Strong Mining Pressure Control in a Deep High-Gas Coal Seam with a Hard Roof Using Hydraulic Fracturing Technology

Abstract

1. Introduction

2. Research Background

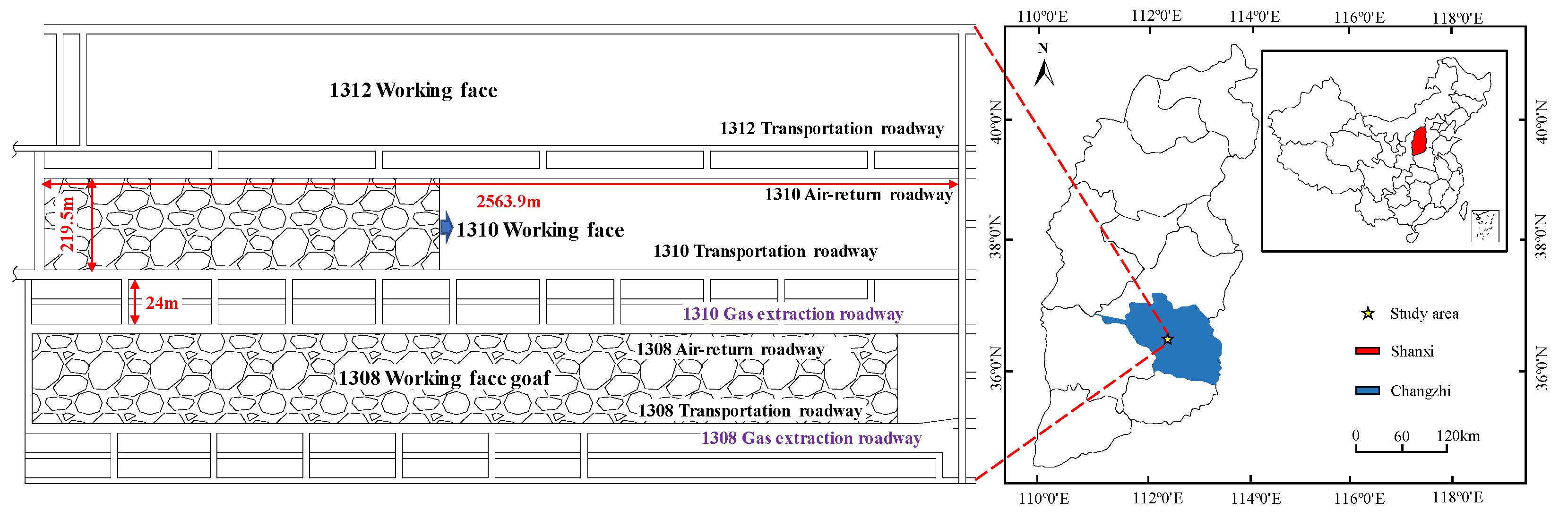

2.1. Working Face Overview

2.2. Analysis of Strong Mining Pressure Events and Inducing Factors

3. Strong Mining Pressure Control Technology for Deep, High-Gas Coal Seams

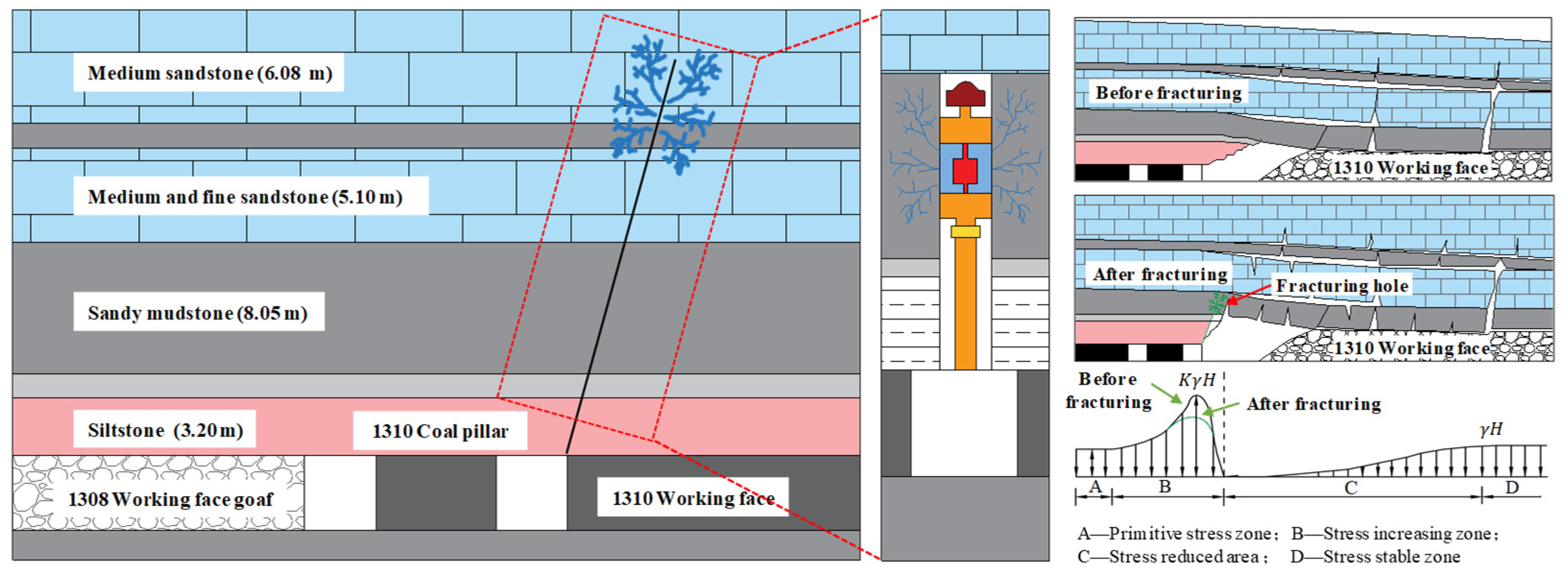

3.1. Principles of Hydraulic Fracturing Technology

3.2. Hydraulic Fracturing Scheme Design

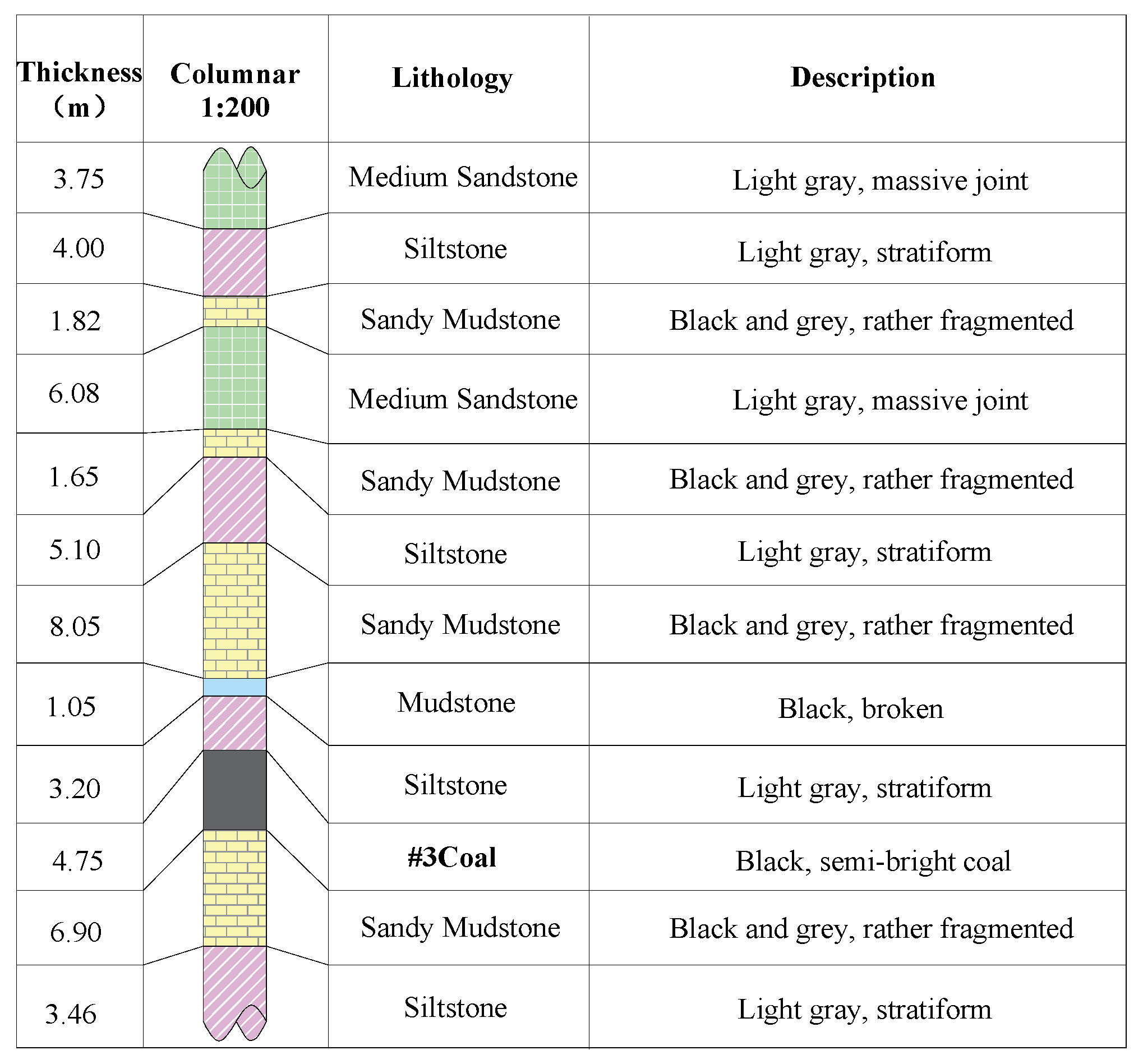

