Abstract

Current understanding of the load-transfer mechanism in the skeletal contact state of asphalt mixtures and its influence on macroscopic mechanical properties remains insufficient. This knowledge gap leads to difficulties in accurately predicting the performance of designed mixtures, thereby restricting the service life of asphalt pavements and the sustainable development of road engineering. This study investigated the skeletal contact characteristics, coarse aggregate movement, and crack propagation of three asphalt mixture types—Stone Mastic Asphalt (SMA), Asphalt Concrete (AC), and Open-Graded Friction Course (OGFC)—under loading. The methodology incorporated Computed Tomography (CT) technology, a Voronoi diagram-based skeletal contact evaluation method, and discrete element numerical simulation. The research aimed to elucidate the influence mechanisms of different skeletal structures on macroscopic performance and to validate the efficacy of the skeletal contact evaluation method. The findings revealed that under splitting load, the tensile stress contact force chains within the asphalt mixture’s skeleton were predominantly distributed along both sides of the specimen’s central axis. For all three gradations, compressive stress contact force chains (points) accounted for over 65% of the total, indicating that the asphalt mixture skeleton primarily bore and transmitted compressive stresses. The interlocking structure formed by coarse aggregates significantly enhanced the stability of the asphalt mixture skeleton, reduced its displacement under load, and improved the mixture’s resistance to cracking. In the three gradations, shear stress-induced cracks outnumbered those caused by tensile stress, with shear stress cracks accounting for over 55% of the total cracks. This suggests that under splitting load, cracks resulting from shear failure were more prevalent than those from tensile failure. SMA-20 demonstrated the best crack resistance, followed by AC-20, while OGFC-20 performed the poorest. These conclusions are consistent with the results of the Voronoi diagram-based skeletal contact evaluation, confirming the correlation between the contact conditions of the asphalt mixture skeleton and its mechanical performance. Specifically, inadequate skeletal contact leads to a significant deterioration in mechanical properties. The research results elucidate the influence of skeletal contact characteristics with different gradations on both mesoscopic features and macroscopic mechanical behavior, providing a crucial basis for optimizing asphalt mixture design.

1. Introduction

Asphalt pavements are prone to damage, such as cracks and rutting, due to long-term exposure to temperature fluctuations, vehicle loads, and rainwater erosion, significantly compromising their service performance and increasing maintenance costs [1,2,3]. Designing high-quality and durable asphalt pavements remains a critical challenge in the field of road engineering. The performance of asphalt mixtures largely depends on the proportion of raw materials and the production process, while their meso-structural characteristics directly influence the macroscopic mechanical properties [4,5,6]. Therefore, an in-depth study of the skeletal contact characteristics of asphalt mixtures not only clarifies the intrinsic relationship between their meso-structure and mechanical behavior, but also establishes a quantitative meso-scale evaluation framework. This framework could provide a scientific basis for optimizing asphalt mixture design, enhancing performance, and improving pavement durability. Coenen et al. [7] developed a Two-Dimensional (2D) image analysis approach for asphalt mixtures, proposing indicators such as aggregate orientation and contact zones to characterize the influence of aggregate structure and compaction conditions. Sefidmazgi et al. [8] proposed new metrics based on image analysis, such as the number of aggregate contact points, contact length/area, and the orientation of contact planes, to reflect the correlation mechanism between the internal structure of asphalt mixtures and their rutting resistance performance. Sun et al. [9] integrated digital image processing with stereological theory to propose a coarse aggregate uniformity coefficient, achieving a quantitative evaluation of the internal distribution characteristics of asphalt mixtures. Shi et al. [10] systematically investigated the key factors influencing the accuracy of 2D image processing for asphalt mixtures, revealed the regulatory mechanism of contact parameters on the skeleton structure, and proposed data accuracy control standards. Busang et al. [11] utilized digital image processing technology to investigate the correlation between the structural performance and mesoscopic characteristics. They proposed the use of the normal contact fabric tensor to evaluate the aggregate interlocking state. Hassan et al. [12] demonstrated that aggregate strength and morphology significantly influence the internal skeleton structure of the asphalt mixture, consequently affecting its macroscopic performance.

However, laboratory testing methods are limited by several factors. These factors include lengthy procedures, uncontrollable variables, and difficulties in meso-structure evolution observation. Consequently, numerical simulation has become a vital tool for investigating the meso-structural and mechanical characteristics of asphalt mixtures [13,14,15]. This approach enables the simulation of stress distribution, deformation characteristics, and damage evolution under various loading and environmental conditions. It thereby establishes a foundation for material optimization and accurate prediction of engineering performance [16,17,18]. Among existing numerical simulation methods, the Discrete Element Method (DEM) has emerged as the preferred approach for investigating the meso-mechanical behavior of asphalt mixtures, owing to its inherent suitability for granular materials and its ability to facilitate visualization and analysis [19,20]. Zhu et al. [21] employed the DEM to investigate the Marshall Impact Compaction process of asphalt mixtures and proposed a novel indicator for characterizing the contact imbalance force among coarse aggregate particles. Liu et al. [22] established DEM models for six types of mineral mixtures to quantitatively investigate the force chains within asphalt mixture skeletons. Their study concluded that strong force chains serve as the primary load-bearing components. Under the same Nominal Maximum Aggregate Size (NMAS), Stone Mastic Asphalt (SMA) mixtures demonstrated significantly superior load-bearing capacity compared to Asphalt Concrete (AC). Gao et al. [23] found that the average orientation angle of strong force chains formed by fine aggregates is significantly larger than that of coarse aggregates. Furthermore, while the mixture composed of fine aggregates exhibited a broader range of load transfer, its transfer efficiency was lower. Camara et al. [24] employed a Three-Dimensional (3D) DEM model to evaluate the impact of encapsulated rejuvenators on the performance of asphalt mixtures. The results indicated that the mass ratio of rejuvenator to mastic, as well as the number of contact points modified by the rejuvenator, significantly influence the stiffness properties of the asphalt mixture. Zhao et al. [25] established the indirect tensile test model using the DEM to investigate the influence of rubber content on the meso-cracking characteristics of Rubberized Cement-Stabilized Aggregate mixtures. They concluded that the optimal rubber content should be limited to within 80% of the volume of the corresponding aggregate gradation. Li et al. [26] established three DEM models with different coarse aggregate morphologies, revealing the influence mechanisms of aggregate morphological characteristics on the performance of asphalt mixtures. Quezada et al. [27] demonstrated that the 3D numerical model based on the DEM not only accurately simulates the viscoelastic mechanical response but also effectively reveals the influence of irregular aggregate morphology on the mechanical properties of asphalt mixtures.

Overall, scholars have made significant progress in researching the meso-mechanical properties and skeletal structural characteristics of asphalt mixtures through the application of advanced techniques such as digital image processing and numerical simulation. However, existing research still faces several unresolved issues. In terms of the skeleton structure evaluation system, researchers have proposed a series of mesoscopic parameters, such as contact length, number of contact points and normal contact force, which provide basic tools for quantitatively characterizing the contact characteristics of aggregates in asphalt mixtures [28,29,30,31]. However, there are currently no unified terminology definitions, measurement criteria and evaluation standards in this field, resulting in weak data comparability and generalizability of conclusions across different studies. Furthermore, systematic validation is insufficient, hindering the practical application and promotion of these methods in engineering practice. More importantly, key issues such as the load-transfer mechanism of skeletal contact and their influence on the macroscopic mechanical properties of mixtures still lack in-depth and systematic investigation. This situation has, to some extent, hinders the advancement of asphalt mixture design theory and the improvement of its engineering performance.

