Application of Water-Sensitive Paper for Spray Performance Evaluation in Aeroponics via a Segmentation-Based Algorithm

Abstract

1. Introduction

- 1

- To demonstrate the application of water-sensitive paper (WSP) as a practical tool for evaluating spray performance within an aeroponic system.

- 2

- To investigate the influence of different flow rates on spray performance parameters, including droplet coverage area, size, density, and uniformity index under manually controlled aeroponic conditions.

2. Materials and Methods

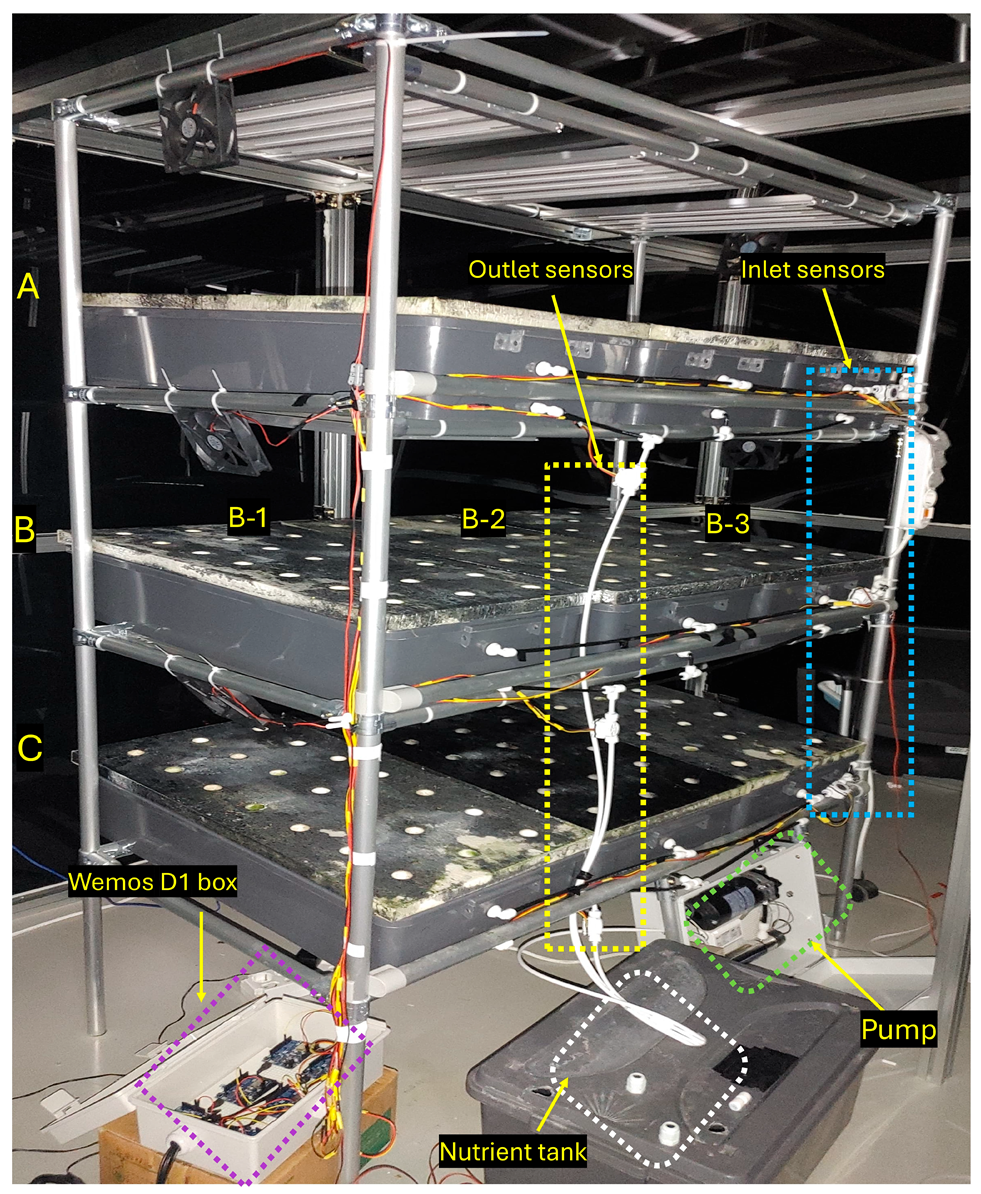

2.1. Experimental Site and Structure

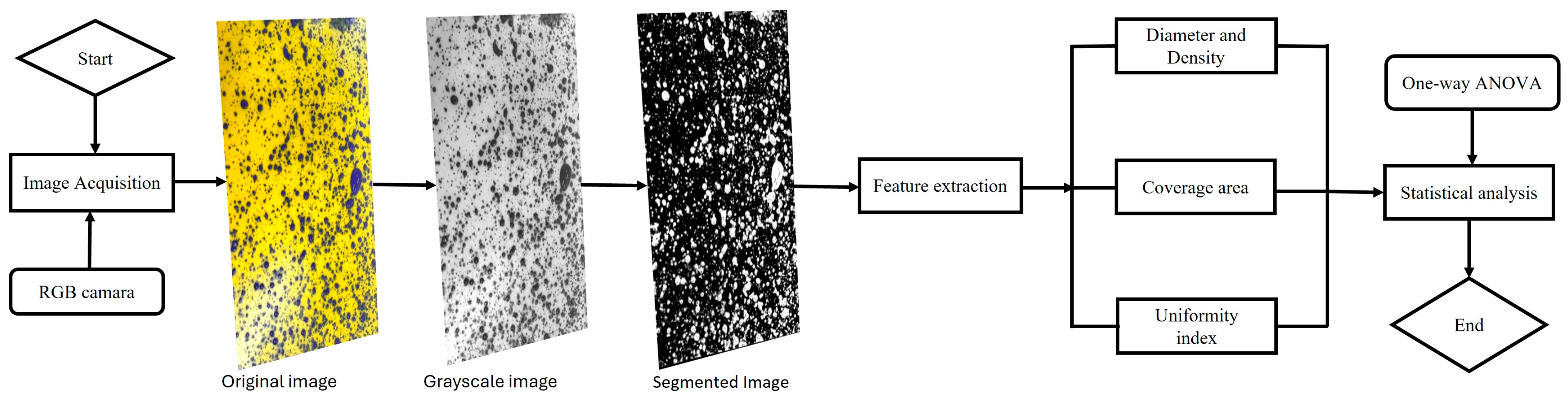

2.2. Testing the Image-Processing Technique

2.3. Statistical Analysis

3. Results and Discussion

3.1. Validation of Image-Processing Technique for Spray Distribution on WSP

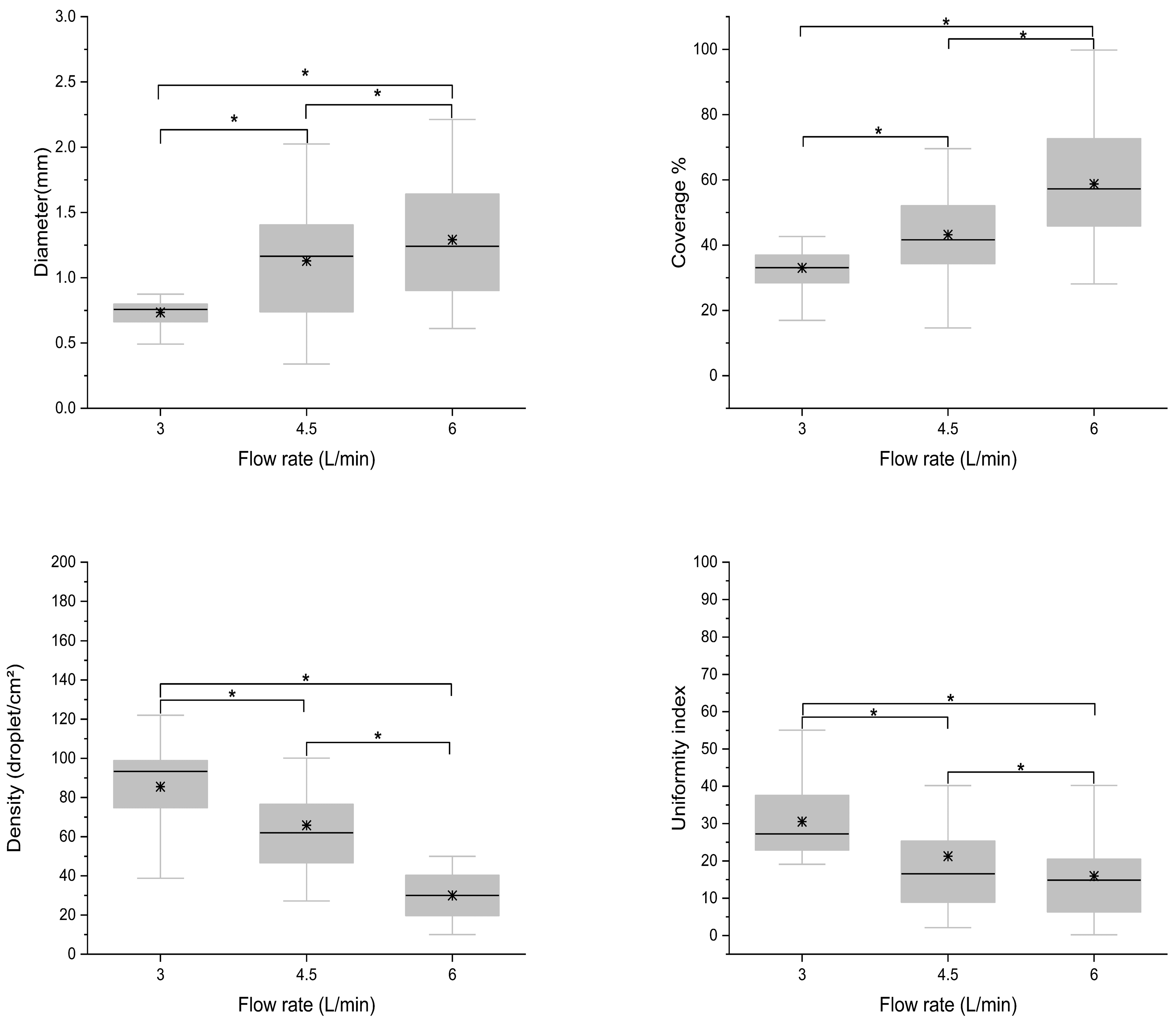

3.2. Comparative Evaluation of Spray Performance

4. Limitations and Future Directions

- ➢

- Flow rate was manually adjusted using a valve, which resulted in occasional fluctuations in the actual flow rate. At times, the flow exceeded or fell below the intended fixed value, resulting in variability in the spray conditions. A more accurate evaluation of the spray performance would necessitate an automated flow rate control system to maintain a consistent and stable flow throughout the experiment.

