1. Introduction

Prior to the establishment of modern standards for compressed metal members, the design of metallic structures relied mainly on empirical formulas derived from construction experience. Early metal frameworks, particularly those incorporating wrought iron, were developed according to simplified empirical rules informed by rudimentary experimental observations. In the absence of theoretical models, builders adjusted member dimensions based on structural failures observed in existing constructions.

The emergence of scientific theories marked a significant advancement, providing a more rigorous understanding of buckling, or static instability of compressed members. Leonhard Euler [

1] first established a comprehensive theory of buckling, providing the renowned formula for the critical load of an ideal compressed column. Euler’s formula, as we use it now, accounts for the modulus of elasticity of the material, the second moment of area of the cross-section about the major inertia axis normal to the plane of buckling, the length of the element, and an effective length factor that accounts for the end constraints of the element. However, it assumes perfect elements without imperfections or plasticity, limiting its applicability to real-world scenarios.

With the rise of metallic structures, refined theories incorporated more realistic features: Ayrton and Perry [

2] assume that real columns have geometric imperfections and find a critical load lower than Euler’s theoretical one. Engesser [

3] and Tetmajer [

4] refine Euler’s formula considering both geometric imperfections and plasticity. Experimental tests proved that even small geometric deviations from the case of pure bending significantly reduce the critical load. Von Kármán [

5] further explored the influence of imperfections and plasticity, showing that the yield strength of metallic materials also plays a role. These studies led to the development of more realistic nonlinear models of buckling.

The evolution of verification methods for compressed metal elements was marked by the introduction of empirical buckling curves that represent the actual structural behavior better, accounting for initial imperfections, variations in material properties, and various loadings. This advancement, achieved during the 20th century, paved the way for the standardization of verification techniques. Design reliability was further enhanced through the development of standards, supported by extensive experimental testing.

Standards organizations, such as the American Institute of Steel Construction (AISC) and the American Concrete Institute (ACI), introduced reduction factors to match theoretical models and experimental results, correlating the critical buckling stress with the material yield strength. Compression tests also revealed distinct failure mechanisms depending on the elements’ slenderness. These findings shaped the formulation of modern design standards; Eurocode 3 [

6] consolidated these advancements by proposing a unified approach incorporating experimentally validated buckling curves and advanced numerical analyses, thereby improving both the accuracy and reliability of structural design.

However, the adoption of standards such as Eurocode 3 [

6] and AISC 360 [

7] for the verification of compressed elements may limit the range of solutions when resistance requirements are not met. Further, conventional approaches, such as increasing the cross-section of elements, can be costly and sometimes suboptimal. To overcome these limitations, researchers explored alternative solutions to enhance the stability of compression members: Wen et al. [

8], Chen et al. [

9], and Manigandan and Kumar [

10] investigated the use of concrete-filled steel tubes; Xi et al. [

11] focused on self-stressing techniques in concrete members, where prestressing is achieved through the material’s own expansive properties, thus improving stiffness and reducing lateral displacements.

Among other methods aimed at reducing the lateral displacement of steel compression members, we may quote the work of Andrade et al. [

12,

13], who prove that CHSs are effective as very slender columns for supporting lightweight structures. For example, in the construction of the “Rock in Rio III” stadium in Brazil, CHS columns were built and prestressed on-site to support the stadium roof. This approach eliminated the need for expensive shoring systems, greatly reducing both construction time and cost. More recent studies have further expanded the field. Saito and Wadee [

14] showed that for a given configuration, defined by the dimensions of the deviator, main member, and cable, there exists an optimal prestressing force that maximizes the critical buckling load, for which the post-buckling behavior becomes highly complex and nonlinear. Hoveidae and Ragezy [

15] described Buckling-Restrained Braces (BRBs), which consist of an inner core tube and an external restraining mechanism of larger diameter, both CHSs. The external restraint provides lateral confinement, allowing the inner core to yield fully under compression without inducing global instability. Takeuchi et al. [

16] carried out numerical and experimental investigations to evaluate the local buckling restraint conditions in BRBs. Mirtaheri et al. [

17] optimized the core member length through experimental tests. Zhao et al. [

18] introduced a novel steel BRB design and experimentally studied its mechanical response and failure modes. Guo et al. [

19,

20] and Zhu et al. [

21,

22] developed a core-separated BRB system, in which multiple spaced cores enhance both bending stiffness and load-bearing capacity and are interconnected using steel plates. Serra et al. [

23] proved that a slender CHS main member, reinforced with transverse stiffening elements and prestressed cables, can overcome the challenge of low buckling loads. This system, combining structural efficiency and architectural appeal, was notably applied in the Algarve Stadium in Portugal (2004). Based on this concept, Liu and Zhang [

24] carried out numerical and experimental investigations to assess the effect of prestress levels on the nonlinear post-buckling interaction behavior of the deviators. Wu et al. [

25] examined the nonlinear stability of prestressed stayed columns under fire, showing the impact of non-uniform temperature distributions. Mehdi et al. [

26] developed a spatial stability theory for thin-walled steel beams prestressed by inclined unbonded cables, supported by finite element formulations. Li et al. [

27] introduced a multi-dimensional global optimization algorithm for determining the crossarm length of prestressed stayed columns, achieving higher efficiency than traditional parametric approaches.

Most studies on cable-reinforced steel columns focus on CHSs, often analyzed as isolated elements for local reinforcement, such as those in the Nanjing International Exhibition Centre in China. In contrast, open cross-sections like H-shaped profiles, widely used in practice, have received little attention in the context of cable prestressing.

Another limitation lies in dealing with imperfections: while a few experimental investigations exist, most numerical and analytical studies rely on fixed imperfection amplitudes, typically L/200 or L/300, as a simplified representation of initial defects. Although such assumptions are convenient and widely used, they may not fully capture the combined effects of member geometry defects and residual stresses. Indeed, these combined effects can be effectively captured in compressed members by Eurocode 3 formulations in the absence of prestress, but in its presence, the same approach cannot be directly applied, since the prestress alters the structural response.

Thus, this study has two objectives: first, to widen the research on compressed members prestressed by cables, considering H-shaped elements and frames consisting thereof; on the other hand, to propose an equivalent initial imperfection, obtained from the analytical equivalence between Eurocode 3 and Ayrton–Perry formulations. Unlike fixed ratios, the proposed expression depends explicitly on section geometry, slenderness, and an imperfection factor that reflects both geometric defects and residual stresses. This provides a more rational framework for GMNIA simulations with Abaqus [

28] and extends the applicability of imperfection modeling beyond the CHS-focused literature.

2. Present Standards, Novel Suggestions

When the strength of a compressed element is found insufficient, standards such as Eurocode 3 [

6] and AISC 360 [

7] typically recommend conventional but often costly solutions, e.g., increasing the cross-sectional dimensions. Here, we outline the key factors motivating these recommendations and supporting the proposed alternative solution.