Based on the aforementioned background, this study first utilized non-destructive X-ray computed tomography (CT) scanning to obtain cross-sectional images of asphalt mixtures. Subsequently, a skeletal contact evaluation method based on Voronoi Diagram—which fully incorporates the mesoscopic characteristics of asphalt mixtures—was employed to assess the skeletal contact conditions of mixtures with different gradations. Furthermore, by extracting characteristic indicators of coarse aggregate contours from CT images, a DEM model was developed to simulate virtual splitting tests of asphalt mixtures. Numerical simulations and experimental analyses were then conducted to investigate the skeletal contact characteristics, coarse aggregate displacement variations, and crack propagation behavior of asphalt mixtures under loading conditions. The results revealed the influence mechanisms of different graded skeleton structures on macroscopic performance and validated the effectiveness of the skeletal contact evaluation method. These findings not only advance the understanding of how skeletal contact characteristics in various graded asphalt mixtures influence their mesoscopic features and macroscopic mechanical behavior, but also provide a theoretical basis for optimizing asphalt mixture design. Furthermore, this study extends the application of computational geometry methods to the analysis of meso-structural characteristics in pavement materials.

2. Test Materials and Methods

2.1. Raw Materials

The specimen preparation in this study primarily utilized three types of asphalt binders: 70# base asphalt, Styrene-Butadiene-Styrene (SBS) modified asphalt, and high-viscosity asphalt. Their respective performance indicators are detailed in Table 1, Table 2 and Table 3. The aggregates consisted mainly of granite, with limestone mineral powder employed as filler. These materials were supplied by the Xiaoning Institute of Roadway Engineering (Guangzhou, China).

Table 1.

Technical parameters of 70# base asphalt.

Table 2.

Technical parameters of SBS modified asphalt.

Table 3.

Technical parameters of high-viscosity asphalt.

2.2. Asphalt Mixture Gradation

To further investigate the meso-mechanical mechanisms of the skeletal structure in asphalt mixtures, this study selected three typical types: SMA with a skeleton-dense structure, AC with a suspended-dense structure, and open-graded friction course (OGFC) with a skeleton-void structure. Among these, SMA boasts a compact and uniform skeleton structure, endowing it with strong resistance to deformation and shear forces. AC, characterized by its continuous gradation, is renowned for its aging resistance and impermeability. OGFC features high porosity and excellent drainage performance, making it suitable for rainy regions. This study investigated SMA-20, AC-20, and OGFC-20 asphalt mixtures (“20” indicates that the NMAS of the coarse aggregate in the gradation is 20 mm). The mix design for all three mixtures was conducted using the volumetric method, as detailed in Table 4 and Table 5. The specimens were prepared using the standard Marshall compaction method, with dimensions of Φ101.6 mm × 63.5 mm, and compacted 75 times on both sides.

Table 4.

Gradation of three asphalt mixtures.

Table 5.

Asphalt-aggregate ratio and void content of the three gradations.

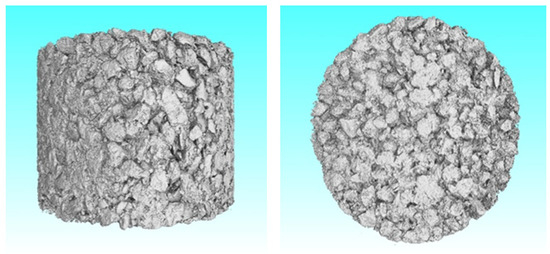

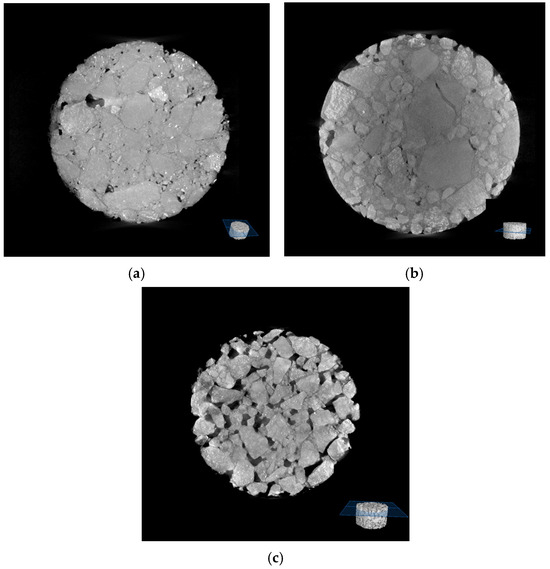

2.3. CT Scan

To characterize the contact conditions of the intact internal skeleton structure in asphalt mixtures, CT scanning was performed on the specimens of three different gradations. The scanning was conducted along the longitudinal axis of the specimens, with a set inter-slice spacing of 0.05 mm between CT cross-sectional images, resulting in the acquisition of N CT images. The CT acquisition parameters were set as follows: a maximum pixel matrix of 3072 × 3072, a maximum frame count of 6, at a test temperature of 28 °C, humidity of 46%, and an altitude of 100 m. Detailed information is shown in Figure 1, Figure 2 and Figure 3.

Figure 1.

CT scanning equipment.

Figure 2.

Three-dimensional scanned image of asphalt mixture specimen.

Figure 3.

Representative CT scan images of different gradations. (a) SMA-20; (b) AC-20; (c) OGFC-20.

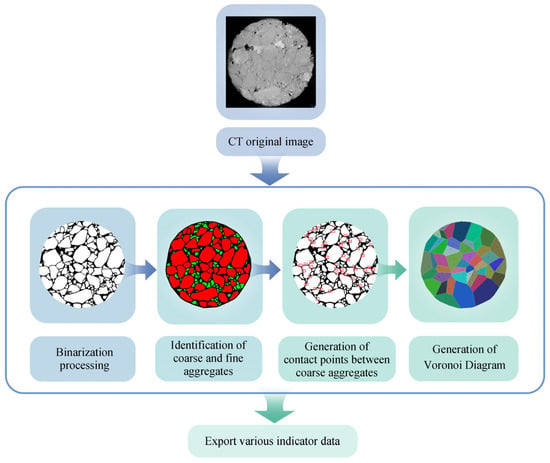

2.4. Voronoi-Based Evaluation Method for Skeletal Contact in Asphalt Mixtures

Voronoi diagrams, a significant technique in computational geometry, serve as an efficient data structure for spatial partitioning and hold substantial application value in fields related to spatial queries [32]. The duality between Voronoi diagrams and Delaunay triangulation is frequently and extensively utilized [33,34]. Delaunay triangulation is a geometric algorithm that partitions a set of given points on a plane into a non-overlapping mesh of triangles, where the circumcircle of each triangle contains no other points. Voronoi diagrams effectively represent spatial neighborhood relationships of data and possess fundamental characteristics of vector-based and continuously tiled data models, making them well-suited for spatial data management [35]. This technique has been widely adopted in the field of geometric information processing and has also made significant progress in materials science, particularly in the modeling of meso-structures such as polycrystalline metals and porous materials. In asphalt mixture research, the contact point network of coarse aggregate skeletons constitutes the load transmission path, exhibiting well-defined geometric topological relationships. Leveraging the excellent topological and geometric properties of Voronoi diagrams, their application to the investigation of mesoscopic characteristics of mixture skeletal contact has proven highly feasible.

This study adopted the Voronoi diagram-based skeletal contact meso-structural evaluation method, as proposed by Wang et al. [36]. This method integrates Voronoi diagram with Python (version 3.8)-based meso-structural identification software for asphalt mixtures to analyze slices images. It proposes three critical mesoscopic indicators for evaluating skeletal contact characteristics: the total length of coarse aggregate contact points, the proportion of Voronoi polygon areas (30–180 mm²), and the proportion of low-to-medium order connectivity trees. Among these, larger values for the first two indicators reflect better skeletal contact properties, while a smaller value for the last indicator indicates superior skeletal contact performance.

