AI-Enhanced Manufacturing in Latin America: Opportunities, Challenges, Applications, and Regulatory Policy Frameworks for Intelligent Production Systems

Abstract

1. Introduction

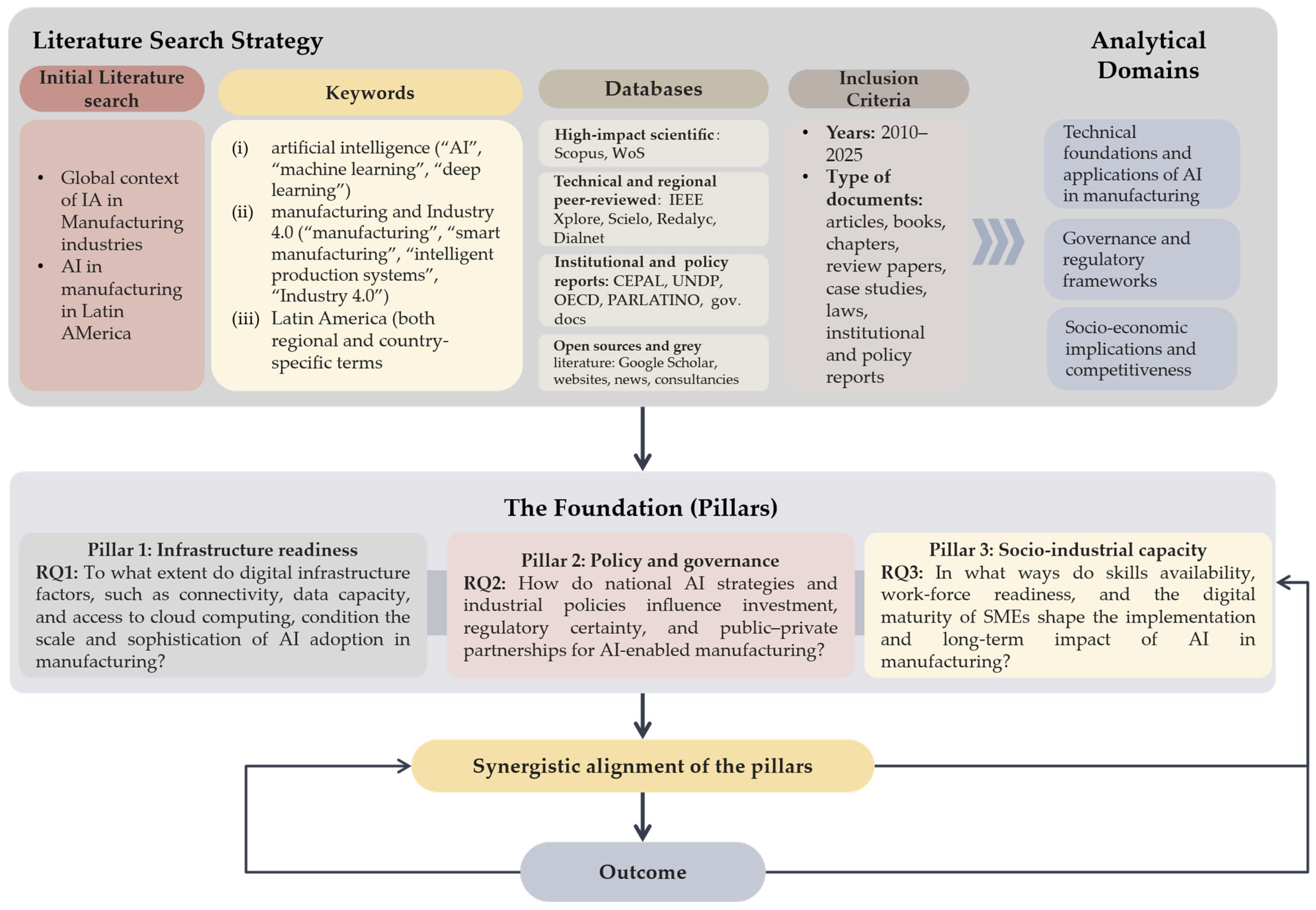

2. Methodology

2.1. Literature Search Strategy

2.2. Analytical Domains of the Review

2.3. Research Problem and Questions

- RQ1: Infrastructure readiness—To what extent do digital infrastructure factors, such as connectivity, data capacity, and access to cloud computing, condition the scale and sophistication of AI adoption in manufacturing?

- RQ2: Policy and governance—How do national AI strategies and industrial policies influence investment, regulatory certainty, and public–private partnerships for AI-enabled manufacturing?

- RQ3: Socio-industrial capacity—In what ways do skills availability, workforce readiness, and the digital maturity of SMEs shape the implementation and long-term impact of AI in manufacturing?

2.4. The Research Model: The Triadic Integration Framework for AI Adoption

- Digital Infrastructure (representing the technological context) emphasizes the foundational role of technological readiness, including connectivity, data capacity, and cloud computing access, as a non-negotiable prerequisite for deploying sophisticated AI applications [49].

- Policy and Governance (representing the environmental context) highlights how external factors, such as national strategies and regulatory certainty, create the necessary ecosystem for investment and risk mitigation [50].

Logical Sequence of the Model

- The Foundation (The Three Pillars)

- The Mechanism (Synergistic Alignment)

- The Outcome (AI Adoption and Impact)

- The Feedback Loop

3. Technical Foundations of AI in Manufacturing

3.1. Types of Manufacturing Process

3.2. AI Potential for Manufacturing Processes

3.3. Applications of Artificial Intelligence in Manufacturing

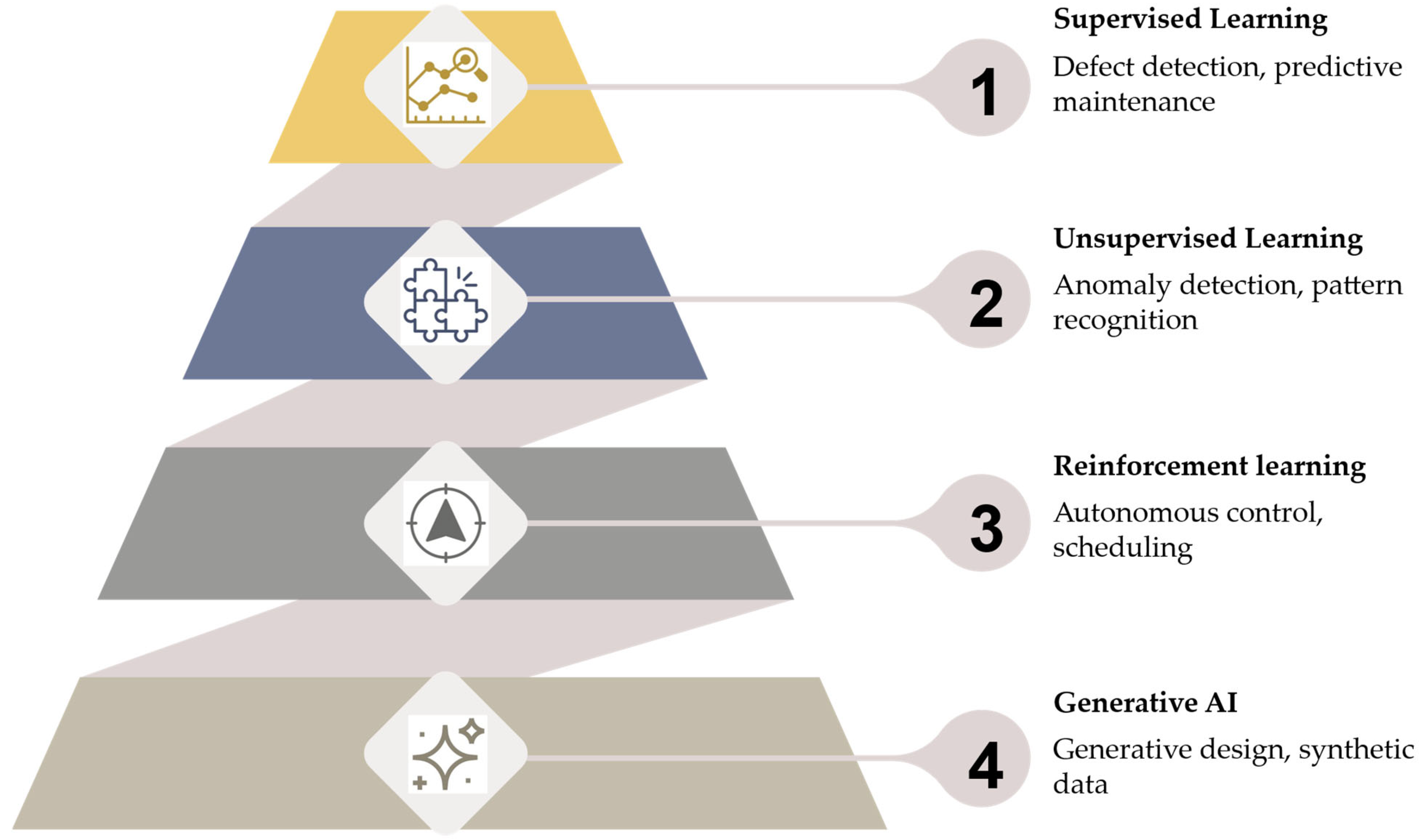

3.3.1. Overview of AI Capabilities in Manufacturing

- Supervised Learning: Algorithms learn from labeled data (i.e., input-output pairs), making it ideal for tasks such as predicting product quality, tool wear, or machine failures. It is widely used in predictive maintenance and defect classification.

- Unsupervised Learning: These algorithms discover hidden patterns in unlabeled data, such as clustering similar process behaviors or detecting anomalies without prior examples. Applications include dimensionality reduction and anomaly detection.

- Reinforcement Learning (RL): RL models learn by interacting with an environment and receiving feedback in the form of rewards or penalties. This approach is increasingly used in production scheduling, autonomous control of machinery, and adaptive planning under uncertainty [111].

- Generative AI: These models learn to generate new data resembling the training set and are increasingly applied in generative design, process simulation, and synthetic data generation for training other ML models in data-scarce contexts. These paradigms are depicted in Figure 2.