3.2.1. Layer Selection

3.2.2. Drilling Parameter

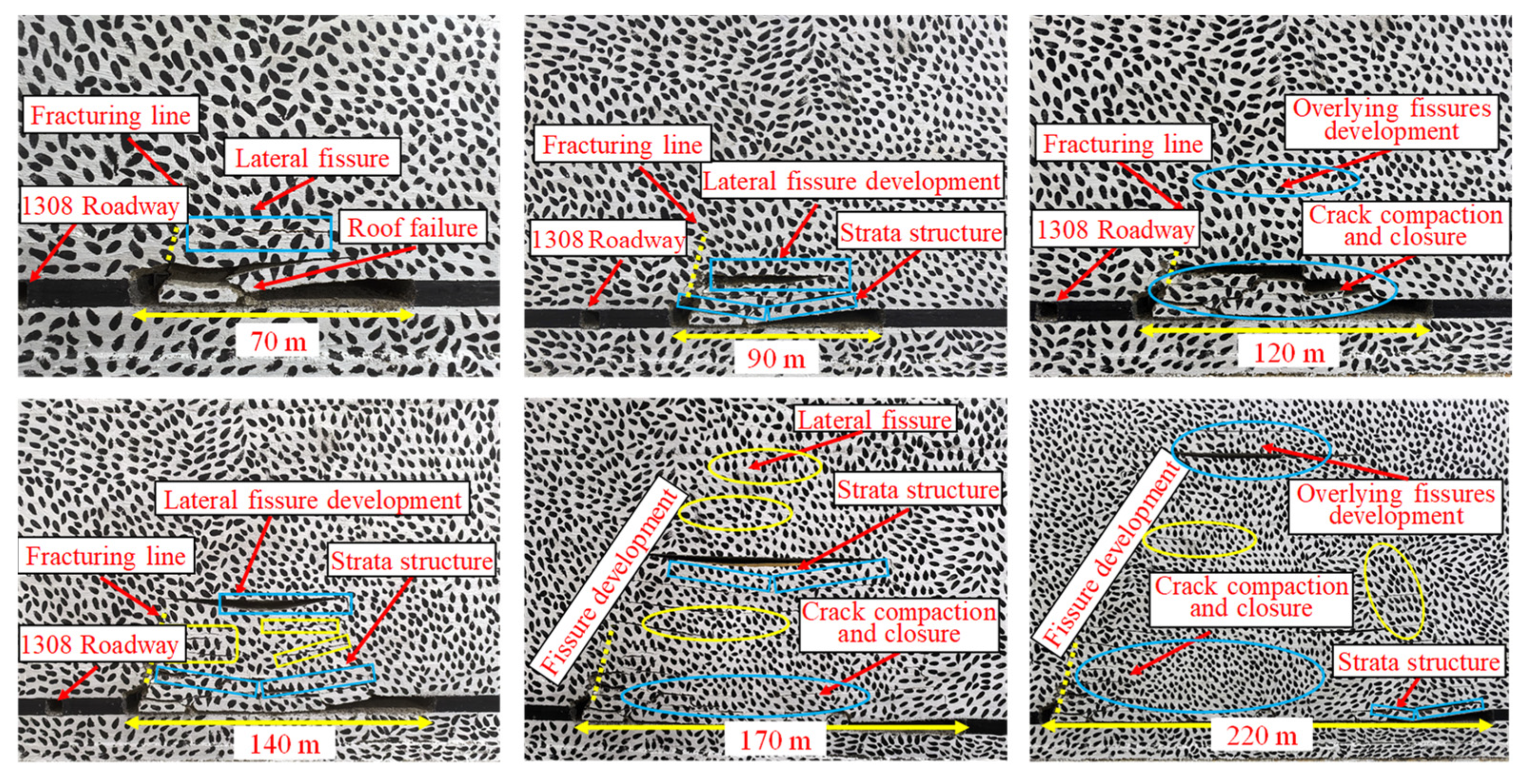

4. Mining Pressure Weakening Effect Simulation Experiment of Hydraulic Fracturing

4.1. Experimental Scheme Design

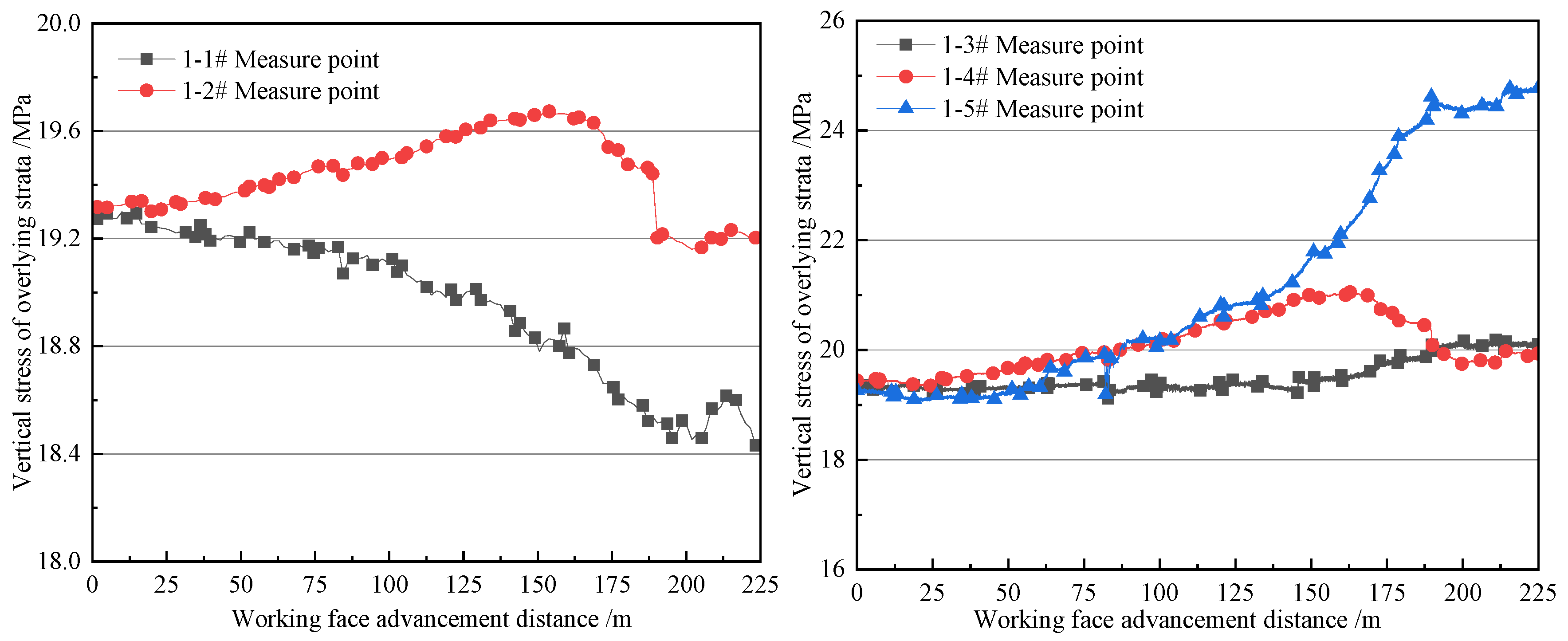

4.2. Experimental Results

5. Engineering Application Analysis

6. Discussion

7. Conclusions

- (1)

- Aiming to mitigate strong mining pressure in the deep composite hard roof high-gas coal seam mining in the southeastern mining area of Shanxi Province, China, a new active pressure-relief technology method with hydraulic fracturing as the core was proposed in this study. By comparing blasting-induced fracturing, water injection weakening, and hydraulic fracturing techniques, the comprehensive advantages of hydraulic fracturing in terms of construction safety, weakening accuracy, and economy were clarified. Based on the structural characteristics of the 1310 working face roof, sandy mudstone (8.05 m) and medium sandstone (6.08 m) were selected as the fracturing layers, effectively weakening the cantilever structure of the roof.