To clarify the less intuitive third indicator, in discrete mathematics, a tree is defined as an acyclic connected graph. Based on this definition, interconnected coarse aggregate clusters can be abstracted as a connectivity tree, where nodes represent the centroid points of coarse aggregates and the order denotes the number of nodes within the tree. Consequently, trees can be further classified as follows: primary-order trees (Tr-1) refer to 2nd-order trees (containing only two connected nodes), medium-order trees (Tr-2) denote 3rd to 4th-order trees, and high-order trees (Tr-3) represent trees of 5th order and above. This classification approach facilitates quantitative analysis of the contact network structure in coarse aggregates. According to the proposed criteria, an asphalt mixture is considered to possess satisfactory skeletal contact characteristics if it meets the following mesoscopic indices: (1) Total length of coarse aggregate contact points (L) ≥ 70 mm; (2) Voronoi polygon areas (Vs) (30–180 mm2) proportion ≥ 75%; and (3) Tr-1 and Tr-2 combined proportion ≤ 75% [36]. The specific workflow of this evaluation method is illustrated in Figure 4.

Figure 4.

Evaluation method for skeletal contact characteristics of asphalt mixture using Voronoi diagrams.

3. DEM Models Construction

The road performance of asphalt mixtures is primarily reflected in resistance to rutting, cracking, moisture damage, and skidding. These performance indicators are closely related to the skeletal contact characteristics of the mixture. In recent years, cracking issues in asphalt pavements have become increasingly prominent and have emerged as one of the most critical forms of distress, posing significant threats to road service life and traffic safety [37,38]. To delve deeper into this issue, this study utilized DEM numerical simulation analysis by establishing a virtual splitting test model to investigate the meso-mechanical behavior of asphalt mixtures with different gradations under loading conditions. The analysis focused on the evolution patterns of skeletal contact characteristics, displacement variations in coarse aggregates, and crack propagation processes. Based on numerical simulation results, a quantitative assessment was conducted to evaluate the impact of skeletal contact conditions on the cracking resistance of asphalt mixtures.

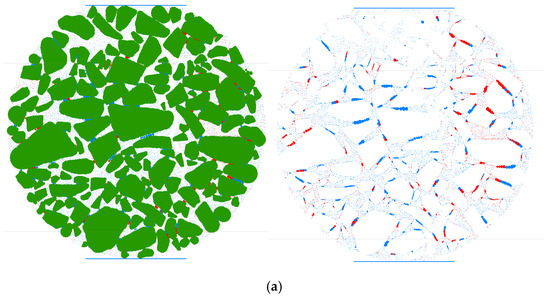

3.1. Virtual Specimen Construction

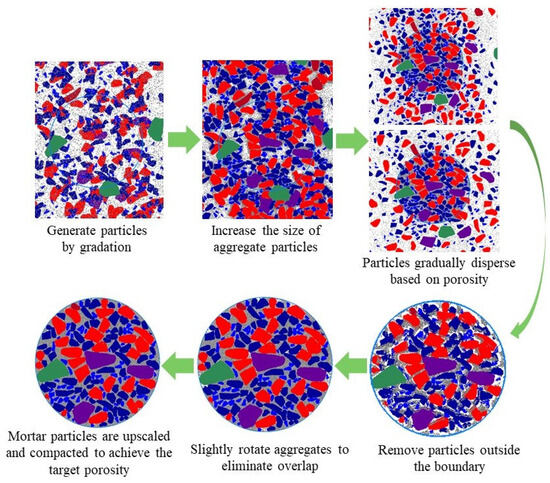

Based on the DEM theory, the Particle Flow Code (PFC) effectively computes key parameters characterizing both the macroscopic mechanical properties and mesoscopic structural features of asphalt mixtures. PFC 2D (version 5.0) software offers substantial advantages in reducing computational costs, simplifying the modeling process, and providing superior visualization of phenomena such as force chain networks, particle displacement, and crack evolution. Therefore, this study employed PFC 2D (version 5.0) to develop a custom program and generate three types of 2D asphalt mixture specimen models—SMA-20, AC-20, and OGFC-20—based on the gradation specifications provided in Table 4. The generated models feature a circular cross-section with a diameter of 101.6 mm, corresponding to the standard Marshall specimen’s transverse section. The models were generated using a clump template combined with a porosity-based stochastic generation method. The specific workflow is as follows: First, the number of clump clusters (representing coarse aggregate particles) for the gradation was determined based on the volumetric method. Subsequently, particles were randomly generated according to parameters such as size and geometric shape. Next, the clump distribute command was employed to generate particles according to the target porosity level. The actual porosity was then calculated by computing the ratio of the total particle area to the area of the generation domain. Finally, the built-in algorithm in PFC was utilized to adjust particle positions until the model achieved mechanical equilibrium.

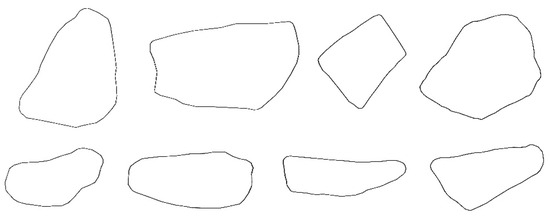

The morphology of aggregates plays a critical role in influencing the mechanical properties of asphalt mixtures. To enhance the realism of the established DEM model, this study incorporated genuine aggregate geometric shapes imported to generate clump templates. The specific procedure is as follows: first, cross-sectional images of the mixture were obtained through CT scanning to extract geometric information of aggregates. Subsequently, AutoCAD (version 2020) was utilized to draft geometric contours of eight typical types of coarse aggregates (such as elongated/flaky, rectangular, near-elliptical, triangular, etc.), as illustrated in Figure 5. Finally, the graphic files were exported in DXF format for import into PFC as clump templates for aggregate generation. To improve computational efficiency, the asphalt mortar composed of fine aggregates (aggregate size < 2.36 mm) and asphalt binder was represented by filling with circular particles ranging from 0.2 to 1.0 mm in diameter. Accordingly, aggregates with particle sizes greater than 2.36 mm were classified as coarse aggregates in this DEM analysis. It should be noted that for a 20 mm NMAS gradation, the “Bailey Design Method” typically sets 4.75 mm as the coarse/fine aggregate cut-off. However, this analysis used a 2.36 mm cut-off to ensure computational efficiency and maximize the investigation scope for coarse aggregates.

Figure 5.

The generated coarse aggregate contour template.

In the PFC program, a large number of small circular particles and clump templates were initially generated at random within the computational domain. During the filling process, particles were first reduced in size and then expanded, meaning an expansion coefficient was set to control the gaps between particles and the filling density, thereby simulating the mixture structure under different compactness conditions. Finally, after the filling process was completed, particles extending beyond the specimen boundaries were removed to ensure the accuracy and reliability of the simulation results. The generation process of the asphalt mixture DEM model is illustrated in Figure 6. Moreover, in the virtual model of the asphalt mixture, the aggregate size range, shapes, and representative colors of the Clump aggregates are presented in Table 6.

Figure 6.

Generation process of the SMA-20 virtual specimen.

Table 6.

Color coding of Clump aggregate clusters.

