From BIM to UAVs: A Systematic Review of Digital Solutions for Productivity Challenges in Construction

Abstract

1. Introduction

- Mapping the technologies in use:

- ○

- Q1. What are the main technologies used to measure/manage construction productivity on-site?

- ○

- Q2. How can these technologies increase the productivity of direct labor?

- Analysis of the impact of specific technologies:

- ○

- Q3. What is the relative importance of point cloud technologies, and how has this importance varied over time?

- ○

- Q5. What is the importance, and how do video and images enhance labor productivity?

- ○

- Q7. What is the importance, and how do sensors enhance labor productivity?

- Supporting and integrative technologies:

- ○

- Q4. What digital tools help in training for on-site activities?

- ○

- Q6. Is BIM necessary to support an automatic productivity control solution on-site? And what are the benefits?

- Empirical grounding:

- ○

- Q8. Do the articles present empirical results from real-world case studies?

2. Materials and Methods

2.1. Study Type and Justification

2.2. Methodological Framework

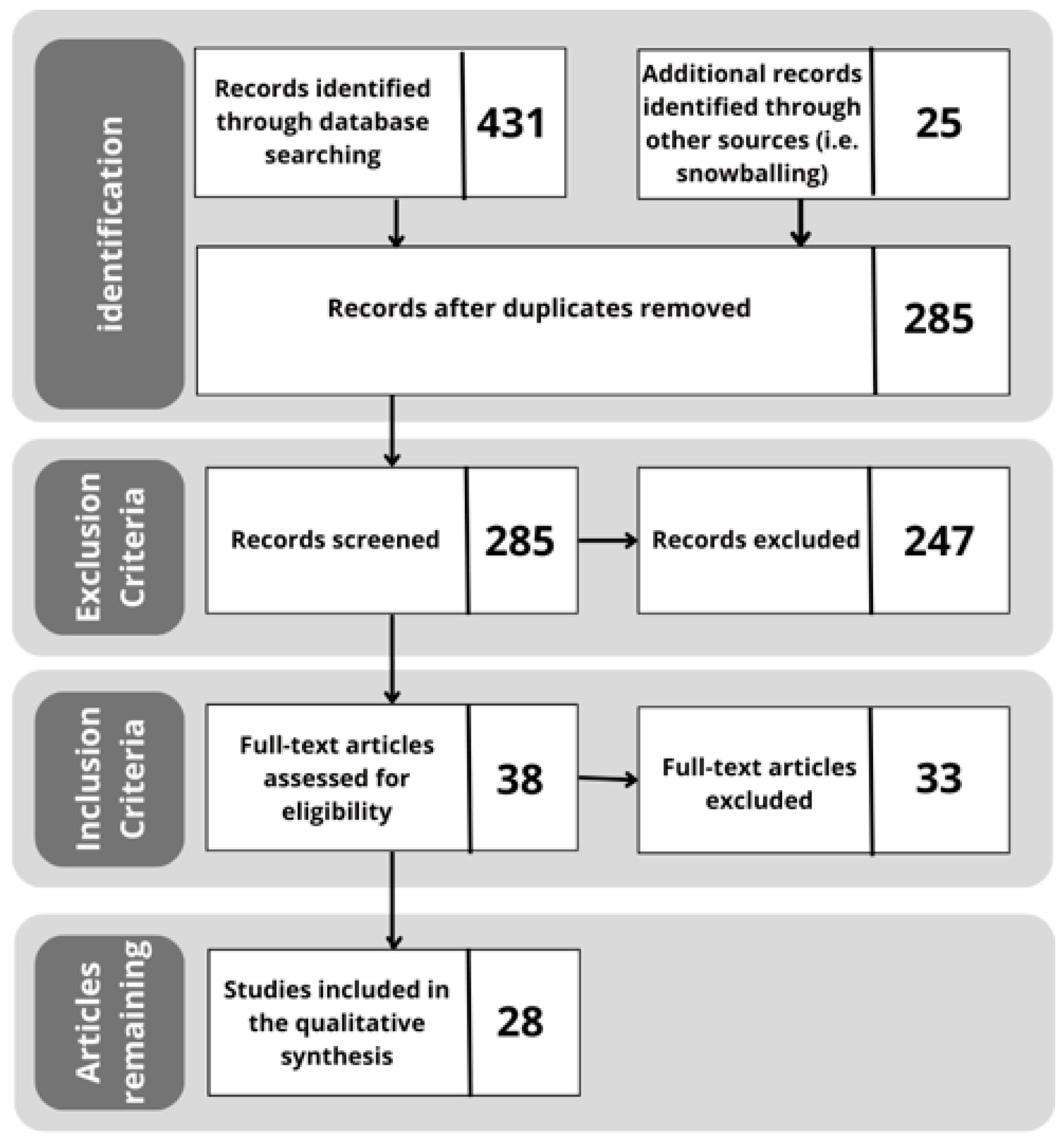

2.3. Main Process Stages

2.4. Search Strategy and Information Sources

2.5. Selection Criteria and Screening Process

- Peer-reviewed articles examining digital technologies in construction contexts;

- Studies reporting productivity outcomes, progress monitoring, or construction automation applications;

- Research involving Building Information Modeling (BIM) integration with digital technologies;

- Publications in the English language;

- No chronological restrictions to capture both foundational and contemporary research.

- Non-peer-reviewed publications (conference abstracts, editorials, opinion pieces);

- Studies not specifically addressing construction productivity or progress monitoring;

- Research focusing solely on design applications without construction implementation;

- Publications in languages other than English due to resource constraints

- Duplicate publications across databases.

2.6. Quality Assurance and Validation Strategies

- Snowballing Technique: Reference lists of initially retrieved papers were systematically reviewed to identify additional relevant studies not captured in the primary database searches, continuing until no new relevant materials were identified;

- PRISMA Compliance: The complete review followed PRISMA-P guidelines [14], with systematic documentation of all screening decisions and exclusions to ensure transparency and reproducibility.

