Abstract

The rehabilitation of heritage steel bridges raises specific challenges due to their historical significance and structural complexity. These structures, often subjected to ageing, corrosion, and insufficient documentation, require specialized approaches that balance preservation with modern infrastructure demands. In this context, digitalization offers a transformative pathway, enabling more precise maintenance planning, enhanced decision-making, and better alignment with sustainability goals, with Building Information Modelling (BIM) fostering seamless information transfer and integration across project lifecycle. This paper highlights the potential of BIM in predictive maintenance, resource optimization, and strategic rehabilitation planning. It proposes a structured approach for defining and implementing information requirements (IRs), ensuring alignment between organizational objectives, asset-level needs, and project-specific deliverables. A significant contribution of this research is the development of a template for information delivery specification (IDS), providing a robust framework for data exchange and quality control throughout project phases. The IDS supports the integration of technical and historical data into a centralized digital repository, addressing both operational and heritage preservation needs. Finally, the article discusses structural assessment and strengthening strategies within the BIM workflow, emphasizing their role in achieving efficient and sustainable bridge rehabilitation.

1. Introduction

Transportation infrastructure is the cornerstone of economic growth, national security, and social well-being. Its reliability and safety in use directly impact the movement of goods and people, fueling economic prosperity and societal development. However, as these systems age, while the mobility demand grows, maintaining and rehabilitating transportation networks becomes a critical challenge, driving the need for innovative, efficient, and cost-effective solutions.

Unlike buildings, transportation infrastructure, comprising roadways, utilities, and environmental assets, is inherently expansive and interconnected [1]. Three out of five domains within transportation infrastructure are characterized by a mesh network of assets, where longitudinal structures like roads, railways, and pipelines connect point structures such as bridges and intersections. This unique configuration generates significant differences in project breakdown structures compared to building projects. The expansive size of transportation networks necessitates greater reliance on Geographic Information Systems (GISs) to effectively map, monitor, and manage these assets. When integrated with Building Information Modelling (BIM), GISs can support the development of a powerful framework that can be employed to comprehensively address the challenges of infrastructure management. As shown in recent studies [2,3,4], the convergence of BIM and GISs facilitates the integration of non-graphical data (current condition assessment and maintenance schedules) into project models, enabling a holistic understanding of infrastructure assets like bridges and optimizing their lifecycle management.

BIM can be seen as focusing on detailed, component-level design and data management, while GISs can be used for spatial analysis and geospatial data visualization. The integration of these systems closes the gap between localized design information and broader geographical context, allowing stakeholders to monitor and manage infrastructure more effectively. Moreover, this integration enhances decision-making by streamlining data flow between design, construction, and operational phases, as GISs can provide critical environmental and geographical data (e.g., flood zones or seismic activity regions), which, in turn, can inform bridge design and material selection in BIM. Conversely, BIM’s detailed structural models can be layered onto GIS maps, offering a comprehensive view of how individual assets interact within a larger transportation network.

Furthermore, data structures in transportation projects are more varied and interconnected, requiring a strong focus on integrating diverse information sources. This requirement is paramount for collaborative teams, often larger and more complex, to be able to account for the expansive scope of transportation projects.

A key component of road infrastructure is represented by bridges. Emerging in the late 18th century with the construction of the Iron Bridge in Coalbrookdale, steel structures have evolved through distinct phases—cast iron, wrought iron, and mild steel, with the latter becoming dominant. For Europe, a significant role in this evolution was played by Romania, with its steel industry taking root in the 18th century. By the second half of the 19th century, the Austrian Railways Company, STEG, had introduced modern steel production technologies in the western region of Romania, at Reșița (Reschitza). The riveted steel bridges produced here stand as an innovative testament to the industrial revolution. This period noy only saw advancements in steel elaboration methods but also a broader recognition of steel’s potential use in infrastructure, paving the way for the widespread use of this material. Recognizing that no structure is built to last indefinitely, developed societies have embraced the importance of maintaining architectural heritage to preserve cultural identity while ensuring functional infrastructure. Aligned with this, the rehabilitation of heritage steel bridges has become a cornerstone of sustainable development and cultural preservation. Furthermore, refurbishing these structures aligns with the principles of sustainability by reducing the need for new materials and construction, limiting CO2 emissions while retaining historical and aesthetic value.

To address the pressing challenges of ageing structures and enable better decision-making, while also accounting for multidimensional complexity, advanced technologies are being increasingly integrated into infrastructure management. Among these, Building Information Modelling (BIM) has emerged as a revolutionary digital process, transforming the way we approach design, construction, and rehabilitation. It facilitates the definition of information requirements and the creation, management, and exchange of detailed digital representations of the physical and functional characteristics of assets throughout their lifecycles. By enhancing efficiency in project development and implementation and by fostering collaboration, BIM offers a robust solution for streamlining the information flow during the rehabilitation of heritage steel bridges, supporting cultural heritage preservation and sustainable development.

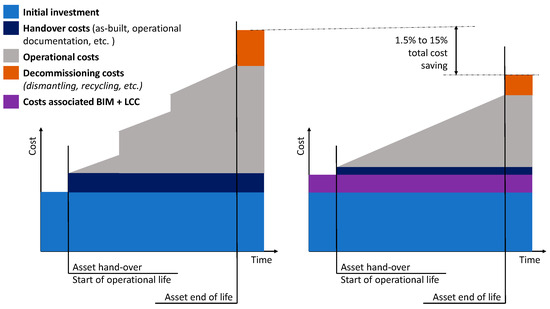

Despite its success in the building sector, the adoption of BIM in transportation infrastructure has been slower and less uniform [5]. Authorities, industry, and academia alike are increasingly focusing on the implementation of BIM in non-building civil infrastructure, including bridges, tunnels, and railways. However, much of this effort lacks a structured framework tailored specifically to the unique challenges and requirements of transportation systems. Currently, there is a notable gap in the development of BIM workflows for the rehabilitation of ageing transportation infrastructure, especially steel bridges, which form a critical subset of these systems. Addressing this gap requires an understanding of both the initial costs, i.e., operational and maintenance costs, together with the substantial long-term benefits of implementing a BIM workflow. While the upfront investment in BIM may appear significant during initial project phases (i.e., current estimations brings BIM use within projects to the level of design costs), research consistently shows that the long-term benefits far surpass these costs, often leading to savings ranging from 1.5% to 15% [6], with a 5% to 9% [7] cost reduction seen during the construction phase alone due to reduced change orders and rework. Additionally, BIM workflows enable the incorporation of lifecycle cost (LCC) considerations into the design phase, adding significant value. This approach enables a thorough analysis of costs throughout the asset’s lifecycle, spanning from planning, design, material selection, construction, operation, and maintenance to eventual decommissioning. LCC integration within the BIM workflow supports informed decision-making, optimizing outcomes in terms of both cost and performance. For instance, prioritizing durable, corrosion-resistant materials might increase upfront expenses but drastically reduces maintenance needs and repair costs over time. Additionally, designing with ease of access for inspections, enabled by 3D modelling and providing special consideration for soft collisions, simplifies routine maintenance, cutting labour and equipment expenses.

Figure 1 (an adaptation of the LCC concept [8]) illustrates two contrasting approaches to project cost management over the lifecycle of an asset. The graph on the left represents the scenario where sharp cost increases occur due to unplanned rehabilitation interventions and repairs, while the graph on the right demonstrates a smoother, more predictable distribution of costs stemming from a planned and proactive lifecycle asset management. The unexpected spikes in costs shown on the left will likely result from reactive maintenance strategies, where issues are addressed only after they arise. This approach often leads to higher expenditures in the form of emergency repairs, operational disruptions, and potentially large-scale replacements that could have been avoided with earlier, planned intervention. Such unplanned costs strain budgets, disrupt operational schedules, and can compromise the asset’s performance and safety over time. In addition, each intervention usually includes an asset down-time, with traffic stops, deviations or, at least, restrictions. In contrast, the right-hand side reflects a strategic approach, where costs are evenly distributed over the asset’s lifecycle. Planned maintenance, informed by LCC considerations and a clear information flow enabled by the BIM process, allows for the early identification and mitigation of potential issues. Such proactive strategies (i.e., the use of more durable materials, the implementation of advanced monitoring technologies coupled with a clear schedule of regular inspections) ensure long-term financial predictability, asset reliability, and operational safety.

