationships: AWP schedules significantly expanded activities compared to the traditional baseline.

- ✓

- Engineering (AE/BOP) increased 6.6×, and NSSS/RCB about 1.8×, due to CWA segmentation and replicated activities.

- ✓

- Procurement activities increased almost 4× (33 → 120) as previously common items were allocated to CWAs.

- ✓

- Construction activities showed minor increases since traditional schedules already applied area-based planning.

- ✓

- Relationships expanded substantially: ENG–ENG links increased 5.4×, and ENG–PRO nearly 2×. Traditional interface activities (281) disappeared, replaced by IEWP and ENG-IF logic, providing stronger integration across phases.

- Schedule Impacts: Applying a 25% construction productivity improvement shortened durations by about 120 days, while the 90-day lag for EWP issuance included 60 days of readiness for IWP development, which offset part of the gains. The net outcome was a 60-day earlier project completion compared to the traditional baseline.

- Delay Simulation and Mitigation: In Scenario ① (360-day engineering delays), the traditional critical path remained in RCB-related construction, while AWP shifted the critical path toward delayed activities in CWA2, demonstrating segmentation-driven responsiveness. In Scenario ② (re-sequencing), substantial recovery was observed in successive CWAs (e.g., I-EWP41 mitigated 23 days, I-EWP57 recovered 74 days). These results confirm that AWP’s zonal structure enables localized delay absorption when alternative workfaces exist. Recovery concentrated in the AB because spatial redundancy across adjacent CWAs enabled parallel advancement of similar work types, whereas the RCB’s contiguous, critical structural scope offered few viable substitutes.

- These conclusions should be interpreted with caution, as they are derived from a simplified, scaled model of the Nuclear Island, applied under generalized productivity and lead-time assumptions, with delays treated deterministically. While sufficient for a preliminary study, these boundaries limit direct generalization to full-scale NPP projects.

6.2. Limitations

- Simplified Modeling Assumptions: The schedules developed in this study relied on a simplified standard work logic and assumptions rather than fully reflecting the detailed complexities of an actual project. For example, construction productivity was adjusted uniformly by 25%, and 90-day engineering/procurement lead time were modeled in a generalized manner. Such simplifications limit the direct applicability of the results to real projects, where variability and uncertainty are more pronounced. Furthermore, the AWP-based WBS was structured around CWAs, EWPs, PWPs, and CWPs in accordance with industry guidelines. However, not all possible variations of work package configurations were considered. For instance, procurement strategies were simplified by excluding detailed vendor-specific practices and fabrication steps that could significantly influence the applicability.

- Limited Risk Coverage: The delay simulations were designed around selected engineering activities across disciplines. While effective for comparative analysis, they did not incorporate the broader range of risks that typically affect nuclear projects, such as regulatory reviews, vendor-related delays, or site-specific conditions. The mitigation effects observed should therefore be interpreted within this limited scope.

- Re-Sequencing Assumptions: In this study, Scenario ② re-sequencing was applied only to AWP schedules, under the assumption that such adjustments are uniquely aligned with WFP practices. However, in reality, similar resequencing and adjustments are also carried out in traditional project execution once construction readiness allows. This limitation may have led to an overestimation of the differential benefit attributed solely to AWP.

6.3. Recommendations for Future Research

- Detailed Schedule Development: Current industry practice using Level 3 IPS (Integrated Project Schedule) or CPS (Critical Path Schedule) provides activity relationships but lacks the level of granularity required for accurate critical path analysis. Future research should develop model-based detailed schedules in which CWAs, POCs and IWPs are explicitly linked to 4D/5D BIM objects, enabling higher-precision critical path monitoring, quantity-driven progress validation, and automated look-ahead generation.

- Stakeholder Engagement at Project Initiation: Successful AWP implementation requires active involvement of procurement and construction stakeholders from the project outset. Future research should investigate contractual and procedural approaches that move away from the traditional reliance on fixed interface activities, enabling earlier alignment of deliverables and responsibilities.

- FOAK (For first of a kind) Considerations: Adopting AWP in FOAK settings requires rethinking how engineering deliverables, procurement packages, and construction packages are defined. Packages should be BIM-addressable from the start of the project (e.g., derive the Path of Construction from the model; tie fabrication lots to model assemblies). Future work should also assess the practical and business impacts on EPC delivery—such as data governance, change control, and traceability.

6.4. Contributions of the Study

- Applying the AWP Project Definition Assessment Tool to a Korean nuclear EPC context, identifying current alignment and gaps.

- Demonstrating a practical methodology for constructing AWP-based schedules and comparing them against traditional schedules using Primavera P6.

- Quantitatively analyzing differences in work packages, deliverables, activities, and relationships, clarifying the impacts of AWP adoption.

- Testing delay simulation scenarios, showing how AWP segmentation and re-sequencing provide resilience to schedule disruptions.

- Offering practical recommendations on WBS standardization, tool integration, risk-driven planning, and FOAK implications, bridging theoretical research with industrial application.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | Auxiliary Building |

| AWP | Advanced Work Packaging |

| AWP-M1 | Advanced Work Packaging Method 1 |

| AWP-M2 | Advanced Work Packaging Method 2 |

| BIM | Building Information Modeling |

| CI | Construction Issue |

| CII | Construction Industry Institute |

| COAA | Construction Owners Association of Alberta |

| CP | Construction Package |

| CPM | Critical Path Method |

| CWA | Construction Work Area |

| CWP | Construction Work Package |

| EPC | Engineering, Procurement, and Construction |

| EWP | Engineering Work Package |

| FBS | Functional Breakdown Structure |

| FSAR | Final Safety Analysis Report |

| IEWP | Issuance of Engineering Work Package |

| ITT | Invitation to Tender |

| IWP | Installation Work Package |

| NPP | Nuclear Power Plant |

| OBS | Organizational Breakdown Structure |

| PBS | Physical Breakdown Structure |

| PI | Preliminary Issue |

| PO | Purchase Order |

| POC | Path of Construction |

| PWP | Procurement Work Package |

| R&A | Review & Approval |

| RCB | Reactor Containment Building |

| RV | Reactor Vessel |

| VD | Vendor Data |

| WBS | Work Breakdown Structure |

| WFP | Workface Planning |

Appendix A

Appendix A.1. Work Breakdown Structures

Appendix A.2. Work Packaging Alternatives

Appendix A.3. Advanced Work Packaging (AWP) Assessment Criteria

| No. | Criteria | Description | Importance | Weight (%) | Scoring Criteria |

|---|---|---|---|---|---|

| Planning | 80 | 5: Fully Compliant; The criterion is fully met. The implementation is highly effective, and aligns perfectly with best practices. 4: Largely Compliant; The criterion is largely met. While minor improvements may be needed, the implementation is generally effective and well-established. 3: Partially Compliant; The criterion is partially met. The application presents significant gaps certain areas. 2: Minimally Compliant; The criterion is minimally met. Minor efforts have been made, but the actual application level is very low. 1: Not Compliant (Concept Acknowledged); The concept of the evaluation criterion is known, but there is no structured or concrete effort to apply it. 0: Not Addressed; There is no awareness of this criterion, and no attempt has been made to apply it. N/A: Not applicable for this assessment | |||

| 1 | Scope Definition of EWP | The package is defined by a specific scope of work and has clear boundaries, leaving no room for scope disputes. | Medium | 8 | |

| 2 | Scope Definition of PWP | The package is defined by a specific scope of work and has clear boundaries, leaving no room for scope disputes. | Medium | 8 | |

| 3 | WBS Compatibility of EWP | EWP structure is compatible with the project’s WBS hierarchy. | Medium | 8 | |

| 4 | WBS Compatibility of PWP | PWP structure is compatible with the project’s WBS hierarchy. | Medium | 8 | |

| 5 | EWP as a Schedule Unit | EWP structure is suitable as a unit within the schedule. | Low | 6 | |

| 6 | PWP as a Schedule Unit | PWP structure is suitable as a unit within the schedule. | Low | 6 | |

