Research on Mechanical Behavior of Geogrid–Soil Interface Under Rainfall Infiltration

Abstract

1. Introduction

2. Materials and Methods

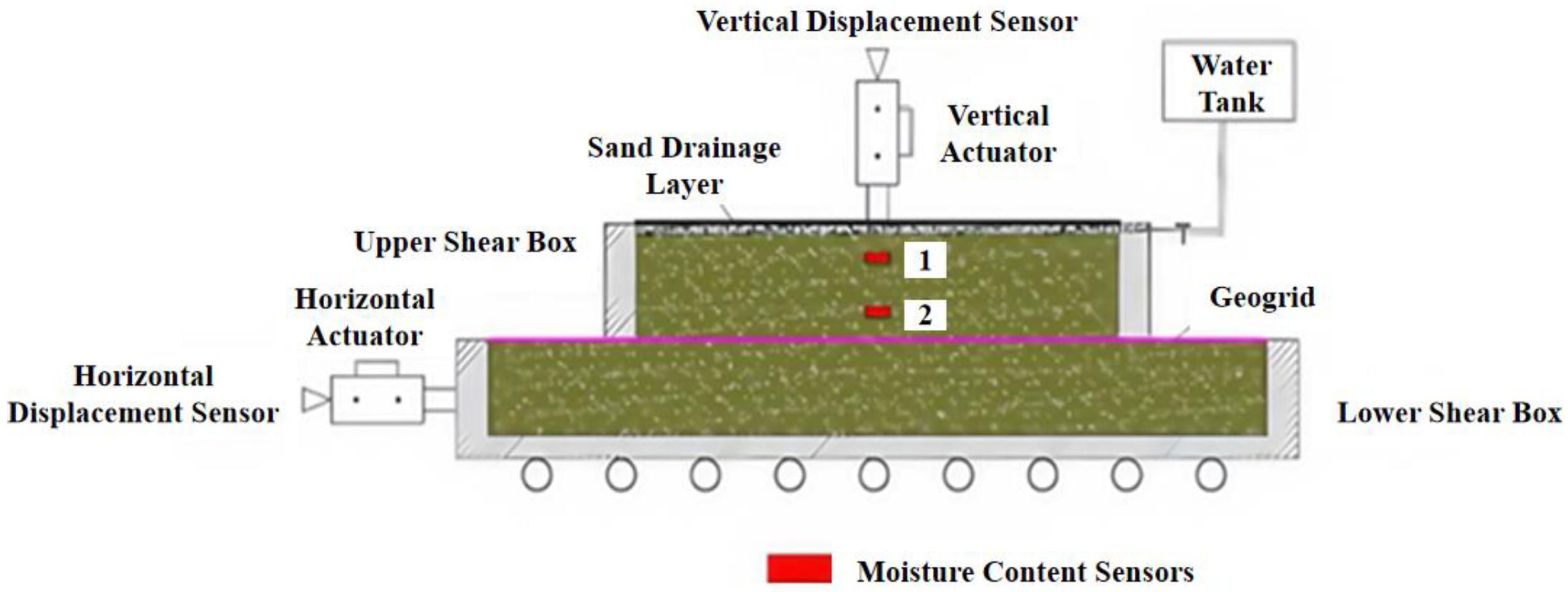

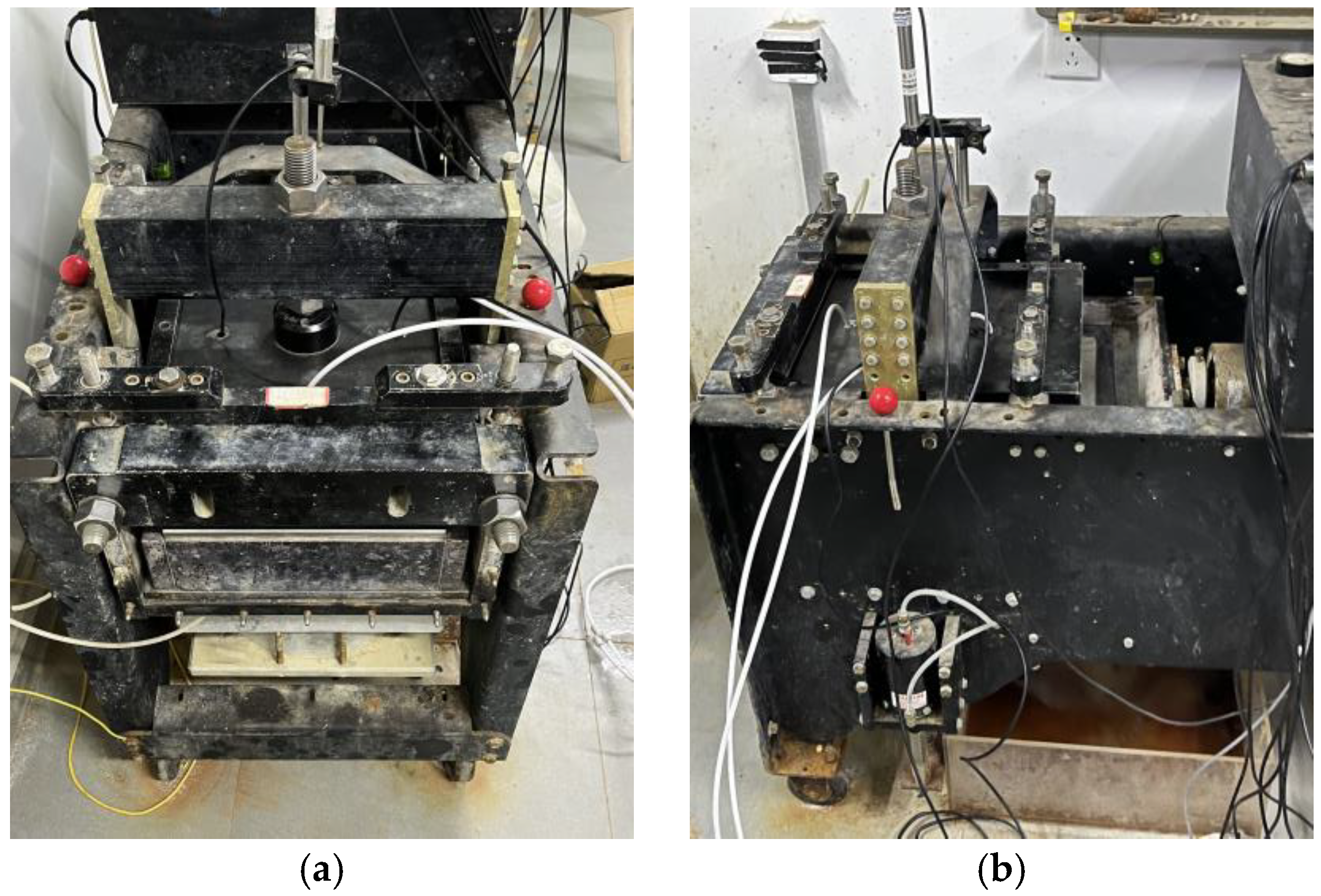

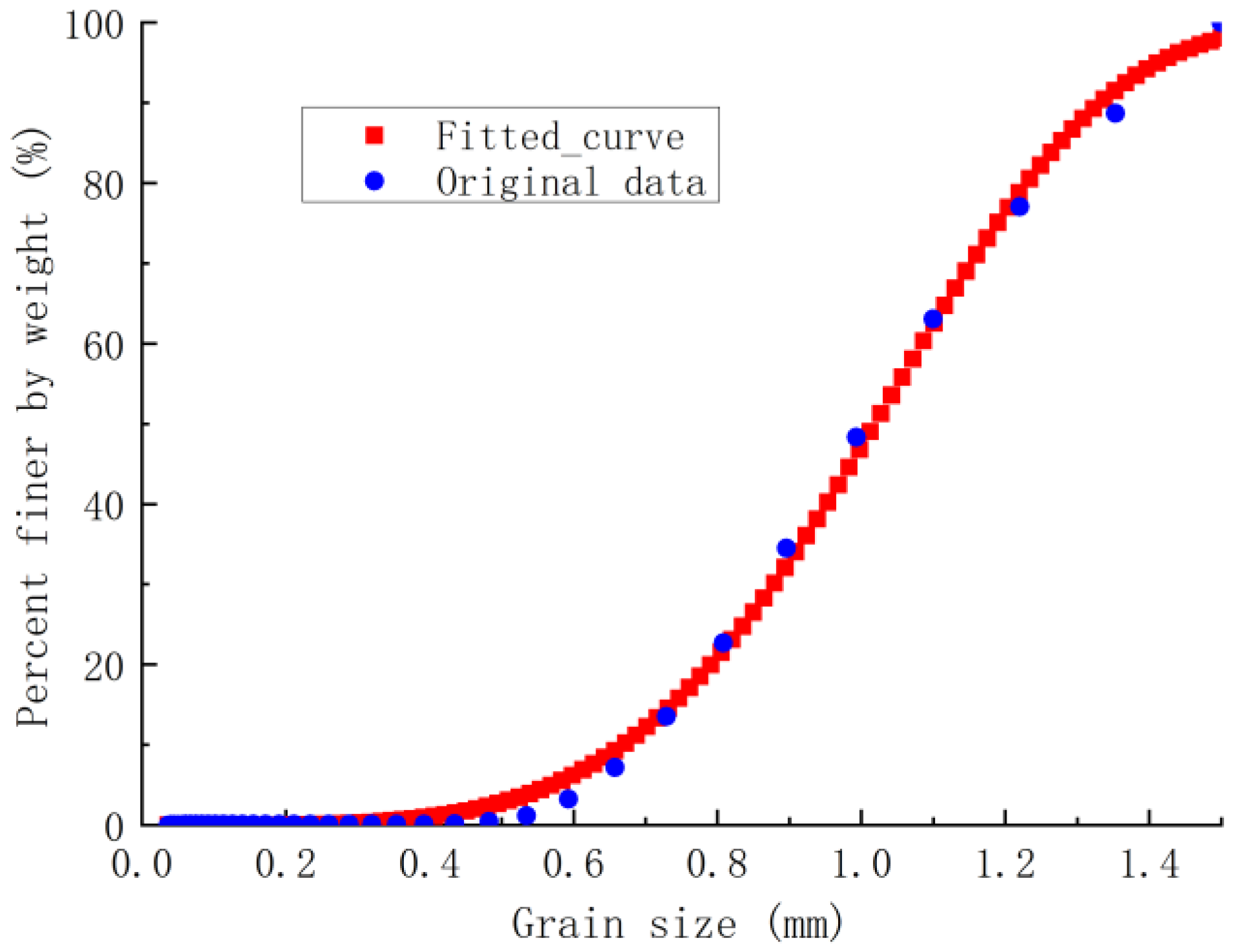

2.1. Apparatus and Materials

2.2. Methods

3. Results and Discussion