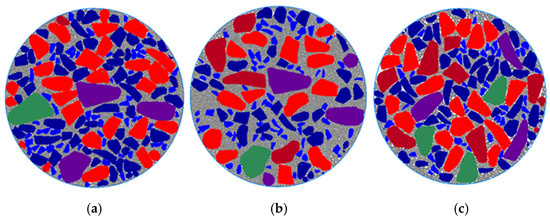

The PFC offers various contact models, among which the parallel bond model simulates localized bonding behavior by assuming the formation of microscopic bonding films between particles. Since this model effectively characterizes the cohesive properties of asphalt binder coating aggregates in asphalt mixtures, it was selected as the bonding constitutive model in this study. Based on existing literature and laboratory splitting test results, the finalized computational parameters for the virtual specimens of asphalt mixtures are presented in Table 7 [25,39,40,41]. The models for the three gradations are illustrated in Figure 7.

Table 7.

Parameters employed in the DEM models.

Figure 7.

Three virtual specimens with different gradations; (a) SMA-20; (b) AC-20; (c) OGFC-20.

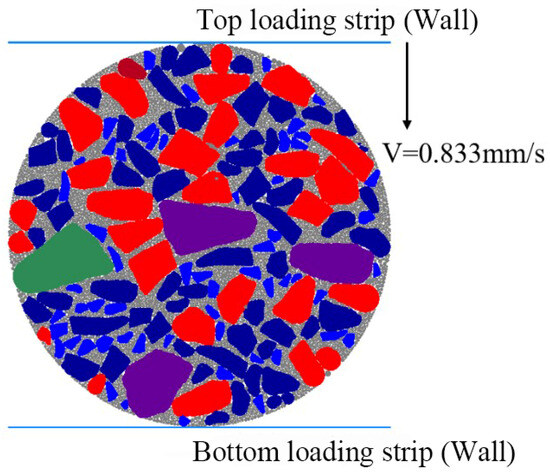

3.2. Simulation of the Splitting Test

The asphalt mixture splitting test is a standard method for evaluating the crack resistance of mixtures. This study simulated the indoor splitting test at 15 °C using three established DEM models. In these models, the configuration of boundary conditions not only constrains the movement range of particles but also enables the simulation of specimen loading processes by assigning velocity and direction to the boundaries. Accordingly, this study employed walls to simulate the loading strips of the physical testing machine. By positioning walls at the top and bottom of the 2D DEM asphalt mixture model, the mechanical function of the upper and lower loading strips in the experimental setup was accurately represented. The splitting load was applied using a servocontrol program written in the built-in Fish language of PFC 2D (version 5.0) software. The specific implementation involved: assigning the top wall a downward vertical velocity (negative y-direction) of 0.833 mm/s to equivalently simulate the standard loading rate of 50 mm/min in laboratory tests. Simultaneously, the velocity of the bottom wall was set to 0 mm/s to represent the fixed boundary constraint condition at the base in the physical experiment. Moreover, this simulation employed time steps as a termination criterion. To ensure the specimens reached complete splitting failure, extensive parameter debugging was conducted. The final termination condition for all three gradation specimens was set at 130,000 time steps. Figure 8 illustrates the numerical simulation process of this splitting test, while Table 8 presents the quantitative distribution of aggregates with various sizes in the model.

Figure 8.

Splitting test model.

Table 8.

Number Distribution of Particles with Different Sizes in the Model.

In summary, this study utilized PFC 2D (version 5.0) software to achieve the importation of aggregate with realistic geometric shapes and particle packing through programming, successfully constructing a DEM model of asphalt mixture with authentic meso-structural characteristics. This modeling method can accurately characterize the geometric features and contact relationships of aggregates within the mixture, significantly improving the simulation accuracy of 2D DEM virtual splitting tests. It provides crucial technical support for research on the meso-structural mechanisms of asphalt mixture mechanical properties and the reliability of virtual test data.

4. Test Results and Analysis

4.1. Analysis of Evaluation Indicators for Skeletal Contact State

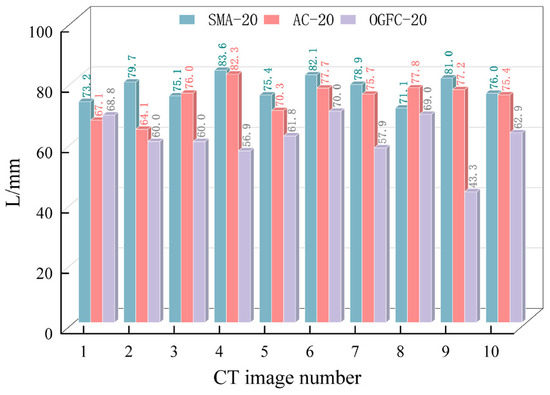

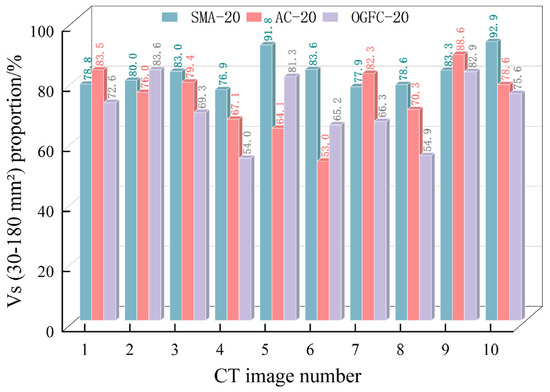

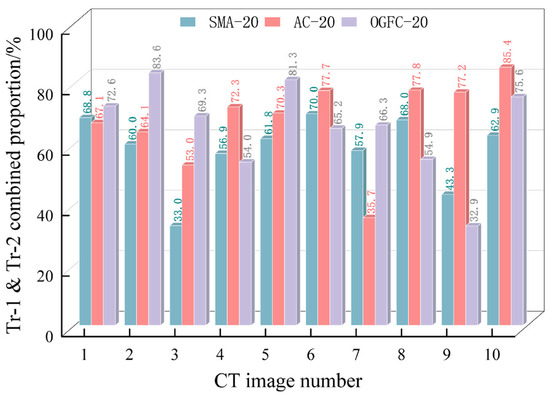

In order to preliminarily evaluate the actual skeletal contact conditions of SMA-20, AC-20, and OGFC-20 gradations, the Voronoi diagram-based meso-structural evaluation method was employed. This method was used to quantify three critical meso-indicators: the L, Vs (30–180 mm2) proportion, and Tr-1 and Tr-2 combined proportion. The application of this method requires obtaining actual cross-sectional images of the graded specimens. To ensure the reliability of the analytical results and avoid extensive repetitive work, this study selected ten representative CT cross-sectional images of each gradation for analysis and measurement. Figure 9, Figure 10 and Figure 11 illustrate the distribution of meso-structural indicators obtained from CT cross-sectional images of the three gradations.

Figure 9.

The L in CT images for each gradation.

Figure 10.

The Vs (30–180 mm2) proportion in CT images for each gradation.

Figure 11.

The Tr-1 and Tr-2 combined proportion in CT Images for each gradation.

Based on Figure 9, Figure 10 and Figure 11, the following conclusions can be drawn: (1) Significant differences were observed in the three meso-structural indicators among the three gradations, indicating distinct skeletal contact characteristics. This verifies the differences in skeletal contact behavior between continuously dense gradations, gap-graded mixtures, and open-graded mixes. (2) All measured values from the 10 CT cross-sectional images of SMA-20 met the following criteria: L ≥ 70 mm, Vs (30–180 mm2) proportion ≥ 75%, and Tr-1 and Tr-2 combined proportion ≤ 75%. The average values of the three meso-indicators were: L = 77.6 mm, Vs (30–180 mm2) = 82.7%, and Tr-1 and Tr-2 combined proportion = 58.3%. These results indicated that the skeletal contact condition of SMA-20 is highly optimal. (3) The average values of the three meso-structural indicators measured from the CT cross-sectional images of AC-20 are as follows: L = 74.3 mm, Vs (30–180 mm2) = 74.3%, and Tr-1 and Tr-2 combined proportion = 68.0%. While both L and the Tr-1 and Tr-2 combined proportion met the specified thresholds, the Vs (30–180 mm2) proportion, at 74.3%, narrowly missed the 75% criterion. These results demonstrated that the skeletal contact condition of AC-20 remains highly favorable. (4) The test results for OGFC-20 yielded the following average values for the three meso-structural indicators: L = 61.1 mm, Vs (30–180 mm2) proportion = 70.6%, and Tr-1 and Tr-2 combined proportion = 65.6%. Among these, only the Tr-1 and Tr-2 combined proportion met the established standard, while both the L value and the Vs (30–180 mm2) proportion fell short of the required thresholds. Consequently, the skeletal contact condition of OGFC-20 is relatively weak.