| 7 | EWP Compatibility with Schedule Hierarchy | The EWP schedule is structured at an appropriate level and aligns with the schedule hierarchy. | Medium | 8 | |

| 8 | PWP Compatibility with Schedule Hierarchy | The PWP schedule is structured at an appropriate level and aligns with the schedule hierarchy. | Medium | 8 | |

| 9 | Constructability of EWP | EWPs align with and support the construction sequence defined in the POC. | High | 10 | |

| 10 | Constructability of PWP | PWPs align with and support the construction sequence defined in the POC. | High | 10 | |

| 11 | Support for IWPs by EWP | EWP’s information is detailed enough to be easily broken down into IWPs, the smallest unit of field work. | N/A | - | |

| 12 | Support for IWPs by PWP | PWP’s material list accurately tracks items needed for an IWP and clearly indicates how they should be distributed to the field. | N/A | - | |

| 13 | Completeness of Engineering Information in EWP | EWP includes all necessary and up-to-date information for work execution, such as drawings, specifications, and vendor drawings. | N/A | - | |

| 14 | Procurement Readiness of PWP | PWP is structured to ensure all necessary materials are planned for procurement, have a delivery schedule, and are confirmed to be on-site when needed. | N/A | - | |

| 15 | Level of Detail of EWP | EWP drawings include detailed dimensions, installation methods, and material information that can be easily understood by a craft worker. | N/A | - | |

| 16 | Level of Detail of PWP | PWP’s material distribution plan clearly specifies which IWP each material should be delivered to. | N/A | - | |

| Execution | - | ||||

| 17 | Prerequisite Completion | All prerequisite tasks are complete before the work in the package can begin. | N/A | - | |

| 18 | Material and Equipment Readiness | All materials, equipment, tools, and personnel required for the package are available at the job site. | N/A | - | |

| 19 | Field Productivity | Ability of the CWP structure to reduce idle time for workers and improve direct work productivity | N/A | - | |

| 20 | Rework Minimization | Prevent rework caused by incomplete or inaccurate information. | N/A | - | |

| 21 | EWP Operational Complexity | Intuitiveness and ease of management for EWP structures | N/A | - | |

| 22 | PWP Operational Complexity | Intuitiveness and ease of management for PWP structures | N/A | - | |

| Monitoring/Control | 20 | ||||

| 23 | Progress Measurement by EWP | EWP progress measured based on quantitative completion criteria, with the results linked to the higher-level schedule to ensure overall project visibility and ease of management. | High | 10 | |

| 24 | Progress Measurement by PWP | PWP progress measured based on quantitative completion criteria, with the results linked to the higher-level schedule to ensure overall project visibility and ease of management. | High | 10 | |

| 25 | Controllability of EWP | EWP controllable to ensure stable project execution by systematically managing and responding to changes, constraints, and potential risks. | N/A | - | |

| 26 | Controllability of PWP | PWP controllable to ensure stable project execution by systematically managing and responding to changes, constraints, and potential risks. | N/A | - | |

| No. | Criteria | Method 1 | Method 2 | Method 3 | Method 4 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Score | Rationale | Score | Rationale | Score | Rationale | Score | Rationale | ||

| 1 | Scope Definition of EWP | 5 | Discipline/function-based packaging; sub-discipline and function specific range of work. | 5 | Discipline-based packaging; discipline specific range of work. | 3 | Discipline/phase-based packaging; discipline specific range of work; may require overlapping phases of work | 5 | Discipline-based packaging; discipline specific range of work. |

| 2 | Scope Definition of PWP | 5 | Type-based packaging | 5 | Type-based packaging | 3 | Discipline (Multi-material type)/phase-based packaging; compatibility with PO & process needed. | 4 | Discipline (Multi-material type)-based packaging; compatibility with PO needed. |

| 3 | WBS Compatibility of EWP | 5 | Aligns with WBS hierarchy. | 5 | Aligns with WBS hierarchy. | 4 | Can align with WBS hierarchy; but duplicated functions required | 5 | Aligns with WBS hierarchy. |

| 4 | WBS Compatibility of PWP | 5 | Aligns with WBS hierarchy. | 5 | Aligns with WBS hierarchy. | 4 | Can align with WBS hierarchy; but duplicated types required | 5 | Aligns with WBS hierarchy. |

| 5 | EWP as a Schedule Unit | 5 | Compliant as an independent schedule unit; may require supplementary activity relationships. | 4 | Compliant as an independent schedule unit; but require supplementary activity relationships. | 3 | Compliant as an independent schedule unit; but require supplementary activity relationships and overlapping for phased functions. | 4 | Compliant as an independent schedule unit; but require supplementary activity relationships. |

| 6 | PWP as a Schedule Unit | 4 | Compliant as an independent schedule unit; may require supplementary activity/relationship; require a separate plan for field-requested dates | 4 | Compliant as an independent schedule unit; may require supplementary activity/relationship; require a separate plan for field-requested dates | 3 | Compliant as an independent schedule unit; require supplementary activity/relationship; require a separate plan for field-requested dates; overlap in phased procurement; require compatibility with PO. | 3 | Compliant as an independent schedule unit; require supplementary activity/relationship; require a separate plan for field-requested dates; require compatibility with PO. |

| 7 | EWP Compatibility with Schedule Hierarchy | 4 | Appropriate and align with WBS hierarchy; but may generate an extensive number of work packages | 5 | Appropriate and align with WBS hierarchy. | 3 | Appropriate and align with WBS hierarchy; but may generate an extensive number of work packages as the phases increase | 5 | Appropriate and align with WBS hierarchy. |

| 8 | PWP Compatibility with Schedule Hierarchy | 4 | Appropriate and align with WBS hierarchy; but may have extensive number of work packages | 4 | Appropriate and align with WBS hierarchy; but may have extensive number of work packages | 3 | Appropriate and align with WBS hierarchy; but may generate an extensive number of work packages as the phases increase; require compatibility with PO. | 4 | Appropriate and align with WBS hierarchy; require compatibility with PO. |

| 9 | Constructability of EWP | 5 | Align with and support the POC | 5 | Align with and support the POC | 5 | Align with and support the POC | 5 | Align with and support the POC |

| 10 | Constructability of PWP | 4 | Align with and support the POC; however, a separate material delivery management plan is needed to prevent a large amount of inventory from being stored on-site for a long period. | 4 | Align with and support the POC; however, a separate material delivery management plan is needed to prevent a large amount of inventory from being stored on-site for a long period. | 3 | Align with and support the POC; separate material delivery management plan is needed to prevent a large amount of inventory from being stored on-site for a long period; require compatibility with PO. | 3 | Align with and support the POC; separate material delivery management plan is needed to prevent a large amount of inventory from being stored on-site for a long period; require compatibility with PO. |

| 11 | Progress Measurement by EWP | 5 | Measurable. | 4 | Measurable; but require separate plan to track specific tasks | 4 | Measurable; but require separate plan to track specific tasks | 4 | Measurable; but require separate plan to track specific tasks |

| 12 | Progress Measurement by PWP | 5 | Measurable. | 5 | Measurable. | 3 | Measurable; but require separate plan to track specific tasks; require compatibility with PO. | 3 | Measurable; but require separate plan to track specific tasks; require compatibility with PO. |