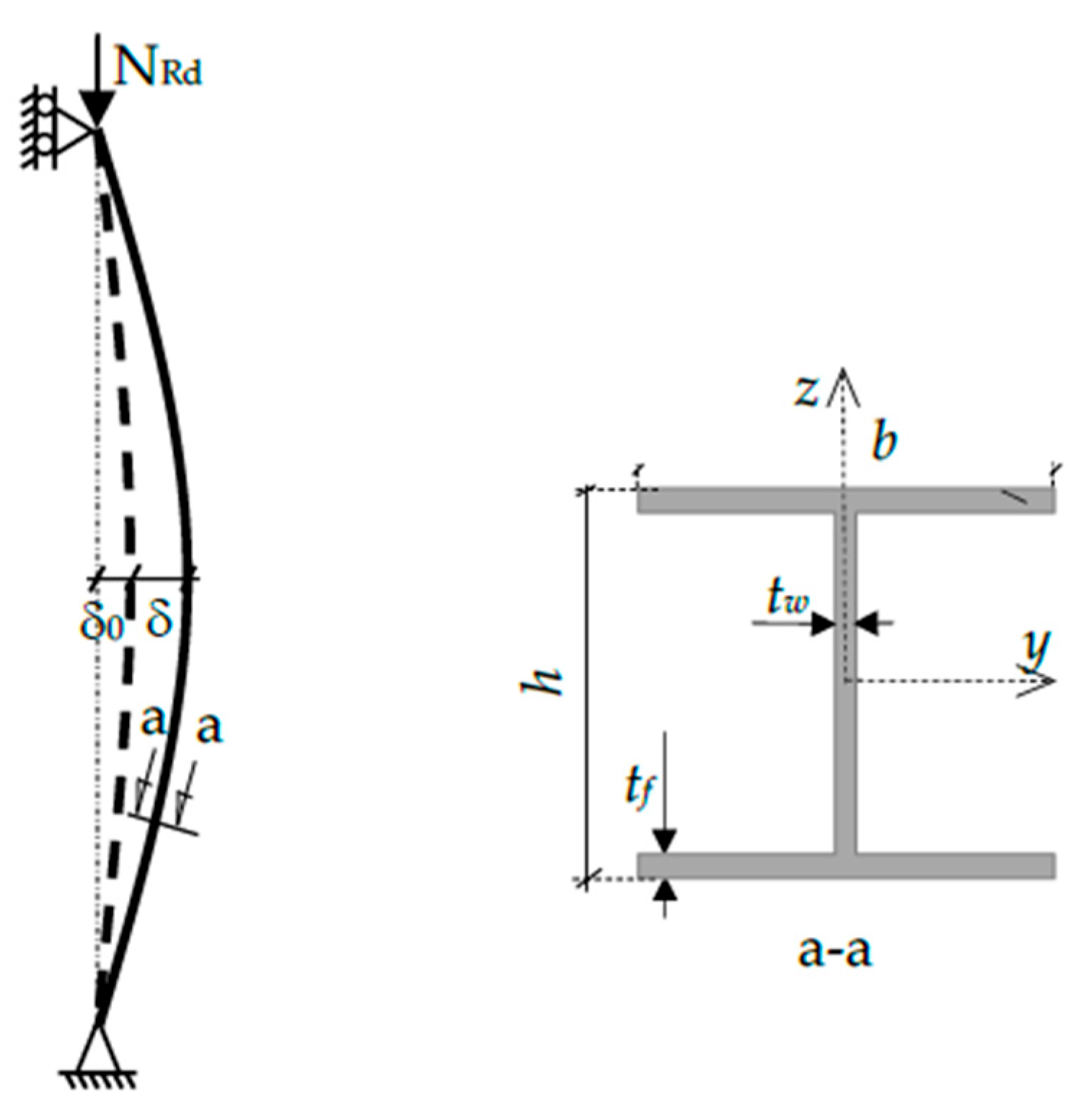

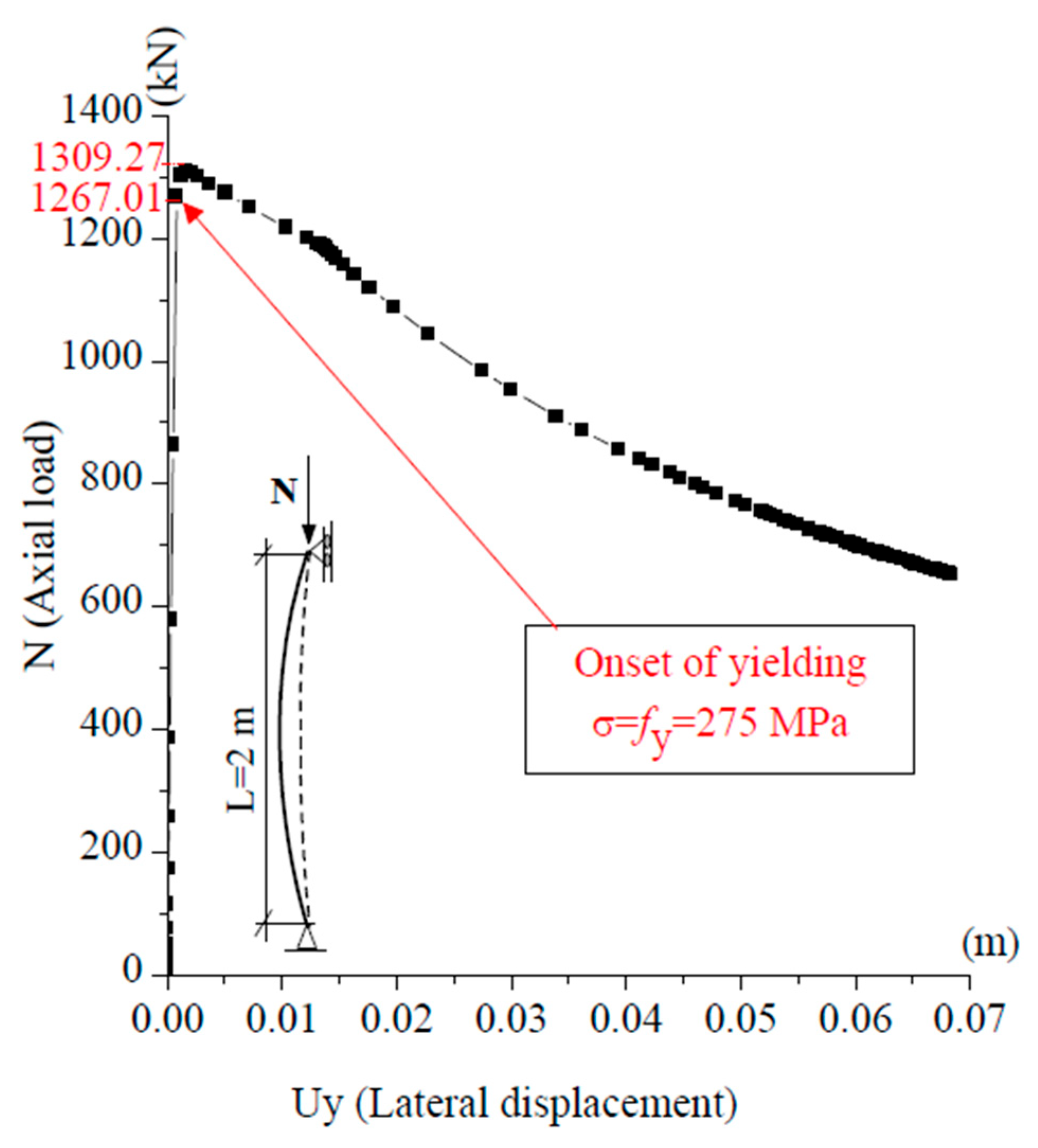

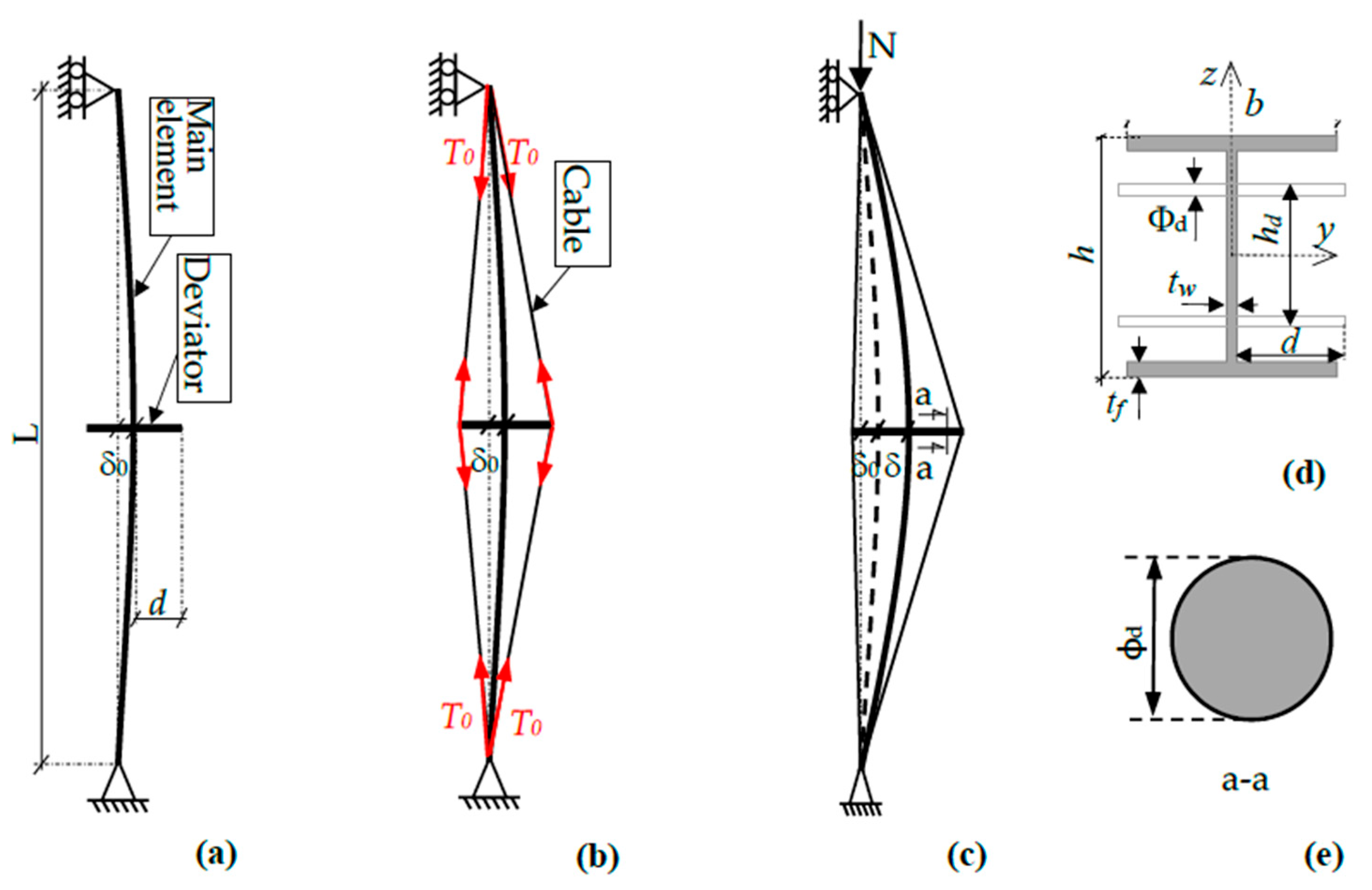

To this end, Geometrically and Materially Nonlinear Imperfection Analysis (GMNIA) of a compressed simply supported HEA200 column with initial imperfection δ

0 (see

Figure 1) is performed by Abaqus software; the column properties (the cross-sectional dimensions

are shown in

Figure 2, the cross-section area, elastic modulus, Young’s modulus, and yield stress,

and

, respectively) are given in

Table 1.

The design resistance of a compressed member is given analytically by

which is adopted in principal standards such as Eurocode 3 [

6] and AISC 360 [

7]. The reduction factor

was first introduced in the Ayrton–Perry formulation [

2] as

being the imperfection parameter and the non-dimensional slenderness, respectively; the first is defined by

with

being Euler’s critical load. Ayrton and Perry (whence the subscripts) take

as

where

is the maximum amplitude of the initial geometric imperfection. Eurocode 3 [

6] follows the same framework but replaces this purely geometric parameter with

where

is the imperfection factor characterizing the buckling curve and the subscripts recall the Eurocode, and Ayrton–Perry’s approach is extended by adding the effects of residual stresses to geometric imperfections. For practical analytical or numerical studies, Eurocode 3 further proposes simplified alternatives in the form of fixed imperfection amplitudes (e.g., L/200, L/250, etc.). Here, we suggest an equivalence between the two formulations, i.e., we pose

:

which leads to an explicit expression for

:

This

no longer represents a purely geometric imperfection, but an equivalent one that reflects both geometric deviations and residual stresses through the Eurocode imperfection factor α. Thus, it depends explicitly on the cross-section geometry, the slenderness