Based on the comprehensive evaluation of the meso-structural indicators obtained from CT cross-sectional images, the following conclusions can be drawn regarding the three gradations: SMA-20 demonstrated the optimal performance across all indicators, exhibiting the most favorable skeletal contact conditions. AC-20 ranked second, while OGFC-20 showed the poorest performance. Based on the aforementioned analytical results, subsequent research would incorporate numerical simulation methods to further investigate the cracking behavior of the three gradations under load conditions.

4.2. Asphalt Mixture Skeletal Contact Characteristics

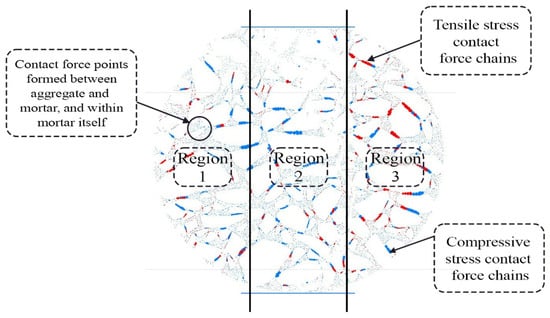

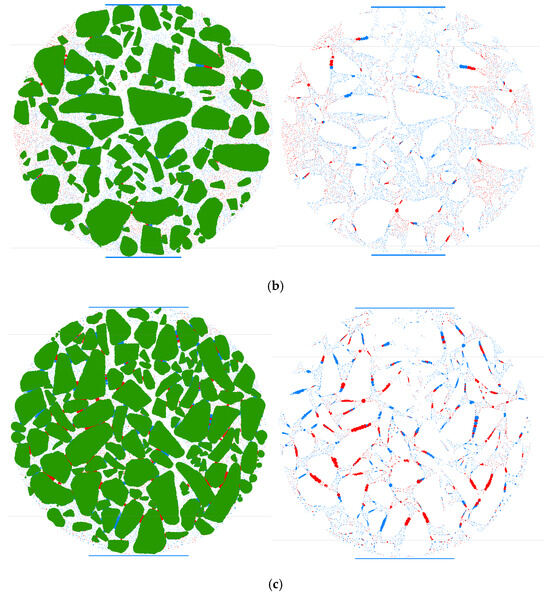

To investigate the relationship between skeletal contact characteristics and mechanical performance, this study established numerical models for splitting tests for asphalt mixtures of three different gradations. As shown in Figure 12, the contact force chain network between skeletal structures is visualized with blue to represent compressive stress contact force chains and red to represent tensile stress contact force chains. The thickness of the force chains indicates the magnitude of contact stress between aggregates. In the skeletal contact force chain network diagram, the specimen was equally divided into three parts based on its diameter: Region 1, Region 2, and Region 3. This division method distinguishes the direct pressure-bearing regions (the central area) from the indirect pressure-bearing regions (the two side areas), thereby facilitating a clearer comparison of the number and spatial distribution of contact force chains between the two regions. The skeletal contact characteristics of the three asphalt mixtures after splitting tests are shown in Figure 13 and Figure 14. By analyzing the contact characteristics, this study revealed the cracking failure mechanism of asphalt mixtures under loading and elucidated the intrinsic relationship between the skeletal structure and the macroscopic mechanical properties of the material.

Figure 12.

Skeletal contact force chain network after splitting.

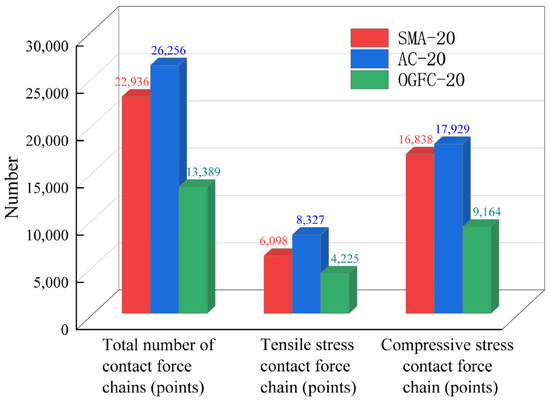

Figure 13.

Contact characteristics of skeletal structures with different coarse aggregate morphologies at the end of loading; (a) SMA-20; (b) AC-20; (c) OGFC-20.

Figure 14.

Number of contact force chains (points) for different gradations.

According to Figure 13 and Figure 14, the following conclusions can be drawn: (1) As the top pressure strip of the specimen moved downward, applying compressive load, skeletal contact tensile stress was generated between the aggregates of the asphalt mixture. A contact force chain network formed between the skeletal structures, while numerous contact force points developed within the asphalt mortar. Some aggregate contact force chains appeared longer and thicker, indicating stronger tensile resistance and a lower likelihood of cracking in these regions. In contrast, areas with shorter and thinner force chains suggested weaker tensile capacity between aggregates, making them more susceptible to fracture formation. (2) Asphalt mixtures with different gradations exhibited distinct skeletal contact characteristics during splitting tests. SMA-20, AC-20, and OGFC-20 demonstrated varying stress distribution patterns at different locations. At crack initiation sites, no tensile stress contact force chains were observed, the fracture occurred precisely where the tensile stress contact force chains become discontinuous. Following the splitting test, the main fractures in all three gradation types were distributed along the central axis (Region 2) of the 2D circular specimens. Consequently, tensile stress contact force chains were sparsely distributed in Region 2 for SMA-20, AC-20, and OGFC-20 mixtures, with the majority concentrated on bilateral regions of the central axis—specifically in Regions 1 and 3. (3) After external load application, tensile stress contact force chains progressively increased over time, leading to elevated internal tensile stress within the specimen. This manifested externally as the emergence of microcracks, accompanied by fracture of the contact force chains between skeletal structures. As the loading process progressed, the contact stress demonstrated distinct distribution characteristics. The interfacial stress between skeletal structures exhibited complex yet regular patterns that vary both temporally and spatially. At the initial state, only compressive stress existed at contact points. After load application, tensile stress and tensile-compressive composite stress emerged at skeletal contact areas. Within the load-effective zone, aggregate interactions were predominantly characterized by compressive stress. (4) After the splitting loading was completed, the total number of contact force chains (points) followed the order: OGFC-20 < SMA-20 < AC-20. The same order was observed for both tensile stress and compressive stress contact force chains (points). For all three indicators, AC-20 showed the highest values, followed by SMA-20, while OGFC-20 exhibited the lowest values. However, it is evident that the number of longer and thicker contact force chains followed the order: AC-20 < OGFC-20 < SMA-20. This indicates that the total contact force chains (points) in AC-20 were predominantly composed of interactions between coarse aggregates and mortar, as well as within the asphalt mortar itself, while contact force chains directly between coarse aggregates were significantly fewer. These contact points formed between coarse aggregates and mortar or within the mortar matrix cannot effectively establish a robust skeletal framework. This further demonstrated that the AC gradation contained relatively low proportions of large-sized coarse aggregates, resulting in a weak skeletal interlocking structure among coarse aggregates. Consequently, under loading conditions, the material relied primarily on the bonding effect of the asphalt mortar to withstand stress. Existing research has also demonstrated [42] that coarse aggregates larger than 4.75 mm constitute the critical particle size for forming a stable skeleton structure, making the most significant contribution to the establishment of a robust framework. In comparison, both OGFC-20 and SMA-20 mixtures contained higher proportions of large-sized coarse aggregates, which enabled the formation of a more complete skeletal interlocking structure. This enhanced structural integrity allowed these graded mixtures to withstand greater stress under mechanical loading. (5) Comparative analysis revealed that the proportions of compressive stress contact force chains (points) in SMA-20, AC-20, and OGFC-20 accounted for 73.4%, 68.3%, and 68.4% of their total contact force chains (points), respectively. All these values exceed 65%, demonstrating that under splitting load conditions, the skeletal structure of asphalt mixtures primarily bore and transmitted compressive stresses.