| Score total /Converted Score | 56/93.6% | 55/92% | 41/69.2% | 50/83.2% | |||||

Appendix A.4. Scheduling Assumptions

| Discipline | FBS No. * | Description |

|---|---|---|

| All/Common | 4XX | System design criteria |

| C | 1XX | Structural drawing |

| 1XX | Liner plate drawing | |

| 1XX | Structure detail drawing | |

| 2XX | Specification-reinforcing steel bar | |

| 2XX | Specification-containment liner plates | |

| 2XX | Specification-ready mixed concrete | |

| 3XX | Structural analysis | |

| 3XX | Liner plate calculation | |

| E | 1XX | Single line diagram |

| 1XX | Cable tray drawing | |

| 1XX | Conduit plan drawing | |

| 2XX | Specification-cables | |

| 2XX | Specification-cable trays and fittings | |

| J | 1XX | C&ID |

| 1XX | Instrument location drawing | |

| 2XX | Specification-instruments | |

| M | 1XX | P&ID |

| 2XX | Specification-pumps | |

| 2XX | Specification-crane | |

| NSSS | Specification-nsss equipment | |

| 1XX | P&ID | |

| P | 1XX | Piping support drawing |

| 1XX | General arrangement drawing | |

| 1XX | Piping iso drawing | |

| 2XX | Specification-piping | |

| 2XX | Specification-valves | |

| 3XX | Piping stress analysis |

| PO * | Description |

|---|---|

| CXXX | Reinforcing steel bar |

| CXXX | Ready mixed concrete |

| CXXX | Containment liner plates |

| MXXX | Pumps |

| MXXX | Hoists & cranes |

| NSSS | NSSS equipment |

| PXXX | Valves |

| PXXX | Piping |

| JXXX | Instruments |

| EXXX | Cable trays and fittings |

| EXXX | Cables |

| CP * | Description | Activity Type * | Description |

|---|---|---|---|

| CP-AX | Major building and Related structure | AX | Basemat & slab |

| AX | Wall & column | ||

| AX | Steel liner plate | ||

| CP-PX | Piping work | PX | Pipe & support |

| CP-EX | Cable tray | EX | Cable tray & support |

| CP-EX | Cabling and termination | EX | Cabling & termination |

| CP-JX | Instrument and Control installation | JX | Instrument and Control installation |

| BLDG | Sys. | Predecessor | Successor * | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCB | AB | OBS | FBS * | DESCRIPTION | CXXX | CXXX | CXXX | MXXX | MXXX | NSSS | PXXX | PXXX | JXXX | EXXX | EXXX | |

| O | O | P | XXX | GENERAL ARRANGEMENT DRAWING | O | O | O | O | O | O | O | O | O | O | ||

| O | O | O | All | XXX | SYSTEM DESIGN CRITERIA | |||||||||||

| X | O | O | M | XXX | P&ID | O | O | O | O | |||||||

| O | X | O | N | XXX | P&ID | O | O | |||||||||

| O | O | P | XXX | PIPING STRESS ANALYSIS | ||||||||||||

| O | O | P | XXX | PIPING ISO DRAWING | O | O | O | O | O | |||||||

| O | O | P | XXX | PIPING SUPPORT DRAWING | O | O | ||||||||||

| O | O | C | XXX | STRUCTURAL ANALYSIS | ||||||||||||

| O | O | C | XXX | STRUCTURAL DRAWING | O | O | O | O | ||||||||

| O | O | C | XXX | STRUCTURE DETAIL DRAWING | O | O | O | O | ||||||||

| O | X | C | XXX | LINER PLATE CALCULATION | ||||||||||||

| O | X | C | XXX | LINER PLATE DRAWING | O | |||||||||||

| O | O | O | E | XXX | SINGLE LINE DIAGRAM | O | O | |||||||||

| O | O | E | XXX | CABLE TRAY DRAWING | O | O | ||||||||||

| O | O | E | XXX | CONDUIT PLAN DRAWING | O | O | ||||||||||

| O | O | O | J | XXX | C&ID | O | ||||||||||

| O | O | J | XXX | INSTRUMENT LOCATION DRAWING | O | |||||||||||

| O | O | C | XXX | SPECIFICATION-REINFORCING STEEL BAR | O | |||||||||||

| O | O | C | XXX | SPECIFICATION-READY MIXED CONCRETE | O | |||||||||||

| O | X | C | XXX | SPECIFICATION-CONTAINMENT LINER PLATES | O | |||||||||||

| X | O | M | XXX | SPECIFICATION-PUMPS | O | |||||||||||

| O | X | M | XXX | SPECIFICATION-CRANE | O | |||||||||||

| O | X | M | XXX | SPECIFICATION-NSSS EQUIPMENT | O | |||||||||||

| X | O | P | XXX | SPECIFICATION-VALVES | O | |||||||||||

| O | O | P | XXX | SPECIFICATION-PIPING | O | |||||||||||

| O | O | J | XXX | SPECIFICATION-INSTRUMENTS | O | |||||||||||

| O | O | E | XXX | SPECIFICATION-CABLE TRAYS AND FITTINGS | O | |||||||||||

| O | O | E | XXX | SPECIFICATION-CABLES | O | |||||||||||

| BLDG | Sys. | Predecessor | Successor * | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCB | AB | OBS | FBS * | Description | CX | CX | SX | PX | EX | EX | EX | JX | MX | MX | |

| O | O | P | XXX | GENERAL ARRANGEMENT DRAWING | |||||||||||

| O | O | O | All | XXX | SYSTEM DESIGN CRITERIA | ||||||||||

| X | O | O | M | XXX | P&ID | ||||||||||

| O | X | O | N | XXX | P&ID | ||||||||||

| O | O | P | XXX | PIPING STRESS ANALYSIS | |||||||||||

| O | O | P | XXX | PIPING ISO DRAWING | O | O | O | ||||||||

| O | O | P | XXX | PIPING SUPPORT DRAWING | O | O | O | ||||||||

| O | O | C | XXX | STRUCTURAL ANALYSIS | |||||||||||

| O | O | C | XXX | STRUCTURAL DRAWING | O | O | |||||||||

| O | O | C | XXX | STRUCTURE DETAIL DRAWING | O | O | |||||||||

| O | X | C | XXX | LINER PLATE CALCULATION | |||||||||||

| O | X | C | XXX | LINER PLATE DRAWING | O | O | O | ||||||||

| O | O | O | E | XXX | SINGLE LINE DIAGRAM | ||||||||||

| O | O | E | XXX | CABLE TRAY DRAWING | O | O | O | O | |||||||

| O | O | E | XXX | CONDUIT PLAN DRAWING | O | O | O | ||||||||

| O | O | O | J | XXX | C&ID | ||||||||||

| O | O | J | XXX | INSTRUMENT LOCATION DRAWING | O | ||||||||||

| O | O | C | XXX | SPECIFICATION-REINFORCING STEEL BAR | O | O | |||||||||

| O | O | C | XXX | SPECIFICATION-READY MIXED CONCRETE | O | O | |||||||||

| O | X | C | XXX | SPECIFICATION-CONTAINMENT LINER PLATES | O | ||||||||||

| X | O | M | XXX | SPECIFICATION-PUMPS | O | ||||||||||

| O | X | M | XXX | SPECIFICATION-CRANE | O | ||||||||||

| O | X | M | NSSS | SPECIFICATION-NSSS EQUIPMENT | O | ||||||||||

| X | O | P | XXX | SPECIFICATION-VALVES | O | ||||||||||

| O | O | P | XXX | SPECIFICATION-PIPING | O | ||||||||||

| O | O | J | XXX | SPECIFICATION-INSTRUMENTS | O | ||||||||||

| O | O | E | XXX | SPECIFICATION-CABLE TRAYS AND FITTINGS | O | O | |||||||||

| O | O | E | XXX | SPECIFICATION-CABLES | O | ||||||||||

| BLDG | Sys. | Predecessor | Successor * | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCB | AB | OBS | FBS * | DESCRIPTION | CX | CX | SX | PX | EX | EX | EX | JX | MX | MX | |