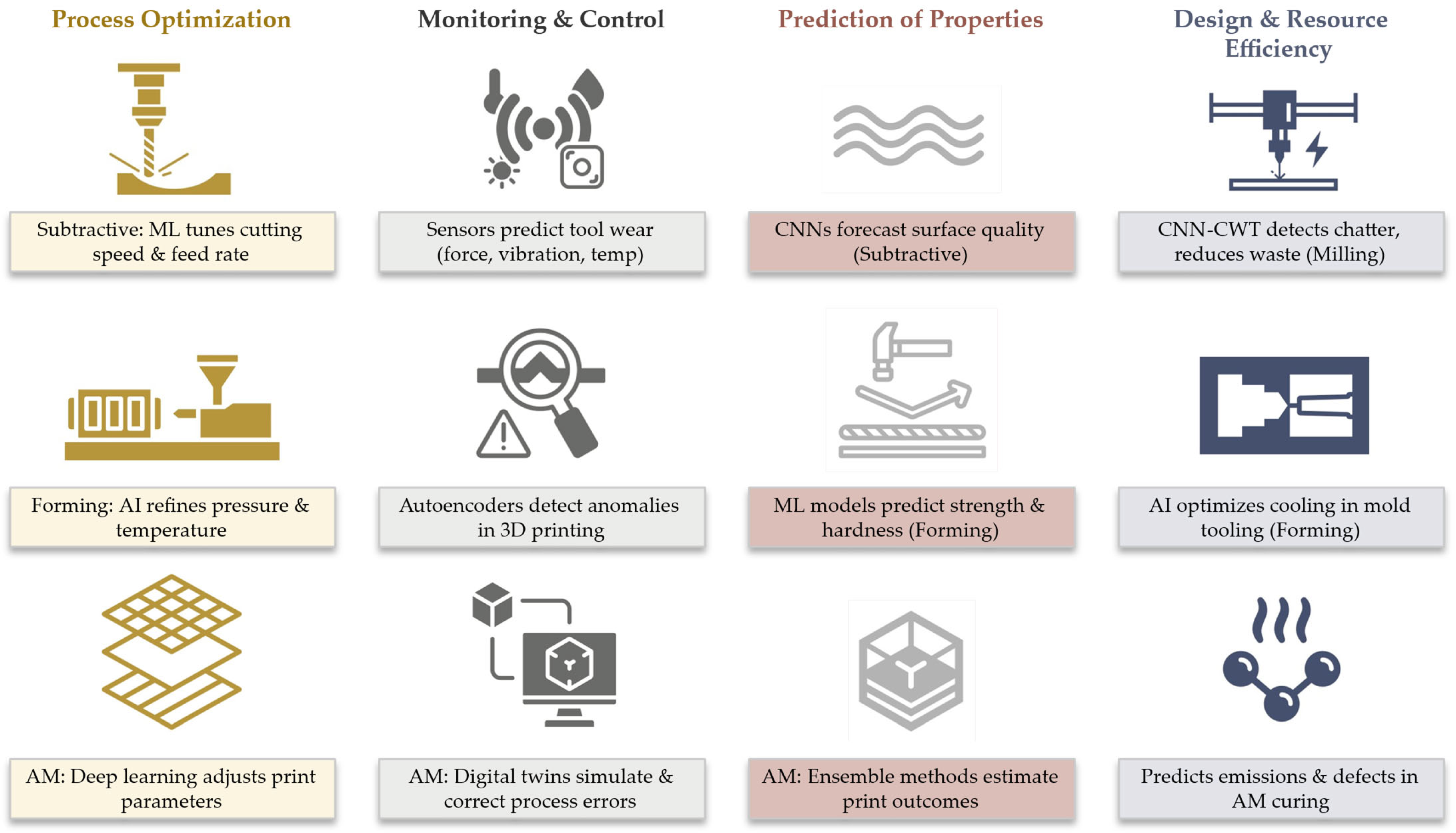

3.3.2. Process-Level Applications

- Process optimization

- Process Monitoring and Control

- Prediction and Optimization of Final Product Properties

- Design optimization and Resource Efficiency

4. Policy and Regulatory Landscape in Latin America

4.1. Current Status of AI and Manufacturing Policies

4.2. Challenges in Governance

4.2.1. Regulatory Lag and Policy Fragmentation

4.2.2. Issues of Data Privacy, Intellectual Property, and Algorithmic Transparency

4.2.3. Cybersecurity Challenges in AI and ML for Manufacturing

4.3. Ethical and Social Considerations

4.3.1. Inclusion, Labor Displacement, Environmental Sustainability, and Digital Equity

4.3.2. Challenges and Opportunities for SMEs in AI Implementation in Industrial Manufacturing

- Unlike large corporations, SMEs often lack the capital required to invest in advanced AI technologies, infrastructure, and skilled personnel. High upfront costs can slow down adoption.

- Access to trained AI specialists and data scientists is limited, particularly in emerging economies, making it difficult for SMEs to build internal capabilities [3].

- AI systems require large volumes of high-quality data. SMEs may lack the digital maturity to collect, store, and process data effectively, which limits the performance of AI applications.

- AI can help SMEs reduce production costs, minimize waste, and improve efficiency, making them more competitive against larger players.

- AI-driven tools can enable SMEs to offer personalized products and adapt more quickly to shifting market demands, which is often an advantage of smaller-scale operations.

- Through AI-enhanced predictive analytics and supply chain optimization, SMEs can better integrate into global value chains and expand their reach.

- AI-powered resource management systems can help SMEs adopt cleaner production practices, aligning with environmental regulations and consumer expectations.

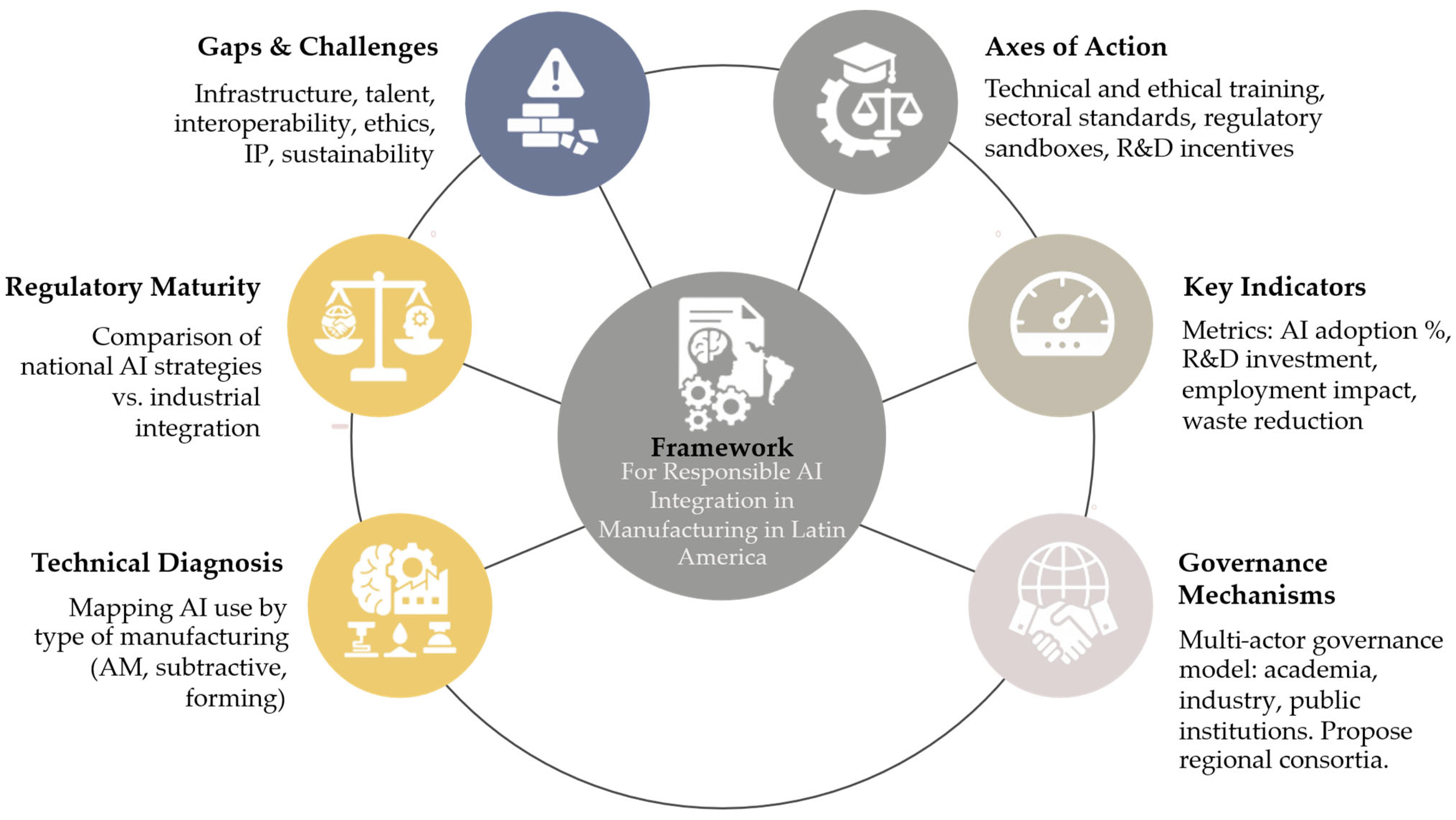

5. Bridging Technology and Policy: A Discussion on Strategic Opportunities

5.1. Addressing the Research Questions: Evaluating the Structural Conditions for AI in Latin American Manufacturing

- Infrastructure (RQ1) as the foundational technical enabler.

- Policy and Governance (RQ2) as the framework providing certainty, incentives, and direction.

- Socio-Industrial Capacity (RQ3) as the human and organizational engine that ultimately drives technology implementation and absorption.

5.2. The Need for Integrated Frameworks: Aligning Innovative Ecosystems with Policy Development

5.3. Stakeholder Engagement: The Role of Academia, Industry, and Civil Society in Shaping Regulation

5.4. Regional Cooperation and Capacity Building: The Importance of Cross-Border Collaboration and Institutional Strengthening

5.5. Strategic Opportunities and Broader Impacts

5.5.1. Economic Potential and Competitiveness

5.5.2. Employment, Skills, and SME Inclusion

5.5.3. Sustainability and Circular Manufacturing

5.5.4. Governance, Digital Infrastructure, and Security

5.5.5. Political Tariffs and the Impact of AI Implementation in Manufacturing

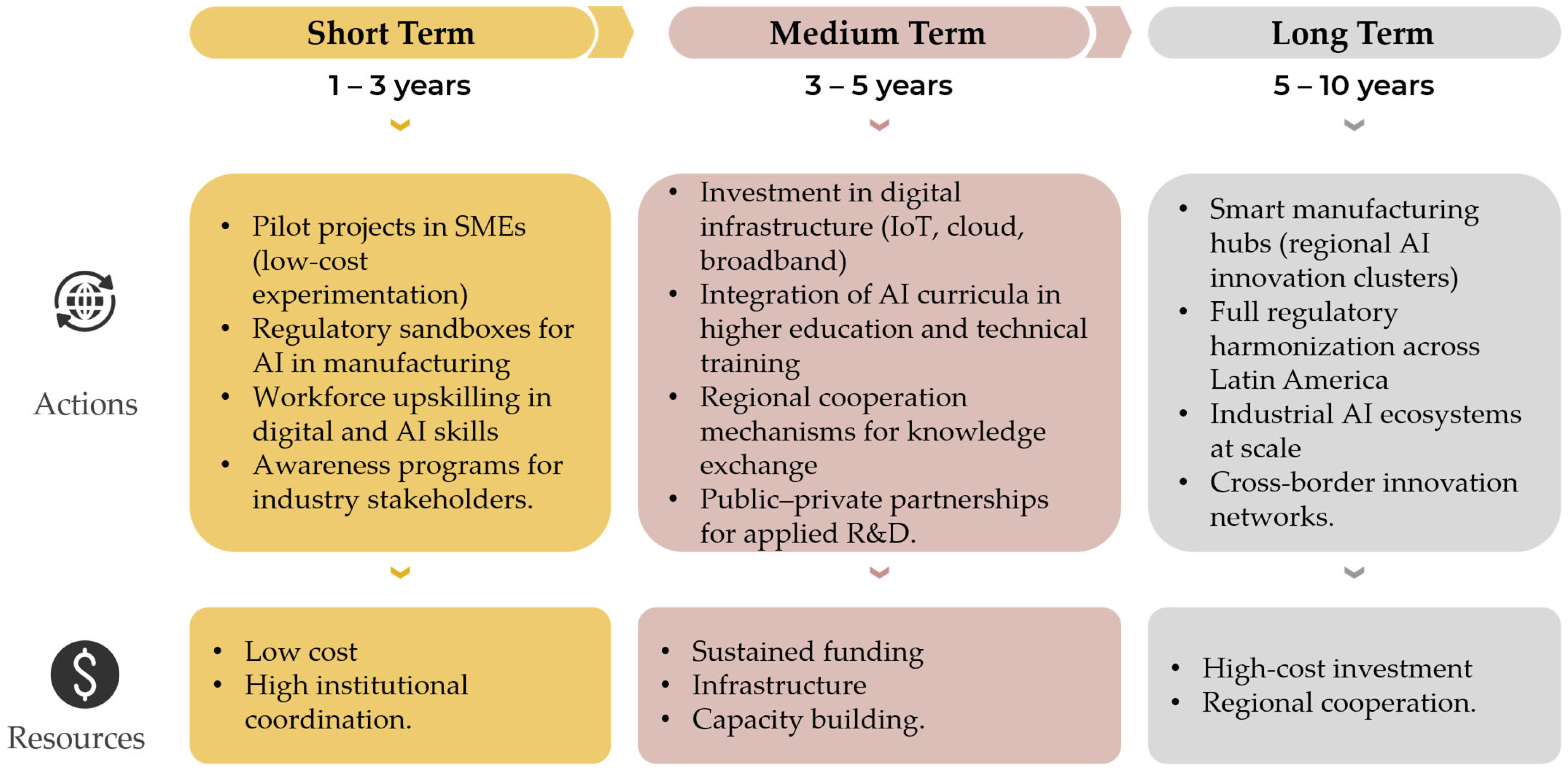

5.6. A Roadmap for Action: Prioritized Initiatives for Stakeholders

5.6.1. Short-Term Actions (0–18 Months): Laying the Foundation

- Establish National AI in Manufacturing Task Forces:

- Action: Create public–private task forces with representatives from industry associations, leading universities, and relevant ministries, such as Economy, Science and Technology, Labor, or national equivalent.

- Responsible Stakeholders: National Governments, Ministry Leads.

- Goal: To diagnose sector-specific needs, identify quick-win projects, and draft national AI-in-manufacturing strategy documents.

- Launch Modular Upskilling and Reskilling Certificates:

- Action: Develop and deploy short, focused certificate programs in data literacy, AI fundamentals for managers, and basic IoT maintenance for technicians.

- Responsible Stakeholders: Technical Universities & Vocational Schools, Industry Associations, to define curriculum needs accordingly.