2.7. Identified Potential Biases

- Publication Bias: The review may be subject to publication bias, as studies reporting positive outcomes of digital technology implementation are more likely to be published than those reporting negative or null results. This bias could lead to overestimating technology effectiveness and underrepresenting implementation challenges.

- Language Bias: The restriction to English-language publications may have excluded relevant research published in other languages, particularly studies from non-English speaking countries with significant construction technology development, potentially limiting the global representativeness of findings.

- Database Coverage Bias: While Scopus and Web of Science provide extensive coverage, the exclusive reliance on these databases may have missed relevant studies indexed in specialized construction or regional databases, potentially affecting the comprehensiveness of the evidence base.

3. Results

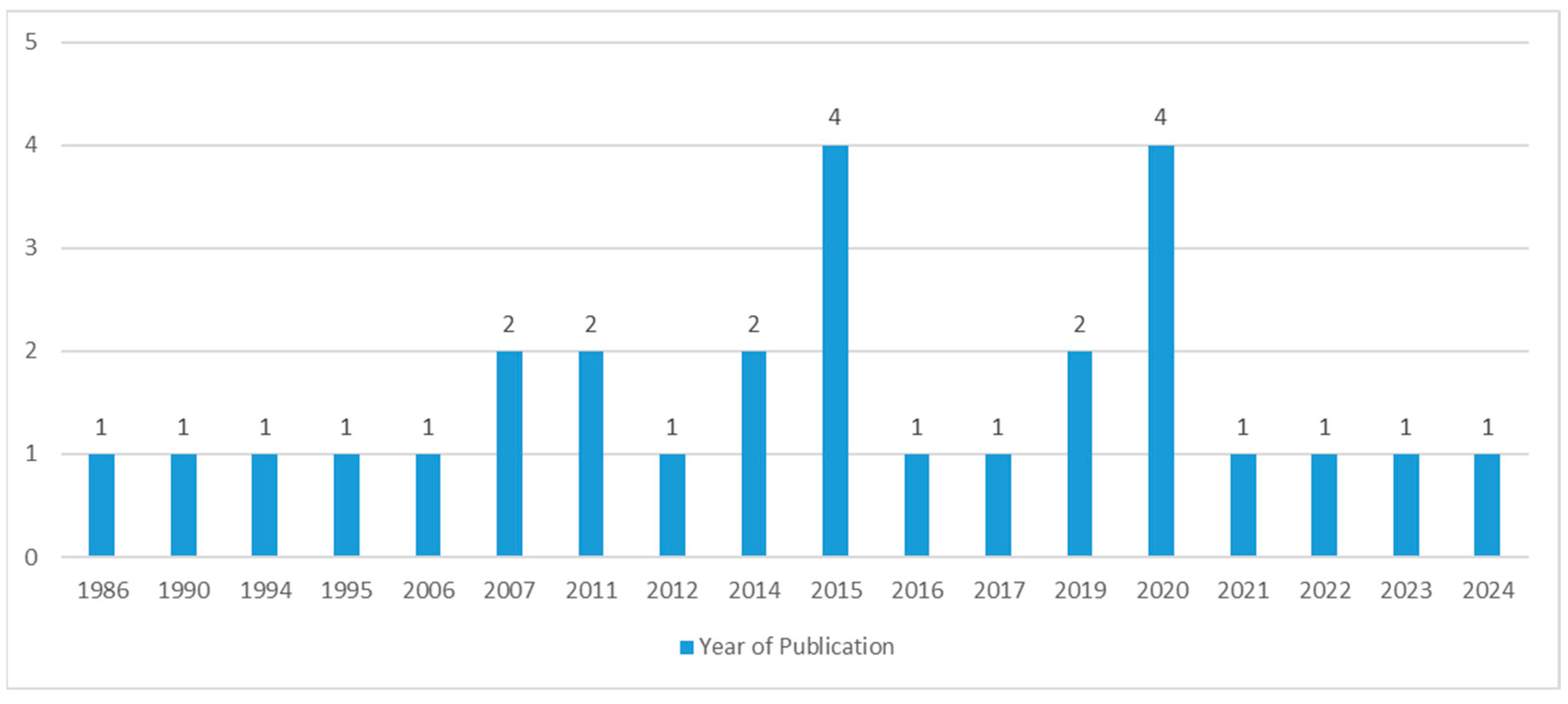

3.1. Selected Articles

3.2. Characteristics of the Included Studies

3.3. Technologies Used to Measure the Construction Productivity: On-Site and Field Analysis

- Building Information Modeling (BIM)—Facilitates the object-oriented physical representation of buildings, supports the visualization of real-world objects, improves coordination among project stakeholders, and aids in creating construction documents for project delivery. BIM-enabled collaboration reduces rework, costs, and errors throughout the building’s entire lifecycle, with significant benefits during the pre-planning phase. Implementation: High-performance workstations (16 GB RAM), cloud platforms, standardized software, and BIM Execution Plans [50].Costs: $50,000–150,000 first year; software $2825–4180/year; consultants $5000–50,000 (BIM.com.sg, 2024). ROI ranges −83.3% to 39,900% [51].Learning Curve: 6–12 months; 40–60 h basic training; 20–30% productivity decrease initially [52];

- Point Clouds Technologies—digital methods used to capture, represent, and process spatial data in the form of dense sets of 3D points. Implementation: Digital cameras (20 MP+), UAV platforms, LiDAR scanners, processing software (Pix4D, Agisoft).Learning Curve: Photogrammetry 2–4 weeks; LiDAR 4–8 weeks; advanced processing 3–6 months [54];

- ○

- Photogrammetry (digital cameras)—Captures real-time images on-site to identify deviations in construction, monitor activities, and assess productivity and activity progress;

- ○

- LiDAR and Total Station—Enable data collection and monitor potential deviations from the constructed work while calculating real-time productivity and comparing it with the calibrated productivity benchmarks;

- Augmented Reality (AR)—The combination of real and virtual images provides a real-time experience for the user and assists in inspection and error identification, improving productivity and safety on-site. Implementation: Tablets/smartphones, head-mounted displays, Unity3D/Vuforia platforms, 3D model preparation.Learning Curve: Basic operation 1–2 weeks; development 3–6 months; advanced implementation 6–12 months [56];

- Global Navigation Satellite System (GNSS)—Offers spatial and location-based data that can significantly reduce labor-intensive data collection and lower associated costs. Implementation: RTK base stations, rover units, machine control integration, communication networks [57]. Costs: RTK systems $25,000–50,000/machine; receivers $8000–15,000; base stations $15,000–30,000; Basic RTK setup from $300 [29].Learning Curve: Basic operation 1–2 weeks; RTK configuration 4–6 weeks; advanced applications 2–4 months [58].