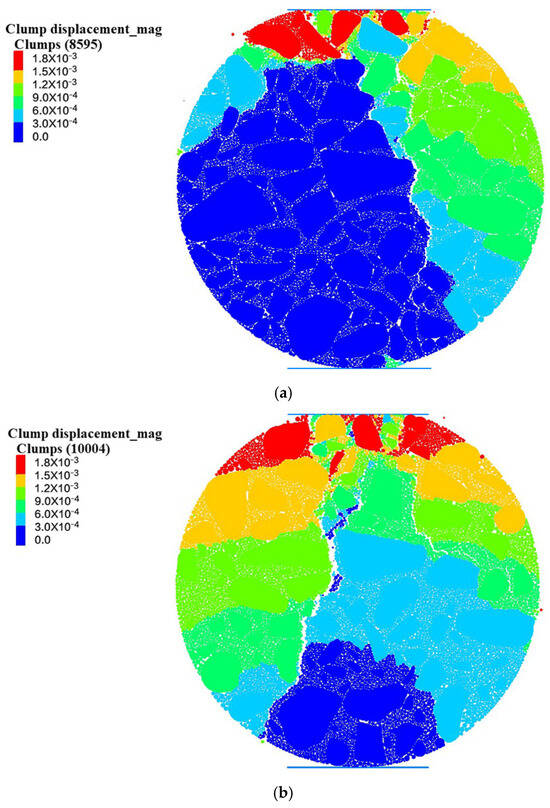

4.3. Displacement Characteristics of Coarse Aggregates in Asphalt Mixtures

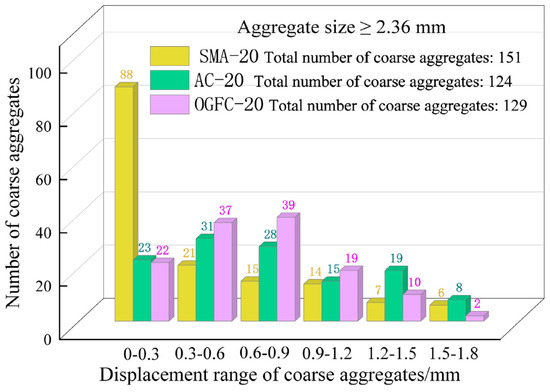

This study further investigated the displacement response of coarse aggregates under loading conditions, aiming to elucidate the mechanism through which skeletal contact interactions contribute to crack resistance. According to automated calculations by the PFC program, the displacement range of specimens under loading was determined. Comprehensive analysis indicated that the aggregate displacement range for all three gradations spanned from 0 to 1.8 mm. To enable comparative analysis across different gradations while maintaining consistency in controlled variables, the displacement nephograms for all gradations were configured to display a uniform range of 0–1.8 mm, with a class interval of 0.3 mm, resulting in six defined displacement ranges. Figure 15 illustrates the distribution characteristics of aggregate movement for each gradation after the completion of loading. By statistically analyzing the number of coarse aggregates within each displacement range for all gradations after splitting (as shown in Figure 16), quantitative analysis of the motion characteristics of coarse aggregates in different gradations and their correlation with crack resistance can be conducted.

Figure 15.

Displacement distribution of coarse aggregates for each gradation; (a) SMA-20; (b) AC-20; (c) OGFC-20.

Figure 16.

Coarse aggregate movement distance after splitting.

Based on Figure 15 and Figure 16, the following conclusions can be drawn: (1) During the splitting test loading process, the gradation differences exerted distinct influences on the displacement behavior of coarse aggregates. (2) For SMA-20, the majority of coarse aggregates exhibited minimal movement: 72.2% experience displacement within 0–0.6 mm, while 19.2% shift within 0.6–1.2 mm. Only 8.6% undergo significant displacement, reaching 1.2–1.8 mm. This indicated that under loading conditions, SMA-20 demonstrated excellent skeletal interlocking, with limited coarse aggregate displacement, effectively resisting splitting forces and exhibiting outstanding crack resistance. (3) For OGFC-20, a relatively small proportion of aggregates underwent extensive displacement: 45.7% of coarse aggregates exhibit movement within 0–0.6 mm, while 45.0% shift within 0.6–1.2 mm. Only 9.3% experience significant displacement, reaching 1.2–1.8 mm. Consequently, OGFC-20 also demonstrated a well-developed skeletal structure. (4) In contrast, AC-20 exhibited a notably higher proportion of coarse aggregates undergoing substantial displacement: merely 43.5% experience movement within 0–0.6 mm, while 34.7% shift within 0.6–1.2 mm. Notably, as much as 21.8% of coarse aggregates underwent significant displacement, reaching 1.2–1.8 mm. Consequently, this led to the development of wider cracks. Analysis suggested that compared to the other two gradations, the continuous dense AC gradation contained a lower proportion of large-sized coarse aggregates, resulting in a relatively weaker skeletal structure. However, it possessed a higher content of asphalt mortar composed of fine aggregates and bitumen, which consequently enhanced the bonding effectiveness of the asphalt mortar. During the initial phase of loading, the deformation resistance of the AC gradation was jointly supported by the bonding effect of the asphalt mortar and the skeletal structure. At this stage, the strong mortar bonding effectiveness effectively compensated for the deficiency in skeletal strength. However, as the loading continued, internal cracks within the mixture proliferated, and the bonding effect of the asphalt mortar gradually weakened. At this stage, the load-transfer mechanism shifted to being primarily supported by the skeletal structure. Due to the limited number and insufficient strength of skeletal contact force chains in this gradation, sustained loading would trigger large-scale displacement of aggregates, ultimately leading to rapid cracking of the specimen. (5) The results demonstrated that the cracking behavior of asphalt mixtures was significantly influenced by the characteristics of skeletal contact. Effective skeletal interlocking enhanced the stability of the asphalt mixture’s skeletal structure, reduced the displacement of coarse aggregates under loading, and ultimately improved the crack resistance of the material.

