Maintenance-Aware Risk Curves: Correcting Degradation Models with Intervention Effectiveness

Abstract

Featured Application

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Failure Indicator: Risk Curves

3.2. Maintenance Effectiveness Evaluation

3.3. Risk Curve Correction Based on Effectiveness

4. Results

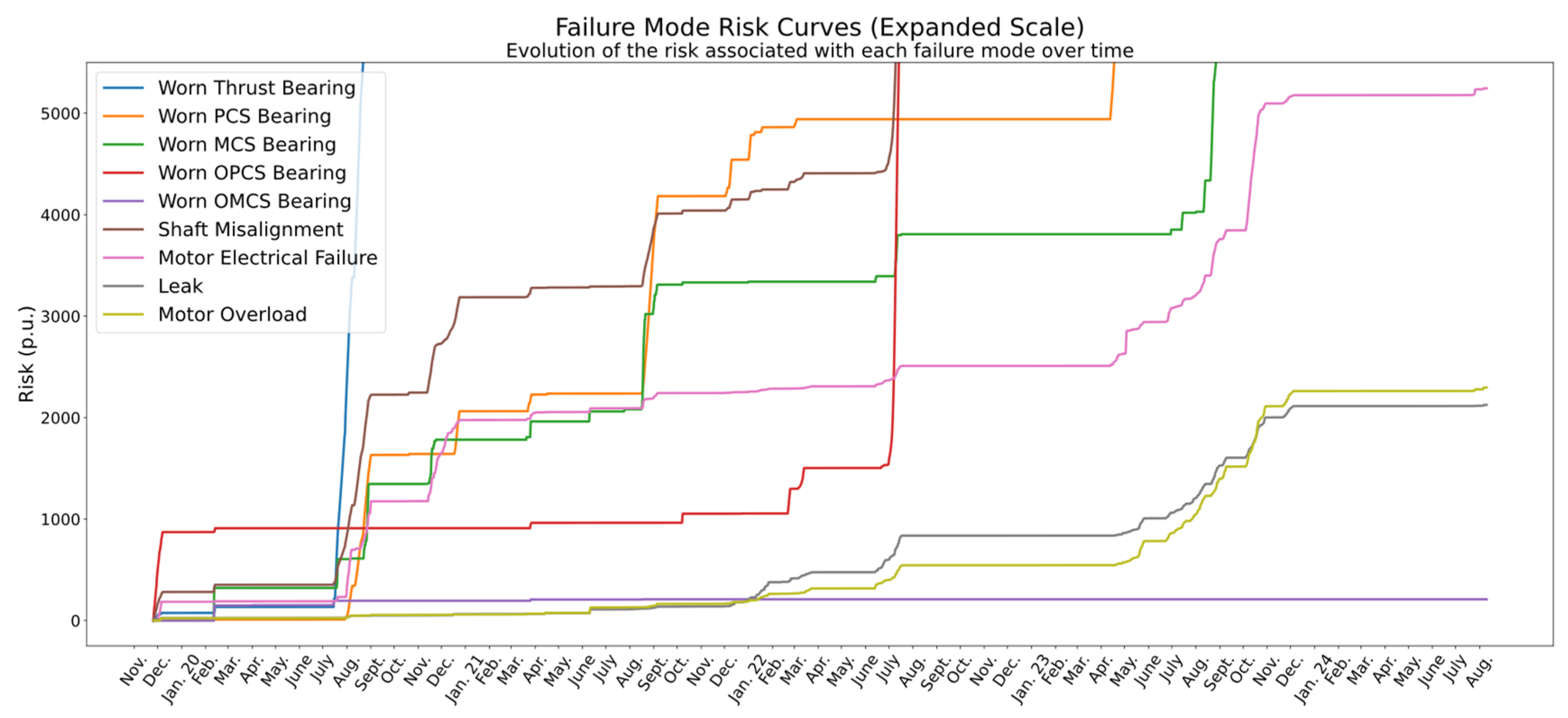

4.1. Failure Modes and Risk Curves

- : Motor overload, identified through abnormal current and temperature behaviour.

- : Worn opposite motor coupling side (OMCS) bearing, detected via vibration and thermal signatures on the non-drive side of the motor.

- : Worn motor coupling side (MCS) bearing, located on the drive end of the motor.

- : Worn opposite pump coupling side (OPCS) bearing, positioned on the non-drive end of the pump.

- : Worn pump coupling side (PCS) bearing, on the drive end of the pump shaft.

- : Worn thrust bearing, related to axial loads within the pump system.

- : Leak, typically inferred from mass imbalance or sealing pressure deviations.

- : Shaft misalignment, diagnosed via vibration patterns and coupling torque anomalies.

- : Motor electrical failure, signalled by current imbalance, harmonic distortion, or insulation issues.