- Radio Frequency Identification (RFID)—Improves the ability to obtain data, identify, and track equipment. Implementation: Tag selection (passive/active), reader infrastructure, and inventory management integration [59]. Costs: Passive tags $0.10–0.50; active tags $5–15; readers $500–3500; complete system $25,000–75,000 [60];Learning Curve: Basic operation 1week; configuration 2–3 weeks; advanced analytics 2–4 months [61];

- Unmanned Aerial Vehicle (UAV)—Increases efficiency and safety, reduces labor costs, and collects data and photographs. Implementation: Pilot certification, flight planning software, data processing capabilities, and regulatory compliance. Costs: Consumer drones $1000–5000; professional systems $10,000–50,000; DJI Matrice RTK $15,370; Certification $3000–8000 [62].Learning Curve: Basic operation 2–4 weeks; professional surveying 6–8 weeks; advanced applications 3–6 months [63];

- Machine Learning (ML)—enhances accuracy by processing large datasets, predicts delays through historical analysis, and automates monitoring tasks using tools like computer vision. It identifies key productivity drivers, provides real-time decision support, and optimizes resource allocation. Implementation: Data collection infrastructure, cloud computing, model development platforms, specialized personnel [64]. Costs: Infrastructure $50,000–200,000; cloud computing $500–5000/month; specialists $80,000–150,000/year [65].

- Factors affecting productivity;

- Productivity modeling and evaluation.

- Method and technology for productivity improvement

3.4. The Impact of BIM on Labor Productivity

3.5. Video and Image to Enhance Productivity

4. Discussion

4.1. Summary of Evidence

4.2. Productivity Improvement Measurement

4.3. Limitations of the Systematic Review

5. Conclusions

5.1. Technology Selection by Project Context

5.2. Implementation Strategy

5.3. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AECO | Architecture, Engineering, Construction and Operation |

| AR | Augmented reality |

| BIM | Building Information Modeling |

| CI | Construction Industry |

| GNSS | Global Navigation Satellite System |

| KPI | Key Performance Indicators |

| MR | Mixed Reality |

| RFID | Radio Frequency Identification |

| UAV | Unmanned Aerial Vehicle |

| VR | Virtual Reality |

| WOS | Web of Science |

References

- Calvetti, D.; Mêda, P.; Gonçalves, M.C.; Sousa, H. Worker 4.0: The Future of Sensored Construction Sites. Buildings 2020, 10, 169. [Google Scholar] [CrossRef]

- Azeem, M.; Ullah, F.; Thaheem, M. Competitiveness in the construction industry: A contractor’s perspective on barriers to improving the construction industry performance. J. Constr. Eng. 2020, 3, 193–219. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction Through a Productivity Revolution. McKinsey Global Institute. 2017. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/operations/our%20insights/reinventing%20construction%20through%20a%20productivity%20revolution/mgi-reinventing-construction-a-route-to-higher-productivity-full-report.pdf (accessed on 24 November 2024).

- Bohn, J.; Teizer, J. Benefits and Barriers of Construction Project Monitoring using Hi-Resolution Automated Cameras. J. Constr. Eng. Manag. 2010, 136, 632–640. [Google Scholar] [CrossRef]

- Shahi, A.; West, J.; Haas, C. Onsite 3D marking for construction activity tracking. Autom. Constr. 2013, 30, 136–143. [Google Scholar] [CrossRef]

- Goodrum, P.; Haas, C.; Caldas, C.; Zhai, D.; Yeiser, J.; Homm, D. Model to predict the impact of a technology on construction productivity. J. Constr. Eng. Manag. 2010, 137, 678–688. [Google Scholar] [CrossRef]

- Bosché, F. Automated recognition of 3D CAD model objects in laser scans and calculation of as-built dimensions for dimensional compliance control in construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Golpavar-Fard, M.; Arboleda, C.; Peña-Mora, F.; Lee, S. Visualization of construction progress monitoring with 4D simulation model overlaid on time-lapse photographs. J. Comput. Civ. Eng. 2009, 23, 391–404. [Google Scholar] [CrossRef]

- Navon, R. Research in automated measurement of project performance indicators. Autom. Constr. 2007, 16, 176–188. [Google Scholar] [CrossRef]

- Quiñones-Rozo, C.; Hashash, Y.; Liu, L. Digital image reasoning for tracking excavation activities. Autom. Constr. 2008, 17, 608–622. [Google Scholar] [CrossRef]

- Green, S. Systematic reviews and meta-analysis. Singap. Med. J. 2005, 46, 270–274. Available online: https://pubmed.ncbi.nlm.nih.gov/15902354/.pdf (accessed on 1 December 2024).