Figure 1.

Life-cycle costs.

The comparison presented in Figure 1 highlights the critical role of integrating lifecycle management principles into project planning and execution, supported by a robust information management system i.e., BIM-enabled LCC. A proactive strategy can yield significant cost savings and offer enhanced asset resilience with improved operational performance, outcomes which are fully aligned with global sustainability objectives. Transitioning from traditional documentation to BIM-enabled digital workflows offers significant advantages beyond asset management, operation, and maintenance. This shift provides stakeholders with both financial and technical benefits while streamlining data collection and storage processes. Enhanced data reliability reduces the cost, time, and overall effort during the operational phase of projects, while creating a solid foundation for detailed analyses that can, in turn, lead to future cost savings. For public authorities, custodians of transportation infrastructure, the integration of lifecycle costing (LCC) within the BIM framework empowers informed decision-making and more effective resource allocation. Furthermore, aligning BIM processes with sustainability goals ensures that infrastructure investments maximize public value throughout the asset’s entire lifecycle [9].

2. Current State of the Art

Typically, the rehabilitation process starts with a triggering event, such as (i) the identification of structural issues during routine inspections or noticeable signs of wear, such as corrosion or cracks; (ii) natural disasters, increased traffic loads as a change in standards, or changes in safety regulations; or (iii) mandated assessments as part of infrastructure upgrade strategies. The decision to initiate an evaluation process is often made by public agencies or bridge operators, with the national legal framework governing the subsequent steps. For instance, in most jurisdictions, bridge evaluations must align with national safety standards and engineering codes. Once the rehabilitation need is identified, a legal process, including the procurement of services, the approval of budgets, and the establishment of project timelines, guides the rehabilitation journey. The rehabilitation of existing steel bridges is a critical process, requiring a balance between traditional techniques and the adoption of emerging technologies to ensure structural integrity, safety, and longevity. As infrastructure ages, steel bridges are increasingly subject to rehabilitation interventions to address deterioration, adapt to evolving regulatory requirements, and meet present demands for mobility, functionality, and sustainability. Historically, the rehabilitation of steel bridge reliec on manual on-site inspections. While usually effective, these approaches are labour-intensive and highly dependent on personal experience, leading to subjective assessments.

2.1. Traditional Methods and Emerging Technologies for Bridge Inspection, Monitoring and Management

Nowadays, engineering processes related to infrastructure engineering still rely heavily on manual processes performed by qualified bridge engineers. On-site inspections form the backbone of these methods, focusing on the assessment of critical elements within the structure, including decks, beams, joints, and supports. Specialists and technical experts visually examine these components, searching for signs of deterioration (e.g., corrosion, cracking, spalling, and misalignment) while also evaluating the bridge’s load-bearing capacity in order to identify weaknesses that require intervention. While visual inspection is usually a straightforward and cost-effective process, reliance on subjective assessments and the potential for human error limits its efficiency. Hidden damage (e.g., internal cracks or flaws within elements’ material) can go unnoticed without additional diagnostic tools. To address these gaps, specialized techniques, such as (i) non-destructive testing (NDT) methods like ultrasonic testing, magnetic particle inspection, and radiographic testing, are employed to detect internal defects and assess material properties without damaging the structure; (ii) simulated or live load testing are used to evaluate the bridge’s performance under controlled conditions and help engineers estimate the real loadbearing capacity and determine the load–deflection curve; and (iii) hammer sounding is used to identify delamination in elements by listening to changes in sound pitch when tapping the surface.

However, on-site inspections often rely heavily on the personal expertise and subjective assessments of bridge specialists and/or technical experts. While these assessments are effective at identifying visible issues, they have notable limitations that include the difficulty of detecting hidden defects and the labour-intensive nature of manual, in-person evaluations. To address these shortcomings, advanced technologies are increasingly being employed to complement traditional methods. This integration combines the practicality and familiarity of manual inspections with the precision and efficiency of modern tools. The result is a more comprehensive approach, leading to a better understanding of a bridge’s condition, enhancing the ability to detect potential issues early and significantly improving maintenance and rehabilitation processes.

Several emerging technologies can be particularly transformative for bridge operation, maintenance, rehabilitation and, ultimately, overall lifecycle management. Building Information Modelling (BIM) enhances collaboration among all stakeholders, enabling the development of information reach 3D models to reduce inefficiencies and communication gaps. In addition, several other technologies can be considered to significantly improve bridge operation, maintenance, and rehabilitation. These include advanced materials, smart construction technologies, digital twins combined with bridge management systems (BMSs), and structural health monitoring systems, all of which streamline and enhance the overall efficiency of bridge-related processes. The adoption of smart construction methods, including artificial intelligence (AI), drones, and LiDAR sensors, is revolutionizing bridge assessments. For example, drones equipped with sensors enable precise inspections in hard-to-reach areas, while 3D scanning [10], LiDAR, and GPS ensure accurate site positioning. Moreover, integrated systems like SCADA (Supervisory Control and Data Acquisition) enable the real-time monitoring of structural health, offering early warning signs of deterioration or damage. Digital twins can be employed to create virtual representations of physical assets, enabling real-time analysis and predictive maintenance.

Modern bridge management systems (BMSs) integrate these technologies to enhance decision-making across a bridge’s lifecycle. As highlighted by the literature [11], such systems allow for efficient condition assessments and the optimization of maintenance strategies based on structural health and risk analyses. Often, BMSs limit their scope to modules [12], i.e., (i) data management, dealing with data about bridges and the status of their components; (ii) diagnosis, consisting of condition rating and deterioration assessment; (iii) prognosis, gathering all the activities connected to the prediction of future bridge conditions; and (iv) decision-making, identifying optimal management actions, and guiding decisions based on engineering judgment. The modules are generally interconnected. While diagnosis and prognosis rely on data pertaining to bridges and their components, decision-making is influenced by the outcomes of diagnosis and prognosis and can also impact data management.

Structural health monitoring (SHM) systems deploy sensors [13] (e.g., fiber optic sensors (FOS), piezoelectric sensors, vision-based displacement measurement systems, and magnetostrictive sensors (MsSs)) to monitor factors like stress, structural vibration, and/or temperature. These systems continuously track structural health, allowing operators to identify damage early and mitigate risks. For example, MEMS (micro-electromechanical system) sensors are increasingly used for their precision and compactness, enabling data capture on bridge behaviour over time.

The integration of advanced computer-aided design (CAD) tools with finite element analysis (FEA) capabilities provides engineers with a powerful framework for designing and evaluating bridges [14,15], especially in scenarios requiring extensive rehabilitation. Modern CAD tools allow engineers to create detailed and accurate 3D representations of bridges, incorporating geometric, material, and even environmental factors. When combined with advanced FEA capabilities, these models can simulate a structure’s behaviour under various conditions, such as multiple load distributions, environmental stresses, and potential failure scenarios. Using advanced numerical models, the CAD-FEA approach enables bridge specialists to (i) identify weak points before the rehabilitation begins and (ii) evaluate multiple design alternatives and test extreme conditions without physical prototyping. The added value of these tools can be further augmented by incorporating feedback from real-world bridges. Leveraging the capabilities of IoT-enabled monitoring systems [5] that provide reliable data on stresses, vibrations, and/or environmental conditions on existing bridges, digital models are updated and augmented to reflect actual conditions rather than purely theoretical scenarios.

With drones equipped with advanced sensors becoming more and more accessible, they are frequently employed to access hard-to-reach areas (e.g., the underside of bridge decks or tall piers), where manual inspections are hazardous and/or impractical. Taking this one step further, the rise in the use of artificial intelligence (AI) coupled with drones enhances both efficiency and accuracy as AI algorithms, combined with high-resolution images collected by drones, are increasingly used to automatically detect cracks, corrosion, and other structural anomalies. This combined approach significantly reduces reliance on manual assessments [16], while enhancing reliability. Furthermore, the integration of AI enables the classification of detected defects based on severity, prioritizing areas that require immediate attention and streamlining maintenance workflows.