- Goal: To quickly build a baseline of digital competence within the existing manufacturing workforce.

- Create Regulatory “Sandboxes” for Manufacturing:

- Action: Implement controlled environments where SMEs can test AI solutions, for instance, AI for predictive maintenance or quality control, with temporary regulatory flexibility.

- Responsible Stakeholders: National Regulatory Agencies, Innovation Ministries.

- Goal: To reduce the risk of adoption of SMEs and generate real-world data to inform sensible, evidence-based regulations.

5.6.2. Medium-Term Actions (2–4 Years): Building Capacity and Scaling

- Fund Regional AI Innovation Hubs:

- Action: Establish physical hubs centered around key manufacturing regions (e.g., automotive in Mexico, aerospace in Brazil). These hubs should provide shared access to computing power, technical expertise, and collaboration space.

- Responsible Stakeholders: National Governments (funding), State Governments (hosting), Universities (operating).

- Goal: To create centers of excellence that serve as a resource for local industries, particularly SMEs, lowering the barrier to entry for AI experimentation.

- Implement Fiscal Incentive Programs:

- Action: Introduce tax credits or soft loans for manufacturing firms, especially SMEs, that invest in certified AI technologies or employee digital upskilling.

- Responsible Stakeholders: Ministry of Economy, Finance Ministries, Development Banks.

- Goal: To directly offset the high initial costs of adoption and make investing in human capital financially attractive for companies.

- Develop Regional Data Sharing Frameworks:

- Action: Collaborate on regional standards for industrial data governance that ensure security and privacy while enabling anonymized data pooling for training more robust AI models.

- Responsible Stakeholders: Regional Bodies, for instance, Pacific Alliance, Mercosur, among others, Data Protection Authorities.

- Goal: To overcome the problem of “small data” that individual companies face, fostering innovation without compromising proprietary or personal information.

5.6.3. Long-Term Actions (5+ Years): Sustaining Transformation

- Integrate AI and Advanced Digital Skills into Core Education:

- Action: Revamp national STEM curricula from secondary to postgraduate levels to fully integrate AI, machine learning, and robotics, with a focus on manufacturing applications.

- Responsible Stakeholders: Ministries of Education, Accrediting Bodies, Universities.

- Goal: To future-proof the talent pipeline and ensure a steady supply of graduates ready to contribute to an intelligent production ecosystem.

- Achieve Regional Regulatory Harmonization:

- Action: Fully align national AI strategies and manufacturing regulations across key Latin American markets, building on initiatives like the PARLATINO model law.

- Responsible Stakeholders: Regional Political Bodies, National Legislatures.

- Goal: To create a unified regional market that reduces compliance complexity for multinational manufacturers and strengthens the global positioning of the Latin American industry.

- Establish a Latin American Observatory for AI in Manufacturing:

- Action: Create a permanent, multinational institution to continuously monitor adoption metrics, evaluate policy impacts, disseminate best practices, and update this strategic roadmap.

- Responsible Stakeholders: Multilateral Organizations (e.g., Inter-American Development Bank, Economic Commission for Latin America and the Caribbean, among others), Consortia of Research Universities.

- Goal: To ensure the region’s strategy remains adaptive, evidence-based, and responsive to the rapid pace of technological change.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, S.W.; Kong, J.H.; Lee, S.W.; Lee, S. Recent Advances of Artificial Intelligence in Manufacturing Industrial Sectors: A Review. Int. J. Precis. Eng. Manuf. 2022, 23, 111–129. [Google Scholar] [CrossRef]

- Moosavi, S.; Farajzadeh-Zanjani, M.; Razavi-Far, R.; Palade, V.; Saif, M. Explainable AI in Manufacturing and Industrial Cyber–Physical Systems: A Survey. Electronics 2024, 13, 3497. [Google Scholar] [CrossRef]

- Briatore, F.; Mosca, M.T.; Mosca, R.N.; Braggio, M. A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises. AI 2025, 6, 54. [Google Scholar] [CrossRef]

- Kliestik, T.; Kral, P.; Bugaj, M.; Durana, P. Generative artificial intelligence of things systems, multisensory immersive extended reality technologies, and algorithmic big data simulation and modelling tools in digital twin industrial metaverse. Equilib. Q. J. Econ. Econ. Policy 2024, 19, 429–461. [Google Scholar] [CrossRef]

- Shabur, M.A.; Shahriar, A.; Ara, M.A. From automation to collaboration: Exploring the impact of industry 5.0 on sustainable manufacturing. Discov. Sustain. 2025, 6, 341. [Google Scholar] [CrossRef]

- Geng, X.; Wang, F.; Wu, H.-H.; Wang, S.; Wu, G.; Gao, J.; Zhao, H.; Zhang, C.; Mao, X. Data-driven and artificial intelligence accelerated steel material research and intelligent manufacturing technology. Mater. Genome Eng. Adv. 2023, 1, e10. [Google Scholar] [CrossRef]

- Selvan, S.P.; Raja, D.E.; Muthukumar, V.; Sonar, T. Optimization of process parameters and predicting surface finish of PLA in additive manufacturing—A neural network approach. Int. J. Interact. Des. Manuf. 2025, 19, 2511–2520. [Google Scholar] [CrossRef]

- Yehia, H.M.; Hamada, A.; Sebaey, T.A.; Abd-Elaziem, W. Selective Laser Sintering of Polymers: Process Parameters, Machine Learning Approaches, and Future Directions. J. Manuf. Mater. Process. 2024, 8, 197. [Google Scholar] [CrossRef]

- Chandra, M.; Vimal, K.E.K.; Rajak, S. A comparative study of machine learning algorithms in the prediction of bead geometry in wire-arc additive manufacturing. Int. J. Interact. Des. Manuf. 2024, 18, 6625–6638. [Google Scholar] [CrossRef]

- Cannizzaro, D.; Antonioni, P.; Ponzio, F.; Galati, M.; Patti, E.; Di Cataldo, S. Machine learning-enabled real-time anomaly detection for electron beam powder bed fusion additive manufacturing. J. Intell. Manuf. 2025, 36, 2105–2119. [Google Scholar] [CrossRef]

- Manikanta, J.E.; Ambhore, N.; Dhumal, A.; Gurajala, N.K.; Narkhede, G. Machine Learning and Artificial Intelligence Supported Machining: A Review and Insights for Future Research. J. Inst. Eng. Ser. C 2024, 105, 1653–1663. [Google Scholar] [CrossRef]

- Abide, H.M.; Chehade, F.H.; Makki, Z.F. HARNESSING IoT AND DEEP LEARNING FOR SUSTAINABLE WASTE REUSE IN CEMENT FACTORIES. J. Theor. Appl. Inf. Technol. 2025, 103, 1365–1375. [Google Scholar]

- Athayde, A.; Vergara, S. Regulação da IA e seu impacto nas políticas e práticas de concorrência na América Latina. Rev. Direito Empres. 2024, 21, 7205. [Google Scholar] [CrossRef]

- Kuzior, A.; Sira, M.; Brożek, P. Use of Artificial Intelligence in Terms of Open Innovation Process and Management. Sustainability 2023, 15, 7205. [Google Scholar] [CrossRef]

- Wang, M.; Li, X. Application of artificial intelligence techniques in meat processing: A review. J. Food Process Eng. 2024, 47, e14590. [Google Scholar] [CrossRef]

- Zhekova, M. Application of artificial intelligence in the food industry. Food Sci. Appl. Biotechnol. 2025, 8, 112–122. [Google Scholar] [CrossRef]

- Martínez, M.A.D.; Salinas, R.V.R.; Hernández, S.R.; Domínguez, H.S.R.; Zubirías, G.C.; Rodríguez, M.A.M. Artificial intelligence an essential factor for the benefit of companies: Systematic review of the literature. Cogent Eng. 2024, 11, 2380344. [Google Scholar] [CrossRef]

- IMARC. Latin America Artificial Intelligence Market Size|2033; IMARC: Noida, India, 2024; Available online: https://www.imarcgroup.com/latin-america-artificial-intelligence-market (accessed on 5 October 2025).

- IBM Newsroom. IBM: Empresas de Latinoamérica Aceleraron el uso de Inteligencia Artificial en 67%. Available online: https://latam.newsroom.ibm.com/2024-03-20-IBM-empresas-de-Latinoamerica-aceleraron-el-uso-de-Inteligencia-Artificial-en-67 (accessed on 30 August 2025).

- Monitoring Consult IBM. IBM GLOBAL AI ADOPTION INDEX–ENTERPRISE REPORT; IBM, 2023; Available online: https://filecache.mediaroom.com/mr5mr_ibmspgi/179414/download/IBM%20Global%20AI%20Adoption%20Index%20Report%20Dec.%202023.pdf (accessed on 5 October 2025).

- Oguntola, O.; Boakye, K.; Simske, S. Towards Leveraging Artificial Intelligence for Sustainable Cement Manufacturing: A Systematic Review of AI Applications in Electrical Energy Consumption Optimization. Sustainability 2024, 16, 4798. [Google Scholar] [CrossRef]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Vegas, J.; Llamas, C. Opportunities and Challenges of Artificial Intelligence Applied to Identity and Access Management in Industrial Environments. Future Internet 2024, 16, 469. [Google Scholar] [CrossRef]

- Bitzenis, A.; Koutsoupias, N.; Nosios, M. Artificial intelligence and machine learning in production efficiency enhancement and sustainable development: A comprehensive bibliometric review. Front. Sustain. 2025, 5, 1508647. [Google Scholar] [CrossRef]

- Valenzuela-Cobos, A.; Vera-Cabanilla, B.; Castillo-Heredia, L.; Valenzuela-Cobos, J. Industry 4.0 in logistics management in Latin America: A bibliometric review. J. Ind. Eng. Manag. 2025, 18, 115–129. [Google Scholar] [CrossRef]

- Bas, T.G.; Astudillo, P.; Rojo, D.; Trigo, A. Opinions Related to the Potential Application of Artificial Intelligence (AI) by the Responsible in Charge of the Administrative Management Related to the Logistics and Supply Chain of Medical Stock in Health Centers in North of Chile. Int. J. Environ. Res. Public Health 2023, 20, 4839. [Google Scholar] [CrossRef] [PubMed]

- Filgueiras, F. 12: Artificial Intelligence and Governance Challenges in Latin America–the Game Between Decolonization and Dependence. In Handbook on Governance and Data Science; Edward Elgar Publishing: Cheltenham, UK, 2025; ISBN 978-1-0353-0134-8. [Google Scholar]

- Shui, K.; Mak, A.; Vertesy, D. Technology and Innovation Report 2025: Inclusive Artificial Intelligence for Development; United Nations Publication; United Nations: Geneva, Switzerland, 2025; ISBN 978-92-1-003283-4. [Google Scholar]

- Liu, Y.; Xu, Q.; Wang, Z.; Qi, L.; Lu, J. Estimation of carbon dioxide emissions from the cement industry in Beijing-Tianjin-Hebei using neural networks. PLoS Clim. 2025, 4, e0000544. [Google Scholar] [CrossRef]

- Linares, R.; Acharyya, P. Implementation of Artificial Intelligence Technology to Optimize Clinker Coolers. In Proceedings of the 2021 IEEE-IAS/PCA Cement Industry Conference (IAS/PCA), Online, 24–28 May 2021; pp. 1–5. [Google Scholar]

- Alizadehsalehi, S.; Hadavi, A. Leveraging AI to Enhance XR in the AEC Industry. In Proceedings of the International Conference on Smart and Sustainable Built Environment (SASBE 2024), Auckland, New Zealand, 7–9 November 2024; GhaffarianHoseini, A., Ghaffarianhoseini, A., Rahimian, F., Babu Purushothaman, M., Eds.; Springer Nature: Singapore, 2025; pp. 1099–1108. [Google Scholar]

- Gil-Arroyo, B.; Sanz, J.M.; Arroyo, Á.; Urda, D.; Basurto, N.; Herrero, Á. Dataset for defect detection in textile manufacturing. Data Brief 2025, 59, 111451. [Google Scholar] [CrossRef]

- Alwy, D. Richard The Integration of Artificial Intelligence in the Fashion Industry and Its Impact on Sustainable Fashion: A Systematic Literature Review. In Advances in Intelligent Manufacturing and Robotics; Tan, A., Zhu, F., Jiang, H., Mostafa, K., Yap, E.H., Chen, L., Olule, L.J.A., Myung, H., Eds.; Springer Nature: Singapore, 2024; pp. 217–234. [Google Scholar]