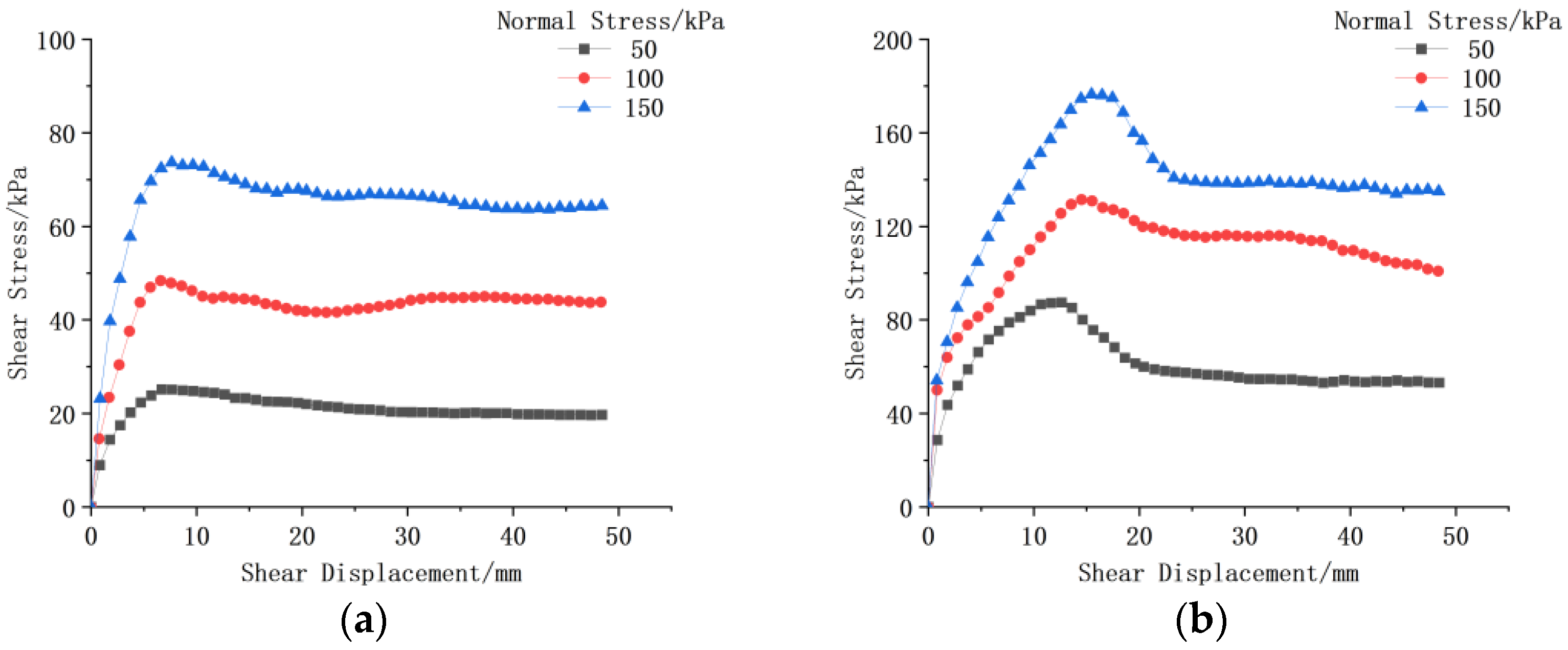

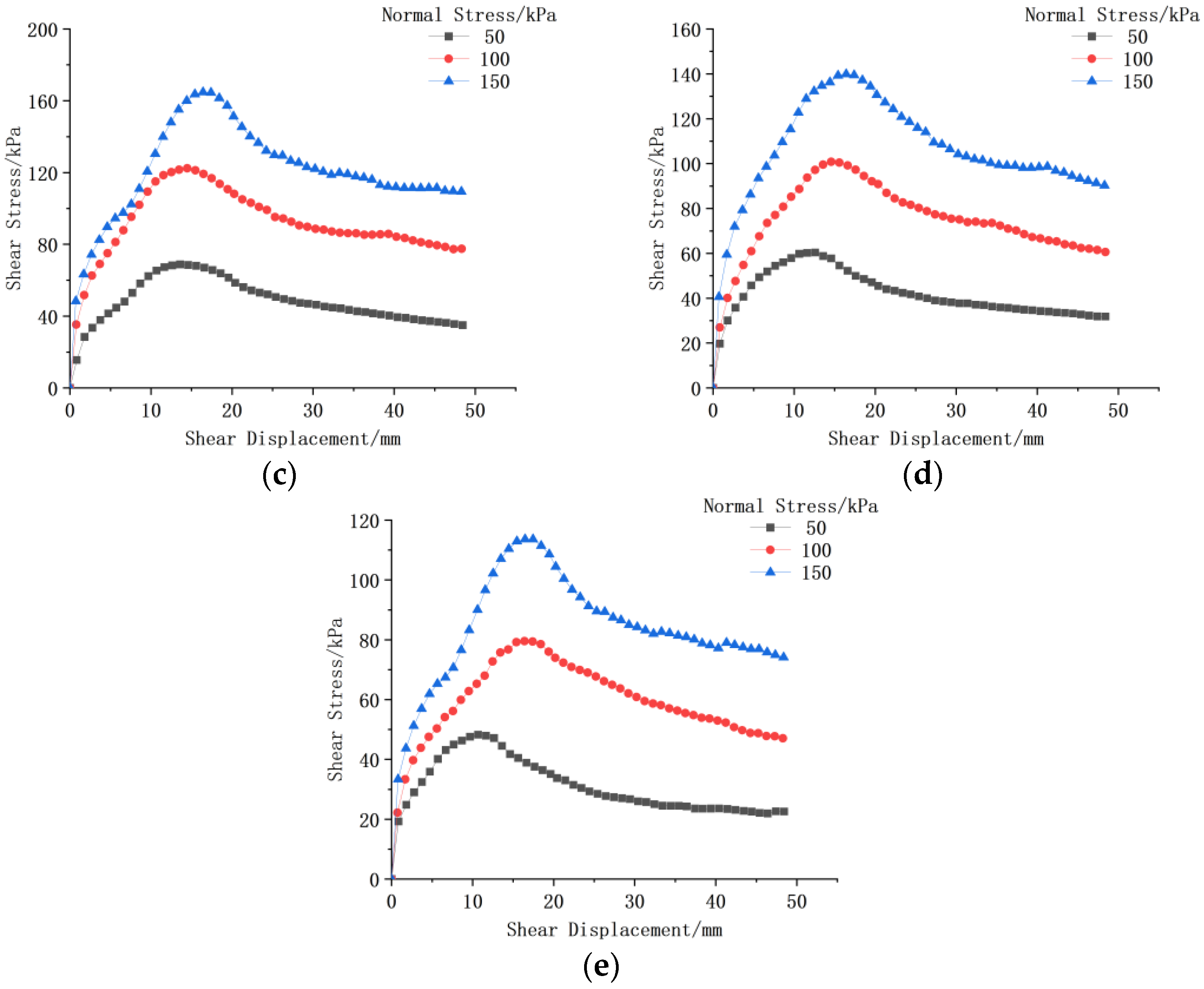

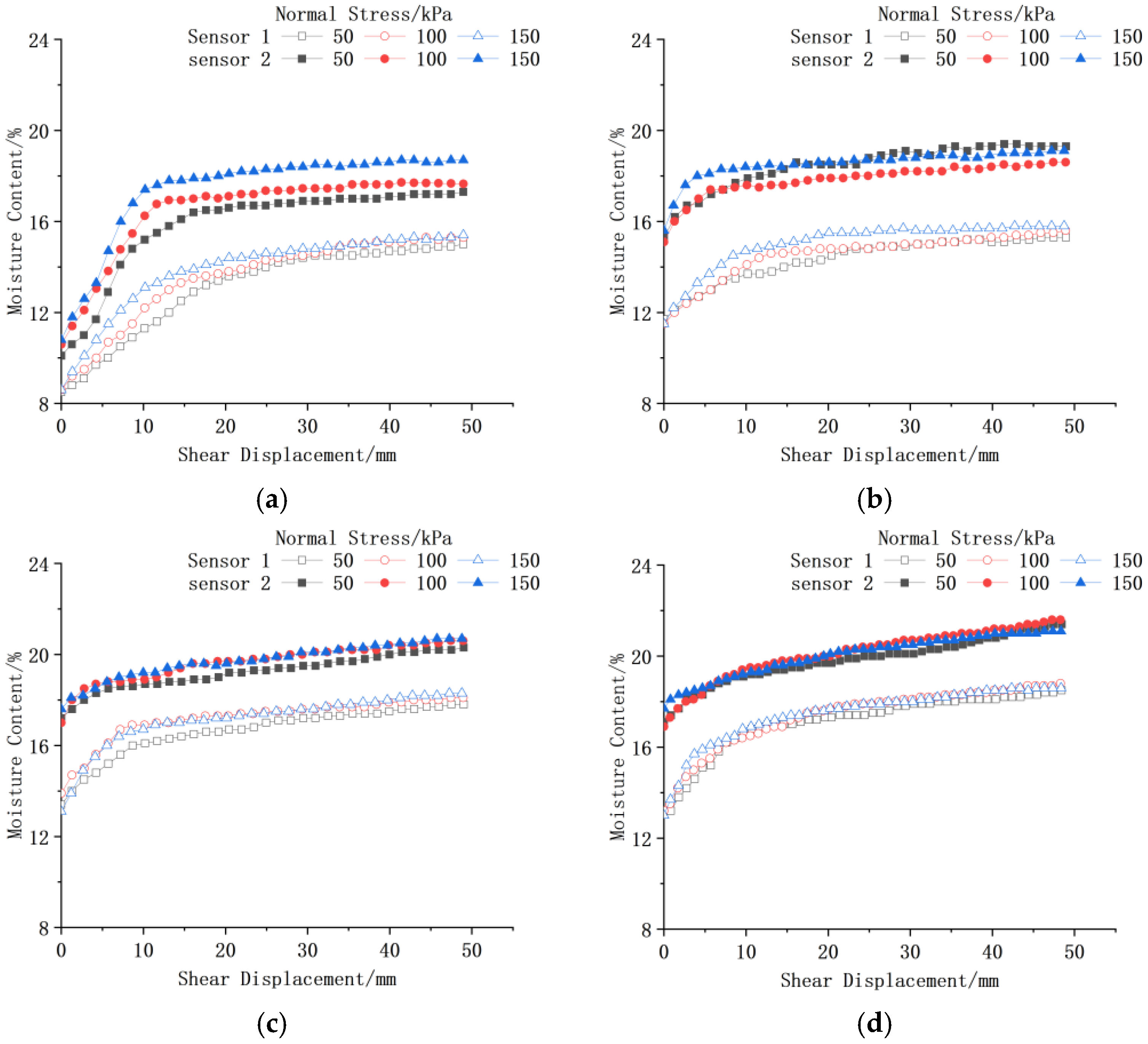

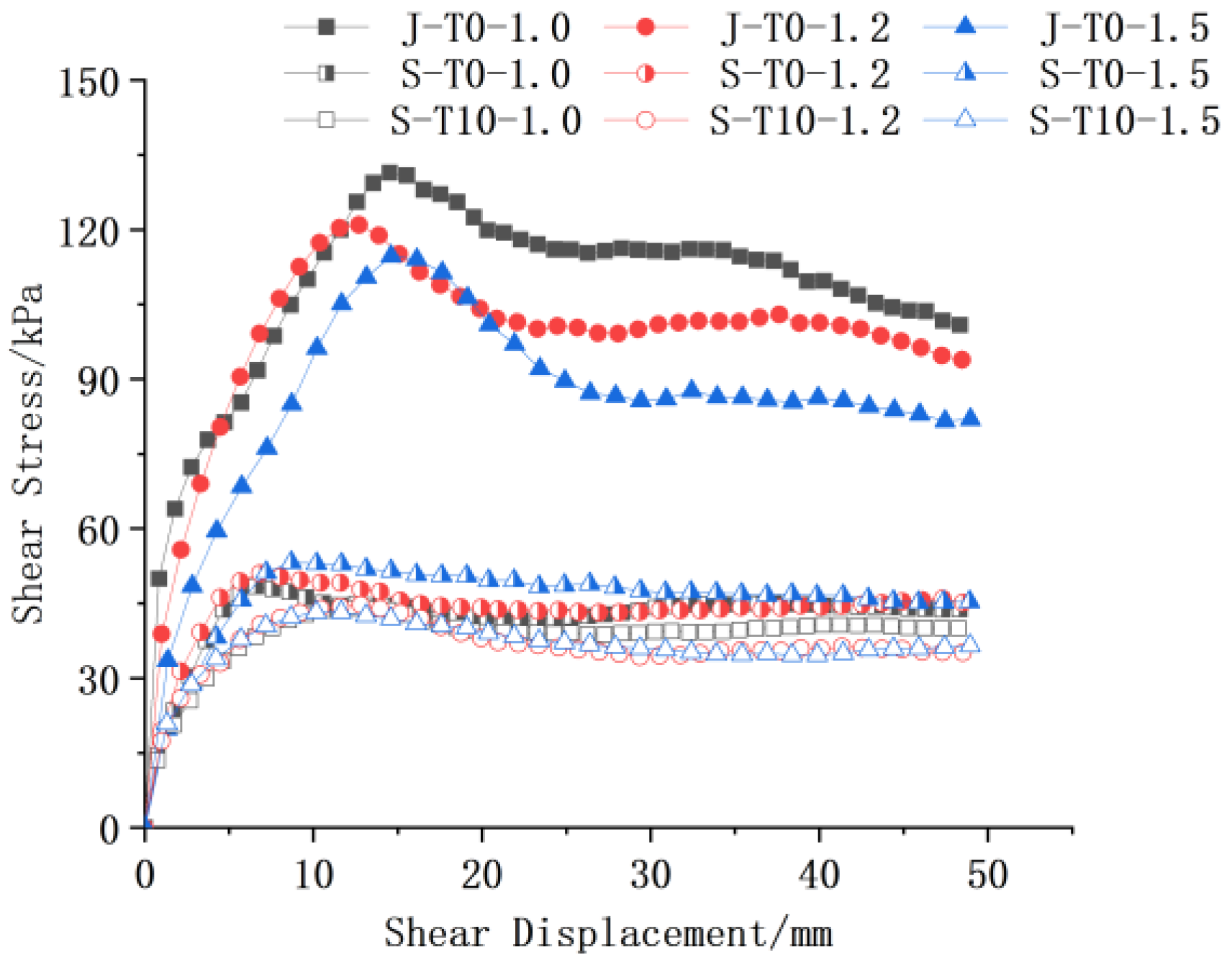

3.1. Effect of Normal Stresses on Geogrid–Soil Interface Characteristics

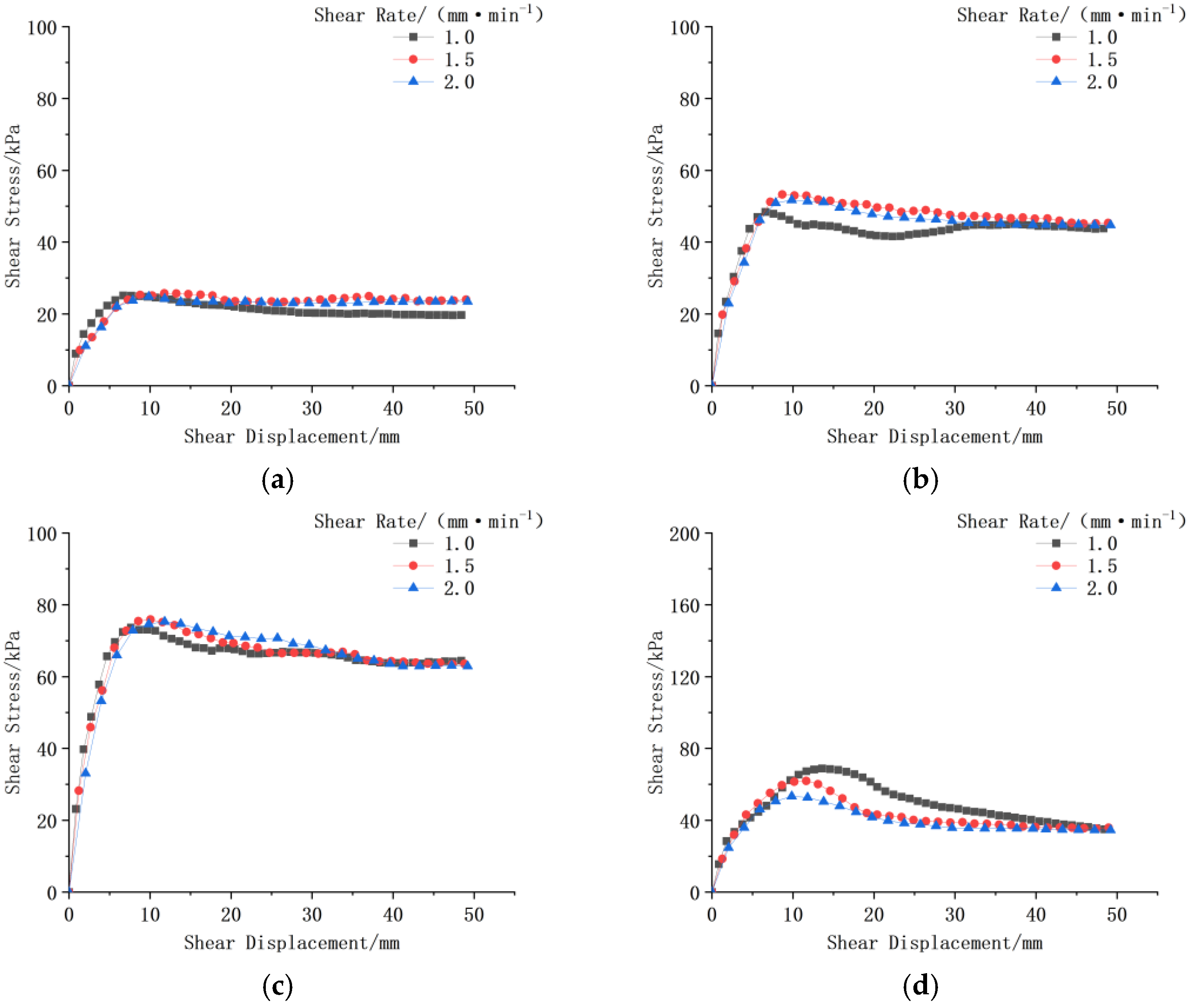

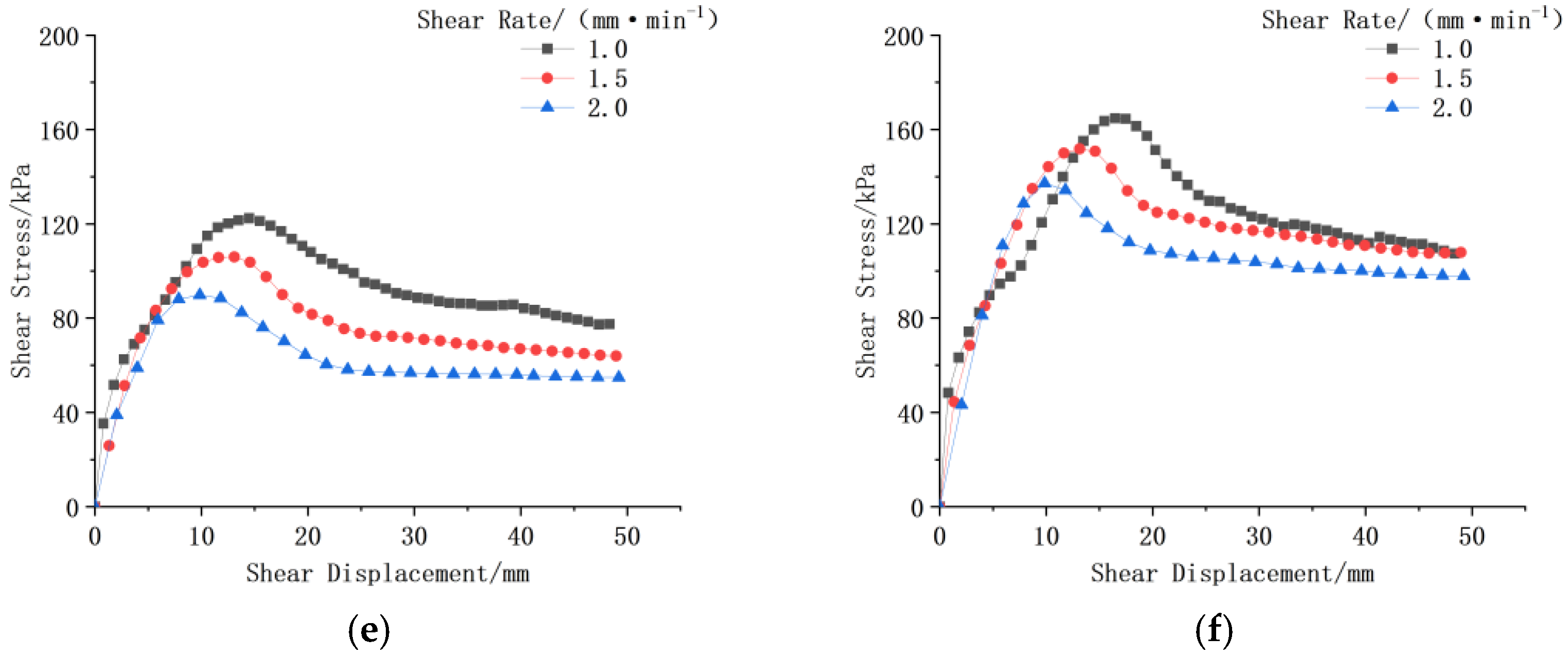