, and the buckling curve, rather than on fixed ratios. Previous works relied on simplified alternatives instead: Serra et al. [

23] adopted imperfections close to L/200 and validated them experimentally on prestressed columns; Liu and Zhang [

24] used mode-shape imperfections with a fixed amplitude of L/300 in GMNIA simulations. These studies confirm the reliability of the Eurocode imperfection approach, while the present work extends it by providing an explicit expression for the equivalent initial imperfection.

In FEM, it is well known that the accuracy of results increases as the mesh size decreases, within the limits of applicability of the element formulation. According to Mahieddine et al. [

29,

30], convergence for beam elements is achieved more rapidly compared to shell or solid elements. In this study, quadratic beam elements (B32OS) were employed for the main H-shaped member. The maximum element length was controlled within 100 mm to ensure adequate representation of buckling modes. The column was modeled as bi-articulated, with all translations and the torsion rotation restrained at the base (U1 = U2 = U3 = UR3 = 0) and translations parallel to the flanges and torsion rotation restrained at the loaded head (U1 = U2 = UR3 = 0). The analysis was carried out in two steps: In the first, a linear buckling analysis (“Buckle”) was performed by applying a unit concentrated load at the column head to identify the buckling modes. Mesh sensitivity was verified by halving the element size; the variation in critical loads remained below 2%, confirming convergence. The fundamental buckling mode was then scaled by the equivalent initial imperfection

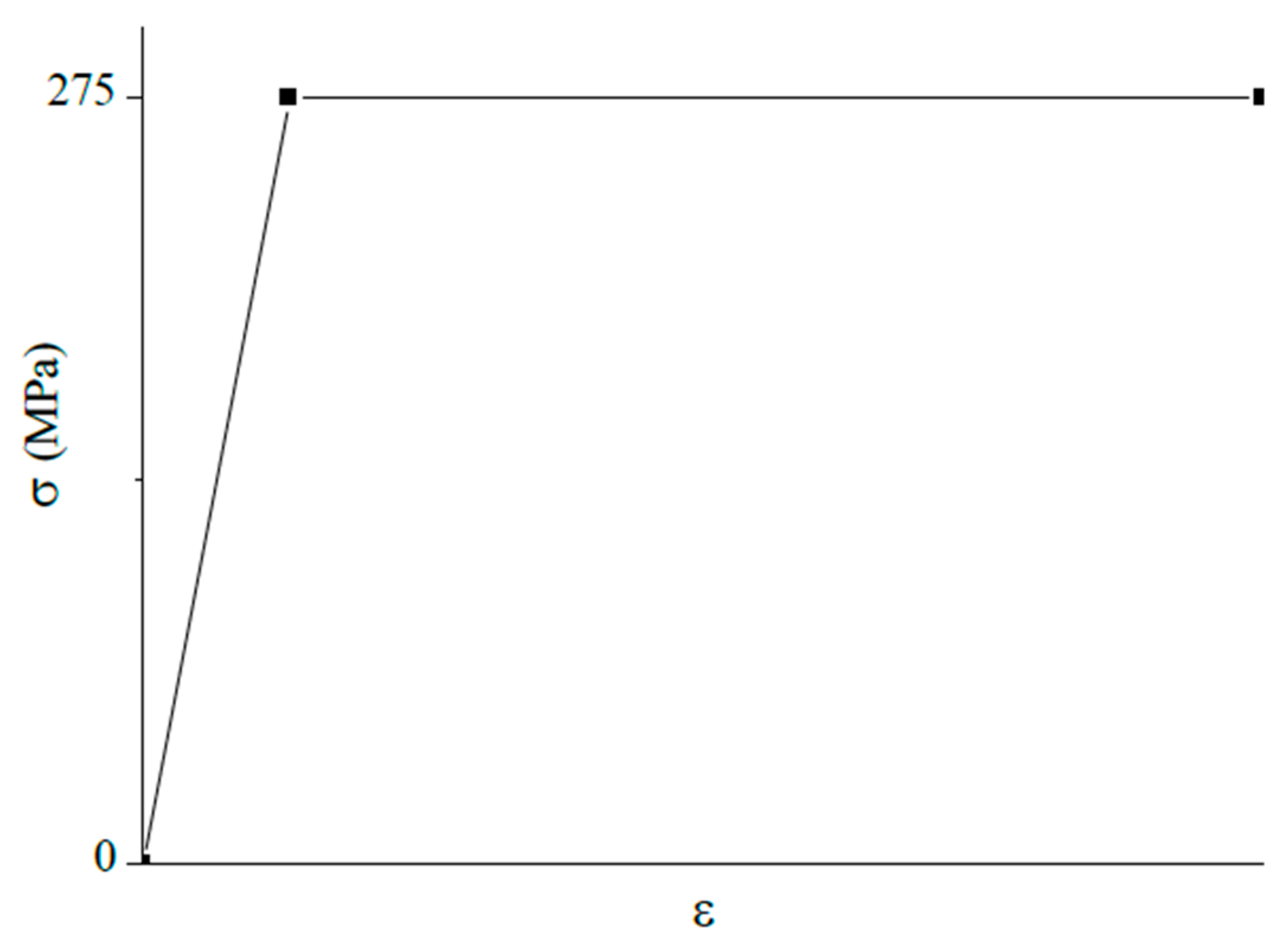

, as given in Equation (8), and introduced into the duplicated model. In the second step, this modified model was analyzed using the GMNIA procedure with the “Static Riks” method. The steel was modeled as elastic–perfectly plastic (see

Figure 2), and the nonlinear equilibrium path was traced.