- (2)

- Physical analog material (PAM) experiments revealed the evolution law of overlying rock movement and stress distribution after top cutting and pressure relief. The results show that after cutting the roof, the collapse angle of the roof increases, and a complex roof structure composed of collapse zones, crack zones, and curved subsidence zones is formed above the roadway. The top plate of the left roadway shows a stress variation from a steady rise to a stable state. The stress on the top plate on the left side of the cutting line gradually increases, and the stress relief effect on the right side is significant. The vertical stress decreases from 20 to 5 MPa. The simulation verified that hydraulic fracturing effectively suppresses the accumulation of elastic strain energy induced by large-scale overhanging by forming a controllable fracture network, providing a theoretical basis for preventing and controlling strong mining pressure.

- (3)

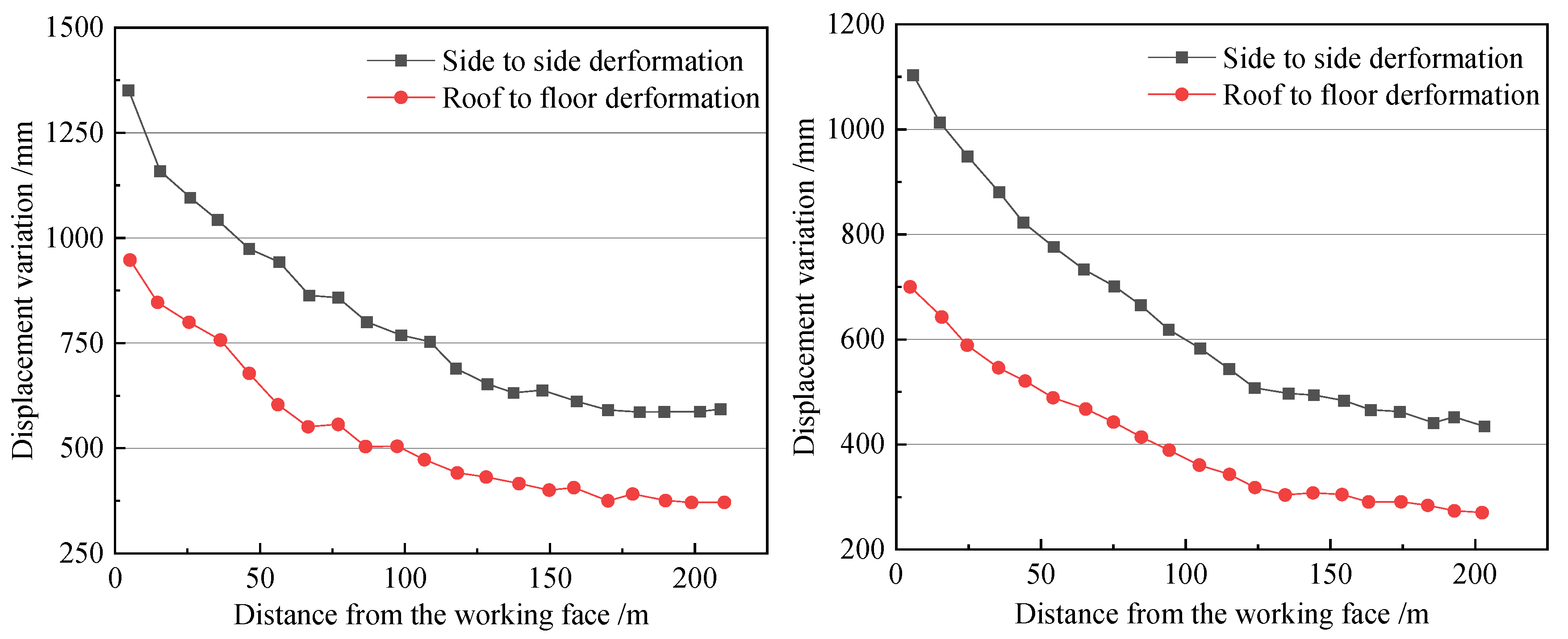

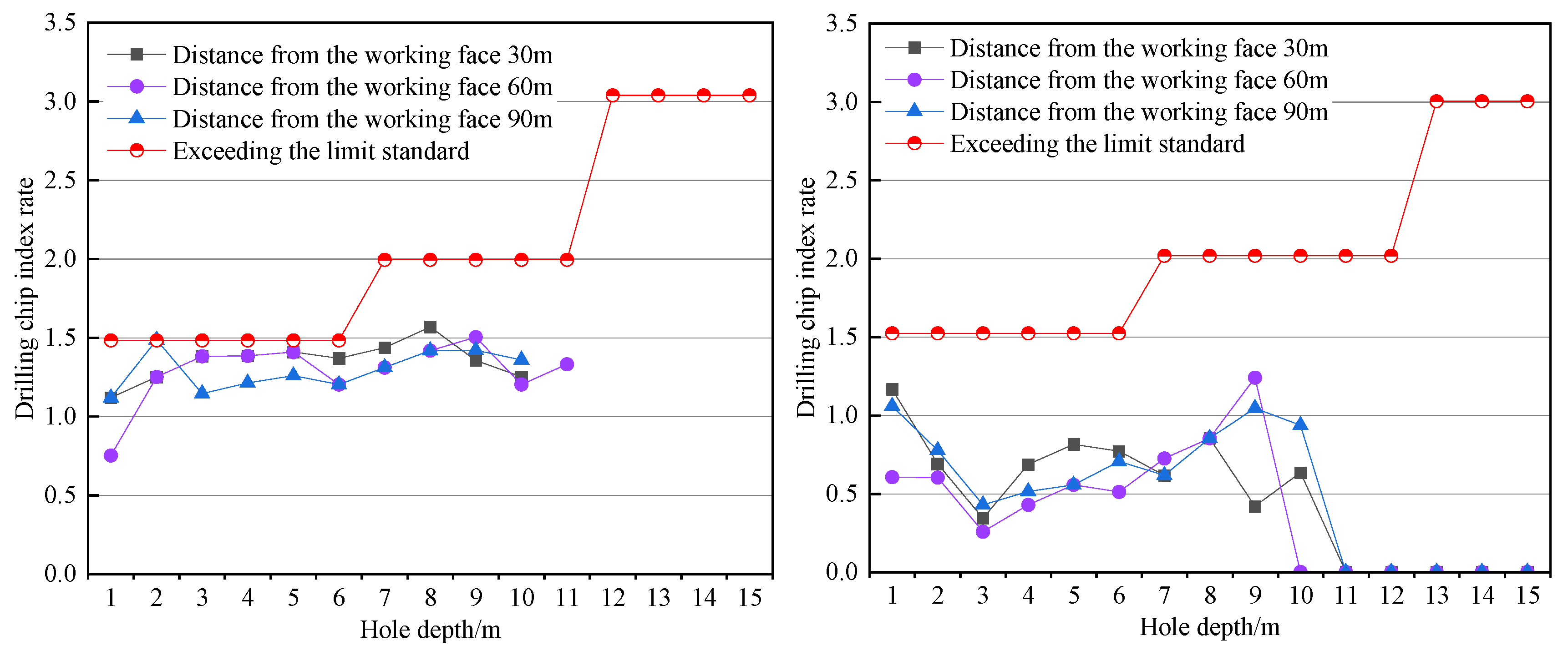

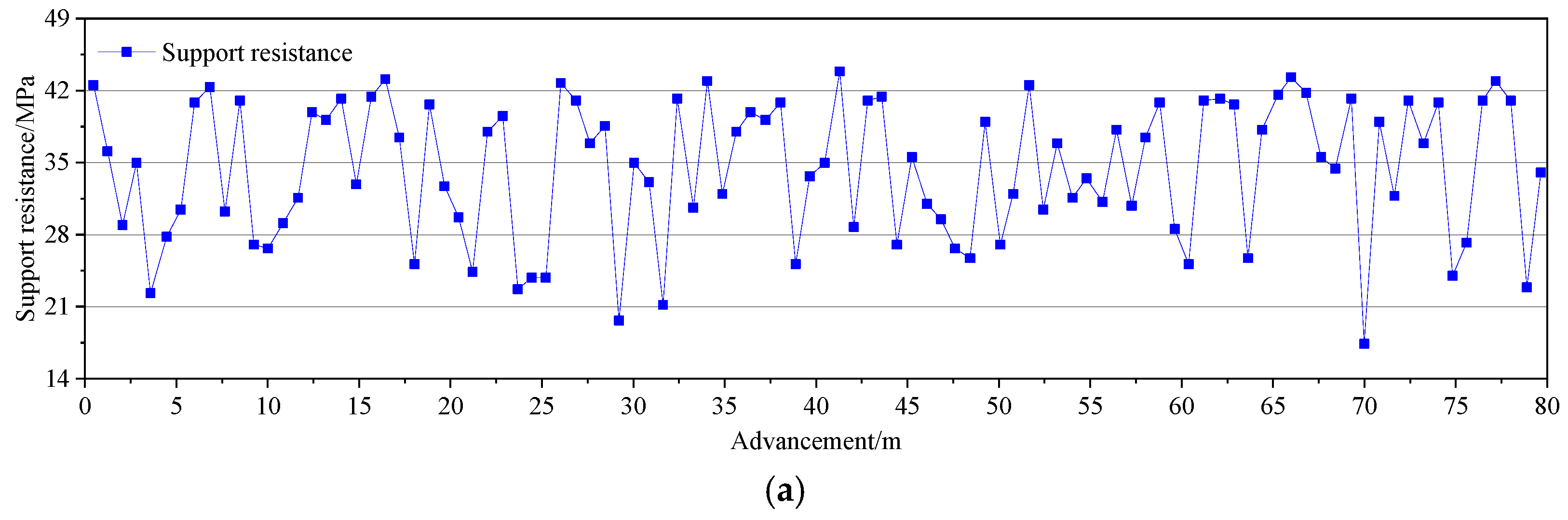

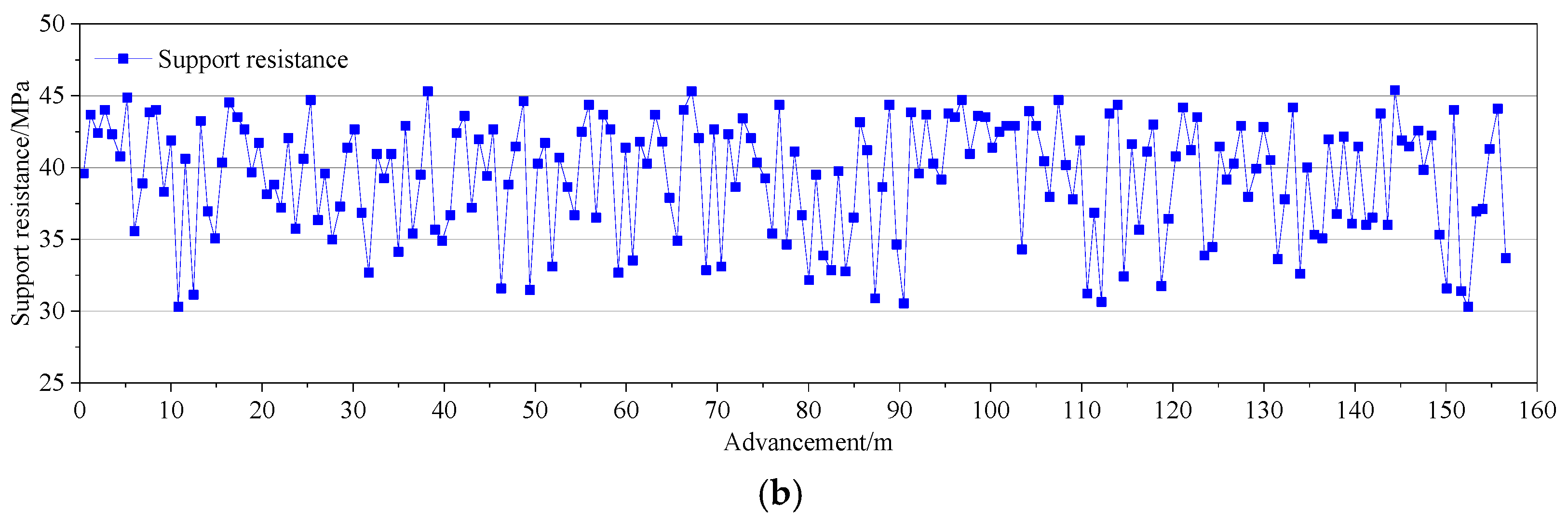

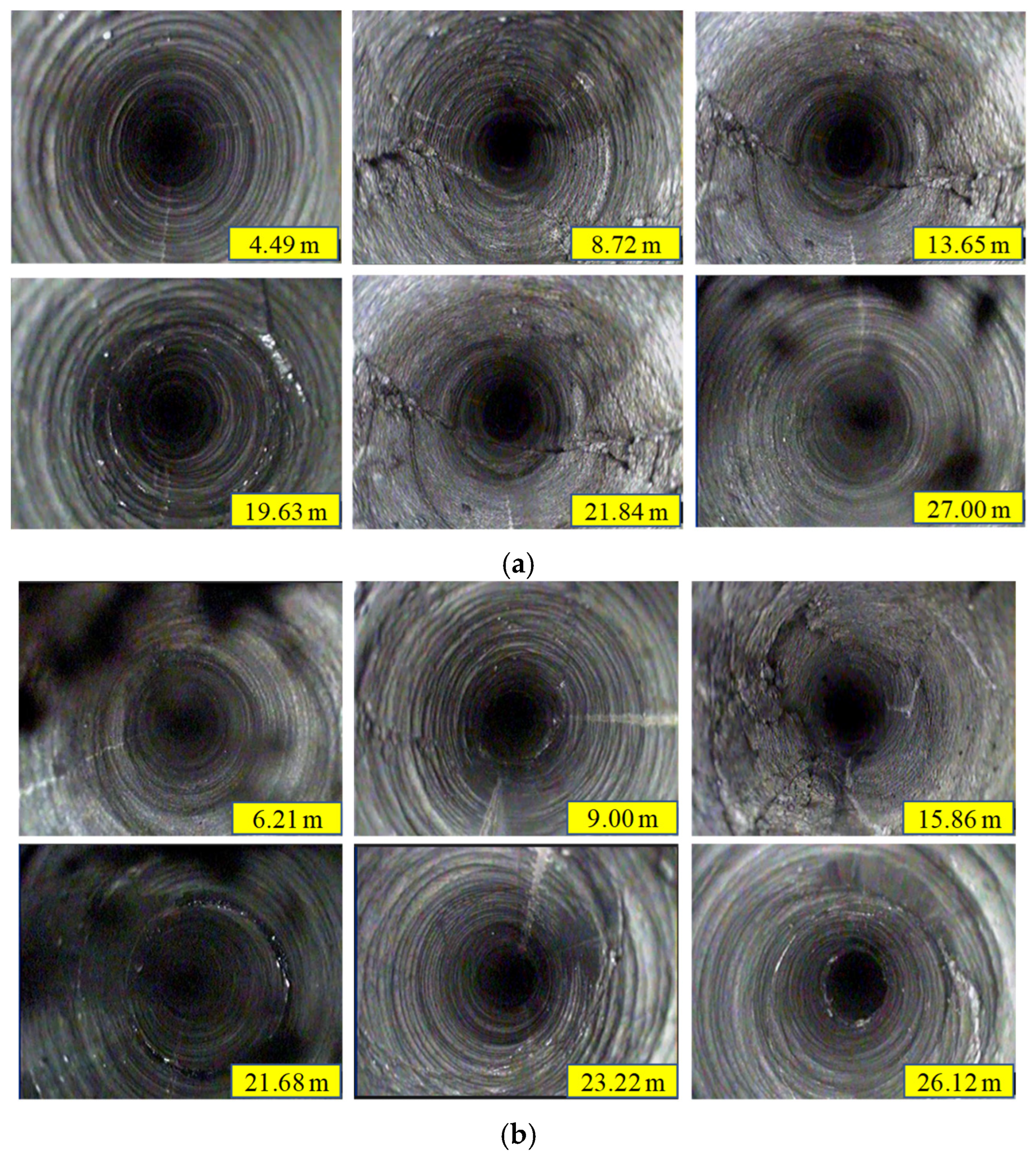

- On-site monitoring data analysis proved that hydraulic fracturing technology significantly improved the manifestation of strong mining pressure. Thus, the surrounding rock deformation of the roadway significantly dropped, and after treatment, the displacement of the two sides dropped from 1350 to 1100 mm, i.e., by 18.5%. The displacement of the top and bottom plates decreased from 950 to 700 mm, i.e., by 26.3%. Data monitoring via the drilling cuttings method (DCM) proved that the drilling cuttings index rate decreased from 1.0~1.5 to below 1.0, and treatment effectively reduced the respective data. Monitoring of the support working resistance showed that the average pressure step distance was stable below 10 m per cycle. Drilling inspection confirmed that the fracturing range was approximately 8.72~23.22 m, with dense crack development and significant pre-fracturing effect.

