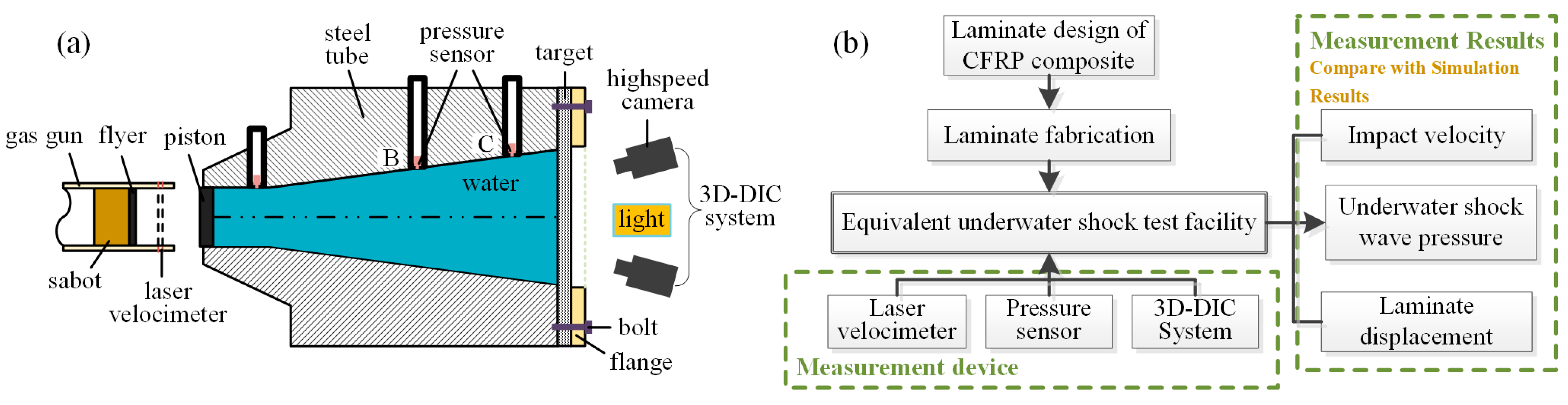

When analyzing the effects of underwater explosive impact loading, the fluid–structure interaction (FSI) plays a pivotal role in the structural response, as it significantly influences the deformation and energy absorption characteristics of these structures. A new experimental method was proposed to simulate the FSI effect encountered in various applications, especially underwater explosions [

3]. The experimental setup is based on scaled analysis and can be used as a laboratory-scale device to simulate the deformation and destruction of large-scale structures. Liang et al. [

4] studied the impact resistance performance of sandwich structures with three core topologies: square honeycomb, I-core, and corrugated plate. The research highlighted a critical domain where water cavitation occurs prior to core crushing. The results help design high-performance sandwich structures. Mori et al. [

5] investigated the underwater blast resistance of stainless-steel sandwich panels with honeycomb cores, pyramidal lattice cores, and I-cores. Compared to solid plates with the same areal density, soft-core sandwich structures can achieve significant performance enhancements, with a maximum panel deflection reduction of up to 68%. McShane et al. [

6] studied the response of freely supported metal sandwich panels with a square honeycomb core and a corrugated core subjected to underwater shock. It was found that the response of sandwich panels is affected by core strength, the mass of the wet panel, and the explosion impulse time constant. By using an underwater shock loading simulator, the dynamic failure behavior of metal square honeycomb cores, PVC foam cores, and composite sandwich structures under shock loading was studied, focusing particularly on the influence of different core material densities and structural properties on deformation and failure mechanisms [

7,

8,

9,

10,

11]. Huang and Zhang et al. assessed the failure modes and underlying mechanisms of aluminum sandwich structures with different cores under underwater shock load under both air-backed and water-backed scenarios [

12,

13,

14,

15,

16]. Rong and He et al. employed a 3D-DIC system to measure the transverse deformation of targets, conducting a systematic study on the fracture modes of foam and honeycomb sandwich panels [

17,

18]. Based on the aforementioned research methods, there have also been many advancements in the study of the underwater impact resistance of composite laminates and sandwich panels. LeBlanc and Shukla [

19] studied the response of circular composite plates under underwater explosion loading and found that the thickness and radius of the plate significantly affect the dynamic response of the structure. LeBlanc and Shukla [