Another trending technology for infrastructure assessment is satellite-based monitoring, which is used to complement the aforementioned technologies by providing macroscopic data on bridge performance over time. Synthetic Aperture Radar (SAR) and similar satellite techniques enable the detection of structural movements (e.g., displacements or vibrations), which may indicate emerging issues in the bridge’s load-bearing capacity. For heritage steel bridges, this information is crucial as it helps bridge custodians track how modern usage, such as increased traffic loads or environmental stressors, is impacting the structure. By integrating satellite data into a BIM or digital twin framework, stakeholders can combine macro-level monitoring with micro-level details for comprehensive asset management [17].

When applied to heritage steel bridges, these technologies not only enhance safety and operational performance but also support preservation efforts. The detailed insights provided by AI, drones, and satellites ensure that interventions are precise and minimally invasive, aligning with the goal of maintaining the original materials and design features. Moreover, these tools facilitate the documentation of a bridge’s condition over time, creating a valuable historical record that can guide future restoration efforts.

2.2. Traditional Heritage Steel Bridge Rehabilitation Process

As mentioned before, the rehabilitation of heritage steel bridges presents a range of technical challenges, primarily driven by structural deterioration, corrosion, and fatigue. Over time, these factors compromise the integrity and performance of bridge components, posing risks to safety and functionality. As the structure is subjected to loads from traffic and environmental forces, critical structural elements are subjected to wear and tear, weakening their capacity to withstand additional stress. Cracking, deformation, and material thinning are common issues that arise and they require rigorous inspection and repair strategies. For steel bridges, corrosion remains one of the most persistent challenges, especially in joints and connection points. Prolonged exposure to moisture and de-icing salts accelerates material degradation, compromising both structural integrity and durability. Corroded elements reduce load-bearing capacity, increasing the vulnerability of the structure. This degradation often complicates maintenance and repair efforts, as the weakened components carry a heightened risk of further damage during intervention. Corrosion can cause additional issues due to stuck bearings, which are meant to allow free movement (e.g., a simply supported bridge may be transformed into a double-pinned one). This unintended shift alters load distribution, increasing stress on certain components (e.g., piers), potentially leading to unaccounted failure modes. Another key issue of steel bridges is posed by fatigue (i.e., the repeated stress cycles from dynamic loads, leading to micro-cracks that propagate over time). This issue is particularly critical in bridges with high traffic volumes or those exposed to heavy vehicles. Fatigue-related failures are challenging to predict, requiring advanced monitoring techniques and detailed modelling to identify vulnerable areas.

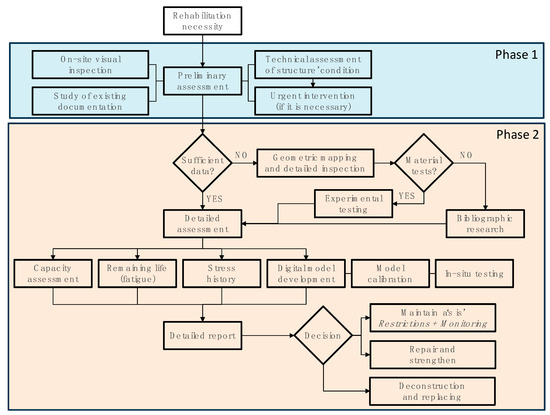

The rehabilitation of heritage steel bridges involves complex processes that require the integration of diverse data sources, stakeholder collaboration, and compliance with technical standards. Efficient and effective information workflows are crucial in order to streamline these activities, reduce uncertainties, and ultimately enhance decision-making. The general process is presented in Figure 2 and focuses on two key aspects: these are (i) structural integrity, emphasizing the technical assessments and interventions required to ensure the safety and functionality, and (ii) compliance with standards, ensuring that all legal and engineering requirements are met.

Figure 2.

Technical process for rehabilitation of heritage steel bridges.

The rehabilitation process starts with the identification of intervention needs, often prompted by routine inspections, structural performance reviews, or general safety concerns, as presented before. Next, phase 1 starts. Within this phase, a preliminary on-site visual inspection is performed that allows the study of the bridge’s current state, followed by a thorough review of historical records, including design documents, maintenance logs, and past inspection reports, to piece together its operational history. Putting together all these details, a preliminary technical assessment is performed that focuses on visible issues such as corrosion, cracking, or noticeable deformations. If critical problems are identified, immediate safety measures are implemented, while further investigations are carried out.

Next, phase 2 commences. The available information is assessed to determine whether it provides sufficient information to correctly evaluate the bridge’s condition. When information is lacking, or it is unreliable, additional investigations are required. Along these lines, advanced technologies like laser scanning or drone surveys might be used to create precise geometric models, while detailed inspections with non-destructive testing methods, such as ultrasonic or radiographic tests, can offer deeper insights into the structure’s material and overall health. Regarding material, it must be mentioned that a wealth of experimental test results on heritage steel bridge materials has been accumulated over the years, resulting in a highly reliable and statistically robust database. This extensive body of data provides detailed insights into the properties of steels used in various periods, making it a valuable resource for assessing material performance. Given the database extent, performing new experimental tests on materials for existing bridges rarely changes the statistical understanding of their properties. Due to this, bibliographic research has become a reliable and common approach for material assessment, particularly for bridges whose construction period is well documented. By referencing historical data and leveraging the wealth of experimental results available, the materials’ behaviour can be accurately predicted, thus removing the need for additional testing. As a result, experimental tests are typically reserved for cases where unusual conditions, damage, or a lack of historical documentation warrant additional investigation.

Once enough data have been collected, an exhaustive assessment is conducted. This includes the assessment of a bridge’s load-carrying capacity, the analysis of its stress history, the identification of areas most susceptible to failure and, finally, the estimation of its remaining fatigue life. A CAD model of the bridge is usually developed, providing detailed insights into bridge behaviour under various conditions. To ensure accuracy, the digital model is developed to account for geometric data mapped on site and specific material properties, and is generally calibrated against on-site tests. The results of such assessments are used to guide the next steps. If the structure is deemed safe, or it requires minimal intervention, it can remain operational under specific restrictions, supplemented by ongoing monitoring to ensure safety. For bridges requiring more significant attention, repair or strengthening strategies can be implemented to restore their full, or at least partial, functionality. For cases where the structure is severely damaged or the rehabilitation costs are prohibitive, the focus may shift toward planning and executing deconstruction and/or replacement. Alternatively, the bridge can be considered for repurposing, e.g., the conversion of a railway bridge for automotive use, the conversion of an automotive bridge for pedestrian or cyclist traffic, or other adaptive reuse scenarios that align with the community’s needs.

Throughout the entire process, a technical report is developed, documenting findings, analyses, and recommendations that are to serve as a critical references for stakeholders. In most cases, information exchange is conducted using traditional paper-based methods (or digitalized paper, i.e., a pdf), and the technical documentation typically includes only the information mandated by law. While the focus remains on the technical aspects of rehabilitation, this workflow underscores the importance of comprehensive assessment and strategic decision-making in tackling the unique challenges associated with ageing steel bridges effectively.

2.3. BIM for Infrastructure Management

The application of the BIM framework to infrastructure projects has increased rapidly due to its capacity to streamline the management processes. During the planning stage, BIM enables rapid solution exploration with the fast identification of the best solution. For large-scale projects, BIM streamlines communication, enhances collaboration among stakeholders, reduces coordination errors, augments quality checks and fast clash detection, etc. A well-developed BIM model reduces errors during the construction phase, limiting the number of missing details and on-site clashes, while streamlining construction processes and increasing overall construction quality [18]. A specific BIM project for road infrastructure is generally characterized by a topographic nature, with point clouds linked to laser scans used for the acquisition of refitting data and meshes with precise geo-referencing [19]. The usual first step is to create a Digital Terrain Model (DTM) from the available cartographic maps, composed of nodes with associated elevations. The horizontal alignment and vertical profile are generally implemented in BIM with the cross section to realize the 3D parametric model. Next, the geometry of various assemblies within the structure is defined, along with the characteristics of the materials and the necessary details for the work breakdown structure. This information is then used to calculate quantities for various processes, which in turn are utilized to estimate costs.