- Fornasiero, R.; Kiebler, L.; Falsafi, M.; Sardesai, S. Proposing a maturity model for assessing Artificial Intelligence and Big data in the process industry. Int. J. Prod. Res. 2025, 63, 1235–1255. [Google Scholar] [CrossRef]

- Sharma, P.; Shah, J.; Patel, R. Artificial intelligence framework for MSME sectors with focus on design and manufacturing industries. Mater. Today Proc. 2022, 62, 6962–6966. [Google Scholar] [CrossRef]

- Kalla, D.K. Adoption of Digital Twin and Artificial Intelligence in Metal Additive Manufacturing. In Proceedings of the Current Status and Vision for Future, Portland, OR, USA, 23–26 June 2024. [Google Scholar]

- Flatscher, M.; Fessler, A.; Janez, I. Sustained Enablement of AI Ethics in Industry. In Systems, Software and Services Process Improvement; Yilmaz, M., Clarke, P., Riel, A., Messnarz, R., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 3–19. [Google Scholar]

- Tripathi, A.; Kumar, V. Ethical practices of artificial intelligence: A management framework for responsible AI deployment in businesses. AI Ethics 2025, 5, 3845–3856. [Google Scholar] [CrossRef]

- Roumate, F. Artificial Intelligence Transformation in the Industry: Challenges and Opportunities. In Digital Transformation in Industry; Kumar, V., Kyriakopoulos, G.L., Akberdina, V., Kuzmin, E., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 381–388. [Google Scholar]

- Burnett, D.; El-Haber, N.; Alahakoon, D.; Karnouskos, S.; De Silva, D. Advancing an Artificial Intelligence Ethics Framework for Operator 4.0 in Sustainable Factory Automation. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Joblot, L., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 363–375. [Google Scholar]

- Pasas-Farmer, S.; Jain, R. From discovery to delivery: Governance of AI in the pharmaceutical industry. Green Anal. Chem. 2025, 13, 100268. [Google Scholar] [CrossRef]

- Robles, P.; Mallinson, D.J. Artificial intelligence technology, public trust, and effective governance. Rev. Policy Res. 2025, 42, 11–28. [Google Scholar] [CrossRef]

- Andrade-Girón, D.; Marín-Rodriguez, W.; Sandivar-Rosas, J.; Carreño-Cisneros, E.; Susanibar-Ramirez, E.; Zuñiga-Rojas, M.; Angeles-Morales, J.; Villarreal-Torres, H. Generative artificial intelligence in higher education learning: A review based on academic databases. Iberoam. J. Sci. Meas. Commun. 2024, 4, 1–16. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Samaan, Z.; Mbuagbaw, L.; Kosa, D.; Borg Debono, V.; Dillenburg, R.; Zhang, S.; Fruci, V.; Dennis, B.; Bawor, M.; Thabane, L. A systematic scoping review of adherence to reporting guidelines in health care literature. J. Multidiscip. Health 2013, 6, 169–188. [Google Scholar] [CrossRef]

- Zenteno, J.A.C.; Vintimilla, A.D.O.; Espinoza, J.J.S. The Impact of Artificial Intelligence on Project Management. Rev. Tecnológica-ESPOL 2024, 36, 52–66. [Google Scholar] [CrossRef]

- Pérez-Pacheco, Y.; Castellano, P.S. La inteligencia artificial en los sistemas judiciales de América Latina: Una revisión sobre desafíos y oportunidades. AC-Rev. Direito Adm. Const. 2025, 25, 95–129. [Google Scholar] [CrossRef]

- Masod, M.Y.B.; Zakaria, S.F. Artificial Intelligence Adoption in the Manufacturing Sector: Challenges and Strategic Framework. IJRISS 2024, 8, 150–158. [Google Scholar] [CrossRef]

- Filho, J.J. de S.; Paço, A. do; Gaspar, P.D. Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste. Appl. Sci. 2025, 15, 4758. [Google Scholar] [CrossRef]

- Gofur, A.; Satrio, E.; Wicaksono, F.A. Strategic Integration of Artificial Intelligence in Manufacturing Processes: Enhancing Sustainability and Efficiency. J. Ilm. Manaj. Ekon. Dan Bisnis 2025, 4, 103–114. [Google Scholar] [CrossRef]

- Jöhnk, J.; Weißert, M.; Wyrtki, K. Ready or Not, AI Comes—An Interview Study of Organizational AI Readiness Factors. Bus. Inf. Syst. Eng. 2021, 63, 5–20. [Google Scholar] [CrossRef]

- Akoh, E. Adoption of artificial intelligence for manufacturing SMEs’ growth and survival in South Africa: A systematic literature review. Int. J. Res. Bus. Soc. Sci. 2024, 13, 23–37. [Google Scholar] [CrossRef]

- Binsaeed, R.H.; Yousaf, Z.; Grigorescu, A.; Samoila, A.; Chitescu, R.I.; Nassani, A.A. Knowledge Sharing Key Issue for Digital Technology and Artificial Intelligence Adoption. Systems 2023, 11, 316. [Google Scholar] [CrossRef]

- Kano, S. A Short Review: Tribology in Machining to Understand Conventional and Latest Modeling Methods with Machine Learning. Machines 2025, 13, 81. [Google Scholar] [CrossRef]

- Charia, O.; Rajani, H.; Ferrer Real, I.; Domingo-Espin, M.; Gracias, N. Real-Time Stringing Detection for Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 74. [Google Scholar] [CrossRef]

- Seid Ahmed, Y.; Amorim, F.L. Advances in Computer Numerical Control Geometric Error Compensation: Integrating AI and On-Machine Technologies for Ultra-Precision Manufacturing. Machines 2025, 13, 140. [Google Scholar] [CrossRef]

- Brauer, D.; Cesarone, J. Total Manufacturing Assurance: Controlling Product Quality, Reliability, and Safety, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-003-20805-1. [Google Scholar]

- Chakraborty, S.; Chakraborty, S. Applications of artificial neural networks in machining processes: A comprehensive review. Int. J. Interact. Des. Manuf. 2024, 18, 1917–1948. [Google Scholar] [CrossRef]

- Rahman, M.A.; Saleh, T.; Jahan, M.P.; McGarry, C.; Chaudhari, A.; Huang, R.; Tauhiduzzaman, M.; Ahmed, A.; Mahmud, A.A.; Bhuiyan, M.S.; et al. Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines 2023, 14, 508. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, S.; Gao, D.; Sun, Y.; Bai, W. A Review of Physics-Based, Data-Driven, and Hybrid Models for Tool Wear Monitoring. Machines 2024, 12, 833. [Google Scholar] [CrossRef]

- Liu, M.; Xie, H.; Pan, W.; Ding, S.; Li, G. Prediction of cutting force via machine learning: State of the art, challenges and potentials. J. Intell. Manuf. 2023, 36, 703–764. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Qu, X.; Wang, M.; Wang, Y.; Zhang, C. A review of the application of machine learning techniques in thermal error compensation for CNC machine tools. Meas. J. Int. Meas. Confed. 2025, 243, 116341. [Google Scholar] [CrossRef]

- Pawanr, S.; Gupta, K. A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies 2024, 17, 3659. [Google Scholar] [CrossRef]

- Le, V.; Tran, M.; Ding, S. Subtractive manufacturing of composite materials with robotic manipulators: A comprehensive review. Int. J Adv. Manuf. Technol. 2024, 135, 81–117. [Google Scholar] [CrossRef]

- Ishfaq, K.; Sana, M.; Ashraf, W.M. Artificial intelligence–built analysis framework for the manufacturing sector: Performance optimization of wire electric discharge machining system. Int. J. Adv. Manuf. Technol. 2023, 128, 5025–5039. [Google Scholar] [CrossRef]

- Dvorak, J.; Cornelius, A.; Corson, G.; Zameroski, R.; Jacobs, L.; Penney, J.; Schmitz, T. A machining digital twin for hybrid manufacturing. Manuf. Lett. 2022, 33, 786–793. [Google Scholar] [CrossRef]

- Bakhtiyari, A.N.; Wang, Z.; Wang, L.; Zheng, H. A review on applications of artificial intelligence in modeling and optimization of laser beam machining. Opt. Laser Technol. 2021, 135, 106721. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with artificial intelligence in additive manufacturing: A systematic review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Melo, J.; Marques, T.; Pontes, A. A Review on Injection Molding: Conformal Cooling Channels, Modelling, Surrogate Models and Multi-Objective Optimization. Polymers 2025, 17, 919. [Google Scholar] [CrossRef]

- Mattera, G.; Marchesano, M.G.; Caggiano, A.; Guizzi, G.; Nele, L. Process Monitoring of One-Shot Drilling of Al/CFRP Aeronautical Stacks Using the 1DCAE-GMM Framework. Electronics 2025, 14, 1777. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Lu, L.; Wang, Z.; Liang, X.; Zhang, Y. Intelligent modeling and detection in grinding: A review of advances, challenges, and prospects. Int. J. Adv. Manuf. Technol. 2025, 138, 4995–5055. [Google Scholar] [CrossRef]

- Liang, Y.; Dai, C.; Wang, J.; Zhang, G.; To, S.; Zhao, Z. Typical applications and perspectives of machine learning for advanced precision machining: A comprehensive review. Expert Syst. Appl. 2025, 283, 127770. [Google Scholar] [CrossRef]

- Devagiri, J.S.; Paheding, S.; Niyaz, Q.; Yang, X.; Smith, S. Augmented Reality and Artificial Intelligence in industry: Trends, tools, and future challenges. Expert Syst. Appl. 2022, 207, 118002. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Mulik, H.; Varude, P.; Atole, S.; Mundada, N. A review of emerging hydroforming technologies: Design considerations, parametric studies, and recent innovations. J. Eng. Appl. Sci. 2024, 71, 205. [Google Scholar] [CrossRef]

- Grigoras, C.C.; Zichil, V.; Ciubotariu, V.A.; Cosa, S.M. Machine Learning, Mechatronics, and Stretch Forming: A History of Innovation in Manufacturing Engineering. Machines 2024, 12, 180. [Google Scholar] [CrossRef]

- Nikzad, M.H.; Heidari-Rarani, M.; Rasti, R.; Sareh, P. Machine learning-driven prediction of tensile strength in 3D-printed PLA parts. Expert Syst. Appl. 2025, 264, 125836. [Google Scholar] [CrossRef]

- Nikooharf, M.H.; Shirinbayan, M.; Arabkoohi, M.; Bahlouli, N.; Fitoussi, J.; Benfriha, K. Machine learning in polymer additive manufacturing: A review. Int. J. Mater. Form. 2024, 17, 52. [Google Scholar] [CrossRef]

- Das, A.; Ghosh, D.; Lau, S.F.; Srivastava, P.; Ghosh, A.; Ding, C.F. A critical review of process monitoring for laser-based additive manufacturing. Adv. Eng. Inform. 2024, 62, 102932. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Additive manufacturing modification by artificial intelligence, machine learning, and deep learning: A review. Addit. Manuf. Front. 2025, 4, 200198. [Google Scholar] [CrossRef]

- Suresh, V.; Balasubramaniam, B.; Yeh, L.H.; Li, B. Recent Advances in In Situ 3D Surface Topographical Monitoring for Additive Manufacturing Processes. J. Manuf. Mater. Process. 2025, 9, 133. [Google Scholar] [CrossRef]

- Moseley, Q.; Quiel, N.; Medina, M.; Montenegro, J.; Castano, C.; Caballero, R. Analysis of Parameters for Additive Manufacturing from Recycled HDPE Material. In Proceedings of the 2024 9th International Engineering, Sciences and Technology Conference, Panama City, PA, USA, 23–25 October 2024; IESTEC 2024. Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2025; pp. 216–221. [Google Scholar]

- Ali, S.; Prajapati, M.J.; Bhat, C.; Jiang, C.P.; Jeng, J.Y. Additive manufactured enabled digital metallurgy processes, challenges and future prospects. Appl. Mater. Today 2025, 42, 102580. [Google Scholar] [CrossRef]

- Dospinescu, O.; Buraga, S. Integrated ERP Systems—Determinant Factors for Their Adoption in Romanian Organizations. Systems 2025, 13, 667. [Google Scholar] [CrossRef]