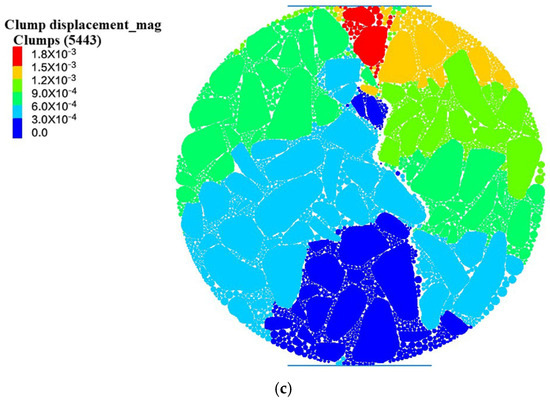

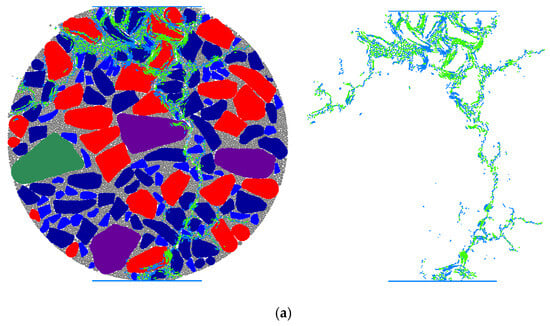

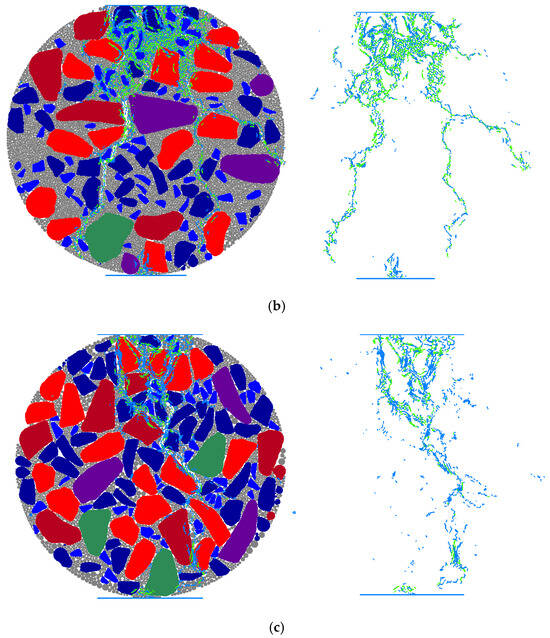

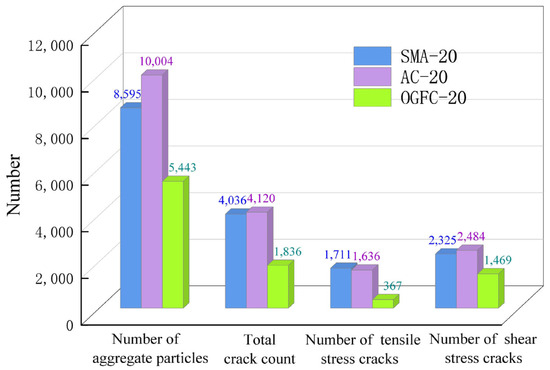

4.4. Development Patterns and Mechanisms of Cracks in Asphalt Mixtures

To further analyze the virtual splitting test results and reveal the crack development patterns of the three gradations, Figure 17 demonstrates the morphological characteristics of micro-cracks in the asphalt mixture at the termination of loading. Based on fracture mechanisms, cracks can be categorized into tensile type (green) and shear type (blue). The discrete fracture network (DFN) function in PFC 2D (version 5.0) software was employed to visualize and analyze the crack structure, enabling quantitative statistical analysis of various parameters within the fracture network. Through DFN analysis, statistical results of the total number of cracks, tensile cracks, and shear cracks were obtained, as shown in Figure 18. It should be noted that in this splitting model, coarse aggregates themselves were set not to fracture.

Figure 17.

Crack distribution in specimens of different gradations; (a) SMA-20; (b) AC-20; (c) OGFC-20.

Figure 18.

Number of cracks in specimens of different gradations.

Based on the analysis of Figure 17 and Figure 18, the following conclusions can be drawn: (1) Micro-cracks in asphalt mixtures induced by tensile stress were predominantly located at aggregate-aggregate contact interfaces. Under sustained loading, cracks initiated and propagated within the mixture, accompanied by displacement and rearrangement of aggregates and asphalt mortar. The contact area between aggregates generated significant shear forces due to stress concentration. Shear stress cracks at aggregate-aggregate contact interfaces and tensile stress cracks within the asphalt mortar progressively interconnected to form continuous penetrating cracks, ultimately leading to complete fracture of the asphalt mixture. (2) The vertically downward loading causes the asphalt mixture specimen to bulge outward on both left and right sides. Micro-cracks induced by tensile stress within the asphalt mixture were predominantly distributed along the central diameter of the cross-section. All three gradation mixtures exhibited numerous tensile stress cracks at aggregate-aggregate contact interfaces, as well as within the asphalt mortar. (3) As the loading process continued, micro-cracks gradually appeared on the surface of the asphalt mixture, exhibiting different crack patterns and distribution characteristics. The total number of cracks followed the order: AC-20 > SMA-20 > OGFC-20. Given that the skeletal structure of continuous dense-graded mixtures was generally weaker to that of gap-graded and open-graded mixtures, this observation further confirmed that gradations with better skeleton structures offer greater advantages in reducing crack formation. Under loading, the specimen primarily develops two distinct types of micro-crack propagation: shear stress cracks and tensile stress cracks. All three gradations exhibited a higher number of shear stress cracks compared to tensile stress cracks. Specifically, shear cracks accounted for 57.6% of the total cracks in SMA-20, 60.3% in AC-20, and 80.0% in OGFC-20, all exceeding 55%. This indicated that during the splitting test, the specimen actually developed more cracks caused by shear failure than those resulting from tensile failure. (4) Analysis of the simulated meso-scale cracks indicated that the established splitting test model effectively captured both the propagation and diffusion processes of cracks. Cracks mainly appear in three locations: fracture at coarse aggregate-coarse aggregate contact interfaces, debonding between asphalt mortar and coarse aggregates, and fracture within the asphalt mortar. Therefore, the uniform distribution of asphalt mortar and coarse aggregates, as well as the effective interlocking structure formed by coarse aggregates, are effective in improving the crack resistance of asphalt mixtures.

4.5. Analysis of Mechanical Properties of Asphalt Mixtures

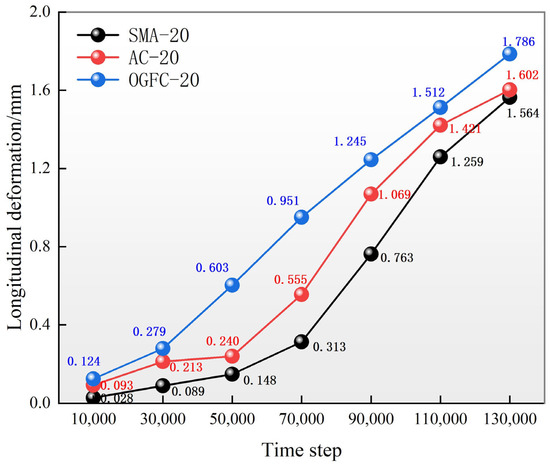

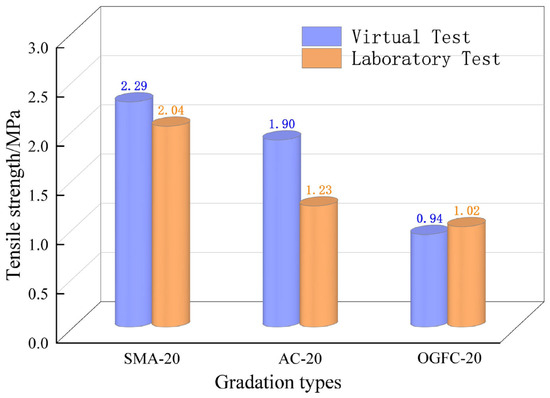

To investigate the influence of gradation-induced skeletal contact conditions on the macroscopic mechanical behavior of asphalt mixtures, the mechanical properties and deformation indicators of DEM models for three different gradations were analyzed. Critical monitoring data during the loading process were obtained through the data export function of the PFC program, including the peak load of the three gradation models and the corresponding longitudinal deformation of the specimens at identical time steps. The peak load must be further converted into tensile strength using Formula 1. Finally, the tensile strength measured through virtual testing was compared with that obtained from laboratory tests to validate the reliability of the numerical simulation results. The specific data are presented in Figure 19 and Figure 20. This study provides a numerical analysis basis for revealing the correlation between aggregate contact conditions of gradation and the macroscopic mechanical behavior of asphalt mixtures.