Further BIM uses for infrastructure projects may include the development of models that leverage combined BIM–GIS models [20]. This approach can be successfully employed to enhance construction efficiency and construction safety. Koch et al. [21] proposed a tunnel information modelling framework for safe tunnel construction. For the sequential construction and reconstruction of highways, Mawlana et al. [22] proposed 4D BIM to prevent the probability of potential clashes. Ding et al. [23] developed an advanced multidimensional modelling technique that integrates a work breakdown structure and other construction code structures for rail transit construction.

By leveraging the complementary strengths of BIM and GISs within a holistic system, authorities can achieve multiple objectives of modern urban development, foster innovation, optimize resource allocation, and improve the efficiency and safety of urban systems for real smart cities [2]. Nevertheless, BIM–GIS integration presents a series of challenges related to spatial scale, granularity level, geometric representation methods, archiving and access methods, and semantic discrepancies. A key issue lies in the divergent purposes of BIM and GISs as BIM focuses on object relationships, while GISs emphasize geospatial context and georeferencing.

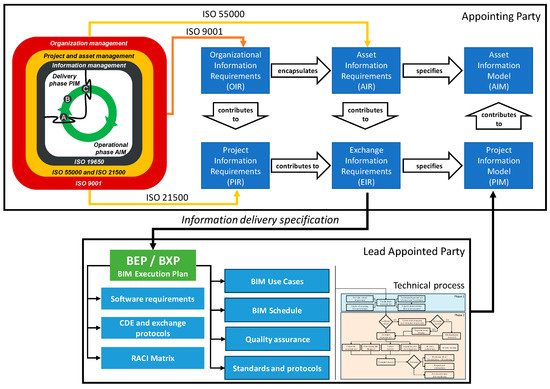

3. The Information Management Framework

To overcome the limitations on information exchange posed by the traditional process, while keeping a thorough technical process in place, a BIM workflow should be considered. It should integrate structured processes and data management principles to align organizational objectives, asset operational and maintenance needs, and project-level objectives throughout the lifecycle. As depicted in Figure 3, this approach uses international standards, such as ISO 19650 [24] for information management, ISO 55000 [25,26] for asset management, and ISO 21500 [27] for project management, to ensure consistency and interoperability across all project phases. It can be easily observed that the entire standard landscape is enabled by ISO 9001 [28], which ensures process quality, transparency, traceability, and accountability.

Figure 3.

BIM-enabled process for rehabilitation of heritage steel bridges.

According to ISO 19650 [24], the process begins with a statement of need formulated by the appointing party (for example, the client). This must ensure that the information requirements are clearly defined at the start of the project along with how the concepts and principles of information management are to be implemented and the benefits that are expected. Information management and associated processes can also be considered as far as they can be determined by the appointing party [29]. Next, each prospective lead appointed party (e.g., designer, main contractor) responds to these information requirements in their (pre-appointment) BEP (i.e., BIM execution plan), which includes their statements of capability and capacity to apply the ISO 19650 [24]. The appointing party considers the contents of each BEP, evaluates them, and then selects the lead appointed party. During mobilization (the initial project phase), the appointing party (for example the client), the lead appointed party (for example the contractor), and other appointed party/parties (for example the subcontractors) collaborate to agree key roles and responsibilities and to agree an IDP (i.e., Information Delivery Plan). Next, in accordance with ISO 7817 [30], these parties establish the level of informational need required at every project stage and approval, authorization, and acceptance procedures. This enables the configuration and implementation of appropriate information management systems that must provide and consider the needs of the project team and stakeholders, the process of information delivery, and the selection and use of appropriate technologies required for delivery.

At the beginning of the process, the appointing party clearly expresses the information requirements to other organizations and individuals through their exchange information requirements in order to specify or inform their work. A clear information hierarchy is linked to the project, asset(s), and organizational objectives, as shown in ISO 19650-1 [24] and Figure 2 and Figure 3 of the present document.

Determined by the appointing party or a party representing it, the development of Organizational Information Requirements (OIRs) encapsulates the strategic goals (defined in alignment with ISO 9001 [28]) and the organization information needs that are linked with the project. Next, the OIRs inform the development of Asset Information Requirements (AIRs), which further detail the information required for effective asset management, contributing to the creation and maintenance of the Asset Information Model (AIM) during the operational phase. The development of the AIRs, guided by ISO 55000 [25,26], is aligned with the operational and maintenance requirements of the asset. At the project level, Project Information Requirements (PIRs), usually derived from the OIRs, AIRs, and project-specific requirements and supported by ISO 21500 [27] specifications, focus on specific information needs for the successful development and implementation of the project. PIRs and AIRs are further refined into Exchange Information Requirements (EIRs), which establish the precise data exchanges needed during project execution and delivery. The EIRs directly inform the development of the Project Information Model (PIM), which consolidates all relevant project data in a structured format for collaboration and decision-making during the project lifecycle.

The workflow is designed to improve infrastructure management by enhancing collaboration, streamlining information exchange, and ensuring that all data collected and managed throughout the lifecycle of an asset are precise, relevant, and actionable. A BIM-enabled approach integrates a range of focus areas, each addressing critical aspects of bridge rehabilitation, to transform traditional methods into a more informed and efficient process. Once the information requirements are clearly stated, the technical process can be easily integrated within the digital workflow to tackle the following areas:

- Data collection and the integration of historical records in terms of existing design documents, maintenance logs, and existing on-site inspection reports.

- Structural simulations, enabled by Terrestrial Laser Scanning (TLS) and photogrammetry, that offer precise geometric representations, critical for conducting simulations within BIM, ensuring that engineers can reliably assess load distributions, identify stress points, and evaluate structural integrity under various scenarios [31,32].

- Comprehensive scenario analyses that enable stakeholders to simulate various rehabilitation or intervention strategies, such as retrofitting or material replacements, allowing for the easy visualization of potential impacts. This approach allows stakeholders to evaluate and compare the effectiveness of different approaches, ensuring that selected strategies are both technically sound and cost-effective [33,34].

- Advanced predictive maintenance to monitor structure’s condition through successive scans, allowing for the early detection of deterioration or vulnerabilities. By continuously updating BIM models with real-time data, stakeholders can implement timely interventions, reducing the risk of unexpected failures and optimizing maintenance schedules. This proactive approach extends the lifespan of infrastructure while minimizing maintenance costs [35,36].

- Dynamic digital twins that provide a comprehensive platform for real-time monitoring, analysis, and simulation, supporting decision-making across the entire lifecycle of an asset [37,38].

- Environmental data [39] on weathering, corrosion rates, and environmental impacts. Integrating these datasets into a common digital environment, such as a BIM platform, ensures accessibility and consistency, enabling stakeholders to analyze the bridge’s condition holistically.

- Information structuring and standardization to ensure compatibility and ease of use across software tools and project teams. Implementing industry foundation classes (IFCs) [40,41,42,43] for data exchange and information delivery specifications (IDSs) ensures that all required data are correctly formatted and available at the appropriate project stages. Defining Organizational Information Requirements (OIRs) and Asset Information Requirements (AIRs) early in the project lifecycle further streamlines data management.

- Model creation and simulation [44] to develop a federated model to act as a single source of truth central repository for graphical and non-graphical data. This enables the following actions:

- Visualization for stakeholders to assess bridge’s current condition and/or proposed rehabilitation strategies through immersive visualizations.

- Simulation [45] for structural and fatigue assessment [46], and corrosion propagation to allow engineers to evaluate potential failure modes and test repair scenarios.

- Collaboration, fostering coordination among architects, engineers, contractors, and regulatory authorities.

- Rehabilitation Planning and Optimization [47] leveraging the insights gained from the BIM model to optimize the following:

- Material selection to allow for the evaluation of the durability and sustainability of repair materials.

- Repair strategies, allowing for the identification of the most efficient and cost-effective methods for strengthening or replacing deteriorated components.