- Chuo, Y.S.; Lee, J.W.; Mun, C.H.; Noh, I.W.; Rezvani, S.; Kim, D.C.; Lee, J.; Lee, S.W.; Park, S.S. Artificial intelligence enabled smart machining and machine tools. J. Mech. Sci. Technol. 2022, 36, 1–23. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Wang, B.; Song, Q.; Wang, H.; Zhang, L. Leveraging artificial intelligence for real-time indirect tool condition monitoring: From theoretical and technological progress to industrial applications. Int. J. Mach. Tools Manuf. 2024, 202, 104209. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Ercetin, A.; Der, O.; Mikolajczyk, T.; Giasin, K. State-of-the-art review of applications of image processing techniques for tool condition monitoring on conventional machining processes. Int. J. Adv. Manuf. Technol. 2024, 130, 57–85. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Wojciechowski, S.; Sharma, V.S.; Gupta, M.K.; Kuntoğlu, M. Artificial intelligence systems for tool condition monitoring in machining: Analysis and critical review. J. Intell. Manuf. 2023, 34, 2079–2121. [Google Scholar] [CrossRef]

- Ercetin, A.; Der, O.; Akkoyun, F.; Chandrashekarappa, M.P.G.; Şener, R.; Çalışan, M.; Olgun, N.; Chate, G.; Bharath, K.N. Review of Image Processing Methods for Surface and Tool Condition Assessments in Machining. J. Manuf. Mater. Process. 2024, 8, 244. [Google Scholar] [CrossRef]

- Murzin, S.P. Artificial Intelligence-Driven Innovations in Laser Processing of Metallic Materials. Metals 2024, 14, 1458. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, R.; Aggarwal, H. Systematic Review of Artificial Intelligence, Machine Learning, and Deep Learning in Machining Operations: Advancements, Challenges, and Future Directions. Arch. Comput. Methods Eng. 2025. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Nasiri, S. Injection molding manufacturing process: Review of case-based reasoning applications. J. Intell. Manuf. 2020, 31, 847–864. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Raj, A.; Mahadevan, R.R.; Chadha, U.; Paramasivam, V. A Review on Machine Learning Models in Injection Molding Machines. Adv. Mater. Sci. Eng. 2022, 2022, 1949061. [Google Scholar] [CrossRef]

- Cao, D.; Liu, W.; Ge, J.; Du, S.; Liu, W.; Deng, Z.; Chen, J. Research progress on intelligent monitoring of tool condition based on deep learning. Int. J. Adv. Manuf. Technol. 2024, 134, 2129–2150. [Google Scholar] [CrossRef]

- Nan, W.; Ge, L.; He, Z.; Sun, Z.; Lu, J. Powder spreading and spreadability in powder-based additive manufacturing: State of the art and perspectives. Powder Technol. 2025, 449, 120393. [Google Scholar] [CrossRef]

- Khan, N.; Asad, H.; Khan, S.; Riccio, A. Towards defect-free lattice structures in additive manufacturing: A holistic review of machine learning advancements. J. Manuf. Process. 2025, 144, 1–53. [Google Scholar] [CrossRef]

- Awd, M.; Walther, F. AI-Powered Very-High-Cycle Fatigue Control: Optimizing Microstructural Design for Selective Laser Melted Ti-6Al-4V. Materials 2025, 18, 1472. [Google Scholar] [CrossRef] [PubMed]

- Fanyu, L. Thermal optimization of alloy additive manufacturing process and visual design of metal process products based on edge computing. Therm. Sci. Eng. Prog. 2024, 55, 102924. [Google Scholar] [CrossRef]

- Saimon, A.I.; Yangue, E.; Yue, X.; Kong, Z.J.; Liu, C. Advancing Additive Manufacturing through Deep Learning: A Comprehensive Review of Current Progress and Future Challenges. IISE Trans. 2024, 1–24. [Google Scholar] [CrossRef]

- Patro, S.; Mahapatra, T.R.; Dash, S.; Murty, V.K. Artificial intelligence techniques for fault assessment in laminated composite structure: A review. E3S Web Conf. 2021, 309, 01083. [Google Scholar] [CrossRef]

- Singh, A.P.; Asgar, E.; Ranjan, R.; Kaushik, Y.; Reji, J.K.; Student, T.T. A REVIEW ON ROLE OF AI IN DAMAGE ASSESSMENT IN LAMINATED COMPOSITE STRUCTURES. Int. J. Eng. Appl. Sci. Technol. 2023, 8, 220–229. [Google Scholar]

- Redchuk, A.; Mateo, F.W. New Business Models on Artificial Intelligence—The Case of the Optimization of a Blast Furnace in the Steel Industry by a Machine Learning Solution. Appl. Syst. Innov. 2022, 5, 6. [Google Scholar] [CrossRef]

- Matoc, D.A.; Kanabar, B.K.; Sata, A. Machine learning-driven prediction and digital twins implementation for VOC emissions in VAT photopolymerization additive manufacturing. Eng. Res. Express 2025, 7, 015554. [Google Scholar] [CrossRef]

- Gurrammagari, D.R.; Boopathy, P. A Survey on AI Integration into Industry 5.0. Gazi Univ. J. Sci. 2025, 38, 99–113. [Google Scholar] [CrossRef]

- Martini, B.; Bellisario, D.; Coletti, P. Human-Centered and Sustainable Artificial Intelligence in Industry 5.0: Challenges and Perspectives. Sustainability 2024, 16, 5448. [Google Scholar] [CrossRef]

- Beusch, P.; Frisk, J.E.; Rosén, M.; Dilla, W. Management control for sustainability: Towards integrated systems. Manag. Account. Res. 2022, 54, 100777. [Google Scholar] [CrossRef]

- Irene Gomes. Umberlândia Cabral 84.9% of Medium and Large Sized Industrial Companies Make Use of Advanced Digital Technology|News Agency. Available online: https://agenciadenoticias.ibge.gov.br/en/agencia-news/2184-news-agency/news/37991-84-9-of-medium-and-large-sized-industrial-companies-make-use-of-advanced-digital-technology (accessed on 26 August 2025).

- Ascúa, R.A. Industry 4.0 in manufacturing SMEs of Argentina and Brazil. J. Int. Counc. Small Bus. 2021, 2, 203–222. [Google Scholar] [CrossRef]

- Poveda-Valverde, F. AI Applications That Can Support Sustainable Practices in Small and Medium-Sized Enterprises in Latin America: A Systematic Review. Preprints 2025, 2025070880. [Google Scholar] [CrossRef]

- Gonzalez-Tamayo, L.A.; Maheshwari, G.; Bonomo-Odizzio, A.; Herrera-Avilés, M.; Krauss-Delorme, C. Factors influencing small and medium size enterprises development and digital maturity in Latin America. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100069. [Google Scholar] [CrossRef]

- Vergara Villegas, O.O.; Nandayapa, M.; Sossa Azuela, J.H.; Cossio Franco, E.G.; Rubin Linares, G.T.; Vergara Villegas, O.O.; Nandayapa, M.; Sossa Azuela, J.H.; Cossio Franco, E.G.; Rubin Linares, G.T. Artificial Intelligence for Industry 4.0 in Iberoamerica. Comput. Y Sist. 2021, 25, 761–773. [Google Scholar] [CrossRef]

- Banerjee, D.K.; Sharma, K.; Kumar, A. Artificial Intelligence-Based Device For Pipe Manufacturing. Int. J. Creat. Res. Thoughts 2025, 13, 2320–2882. [Google Scholar] [CrossRef]

- Zhu, W.; Li, H.; Shen, S.; Wang, Y.; Hou, Y.; Zhang, Y.; Chen, L. In-situ monitoring additive manufacturing process with AI edge computing. Opt. Laser Technol. 2024, 171, 110423. [Google Scholar] [CrossRef]

- Jarosz, K.; Chen, Y.-T.; Liu, R. Investigating the differences in human behavior between conventional machining and CNC machining for future workforce development: A case study. J. Manuf. Process. 2023, 96, 176–192. [Google Scholar] [CrossRef]

- Wu, C.; Wang, C.; Kim, J.-W. Welding sequence optimization to reduce welding distortion based on coupled artificial neural network and swarm intelligence algorithm. Eng. Appl. Artif. Intell. 2022, 114, 105142. [Google Scholar] [CrossRef]

- Sani, A.R.; Zolfagharian, A.; Kouzani, A.Z. Artificial Intelligence-Augmented Additive Manufacturing: Insights on Closed-Loop 3D Printing. Adv. Intell. Syst. 2024, 6, 2400102. [Google Scholar] [CrossRef]

- Dziubek, M.; Rysiński, J.; Jancarczyk, D. Exploring the ViDiDetect Tool for Automated Defect Detection in Manufacturing with Machine Vision. Appl. Sci. 2023, 13, 11098. [Google Scholar] [CrossRef]

- Wang, W.; Wang, P.; Zhang, H.; Chen, X.; Wang, G.; Lu, Y.; Chen, M.; Liu, H.; Li, J. A Real-Time Defect Detection Strategy for Additive Manufacturing Processes Based on Deep Learning and Machine Vision Technologies. Micromachines 2024, 15, 28. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Zheng, L.; Zhou, J. Online Surface Roughness Prediction for Assembly Interfaces of Vertical Tail Integrating Tool Wear under Variable Cutting Parameters. Sensors 2022, 22, 1991. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, F.; Tashiro, S.; Chen, S.; Tanaka, M. A physics-informed and data-driven framework for robotic welding in manufacturing. Nat. Commun. 2025, 16, 4807. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, X.; Sun, J.; Wang, Y.; Chen, Z.; Wang, J.; Xu, X. Artificial intelligence powered real-time quality monitoring for additive manufacturing in construction. Constr. Build. Mater. 2024, 429, 135894. [Google Scholar] [CrossRef]

- Aggogeri, F.; Pellegrini, N.; Tagliani, F.L. Recent advances on machine learning applications in machining processes. Appl. Sci. 2021, 11, 8764. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Y.; Huang, B.; Ding, W. The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review. Machines 2024, 12, 876. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, L.; Feng, G.; Xi, K.; Algadi, H.; Dong, M. Laser technologies in manufacturing functional materials and applications of machine learning-assisted design and fabrication. Adv. Compos. Hybrid Mater. 2025, 8, 76. [Google Scholar] [CrossRef]

- Yang, H.; Zheng, H.; Zhang, T. A review of artificial intelligent methods for machined surface roughness prediction. Tribol. Int. 2024, 199, 109935. [Google Scholar] [CrossRef]

- Mu, S.; Yu, C.; Lin, K.; Lu, C.; Wang, X.; Wang, T.; Fu, G. A Review of Machine Learning-Based Thermal Error Modeling Methods for CNC Machine Tools. Machines 2025, 13, 153. [Google Scholar] [CrossRef]

- Kreutz, M.; Böttjer, A.; Trapp, M.; Lütjen, M.; Freitag, M. Towards individualized shoes: Deep learning-based fault detection for 3D printed footwear. Procedia CIRP 2022, 107, 196–201. [Google Scholar] [CrossRef]

- Tayalati, F.; Boukrouh, I.; Bouhsaien, L.; Azmani, A.; Azmani, M. Hybrid Approach Integrating Deep Learning-Autoencoder With Statistical Process Control Chart for Anomaly Detection: Case Study in Injection Molding Process. IEEE Access 2024, 12, 95576–95598. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.; Dang, K.; Zhao, B.; Chen, A.; Yang, W.; Xie, P. Fault diagnosis of injection molding machine non-return valve based on data-driven model. J. Manuf. Process. 2024, 117, 145–153. [Google Scholar] [CrossRef]

- Rønsch, G.Ø.; López-Espejo, I.; Michelsanti, D.; Xie, Y.; Popovski, P.; Tan, Z.-H. Utilization of acoustic signals with generative Gaussian and autoencoder modeling for condition-based maintenance of injection moulds. Int. J. Comput. Integr. Manuf. 2024, 37, 438–453. [Google Scholar] [CrossRef]

- Vasconcelos, G.A.V.B.; Francisco, M.B.; da Costa, L.R.A.; Junior, R.F.R.; Melo, M. de L.N.M. Prediction of surface roughness in duplex stainless steel face milling using artificial neural network. Int. J. Adv. Manuf. Technol. 2024, 133, 2031–2048. [Google Scholar] [CrossRef]

- Behvar, A.; Sojoodi, M.; Celebi, A.; Elahinia, M. Insights into the Future of Manufacturing and Designing NiTi-Cu Shape Memory Alloys with Powder Sintering-Based Process Binder Jet Additive Manufacturing: A Short Review. Shape Mem. Superelast. 2025. [Google Scholar] [CrossRef]

- Nurudeen, M.O.; Latilo, A.; Imosemi, H.O.; Imosemi, Q.A. Comparative legal frameworks for regulating artificial intelligence: A model for harmonizing AI laws in Latin America, Africa, and globally. J. Res. Multidiscip. Stud. 2024, 2, 34–49. [Google Scholar] [CrossRef]

- Juárez-Merino, M.A. ARTIFICIAL INTELLIGENCE AND CITIZENSHIP IN LATIN AMERICAN GOVERNMENTS. Manag. Probl. Theory Pract. 2025, 5, 71–86. [Google Scholar] [CrossRef]

- Quindimil, M. Article: Artificial Intelligence and International Trade from a Latin American Perspective. GTCJ 2024, 19, 748–756. [Google Scholar] [CrossRef]

- Veronese, A.; Nunes Lopes Espiñeira Lemos, A. Regulatory paths for artificial intelligence in Latin American countries with data protection law frameworks: Limits and possibilities of integrating policies. RLESD 2021. [Google Scholar] [CrossRef]

- Vyhmeister, E.; Gonzalez-Castane, G.; Östbergy, P.-O. Risk as a driver for AI framework development on manufacturing. AI Ethics 2023, 3, 155–174. [Google Scholar] [CrossRef]

- De Almeida, P.G.R.; dos Santos, C.D.; Farias, J.S. Artificial Intelligence Regulation: A framework for governance. Ethics Inf. Technol. 2021, 23, 505–525. [Google Scholar] [CrossRef]

- Hadzovic, S.; Mrdovic, S.; Radonjic, M. A Path Towards an Internet of Things and Artificial Intelligence Regulatory Framework. IEEE Commun. Mag. 2023, 61, 90–96. [Google Scholar] [CrossRef]

- Consorcio AlSur Los. Caminos Regulatorios para la IA en América Latina Recopilación de Estudios de Caso en Brasil, México, Perú y Colombia; 2024. Available online: https://www.alsur.lat/sites/default/files/2024-09/ALSUR%20-%20IA%20en%20Latam%20%5BESP%5D.pdf (accessed on 5 October 2025).