- ➢

- WSP samples were scanned using a smartphone, which does not necessarily produce images of standard quality. This inconsistency can affect the precision of measurements related to the droplet stain characteristics and ultimately compromise the accuracy of the spray analysis. In the future, it would be necessary to overcome this limitation by using controlled lighting and dedicated scanners to enhance the quality of WSP images, ensuring that they are produced according to the same specifications [29].

- ➢

- When the spray coverage on WSP becomes too high, many droplets are positioned very close to each other or even overlap. This makes it difficult for the algorithm to identify and separate individual droplets correctly. As a result, the algorithm may fail to detect all droplets or incorrectly estimate their size and position. Solving this problem would require further data, such as the initial droplet coordinates and the direction of the nozzles. This issue could be addressed by applying deep learning-based methods such as Mask R-CNN or YOLO to improve the detection and separation of overlapping droplets. These approaches have accomplished similar image segmentation tasks with high accuracy under dense and occluded conditions [30].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wanapat, M.; Suriyapha, C.; Dagaew, G.; Matra, M.; Phupaboon, S.; Sommai, S.; Pongsub, S.; Muslykhah, U. Sustainable livestock production systems are key to ensuring food security resilience in response to climate change. Agric. Nat. Resour. 2024, 58, 537–546. [Google Scholar] [CrossRef]

- Alexandratos, N.; Bruinsma, J. World Agriculture Towards 2030/2050: The 2012 Revision; FAO: Rome, Italy, 2012. [Google Scholar]

- Qureshi, W.A.; Gao, J.; Elsherbiny, O.; Mosha, A.H.; Tunio, M.H.; Qureshi, J.A. Boosting Aeroponic System Development with Plasma and High-Efficiency Tools: AI and IoT—A Review. Agronomy 2025, 15, 546. [Google Scholar] [CrossRef]

- Shin, S.; Aziz, D.; El-Sayed, M.E.; Hazman, M.; Almas, L.; McFarland, M.; El Din, A.S.; Burian, S.J. Systems thinking for planning sustainable desert agriculture systems with saline groundwater irrigation: A review. Water 2022, 14, 3343. [Google Scholar] [CrossRef]

- Amjad, M.; Arulmozhi, E.; Shin, Y.-H.; Kang, M.-K.; Cho, W.-J. A Review of IoT and Machine Learning for Environmental Optimization in Aeroponics. Agronomy 2025, 15, 1627. [Google Scholar] [CrossRef]