- Monitoring and the use of feedback loops post-rehabilitation [48,49] to maintain an up-to-date (as-built) Asset Information Model (AIM) and enable monitoring and maintenance. Integrating Internet of Things (IoT) sensors into AIM for post-rehabilitation monitoring provides real-time data on structural performance, enabling the BIM model to remain up to date and reflect the structure’s actual condition. Such models are paramount for ongoing operation and for future rehabilitation efforts as IoT sensors can collect data on various parameters (e.g., stress, vibration, temperature, humidity, etc.) which, in turn, indicate a structure’s health at the element and/or global level [31,34,36]. This real-time information allows for the early detection of potential issues, enabling timely maintenance interventions that can prevent minor problems from escalating into major concerns [33,34]. Moreover, IoT sensors support predictive maintenance strategies by enabling trend and pattern analyses to forecast future deterioration or failure points, allowing for maintenance activities to be scheduled proactively [32,38]. By integrating IoT sensor (monitoring) data into BIM models, these models can become digital twins—dynamic representations of physical structures—and serve their purpose as comprehensive platforms for simulation, analysis, and decision-making throughout the asset’s lifecycle. This approach leads to more effective and efficient future rehabilitations [31,36,37]. It must be mentioned that, in addition to the sensing part, a real digital twin has an acting part (actuator) that performs various actions on the physical twin.

- Legal and regulatory considerations, including compliance with transportation regulations, structural codes, and environmental policies, to ensure that all interventions meet legal and operational benchmarks.

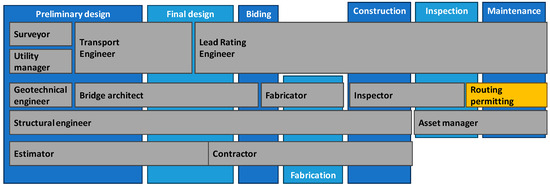

The BIM for Bridges and Structures initiative, particularly the TPF-5 (372) project [50], provides significant added value in terms of establishing clear and efficient BIM workflows for bridge structures. One high-value result is the Bridge Lifecycle Management Overview Map [51] (schematically presented in Figure 4), which highlights the interconnected stages of a bridge’s lifecycle, from initial planning and design through to construction, operation, and eventual decommissioning or replacement. This process map emphasizes the importance of aligning information needs with lifecycle phases, fostering better collaboration, decision-making, and project efficiency. This map enables stakeholders to understand how information is generated, exchanged, and utilized at different phases, from visualization and analysis in the design phase to the coordination of fabrication and on-site assembly using data-rich models in the construction phase and condition monitoring for proactive maintenance in the operational phase.

Figure 4.

Bridge lifecycle management overview map.

A strategic plan for collecting, storing, retrieving, and using information is paramount for the successful development of a comprehensive strategy for managing lifecycle asset data across multiple projects. For road infrastructure, the information management process has two main phases i.e., (i) development of asset information in the project delivery phase, and (ii) the use and updating of asset information in the operational phase [52]. Furthermore, the growing stock of bridges and the increasing need to optimize investments in bridge maintenance, while ensuring safe operation, have created a pressing demand for optimized bridge management [53]. Along these line, the “Information Requirements Framework” shown in Figure 3 provides a hierarchical structure that connects the organization’s strategic goals with the detailed information needed for effective decision-making through three distinct but interconnected layers i.e., OIRs, AIRs, and PIRs. Each of these tiers addresses a specific aspect of the broader information ecosystem, ensuring alignment between high-level objectives and on-the-ground project execution.

The templates and guidance developed by the Centre for Digital Built Britain (CDBB) [54,55,56] provide a robust foundation for implementing best practices in BIM and information management. These resources are particularly valuable for aligning project workflows with the ISO 19650 [24] standards, which focus on structuring and delivering information across the lifecycle of built assets. For projects like heritage bridge rehabilitation, these templates are especially useful, emphasizing trust, value creation, and digital accountability, making them ideal for managing complex projects with historical significance. They also cater to interoperability, facilitate smooth data exchange between different software platforms, and ensure compliance with regulatory and sustainability goals. The following sections offer a brief view of OIRs, AIRs, and PIRs for the case of heritage steel bridges.

3.1. The Organizational Information Requirements

This document focuses on the strategic needs of organizations, defining the information necessary to achieve long-term objectives. This includes supporting portfolio-level decision-making, optimizing resource allocation, and addressing compliance with regulatory and sustainability standards. A robust OIR ensures that an organization’s vision, mission, and values are reflected in its asset management strategy while addressing the specific information needs across all operational phases.

This alignment is particularly vital for structures like heritage bridges, which combine historical significance with contemporary engineering challenges. From initial planning to the operational phase, the integration of information requirements serves as the backbone of strategic decision-making, ensuring that maintenance, rehabilitation, and eventual replacement are handled efficiently and sustainably.

OIR documents detail the following aspects:

- The organization’s vision and mission that inform its objectives and drive the creation of structured workflows to handle information management (requirements, creation, exchange, storage, and use);

- The organizational structure and RACI matrix should demonstrate how clear roles and responsibilities enhance collaboration and accountability;

- Asset portfolio planning (e.g., exploitation, maintenance, space utilization, and portfolio adjustments) supported by a comprehensive roadmap for tailored asset management;

- The assessment of lifecycle costs, risk assessments, and approaches to rehabilitation, replacement, and/or decommissioning;

- Environmental considerations, sustainability, and investments, emphasized as key components of a holistic approach.

- An information exchange strategy across the organization, including relevant policies, internal and external factors, and implementation plans.

- Continuous evaluation and review to ensure that information remains accessible, consistent, and actionable in order to form the foundation for informed decision-making and long-term organizational success.

3.2. The Asset Information Requirements

A recurring theme is the challenges in capturing, storing and validating data across a diverse and complex asset portfolio. The AIR document shifts the focus from organization to individual assets, specifying the information needed for their operation, maintenance, and management throughout the lifecycle. It addresses aspects such as inspection data, performance metrics, and maintenance schedules, ensuring that assets like steel bridges are managed effectively, whether they require rehabilitation, repurposing, or eventual replacement.

James Heaton et al. [57] proposed a 7-step process to support the development of information requirements. This process is summarized as follows:

- Identify, extract, and categorize organizational requirements to ensure that the AIRs align with the strategic objectives of the organization.

- Develop asset functions, systems, and products within a classification system to create a standardized understanding of how assets contribute to organizational functions, aiding in effective information management and interoperability.

- Identify Organizational Information Requirements (OIRs) that directly support the organizational goals and processes identified in step 1. The OIRs should align seamlessly with the previously categorized requirements to ensure the relevance and utility of the information.

- Develop functional information requirements by translating the OIR into specific functional requirements. This step involves detailing the type of information needed for various operational, maintenance, and management functions, ensuring that all stakeholders have the data they require for decision-making.

- Develop Asset Information Requirements (AIRs), using the functional information requirements as a basis. This should outline the data that should be collected, how they should be formatted, and the processes for their maintenance throughout the asset’s lifecycle.

- Validate the Developed Information Requirements to confirm their fitness for purpose. This includes checking their completeness, alignment with organizational needs, and practicality for implementation. If the AIRs are not adequate, review and refine them by revisiting earlier steps.

- Document and communicate the Developed Information Requirements in a clear and accessible format to all relevant stakeholders, ensuring that the requirements are clearly understood and then integrated into the organizational workflows.

This process emphasizes continuous improvement and alignment with organizational goals, ensuring that the information requirements evolve with changing organizational needs. Key milestones like validation and feedback loops maintain a focus on quality and relevance.

The AIR document should address the following key areas:

- Alignment with organizational goals, which connect to the broader organizational strategy outlined in the OIRs, including the organization’s commitment to preserving cultural heritage, sustainability, and efficient resource utilization, especially in the context of heritage steel bridges.

- Asset inventory and maintainable components for all maintainable components, including unique identifiers for structural elements like trusses, beams, and rivets. For heritage assets, the inventory must also capture decorative and historically significant features.