- García, J.M. América Latina ante la Inteligencia Artificial: Mapeo de Iniciativas Regulatorias en la Región. Derechos Digit. 2023. Available online: https://www.nodal.am/2024/02/america-latina-ante-la-inteligencia-artificial-mapeo-de-iniciativas-regulatorias-por-juan-manuel-garcia/ (accessed on 5 October 2025).

- Eduardo Bismarck PL 21/2020-Senado Federal; 2020. Available online: https://www.camara.leg.br/proposicoesWeb/fichadetramitacao?idProposicao=2236340 (accessed on 5 October 2025).

- Veneziano Vital PL 872/2021-Senado Federal. Available online: https://www25.senado.leg.br/web/atividade/materias/-/materia/147434 (accessed on 5 October 2025).

- Styvenson Valentim PL 5051/2019-Senado Federal; 2019. Available online: https://www25.senado.leg.br/web/atividade/materias/-/materia/138790 (accessed on 5 October 2025).

- Contreras Vásquez, P. Convergencia internacional y caminos propios: Regulación de la inteligencia artificial en América Latina. Actual. Jurídica Iberoam. 2024, 468–493. [Google Scholar]

- Council of Europe Uruguay Ratifies Convention 108+—Data Protection. Available online: https://www.coe.int/en/web/data-protection/-/uruguay-ratfies-convention-108- (accessed on 28 July 2025).

- Parlamento Latinoamericano y Caribeño. LEY MODELO DE INTELIGENCIA ARTIFICIAL PARA AMÉRICA LATINA Y EL CARIBE; 2024. Available online: https://parlatino.org/wp-content/uploads/2017/09/LEY-MODELO-INTELIGENCIA-ARTIFICIAL.pdf (accessed on 5 October 2025).

- Liu, J.; Jiang, X.; Shi, M.; Yang, Y. Impact of Artificial Intelligence on Manufacturing Industry Global Value Chain Position. Sustainability 2024, 16, 1341. [Google Scholar] [CrossRef]

- Pettersson, A.B.V.; Ballardini, R.M.; Mimler, M.; Li, P.; Salmi, M.; Minssen, T.; Gibson, I.; Mäkitie, A. Core Legal Challenges for Medical 3D Printing in the EU. Healthcare 2024, 12, 1114. [Google Scholar] [CrossRef]

- Yadav, A.; Garg, R.K.; Sachdeva, A.; Qureshi, K.M.; Qureshi, M.R.N.M. Strategic Framework for Additive Manufacturing with Smart Polymer Composites: A Pathway to Net-Zero Manufacturing. Polymers 2025, 17, 1336. [Google Scholar] [CrossRef]

- Connole, K.; McDermott, O. The Challenges in the Regulatory Approval of Additive-Manufactured Medical Devices: A Quantitative Survey. Ther. Innov. Regul. Sci. 2025, 59, 1160–1170. [Google Scholar] [CrossRef]

- Sato, R.; Li, K.; Michihata, M.; Takahashi, S.; Gao, W. Advanced Sensing and Machine Learning Technologies for Intelligent Measurement in Smart and Precision Manufacturing. IJAT 2024, 18, 545–580. [Google Scholar] [CrossRef]

- Pant, R.; Singh, R.; Gehlot, A.; Akram, S.V.; Gupta, L.R.; Thakur, A.K. A Systematic Review of Additive Manufacturing Solutions Using Machine Learning, Internet of Things, Big Data, Digital Twins and Blockchain Technologies: A Technological Perspective Towards Sustainability. Arch. Comput. Methods Eng. 2024, 31, 4601–4616. [Google Scholar] [CrossRef]

- Berdine, G.G.; DiPaola, M.; Weinberg, M. Economic and Regulatory Perspectives on Additive Manufacturing. In 3D Printing in Orthopaedic Surgery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 41–48. ISBN 978-0-323-58118-9. [Google Scholar]

- Vasiliki Fytrou Global Dynamics of Digital Platforms: Transforming Creative Industries with Equity and Sustainability. ICRBME 2025, 2, 1–15. [CrossRef]

- Zheng, T.; Yu, X.; Fan, Y.; Ding, X.; Ye, R.; Zhang, Y. The Role of Artificial Intelligence in Reshaping International Political Economy: Perspectives on Economic Governance and Policy Management. AJMSS 2024, 9, 83–91. [Google Scholar] [CrossRef]

- Van Erp, T.; Carvalho, N.G.P.; Gerolamo, M.C.; Gonçalves, R.; Rytter, N.G.M.; Gladysz, B. Industry 5.0: A new strategy framework for sustainability management and beyond. J. Clean. Prod. 2024, 461, 142271. [Google Scholar] [CrossRef]

- Superintendence of Industry and Commerce Colombia. Sandbox on Privacy by Design and by Default in Artificial Intelligence Projects; Superintendence of Industry and Commerce Colombia: Bogotá, Colombia, 2021. [Google Scholar]

- OECD MEXICO’S NATIONAL AI STRATEGY|STIP Compass. Available online: https://stip.oecd.org/stip/interactive-dashboards/policy-initiatives/2021%2Fdata%2FpolicyInitiatives%2F26703 (accessed on 28 July 2025).

- MINISTÉRIO DA CIÊNCIA, TECNOLOGIA E INOVAÇÕES Estratégia Brasileira de Inteligência Artificial-EBIA 2021. Available online: https://www.gov.br/mcti/pt-br/acompanhe-o-mcti/transformacaodigital/inteligencia-artificial (accessed on 5 October 2025).

- Consejo Nacional de Política Económica y Social República de Colombia. Política Nacional para la Transformación Digital e Inteligencia Artificial; Consejo Nacional de Política Económica y Social República de Colombia: Bogota, Colombia, 2019. [Google Scholar]

- Ministerio de Ciencia, Conocimiento, Tecnología e Innovación (MinCiencia). Política Nacional de Inteligencia Artificial; Chile, 2021; Available online: https://minciencia.gob.cl/uploads/filer_public/bc/38/bc389daf-4514-4306-867c-760ae7686e2c/documento_politica_ia_digital_.pdf (accessed on 5 October 2025).

- Taeihagh, A. Governance of artificial intelligence. Policy Soc. 2021, 40, 137–157. [Google Scholar] [CrossRef]

- Mirakhori, F.; Niazi, S.K. Harnessing the AI/ML in Drug and Biological Products Discovery and Development: The Regulatory Perspective. Pharmaceuticals 2025, 18, 47. [Google Scholar] [CrossRef]

- Al-Adwan, M.A.S. Harnessing Artificial Intelligence for Environmental Sustainability: Ethical Considerations and Practical Implications in Achieving SDG 9 And SDG 16. J. Lifestyle SDGs Rev. 2025, 5, e03779. [Google Scholar] [CrossRef]

- Levy, H.V. Ethical, legal, and governance dimensions of responsible research and innovation: Global perspectives and challenges in emerging technologies. Law Ethics Technol. 2025, 2, 0012. [Google Scholar] [CrossRef]

- Subsecretaríade Relaciones Económicas Internacionales DEPA. Available online: https://www.subrei.gob.cl/en/landings/depa (accessed on 26 August 2025).

- Mercosur. Declaración de Ministros y Altas Autoridades Sobre Derechos Humanos de Los Estados Partes del Mercosur Sobre Los Principios de Derechos Humanos en el Ámbito de la Inteligencia Artificial; Mercosur: Montevideo, Uruguay, 2023. [Google Scholar]

- Folorunso, A.; Olanipekun, K.; Adewumi, T.; Samuel, B. A policy framework on AIusage in developing countries its impact Global, J. Eng. Technol. Adv. 2024, 21, 154–166. [Google Scholar] [CrossRef]

- Nakajima, R. The generative artificial intelligence governance paradox: Driving innovation while challenging global corporate oversight in multinational firms. In Corporate Governance: Scholarly Research and Practice; Virtus Interpress: Sumy, Ukraine, 2024; pp. 91–95. [Google Scholar]

- Sepasspour, R. A reality check and a way forward for the global governance of artificial intelligence. Bull. At. Sci. 2023, 79, 304–315. [Google Scholar] [CrossRef]

- Li, C. AI-Driven Governance: Enhancing Transparency and Accountability in Public Administration. DSVG 2025, 1, 1–16. [Google Scholar] [CrossRef]

- PROSA ESTUDIO. Índice Latinoamericano de Inteligencia Artificial. Available online: https://indicelatam.cl/ (accessed on 26 August 2025).

- Santhiya, M.; Jeyalakshmi, J.; Venu, H. Emerging networking technologies for industry 4.0. In Privacy Preservation and Secured Data Storage in Cloud Computing; IGI Global Scientific Publishing: Hershey, PA, USA, 2023; pp. 322–340. ISBN 979-836930594-2. [Google Scholar]

- Rezaei, M.; Pironti, M.; Quaglia, R. AI in knowledge sharing, which ethical challenges are raised in decision-making processes for organisations? Manag. Decis. 2024. [Google Scholar] [CrossRef]

- Winter, J.S. AI in healthcare: Data governance challenges. J. Hosp. Manag. Health Policy 2020, 5, 8. [Google Scholar] [CrossRef]

- Asif, M.; Shen, H.; Zhou, C.; Guo, Y.; Yuan, Y.; Shao, P.; Xie, L.; Bhutta, M.S. Recent Trends, Developments, and Emerging Technologies towards Sustainable Intelligent Machining: A Critical Review, Perspectives and Future Directions. Sustainability 2023, 15, 8298. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Gnanasekaran, S.; Thangamuthu, M.; Rakkiyannan, J. Machine-Learning- and Internet-of-Things-Driven Techniques for Monitoring Tool Wear in Machining Process: A Comprehensive Review. JSAN 2024, 13, 53. [Google Scholar] [CrossRef]

- Tran, M.-Q.; Doan, H.-P.; Vu, V.Q.; Vu, L.T. Machine learning and IoT-based approach for tool condition monitoring: A review and future prospects. Measurement 2023, 207, 112351. [Google Scholar] [CrossRef]

- Samarawickrama, M. AI Governance and Ethics Framework for Sustainable AI and Sustainability. arXiv 2022, arXiv:2210.08984. [Google Scholar] [CrossRef]

- Fosch-Villaronga, E.; Poulsen, A. Diversity and Inclusion in Artificial Intelligence. In Law and Artificial Intelligence: Regulating AI and Applying AI in Legal Practice; Custers, B., Fosch-Villaronga, E., Eds.; T.M.C. Asser Press: The Hague, The Netherlands, 2022; pp. 109–134. ISBN 978-94-6265-523-2. [Google Scholar]

- Cachat-Rosset, G.; Klarsfeld, A. Diversity, Equity, and Inclusion in Artificial Intelligence: An Evaluation of Guidelines. Appl. Artif. Intell. 2023, 37, 2176618. [Google Scholar] [CrossRef]

- Kandula, N. Innovative Fabrication of Advanced Robots Using The Waspas Method A New Era In Robotics Engineering. IJRMLT 2025, 1, 1–13. [Google Scholar] [CrossRef]