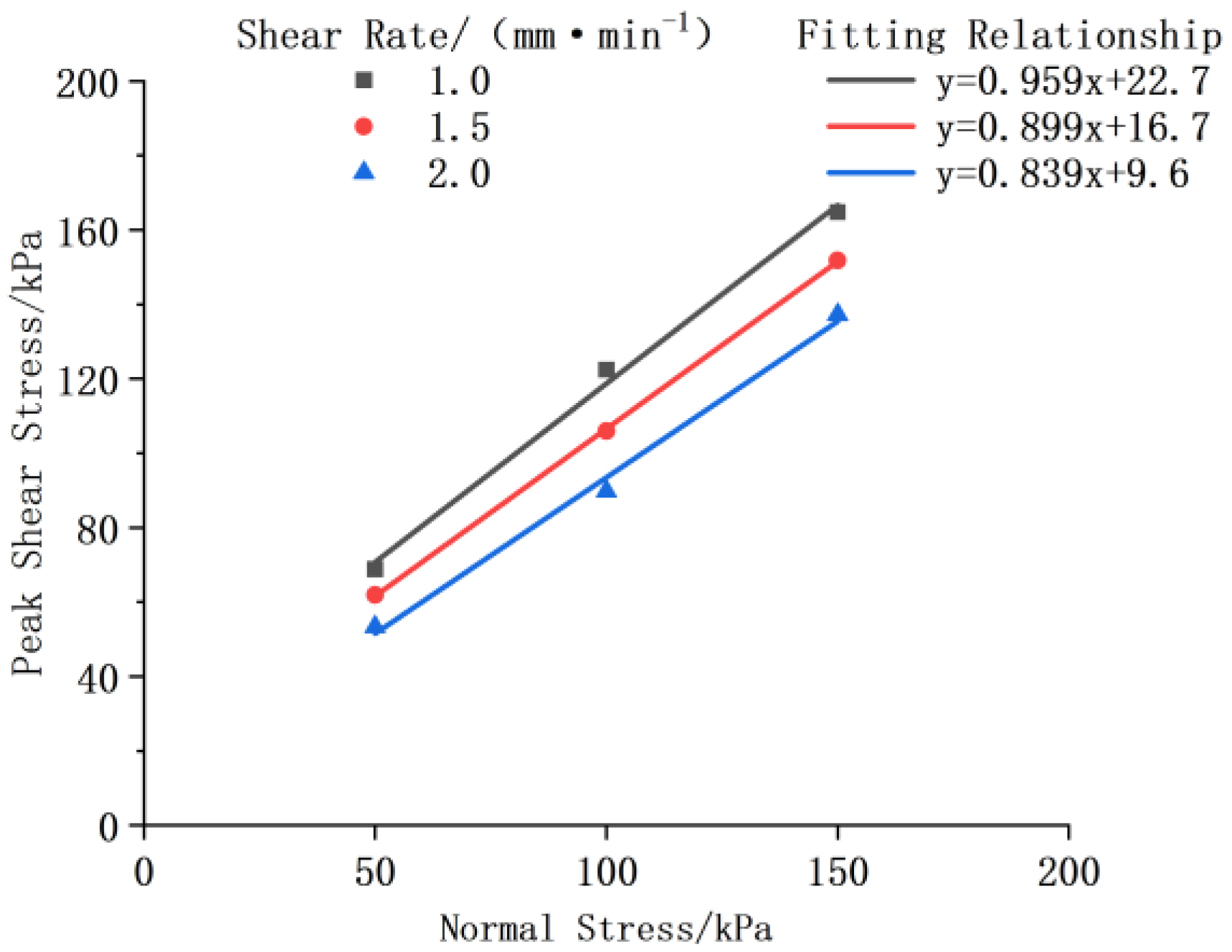

3.2. Effect of Shear Rates on Geogrid–Soil Interface Characteristics

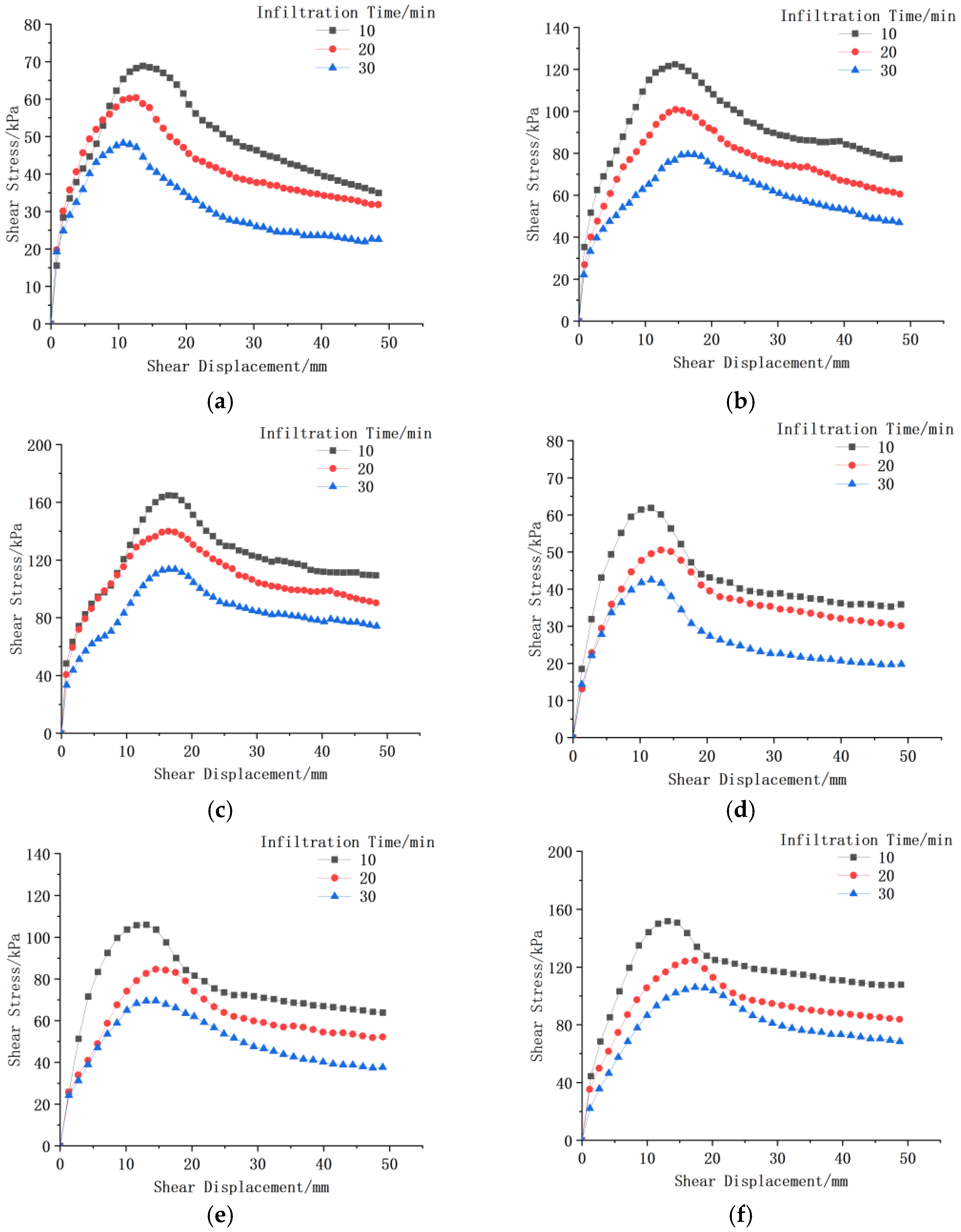

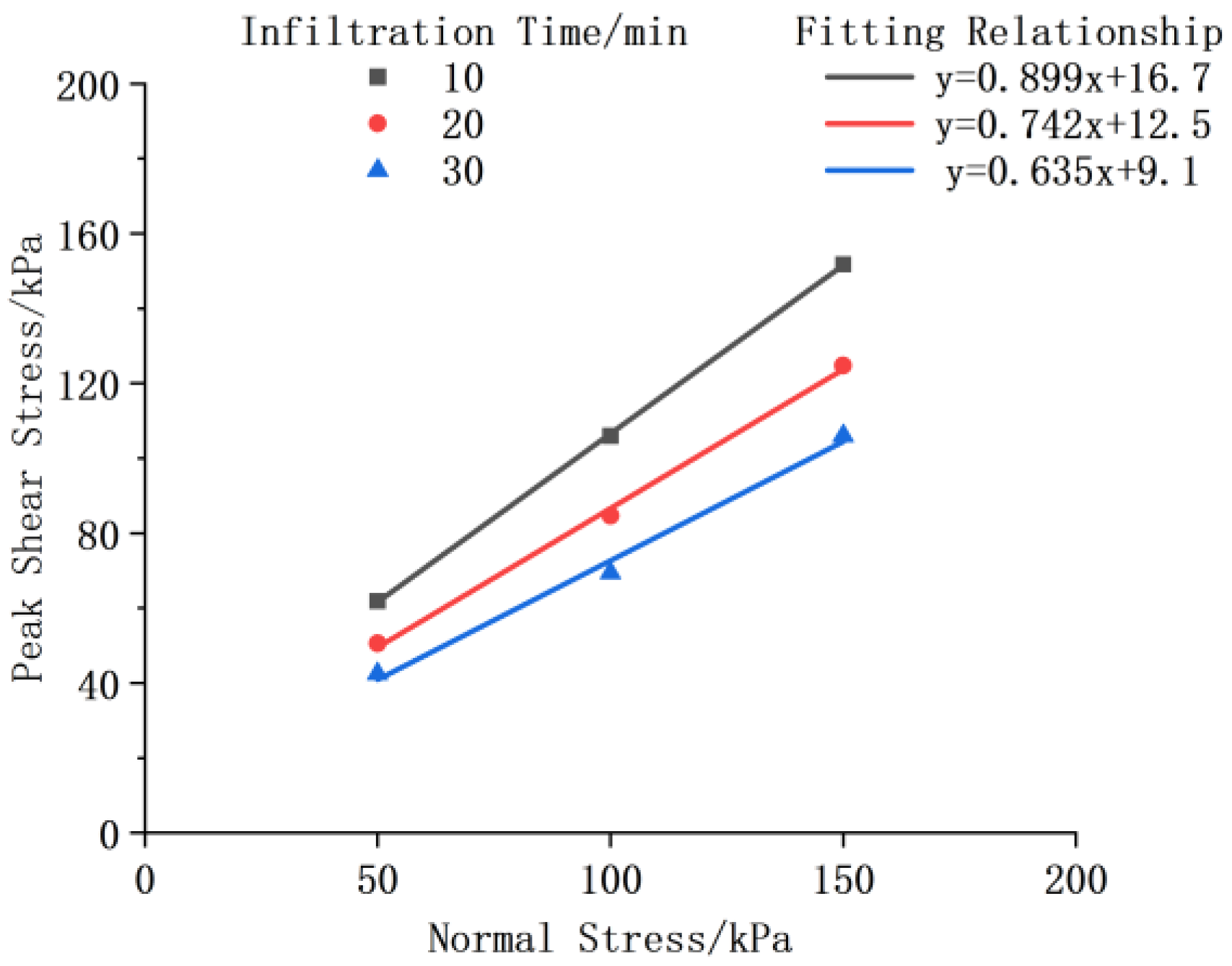

3.3. Effect of Infiltration Time on Geogrid–Soil Interface Characteristics

4. Conclusions

- The normal stress exerts a substantial influence on the shear strength of the geogrid–soil interface, with the shear strength increasing as the normal stress rises. Even in the presence of rainfall infiltration, the soil’s behavior adheres to the Mohr–Coulomb criterion. Consequently, in practical engineering applications, the normal stress at critical locations can be augmented by rationally adjusting the structural configuration or applying external loads. For instance, in the design of the slope of a dam, a suitable increase in the weight at the top of the slope can enhance the normal stress within the soil of the dam slope, thereby improving its shear strength. For the soil affected by rainfall infiltration, careful attention should be paid to the alterations in soil parameters induced by rainfall, and the increased amount of normal stress should be calculated judiciously. In regions with frequent rainfall, a certain safety margin should be reserved and the increased value of normal stress in the design should be appropriately enhanced.