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 explanation and elaboration: Updated guidance and exemplars for reporting systematic reviews. BMJ 2020, 372, 160. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 Statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Liang, D.; Chen, S.-H.; Chen, Z.; Wu, Y.; Chu, L.Y.; Xue, F. 4D point cloud-based spatial-temporal semantic registration for monitoring mobile crane construction activities. Autom. Constr. 2024, 165, 105576. [Google Scholar] [CrossRef]

- Kim, J.; Chi, S. Multicamera vision-based productivity monitoring of earthmoving operations. Autom. Constr. 2020, 112, 103121. [Google Scholar] [CrossRef]

- Martinez, P. A vision-based approach for automatic progress tracking of floor paneling in offsite construction facilities. Autom. Constr. 2021, 12, 103620. [Google Scholar] [CrossRef]

- Nath, T.; Attarzadeh, M.; Tiong, R.L.; Chidambaram, C.; Yu, Z. Productivity improvement of precast shop drawings generation through BIM-based process re-engineering. Autom. Constr. 2015, 54, 54–68. [Google Scholar] [CrossRef]

- Navon, R.; Sack, R. Assessing research in automated project performance control (APPC). Autom. Constr. 2007, 16, 474–484. [Google Scholar] [CrossRef]

- Gong, J.; Caldas, C. An object recognition, tracking, and contextual reasoning-based video interpretation method for rapid productivity analysis of construction operations. Autom. Constr. 2011, 20, 1211–1226. [Google Scholar] [CrossRef]

- Poirier, E. Measuring the impact of BIM on labor productivity in a small specialty contracting enterprise through action-research. Autom. Constr. 2015, 58, 74–84. [Google Scholar] [CrossRef]

- Lee, J.; Park, Y.-J.; Choi, C.-H.; Han, C.-H. BIM-assisted labor productivity measurement method for structural formwork. Autom. Constr. 2017, 84, 121–132. [Google Scholar] [CrossRef]

- Jarkas, A.; Bitar, C. Factors Affecting Construction Labor Productivity in Kuwait. J. Constr. Eng. Manag. 2011, 138, 811–820. [Google Scholar] [CrossRef]

- Halligan, D.W.; Demsetz, L.A.; Brown, J.D.; Pace, C.B. Action-Response Model and Loss of Productivity in Construction. J. Constr. Eng. Manag. 1994, 120, 47–64. [Google Scholar] [CrossRef]

- Thomas, H.R.; Maloney, W.F.; Horner, R.M.W.; Smith, G.R.; Handa, V.K.; Sanders, S.R. Modeling Construction Labor Productivity. J. Constr. Eng. Manag. 1990, 116, 705–726. [Google Scholar] [CrossRef]

- Liou, F.-S.; Borcherding, J. Work Sampling Can Predict Unit Rate Productivity. J. Constr. Eng. Manag. 1986, 112, 90–103. [Google Scholar] [CrossRef]

- Jarkas, A.M.; Al Balushi, R.A.; Raveendranath, P. Determinants of construction labour productivity in Oman. Int. J. Constr. Manag. 2015, 15, 332–344. [Google Scholar] [CrossRef]

- Hiyassat, M.A.; Hiyari, M.A.; Sweis, G.J. Factors affecting construction labour productivity: A case study of Jordan. Int. J. Constr. Manag. 2016, 16, 138–149. [Google Scholar] [CrossRef]

- Wong, J.H.; Rashidi, A.; Arashpour, M. Evaluating the Impact of Building Information Modeling on the Labor Productivity of Construction Projects in Malaysia. Buildings 2020, 10, 66. [Google Scholar] [CrossRef]

- Ratajczak, J. BIM-based and AR Application Combined with Location-Based Management System for the Improvement of the Construction Performance. Buildings 2019, 9, 118. [Google Scholar] [CrossRef]

- Molaei, A.; Kolu, A.; Haaraniemi, N.; Geimer, M. Automatic Estimation of Excavator’s Actual Productivity in Trenching and Grading Operations Using Building Information Modeling (BIM). Actuators 2023, 12, 423. [Google Scholar] [CrossRef]

- Park, J.; Lee, K. Efficiency Analysis of Construction Automation Using 3D Geospatial Information. Sens. Mater. 2022, 34, 415–425. [Google Scholar] [CrossRef]

- Arif, F.; Khan, W. A Real-Time Productivity Tracking Framework Using Survey-Cloud-BIM Integration. Arab. J. Sci. Eng. 2020, 45, 8699–8710. [Google Scholar] [CrossRef]

- Lee, U.-K.; Kang, K.-I.; Kim, G.-H.; Cho, H.-H. Improving tower crane productivity using wireless technology. Comput.-Aided Civ. Infrastruct. Eng. 2006, 21, 594–604. [Google Scholar] [CrossRef]

- Yi, M.; Chan, A. Critical Review of Labor Productivity Research in Construction Journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef]

- Yang, J.; Park, M.-W.; Vela, P.A.; Golparvar-Fard, M. Construction performance monitoring via still images, time-lapse photos, and video streams: Now, tomorrow, and the future. Adv. Eng. Inform. 2015, 29, 211–224. [Google Scholar] [CrossRef]

- Sabet, P.; Chong, H.-Y. Pathways for the improvement of construction productivity: A perspective on the adoption of advanced techniques. Adv. Civ. Eng. 2020, 2, 1–17. [Google Scholar] [CrossRef]

- Mandanayake, U.; Çıdık, M. The potential of digital technology to improve construction productivity. In Proceedings of the 35th Annual ARCOM Conference, Leeds, UK, 2–4 September 2019. [Google Scholar]

- Crawford, P.; Vogl, B. Measuring productivity in the construction industry. Build. Res. Inf. 2006, 34, 208–219. [Google Scholar] [CrossRef]

- Lim, E.C.; Alum, J. Construction productivity: Issues encountered by contractors in Singapore. Int. J. Proj. Manag. 1995, 13, 51–58. [Google Scholar] [CrossRef]

- Thomas, A.; Sudhakumar, J. Factors Influencing Construction Labour Productivity: An Indian Case Study. J. Constr. Dev. Ctries. 2014, 19, 53. [Google Scholar]

- Liberda, M.; Ruwanpura, J.; Jergeas, G. Construction Productivity Improvement: A Study of Human, Management and External Issues. Constr. Res. Congr. Wind. Change Integr. Innov. 2012, 26, 1–8. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Gray, J.; Rumpe, B. Models for digitalization. Softw. Syst. Model. 2015, 14, 1319–1320. [Google Scholar] [CrossRef]

- Brandon, P.S.; Lu, S.L. Clients Driving Innovation; Wiley-Blackwell: Chichester, UK, 2008. [Google Scholar]

- Froese, T. The impact of emerging information technology on project management for construction. Autom. Constr. 2010, 19, 531–538. [Google Scholar] [CrossRef]

- Patacas, J.; Dawood, N.; Vukovic, V.; Kassem, M. BIM for facilities management: Evaluating BIM standards in asset register creation and service life planning. J. Inf. Technol. Constr. 2015, 20, 313–331. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84979562033&origin=inward&txGid=6fd2c2f0d918167d866ef364ae9cd5fc (accessed on 7 December 2024).