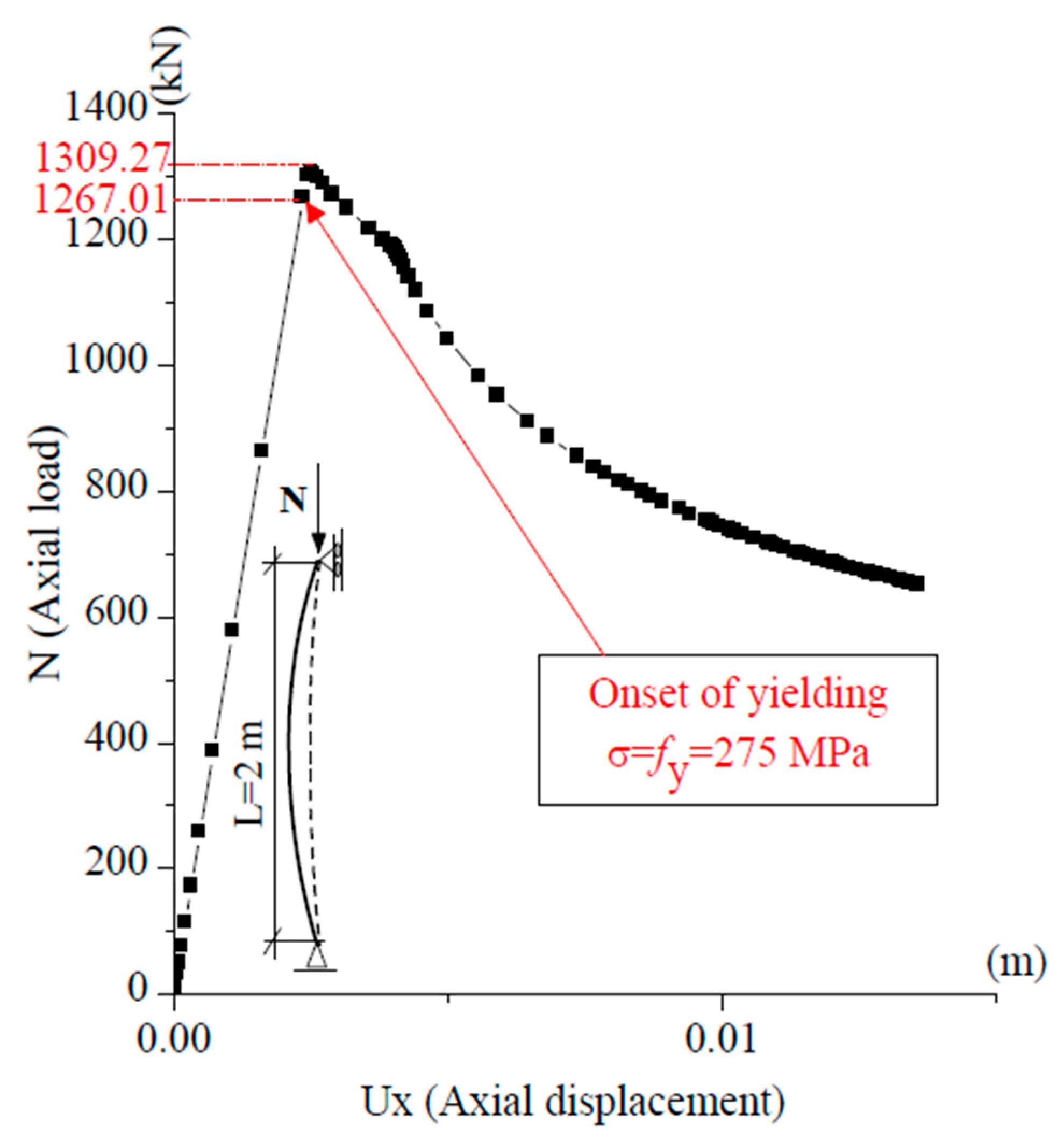

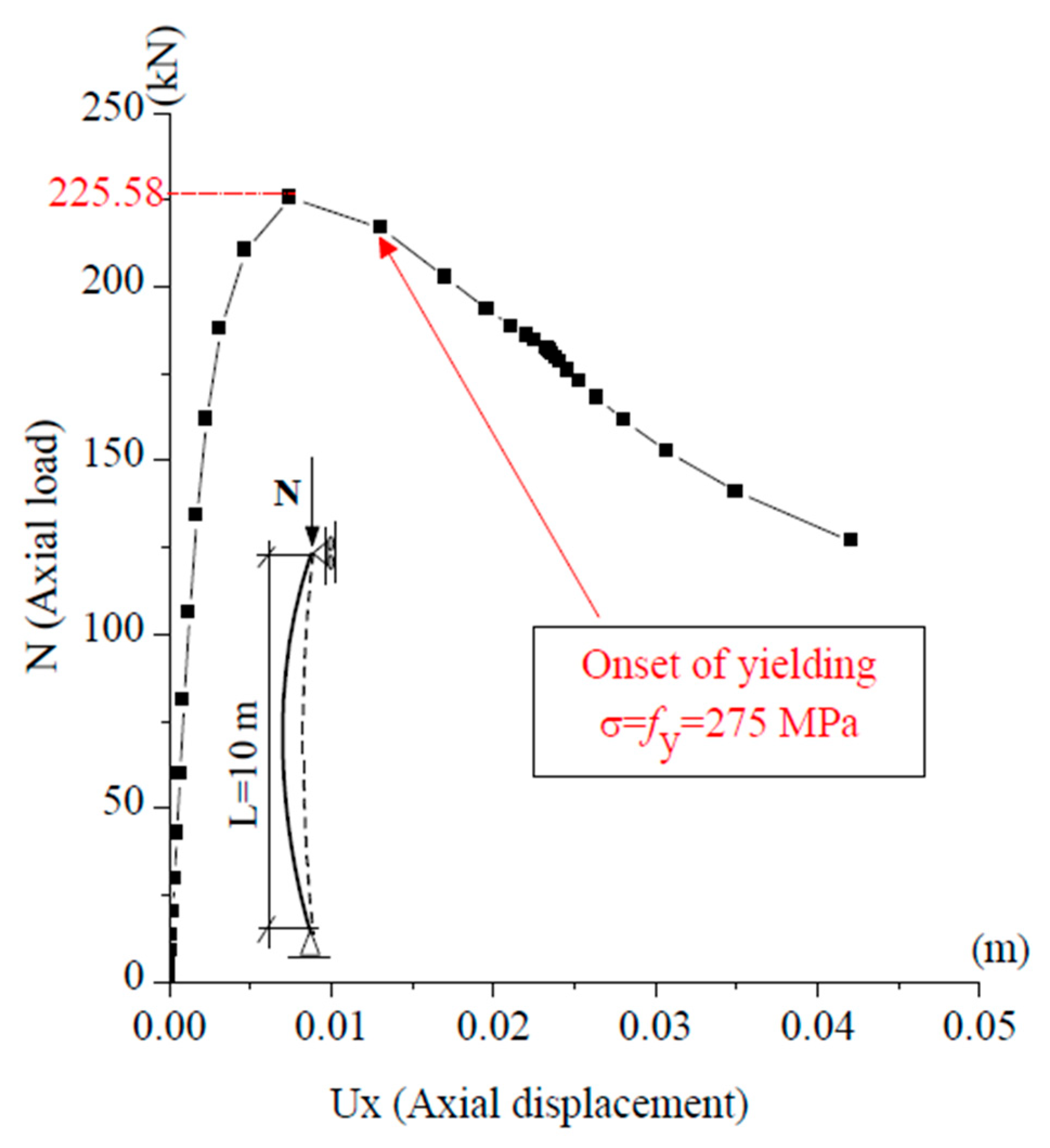

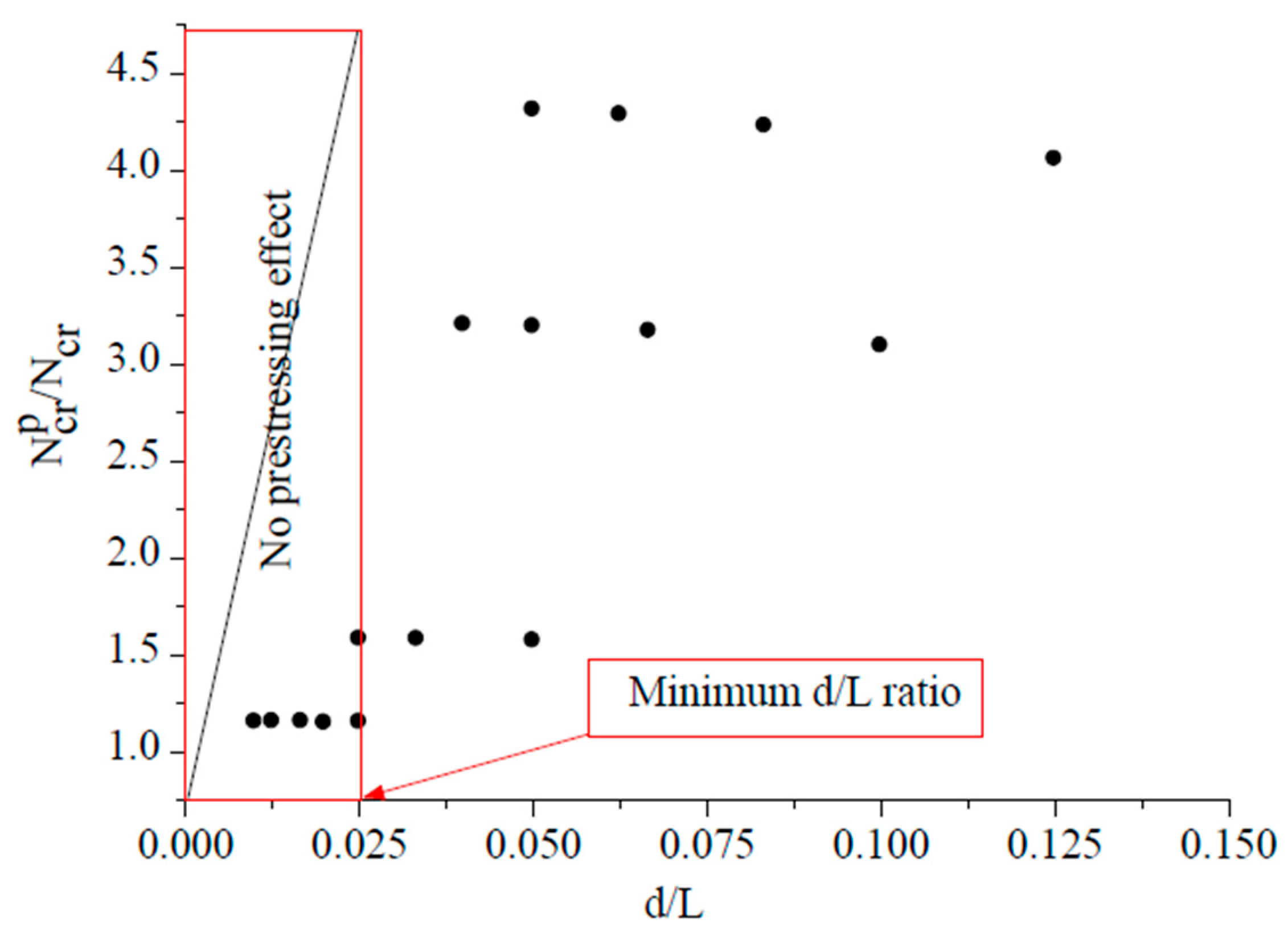

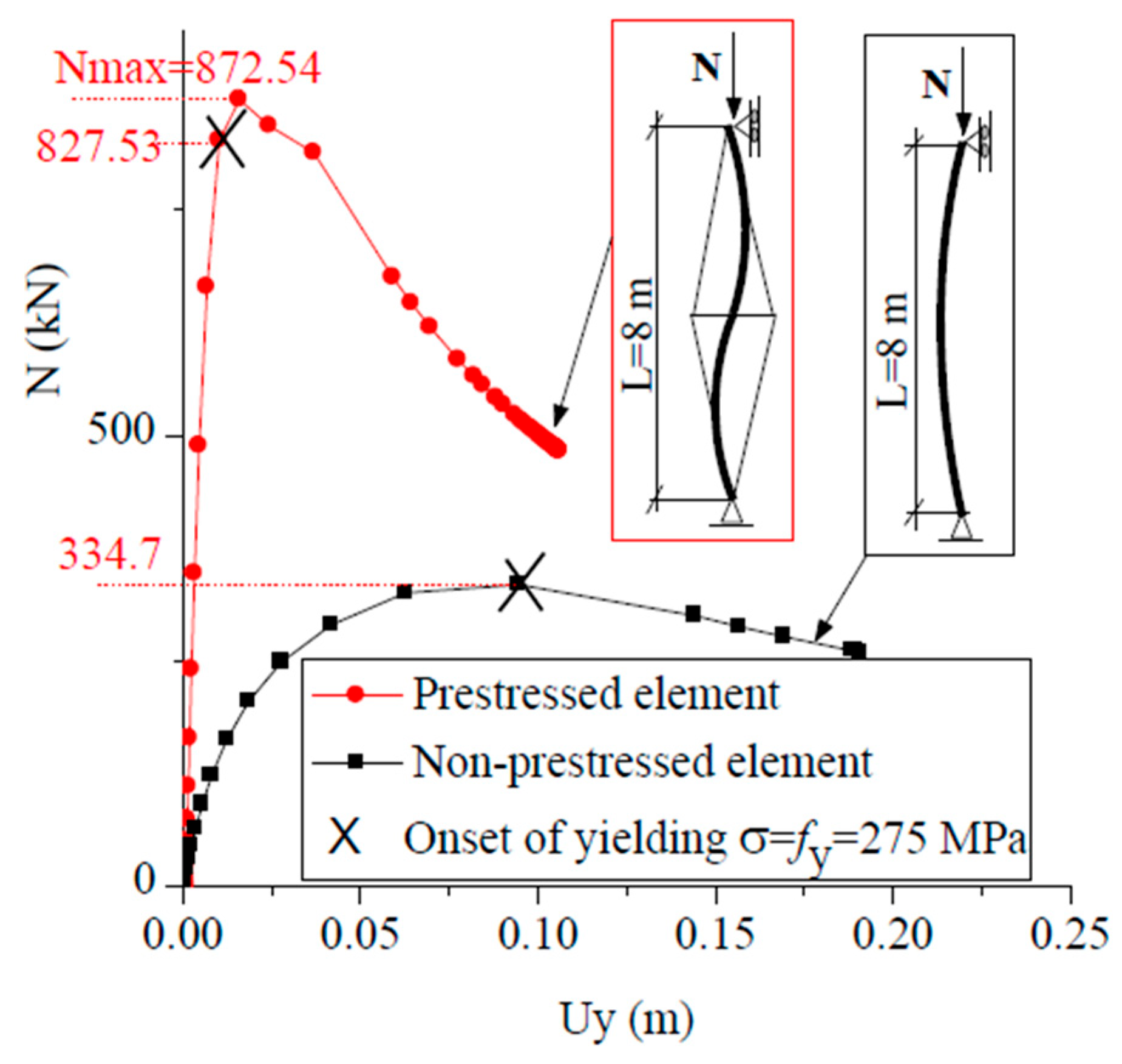

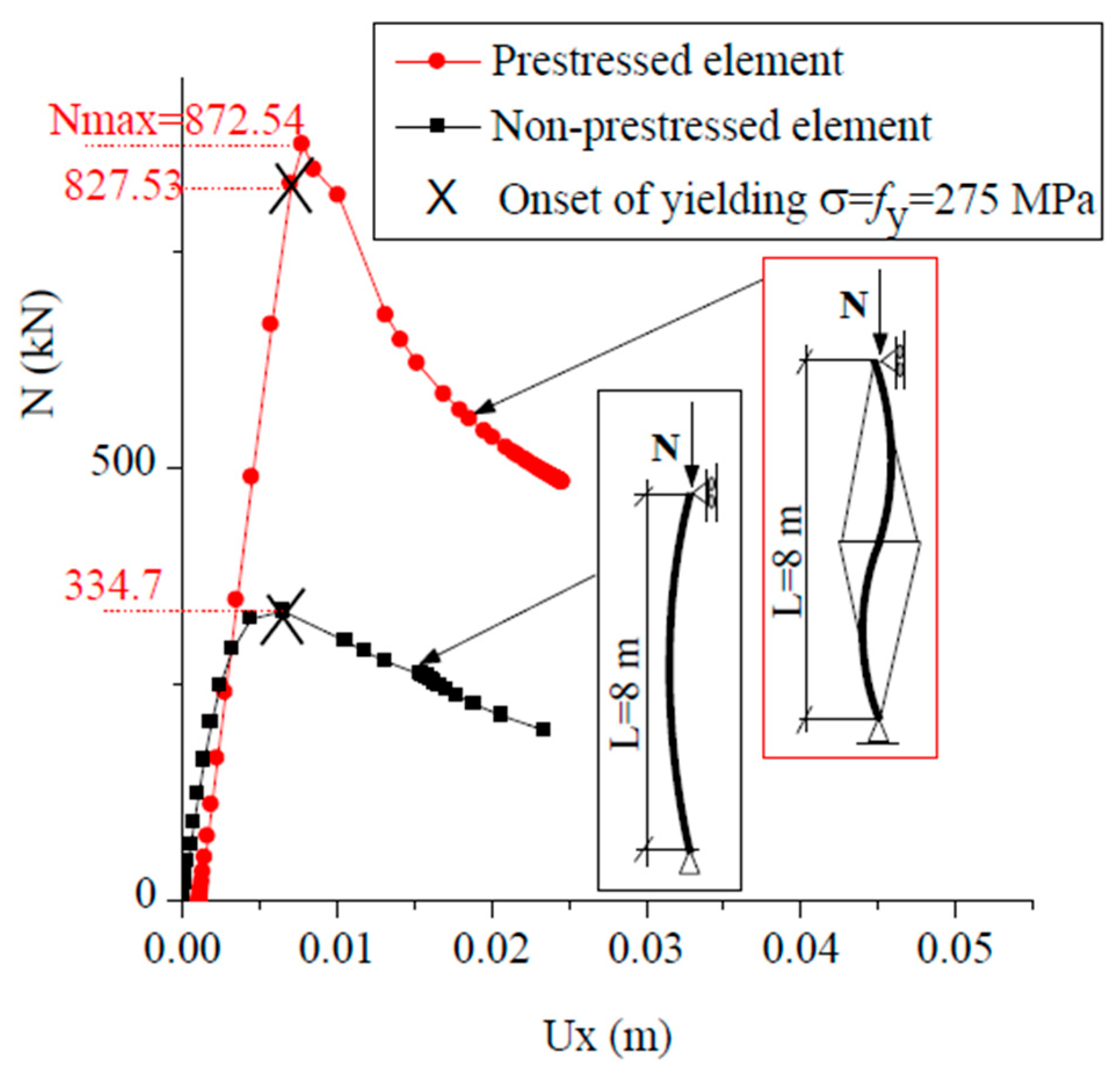

As shown in

Table 2, the GMNIA peak loads, i.e., the maxima of the load–displacement curves in

Figure 3,

Figure 4,

Figure 5 and

Figure 6, are in very good agreement with the design resistance predicted by Eurocode 3 (Equation (6)), according to the standard procedure described above. The relative error between GMNIA and Eurocode 3 does not exceed 4.80%, which is fully consistent with the fact that Eurocode 3 is already a reliable reference for simple non-prestressed columns. In contrast, predictions based on the Ayrton–Perry formulation (Equation (5)) are highly sensitive to the assumed initial imperfection

. For the short column, close agreement with GMNIA is achieved only for

, while larger values, such as

lead to significant underestimation. For the slender column, the best match occurs for

, whereas other assumptions either under- or overestimate the resistance. These comparisons highlight the limitation of prescribing fixed imperfection amplitudes and stress the need for a more rational definition of an equivalent initial imperfection.

The GMNIA results in

Table 2 and

Figure 3Figure 4Figure 5 and

Figure 6 provide physical insight into the structural response. For the short column (L = 2 m), yield initiates in the outer fibers before the maximum load is reached, reflecting a material-driven limit state. In contrast, the slender column (L = 10 m) reaches its peak load while staying elastic, and yield occurs after buckling. In both cases, yield initiates at the outer fibers of the cross-section (

). These numerical and physical observations confirm the consistency of Eurocode 3 for ordinary columns; however, no corresponding formulas exist for prestressed steel ones. This motivates the introduction of the equivalent initial imperfection in Equation (8), providing a rational alternative to fixed imperfection ratios and forming the basis for our study.