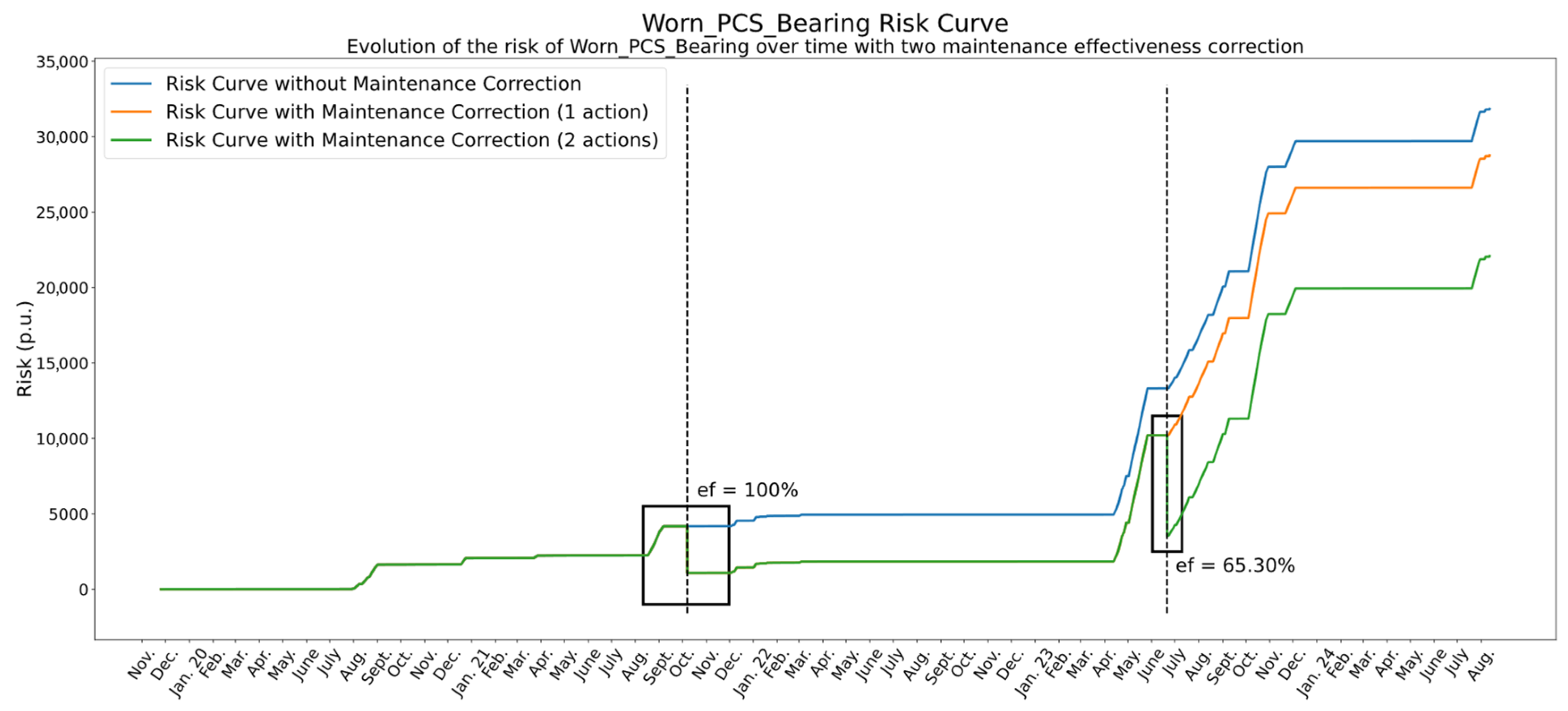

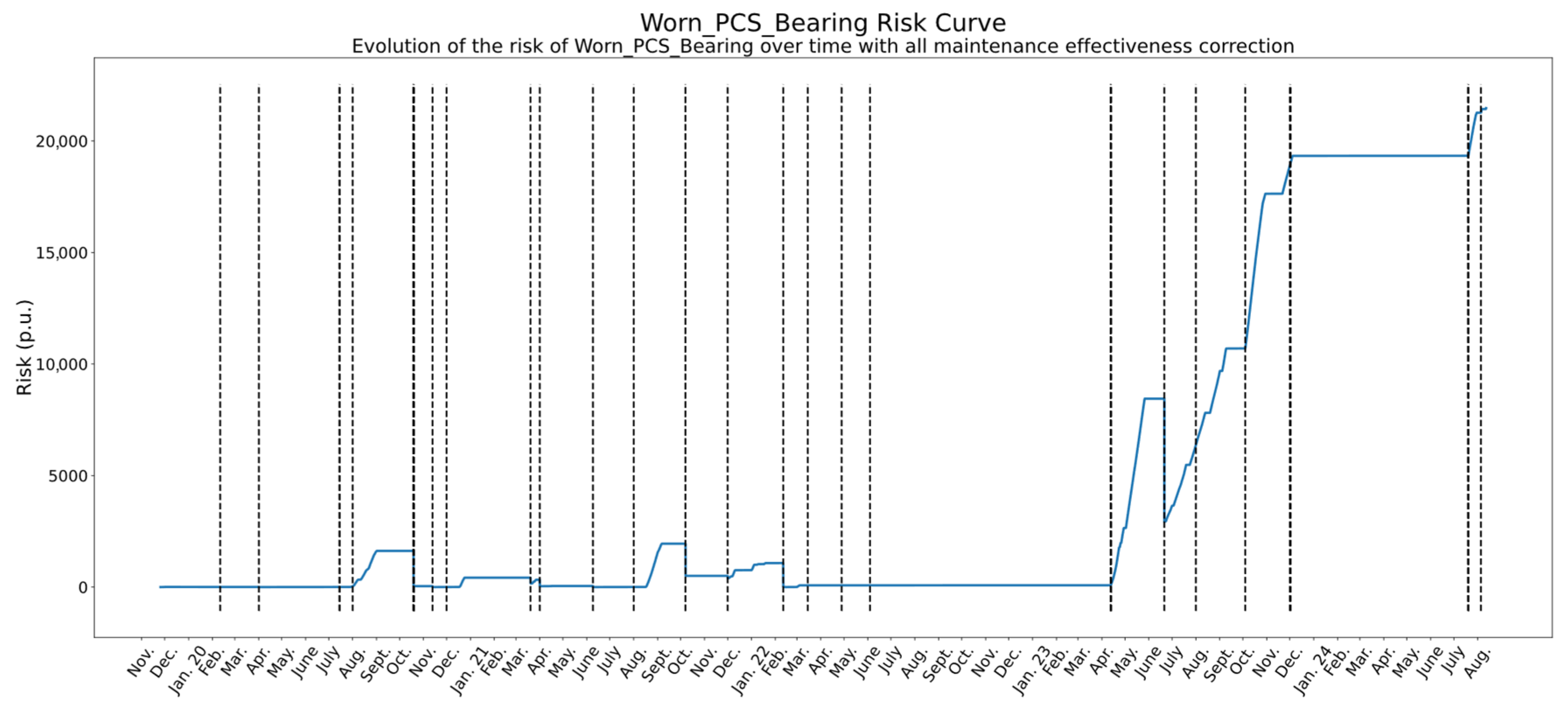

4.2. Illustrative Example: Risk Curve Correction for Worn PCS Bearing

4.2.1. Risk Curve Without Maintenance Correction

4.2.2. Risk Correction with a Single Effective Action

4.2.3. Extension to Multiple Maintenance Actions

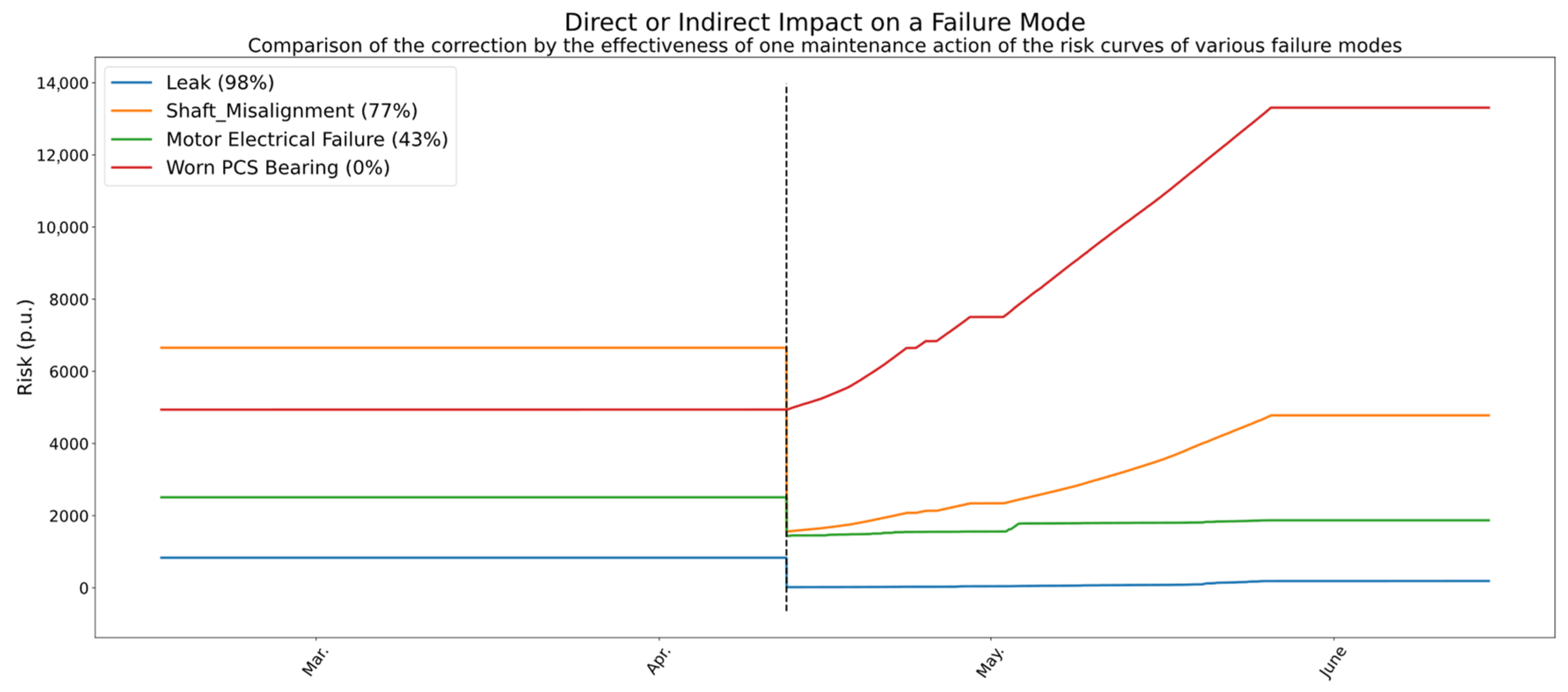

4.3. Cross-Mode Impact of a Maintenance Action

- Leak (98%)—Direct effect: This mode was the explicit target of the intervention, and the very high effectiveness confirms the success of the repair. Beyond that, the fact that the model quantifies the effect as 98% (rather than 100%) demonstrates its ability to reflect non-binary outcomes, capturing nuances in how completely a failure mode is mitigated.