- Ruwanpura, J.; Hewage, K.; Silva, L. Evolution of the i-Booth© onsite information management kiosk. Autom. Constr. 2012, 21, 52–63. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated progress control using laser scanning technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Ahmed, S. Barriers to implementation of building information modeling (BIM) to the construction industry. J. Civ. Eng. Constr. 2018, 7, 107–113. [Google Scholar] [CrossRef]

- Giel, B.K.; Issa, R.R. Return on investment analysis of using building information modeling in construction. J. Comput. Civ. Eng. 2013, 27, 511–521. [Google Scholar] [CrossRef]

- Ullah, K.; Lill, I.; Witt, E. An overview of BIM adoption in the construction industry. Emerald Insight 2019, 2, 297–303. [Google Scholar] [CrossRef]

- JOUAV. How Much Does a Drone Cost in 2025? 2024. Available online: https://www.jouav.com/blog/how-much-does-a-drone-cost.html (accessed on 25 September 2025).

- Tkáč, M.; Mésároš, P. Utilizing drone technology in the civil engineering. Slovak J. Civ. Eng. 2019, 27, 23–32. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Archit. Manag. 2022, 29, 3181–3209. [Google Scholar] [CrossRef]

- Zaher, M.; Greenwood, D.; Marzouk, M. Mobile augmented reality applications for construction projects. Constr. Innov. 2018, 18, 152–166. [Google Scholar] [CrossRef]

- Bench-Mark. How RTK Is Transforming the Construction Industry. Available online: https://bench-mark.ca/how-rtk-is-transforming-the-construction-industry/ (accessed on 25 September 2025).

- Point One Nav. Build Your Own RTK Base Station? 2023. Available online: https://pointonenav.com/news/is-build-your-own-rtk-really-worth-it/ (accessed on 25 September 2025).

- Valero, E.; Adán, A.; Cerrada, C. Evolution of RFID applications in construction: A literature review. Sensors 2015, 15, 15988–16008. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Almujibah, H.; Khan, M.B.; Alotaibi, S.; Eldin, S.M. Integration of passive RFID for small-scale construction material tracking and management. Structures 2023, 51, 1549–1559. [Google Scholar] [CrossRef]

- Goodrum, P.M.; McLaren, M.A.; Durfee, A. The application of active radio frequency identification technology for tool tracking on construction job sites. Autom. Constr. 2006, 15, 292–302. [Google Scholar] [CrossRef]

- Superior Instrument. UAVs for Surveying & Mapping—Construction Drones. 2024. Available online: https://www.superiorinstrument.com/UAV-s/4169.htm (accessed on 25 September 2025).

- The Drone, U. Drone Surveying Guide: Why UAV Surveying Is the Future? 2024. Available online: https://www.thedroneu.com/blog/drone-surveying/ (accessed on 25 September 2025).

- Bilal, M.; Oyedele, L.O. Guidelines for applied machine learning in construction industry—A case of profit margins estimation. Adv. Eng. Inform. 2020, 42, 100965. [Google Scholar] [CrossRef]

- Coherent Solutions. AI Development Cost Estimation: Pricing Structure, ROI. 2025. Available online: https://www.coherentsolutions.com/insights/ai-development-cost-estimation-pricing-structure-roi (accessed on 25 September 2025).

- Fayek, A.; Oduba, A. Predicting Industrial Construction Labor Productivity Using Fuzzy Expert Systems. J. Constr. Eng. Manag. 2005, 131, 938–941. [Google Scholar] [CrossRef]

- Tam, C.; Tong, T.K.; Tse, S.L. Artificial neural networks model for predicting excavator productivity. Eng. Constr. Archit. Manag. 2002, 9, 446–452. [Google Scholar] [CrossRef]

- Herbsman, Z.; Ellis, R. Research of factors influencing construction productivity. Constr. Manag. Econ. 1990, 8, 49–61. [Google Scholar] [CrossRef]

- Azhar, S.; Carlton, W.A.; Olsen, D.; Ahmad, I. Building information modeling for sustainable design and LEED (R) rating analysis. Autom. Constr. 2011, 20, 217–224. [Google Scholar] [CrossRef]

- Wemegah, T.D.; Zhu, S.; Yeboah, G.; Atombo, C. Explorative analysis of vehicular movement patterns using RFID-based transport data: An eulerian perspective. Adv. Transp. Stud. 2018, 44, 47–62. Available online: https://wrap.warwick.ac.uk/id/eprint/126684/ (accessed on 1 October 2025).

- Li, Y.; Liu, C. Applications of multirotor drone technologies in construction management. Int. J. Constr. Manag. 2018, 19, 401–412. [Google Scholar] [CrossRef]

- National Institute of Building Science. National Building Information Modeling Standard, Version 1.0, Part 1—Overview, Principles and Methodologies, 1st ed.; National Institute of Building Science: Washington, DC, USA, 2007. [Google Scholar]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors, 2nd ed.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.; Reed, D. Benefits and lessons learned of implementing Building Virtual Design and Construction (VDC) technologies for coordination of Mechanical, Electrical, and Plumbing (MEP) systems on a large Healthcare project. Electron. J. Inf. Technol. Constr. 2008, 13, 324–342. [Google Scholar]

- Sacks, R.; Barak, R. Impact of three-dimensional parametric modeling of buildings on productivity in structural engineering practice. Autom. Constr. 2008, 17, 439–449. [Google Scholar] [CrossRef]

- Coates, P.; Arayici, Y.; Koskela, K.; Kagioglou, M.; Usher, C.; O’Reilly, K. The Key Performance Indicators of the BIM Implementation Process. Available online: https://scispace.com/pdf/the-key-performance-indicators-of-the-bim-implementation-21wednumzi.pdf (accessed on 8 December 2024).