- (4)

- With the increased coal seam mining depth, it became more challenging to control strong mining pressure and minimize the risks of high-gas-related disasters. In this respect, the hydraulic fracturing technology with reasonable parameter design is conducive to its wider implementation, achieving safe, efficient, and green coal mining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jing, Z.R.; Min, X.Y.; Li, S.J.; Li, J.Y.; Song, W. Trade-off or synergy? The impacts of coal energy consumption on compound system vulnerability: A perspective from coal resource base assessment. Ecol. Indic. 2025, 170, 113124. [Google Scholar] [CrossRef]

- Guo, X.J.; Wang, X.; Wu, X.L.; Chen, X.P.; Li, Y. Carbon emission efficiency and low-carbon optimization in shanxi province under “Dual Carbon” background. Energies 2022, 15, 2369. [Google Scholar] [CrossRef]

- Bai, X.X.; Cao, A.Y.; Cai, W.; Wen, Y.Y.; Liu, Y.Q.; Wang, S.W.; Li, X.W. Rock burst mechanism induced by stress anomaly in roof thickness variation zone: A case study. Geomat. Nat. Hazards Risk 2022, 13, 1805–1830. [Google Scholar] [CrossRef]

- Koziel, K.; Skoczylas, N.; Soroko, K.; Gola, S. Gas and dolomite outbursts in ore mines-analysis of the phenomenon and the energy balance. Energies 2020, 13, 2999. [Google Scholar] [CrossRef]

- Ju, J.F.; Qi, C.G.; Li, Z. Effect of Thick–hard main roof fracturing on the spatiotemporal evolution of overburden fractures. Appl. Sci. 2024, 14, 10308. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.B.; Zhang, W.Y. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 1101129. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.W.; Yu, B.; Yu, P.; Luo, Y.F.; Gao, Y.G. Determination of the key parameters of high-position hard roofs for vertical-well stratified fracturing to release strong ground pressure behavior in extra-thick coal seam mining. Energy Sci. Eng. 2020, 8, 2216–2238. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Yang, W.; Liu, T.; Xiao, W.; Zha, W. Study of effects of hard thick roof on gas migration and field experiment of roof artificially guided pre-splitting for efficient gas control. Nat. Resour. Res. 2020, 29, 1819–1841. [Google Scholar] [CrossRef]

- Bu, Q.W.; Tu, M.; Zhang, X.Y.; Zhang, M.; Zhao, Q.C. Analysis of energy accumulation and dispersion evolution of a thick hard roof and dynamic load response of the hydraulic support in a large space stope. Front. Earth Sci. 2022, 10, 884361. [Google Scholar] [CrossRef]

- Zhang, J.W.; Dong, X.K.; Bai, J.J.; Jia, L.L. The mechanism and prevention of rockburst induced by the instability of the composite hard-roof coal structure and roof fractures. Eng. Fract. Mech. 2024, 310, 110512. [Google Scholar] [CrossRef]

- Ma, J.K.; Li, H.; Guo, X.M.; Tian, F.C.; Guo, H.G. A control method for hydraulic fracturing of the hard roof with long and short boreholes. Front. Mater. 2022, 9, 1035815. [Google Scholar] [CrossRef]

- Zhang, F.T.; Wang, X.Y.; Bai, J.B.; Wu, B.W.; Wang, G.H.; Li, J.C.; Chen, D.C. Study on hydraulic fracture propagation in hard roof under abutment pressure. Rock Mech. Rock Eng. 2022, 55, 6321–6338. [Google Scholar] [CrossRef]

- Dou, L.T.; Yang, K.; Liu, W.J.; Chi, X.L. Mining-induced stress-fissure field evolution and the disaster-causing mechanism in the high gas working face of the deep hard strata. Geofluids 2020, 2020, 8849666. [Google Scholar] [CrossRef]

- Huang, B.X.; Cheng, Q.Y.; Zhao, X.L.; Kang, C. Hydraulic fracturing of hard top coal and roof for controlling gas during the initial mining stages in longwall top coal caving: A case study. J. Geophys. Eng. 2018, 15, 2492–2506. [Google Scholar] [CrossRef]

- Symanovych, H.; Odnovol, M.; Yakovenko, V.; Sachko, R.; Shaikhlislamova, I.; Reshetilova, T.; Stadnichuk, M. Assessing the geomechanical state of the main working network state in the case of undermining in the conditions of weak rocks. Min. Miner. Deposits 2023, 17, 91–98. [Google Scholar] [CrossRef]

- Symanovych, H.; Lisovytska, I.; Odnovol, M.; Ahaiev, R.; Poimanov, S. Rationale and modeling of technology for complex bottom-hole zone de-stressing of gas-dynamically active rock mass. Min. Miner. Depos. 2024, 18, 83–92. [Google Scholar] [CrossRef]

- Fu, Q.; Yang, J.; Gao, Y.B.; Li, C.J.; Song, H.X.; Liu, Y.X.; Wu, X. Combined blasting for protection of gob-side roadway with thick and hard roof. J. Rock Mech. Geotech. Eng. 2024, 16, 3165–3180. [Google Scholar] [CrossRef]

- Wang, C.G.; Bai, J.B.; Wang, T.C.; Wu, W.D. Energy Evolution Characteristics and hydraulic fracturing roof cutting technology for hard roof working face during initial mining: A case study. Appl. Sci. 2024, 14, 7405. [Google Scholar] [CrossRef]

- Serdyukov, S.V.; Kurlenya, M.V.; Patutin, A.V.; Rybalkin, L.A.; Shilova, T.V. Experimental test of directional hydraulic fracturing technique. J. Min. Sci. 2016, 52, 615–622. [Google Scholar] [CrossRef]