- Kumar, P.; Jaisuriyan, K.; Gopika, B.; Subhash, B. Aeroponics: A Modern Agriculture Technology Under Controlled Environment. In Hydroponics: The Future of Sustainable Farming; Springer: Berlin/Heidelberg, Germany, 2024; pp. 263–294. [Google Scholar]

- NASA Spinoff. Progressive plant growing has business blooming. In Environmental and Agricultural Resources; NASA Spinoff: New York, NY, USA, 2006; pp. 64–77. [Google Scholar]

- Ramu, M.; Priya, R.M.; Priya, R.S. Aeroponics System and Its Methods. In Utilizing Aeroponics Techniques for Improved Farming; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 1–28. [Google Scholar]

- Johnson, T.J. Aeroponic System Optimization for Butterhead Lettuce Growth and Future Sustainability Using Flow Blurring Atomization: An Overview. Beyond Undergrad. Res. J. 2025, 8, 11. [Google Scholar]

- Tang, L.; Syed, A.-u.-A.; Otho, A.R.; Junejo, A.R.; Tunio, M.H.; Hao, L.; Asghar Ali, M.N.H.; Brohi, S.A.; Otho, S.A.; Channa, J.A. Intelligent Rapid Asexual Propagation Technology—A Novel Aeroponics Propagation Approach. Agronomy 2024, 14, 2289. [Google Scholar] [CrossRef]

- Krishnan, G.; Cryer, S.A.; Turner, J.E.; Rajan, N.S. Spray atomisation in multiphase flows with reference to tank mixes of agricultural products. Biosyst. Eng. 2022, 223, 232–248. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Xu, X.; Syed, T.N.; Chandio, F.A.; Jing, Z.; Buttar, N.A. Effects of Various Aeroponic Atomizers (Droplet Sizes) on Growth, Polyphenol Content, and Antioxidant Activity of Leaf Lettuce (Lactuca sativa L.). Trans. ASABE 2019, 62, 1475–1487. [Google Scholar] [CrossRef]

- Privitera, S.; Manetto, G.; Pascuzzi, S.; Pessina, D.; Cerruto, E. Drop size measurement techniques for agricultural sprays: A state-of-the-art review. Agronomy 2023, 13, 678. [Google Scholar] [CrossRef]

- Al-Mamury, M. Smart Electrostatic Crop Spraying Using Remote Sensing Technology; Brunel University London: Uxbridge, UK, 2015. [Google Scholar]

- Sassu, A.; Psiroukis, V.; Bettucci, F.; Ghiani, L.; Fountas, S.; Gambella, F. Unmanned aerial system plant protection products spraying performance evaluation on a vineyard. Precis. Agric. 2024, 25, 2082–2112. [Google Scholar] [CrossRef]

- Semenišin, M.; Steponavičius, D.; Kemzūraitė, A.; Savickas, D. Optimizing UAV spraying for sustainability: Different system spray drift control and adjuvant performance. Sustainability 2025, 17, 2083. [Google Scholar] [CrossRef]

- Lan, Y. Study on Aerial Spraying Control Effect and Efficacy. In Precision Agricultural Aviation Application Technology; Springer: Berlin/Heidelberg, Germany, 2025; pp. 393–445. [Google Scholar]

- Sies, M.; Madzlan, N.; Asmuin, N.; Sadikin, A.; Zakaria, H. Determine spray droplets on water sensitive paper (WSP) for low pressure deflector nozzle using image J. IOP Conf. Ser. Mater. Sci. Eng. 2017, 243, 012047. [Google Scholar]

- Qin, W.; Xue, X.; Zhang, S.; Gu, W.; Wang, B. Droplet deposition and efficiency of fungicides sprayed with small UAV against wheat powdery mildew. Int. J. Agric. Biol. Eng. 2018, 11, 27–32. [Google Scholar] [CrossRef]

- Chen, H.; Lan, Y.; Fritz, B.K.; Hoffmann, W.C.; Liu, S. Review of agricultural spraying technologies for plant protection using unmanned aerial vehicle (UAV). Int. J. Agric. Biol. Eng. 2021, 14, 38–49. [Google Scholar] [CrossRef]

- Prakash, D.C.; Narayanan, R.; Ganesh, N.; Ramachandran, M.; Chinnasami, S.; Rajeshwari, R. A study on image processing with data analysis. AIP Conf. Proc. 2022, 2393, 020225. [Google Scholar]