- Lifecycle management, specifying the requirements for inspection, rehabilitation, and replacement schedules, supported by detailed lifecycle cost analyses and risk assessments. Strategies for extending the lifespan of the asset while preserving its historical and structural integrity should also be included.

- Environmental and sustainability considerations on materials and techniques for rehabilitation. Data on the environmental impact of interventions, including carbon footprint and resource efficiency, should be considered.

- Operational efficiency and maintenance strategies for asset performance monitoring, including the integration of IoT sensors to capture real-time data on stress, vibration, and temperature. This ensures proactive maintenance and long-term operational efficiency.

- Data standards and classifications, such as industry foundation classes (IFCs), to ensure compatibility across BIM tools and platforms. Specific classifications for heritage elements must be included, ensuring accessibility and consistency in information exchange.

- Data exchange and integration protocols provide comprehensive guidelines for information exchange, storage, and access. This includes specifying data formats (e.g., IFC4, JSON) and ensuring interoperability with organizational systems and external stakeholders.

- Validation and quality control metrics for data validation, including model-checking tools (e.g., Solibri, Navisworks) and/or rule-based scripts. Metrics for completeness, accuracy, and adherence to preservation standards are essential for maintaining asset quality.

- Continuous review and improvement, emphasizing the need for ongoing evaluation to adapt to changing organizational needs and technological advancements. This ensures that the information remains relevant and supports informed decision-making throughout the asset lifecycle.

3.3. The Project Information Requirements

This document focuses on the detailed information required for the successful development, implementation, and delivery of the project. This includes detailed data on design, construction, and commissioning, as well as the documentation of decisions made during the project lifecycle. Aligned with ISO 19650 [24], the PIR content bridges the gap between the strategic OIRs and the asset-specific AIRs, ensuring that project-level activities align with organizational and asset management goals. The document’s development is typically a collaborative effort, often requiring the expertise of a consultancy construction company. In specific cases, the lead appointed party (such as the main contractor) can also support the development. These collaborations play a crucial role in helping the appointing party (i.e., client organization or the operator) identify and articulate the critical information needed at each stage of the project. Their support ensures that the information requirements are practical, achievable, and aligned with both organizational objectives and the data related to project delivery. To achieve this, several types of information needs must be addressed and agreed upon collaboratively:

- Concept phase information needs, such as feasibility studies, preliminary design documents, and sustainability considerations, must be addressed; clear protocols must also be established for information exchange at this stage—particularly between the client and design teams—including formats, classifications, and delivery deadlines.

- Detailed design phase requirements, outlining the information necessary to develop a detailed design that addresses technical, regulatory, and operational criteria, such as geometric and performance data for models and drawings, material specifications and engineering calculations, and documentation on safety and constructability reviews, must be established. The lead appointed party should ensure that data formatting adheres to recognized standards (e.g., industry foundation classes—IFCs) to enable seamless integration into the project’s BIM environment.

- The construction phase needs to account for construction sequencing and scheduling data, inspection and testing plans, records of materials and equipment used, daily reports, and deviations from the design. The information exchange protocol for this phase is critical, ensuring that the contractor’s data can be efficiently integrated into the federated model and ultimately the Project Information Model (PIM).

- Commissioning and handover phase information, specifying the deliverables required to transition the project into operation, must be established. This includes the as-built models and drawings, operation and maintenance (O&M) manuals, and warranty documents and certificates, as well as digital data for IoT sensor integration, if applicable. The lead appointed party ensures that all information is delivered in formats compatible with the asset management systems defined in the AIRs.

- Operation and maintenance phase data must be established to ensure continuity post-handover. The PIR must include guidelines for ongoing information exchange between the project delivery team and asset managers. This encompasses regular updates to the AIM based on PIM data, performance monitoring data, and feedback loops for future asset interventions.

3.4. The Information Delivery Specification

Following the development of the OIRs, AIRs, and PIRs, the creation of a technical document, called an information delivery specification (IDS), is usually recommended, as it ensures the seamless integration of information requirements into practical workflows. The IDS serves as a technical document that translates natural language and unstructured information requirements into actionable specifications for information exchanges. It bridges the gap between strategic requirements and technical implementation, ensuring that the data delivered align precisely with the expectations set out in the OIRs, AIRs, and PIRs. Technically, the IDS [58] is a standard development by buildingSMART to define information requirements in a way that is easily read by humans and can be directly interpreted by computers. It defines the structure, format, and level of detail required for each information exchange, promoting consistency and interoperability across teams and software platforms. It outlines clear rules for data quality, validation, and delivery milestones, facilitating smooth transitions between project phases and ensuring compliance with standards like ISO 19650 [24]. For instance, during the design phase of a steel bridge, metrics such as bill of material accuracy, 3D model completeness, correlation with in-field measurements, and assembly information consistency are pivotal in validating whether the information meets predefined standards and project requirements. Accuracy ensures that quantity, dimensions, tolerances, and material properties are correctly represented in the design models. For example, the specification of steel grades must align precisely with the requirements for load-bearing capacity, environmental conditions, and heritage structure rehabilitation. Completeness ensures that all necessary details, such as connection types (e.g., riveted, bolted or welded joints, if allowed) and cross-sectional geometries, are included in the model to avoid ambiguities during fabrication. Consistency verifies that different aspects of the design—such as the alignment of trusses, bracing systems, and load distribution calculations—are coherent across various models and drawings.

Validation during this phase directly influences decisions regarding the next project phases. Accurate material specifications can support the most cost-effective procurement strategies while ensuring that the selected materials meet both heritage rehabilitation, performance, and sustainability criteria. Similarly, validated geometric data support the performance of structural simulations to predict the bridge’s response to future loads, such as vehicular traffic or environmental stresses, informing decisions on reinforcement strategies and correct material use, and thus potentially reducing costs without compromising safety

As the project transitions to the construction phase, these validation metrics ensure that the information used for execution aligns closely with the design intent, minimizing discrepancies that could lead to rework and project timeline extension. Accurate and complete design information, validated during the design phase, ensures that misalignments are avoided during the construction phase, which is particularly crucial for complex structures like skewed or curved steel bridges. Inconsistent or incomplete data at this stage, more often than not, result in costly fabrication errors and delays during erection.

It must be mentioned that IDS is particularly critical for managing BIM workflows, as it provides clarity on how the information should be produced, shared, and utilized. Moreover, IDS mitigates risks associated with incomplete or inaccurate data, which can lead to inefficiencies, cost overruns, and delays.

An important scope of IDS is that it only focuses on ‘information delivery specifications’, meaning that it can define what information is needed and how it should be structured. The use of XML (Extensible Markup Language) ensures that these specifications are encoded in a standardized, machine-readable format, providing a versatile framework for defining structured data. This standardization is critical for aligning the IDS requirements with industry standards like IFC (as given by ISO 16739-1:2024 [40]) in openBIM workflows. By leveraging XML, IDS can define what information is required together with the format, classification, and validation rules that ensure data interoperability across various BIM platforms. It also allows for validation automatization. It must be mentioned that IDS has been identified by the international community as the most advantageous method for automated compliance checking via the validation of alphanumerical information requirements. Extensive technical information related to IDS can be found on GitHub [59], where code development, documentation, and examples are kept.

4. Case Study for the Savârșin Heritage Steel Bridge

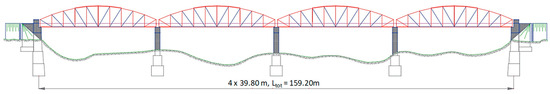

The case study presented hereafter is focused on the Săvârșin heritage steel bridge (see Figure 5), a historical structure located in Romania, crossing the Mures River on the local DJ 707 road. The bridge, constructed in 1895, embodies the classical structural design characteristic of its era. Its primary load-bearing elements are parabolic lattice beams, featuring descending diagonals (in tension) and vertical struts (in compression). Spanning 159.2 m, the bridge consists of four simply supported truss girders, each measuring 39.8 m, with a length-to-height ratio of 1/6.4 (39.6 m/6.22 m). The main beams give the bridge a graceful and harmonious appearance, perfectly integrating into the picturesque landscape near the former summer residence of Romania’s royal family. The bridge’s stability is enhanced by a transversal bracing system located in the four central panels at the top of the longitudinal beams. Its load-bearing track structure comprises an orthogonal network of stringers and struts supported by Zores profiles. Above this framework there lies a 20 cm ballast layer, topped with a 5 cm layer of asphalt concrete, forming the final roadway surface. As a riveted structure, built using a construction method that was widely used in the past but which is less common today, the bridge holds significant historical value, adding further complexity to its maintenance. This combination of historical design and technical sophistication underscores its importance as an engineering marvel and also as a cultural landmark. For the structural elements of the bridge trusses, the elements in tension (i.e., bottom chord and diagonals) are depicted in blue, while the compression elements (i.e., struts and top chord) are depicted in red.