- Liu, Y.X.; Xu, C.H.; Xu, J.; Zeng, X.M. Hydro-mechanical coupling characteristics and weakening mechanisms of filling joint resulting from water injection. Sci. Rep. 2022, 12, 21957. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.Y.; Yang, J.X.; Yu, B. Rock-breaking mechanism and experimental analysis of confined blasting of borehole surrounding rock. Int. J. Min. Sci. Technol. 2017, 27, 795–801. [Google Scholar] [CrossRef]

- Tang, X.Y.; Wan, W.; Lu, Z.X.; Chen, W. Study on composite fracture characteristics and hydraulic fracturing behavior of hard rock. Appl. Sci. 2024, 14, 2585. [Google Scholar] [CrossRef]

- Cao, X.; Wu, S.S.; He, Q.Y. Investigation into influences of hydraulic fracturing for hard rock weakening in underground mines. Appl. Sci. 2024, 14, 1948. [Google Scholar] [CrossRef]

- Sun, Q. Mechanism and Method of Key Aquiclude Strata Reconstruction by Backfill Mining Technology. Ph.D. Dissertation, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Ishibashi, T.; Yamaya, Y.; Asanuma, H. Experimental insights into coupled hydraulic, mechanical, and electrical behaviors of granite fractures: Implications for indirect estimation of crustal permeability changes. Int. J. Rock Mech. Min. Sci. 2025, 188, 106060. [Google Scholar] [CrossRef]

- Li, X.G.; He, Y.T.; Hu, M.; Yang, Z.Z.; Wang, H.Z.; Song, R. Model for calculating the temperature and pressure within the fracture during supercritical carbon dioxide fracturing. Int. J. Hydrogen Energy 2020, 45, 8369–8384. [Google Scholar] [CrossRef]

- Xu, L.K.; Yu, F.H.; Tan, Y.L.; Zhang, C.; Zhou, K. The evolution of fractures in deep, weakly cemented overlying strata and the characteristics of severe and mild fracture zones. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 94. [Google Scholar] [CrossRef]

- Shakib, J.T.; Akhgarian, E.; Ghaderi, A. The effect of hydraulic fracture characteristics on production rate in thermal EOR methods. Fuel 2015, 141, 226–235. [Google Scholar] [CrossRef]

| Lithology | Thickness (m) | Fragmentation Coefficient | Fragmentation Height (m) | Accumulated Fragmentation Height (m) | Cumulative Height of Roof (m) |

|---|---|---|---|---|---|

| Medium sandstone | 6.08 | 1.3 | 1.82 | 6.21 | 25.13 |

| Sandy mudstone | 1.65 | 1.2 | 0.33 | 4.39 | 19.05 |

| Medium and fine sandstone | 5.10 | 1.3 | 1.53 | 4.06 | 17.40 |

| Sandy mudstone | 8.05 | 1.2 | 1.61 | 2.53 | 12.30 |

| Mudstone | 1.05 | 1.2 | 0.21 | 0.92 | 4.25 |

| Siltstone | 3.20 | 1.2 | 0.64 | 0.71 | 3.20 |

| #3 Coal | 4.85 | 1.2 | 0.07 | -- | -- |

| Lithology | Sand (kg) | Calcium Carbonate (kg) | Gypsum (kg) | Thickness (cm) | PAM Strength (kPa) |

|---|---|---|---|---|---|

| Medium sandstone | 36.16 | 1.81 | 4.22 | 2.50 | 311.11 |

| Siltstone | 42.33 | 4.94 | 2.11 | 2.67 | 65.11 |

| Sandy mudstone | 20.00 | 2.00 | 4.67 | 1.21 | 76.44 |

| Medium sandstone | 63.99 | 6.40 | 2.74 | 4.05 | 311.11 |

| Sandy mudstone | 12.83 | 0.64 | 1.49 | 1.10 | 76.44 |

| Siltstone | 54.00 | 2.70 | 6.30 | 3.40 | 65.11 |

| Sandy mudstone | 84.37 | 8.44 | 19.69 | 5.37 | 76.44 |

| Mudstone | 10.13 | 1.01 | 2.36 | 0.70 | 179.07 |

| Siltstone | 26.61 | 1.33 | 3.11 | 2.13 | 65.11 |

| #3 Coal | 36.72 | 3.67 | 1.57 | 3.17 | 69.33 |

| Sandy mudstone | 62.44 | 6.25 | 14.57 | 4.60 | 76.44 |

| Siltstone | 32.65 | 3.27 | 7.62 | 2.31 | 65.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Yuan, H.; Han, Y.; Cheng, X.; Ren, W. Strong Mining Pressure Control in a Deep High-Gas Coal Seam with a Hard Roof Using Hydraulic Fracturing Technology. Appl. Sci. 2025, 15, 10940. https://doi.org/10.3390/app152010940

Sun Q, Yuan H, Han Y, Cheng X, Ren W. Strong Mining Pressure Control in a Deep High-Gas Coal Seam with a Hard Roof Using Hydraulic Fracturing Technology. Applied Sciences. 2025; 15(20):10940. https://doi.org/10.3390/app152010940

Chicago/Turabian StyleSun, Qiang, Hui Yuan, Yong Han, Xiaoming Cheng, and Weiguang Ren. 2025. "Strong Mining Pressure Control in a Deep High-Gas Coal Seam with a Hard Roof Using Hydraulic Fracturing Technology" Applied Sciences 15, no. 20: 10940. https://doi.org/10.3390/app152010940

APA StyleSun, Q., Yuan, H., Han, Y., Cheng, X., & Ren, W. (2025). Strong Mining Pressure Control in a Deep High-Gas Coal Seam with a Hard Roof Using Hydraulic Fracturing Technology. Applied Sciences, 15(20), 10940. https://doi.org/10.3390/app152010940