- Cunha, M.; Carvalho, C.; Marcal, A.R. Assessing the ability of image processing software to analyse spray quality on water-sensitive papers used as artificial targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef]

- Meng, Y.; Liu, X.; Chen, W.; Du, X.; Zhang, Y.; Sun, R.; Han, Y. Evaluation of droplet deposition parameters based on the Genetic-Otsu algorithm. PeerJ 2024, 12, e18036. [Google Scholar] [CrossRef] [PubMed]

- Simões, I.; Sousa, A.J.; Baltazar, A.; Santos, F. Spray quality assessment on water-sensitive paper comparing AI and classical computer vision methods. Agriculture 2025, 15, 261. [Google Scholar] [CrossRef]

- Özlüoymak, Ö.B.; Bolat, A. Development and assessment of a novel imaging software for optimizing the spray parameters on water-sensitive papers. Comput. Electron. Agric. 2020, 168, 105104. [Google Scholar] [CrossRef]

- Marçal, A.; Cunha, M. Image processing of artificial targets for automatic evaluation of spray quality. Trans. ASABE 2008, 51, 811–821. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Privitera, S.; Papa, R.; Longo, D. Effect of image segmentation thresholding on droplet size measurement. Agronomy 2022, 12, 1677. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, Y.; Zhu, Y.; Wang, Y.; Niu, Z.; Abdukamolovich, J.A. An Image Processing Based Approach to Assess the Quality of Pesticide Spray. Smart Agric. Technol. 2024, 8, 100460. [Google Scholar] [CrossRef]

- Wu, C.-L.; Yang, C.-K.; Lin, J.-Y. Water-sensitive paper detection and spray analysis. Multimed. Tools Appl. 2025, 84, 38797–38851. [Google Scholar] [CrossRef]

- Shengde, C.; Junyu, L.; Xiaojie, X.; Jianzhou, G.; Shiyun, H.; Zhiyan, Z.; Yubin, L. Detection and tracking of agricultural spray droplets using GSConv-enhanced YOLOv5s and DeepSORT. Comput. Electron. Agric. 2025, 235, 110353. [Google Scholar] [CrossRef]

| Dependent Variable | Flow Rate (L/min) | Mean ± SD | F-Value | p-Value | Significance |

|---|---|---|---|---|---|

| Coverage Area (cm2) | 3 | 33.02 ± 8.83 | 27.07 | <0.05 | * |

| 4.5 | 43.17 ± 15.61 | ||||

| 6 | 58.71 ± 18.59 | ||||

| Droplet Diameter (mm) | 3 | 0.73 ± 0.13 | 23.20 | <0.05 | * |

| 4.5 | 1.12 ± 0.41 | ||||

| 6 | 1.29 ± 0.44 | ||||

| Droplet Density (drops/cm2) | 3 | 85.53 ± 20.31 | 36.71 | <0.05 | * |

| 4.5 | 55.03 ± 41.44 | ||||

| 6 | 30.00 ± 12.04 | ||||

| Uniformity Index | 3 | 30.53 ± 9.41 | 11.71 | <0.05 | * |

| 4.5 | 21.27 ± 16.77 | ||||

| 6 | 15.95 ± 11.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amjad, M.; Shin, Y.-H.; Park, J.-M.; Cho, W.-J.; Yeo, U.-H. Application of Water-Sensitive Paper for Spray Performance Evaluation in Aeroponics via a Segmentation-Based Algorithm. Appl. Sci. 2025, 15, 10928. https://doi.org/10.3390/app152010928

Amjad M, Shin Y-H, Park J-M, Cho W-J, Yeo U-H. Application of Water-Sensitive Paper for Spray Performance Evaluation in Aeroponics via a Segmentation-Based Algorithm. Applied Sciences. 2025; 15(20):10928. https://doi.org/10.3390/app152010928

Chicago/Turabian StyleAmjad, Muhammad, Yeong-Hyeon Shin, Je-Min Park, Woo-Jae Cho, and Uk-Hyeon Yeo. 2025. "Application of Water-Sensitive Paper for Spray Performance Evaluation in Aeroponics via a Segmentation-Based Algorithm" Applied Sciences 15, no. 20: 10928. https://doi.org/10.3390/app152010928

APA StyleAmjad, M., Shin, Y.-H., Park, J.-M., Cho, W.-J., & Yeo, U.-H. (2025). Application of Water-Sensitive Paper for Spray Performance Evaluation in Aeroponics via a Segmentation-Based Algorithm. Applied Sciences, 15(20), 10928. https://doi.org/10.3390/app152010928