- Shaft Misalignment (77%)—Indirect effect: Although not directly targeted, this mode shows a substantial improvement. A likely explanation is that during the overhaul, components such as bearings or couplings were realigned, which naturally reduces shaft misalignment. This reveals how a single action can have collateral mechanical benefits, and the model successfully attributes part of the risk reduction to the same intervention.

- Motor Electrical Failure (43%)—Indirect and marginal effect: In this case, the impact is moderate. Since a hydraulic leak is not expected to directly influence electrical behaviour, the observed improvement might result from reduced mechanical stress or more stable load conditions after the repair, slightly improving current symmetry or motor performance. The model appropriately captures this partial mitigation while indicating that most of the residual risk is likely due to independent causes.

- Worn PCS Bearing (0%)—No effect: This failure mode exhibits no measurable impact from the intervention, which aligns with expectations. Wear in the PCS bearing is not expected to be influenced by hydraulic sealing issues. Although some improvement might have been anticipated due to the comprehensive nature of the overhaul, the absence of any effect confirms that the methodology is capable of identifying when a failure mode remains unaffected, thereby avoiding false attribution of improvements.

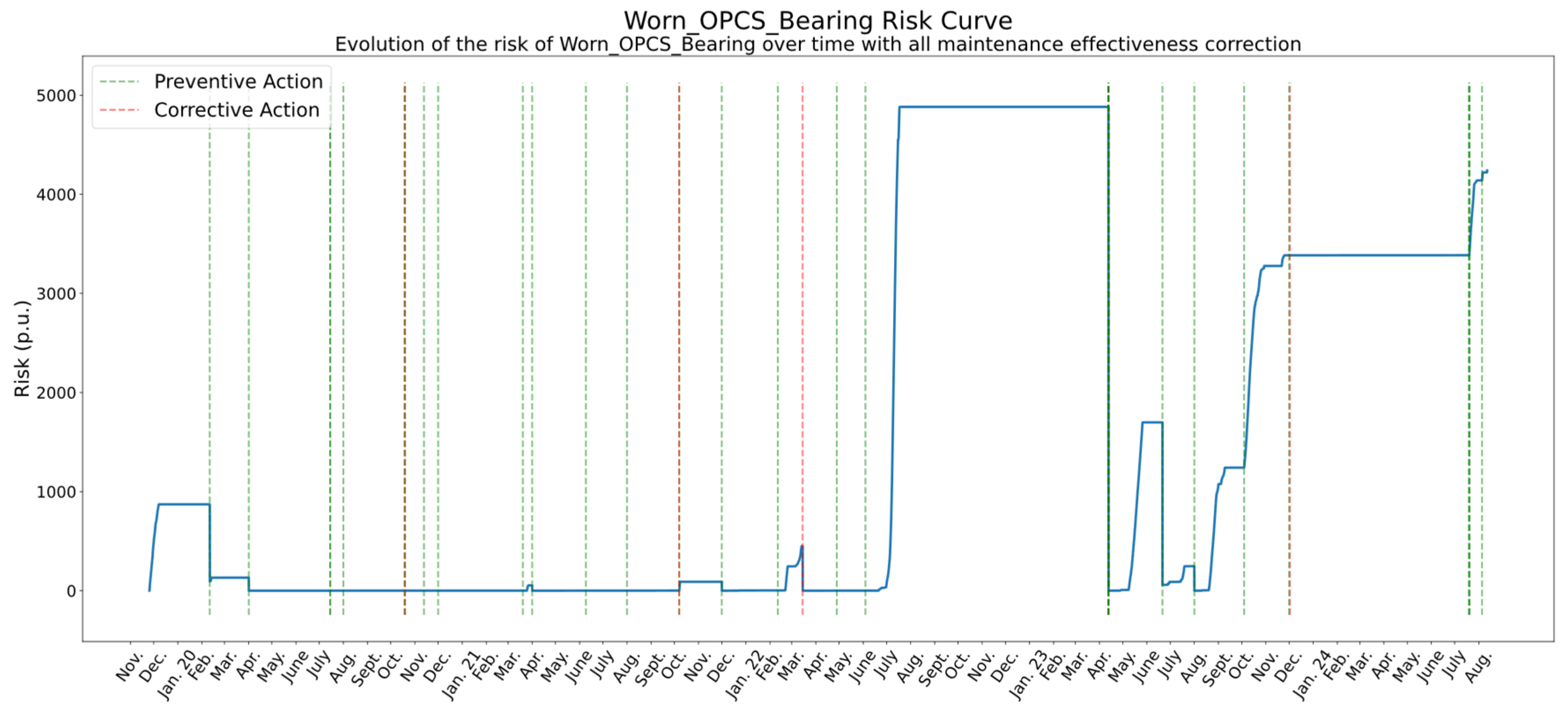

4.4. Risk Evolution of a Specific Failure Mode: Worn OPCS Bearing

- The first four maintenance actions were preventive. The two earliest interventions proved highly effective, reducing the risk to zero. Since the risk remained at zero, the subsequent two preventive actions cannot be meaningfully evaluated; in fact, they might not even have been necessary.