20,

21] studied the response of curved panels under underwater explosion loading and found that curvature significantly affects the dynamic response and damage patterns of the structure. Schiffer et al. [

22] investigated the underwater blast response of composite laminates using experiments and modeling. Circular composite plates were subjected to underwater shock loading, and their dynamic deformation and failure were analyzed. High-speed imaging and finite element simulations were employed to observe fluid–structure interaction and cavitation effects. Latourte et al. [

23] investigated the failure mechanisms of composite panels under underwater impulsive loads through experiments and numerical simulations, revealing the complex damage behavior of composite materials under impact loading. Avachat and Zhou [

24] studied the effect of face sheet thickness on the dynamic response of composite sandwich plates under underwater impulsive loading and found that appropriately increasing the face sheet thickness can improve the structure’s impact resistance. To improve the impact resistance of composite structures, researchers have conducted various explorations. This review paper [

25,

26,

27,

28] comprehensively examines the response of fiber-based polymer composites to shock waves and explosive blasts. It covers FRP laminates, fiber metal laminates, and sandwich composites, analyzing their deformation, damage mechanisms, and energy absorption under blast loading. Gargano et al. [

29] compared the impact resistance performance of different types of composite materials under underwater explosion loading, providing a reference for the selection of composite materials. Ren et al. [

30,

31] studied the dynamic failure behavior of carbon fiber-reinforced plastic sandwich structures under impact loading and found that the failure modes of sandwich structures include core compression, panel buckling, and interlaminar failure, among others. Ren et al. [