- Nosirov, I.; Yormatov, I.; Yuldasheva, N.; Avulchayeva, F. AI and Corporate Sustainability: Exploring the Environmental and Social Impacts of AI Integration. In Proceedings of the 2024 International Conference on Knowledge Engineering and Communication Systems (ICKECS), Chikkaballapur, India, 18–19 April 2024; IEEE: New York, NY, USA, 2024; pp. 1–7. [Google Scholar]

- Isalm, M.d.S. AI for Sustainable Development: Addressing Environmental and Social Challenges. J. Artif. Intell. Gen. Sci. (JAIGS) 2024, 3, 97–105. [Google Scholar] [CrossRef]

- Balan, A. Examining the ethical and sustainability challenges of legal education’s AI revolution. Int. J. Leg. Prof. 2024, 31, 323–348. [Google Scholar] [CrossRef]

- Lefranc, G. Importance of Manufacturing and Industrial Robotics in Latin America’s Economic Development. In Proceedings of the 2024 IEEE International Conference on Automation/XXVI Congress of the Chilean Association of Automatic Control (ICA-ACCA), Santiago, Chile, 20–23 October 2024; IEEE: New York, NY, USA, 2024; pp. 1–6. [Google Scholar]

- Larenas, F.P.; Calero, M.G. Integration of Artificial Intelligence and Behavioral Economics: Optimizing Consumer Processes and Decisions in Complex Environments. J. Inf. Syst. Eng. Manag. 2025, 10, 620–625. [Google Scholar] [CrossRef]

- Torres, A.R.; Montoya, L.N. AI Thrust: Ranking Emerging Powers for Tech Startup Investment in Latin America. Int. J. Trade Econ. Financ. 2024, 15, 102–111. [Google Scholar] [CrossRef]

- Galvez, D.P.C.; Revinova, S. Assessing Digital Technology Development in Latin American Countries: Challenges, Drivers, and Future Directions. Digital 2025, 5, 20. [Google Scholar] [CrossRef]

- Neri, H.; Domingos, V. ProtoSociology Project Navigating the Double Divide: Generative AI and the Dynamics of Inequality in Latin America. ProtoSociology 2023, 40, 342–374. [Google Scholar] [CrossRef]

- Egana-delSol, Pablo; Bravo-Ortega, Claudio (2025): Artificial Intelligence and Labor Market Transformations in Latin America, IZA Discussion Papers, No. 17746, Institute of Labor Economics (IZA), Bonn. Available online: https://www.econstor.eu/bitstream/10419/314643/1/dp17746.pdf (accessed on 5 October 2025).

- Gitler, I.; Gomes, A.T.A.; Nesmachnow, S. The Latin American supercomputing ecosystem for science. Commun. ACM 2020, 63, 66–71. [Google Scholar] [CrossRef]

- DomainTools DomainTools Internet Statistics—IP Addresses. Available online: https://research.domaintools.com/statistics/ip-addresses/ (accessed on 27 August 2025).

- Statista Number of Fixed Broadband Subscriptions per 100 Inhabitants in Latin America in 2023, by Country. Available online: https://www.statista.com/statistics/729179/fixed-broadband-subscriptions-per-100-inhabitants-latin-america-country/ (accessed on 27 August 2025).

- Statista Number of Internet Users in Selected Latin American Countries as of February 2025. Available online: https://www.statista.com/statistics/186919/number-of-internet-users-in-latin-american-countries/ (accessed on 27 August 2025).

- Muschett, M.; Opp, R. The AI Revolution is Here: How will Latin America and the Caribbean Respond? Available online: https://www.undp.org/latin-america/blog/ai-revolution-here-how-will-latin-america-and-caribbean-respond (accessed on 26 August 2025).

- Zapata-Cantu, L.; González, F. Challenges for Innovation and Sustainable Development in Latin America: The Significance of Institutions and Human Capital. Sustainability 2021, 13, 4077. [Google Scholar] [CrossRef]

- Alvarado-Peña, L.J.; Vega Osuna, L.A.; Hernández Medina, S.M.; Vega Esparza, R.M.; Jimeno Espadas, R.; Reyes Bazúa, X. Estado de los sistemas de ciencia tecnología e innovación: Retos y oportunidades para las instituciones educativas en América Latina y el Caribe. Rev. Angolana Cienc. 2025, 7, e070109. [Google Scholar] [CrossRef]

- Dunayevich, E.; Akiyama, H. Ideal Approaches to AI Regulation in LATAM Countries: Promoting Technological Advancement and Human Rights Protections. F1000Research 2025, 14, 305. [Google Scholar] [CrossRef]

- Udo, N.L.E.; Apeh, C.E.; Alagbariya, B.B.; Udeh, C.A.; Ewim, C.P.-M. Review of ethical considerations and dilemmas in the field of AI and machine learning. Int. J. Multidiscip. Res. Growth Eval. 2025, 6, 827–834. [Google Scholar] [CrossRef]

- Green, B.P. Ethical Reflections on Artificial Intelligence. Sci. Fides 2018, 6, 9. [Google Scholar] [CrossRef]

- Guerrero-Quiñonez, A.J.; Bedoya-Flores, M.C.; Mosquera-Quiñonez, E.F.; Mesías-Simisterra, Á.E.; Bautista-Sánchez, J.V. Artificial Intelligence and its scope in Latin American higher education. Ibero-Am. J. Educ. Soc. Res. 2023, 3, 264–271. [Google Scholar] [CrossRef]

- Gries, T.; Naudé, W. Artificial Intelligence, Income Distribution and Economic Growth. SSRN J. 2020. [Google Scholar] [CrossRef]

- Makarov, M.Y. The Impact of Artificial Intelligence on Productivity. Èkonomika I Upr. 2020, 26, 479–486. [Google Scholar] [CrossRef]

- Shahade, A.K.; Deshmukh, P.V. A Critical and Scientific Overview of Artificial Intelligence in the Industrial Revolution. In Proceedings of the 2025 3rd International Conference on Intelligent Data Communication Technologies and Internet of Things (IDCIoT), Bengaluru, India, 5–7 February 2025; IEEE: New York, NY, USA, 2025; pp. 783–788. [Google Scholar]

- Bonsay, J.; Cruz, A.P.; Firozi, H.C.; Camaro, A.P.J.C. Artificial Intelligence and Labor Productivity Paradox: The Economic Impact of AI in China, India, Japan, and Singapore. J. Econ. Financ. Account. Stud. 2021, 3, 120–139. [Google Scholar] [CrossRef]

- Brady, D.; Kaya, Y.; Gereffi, G. Stagnating Industrial Employment in Latin America. Work Occup. 2011, 38, 179–220. [Google Scholar] [CrossRef]

- Ferraz, J.C.; Peres, W. The New Era of Industrial Policy in Latin America and the Caribbean: From SDG Assessment to Policy Solutions; 2024. Available online: https://www.unido.org/sites/default/files/unido-publications/2024-12/IID%20Policy%20Brief%2016%20-%20LAC%20Industrial%20Policy.pdf (accessed on 5 October 2025).

- Aderibigbe, A.O.; Ohenhen, P.E.; Nwaobia, N.K.; Gidiagba, J.O.; Ani, E.C. Artificial intelligence in developing countries: Bridging the gap between potential and implementation. Comput. Sci. IT Res. J. 2023, 4, 185–199. [Google Scholar] [CrossRef]

- Atieh, A.M.; Cooke, K.O.; Osiyevskyy, O. The role of intelligent manufacturing systems in the implementation of Industry 4.0 by small and medium enterprises in developing countries. Eng. Rep. 2023, 5, e12578. [Google Scholar] [CrossRef]

- Abulibdeh, A.; Zaidan, E.; Abulibdeh, R. Navigating the confluence of artificial intelligence and education for sustainable development in the era of industry 4.0: Challenges, opportunities, and ethical dimensions. J. Clean. Prod. 2024, 437, 140527. [Google Scholar] [CrossRef]

- Acker, J.; Rogers, I.; Guerra-Zubiaga, D.; Tanveer, M.H.; Moghadam, A.A.A. Low-Cost Digital Twin Approach and Tools to Support Industry and Academia: A Case Study Connecting High-Schools with High Degree Education. Machines 2023, 11, 860. [Google Scholar] [CrossRef]

- In Proceedings of the Machine Learning-Driven Digital Technologies for Educational Innovation Workshop, Online, 15–17 December 2021; IEEE: New York, NY, USA, 2021. Available online: https://www.proceedings.com/content/062/062892webtoc.pdf (accessed on 5 October 2025).

- Cruz Zuniga, M.; Santrac, N.; Kwiatkowski, A.; Abood, B. What do college students think about artificial intelligence? We ask them. J. Integr. Glob. STEM 2024, 1, 33–40. [Google Scholar] [CrossRef]

- Rastrollo Suarez, J.J.; Ferraro, A.E. How to employ artificial intelligence in public administration?Analysis and discussion of the Ibero American charter on artificial intelligence in civil service. East. J. Eur. Stud. 2024, 15, 127–146. [Google Scholar] [CrossRef]

- Department of Project Manager Great River HealthSystem Burlington Iowa (United States of America, (U.S.A.); Joshi, H. Artificial Intelligence in Project Management: A Study of The Role of Ai-Powered Chatbots in Project Stakeholder Engagement. Indian J. Softw. Eng. Proj. Manag. (IJSEPM) 2024, 4, 20–25. [Google Scholar] [CrossRef]

- Baqueiro, A.H. The Participation of Civil Society Organizations in Public Policies in Latin America. Voluntas 2016, 27, 86–104. [Google Scholar] [CrossRef]

- Abas, A.; Arifin, K.; Ali, M.A.M.; Khairil, M. A systematic literature review on public participation in decision-making for local authority planning: A decade of progress and challenges. Environ. Dev. 2023, 46, 100853. [Google Scholar] [CrossRef]

- Sintos, A.; Chletsos, M.; Kontos, K. The political process in nations: Civil society participation and income inequality. Kyklos 2024, 77, 471–495. [Google Scholar] [CrossRef]

- Rueda-Carvajal, G.D.; Tobar-Rosero, O.A.; Sánchez-Zuluaga, G.J.; Candelo-Becerra, J.E.; Flórez-Celis, H.A. Opportunities and Challenges of Industries 4.0 and 5.0 in Latin America. Sci 2025, 7, 68. [Google Scholar] [CrossRef]

- Fan, H.; Liu, C.; Bian, S.; Ma, C.; Huang, J.; Liu, X.; Doyle, M.; Lu, T.; Chow, E.; Chen, L.; et al. New era towards autonomous additive manufacturing: A review of recent trends and future perspectives. Int. J. Extrem. Manuf. 2025, 7, 032006. [Google Scholar] [CrossRef]

- Shangguan, P.; Zhou, H.; Huang, X.; Su, J.; Yeong, W.Y.; Sing, S.L. Artificial intelligence-driven material development for additive manufacturing: A critical review. IJAMD 2025, 2, 1–26. [Google Scholar] [CrossRef]

- Ma, M.; Yang, Z.; Li, L.; Lam, F.I. How is regional cooperation possible in cross-border institutional conflicts? The Guangdong-Hong Kong-Macao cooperation from the perspective of the sociology of knowledge. J. Infrastruct. Policy Dev. 2024, 8, 7178. [Google Scholar] [CrossRef]

- Lee, H.; Kim, M. BIMSTEC at a Crossroads: Enhancing Regional Cooperation through Institutionalization and Leadership. JoE 2024, 3, 41–51. [Google Scholar] [CrossRef]

- Mondal, K.; Martinez, O.; Jain, P. Advanced manufacturing and digital twin technology for nuclear energy *. Front. Energy Res. 2024, 12, 1339836. [Google Scholar] [CrossRef]

- Valencia, O.; Díaz, J.C. AI Transforming Fiscal and Macroeconomic Policymaking Leveraging AI to Transform Macroeconomic and Fiscal Policymaking in Latin America and the Caribbean. Available online: https://blogs.iadb.org/gestion-fiscal/en/ai-to-transform-macroeconomic-and-fiscal-policymaking/ (accessed on 29 August 2025).