- The next intervention, a corrective action, involved several repair tasks. However, its effect was null, as the risk associated with this failure mode was already non-existent at the time.

- A series of six preventive interventions followed. Given that the risk was already at or near zero, their observable impact was limited. Nevertheless, when the risk began to rise slightly, one of these preventive actions successfully brought it back to zero (April 2021), confirming its relevance.

- Two interventions, one preventive and one corrective, were carried out simultaneously in October 2021. Unexpectedly, instead of stabilizing the system, they appear to have worsened the condition, since the risk curve shows an upward trend immediately afterwards.

- The subsequent sequence consisted of two preventive actions, one corrective action, and two more preventive actions. The first preventive intervention corrected the earlier growth in risk. Then, the corrective action (repair of a leak) fully eliminated the risk that had started to grow consistently, suggesting that the leak was likely inducing vibrations in the bearing. Finally, after two additional preventive actions performed when risk was zero, the system entered a phase of sudden and severe risk escalation. This sharp increase ultimately led to a deliberate pump shutdown, as the risk became unacceptable.

- While the pump was out of service, preventive tasks continued, but also a general overhaul was carried out, focused on repairing leaks and improving shaft alignment. When the pump was restarted in April 2023, the accumulated effectiveness of all these interventions resulted in the risk dropping abruptly to zero.

- Following this major intervention, three preventive actions were performed. In the first two cases, where risk had begun to rise beforehand, the actions were highly effective, restoring risk to low values. However, the third preventive action failed to reduce the risk, indicating that the new issue had a different root cause, beyond the scope of routine preventive measures.

- A significant overhaul was undertaken in December 2023 in response to a sharp increase in risk. However, it was unsuccessful: after the pump was restarted in July 2024, the risk continued to grow unabated.

- The last two preventive interventions also proved ineffective, showing no measurable impact on the failure mode. This confirms that, in its current state, the bearing risk can no longer be managed with standard preventive measures.