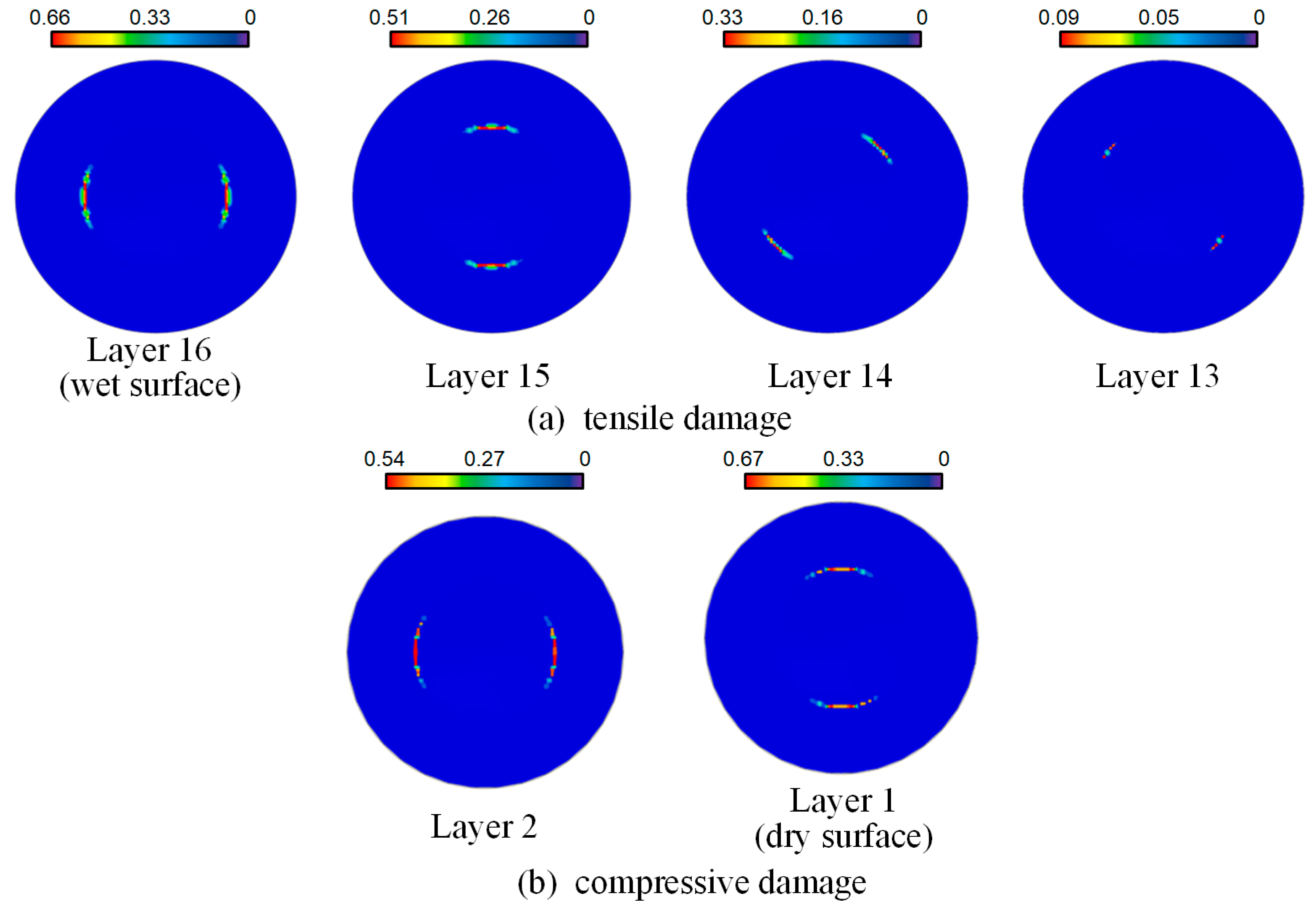

32] conducted experimental research on the dynamic failure behavior of carbon fiber/epoxy laminates under underwater impulsive loading. The results showed that the damage modes of the laminate mainly include matrix cracking, fiber breakage, interlaminar failure, etc. Tao et al. [

33] studied the energy absorption and impact behavior of composite sandwich panels under high-velocity spherical projectile impact. The results indicated that sandwich structures can effectively absorb impact energy, but their energy absorption efficiency is affected by the type of core material and impact velocity. Research [

34] has shown that water-backed composites exhibit higher damage tolerance and localized failure patterns compared to air-backed ones. However, there are still gaps in understanding the detailed failure mechanisms and the influence of various factors such as fiber orientation and stand-off distance. Wang et al. [