- The impact of shear rates on the shear stress–shear displacement curve of the unreinforced sand is not pronounced, and the variations in shear strengths and shear strength indicators with respect to the shear rates are relatively minor. In contrast, compared to the unreinforced sand, the effect of shear rates on the geogrid reinforced sand is more conspicuous, with its peak shear stresses decreasing as the shear rates increase. Therefore, during the design of structural reinforcement, it is essential to anticipate the potential shear rate scenarios that may occur. For areas where high shear rates are likely to manifest (such as regions where the bottom of the slope is scoured by water flow or near the flood discharge outlet of the dam), reinforcement measures with enhanced resistance to high shear rates should be implemented. For example, selecting geogrid types with superior shear resistance performance and optimizing their laying patterns can mitigate the risk of peak shear stress reduction under high shear rates. In unreinforced sand areas, although the influence of the shear rate is not prominent, considering that long-term rainfall may lead to alterations in the properties of local soil, appropriate attention should still be paid. For example, incorporating drainage facilities into the design can reduce the accumulation of rainwater in the sand and lower the potential shear failure risk associated with the increased moisture content.

- Under the influence of rainfall infiltration, the moisture content of the soil undergoes dynamic changes, gradually increasing with the prolongation of infiltration time. Owing to the constraints of the test conditions and apparatus, the final moisture content tends to stabilize. The increase in moisture content leads to a decline in the peak shear stress at the geogrid–soil interface, accompanied by a reduction in both the friction angle and cohesion. Hence, when designing the drainage system, it is crucial to ensure efficient rainwater drainage to control the soil moisture content. For example, installing multiple layers of drainage pipes in slopes and dams, and rationally designing the spacing and diameter of the pipes can be based on the predicted rainfall intensity, and the soil permeability coefficients can maintain the moisture content of the soil at a relatively low level as much as possible, thereby minimizing the reduction in peak shear stress, friction angle, and cohesion caused by increased moisture content. Additionally, measures such as waterproof cover layers can be considered to curtail rainwater infiltration and thus limit the increase in the soil moisture content. For example, laying waterproof geomembranes on the top of the dam and certain dam slope surfaces can prevent rainwater from directly infiltrating into the dam body soil and can maintain the stability of the mechanical properties of the internal soil.

- In this research, only sand is studied, and only the infiltration time under rainfall conditions is explored. There may be disparities in the relationship between the shear strength and rainfall infiltration time for different soil interfaces, and the rainfall intensity and other rainfall conditions may have varying impacts on the mechanical behavior of the geogrid–soil interface. Therefore, further investigations into the shear strength of other types of soil and different rainfall conditions are warranted.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chothodi, S.; Kuniyil, S.; Patidar, H.; Parmar, K.; Scaria, R.; Mishra, R. Linkages and Reactions of Geomorphic Processes in Kerala Flood, 2018. Nat. Hazards 2024, 120, 5953–5986. [Google Scholar] [CrossRef]

- Susilowati; Kusumastuti, D.I. Hydrometeorological Disaster Mitigation Through Rainfall Intensity Mapping Using IDF in Sumatera Island, Indonesia. IJDNE 2024, 19, 571–579. [Google Scholar] [CrossRef]

- Tang, C.; Li, L.; Xu, N.; Ma, K. Microseismic monitoring and numerical simulation on the stability of high-steep rock slopes in hydropower engineering. J. Rock. Mech. Geotech. Eng. 2015, 7, 493–508. [Google Scholar] [CrossRef]

- Li, J.; Zeng, J.; Huang, G.; Chen, W. Urban Flood Mitigation Strategies with Coupled Gray–Green Measures: A Case Study in Guangzhou City, China. Int. J. Disaster Risk Sci. 2024, 15, 467–479. [Google Scholar] [CrossRef]

- Gebeyehu, A.L.; Manna, B. Recent Design Practice of Reinforced Earth Walls for High-Speed Rail Transportation: A State-of-the-Art and Way Forward. Eng. Sci. Technol. 2024, 55, 101747. [Google Scholar] [CrossRef]

- Ettbeb, A.E.; Rahman, Z.A.; Razi Idris, W.M.; Adam, J.; Rahim, S.A.; Ahmad Tarmidzi, S.N.; Lihan, T. Root Tensile Resistance of Selected Pennisetum Species and Shear Strength of Root-Permeated Soil. Appl. Environ. Soil. Sci. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Boru, Y.T.; Negesa, A.B.; Scaringi, G.; Puła, W. Settlement Analysis of a Sandy Clay Soil Reinforced with Stone Columns. Stud. Geotech. Mech. 2022, 44, 333–342. [Google Scholar] [CrossRef]

- Song, G.; Song, X.; He, S.; Kong, D.; Zhang, S. Soil Reinforcement with Geocells and Vegetation for Ecological Mitigation of Shallow Slope Failure. Sustainability 2022, 14, 11911. [Google Scholar] [CrossRef]

- Morsy, A.M.; Zornberg, J.G.; Leshchinsky, D.; Han, J. Soil–Reinforcement Interaction: Effect of Reinforcement Spacing and Normal Stress. J. Geotech. Geoenvironmental Eng. 2019, 145, 04019115. [Google Scholar] [CrossRef]

- Morsy, A.M.; Zornberg, J.G. Soil-Reinforcement Interaction: Stress Regime Evolution in Geosynthetic-Reinforced Soils. Geotext. Geomembr. 2021, 49, 323–342. [Google Scholar] [CrossRef]

- Evaluation of Direct Shear Tests on Geogrid Reinforced Soil. Available online: https://serdigital.com.br/temp/soilsandrocks/article/1668 (accessed on 6 December 2024).

- Nhema, C.C.; Ke, H.; Ma, P.; Chen, Y.; Zhao, S. The Influence of Discrete Fibers on Mechanical Responses of Reinforced Sand in Direct Shear Tests. Appl. Sci. 2021, 11, 8845. [Google Scholar] [CrossRef]

- Infante, D.J.U.; Martinez, G.M.A.; Arrua, P.A.; Eberhardt, M. Shear Strength Behavior of Different Geosynthetic Reinforced Soil Structure from Direct Shear Test. Int. J. Geosynth. Ground Eng. 2016, 2, 17. [Google Scholar] [CrossRef]

- Makkar, F.M.; Chandrakaran, S.; Sankar, N. Experimental Investigation of Response of Different Granular Soil-3D Geogrid Interfaces Using Large-Scale Direct Shear Tests. J. Mater. Civ. Eng. 2019, 31, 04019012. [Google Scholar] [CrossRef]

- Linhares, R.M.; Mirmoradi, S.H.; Ehrlich, M. Evaluation of the Effect of Surcharge on the Behavior of Geosynthetic-Reinforced Soil Walls. Transp. Geotech. 2021, 31, 100634. [Google Scholar] [CrossRef]

- Liu, F.; Ying, M.; Yuan, G.; Wang, J.; Gao, Z.; Ni, J. Particle Shape Effects on the Cyclic Shear Behaviour of the Soil–Geogrid Interface. Geotext. Geomembr. 2021, 49, 991–1003. [Google Scholar] [CrossRef]

- Ying, M.; Liu, F.; Wang, J.; Wang, C.; Li, M. Coupling Effects of Particle Shape and Cyclic Shear History on Shear Properties of Coarse-Grained Soil–Geogrid Interface. Transp. Geotech. 2021, 27, 100504. [Google Scholar] [CrossRef]