| O | O | C | XXX | SPECIFICATION-REINFORCING STEEL BAR | O | O | |||||||||

| O | O | C | XXX | SPECIFICATION-READY MIXED CONCRETE | O | O | |||||||||

| O | X | C | XXX | SPECIFICATION-CONTAINMENT LINER PLATES | O | ||||||||||

| X | O | M | XXX | SPECIFICATION-PUMPS | O | ||||||||||

| O | X | M | XXX | SPECIFICATION-CRANE | O | ||||||||||

| O | X | M | NSSS | SPECIFICATION-NSSS EQUIPMENT | O | ||||||||||

| X | O | P | XXX | SPECIFICATION-VALVES | O | ||||||||||

| O | O | P | XXX | SPECIFICATION-PIPING | O | ||||||||||

| O | O | J | XXX | SPECIFICATION-INSTRUMENTS | O | ||||||||||

| O | O | E | XXX | SPECIFICATION-CABLE TRAYS AND FITTINGS | O | O | |||||||||

| O | O | E | XXX | SPECIFICATION-CABLES | O | ||||||||||

| CWA | Disc | FBS | Activity ID | ||||

|---|---|---|---|---|---|---|---|

| Traditional | AWP-M1 | AWP-M2 | |||||

| A | B | A | B | ||||

| 1: RCB | C | 1XX | 3XXC1XXPI | CWP01-EWP10-3XX1C1XXPI | I-EWP 10 | CWP01-EWP9-3XX1C1XXPI | I-EWP 9 |

| E | 1XX | 3XXE1XXPI | CWP03-EWP16-3XX1E1XXPI | I-EWP 16 | CWP03-EWP13-3XX1E1XXPI | I-EWP 13 | |

| J | 1XX | 3XX1XXPI | CWP06-EWP24-3XX1J1XXPI | I-EWP 24 | CWP06-EWP21-3XX1J1XXPI | I-EWP 21 | |

| P | 1XX | 3XXP1XXPI | CWP07-EWP27-3XX1P1XXPI | I-EWP 27 | CWP03-EWP25-3XX1P1XXPI | I-EWP 25 | |

| 2: AB | C | 1XX | 3XXC1XXPI | CWP09-EWP41-3XX2C1XXPI | I-EWP 41 | CWP09-EWP31-3XX2C1XXPI | I-EWP 31 |

| E | 1XX | 3XXE1XXPI | CWP00-EWP46-3XX2E1XXPI | I-EWP 46 | CWP00-EWP35-3XX2E1XXPI | I-EWP 35 | |

| J | 1XX | 3XXJ1XXPI | CWP12-EWP52-3XX2J1XXPI | I-EWP 52 | CWP12-EWP40-3XX2J1XXPI | I-EWP 40 | |

| P | 1XX | 3XXP1XXPI | CWP10-EWP57-3XX2P1XXPI | I-EWP 57 | CWP10-EWP44-3XX2P1XXPI | I-EWP 44 | |

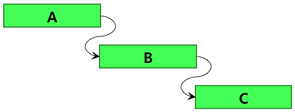

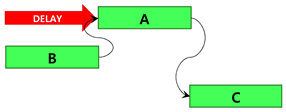

| Steps | Relationships |

|---|---|

| Baseline |  Activities A → B → C follow a standard Finish-to-Start (FS) logic. |

| Delay Occurrence |  A delay in activity A causes a shift in B and C. |

| Re-Sequencing |  While activity A is delayed, activity B is advanced independently by resequencing the relationship, reducing the cumulative schedule impact. |

Appendix A.5. Scheduled Artifacts

| WBS Level | Quantity of Activities | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 | Lev.3 | Lev.4 Amount | AE/BOP | NSSS/RCB | Common | Interface | Total | |

| Milestone/Dummy | - | - | 3 | - | 3 | - | ||

| ENG | C | 8 | 5 | 10 | 2 | 42 | 59 | 91 |

| E | 5 | 4 | 4 | 4 | 16 | 28 | 52 | |

| J | 3 | 4 | 4 | 1 | 3 | 12 | 29 | |

| M | 5 | 2 | 4 | 1 | 20 | 27 | 86 | |

| P | 6 | 7 | 7 | 2 | 17 | 33 | 7 | |

| X | 1 | 2 | 2 | 0 | 0 | 4 | 4 | |

| Sum | 28 | 24 | 31 | 10 | 98 | 163 | 269 | |

| PRO | C | 3 | - | 3 | 6 | 17 | 26 | - |

| E | 2 | - | - | 6 | 11 | 17 | - | |

| J | 1 | - | - | 3 | 4 | 7 | - | |

| M | 3 | - | 6 | 3 | 13 | 22 | - | |

| P | 2 | - | - | 6 | 14 | 20 | - | |

| Sum | 11 | 0 | 9 | 24 | 59 | 92 | - | |

| CON | C(A) | 3 | 36 | 23 | - | 50 | 109 | - |

| E | 2 | 17 | 6 | - | 21 | 44 | - | |

| J | 1 | 4 | 1 | - | 4 | 9 | - | |

| M | 2 | 16 | 11 | - | 24 | 51 | - | |

| P | 1 | 16 | 5 | - | 25 | 46 | - | |

| Sum | 9 | 89 | 46 | 0 | 124 | 259 | - | |

| 4 | 16 | 48 | 113 | 86 | 37 | 281 | 517 | 269 |

| WBS Level | Quantity (Activities/IEWP/ENG-IF) | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 CWA | Lev.3 Phase | Lev.4 OBS | Lev.5 WP | AE/BOP | NSSS/RCB | Common | Total | |