Figure 5.

An overview of the Săvârșin bridge.

As a testament to the engineering ingenuity and architectural sophistication of its era, the Săvârșin Bridge is not only a vital piece of infrastructure but also a cherished landmark, with an emblematical value for the local community. Its enduring legacy reflects the balance of modern preservation techniques and the cultural importance of maintaining such historical structures. Despite comprehensive rehabilitation efforts completed in 2008, the bridge remains in a state of partial disrepair, necessitating ongoing maintenance in order to safeguard its historical significance [60].

The rehabilitation of the bridge stands as a remarkable achievement, exemplifying excellence in preserving heritage while ensuring structural integrity. Recognized by the European Convention for Constructional Steelwork (ECCS), the project received a prestigious award that highlighted its success in addressing both engineering and architectural challenges. Further acclaim came in 2010, when the bridge was honoured with the, underscoring the project’s innovative approach to strengthening all structural elements through both direct and indirect methods.

4.1. The OIR, AIR, and PIR Documents

As shown before, effective information management throughout the rehabilitation of heritage steel bridges, as with the Săvârșin Bridge, requires a well-defined hierarchy of information requirements to ensure that organization’s strategic goals are aligned with operational and project-specific needs in terms of preserving the bridge’s historical, structural, and functional integrity. Public authorities managing infrastructure (i.e., roads, bridges, and/or buildings) can use the principles outlined in UNECE guidance [61] on asset management and BIM to derive a structured set of information requirements. Table 1 provides a proposal for information requirements at the organizational, asset, and project level, as they relate to the Săvârșin Bridge. The information provided within the table accounts for how each requirement contributes to a cohesive and efficient information flow for managing future rehabilitation efforts and the ongoing operation of such significant assets.

Table 1.

Sample information requirements for heritage steel bridges.

The OIRs ensure that public authorities receive information that equip them to manage infrastructure assets effectively, emphasizing sustainability, resilience, and the integration of technology. Next, the AIRs consider efficient decision-making throughout the lifecycle of the bridge, ensuring both its structural functionality and integrity, while preserving its cultural significance. The PIRs ensure that the project progresses efficiently, within time and budget constraints, and meets long-term objectives for heritage preservation and infrastructure functionality.

These requirements ensure that public authorities are equipped to manage infrastructure assets effectively, emphasizing sustainability, resilience, and the integration of technology.

4.2. The IDS File

Based on these documents, the IDS outlines the data requirements for specific tasks and/or phases in within the BIM workflow and ensures that all project stakeholders provide and manage information in a standardized, efficient manner.

A natural language IDS example for heritage steel bridge rehabilitation is presented hereafter.

- 8.

- General Information

- Project ID: SAV-HB-2024;

- Phase: development, implementation, handover.

- BIM-related standards: ISO 19650-1:2019 [24], ISO 16739-1:2024 [40], ISO 7817-1:2024 [30].

- Data Exchange Requirements

- File formats

- IFC4 for interoperability

- Native file formats for design tools (e.g., Revit, Tekla Structures, Bonsai, etc.).

- CSV or JSON for IoT sensor data.

- Software compatibility: must be compatible with common BIM tools and platforms such as Navisworks, BIM 360, and open-source tools adhering to buildingSMART standards

- Information Requirements by Phase

- Development phase

- Structural assessments:

- Input: 3D scans (point cloud in .e57 format), initial condition reports (XML).

- Output: preliminary BIM model with structural analysis data.

- Environmental impact:

- Input: GIS data (.shp files) and climate analysis reports.

- Output: environmental risk assessments incorporated into the BIM model.

- Implementation phase

- Construction data:

- Input: specifications for retrofitting materials (steel grades, paint types, rivets).

- Output: updated BIM model showing real-time construction progress (weekly .ifc updates).

- Monitoring integration:

- Input: IoT sensor placement data (JSON).

- Output: integration into a digital twin for real-time monitoring.

- Handover phase

- As-built documentation:

- Input: final scans and updated design data.

- Output: comprehensive as-built BIM model with maintenance schedules embedded.

- Training materials:

- Input: operation manuals, sensor data management protocols.

- Output: interactive digital guides linked to the BIM model.

- Data Validation and Quality Control

- Validation tools

- Model-checking tools (e.g., Solibri, Navisworks).

- Custom scripts for rule-based validation (e.g., Python scripts).

- Quality control metrics

- Completeness (percentage of mandatory fields populated).

- Accuracy (validation against reference standards e.g., ISO 1090-1, ISO 1090-2).

- Governance and Access Control

- Access levels

- Read-only for public authorities.

- Edit access for BIM managers and contractors.

- Audit trail

- Maintain version history of the BIM model and associated documents.

Complementing the IDS framework described before and enabling the development of an XML-based IDS, Table 2 outlines specific data fields and their requirements, tailored to the case of the rehabilitation of heritage steel bridges.

Table 2.

Sample data fields for the IDS.

Based on information requirements, the IDS XML file is developed, with an example presented in Appendix A.

4.3. The Technical Report and Rehabilitation Decision

The BIM workflow creates the structure for the information exchange. The technical component of the rehabilitation process for existing steel bridges involves several key steps that must be carefully analyzed and addressed by technical experts. As discussed in previous sections, the initial step requires the on-site assessment of the structure’s technical condition, with several key factors to consider, such as identifying whether the bridge is made from wrought iron or mild steel. This distinction is especially important for older bridges, as mild steel became more common after 1900. The technical condition also includes the evaluation of structural damage, particularly to vertical members of the truss girders, which is often caused by insufficient clearance and vehicle impact. Furthermore, many heritage steel bridges in Romania suffer from insufficient maintenance due to historical ownership changes, which leads to significant corrosion and the absence of proper documentation about their construction and maintenance.

For skewed or curved bridges, or continuous truss girders, advanced 3D space analyses enabled by modern computer-aided engineering (CAE) techniques are necessary to assess the current state of a structure as they can offer detailed information. Nevertheless, as older bridges are statically determined structures that are typically constructed perpendicular to their supports to ensure a uniform and direct load transfer, analytical methods can be employed as they offer sufficient accuracy. These old bridges are generally riveted, and the lack of knowledge regarding material quality presents additional challenges. To mitigate this, the Romanian Highway Administration (CNAIR) has developed a qualitative verification methodology, AND 522-2002 [62], to assess the condition of these structures, providing a categorization based on expert evaluation that informs decisions on repairs or replacement. However, this methodology is effective for newer bridges (less than 30 years old) and serves more as an informational tool for older steel structures, which require a more detailed assessment methodology, as outlined in Figure 2.

Based on the AND 522-2002 [62] specifications, the technical condition of the structure is assessed in terms of a quality index given by Equation (1):

where the quality index C is used as follows: C1 accounts for the main girder; C2 accounts for the deck elements; C3 accounts for the infrastructure and bearings; C4 accounts for the riverbed; and C5 accounts for the deck surface quality. F refers to the functional requirements, with F1 referring to the traffic conditions on the bridge, F2 referring to the loading class of the road, F3 referring to the year of construction and type of structure, F4 referring to the quality of fabrication, erection and operation, and F5 referring to the maintenance of the structure.

For every index (from 1 to 5), one mark (1–10) is awarded. Finally, the technical condition of the structure results from the total sum and can be assessed as being in one of the following categories:

- Very good technical condition;

- Good technical condition;

- Satisfactory technical condition;

- Unsatisfactory technical condition;

- The present technical condition cannot assure the safety of the structure.