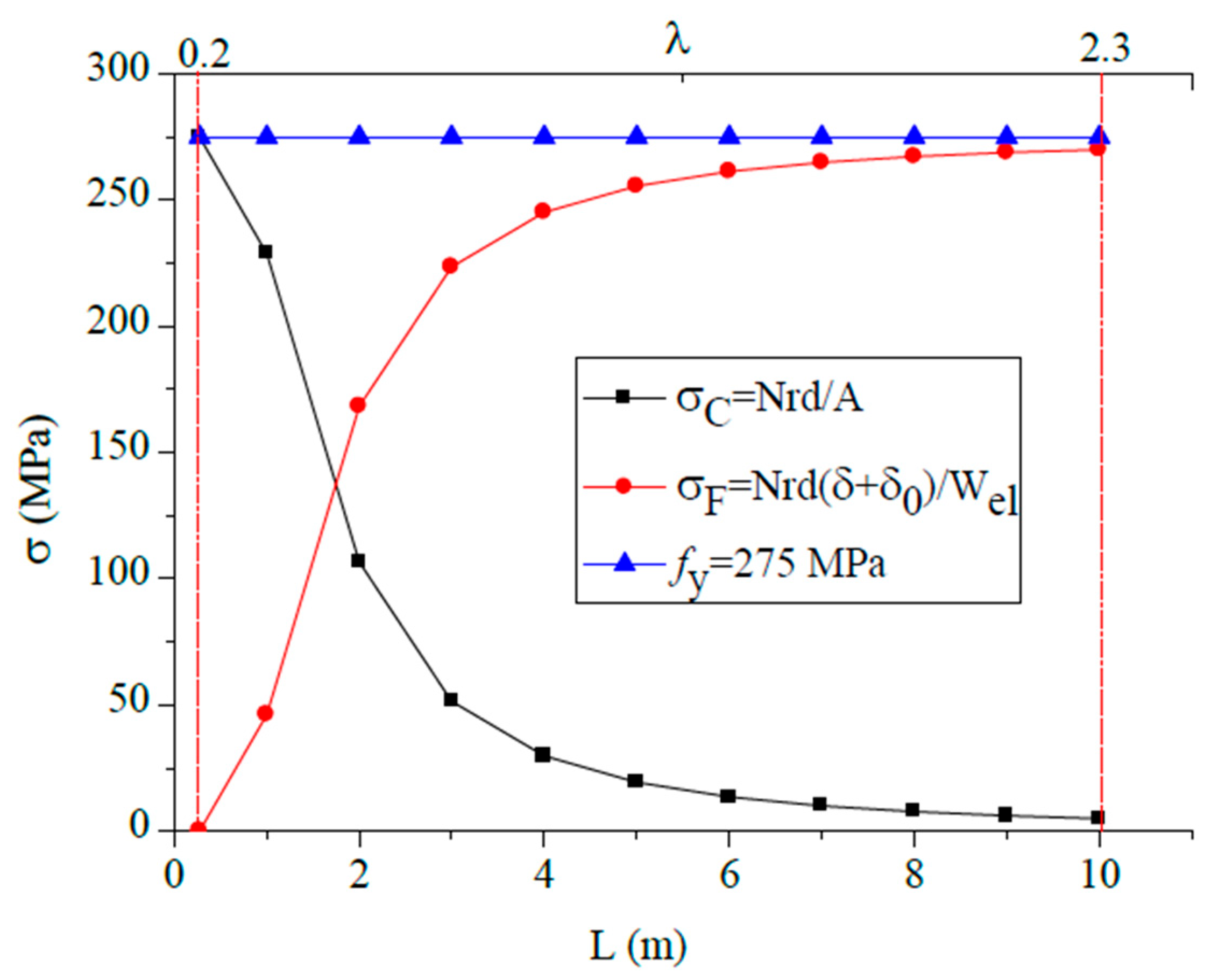

Note that HEA200 columns with

2 m were excluded from the analysis, as for such short members the instability is governed by torsion and their behavior is thus outside the scope of this study on slender compressed columns, for which the flexural instability is dominant and critical. In these cases, the maximum normal stress

does not exceed the yield stress

and can be expressed as the sum of a compressive stress

and a bending stress

when the axial load

approaches the design resistance

:

Here, the expression for the maximum lateral displacement

is taken from a simplified geometrically nonlinear elastic analysis [

31] and, if

is Euler’s critical load, is

Figure 7, based on Equations (9) and (10), illustrates the evolution of stresses as a function of the length of an HEA element and shows that for short columns, the compressive stresses

dominate. However, as the column becomes slenderer, the bending stresses

become increasingly significant, eventually exceeding 90% of the yield stress

. In such cases, it becomes reasonable to neglect compressive stresses and focus only on the bending stresses, which are mainly influenced by the elastic section modulus

and the maximum lateral displacement

.

This highlights a key challenge in the design of slender columns: when the resistance

is much lower than the applied load

, standards such as Eurocode 3 [

6] and AISC 360 [

7] recommend increasing the cross-section dimensions to improve resistance, with the above-mentioned drawbacks. To be more efficient, here we propose an alternative approach: instead of increasing the cross-section, we propose to reduce the maximum lateral displacement

by reinforcing the structural elements with prestressed cables. This method aims to improve performance while limiting material use and cost.