| Milestone/Dummy | - | - | 3 | 3 | - | |||

| 0 | ENG | E | 2 | 2 (1/1/0) | - | 3 (2/1/0) | 5 (3/2/0) | 3 |

| J | 1 | 2 (2/0/0) | 3 (2/1/0) | - | 5 (4/1/0) | 4 | ||

| M | 2 | 2 (2/0/0) | 5 (3/2/0) | - | 7 (5/2/0) | 5 | ||

| X | 1 | 2 (2/0/0) | 3 (2/1/0) | - | 5 (4/1/0) | 4 | ||

| Sum | 6 | 8 (7/1/0) | 11 (7/4/0) | 3 (2/1/0) | 22 (16/6/0) | 16 | ||

| PRO | E | 1 | 3 | - | - | 3 | - | |

| M | 1 | - | 3 | - | 3 | - | ||

| Sum | 2 | 3 | 3 | - | 6 | - | ||

| CON | E | 1 | 1 | - | - | 1 | - | |

| Sum | 1 | 1 | - | - | 1 | - | ||

| Sum | 9 | 12 | 14 | 3 | 29 | 16 | ||

| 1 | ENG | C | 8 | - | 20 (12/8/-) | - | 20 (12/8/-) | 66 |

| E | 9 | - | 33 (16/9/8) | - | 33 (16/9/8) | 100 | ||

| J | 2 | - | 5 (3/2/-) | - | 5 (3/2/-) | 15 | ||

| M | 2 | - | 4 (2/2/-) | - | 4 (2/2/-) | 93 | ||

| P | 10 | - | 31 (15/10/6) | - | 31 (15/10/6) | 2 | ||

| Sum | 31 | - | 93 (48/31/14) | - | 93 (48/31/14) | 276 | ||

| PRO | C | 3 | - | 9 | - | 9 | - | |

| E | 2 | - | 6 | - | 6 | - | ||

| J | 1 | - | 3 | - | 3 | - | ||

| M | 2 | - | 6 | - | 6 | - | ||

| P | 2 | - | 6 | - | 6 | - | ||

| Sum | 10 | - | 30 | - | 30 | - | ||

| CON | A | 2 | - | 23 | - | 23 | - | |

| E | 2 | - | 6 | - | 6 | - | ||

| J | 1 | - | 1 | - | 1 | - | ||

| M | 2 | - | 11 | - | 11 | - | ||

| P | 1 | - | 5 | - | 5 | - | ||

| Sum | 8 | - | 46 | - | 46 | - | ||

| Sum | 49 | - | 169 | - | 169 | 276 | ||

| 2 | ENG | C | 5 | 12 (7/5/-) | - | - | 12 (7/5/-) | 27 |

| E | 8 | 31 (15/8/8) | - | - | 31 (15/8/8) | 71 | ||

| J | 2 | 5 (3/2/-) | - | - | 5 (3/2/-) | 11 | ||

| M | 1 | 2 (1/1/-) | - | - | 2 (1/1/-) | 52 | ||

| P | 8 | 26 (12/8/6) | - | - | 26 (12/8/6) | 1 | ||

| Sum | 24 | 76 (38/24/14) | - | - | 76 (38/24/14) | 162 | ||

| PRO | C | 2 | 6 | - | - | 6 | - | |

| E | 1 | 3 | - | - | 3 | - | ||

| J | 1 | 3 | - | - | 3 | - | ||

| M | 1 | 3 | - | - | 3 | - | ||

| P | 2 | 6 | - | - | 6 | - | ||

| Sum | 7 | 21 | - | - | 21 | - | ||

| CON | A | 1 | 9 | - | - | 9 | - | |

| E | 1 | 4 | - | - | 4 | - | ||

| J | 1 | 4 | - | - | 4 | - | ||

| M | 1 | 4 | - | - | 4 | - | ||

| P | 1 | 4 | - | - | 4 | - | ||

| Sum | 5 | 25 | - | - | 25 | - | ||

| Sum | 36 | 122 | - | - | 122 | 162 | ||

| 3 | Same as CWA 2 | |||||||

| Sum | 36 | 122 | - | - | 122 | 162 | ||

| 4 | Same as CWA 2 | |||||||

| Sum | 36 | 122 | - | - | 122 | 162 | ||

| 5 | Same as CWA 2 | |||||||

| Sum | 36 | 122 | - | - | 122 | 162 | ||

| Total | 202 | 500 | 183 | 6 | 689 | 940 | ||

| WBS Level | Quantity (Activities/IEWP/ENG-IF) | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 CWA | Lev.3 Phase | Lev.4 OBS | Lev.5 WP | AE/BOP | NSSS/RCB | Common | Total | |

| Milestone/Dummy | - | - | 3 | 3 | - | |||

| 0 | ENG | E | 2 | 2 (1/1/0) | - | 3 (2/1/0) | 5 (3/2/0) | 3 |

| J | 1 | 2 | 3 (2/1/0) | - | 5 (4/1/0) | 4 | ||

| M | 2 | 2 | 5 (3/2/0) | - | 7 (5/2/0) | 5 | ||

| X | 1 | 2 | 3 (2/1/0) | - | 5 (4/1/0) | 4 | ||

| Sum | 6 | 8 (1/1/0) | 11 (7/4/0) | 3 (2/1/0) | 22 (16/6/0) | 16 | ||

| PRO | E | 1 | 3 | - | - | 3 | - | |

| M | 1 | - | 3 | - | 3 | - | ||

| Sum | 2 | 3 | 3 | - | 6 | - | ||

| CON | E | 1 | 1 | - | - | 1 | - | |

| Sum | 1 | 1 | - | - | 1 | - | ||

| Sum | 9 | 12 | 14 | 3 | 29 | 16 | ||

| 1 | ENG | C | 5 | - | 17 (12/5/0) | - | 17 (12/5/0) | 66 |

| E | 9 | - | 33 (16/9/8) | - | 33 (16/9/8) | 100 | ||

| J | 2 | - | 5 (3/2/0) | - | 5 (3/2/0) | 15 | ||

| M | 2 | - | 4 (2/2/0) | - | 4 (2/2/0) | 93 | ||

| P | 6 | - | 27 (15/6/6) | - | 27 (15/6/6) | 2 | ||

| Sum | 24 | - | 86 (48/24/14) | - | 86 (48/24/14) | 276 | ||

| PRO | C | 3 | - | 9 | - | 9 | - | |

| E | 2 | - | 6 | - | 6 | - | ||

| J | 1 | - | 3 | - | 3 | - | ||

| M | 2 | - | 6 | - | 6 | - | ||

| P | 2 | - | 6 | - | 6 | - | ||

| Sum | 10 | - | 30 | - | 30 | - | ||

| CON | A | 2 | - | 23 | - | 23 | - | |

| E | 2 | - | 6 | - | 6 | - | ||

| J | 1 | - | 1 | - | 1 | - | ||

| M | 2 | - | 11 | - | 11 | - | ||

| P | 1 | - | 5 | - | 5 | - | ||

| Sum | 8 | - | 46 | - | 46 | - | ||

| Sum | 42 | - | 162 | - | 162 | 276 | ||

| 2 | ENG | C | 1 | 8 (7/1/0) | - | - | 8 (7/1/0) | 27 |

| E | 8 | 31 (15/8/8) | - | - | 31 (15/8/8) | 71 | ||

| J | 1 | 4 (3/1/0) | - | - | 4 (3/1/0) | 11 | ||

| M | 1 | 2 (1/1/0) | - | - | 2 (1/1/0) | 52 | ||

| P | 5 | 23 (12/5/6) | - | - | 23 (12/5/6) | 1 | ||

| Sum | 16 | 68 (38/16/14) | - | - | 68 (38/16/14) | 162 | ||

| PRO | C | 2 | 6 | - | - | 6 | - | |

| E | 1 | 3 | - | - | 3 | - | ||

| J | 1 | 3 | - | - | 3 | - | ||

| M | 1 | 3 | - | - | 3 | - | ||

| P | 2 | 6 | - | - | 6 | - | ||

| Sum | 7 | 21 | - | - | 21 | - | ||

| CON | A | 1 | 9 | - | - | 9 | - | |

| E | 1 | 4 | - | - | 4 | - | ||

| J | 1 | 4 | - | - | 4 | - | ||

| M | 1 | 4 | - | - | 4 | - | ||

| P | 1 | 4 | - | - | 4 | - | ||

| Sum | 5 | 25 | - | - | 25 | - | ||

| Sum | 28 | 114 | - | - | 114 | 162 | ||

| 3 | Same as CWA 2 | |||||||

| Sum | 28 | 114 | - | - | 114 | 162 | ||

| 4 | Same as CWA 2 | |||||||

| Sum | 28 | 114 | - | - | 114 | 162 | ||

| 5 | Same as CWA 2 | |||||||

| Sum | 28 | 114 | - | - | 114 | 162 | ||

| Total | 163 | 468 | 176 | 6 | 650 | 940 | ||

| Predecessor ⇒ Successor | Traditional Schedule (A) | AWP-M1 (B) | AWP-M2 (C) | |||||

|---|---|---|---|---|---|---|---|---|

| B | B-A | B/A | C | C-A | C/A | |||

| ENG ⇒ ENG | ENG ⇒ ENG | 102 | 144 | 42 | 1.41 | 144 | 42 | 1.41 |

| ENG ⇒ ENG-IF | - | 123 | 123 | - | 123 | 123 | - | |

| ENG ⇒ IEWP | - | 136 | 136 | - | 136 | 136 | - | |

| ENG-IF ⇒ ENG | - | 123 | 123 | - | 123 | 123 | - | |

| ENG-IF ⇒ ENG-IF | - | 24 | 24 | - | 24 | 24 | - | |

| Sum | 102 | 550 | 448 | 5.39 | 550 | 448 | 5.39 | |

| ENG ⇒ PRO | ENG ⇒ PRO | 22 | 40 | 18 | 1.82 | 40 | 18 | 1.82 |

| Sum | 22 | 40 | 18 | 1.82 | 40 | 18 | 1.82 | |

| ENG ⇒ CON | ENG ⇒ CON | 174 | - | −174 | - | - | −174 | - |

| IEWP ⇒ CON | - | 96 | 96 | - | 70 | 70 | - | |

| ENG-IF ⇒ CON | - | 57 | 57 | - | 57 | 57 | - | |

| Sum | 174 | 153 | −21 | 0.88 | 127 | −47 | 0.73 | |

| PRO ⇒ PRO | PRO ⇒ PRO | 22 | 80 | 58 | 3.64 | 80 | 58 | 3.64 |

| Sum | 22 | 80 | 58 | 3.64 | 80 | 58 | 3.64 | |

| PRO ⇒ CON | PRO ⇒ CON | 74 | 40 | −34 | 0.54 | 40 | −34 | 0.54 |

| Sum | 74 | 40 | −34 | 0.54 | 40 | −34 | 0.54 | |

| CON ⇒ CON | CON ⇒ CON | 193 | 214 | 21 | 1.11 | 214 | 21 | 1.11 |

| Sum | 193 | 214 | 21 | 1.11 | 214 | 21 | 1.11 | |

| Total | 589 | 1079 | 490 | 1.83 | 1053 | 464 | 1.79 | |

References

- Locatelli, G. Why Are Megaprojects, Including Nuclear Power Plants, Delivered Overbudget and Late? Reasons and Remedies; MIT-ANP-TR-172; Massachusetts Institute of Technology: Cambridge, MA, USA, 2018; pp. 5–21. [Google Scholar]