- Han, K.; Golparvar-Fard, M. Automated Monitoring of Operation-level Construction Progress Using 4D BIM and Daily Site Photologs. Constr. Res. Congr. 2014, 2014, 1033–1042. [Google Scholar] [CrossRef]

- Abeid, J.; Allouche, E.; Arditi, D.; Hayman, M. PHOTO-NET II: A computer-based monitoring system applied to project management. Autom. Constr. 2003, 12, 603–616. [Google Scholar] [CrossRef]

- Ji, Y.; Chang, S.; Qi, Y.; Li, Y.; Li, H.X.; Qi, K. A BIM-Based Study on the Comprehensive Benefit Analysis for Prefabricated Building Projects in China. Adv. Civ. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Aziz, R.; Hafez, S. Applying lean thinking in construction and performance improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef]

- Jung, Y.; Joo, M. Building information modelling (BIM) framework for practical implementation. Autom. Constr. 2011, 20, 126–133. [Google Scholar] [CrossRef]

- Gikas, V.; Sakellariou, M. Settlement analysis of the Mornos earth dam (Greece): Evidence from numerical modeling and geodetic monitoring. Eng. Struct. 2008, 30, 3074–3081. [Google Scholar] [CrossRef]

- Retscher, G. Indoor Navigation—User Requirements, State-of-the-Art and Developments for Smartphone Localization. Geomatics 2022, 3, 1–46. [Google Scholar] [CrossRef]

- Introduction to Operation Research. 2020. Available online: https://abdulkadir.blog.uma.ac.id/wp-content/uploads/sites/621/2020/01/Introduction-to-Operations-Research-Hillier-Lieberman.pdf (accessed on 26 September 2025).

| Source (Name of Peer-Reviewed Journal) | References | Quantity (n) | Percentage (%) |

|---|---|---|---|

| Automation in Construction | [15,16,17,18,19,20,21,22] | 8 | 29 |

| Journal of Construction Engineering and Management | [23,24,25,26] | 4 | 14 |

| International Journal of Construction Management | [27,28] | 2 | 7 |

| MDPI—Buildings | [29,30] | 2 | 7 |

| Other Journals | [31,32,33,34,35,36,37,38,39,40,41,42] | 12 | 43 |

| Total | 28 | 100 |

| References | ||

|---|---|---|

| Field | Factors Affecting Productivity | [23,24,27,28,40,41] |

| Method and technology for productivity improvement | [18,21,29,30,32,34,37,38,42] | |

| Productivity modeling and evaluation | [15,16,17,19,20,22,25,26,31,33,35,36,39] | |

| Digital Technologies | BIM | [15,18,21,22,29,30,31,33] |

| LiDAR/ Total Station | [15,31,32,33] | |

| Video and Image | [16,17,20,31,34,36] | |

| RFID | [34] | |

| GNSS | [31,32] | |

| UAV | [32] | |

| AR | [30,32] |

| Reference | Title | Year | Country | Research |

|---|---|---|---|---|

| [15] | 4D point cloud-based spatial-temporal semantic registration for monitoring mobile crane construction activities | 2024 | China | Determining the optimal placement of a BIM object and achieving high-resolution tracking of hoisting activities |

| [18] | Productivity improvement of precast shop drawings generation through BIM-based process re-engineering | 2020 | Singapore | BIM components which enable the automated shop drawings and reinforcement schedule generation |

| [21] | Measuring the impact of BIM on labor productivity in a small specialty contracting enterprise through action research | 2015 | Canada | BIM was used to visualize, coordinate, and negotiate work between trades, containing details like spool drawings for building the penthouse. It also benefited non-modeling trades, such as the electrical contractor |

| [22] | BIM-assisted labor productivity measurement method for structural formwork | 2017 | South Korea | It develops a method for acquiring field labor productivity data by integrating a 3D model with related information |

| [29] | Evaluating the Impact of Building Information Modeling on the Labor Productivity of Construction Projects in Malaysia | 2020 | Malaysia | This research evaluated the effect of BIM on labor productivity from the perspective of AEC professionals, instead of directly measuring labor productivity on-site |

| [30] | BIM-based and AR application combined with a location-based management system for the improvement of the construction performance | 2019 | Italy | The AR4C application is designed to improve project control by quickly identifying deviations from the project schedule and variations in performance and progress. This will be achieved by overlaying a 3D BIM model onto the real world using augmented reality (AR). |

| [31] | Automatic Estimation of Excavator’s Actual Productivity in Trenching and Grading Operations Using Building Information Modeling (BIM) | 2023 | Finland | The productivity is assessed by comparing the height between the desired mode and the actual map of nearby areas, which is updated every few seconds |

| [33] | A Real-Time Productivity Tracking Framework Using Survey-Cloud-BIM Integration | 2020 | Pakistan | The models were developed to utilize planned quantities for productivity tracking |

| Reference | Title | Year | Country | Research |

|---|---|---|---|---|

| [16] | Multicamera vision-based productivity monitoring of earthmoving operations | 2020 | South Korea | Conducted experiments using video stream data recorded from an actual earthmoving site for highway construction, and analyzed jobsite videos collected from multiple non-overlapping cameras in the field of construction productivity monitoring |

| [17] | A vision-based approach for automatic progress tracking of floor paneling in off-site construction facilities | 2021 | Canada | Tracking the trajectory and movement of construction resources, as well as recognizing workers’ gestures |

| [20] | An object recognition, tracking, and contextual reasoning-based video interpretation method for rapid productivity analysis of construction operations | 2011 | USA | In comparison to the traditional manual construction video analysis method, the new method enables the interpretation of these videos into productivity information |