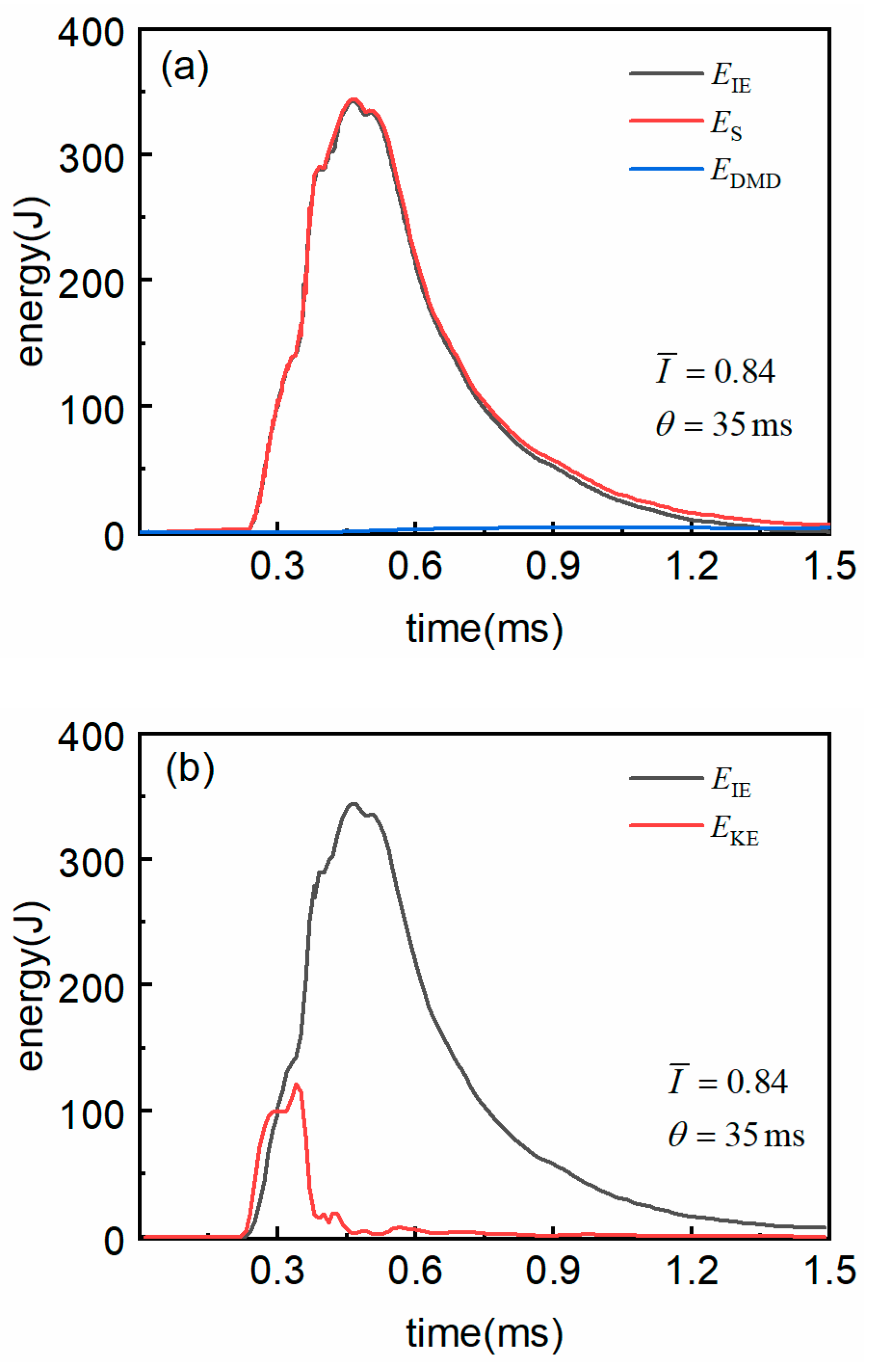

35] examine the dynamic response and failure mechanisms of composite panels under underwater blast loading, focusing on fluid–structure interaction (FSI) effects. The study reveals how FSI influences the dynamic response and failure evolution, providing insights for the blast-resistant design of underwater composite structures. Caldwell et al. [