- Alsharif, S.; Karatas, A. A Framework for Identifying Causal Factors of Delay in Nuclear Power Plant Projects. Procedia Eng. 2016, 145, 1486–1487. [Google Scholar] [CrossRef]

- OECD Nuclear Energy Agency (NEA). Unlocking Reductions in the Construction Costs of Nuclear: A Practical Guide for Stakeholders; NEA No. 7530; OECD Publishing: Paris, France, 2020; p. 17. [Google Scholar]

- Hossen, M.M.; Kang, S.; Kim, J. Construction Schedule Delay Risk Assessment by Using Combined AHP-RII Methodology for an International Project. Nucl. Eng. Technol. 2015, 47, 376–378. [Google Scholar] [CrossRef]

- International Atomic Energy Agency (IAEA). Management of Nuclear Power Plant Projects; IAEA Nuclear Energy Series No. NG-T-1.6; IAEA: Vienna, Austria, 2020; pp. 75–108. [Google Scholar]

- CII/COAA. IR 272-2 Version 3.1 Vol.1: Advanced Work Packaging—Design Through Workface Execution; CII: Austin, TX, USA, 2013; pp. 1–5. [Google Scholar]

- CII/COAA. IR 272-2 Version 3.1 Vol.2: Advanced Work Packaging Implementation Guidance; CII: Austin, TX, USA, 2013; pp. 1–7, 81–83. [Google Scholar]

- CII/COAA. IR 272-2 Version 3.1 Vol.3: Advanced Work Packaging Implementation Case Studies and Expert Interviews; CII: Austin, TX, USA, 2013; pp. 1, 5–6. [Google Scholar]

- CII/COAA. IR 319-2: Validating Advanced Work Packaging as a Best Practice—A Game Changer; CII: Austin, TX, USA, 2015; pp. 15–18, 22–23. [Google Scholar]

- CII/COAA. RR 272-12: Advanced Work Packaging—From Project Definition through Site Execution; CII: Austin, TX, USA, 2013; pp. 9–35. [Google Scholar]

- CII/COAA. RR 319-11: Transforming the Industry—Advanced Work Packaging as a Standard (Best) Practice; CII: Austin, TX, USA, 2015; pp. 11–14. [Google Scholar]

- CII/COAA. RS 319-1: Making the Case for Advanced Work Packaging as a Standard (Best) Practice; CII: Austin, TX, USA, 2015; pp. 7–15. [Google Scholar]

- Hamdi, O. Advanced Work Packaging: Guide for Life Cycle Implementation; BookBaby: Pennsauken, NJ, USA, 2022; pp. 4–9. [Google Scholar]

- Huang, Z.-K.; Zeng, N.-C.; Zhang, D.-M.; Argyroudis, S.; Mitoulis, S.-A. Resilience Models for Tunnels Recovery After Earthquakes. Engineering 2025, in press. [CrossRef]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M.; Masanobu, S.; Kathleen, T.; William, A.W.; von Winterfeldt, D.; et al. A framework to quantitatively assess and enhance the seismic resilience of communities. Earthq. Spectra 2003, 19, 733–752. [Google Scholar] [CrossRef]

- Construction Industry Institute (CII). AWP Execution Planning Guide for Projects and Organizations. 2023. Available online: https://www.construction-institute.org/ (accessed on 17 June 2025).

- Hamdi, O. Advanced Work Packaging from Project Definition Through Site Execution: Driving Successful Implementation of Workface Planning. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2013. Abstract. pp. 253–261. [Google Scholar]

- Halala, M.; Fayek, A.R. A Framework to Assess the Costs and Benefits of Advanced Work Packaging in Industrial Construction. Can. J. Civ. Eng. 2019, 46, 226–228. [Google Scholar]

- O’Connor, J.T.; Leite, F.; Ma, J.W. Expanding Advanced Work Packaging to Include Commissioning and Startup for Industrial Projects. Constr. Innov. 2022, 22, 939–960. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Bridging the Gap between Engineering and Construction 3D Models in Support of Advanced Work Packaging. J. Leg. Aff. Disput. Resolut. Eng. Constr. (ASCE) 2020, 12, 04520029. [Google Scholar] [CrossRef]

- Musarat, M.A.; Faisal, I.; Siddiq, M.Z.; Altaf, A.; Shah, F.; Zhou, Y.; Zhang, X. Advanced Work Packaging (AWP) Implementation and Challenges in the Malaysian Oil and Gas Sector. Sustainability 2024, 16, 1265. [Google Scholar] [CrossRef]

- Rebai, A.; Fakhfakh, N.; Ghedamsi, N. Barriers to Adopting Advanced Work Packaging (AWP) in Construction. Buildings 2024, 14, 1032. [Google Scholar] [CrossRef]

- Construction Owners Association of Alberta (COAA). EWP Readiness Playbook; COAA: Edmonton, AB, Canada, 2019; Available online: https://www.coaa.ab.ca/library/awp-ewp-readiness-playbook/ (accessed on 17 June 2025).

- Choo, D.; Jung, W. Advanced Work Package Application for Nuclear Construction Project: Review on the Work Breakdown Structure. In Proceedings of the Korean Nuclear Society (KNS) Spring Meeting, Jeju, Republic of Korea, 22–23 May 2025. [Google Scholar]

- Rebai, S.; Hamdi, O.; Lafhaj, Z.; Ouchala, H.; AlBalkhy, W. Comparative Analysis of AWP and IPD Methods: Strengths, Challenges, and Opportunities. Buildings 2025, 15, 2893. [Google Scholar] [CrossRef]

- Kim, S.; Choi, H.; Won, S.; Lim, B.; Son, H.; Lee, K.; Shin, I.; Yang, M.; Yang, J. Nuclear Power Plant Business Process Modeling and Procedure Management Method. Republic of Korea Patent KR 10-2015-0001923, 7 January 2015. pp. 3–4. [Google Scholar]

- Moon, B. A Study on the Application of EVMS to Nuclear PowerPlant Construction Project. Master’s Thesis, Soongsil University, Seoul, Republic of Korea, 2009; pp. 30–48, 73–74. [Google Scholar]

- Demetracopoulou, V.; Faust, K.I.; O’Brien, W.J. Benefits and Conditions for Successful Implementation of Advanced Work Packaging in Front-End Planning and Design. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2025, 17, 04525055. [Google Scholar] [CrossRef]

- COAA/CII. Scalable Advanced Work Packaging Report (COP-SWP-PBP-01-2019-v1); COAA/CII: Edmonton, AB, USA; Austin, TX, USA, 2019. [Google Scholar]

- Project Management Institute (PMI). A Guide to the Project Management Body of Knowledge (PMBOK Guide), 7th ed.; PMI: Newtown Square, PA, USA, 2021.