| [31] | Automatic Estimation of Excavator’s Actual Productivity in Trenching and Grading Operations Using Building Information Modeling (BIM) | 2023 | Finland | The productivity is calculated by comparing the height of the desired model to the actual map of surrounding areas, which is updated every few seconds |

| [34] | Improving tower crane productivity using wireless technology | 2006 | South Korea | Video devices integrated with RFID technology provided clear images of the site and materials, enabling workers to rely less on traditional methods of communication and achieve greater productivity |

| [36] | Construction performance monitoring via still images, time-lapse photos, and video streams: now, tomorrow, and the future | 2015 | China | Images, time-lapse photos, and video streams are used to document work in progress, detect, and track workers. From these, productivity information and progress deviations can be inferred based on a reduced video set |

| ID | Answers to the Research Questions |

|---|---|

| A1 | Several advanced technologies are used to measure and manage the productivity of construction on site, each playing a crucial role in optimizing efficiency and resource allocation between these technologies. Among them, which stand out most by reference order are BIM, Cameras, LiDAR, GNSS, AR, UAV, and RFID. |

| A2 | These technologies boost construction productivity by ensuring precision, seamless coordination, and operational efficiency. They enable improved collaboration, reduce errors, guarantee accurate positioning, facilitate real-time monitoring, provide aerial site inspections, generate precise 3D maps, and integrate digital models with the real world. Together, they streamline processes and deliver significant gains in labor productivity. |

| A3 | Point cloud technologies have become essential in construction, significantly improving accuracy and efficiency in tasks like 3D scanning, mapping, and modeling. Initially, their use was limited due to high costs and technical complexity. However, as technology advanced, point cloud applications expanded from specialized surveying to key roles in BIM integration, as-built documentation, and facility management. By 2015, with improved hardware and more accessible software, point clouds became integral to precise measurements, reducing manual errors and enhancing project planning. Today, these technologies are critical in optimizing construction workflows and ensuring greater productivity and precision. Building Information Modeling (BIM), augmented and virtual reality (AR/VR). |

| A4 | Several digital tools are essential for training workers on-site, providing hands-on learning, real-time feedback, and immersive experiences to prepare them for construction tasks. These tools enhance workers’ understanding of processes, safety, and operational procedures in a risk-free and efficient manner. AR and VR are among the most effective tools for on-site training, and BIM is another valuable digital training tool |

| A5 | Video and image-based technologies have become essential tools for enhancing labor productivity in the construction industry. They offer visual insights, real-time monitoring, and actionable data that enable improved decision-making, process optimization, and resource management. Their significance lies in their ability to track progress, observe worker activities, identify inefficiencies, and ensure safety, directly leading to increased productivity |

| A6 | BIM is not strictly necessary to support an on-site automatic productivity control solution, but it significantly enhances such systems’ effectiveness and integration. BIM provides a centralized and highly detailed digital representation of a construction project, which can be used to link real-time data from various automated productivity monitoring tools, such as sensors, cameras, and wearable devices. This integration helps to streamline workflows, ensure data consistency, and facilitate decision-making. While some productivity control systems can function without BIM, relying solely on point cloud data, images, or videos, these systems are often less coordinated and may lack the comprehensive scope that BIM enables. BIM’s ability to provide real-time updates, visualize construction progress, and link with other technologies makes it an asset for automatic productivity control |

| A7 | Sensors are critical in enhancing labor productivity by providing real-time data, automating monitoring processes, and optimizing resource allocation. They improve efficiency by tracking equipment and material usage, monitoring environmental conditions, and providing insights into worker performance. By reducing manual data collection, sensors minimize errors and save time. Furthermore, they enable predictive maintenance, ensuring machinery operates smoothly without unexpected downtime. Sensors also enhance safety by detecting hazardous conditions and alerting workers, which reduces accidents and improves overall productivity on the construction site. Through these capabilities, sensors help streamline operations, improve decision-making, and optimize workflows, ultimately driving higher labor productivity |

| A8 | The presented articles showcase results, with qualitative and quantitative data, which will be detailed below. These results provide a concrete and evidence-based analysis, offering a deeper understanding of the impact of technologies on construction productivity |

| Reference | Results | |

|---|---|---|

| Quantitative Results | Qualitative Results | |

| [15] | F1-score of 99.93–100% in BIM object detection | Safer operations reduce interruptions, sustaining productivity |

| [16] | The average error rate for the extraction of productivity information decreased from 23.8% to 8.8% | Improved accuracy in extracting productivity data. Detailed assessment of construction equipment operational efficiency |

| [17] | The presented approach can calculate the duration and the man-hours required per task with an accuracy above 92% | Enables rapid identification of bottlenecks or delays in production, improving decision-making, facilitates activity planning and prioritization, reducing idle time and increasing overall productivity and identifies errors or rework in early stages, preventing waste and improving overall performance |

| [18] | it was concluded that there would be a substantial time saving of 380 man hours | Reduced manual work through automation, streamlined process through BIM integration and parametric BIM components ensured consistency and reduced errors |

| [19] | Simulations showed a potential reduction of up to 10–15% time (hours/days) in the total control cycle time compared to traditional methods | Faster decision-making due to quicker feedback on project performance indicators (PPIs) and improved tracking of inventory using RFID and sensors |

| [20] | N/A | Interprets construction operation videos into productivity data (work cycles, delays, activity times). Reduces manual analysis effort and Integrates object recognition, tracking, and contextual reasoning (spatial, temporal, semantic) |

| [21] | For labor productivity with time as the input, there was an increase in productivity ranging from 75% to 240%. Percentage increase in output per labor unit in BIM-modeled/prefabricated areas compared to traditional methods | BIM and prefabrication significantly reduced on-site labor effort and improved task completion efficiency and improved accuracy of installation and fewer errors due to clash detection and coordinated planning |

| [22] | Maximum potential productivity (trendline projection): 61.25 m2/man-day | Integration of BIM spatial zoning + quantity take-off + actual labor records. Enables automatic productivity measurement and comparison zone-by-zone and establishes a best-fit trend to predict future productivity and compare planned vs. actual. Useful for control and forecasting |