- Liu, F.; Fu, J.; Lu, Y.; Ying, M. Macro and Micro Analyses of Static and Dynamic Shear Characteristics of Geogrid and Rubber–Sand Mixture Interface. Transp. Geotech. 2023, 43, 101119. [Google Scholar] [CrossRef]

- Liu, F.; Ma, K.; Yu, W. Numerical Simulation and Experimental Analysis of Granite Residual Soil-Concrete Interface under Cyclic Shear. Geomech. Eng. 2024, 39, 305–316. [Google Scholar]

- Liu, F.; Gao, C.; Xu, J.; Yang, J. Cyclic Shear Behavior and BoBiLSTM-Based Model for Soil-Rock Mixture-Concrete Interfaces. Constr. Build. Mater. 2024, 426, 136031. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Direct Shear Behaviour of Residual Soil–Geosynthetic Interfaces—Influence of Soil Moisture Content, Soil Density and Geosynthetic Type. Geosynth. Int. 2015, 22, 257–272. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M.; Lopes, M. de L. Recycled Construction and Demolition Wastes as Filling Material for Geosynthetic Reinforced Structures. Interface Properties. J. Clean. Prod. 2016, 124, 299–311. [Google Scholar] [CrossRef]

- Ensani, A.; Razeghi, H.R.; Mamaghanian, J. Effect of Reinforcement Type and Soil Moisture Content on Marginal Soil-Geosynthetic Interactions. Soil. Mech. Found. Eng. 2022, 59, 314–323. [Google Scholar] [CrossRef]

- Namjoo, A.M.; Soltani, F.; Toufigh, V. Effects of Moisture on the Mechanical Behavior of Sand-Geogrid: An Experimental Investigation. Int. J. Geosynth. Ground Eng. 2021, 7, 5. [Google Scholar] [CrossRef]

- JTGE50-2006; Ministry of Transportation of the People’s Republic of China. Test Methods of Geosynthetics for Highway Engineering. China Communications Press: Beijing, China, 2006; pp. 154–196. (In Chinese)

- Ma, T.; Chen, P.; Zhang, Q.; Zhao, J. A Novel Collapse Pressure Model with Mechanical-Chemical Coupling in Shale Gas Formations with Multi-Weakness Planes. J. Nat. Gas. Sci. Eng. 2016, 36, 1151–1177. [Google Scholar] [CrossRef]

- Fu, Y.; Cao, Y.; Kong, J.; Zheng, J.; Mu, J.; Wang, J.; Zhuang, J. The Dynamic Characteristics of Saturated Remolded Loess under Cyclic Load. Earthq. Res. Adv. 2024, 4, 100235. [Google Scholar] [CrossRef]

- Oh, W.T.; Vanapalli, S.K.; Qi, S.; Han, Z. Estimation of the Variation of Matric Suction with Respect to Depth in a Vertical Unsaturated Soil Trench Associated with Rainfall Infiltration. E3S Web Conf. 2016, 9, 15003. [Google Scholar] [CrossRef]

- Liu, H.; Han, J.; Al-Naddaf, M.; Parsons, R.L.; Kakrasul, J.I. Field Monitoring of Wicking Geotextile to Reduce Soil Moisture under a Concrete Pavement Subjected to Precipitations and Temperature Variations. Geotext. Geomembr. 2022, 50, 1004–1019. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Ksinopoulou, E.; Eleftheriou, V. Evaluation of Mortar Mix Designs for the Conservation of the Acropolis Monuments. J. Cult. Herit. 2022, 55, 300–308. [Google Scholar] [CrossRef]

- Zhang, S.; Leng, X.; Zhang, Z. Study on The Mechanism of Deformation and Failure of Expansive Rock and Soil Slope. In Proceedings of the Conference Proceedings of the 8th International Symposium on Project Management, China (ISPM2020), Beijing, China, 4 July 2022. [Google Scholar]

| Upper Shear Box Dimension/mm | Lower Shear Box Dimension/mm | Load Range/kN | Maximum Displacement/mm | Measurement Accuracy/% | ||

|---|---|---|---|---|---|---|

| Horizontal | Vertical | Horizontal | Vertical | |||

| 305 × 305 × 100 | 405 × 305 × 100 | 45 | 45 | 100 | 50 | 0.25 |

| Specimen | Grain Size/mm | Maximum Void Ratio (emax) | Minimum Void Ratio (emin) | Specific Gravity (Gs) | Coefficient of Uniformity (Cu) | Coefficient of Curvature (Cc) | ||

|---|---|---|---|---|---|---|---|---|

| D10 | D30 | D60 | ||||||

| Quartz sand | 0.67 | 0.88 | 1.08 | 0.77 | 0.51 | 2.65 | 1.61 | 1.07 |

| Type of Test | Reinforced or Not | Intensity of Rainfall/(mm·h−1) | Infiltration Time/min | Normal Stress/kPa | Shear Rate/(mm·min−1) |

|---|---|---|---|---|---|

| Monotonic direct shear test * | Unreinforced sand | 0 | 0 | 50, 100, 150 | 1.0, 1.2, 1.5, 2.0 |

| 120 | 10 | 100 | 1.0, 1.2, 1.5 | ||

| Geogrid reinforced sand | 0 | 0 | 50 100 150 | 1.0 1.0, 1.2, 1.5 1.0 | |

| 120 | 10 | 50, 100, 150 | 1.0, 1.5, 2.0 | ||

| 20 | 50, 100, 150 | 1.0, 1.5 | |||

| 30 | 50 100 150 | 1.0, 1.5 1.0, 1.2, 1.5 1.0, 1.5 |

| Shear Rate/(mm·min−1) | Strength Index | Fitting Relationship | ||

|---|---|---|---|---|

| Cohesion (c)/kPa | Friction Angle (φ)/° | Correlation Coefficient (R2) | ||

| 1.0 | 22.7 | 43.8 | 0.995 | y = 0.959x + 22.7 |

| 1.5 | 16.7 | 42.0 | 0.999 | y = 0.899x + 16.7 |

| 2.0 | 9.6 | 40.0 | 0.994 | y = 0.839x + 9.6 |

| Infiltration Time/min | Strength Index | Fitting Relationship | ||

|---|---|---|---|---|

| Cohesion (c)/kPa | Friction Angle (φ)/° | Correlation Coefficient (R2) | ||

| 10 | 16.7 | 42.0 | 0.999 | y = 0.899x + 16.7 |

| 20 | 12.5 | 36.6 | 0.998 | y = 0.742x + 12.5 |

| 30 | 9.1 | 32.4 | 0.992 | y = 0.635x + 9.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.; Wang, Y. Research on Mechanical Behavior of Geogrid–Soil Interface Under Rainfall Infiltration. Appl. Sci. 2025, 15, 705. https://doi.org/10.3390/app15020705

Lin Y, Wang Y. Research on Mechanical Behavior of Geogrid–Soil Interface Under Rainfall Infiltration. Applied Sciences. 2025; 15(2):705. https://doi.org/10.3390/app15020705

Chicago/Turabian StyleLin, Yongliang, and Yingying Wang. 2025. "Research on Mechanical Behavior of Geogrid–Soil Interface Under Rainfall Infiltration" Applied Sciences 15, no. 2: 705. https://doi.org/10.3390/app15020705

APA StyleLin, Y., & Wang, Y. (2025). Research on Mechanical Behavior of Geogrid–Soil Interface Under Rainfall Infiltration. Applied Sciences, 15(2), 705. https://doi.org/10.3390/app15020705