- Korea Hydro & Nuclear Power Co., Ltd. (KHNP). Shin-Kori Units 3 and 4 Final Safety Analysis Report (FSAR), Chapter 1: General Plant Information, Revision 7; KHNP: Seoul, Republic of Korea, 2023. [Google Scholar]

| Component | Parameter | APR1400 Reference * | AWP Model * | Scaling Ratio (%) |

|---|---|---|---|---|

| RCB | Radius (r) | 0.00 m | 0.00 m | 65.22% |

| Area (A) | 0.00 m2 | 0.00 m2 | 43.06% | |

| Height (S.L.) | 0.00 m | 0.00 m | 49.18% | |

| Height (Dome) | 0.00 m | 0.00 m | 54.22% | |

| Dome Volume | 0.00 m3 | 0.00 m3 | 28.26% | |

| Total Volume (V) | 0.00 m3 | 0.00 m3 | 22.71% | |

| AB | Width | 0.00 m | 0.00 m | 67.31% |

| Depth | 0.00 m | 0.00 m | 82.35% | |

| Area (A) | 0.00 m2 | 0.00 m2 | 55.32% | |

| Height | 0.00 m | 0.00 m | 43.48% | |

| Total Volume (V) | 0.00 m3 | 0.00 m3 | 25.13% |

| Feature | Method 1 | Method 2 | Method 3 | Method 4 |

|---|---|---|---|---|

| EWP grouping | FBS (horizontal) | Discipline (horizontal + vertical) | Disc. + Phase (PI/CI) (vertical) | Discipline (horizontal + vertical) |

| PWP grouping | Equipment type (horizontal) | Equipment type (horizontal) | Equipment by phase (vertical) | Discipline (horizontal + vertical) |

| WBS Level | Quantity of Activities | ENG Deliverable | ||||||

|---|---|---|---|---|---|---|---|---|

| Lev.2 | Lev.3 | Lev.4 | AE/BOP | NSSS/RCB | Common | Interface | Total | |

| Milestone/Dummy | - | - | 3 | - | 3 | - | ||

| ENG | 6 | 28 | 24 | 31 | 10 | 98 | 163 | 269 |

| PRO | 5 | 11 | 0 | 9 | 24 | 59 | 92 | - |

| CON | 5 | 9 | 89 | 46 | 0 | 124 | 259 | - |

| 4 | 16 | 48 | 113 | 86 | 37 | 281 | 517 | 269 |

| Milestone | Scheduled Date | From Project Start |

|---|---|---|

| Project Start (D) | 2026.01.01 | D + 0 month |

| First Concrete | 2027.11.05 | D + 22 month |

| Set Reactor Vessel (RV) | 2028.12.09 | D + 35 month |

| Construction Completion | 2029.06.11 | D + 42 month |

| Predecessor–Successor | Relationship Type | Amount |

|---|---|---|

| Milestone ⇒ CON | FS | 2 |

| ENG ⇒ ENG | FS | 102 |

| ENG ⇒ PRO | FS | 22 |

| ENG ⇒ CON | FS | 174 |

| PRO ⇒ PRO | FS | 22 |

| PRO ⇒ CON | FS | 74 |

| CON ⇒ CON | SS | 8 |

| FS | 178 | |

| FF | 7 | |

| 589 |

| Method | Total Score | Converted Score |

|---|---|---|

| Method 1 | 56/60 | 93.6% |

| Method 2 | 55/60 | 92.0% |

| Method 3 | 41/60 | 69.2% |

| Method 4 | 50/60 | 83.2% |

| Predecessor–Successor | Relationship Type | Amount |

|---|---|---|

| Milestone ⇒ CON | FS | 2 |

| ENG ⇒ ENG | FS | 144 |

| ENG ⇒ IEWP | FS | 136 |

| ENG ⇒ ENG-IF | FS | 123 |

| ENG ⇒ PRO | FS | 40 |

| IEWP ⇒ CON | FS | 96 |

| ENG-IF ⇒ ENG | FS | 123 |

| ENG-IF ⇒ ENG-IF | FS | 24 |

| ENG-IF ⇒ CON | FS | 57 |

| PRO ⇒ PRO | FS | 80 |

| PRO ⇒ CON | FS | 40 |

| CON ⇒ CON | SS | 8 |

| FS | 187 | |

| FF | 19 | |

| 1079 |

| Predecessor–Successor | Relationship Type | Amount |

|---|---|---|

| Milestone ⇒ CON | FS | 2 |

| ENG ⇒ ENG | FS | 144 |

| ENG ⇒ IEWP | FS | 136 |

| ENG ⇒ ENG-IF | FS | 123 |

| ENG ⇒ PRO | FS | 40 |

| IEWP ⇒ CON | FS | 70 |

| ENG-IF ⇒ ENG | FS | 123 |

| ENG-IF ⇒ ENG-IF | FS | 24 |

| ENG-IF ⇒ CON | FS | 57 |

| PRO ⇒ PRO | FS | 80 |

| PRO ⇒ CON | FS | 40 |

| CON ⇒ CON | SS | 8 |

| FS | 187 | |

| FF | 19 | |

| 1053 |

| Scenario | Finish Date | Schedule Variance | Remarks |

|---|---|---|---|

| Baseline Schedule (No Adjustment) (ⓐ) | 11 June 2029 | ±0 days | AWP-M1, M2 schedule without AWP improvements |

| 25% Productivity Improvement Applied (ⓑ) | 11 February 2029 | −120 days (ⓑ − ⓐ) | Reflects 25% reduction in CWP durations |

| ⓑ + 90 day Lag for IEWPto CWP Sequencing (ⓒ) | 12 April 2029 | −60 days (ⓒ − ⓐ) | Accounts for AWP workface planning requirement |

| Delay Activity | Finish Date (A) | Variance (A-Baseline) |

|---|---|---|

| 310C118PI | 8 March 2030 | 270 days |

| 310E145PI | 6 January 2030 | 209 days |

| 310J159PI | 11 June 2029 | 0 days |

| 310P193PI | 8 March 2030 | 270 days |

| 320C118PI | 1 December 2029 | 173 days |

| 320E145PI | 30 November 2029 | 172 days |

| 320J159PI | 11 June 2029 | 0 days |

| 320P193PI | 1 December 2029 | 173 days |

| Delay Activity | 360-Day Delay | 30-Day Backlog | |||

|---|---|---|---|---|---|

| AWP-M1 | AWP-M2 | Finish Date (A) | Variance (A-Baseline) | Finish Date (B) | Variance (B-A) |

| CWP01-EWP10-3101C118PI | CWP01-EWP9-3101C118PI | 7 January 2030 | 270 | 8 December 2029 | −30 |

| CWP03-EWP16-3101E145PI | CWP03-EWP13-3101E145PI | 20 November 2029 | 222 | 21 October 2029 | −30 |

| CWP06-EWP24-3101J159PI | CWP06-EWP21-3101J159PI | 12 April 2029 | 0 | 12 April 2029 | 0 |

| CWP07-EWP27-3101P186PI | CWP03-EWP25-3101P193PI | 7 January 2030 | 270 | 8 December 2029 | −30 |

| CWP09-EWP41-3202C118PI | CWP09-EWP31-3202C118PI | 15 November 2029 | 217 | 16 October 2029 | −30 |

| CWP00-EWP46-3202E145PI | CWP00-EWP35-3202E145PI | 29 December 2029 | 261 | 29 November 2029 | −30 |

| CWP12-EWP52-3202J159PI | CWP12-EWP40-3202J159PI | 12 April 2029 | 0 | 12 April 2029 | 0 |

| CWP10-EWP57-3202P193PI | CWP10-EWP44-3202P193PI | 15 November 2029 | 217 | 16 October 2029 | −30 |

| AWP-M1 | 360-Day Delay | Re-Sequencing | |||

|---|---|---|---|---|---|

| Delay Activity | Finish Date | Variance (A-Baseline) | Finish Date (B) | Variance (B-Baseline) | Variance (B-A) |

| I-EWP10 | 15 October 2029 | 186 | 15 October 2029 | 186 | 0 |

| I-EWP16 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP24 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP27 | 16 May 2029 | 34 | 16 May 2029 | 34 | 0 |

| I-EWP41 | 14 August 2029 | 124 | 22 July 2029 | 0 | −23 |

| I-EWP46 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP52 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP57 | 14 February 2030 | 170 | 17 July 2029 | 96 | −74 |

| AWP-M2 | 360-Day Delay | Re-Sequencing | |||

|---|---|---|---|---|---|

| Delay Activity | Finish Date | Variance (A-Baseline) | Finish Date (B) | Variance (B-Baseline) | Variance (B-A) |

| I-EWP9 | 15 December 2029 | 247 | 15 December 2029 | 247 | 0 |

| I-EWP13 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP21 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP25 | 14 October 2029 | 185 | 14 October 2029 | 185 | 0 |