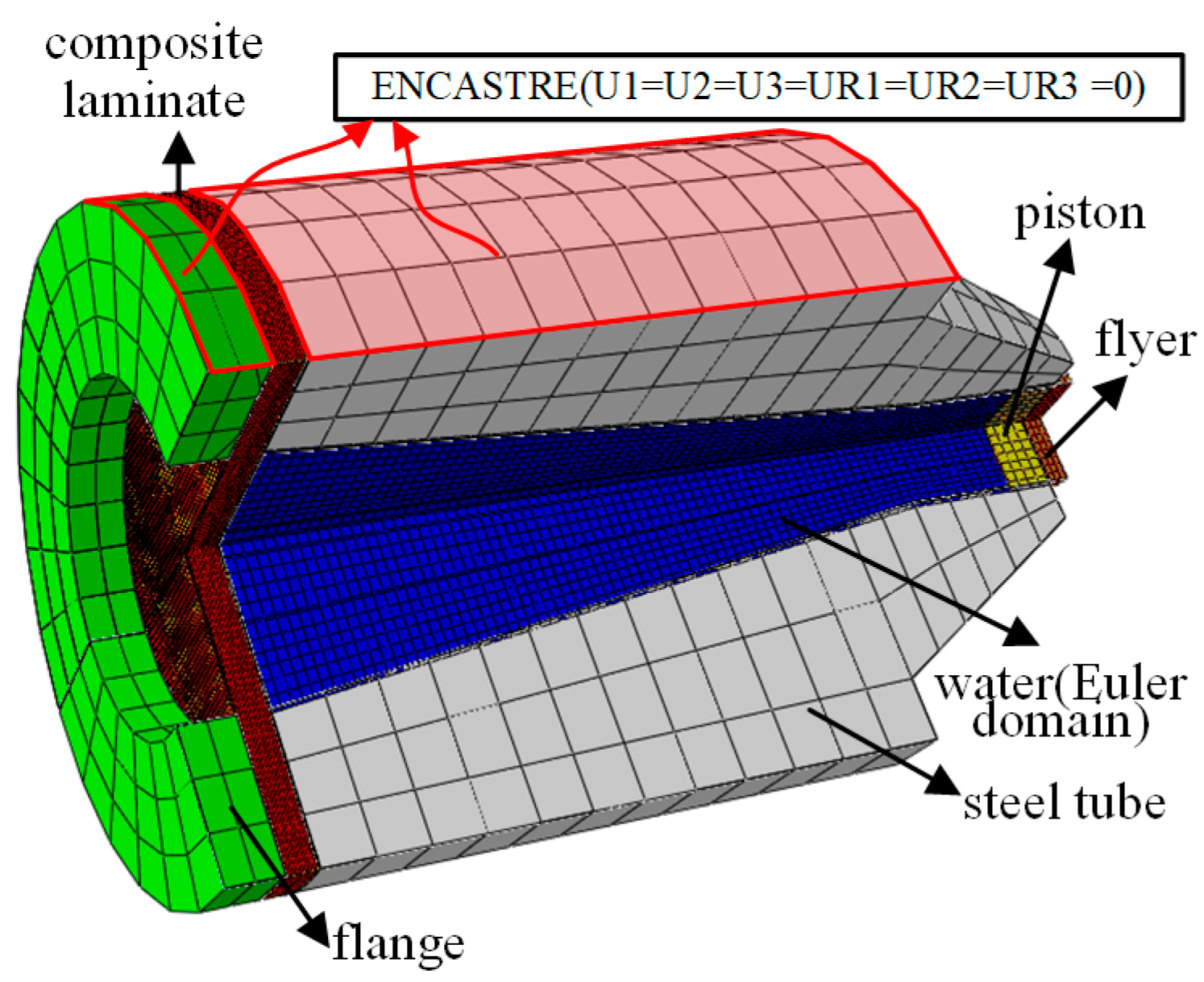

36] explore the dynamic response of marine composite materials under low-velocity impacts in water using a coupled Eulerian–Lagrangian (CEL) numerical model. It investigates the effects of fluid–structure interaction (FSI) on composite laminates’ impact response, revealing that water significantly increases peak impact force and reduces vibration frequency and displacement. The research validates the CEL model against experimental data, paving the way for improved damage-tolerant design of underwater composite structures. Xiang et al. [

37] investigate the effect of stitch density on the impact resistance and compression strength of UHMWPE fiber composites. They found that denser stitching significantly reduces delamination damage and enhances energy absorption. However, excessive stitching can lower the ballistic limit. The research provides valuable insights for optimizing stitch structures in UHMWPE composites. In order to improve the impact resistance of composite structures, researchers have conducted various explorations and prepared carbon fiber laminates and sandwich panels composed of different core layers [

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41]. They studied the deformation and post-impact damage of carbon fiber sandwich structures with different shapes and relative densities under various impact conditions.