- Sanchez-Pi, N.; Martí, L.; Garcia, A.C.B.; Yates, R.B.; Vellasco, M.; Coello, C.A.C. A Roadmap for AI in Latin America. Paris, France, 11–12 November 2021. [Google Scholar]

- Hirata, E.; Watanabe, D.; Chalmoukis, A.; Lambrou, M. A Topic Modeling Approach to Determine Supply Chain Management Priorities Enabled by Digital Twin Technology. Sustainability 2024, 16, 3552. [Google Scholar] [CrossRef]

- Castillo-Velazquez, J.-I.; Silva-Lopez, R.-B. Global Trends and Iberoamerican Contributions To The Academic Production of Artificial Intelligence Applied to Engineering Education. In Proceedings of the 2024 IEEE Colombian Conference on Communications and Computing (COLCOM), Barranquilla, Colombia, 21–23 August 2024; p. 449. [Google Scholar]

- Salas-Pilco, S.Z.; Yang, Y. Artificial intelligence applications in Latin American higher education: A systematic review. Int. J. Educ. Technol. High. Educ. 2022, 19, 21. [Google Scholar] [CrossRef]

- Pino Tarragó, J.C.; Domínguez Gálvez, D.L.; Regalado Jalca, J.J.; Villavicencio Cedeño, E.G. Artificial intelligence and soft skills in civil engineering education: A Latin American curriculum gap with global implications. Res. Glob. 2025, 11, 100307. [Google Scholar] [CrossRef]

- Aziz, N.; Abdullah, N.A.T. Global Competencies and Climate Change Education. IJRISS 2025, 8, 4190–4197. [Google Scholar] [CrossRef]

- Del Rosario, M.D.L.Á.O.; Ortega, A.A.J.; Del Rosario, D.; Ducreux, G.; Chane, R.; Ortega, E. Roles and challenges of innovation, industry 4.0, and sustainability competencies development in engineering students. In Proceedings of the 21st LACCEI International Multi-Conference for Engineering, Education, and Technology Buenos Aires, Buenos Aires, Argentina, 17–21 July 2023. [Google Scholar]

- Alqarni, A.M.Z.; Afy-Shararah, M.; Salonitis, K. Integrating Sustainability into Engineering Curricula: Challenges, Framework, and Impact on Student Competencies in Saudi Arabian Higher Education. In Advances in Manufacturing Technology XXXVI; IOS Press: Amsterdam, The Netherlands, 2023; pp. 175–180. [Google Scholar]

- Sukdeo, N.I.; Mothilall, D. The Impact of Artificial Intelligence on the Manufacturing Sector: A Systematic Literature Review of the Printing and Packaging Industry. In Proceedings of the 2023 International Conference on Artificial Intelligence, Big Data, Computing and Data Communication Systems (icABCD), Durban, South Africa, 3–4 August 2023; IEEE: New York, NY, USA, 2023; pp. 1–5. [Google Scholar]

- Oktavian, R.; Rachmadi, R.F.; Wirawan. Evaluation of Artificial Intelligence (AI) Readiness Level in the Manufacturing Industry in Indonesia. In Proceedings of the 2023 7th International Conference on New Media Studies (CONMEDIA), Bali, Indonesia, 6–8 December 2023; IEEE: New York, NY, USA, 2023; pp. 185–190. [Google Scholar]

- Priyanga, P.; Sridevi, S.; Ashwini, K.; Deepa, S.R. The Smart Factory of Tomorrow: Artificial Intelligence and Machine Learning Reshaping Manufacturing Processes. In Proceedings of the 2023 Second International Conference on Smart Technologies For Smart Nation (SmartTechCon), Singapore, 18–19 August 2023; IEEE: New York, NY, USA, 2024; pp. 1477–1481. [Google Scholar]

| Country | National AI Strategy | Name of Law/Initiative | Regulatory or Institutional Advances | Manufacturing/Industry 4.0 Provisions | Source |

|---|---|---|---|---|---|

| Brazil | Yes (since 2021) | Estratégia Brasileira de Inteligência Artificial (EBIA) | Public consultations, draft bills on ethical AI, and integration with innovation law. | EBIA explicitly created AI centers for Indústria 4.0 applications in manufacturing productivity and SMEs. | [139,140,141,142,143] |

| Chile | Yes (2021) | Política Nacional de Inteligencia Artificial | Strategy focused on economy, ethics, and education. Active in DEPA. | Notes industrial applications within the economy pillar, but no binding provisions for manufacturing. | [144] |

| Colombia | Yes (2019) | CONPES 3975—Política Nacional para la Transformación Digital e IA | Regulatory sandbox for AI ethics and data protection. Data privacy authority is active. | CONPES highlights the adoption of Industry 4.0 (including IoT, Big Data, and AI) in production/logistics. | [139,157] |

| Mexico | In development | Draft bills inspired by the EU AI Act | Legislative discussions: proposal to create Agencia Nacional de Inteligencia Artificial (ANIA) | Multiple bills are under debate; no explicit provisions for manufacturing have been introduced to date. | [139,158] |

| Uruguay | No formal strategy | N/D | Ratified Convention 108, active in DEPA and regional digital governance. | No manufacturing-specific measures. | [144,145] |

| Argentina | No national strategy | N/D | Signed Convention 108+. Engaged in human rights frameworks around AI. | Limited Industry 4.0 programs at the provincial level, not tied to the AI national policy. | [139,144] |

| Peru | No | N/D | Fragmented regulatory approach via consumer law, digital justice, and data protection. | No explicit manufacturing provisions identified. | [139] |

| Costa Rica | No | N/D | Participates in regional initiatives on digital governance and cybersecurity. | Manufacturing is not addressed in current initiatives. | [144] |

| Panama | No national strategy | Modelo de Ley de Inteligencia Artificial para América Latina y el Caribe | PARLATINO-led initiative for regional harmonization of AI governance, with participation from Panama and the Technological University of Panama (UTP) researchers. | The draft mentions industrial/logistics AI applications, but it is not yet binding. | [146] |

| Country | Connectivity & Data Access Indicators | Human Capital (Education, AI/Cyber Talent) 1 | Business Digital Use 2 | Digital Government 3 | HPC/Supercomputing Ecosystem 4 | AI & Startup Ecosystem 5 |

|---|---|---|---|---|---|---|

| Brazil | 188M users, 170 Mbps, $1/GB | 81% higher education, strong cyber workforce | $41B e-commerce, advanced fintech | Advanced, strong cybersecurity (96 pts) | Strongest HPC in the region (Santos Dumont 4.2 PF, SINAPAD) | Rank #1 in startup ecosystem; leads in AI startups, unicorns, and VC investment |

| Mexico | 107M users, 79 Mbps, $4.8/GB | 77% higher education, AI talent concentration | $34B e-commerce, solid fintech | Strong e-government (81 pts) | ABACUS (CINVESTAV) ~0.5 PF | Rank #2 in startup ecosystem; strong VC flows, AI startups in fintech & mobility |

| Chile | 18M users, 266 Mbps, $0.7/GB | 82% higher education | $7B e-commerce, dense fintech | Efficient e-government (68 pts) | NLHPC, highly used for academia | Top 5 ecosystems; strong public support (Start-Up Chile), AI in energy/agritech |

| Argentina | 41M users, 88 Mbps, $1.5/GB | 79% higher education | ~$7B e-commerce, moderate fintech | Mid-level e-gov (49 pts) | Tupac cluster | Top 5 ecosystems; AI startups are growing despite macro instability |

| Colombia | 40M users, 145 Mbps, $3.5/GB | 77% higher education, AI skills expanding | ~$8B e-commerce, growing banking | Mid-level e-gov (63 pts) | SC3UIS cluster | Rank #3 in startup ecosystem; booming AI fintech, government support |

| Uruguay | 3M users, 156 Mbps, $1.6/GB | 83% higher education, high wages | Small e-commerce, strong banking | Strong e-gov (75 pts) | Cluster-UY, open science model | Small but dynamic startup scene; AI startups in logistics and agritech |

| Costa Rica | 5M users, 97 Mbps, $2.7/GB | 75% higher education, high wages | Small e-commerce, strong banking | Mid-level (67 pts) | CeNAT HPC center | Niche ecosystem; AI startups in health tech & biotech |

| Peru | 26M users, 167 Mbps, $2.1/GB | 84% higher education, lower wages | ~$6B e-commerce | Growing | No large-scale HPC | Emerging startup ecosystem, AI startups are still limited |

| Panama | 3.5M users, 152 Mbps, $6.7/GB | 72% school digital coverage, higher wages | Small e-commerce, weak fintech | Weak e-gov (33 pts) | RedCLARA hub (100 Gbps) but no major HPC | Nascent startup ecosystem, AI activity very low |

| Strategic Priority | Recommended Action | Primary Stakeholders | Required Resources | Expected Outcome & KPI |

|---|---|---|---|---|

| Bridge the Infrastructure Gap | Develop national high-performance computing (HPC) hubs to enable SME access to advanced computing resources. | National Governments, Universities, Development Banks | Public funding, technical expertise | Increase in the number of SMEs using cloud/AI services by X%. Decrease in the data costs to <$2/GB. |

| Harmonize Policy | Adopt regional AI standards aligned with the PARLATINO model law. | Regional Bodies, such as Pacific Alliance, Mercosur, Ministries of Industry | Political capital, legal expertise | Number of countries adopting harmonized regulations. Increase in cross-border technology investment. |

| Build Socio-Industrial Capacity | Launch industry–academia “Digital Reskilling” certificate programs to train the workforce in AI literacy and manufacturing 4.0 skills. | Technical Universities, Industry Associations, Ministries of Education | Curriculum development, trainer funding | Increase in the number of workers certified in AI literacy per year. A decrease in the skills gap is reported in industry surveys. |

| Foster SME Adoption | Create regulatory sandboxes for AI testing and innovation in manufacturing. | Regulatory Agencies, Innovation Ministries | Legal frameworks for sandbox creation | Increase in the number of SMEs participating in pilot projects. % of pilots scaling to full implementation. |

| Timeframe | Strategic Initiative | Primary Stakeholders | Key Performance Indicators (KPI) |

|---|---|---|---|

| Short-Term (0–18 m) | Establish National AI in Manufacturing Task Forces | National Governments, Ministry Leads | A task force is formed, and an initial strategy draft is published within 12 months. |

| Launch Modular Digital Literacy Certificates | Technical Universities, Industry Associations | # of workers certified; # of training programs launched. | |

| Create Regulatory Sandboxes for SMEs | Regulatory Agencies, Innovation Ministries | # of SMEs participating in sandbox pilots. | |

| Medium-Term (2–4 y) | Fund Regional AI Innovation Hubs | National/State Governments, Universities | # of hubs operational; # of companies served. |

| Implement Fiscal Incentive Programs | Finance Ministries, Development Banks | $ value of tax credits/loans issued; # of SMEs applying. | |

| Develop Regional Data Sharing Frameworks | Regional Bodies, Data Protection Authorities | Framework adopted by X number of countries. | |

| Long-Term (5+ y) | Integrate AI into Core STEM Education | Ministries of Education, Universities | Revised curricula in place at X% of secondary and tertiary institutions. |

| Achieve Regional Regulatory Harmonization | Regional Political Bodies, National Legislatures | Signing of a regional agreement on AI standards. | |

| Establish an AI in Manufacturing Observatory | Multilateral Organizations, Research Universities | Observatory launched and annual report published. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega-Del-Rosario, M.D.L.A.; Caballero, R.; Domínguez, M.A.M.; Lescure, R.; Noguera, J.C.; Jaén-Ortega, A.A.; Castaño, C. AI-Enhanced Manufacturing in Latin America: Opportunities, Challenges, Applications, and Regulatory Policy Frameworks for Intelligent Production Systems. Appl. Sci. 2025, 15, 11056. https://doi.org/10.3390/app152011056

Ortega-Del-Rosario MDLA, Caballero R, Domínguez MAM, Lescure R, Noguera JC, Jaén-Ortega AA, Castaño C. AI-Enhanced Manufacturing in Latin America: Opportunities, Challenges, Applications, and Regulatory Policy Frameworks for Intelligent Production Systems. Applied Sciences. 2025; 15(20):11056. https://doi.org/10.3390/app152011056

Chicago/Turabian StyleOrtega-Del-Rosario, Maria De Los Angeles, Ricardo Caballero, Max Alejandro Medina Domínguez, Romas Lescure, Juan Carlos Noguera, Antonio Alberto Jaén-Ortega, and Carmen Castaño. 2025. "AI-Enhanced Manufacturing in Latin America: Opportunities, Challenges, Applications, and Regulatory Policy Frameworks for Intelligent Production Systems" Applied Sciences 15, no. 20: 11056. https://doi.org/10.3390/app152011056

APA StyleOrtega-Del-Rosario, M. D. L. A., Caballero, R., Domínguez, M. A. M., Lescure, R., Noguera, J. C., Jaén-Ortega, A. A., & Castaño, C. (2025). AI-Enhanced Manufacturing in Latin America: Opportunities, Challenges, Applications, and Regulatory Policy Frameworks for Intelligent Production Systems. Applied Sciences, 15(20), 11056. https://doi.org/10.3390/app152011056