| I-EWP31 | 14 October 2029 | 185 | 1 August 2029 | 111 | −74 |

| I-EWP35 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP40 | 12 April 2029 | 0 | 12 April 2029 | 0 | 0 |

| I-EWP44 | 29 November 2029 | 231 | 16 September 2029 | 157 | −74 |

| Attribute | Traditional Schedule * | AWP-M1 | AWP-M2 | Remark |

|---|---|---|---|---|

| WBS (or WP) Levels | 4 | 5 | 5 | * Varies on project and purpose |

| WBS Level definition | 1-Project 2-Phase(EPC) 3-Disc/CP 4-FBS/PO/Type | 1-Project 2-CWA 3-Phase(EPC) 4-Discipline 5-WP | 1-Project 2-CWA 3-Phase(EPC) 4-Discipline 5-WP | |

| WP grouping | Function -ENG: FBS -PRO: PO -CON: CP | CWA + Function -ENG: FBS -PRO: Equip. type -CON: Con. type | CWA + Function -ENG: Disc. -PRO: Equip. type -CON: Con. type | |

| WPs | 48 | 202 | 163 | * Lowest WBS level |

| ENG deliverables | 269 | 940 | 940 |

| Attribute | Traditional Schedule (A) | AWP-M1 (B) | AWP-M2 (C) | |||||

|---|---|---|---|---|---|---|---|---|

| B | B-A | B/A | C | C-A | C/A | |||

| ENG | AE/BOP | 24 | 159 | 135 | 6.63 | 159 | 135 | 6.63 |

| NSSS/RCB | 31 | 55 | 24 | 1.77 | 55 | 24 | 1.77 | |

| Common | 10 | 2 | −8 | 0.20 | 2 | −8 | 0.2 | |

| Interface/IEWP/ENG-IF | 98 | 203 | 105 | 2.07 | 164 | 66 | 1.67 | |

| Sum | 163 | 419 | 256 | 2.57 | 380 | 217 | 2.33 | |

| PRO | AE/BOP | - | 87 | 87 | - | 87 | 87 | - |

| NSSS/RCB | 9 | 33 | 24 | 3.67 | 33 | 24 | 3.67 | |

| Common | 24 | - | −24 | - | - | −24 | - | |

| Interface | 59 | - | −59 | - | - | −59 | - | |

| Sum | 92 | 120 | 28 | 1.30 | 120 | 28 | 1.30 | |

| CON | AE/BOP | 89 | 101 | 12 | 1.13 | 101 | 12 | 1.13 |

| NSSS/RCB | 46 | 46 | - | 1.00 | 46 | - | 1.00 | |

| Common | - | - | - | - | - | - | - | |

| Interface | 124 | - | −124 | - | - | −124 | ||

| Sum | 259 | 147 | −112 | 0.57 | 147 | −112 | 0.57 | |

| Sum | 517 | 686 | 169 | 1.33 | 647 | 130 | 1.25 | |

| Predecessor ⇒ Successor | Traditional Schedule (A) | AWP-M1 (B) | AWP-M2 (C) | ||||

|---|---|---|---|---|---|---|---|

| B | B-A | B/A | C | C-A | C/A | ||

| ENG ⇒ ENG | 102 | 550 | 448 | 5.39 | 550 | 448 | 5.39 |

| ENG ⇒ PRO | 22 | 40 | 18 | 1.82 | 40 | 18 | 1.82 |

| ENG ⇒ CON | 174 | 153 | −21 | 0.88 | 127 | −47 | 0.73 |

| PRO ⇒ PRO | 22 | 80 | 58 | 3.64 | 80 | 58 | 3.64 |

| PRO ⇒ CON | 74 | 40 | −34 | 0.54 | 40 | −34 | 0.54 |

| CON ⇒ CON | 193 | 214 | 21 | 1.11 | 214 | 21 | 1.11 |

| Total | 589 | 1079 | 490 | 1.83 | 1053 | 464 | 1.79 |

| Schedule | Finish Date | Schedule Variance |

|---|---|---|

| Traditional | 11 June 2029 | ⓐ |

| AWP applied (25% productivity + 90-day lag) | 12 April 2029 | ⓐ—60 days |

| Delay Activity | Variance on 360-Day Delay | B, C 30-Day Backlog | |||||

|---|---|---|---|---|---|---|---|

| Traditional (A) | AWP-M1 (B) | AWP-M2 (C) | A-Base (ⓐ) | B,C-Base (ⓑ) | ⓑ − ⓐ | Critical Path Changes on ⓑ | |

| 310C118PI | CWP01-EWP10-3101C118PI | CWP01-EWP9-3101C118PI | 270 | 270 | 0 | - | −30 |

| 310E145PI | CWP03-EWP16-3101E145PI | CWP03-EWP13-3101E145PI | 209 | 222 | 13 | Overall Construction → Cable Tray | −30 |

| 310J159PI | CWP06-EWP24-3101J159PI | CWP06-EWP21-3101J159PI | 0 | 0 | 0 | - | 0 |

| 310P193PI | CWP07-EWP27-3101P186PI | CWP03-EWP25-3101P193PI | 270 | 270 | 0 | - | −30 |

| 320C118PI | CWP09-EWP41-3202C118PI | CWP09-EWP31-3202C118PI | 173 | 217 | 44 | RCB → CWA2 | −30 |

| 320E145PI | CWP00-EWP46-3202E145PI | CWP00-EWP35-3202E145PI | 172 | 261 | 89 | RCB → CWA2 Activity(E3) Duration difference | −30 |

| 320J159PI | CWP12-EWP52-3202J159PI | CWP12-EWP40-3202J159PI | 0 | 0 | 0 | - | 0 |

| 320P193PI | CWP10-EWP57-3202P193PI | CWP10-EWP44-3202P193PI | 173 | 217 | 44 | RCB → CWA2 | −30 |

| Delay Activity | Variance on 360-Day Delay Finish Date | Variance on Post Re-Sequencing Delay Finish Date (Mitigated Dates) | |||

|---|---|---|---|---|---|

| AWP-M1 (A) | AWP-M2 (B) | A-Baseline | B-Baseline | A-Baseline | B-Baseline |

| I-EWP10 | I-EWP9 | 186 | 247 | 186 (0) | 247 (0) |

| I-EWP16 | I-EWP13 | 0 | 0 | 0 | 0 |

| I-EWP24 | I-EWP21 | 0 | 0 | 0 | 0 |

| I-EWP27 | I-EWP25 | 34 | 185 | 0 | 0 |

| I-EWP41 | I-EWP31 | 124 | 185 | 101 (−23) | 111 (−74) |

| I-EWP46 | I-EWP35 | 0 | 0 | 0 | 0 |

| I-EWP52 | I-EWP40 | 0 | 0 | 0 | 0 |

| I-EWP57 | I-EWP44 | 170 | 231 | 96 (−74) | 157 (−74) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choo, D.; Jung, W. A Preliminary Study on the Comparative Schedule Analysis of Traditional and Advanced Work Packaging Plans for Nuclear Power Plant Construction. Appl. Sci. 2025, 15, 11113. https://doi.org/10.3390/app152011113

Choo D, Jung W. A Preliminary Study on the Comparative Schedule Analysis of Traditional and Advanced Work Packaging Plans for Nuclear Power Plant Construction. Applied Sciences. 2025; 15(20):11113. https://doi.org/10.3390/app152011113

Chicago/Turabian StyleChoo, Dongwoo, and Wooyong Jung. 2025. "A Preliminary Study on the Comparative Schedule Analysis of Traditional and Advanced Work Packaging Plans for Nuclear Power Plant Construction" Applied Sciences 15, no. 20: 11113. https://doi.org/10.3390/app152011113

APA StyleChoo, D., & Jung, W. (2025). A Preliminary Study on the Comparative Schedule Analysis of Traditional and Advanced Work Packaging Plans for Nuclear Power Plant Construction. Applied Sciences, 15(20), 11113. https://doi.org/10.3390/app152011113