4.5. Comparison of Maintenance Performance Between Two Pumps

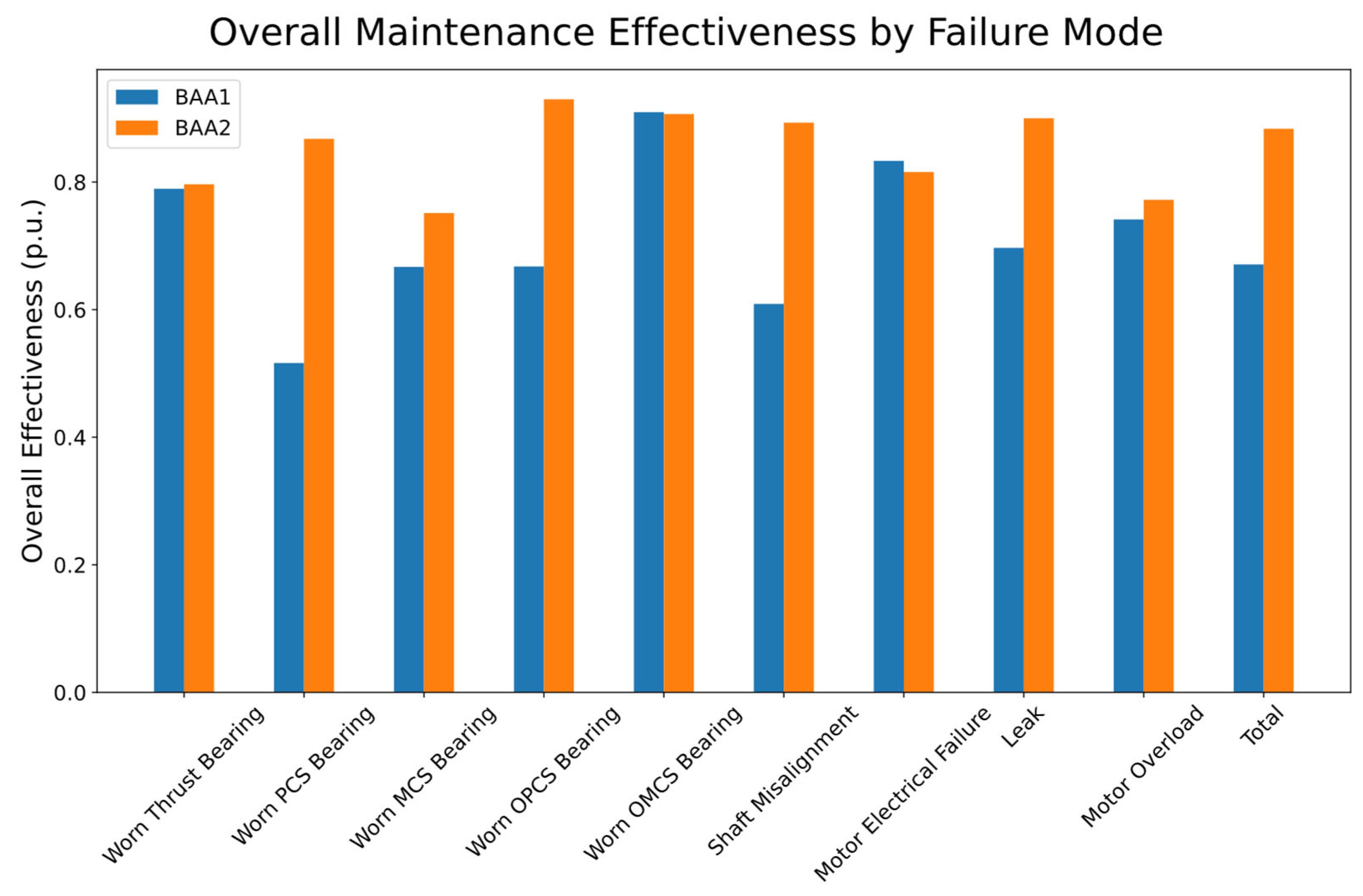

4.5.1. Overall Maintenance Effectiveness by Failure Mode

- Bearings (PCS, MCS, OPCS, OMCS, Thrust): Bearings represent the most significant source of difference. While both pumps reach very high effectiveness in some modes (e.g., OMCS and Thrust bearings), BAA2 systematically outperforms BAA1 in PCS, MCS, and especially OPCS bearings. This indicates that bearing-related maintenance in BAA2 has been more effective, likely due to better preventive practices and higher-quality corrective interventions.

- Shaft Misalignment and Leak: These two modes are also critical differentiators. BAA2 shows much higher effectiveness in addressing misalignment and sealing issues, suggesting greater precision in overhaul tasks such as shaft realignment, tightening, and leak repairs. These improvements not only reduce direct risks but also mitigate indirect effects on other components, such as bearing wear.

- Motor-related failures (Electrical and Overload): In contrast, motor-related modes show comparable effectiveness between pumps, with only marginal differences. Both BAA1 and BAA2 achieve high effectiveness, suggesting that electrical and overload-related maintenance is performed at a similar level of consistency across the two systems.

- Total performance: When results are consolidated across all modes, BAA2 reaches an overall effectiveness of 0.88 compared to 0.67 for BAA1. This substantial difference confirms that BAA2 consistently benefits from more effective maintenance, especially in mechanical subsystems where risk accumulation is typically harder to control.

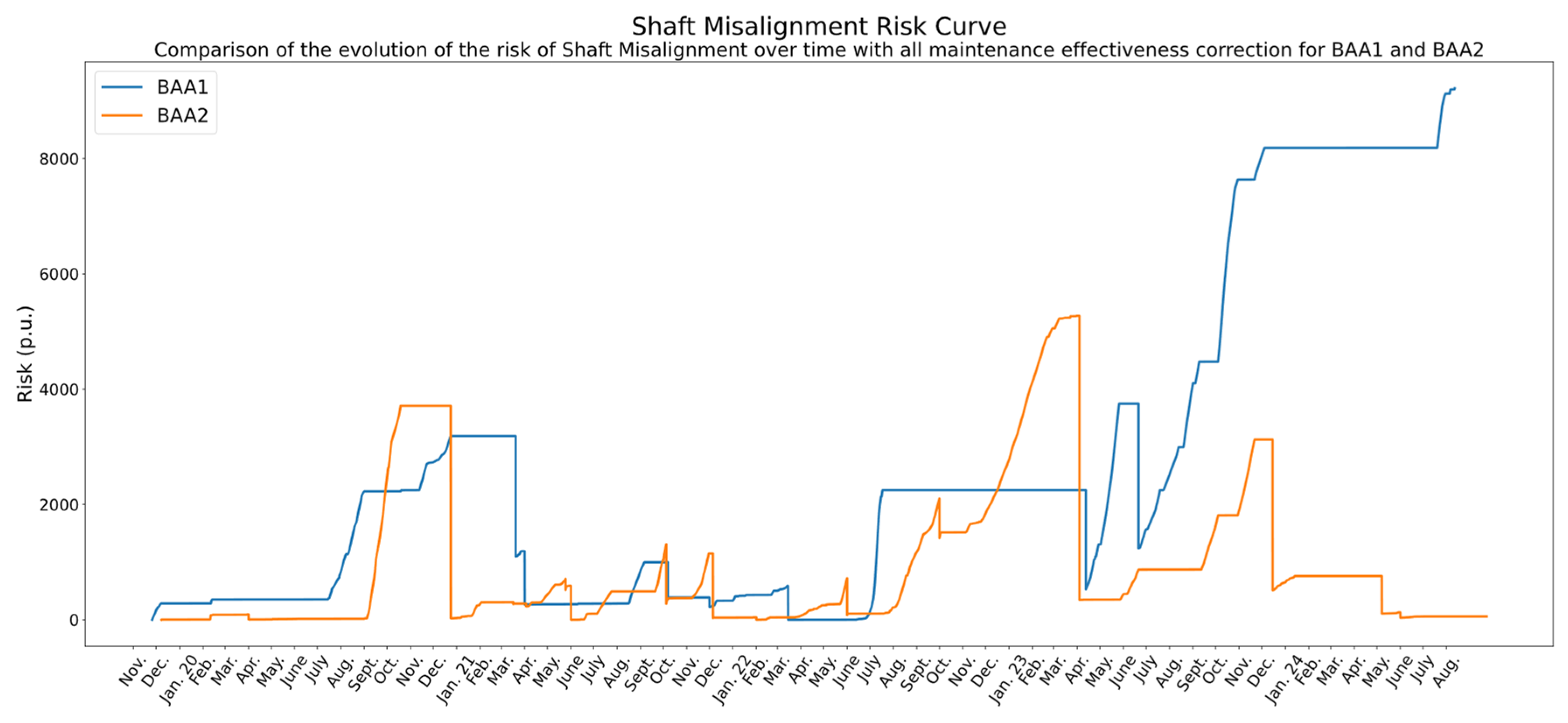

4.5.2. Shaft Misalignment

4.5.3. Motor Overload

4.5.4. Total

5. Discussion

- First, the methodology relies on the availability and quality of data: precise annotation of maintenance actions and reliable sensor records are essential to correctly evaluate intervention effectiveness. In contexts with poor data quality, results may be compromised, although expert validation and preprocessing techniques can mitigate this.