| [23] | N/A | Productivity can be further enhanced by engaging skilled construction managers to deliver strong on-site leadership, enforce effective labor supervision standards, and collaborate with executive management to implement strategic initiatives |

| [24] | Average productivity loss of about 30% on days with change orders | The action-response model defines a new approach to evaluating the causes of productivity loss, divided into three categories: External conditions, Crew responses and Contractor actions |

| [25] | N/A | Is presented as each factor impacts productivity, conceptually, listing the factors such as: Improved Work Methods, Equipment Availability, Skilled Workforce, Material Planning and Logistics, and Supervision and Management |

| [26] | N/A | Demonstrated that the work sampling technique can effectively predict productivity per work unit in construction. This statistical method estimates the proportion of time workers devote to different categories of activities, such as direct work, supportive work, and delay |

| [27] | The RII for each factor investigated varies in value from 0 (not inclusive) to 1. The list of 5 areas: Errors and omissions in project drawings 0.922 Change orders during execution 0.896 Delay in responding to requests for information 0.878 Lack of labor supervision 0.867 Clarity of project specifications 0.862 | The effects of the 33 factors surveyed on labor productivity in construction in Oman are determined. The data collected were analyzed using the relative importance index (RII) technique and listed as five main areas: Errors and omissions in the project drawings; Requests for change during execution; Delay in response to requests for information; Lack of labor supervision and clarity of project specifications |

| [28] | The RII for each factor investigated varies in value from 0 (not inclusive) to 1. The list of 5 areas: Planning 0.83 Worker–management relationship 0.83 Education and experience 0.81 Climate 0.81 Technology and equipment 0.80 | The study highlights five equally important productivity factors forming a single cluster: planning, worker-management relationships, education and experience, technology and equipment. The data collected were analyzed using the relative importance index (RII) technique. |

| [29] | The five underlying factor categories explain about 19% of the variation in perceived labor productivity when BIM is adopted. Individual (Supervision): positive coefficient; highest perceived positive impact on productivity. Individual (Labor): negative coefficient; perceived as reducing labor productivity when adopting BIM | Individual supervision (site supervision, field coordination) has the greatest perceived positive impact when BIM is implemented. Individual (Labor) workers’ skills, experience, and BIM proficiency can negatively affect productivity if not adequately trained and education and training are crucial to mitigate negative impacts from low-skilled labor and to maximize productivity gains from BIM adoption |

| [30] | 10–20% reduction in time (hours/days) required for task completion and up to 15% (days) reduction in delays for critical tasks | 3D model overlay in AR improves workers’ understanding of tasks. Real-time progress visualization helps quickly identify delays |

| [31] | Average productivity in grading (0.03 m2/s) and Average productivity in trenching (0.01 m/s) | Assess productivity and track the progress of operations |

| [32] | Reduced the working time by about 13 h compared with the conventional method. Assuming 8 h of work per day, the number of workdays was reduced by 1.6 days | Productivity has increased |

| [33] | Compliance with planning >90% in test cases | Allows managers to instantly track actual vs. planned progress, enabling quick adjustments. Operators can correct errors and optimize tasks before small issues become delays |

| [34] | The case study showed that the work speed, meaning the total cycle time for each lifting activity, improved by 9.9–38.9%, with an average improvement of 26.5% | Overall productivity increases through error reduction and optimized lifting operations |

| [35] | N/A | Planning and coordination, team communication, task complexity, required skills and use of modern tools and equipment improving productivity |

| [36] | N/A | Visual monitoring of infrastructure or building elements, visual monitoring of equipment and construction workers and use of computer-vision–based techniques |

| [37] | N/A | Emphasizes the importance of fundamentals such as focus on project value, lifecycle concept, and workflow management to reinforce the implementation of advanced techniques that include BIM, automation, 3D printing, modular construction, artificial intelligence, and others for improving productivity |

| [38] | N/A | Emphasizes the importance of integrating advanced digital techniques with productivity fundamentals to enhance construction productivity |

| [39] | Productivity rates for erecting concrete reinforcing footings vary from 0.28 to 2.10 m3 per person-hour | Shows long-term reduction in efficiency; highlights the need for process improvement. Pandemic significantly reduced workforce availability and productivity |

| [40] | Productivity decreases by up to 25% in time (hours/days) | Difficulty recruiting supervisors and skilled workers, leading to errors and rework. Weak supervision and organization lead to inefficiency and waste |

| [41] | Productivity decreased by 12% to 18% in time (hours/days) | Poor planning, inadequate coordination, and unrealistic goals and deadlines have a significant impact on productivity |

| [42] | 6% productivity increase with better workforce management and 50% of the average profit increase comes from a 6% productivity improvement | Identify the most critical aspects in terms of human, external and management issues that affect construction productivity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saraiva Landim, V.F.; Poças Martins, J.; Calvetti, D. From BIM to UAVs: A Systematic Review of Digital Solutions for Productivity Challenges in Construction. Appl. Sci. 2025, 15, 10843. https://doi.org/10.3390/app151910843

Saraiva Landim VF, Poças Martins J, Calvetti D. From BIM to UAVs: A Systematic Review of Digital Solutions for Productivity Challenges in Construction. Applied Sciences. 2025; 15(19):10843. https://doi.org/10.3390/app151910843

Chicago/Turabian StyleSaraiva Landim, Victor Francisco, João Poças Martins, and Diego Calvetti. 2025. "From BIM to UAVs: A Systematic Review of Digital Solutions for Productivity Challenges in Construction" Applied Sciences 15, no. 19: 10843. https://doi.org/10.3390/app151910843

APA StyleSaraiva Landim, V. F., Poças Martins, J., & Calvetti, D. (2025). From BIM to UAVs: A Systematic Review of Digital Solutions for Productivity Challenges in Construction. Applied Sciences, 15(19), 10843. https://doi.org/10.3390/app151910843