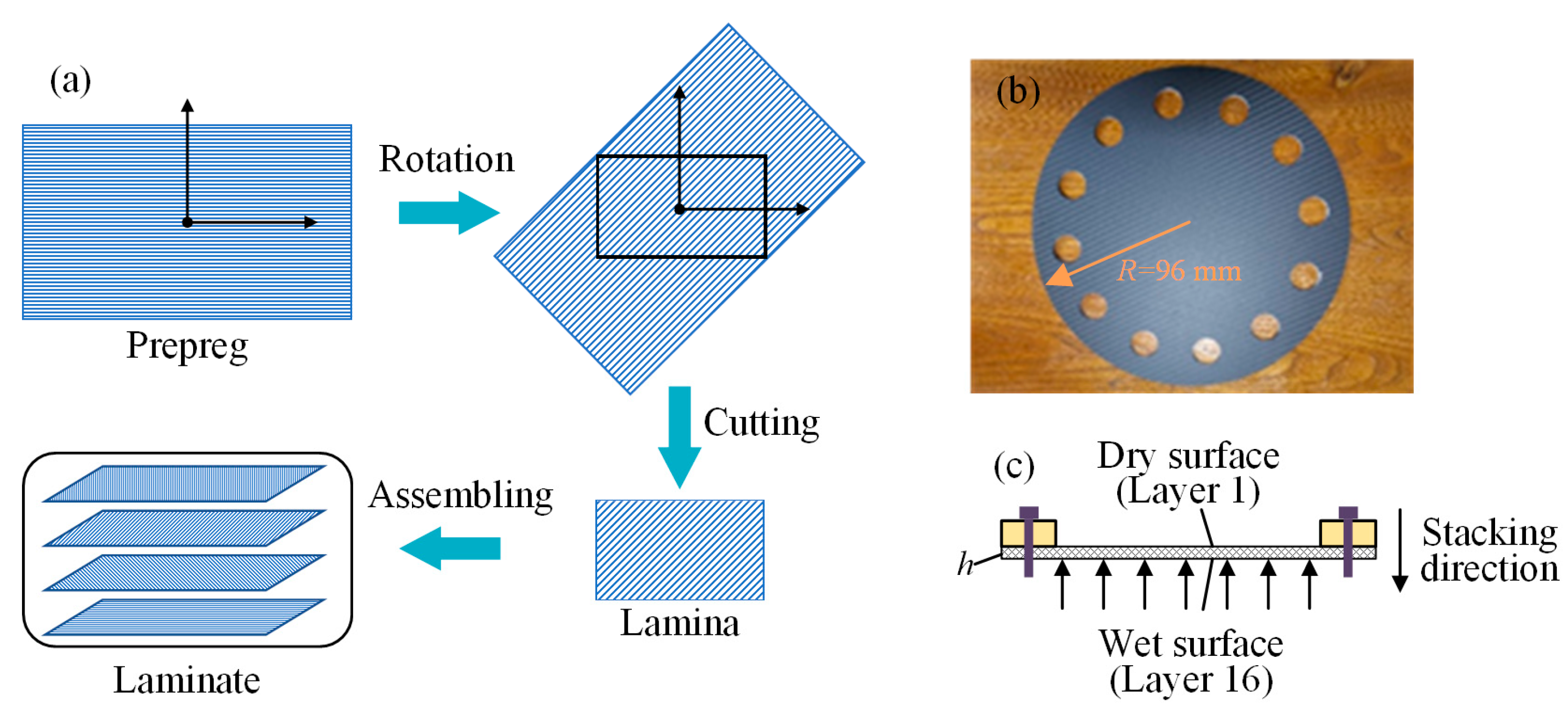

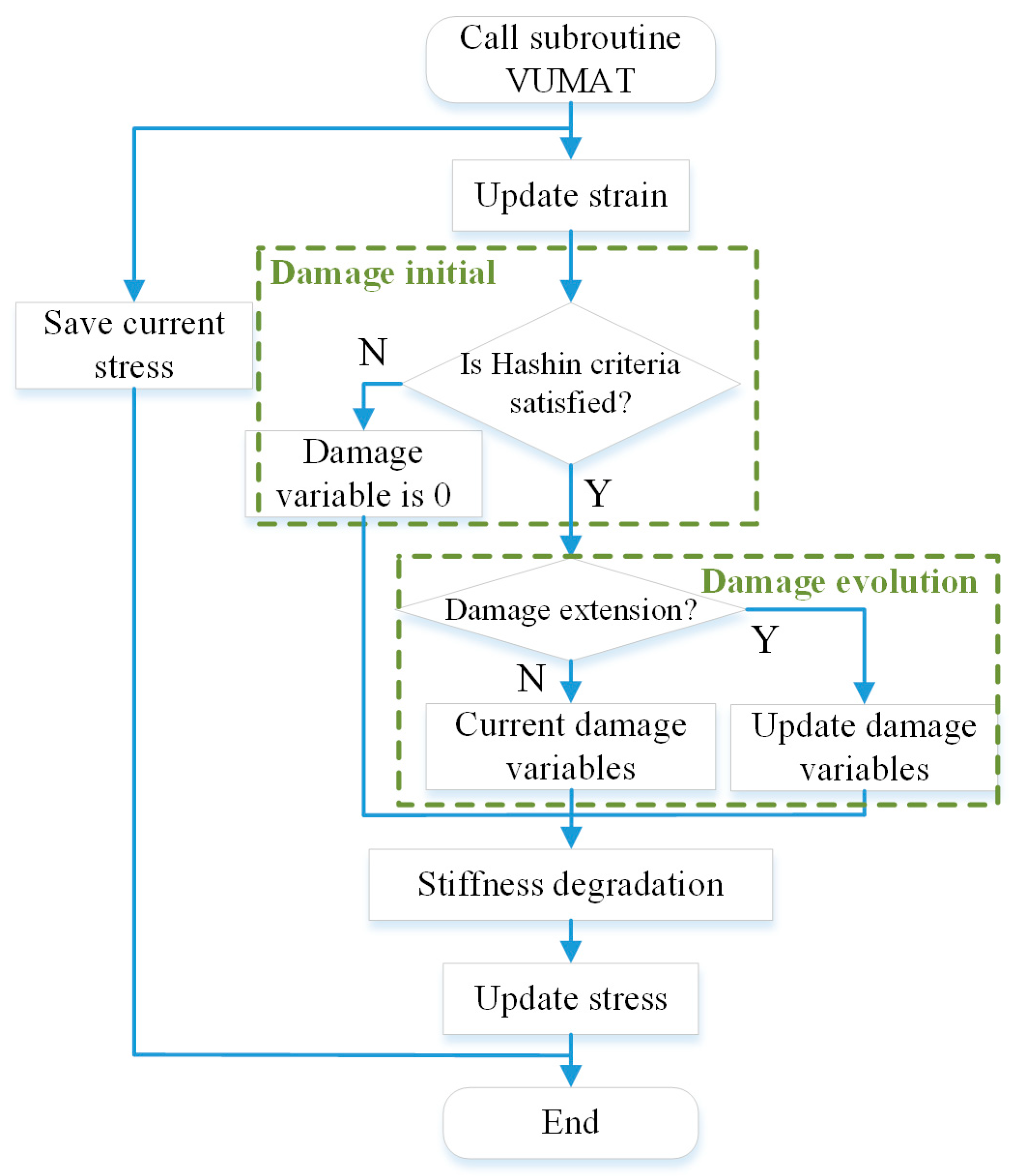

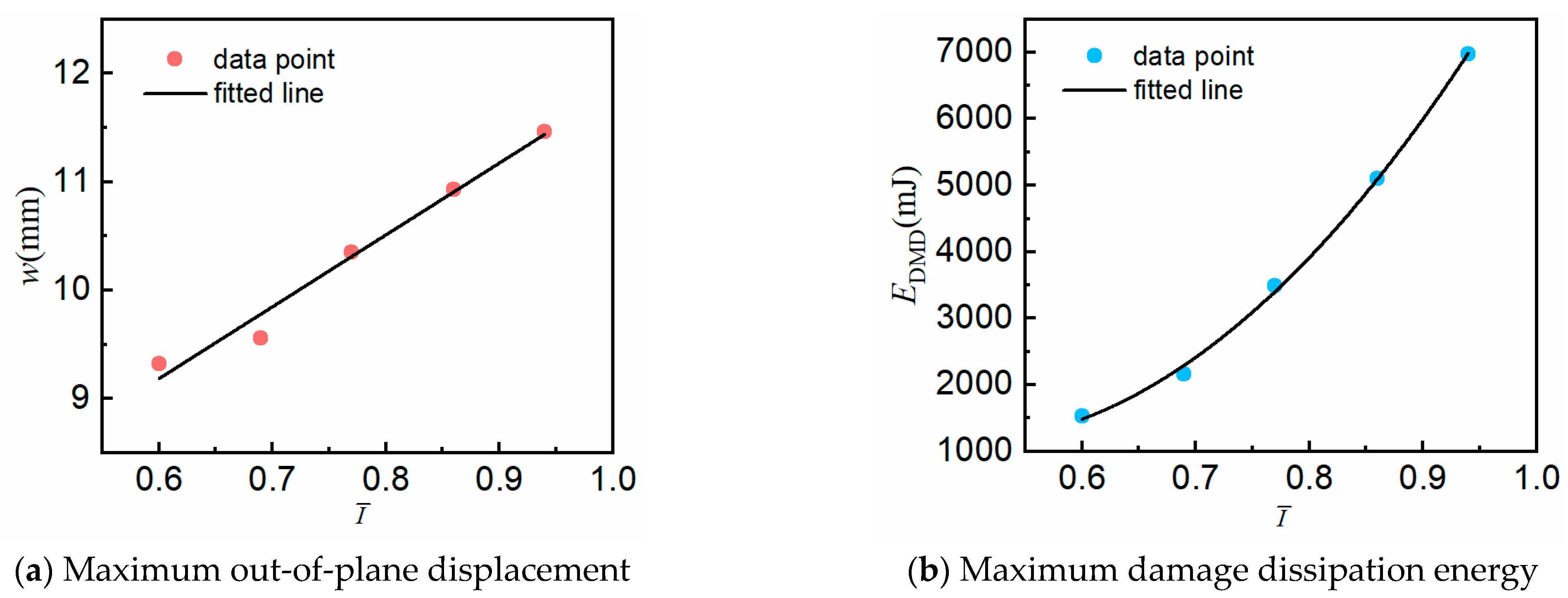

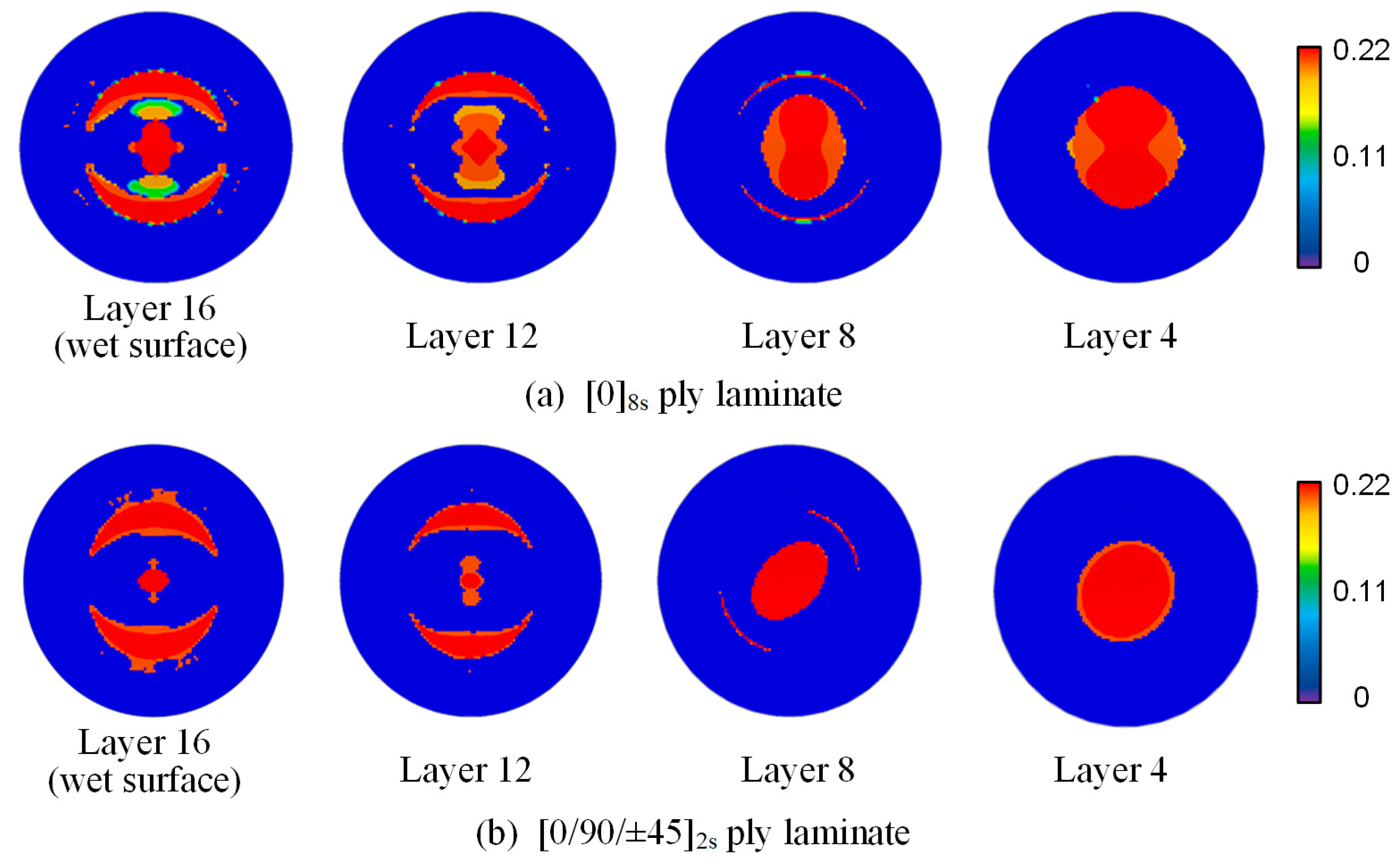

In summary, the dynamic response and damage mechanisms of composite structures under underwater impact loading are complex issues involving various aspects such as material mechanical properties, structural forms, and load characteristics. However, there is still a lack of comparative analysis of their blast resistance and dynamic performance under different anisotropic and load conditions. The purpose of this study is to investigate the dynamic response and damage mechanisms of CFRP composite laminates under underwater shock loading, with a focus on the effects of varying impact intensities, ply orientations, and laminate thicknesses. The specific objectives are to characterize the deformation and failure mechanisms of CFRP composite laminates under underwater shock loading, quantify the damage caused by structural properties and loading rates, and provide design guidelines for optimizing composite laminate configurations to enhance impact resistance and efficiency