For the time being, the Săvârșin bridge was evaluated using a classical simplified analysis. The general stability of the compressed upper chord of the main girder was checked, while the computed structural stresses for the considered load cases exceed the allowable values by 10–40% for specific structural elements.

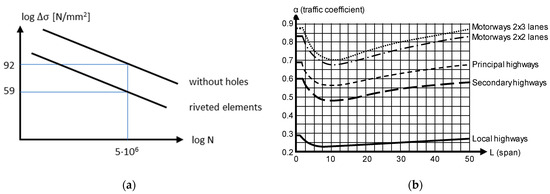

A more complex problem is posed by fatigue assessment. To estimate the fatigue effects, the damage accumulation methodology (usually applied for railway bridges) was employed, even if for usual road bridges this verification was not foreseen by the Romanian code [63] at the time. To implement the procedure, an adaptation of the Wöhler curve was utilized, following the assumptions outlined in the Swiss Railways specification [64] for existing bridges, as illustrated in Figure 6.

Figure 6.

Wöhler curve (a) and traffic coefficients (b) for highway bridges as determined by Swiss Regulation.

Reliable fatigue life predictions for bridges heavily depend on accurate traffic data collected over the bridge’s life span. Furthermore, evaluating the actual stress history of a structure presents significant challenges, as factors like the detailed geometry of the bridge and the number of stress cycles experienced greatly influence its remaining fatigue life. In usual engineering applications, it is often necessary to assume that the traffic load spectrum remains consistent throughout the bridge’s lifespan or, at least, during specific discrete periods. By analyzing this stress history in conjunction with the appropriate Wöhler curve, specialists can estimate the accumulated damage, assess the bridge’s fatigue performance, and give an informed estimation its remaining service life.

For example, in the case of the main girder–lower chord (middle span), the verification is as follows:

for secondary highways (see Figure 6b)

Considering the importance of the structure, its historical value, and its aesthetic appearance (see Figure 7), the decision to strengthen the structure was taken.

Figure 7.

A general view of the Săvârșin bridge.

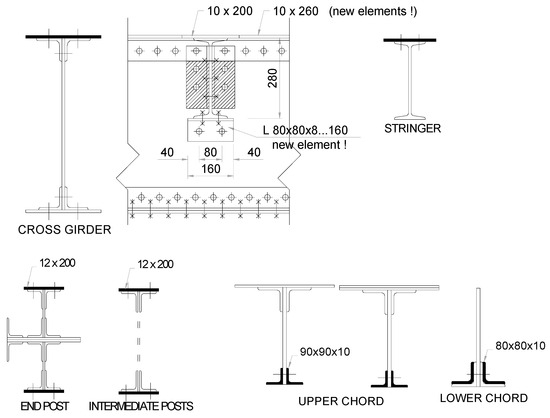

Most structural elements were assessed and reinforced and they presented hereafter:

- The stringers and the flanges were consolidated by supplementary plates (see Figure 8).

Figure 8. Direct reinforcement with additional elements.

Figure 8. Direct reinforcement with additional elements.

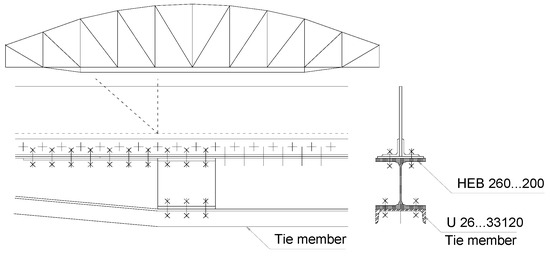

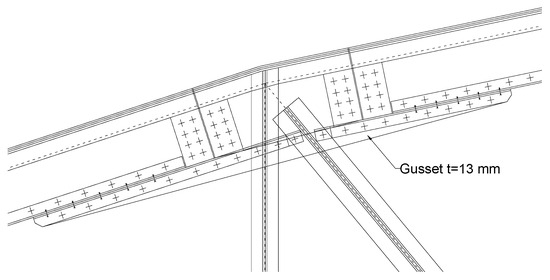

- The cross girders were transformed into switch girders (see Figure 9).

Figure 9. Cross girder reinforcement with a tie member.

Figure 9. Cross girder reinforcement with a tie member.

- A supplementary tie member for the main girder’s lower chord (see Figure 10).

Figure 10. Main girder reinforcement with a tie member.

Figure 10. Main girder reinforcement with a tie member.

- The upper chord’s stability was improved by direct strengthening with two-angle profiles (see Figure 11).

Figure 11. Upper chord stability improvement.

Figure 11. Upper chord stability improvement.

- Diagonals and vertical members had to be, first of all, straightened and strengthened by additional plates.

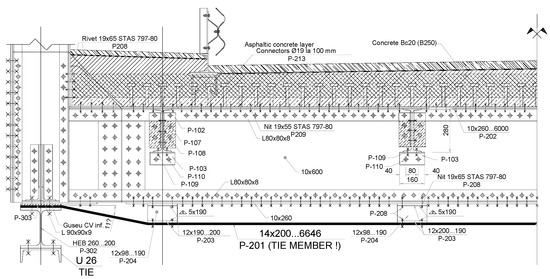

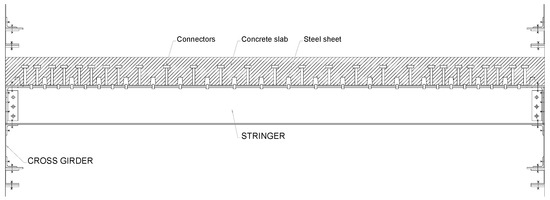

- The old deck system was replaced by a composite deck (see Figure 12).

Figure 12. The bridge’s new composite deck.

Figure 12. The bridge’s new composite deck.

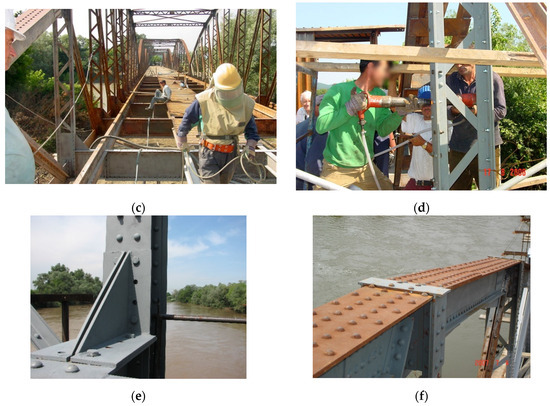

All these operations are difficult and suppose a high technical level of all in situ work, with several in situ procedures presented in Figure 13.

Figure 13.

On-site work for bridge rehabilitation: (a) deck removal; (b) warm post straightening; (c) sand blasting; (d) riveting; (e) new consolidation elements; (f) reinforcement of upper chord joint.

5. Concluding Remarks

The adoption of Building Information Modelling (BIM) workflows to rehabilitate heritage steel bridges marks a transformative shift for national authorities, the custodians of vast infrastructure networks. By centralizing and managing data throughout an asset’s lifecycle, BIM offers unparalleled advantages in ensuring the longevity and functionality of these critical structures. It empowers informed decision-making by enabling infrastructure owners to optimize rehabilitation strategies, allocate resources efficiently, and prioritize interventions using accurate, real-time data. Moreover, the integration of BIM data into digital twins opens new opportunities for advanced operation and maintenance planning, offering dynamic representations of assets. This facilitates predictive analysis and condition-based monitoring, significantly improving infrastructure resilience and sustainability.

Currently, the BIM process and the technical assessment and rehabilitation processes often function in isolation, and yet their integration could yield tremendous benefits. Consolidating current condition data with comprehensive records of past interventions and ongoing performance monitoring creates a robust foundation for future strategies. This approach would enable the development of time-dependent simulations, allowing authorities to assess the long-term impact of various interventions. Additionally, stakeholders could layer intervention data to construct a chronological map of an asset’s evolution, enhancing the ability to make proactive and sustainable management decisions.