- Second, although the methodology has been developed with continuous monitoring in mind, it is not restricted to such settings. The approach can also be applied to inspection-based or periodically sampled systems, provided historical records are sufficient and sampling aligns with degradation dynamics.

- Third, another limitation arises from the definition of effectiveness itself. The current definition assumes that slope variations fully capture intervention outcomes. While intuitive, this may overlook delayed or cumulative effects. Extending the metric to incorporate temporal dynamics remains a key avenue for future work.

- Finally, the validation presented in this study has been carried out on a specific type of equipment, feedwater pumps in a combined-cycle power plant. Although the methodology is general and can be applied to other assets, the current evidence is limited to this industrial case. Expanding validation to other equipment types and across multiple plants will be an important next step to demonstrate the robustness and generality of the approach.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamasha, M.M.; Bani-Irshid, A.H.; Al Mashaqbeh, S.; Shwaheen, G.; Al Qadri, L.; Shbool, M.; Muathen, D.; Ababneh, M.; Harfoush, S.; Albedoor, Q.; et al. Strategical selection of maintenance type under different conditions. Sci. Rep. 2023, 13, 15560. [Google Scholar] [CrossRef]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in predictive maintenance—A review. CIRP J. Manuf. Sci. Technol. 2023, 40, 53–67. [Google Scholar] [CrossRef]

- Karki, B.R.; Basnet, S.; Xiang, J.; Montoya, J.; Porras, J. Digital maintenance and the functional blocks for sustainable asset maintenance service—A case study. Digit. Bus. 2022, 2, 100025. [Google Scholar] [CrossRef]

- Naiya, S. AI-Powered Predictive Maintenance in IoT-Enabled Smart Factories. Res. Ann. Ind. Syst. Eng. 2025, 2, 27–35. [Google Scholar] [CrossRef]

- Moccardi, A.; Conte, C.; Chandra Ghosh, R.; Moscato, F. A Robust Conformal Framework for IoT-Based Predictive Maintenance. Future Internet 2025, 17, 244. [Google Scholar] [CrossRef]

- Prasad, P.B. IoT and Machine Learning-Driven Predictive Maintenance for Enhanced Supply Chain Performance. Commun. Appl. Nonlinear Anal. 2025, 32, 1577–1588. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Sharma, J.; Mittal, M.L.; Soni, G. Condition-based maintenance using machine learning and role of interpretability: A review. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 1345–1360. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Zonta, T.; da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Ojeda, J.C.O.; de Moraes, J.G.B.; Filho, C.V.d.S.; Pereira, M.d.S.; Pereira, J.V.d.Q.; Dias, I.C.P.; da Silva, E.C.M.; Peixoto, M.G.M.; Gonçalves, M.C. Application of a Predictive Model to Reduce Unplanned Downtime in Automotive Industry Production Processes: A Sustainability Perspective. Sustainability 2025, 17, 3926. [Google Scholar] [CrossRef]

- Sang, G.M.; Xu, L.; de Vrieze, P. A Predictive Maintenance Model for Flexible Manufacturing in the Context of Industry 4.0. Front. Big Data 2021, 4, 663466. [Google Scholar] [CrossRef] [PubMed]

- Maierhofer, A.; Trojahn, S.; Ryll, F. Dynamic Scheduling and Preventive Maintenance in Small-Batch Production: A Flexible Control Approach for Maximising Machine Reliability and Minimising Delays. Appl. Sci. 2025, 15, 4287. [Google Scholar] [CrossRef]

- Fadaeefath Abadi, M.; Bordbari, M.J.; Haghighat, F.; Nasiri, F. Dynamic Maintenance Cost Optimization in Data Centers: An Availability-Based Approach for K-out-of-N Systems. Buildings 2025, 15, 1057. [Google Scholar] [CrossRef]

- Hakami, A. Strategies for overcoming data scarcity, imbalance, and feature selection challenges in machine learning models for predictive maintenance. Sci. Rep. 2024, 14, 9645. [Google Scholar] [CrossRef]

- Hurtado, J.; Salvati, D.; Semola, R.; Bosio, M.; Lomonaco, V. Continual learning for predictive maintenance: Overview and challenges. Intell. Syst. Appl. 2023, 19, 200251. [Google Scholar] [CrossRef]

- Wen, Y.; Fashiar Rahman, M.; Xu, H.; Tseng, T.-L.B. Recent advances and trends of predictive maintenance from data-driven machine prognostics perspective. Measurement 2022, 187, 110276. [Google Scholar] [CrossRef]