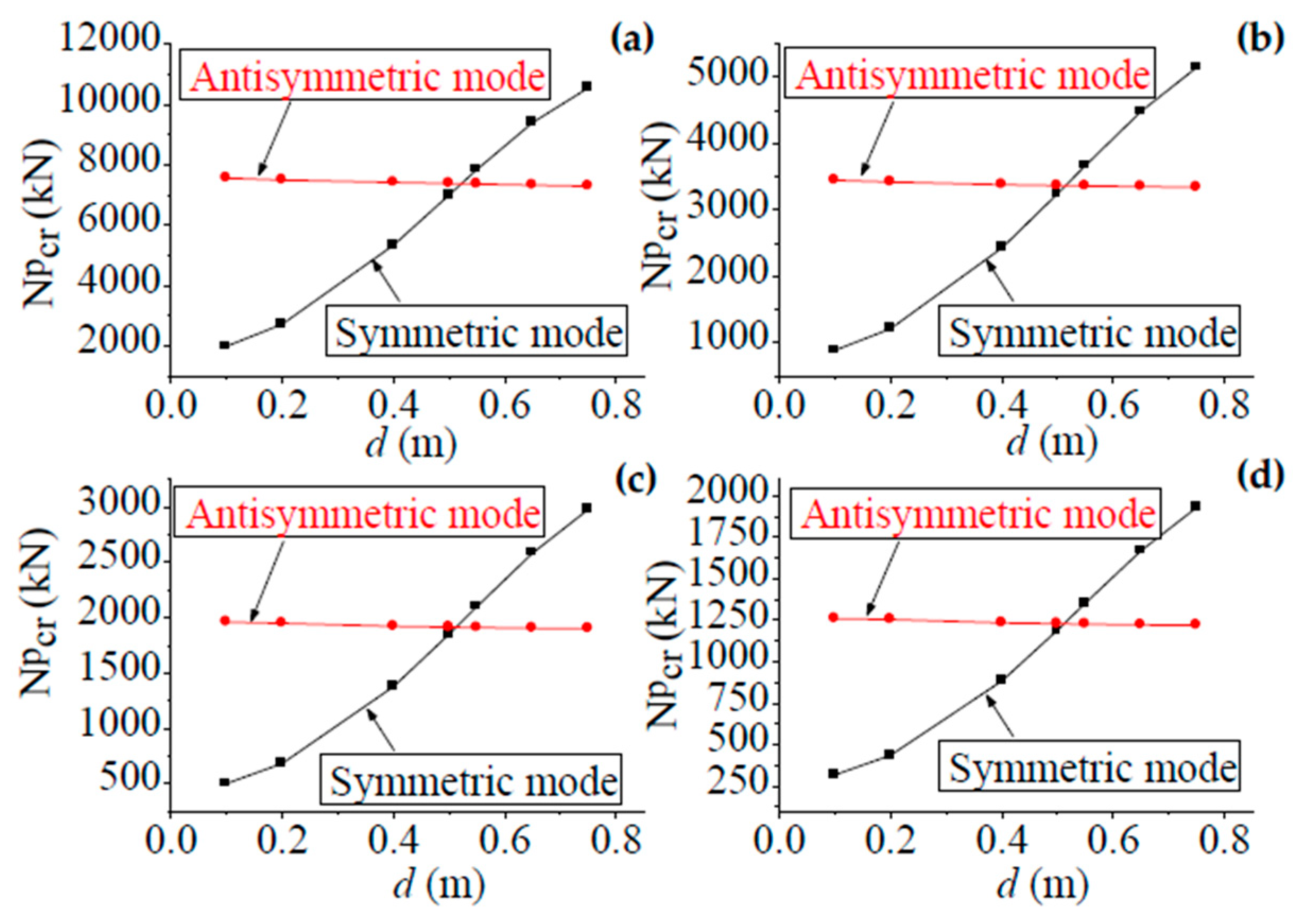

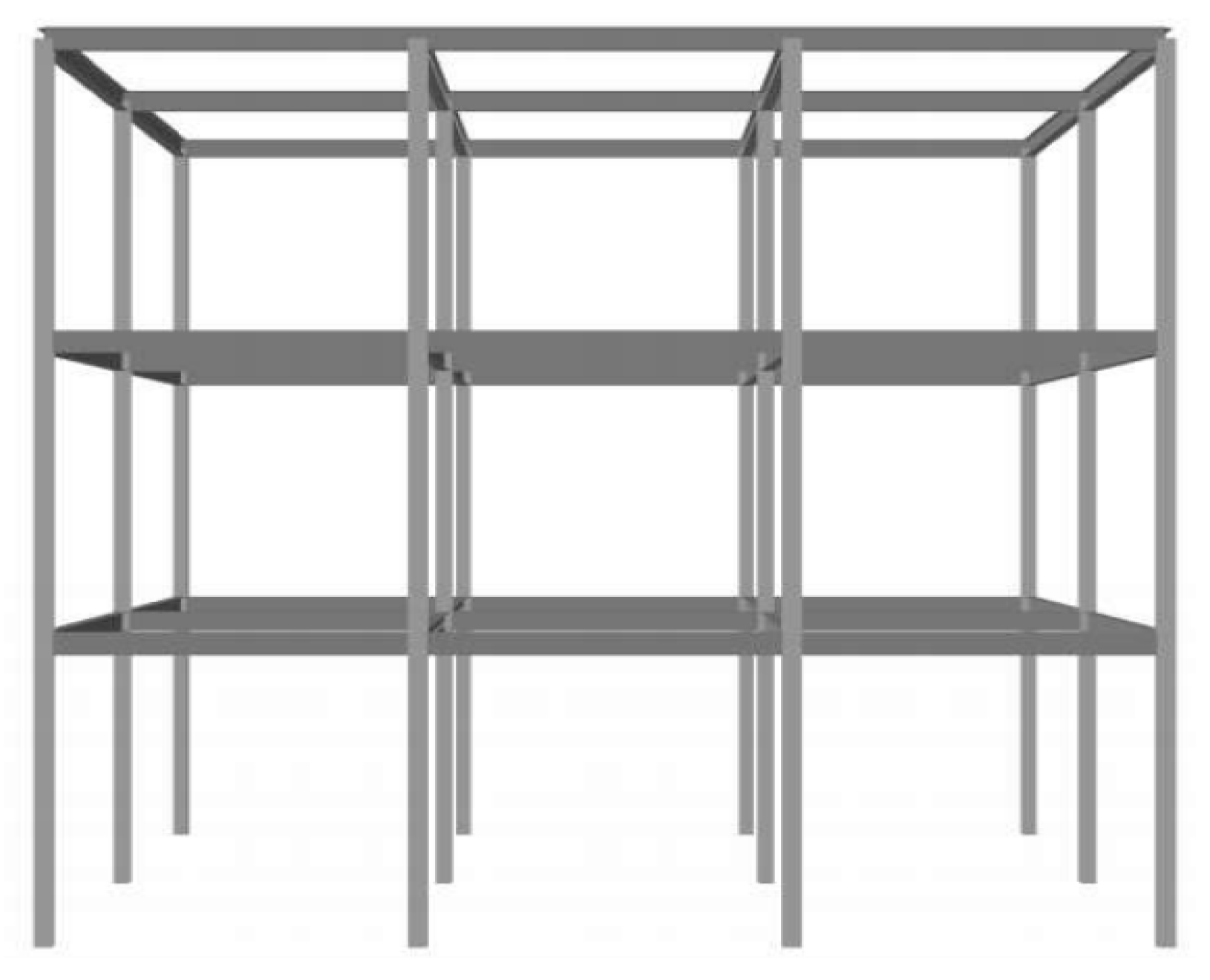

4. Effect of Prestress on the Axial Resistance of Rigid Frames

In this section, we investigate the effect of prestress, focusing on the columns of a two-story building subjected only to axial (vertical) force; horizontal actions (wind, seismic) were not considered. A comparative analysis is performed to examine how prestress influences the axial load-bearing capacity of the columns. The GMNIA procedure described in

Section 2 was adopted here, consistent with approaches previously used in the literature (e.g., by Xu et al. [

32] for short rhombic tubes). This rigid frame was modeled as fixed at the base (U1 = U2 = U3 = UR1 = UR2 = UR3 = 0), with rigid beam–column connections. The prestressing system was represented by cables connected rigidly to the steering devices, ensuring both force transfer and compatibility. It should be noted that this study focuses on the global behavior of the columns; local behavior and the corresponding verification are not addressed here. The data from this analysis are presented in

Figure 18,

Figure 19 and

Figure 20 and

Table 4.

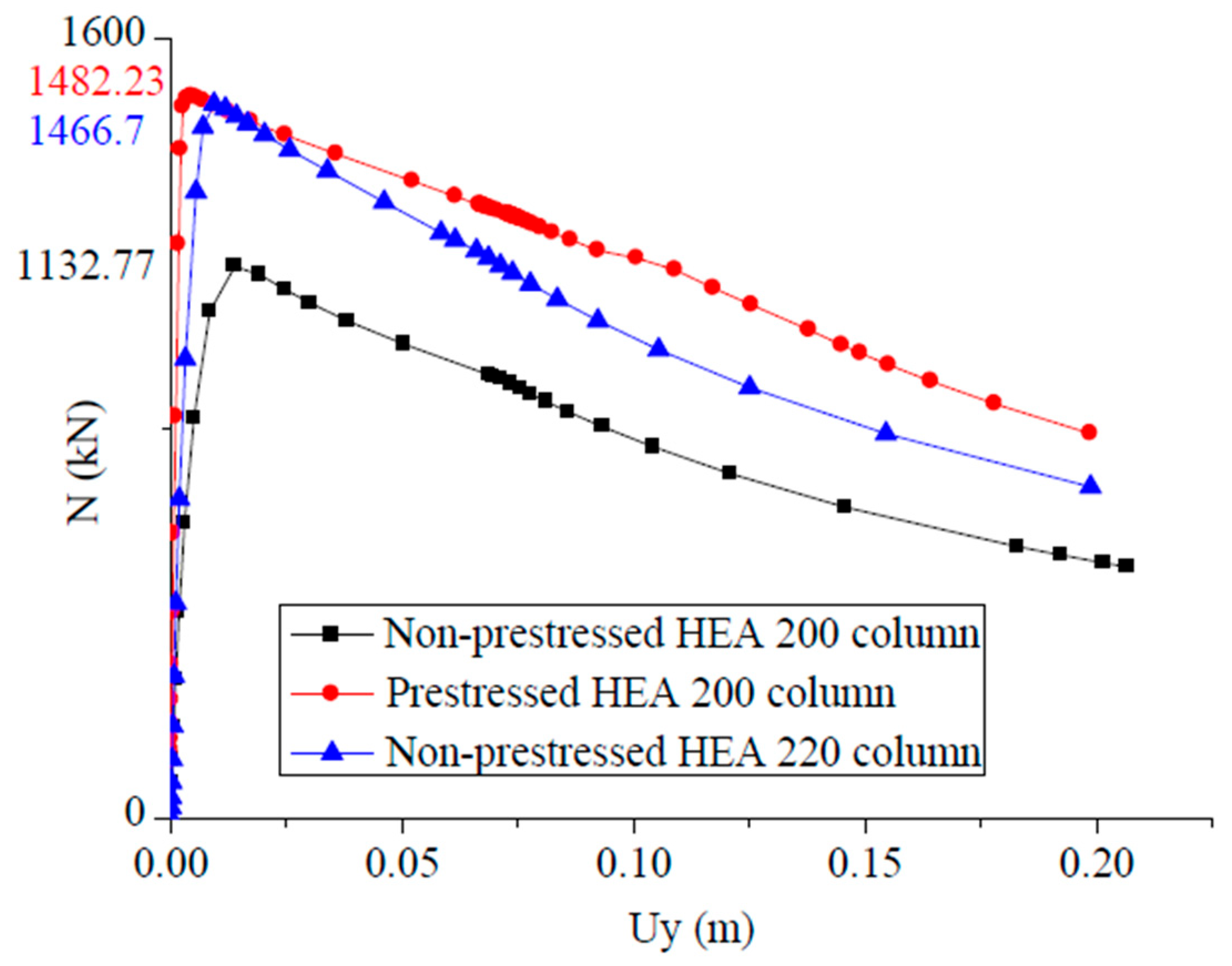

As part of this comparative study, the influence of column selection on the structural strength was analyzed through three distinct configurations, as illustrated in

Figure 21. In the first case, the structure was designed with HEA200 columns, capable of resisting a maximum axial force of 1132.77 kN. For example, considering a design axial force

estimated at 1400 kN, these columns are found to be insufficient. According to the current standards (i.e., Eurocode-3 and AISC 360), the conventional solution involves increasing the column section. Thus, in the second case, the use of HEA220 columns allows a maximum axial force of 1466.7 kN to be achieved, thereby ensuring greater resistance.

However, an alternative solution was proposed, involving the use of HEA200 columns prestressed with cables. This technique enhances resistance, raising the maximum axial force to 1482.23 kN, a value slightly higher than that achieved with the HEA220 columns. In addition to meeting the required structural performance, this approach offers a significant economic advantage, allowing for a reduction of approximately 1.18 tons of steel.

Further,

Figure 22 presents the results obtained by GMNIA for von Mises equivalent stress for the considered frame when base columns are reinforced by prestressing cables. It is apparent that, apart from the better performance against buckling in compression highlighted above and in the previous figure, the proposed technique improves the stress distribution in the frame, once again in favor of an improved performance.