- Hector, I.; Panjanathan, R. Predictive maintenance in Industry 4.0: A survey of planning models and machine learning techniques. PeerJ Comput. Sci. 2024, 10, e2016. [Google Scholar] [CrossRef]

- Benhanifia, A.; Cheikh, Z.B.; Oliveira, P.M.; Valente, A.; Lima, J. Systematic review of predictive maintenance practices in the manufacturing sector. Intell. Syst. Appl. 2025, 26, 200501. [Google Scholar] [CrossRef]

- Abbassi, R.; Arzaghi, E.; Yazdi, M.; Aryai, V.; Garaniya, V.; Rahnamayiezekavat, P. Risk-based and predictive maintenance planning of engineering infrastructure: Existing quantitative techniques and future directions. Process Saf. Environ. Prot. 2022, 165, 776–790. [Google Scholar] [CrossRef]

- Leoni, L.; De Carlo, F.; Paltrinieri, N.; Sgarbossa, F.; BahooToroody, A. On risk-based maintenance: A comprehensive review of three approaches to track the impact of consequence modelling for predicting maintenance actions. J. Loss Prev. Process Ind. 2021, 72, 104555. [Google Scholar] [CrossRef]

- Liao, R.; He, Y.; Feng, T.; Yang, X.; Dai, W.; Zhang, W. Mission reliability-driven risk-based predictive maintenance approach of multistate manufacturing system. Reliab. Eng. Syst. Saf. 2023, 236, 109273. [Google Scholar] [CrossRef]

- da Silva, R.F.; Melani, A.H.d.A.; Michalski, M.A.d.C.; de Souza, G.F.M. Reliability and Risk Centered Maintenance: A Novel Method for Supporting Maintenance Management. Appl. Sci. 2023, 13, 10605. [Google Scholar] [CrossRef]

- Montgomery, N.; Banjevic, D.; Jardine, A.K.S. Minor maintenance actions and their impact on diagnostic and prognostic CBM models. J. Intell. Manuf. 2012, 23, 303–311. [Google Scholar] [CrossRef]

- Cox, L.A. Improving interventional causal predictions in regulatory risk assessment. Crit. Rev. Toxicol. 2023, 53, 311–325. [Google Scholar] [CrossRef]

- Carlo, F.D.; Arleo, M.A.; Carlo, F.D.; Arleo, M.A. Imperfect Maintenance Models, from Theory to Practice. In System Reliability; IntechOpen: London, UK, 2017; ISBN 978-953-51-3706-1. [Google Scholar]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef]

- You, Y.; Chen, C.; Hu, F.; Liu, Y.; Ji, Z. Advances of Digital Twins for Predictive Maintenance. Procedia Comput. Sci. 2022, 200, 1471–1480. [Google Scholar] [CrossRef]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Morato, P.G.; Papakonstantinou, K.G.; Andriotis, C.P.; Nielsen, J.S.; Rigo, P. Optimal inspection and maintenance planning for deteriorating structural components through dynamic Bayesian networks and Markov decision processes. Struct. Saf. 2022, 94, 102140. [Google Scholar] [CrossRef]

- Mahale, Y.; Kolhar, S.; More, A.S. A comprehensive review on artificial intelligence driven predictive maintenance in vehicles: Technologies, challenges and future research directions. Discov. Appl. Sci. 2025, 7, 243. [Google Scholar] [CrossRef]

- Wu, F.; Wu, Q.; Tan, Y.; Xu, X. Remaining Useful Life Prediction Based on Deep Learning: A Survey. Sensors 2024, 24, 3454. [Google Scholar] [CrossRef]

- Bellido-Lopez, F.J.; Sanz-Bobi, M.A.; Muñoz, A.; Gonzalez-Calvo, D.; Alvarez-Tejedor, T. A novel method for evaluation of the maintenance impact in the health of industrial components. Results Eng. 2025, 27, 105809. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellido-Lopez, F.J.; Sanz-Bobi, M.A.; Muñoz, A.; Gonzalez-Calvo, D.; Alvarez-Tejedor, T. Maintenance-Aware Risk Curves: Correcting Degradation Models with Intervention Effectiveness. Appl. Sci. 2025, 15, 10998. https://doi.org/10.3390/app152010998

Bellido-Lopez FJ, Sanz-Bobi MA, Muñoz A, Gonzalez-Calvo D, Alvarez-Tejedor T. Maintenance-Aware Risk Curves: Correcting Degradation Models with Intervention Effectiveness. Applied Sciences. 2025; 15(20):10998. https://doi.org/10.3390/app152010998

Chicago/Turabian StyleBellido-Lopez, F. Javier, Miguel A. Sanz-Bobi, Antonio Muñoz, Daniel Gonzalez-Calvo, and Tomas Alvarez-Tejedor. 2025. "Maintenance-Aware Risk Curves: Correcting Degradation Models with Intervention Effectiveness" Applied Sciences 15, no. 20: 10998. https://doi.org/10.3390/app152010998

APA StyleBellido-Lopez, F. J., Sanz-Bobi, M. A., Muñoz, A., Gonzalez-Calvo, D., & Alvarez-Tejedor, T. (2025). Maintenance-Aware Risk Curves: Correcting Degradation Models with Intervention Effectiveness. Applied Sciences, 15(20), 10998. https://doi.org/10.3390/app152010998