Figure 19.

Monitoring of longitudinal deformation in asphalt mixtures with different gradations.

Figure 20.

Tensile strength of different gradations.

Conversion formula for tensile strength of splitting test:

where RT is the tensile strength (MPa), Fmax is the peak load of specimen measured in splitting test (N), d is the diameter of the specimen (mm), t is the thickness of the specimen (mm). Since this study establishes a 2D specimen model, the thickness of the specimen can be considered as 1.

According to the statistical results from Figure 19 and Figure 20, it can be observed that: (1) Due to gradation differences, the skeletal contact states within the mixtures varied, and such structural differences significantly influenced the macroscopic mechanical response of the materials. The test results indicated that under loading, specimens with different gradations exhibited notable differences in both longitudinal deformation and tensile strength. (2) Under the same time step loading, the longitudinal deformation degrees of the three gradations followed the order: SMA-20 < AC-20 < OGFC-20. Among them, the final longitudinal deformation of SMA-20 was only 1.564 mm, while those of AC-20 and OGFC-20 were 1.02 times and 1.14 times that of SMA-20, respectively. The measured tensile strengths were: SMA-20 > AC-20 > OGFC-20, with SMA-20 reaching 2.29 MPa, while AC-20 and OGFC-20 were 0.83 times and 0.41 times that value, respectively. Therefore, SMA-20 demonstrated the best performance in terms of deformation resistance and tensile strength, followed by AC-20, while OGFC-20 showed the least effectiveness. Analysis suggested that although OGFC-20 contained a higher proportion of large-size aggregates, which could theoretically form a more robust skeletal structure, its relatively low asphalt mortar content and high void content resulted in insufficient overall densification of the mixture. This structural characteristic significantly reduced the bonding effectiveness of the asphalt mortar. Although the use of high-viscosity asphalt can partially improve interfacial bonding performance, under sustained loading, structural deficiencies continued to accumulate and propagate, ultimately led to a notable decline in deformation resistance and tensile strength. In contrast, AC-20 exhibited a higher asphalt mortar content and lower porosity. This enabled the asphalt mortar to fully coat the aggregates and form effective bonding interfaces. The resulting dense structure not only enhanced the overall integrity of the material but also significantly compensated for strength deficiencies in the skeletal framework under load. Consequently, AC-20 demonstrated superior tensile resistance and deformation performance compared to OGFC-20. SMA-20 combined a well-interlocked aggregate skeleton with a moderate asphalt mortar content, while its low porosity ensured high densification of the material. This structural characteristic not only promoted effective bonding between the asphalt mortar and aggregates but also significantly enhanced the overall mechanical performance of the mixture. Consequently, under loading, SMA-20 exhibited superior deformation resistance and tensile strength, thereby effectively inhibiting the initiation and propagation of cracks. (3) The tensile strength results obtained from laboratory tests and virtual tests were generally consistent, with both methods yielding the same strength ranking: SMA-20 > AC-20 > OGFC-20. Although some numerical discrepancy existed for AC-20, the strength values of the other two gradations were highly consistent. These findings confirmed the high reliability of the virtual testing methodology. (4) Comprehensive analysis of DEM models indicated that SMA-20 exhibited the best crack resistance, followed by AC-20, while OGFC-20 demonstrated relatively poorer performance. This conclusion is consistent with results of the Voronoi diagram-based meso-structural evaluation method for skeletal contact, which also established SMA-20 as having the optimal skeletal contact characteristics, followed by AC-20, with OGFC-20 performing the weakest. Thus, the skeletal contact condition in asphalt mixtures has a direct influence on their mechanical properties. When the skeletal contact is poor, the primary mechanical performance of the mixture is significantly reduced. These findings further validate the reliability of this skeletal contact evaluation method for predicting and assessing the performance of asphalt mixtures.

5. Conclusions

This study employed a multi-method approach, incorporating X-ray CT scanning, Voronoi diagram-based evaluation method for skeletal contact characteristics in asphalt mixtures, and DEM numerical simulation. The study systematically investigated the skeletal contact behavior, coarse aggregate movement, and crack evolution under loading. Furthermore, the influence of skeletal contact conditions on the macroscopic performance of mixtures with different gradations was analyzed, and the evaluation results of the skeletal structure were validated. The findings not only revealed the intrinsic relationship between the meso-structural characteristics and macroscopic mechanical behavior of asphalt mixtures, but, more importantly, also provided a critical basis for optimizing crack resistance design. By incorporating mesoscopic indicators that assess the skeleton contact state as key control parameters in the design process, asphalt mixtures with stronger aggregate skeletons and enhanced crack resistance can be developed, thereby improving the durability and service performance of asphalt pavements. The main conclusions of this study are as follows:

- (1)

- Asphalt mixtures with different gradations exhibited different skeletal contact characteristics in the splitting test. SMA-20, AC-20, and OGFC-20 showed varied stress distributions at different locations. Cracks initiated at positions where no tensile stress contact force chains were present, the fracture of these force chains led to crack formation. After splitting, the main cracks in all three gradations were located along the central axis of the 2D circular specimen. Consequently, the tensile stress contact force chains were scarcely distributed in the central axis region for SMA-20, AC-20, and OGFC-20, and were primarily concentrated in the areas on both sides of the central axis.

- (2)

- In the skeletal structure of asphalt mixtures, contact points experience compressive stress, tensile stress, and combined tensile-compressive stress. Within the loaded area, aggregate interactions were predominantly compressive stress, while both compressive and tensile stresses coexisted in regions on both sides of the loading zone. Under loading, AC-20 exhibited the lowest number of long and thick contact force chains among its coarse aggregates, so the skeletal interlocking structure formed by AC-20 was relatively weak. In contrast, OGFC-20 and SMA-20 developed more complete skeletal interlocking structures, enabling them to withstand higher stress levels. For all three gradations, compressive stress contact force chains (points) accounted for over 65% of the total contact force chains (points), indicating that the skeletal system of asphalt mixtures primarily bore and transmitted compressive stresses under splitting load conditions.

- (3)

- The displacement of coarse aggregates under loading was significantly influenced by the skeletal contact characteristics of the asphalt mixture. The results indicated that only 8.6% of coarse aggregates in SMA-20 exhibited a movement range of 1.2–1.8 mm, meaning the majority showed minimal movement. Similarly, only 9.3% of coarse aggregates in OGFC-20 moved within the 1.2–1.8 mm range. In contrast, AC-20 exhibited a significantly higher proportion, with 21.8% of coarse aggregates moved within the range of 1.2–1.8 mm. Consequently, the coarse aggregates in AC-20 demonstrated the largest magnitude of displacement under loading, indicating that its skeletal structure was comparatively weaker than those of SMA-20 and OGFC-20. A well-interlocked skeletal structure formed by a high proportion of coarse aggregates can effectively enhance the long-term stability of the asphalt mixture, reduce coarse aggregates movement under sustained loading, and improve resistance to cracking.

- (4)

- Gradations with superior skeletal structures demonstrated greater advantages in reducing crack initiation. Under loading, the specimens primarily exhibited two typical micro-crack propagation modes: shear stress cracks and tensile stress cracks. Test results indicated that the number of shear stress cracks exceeded that of tensile stress cracks in all three gradations, with shear stress cracks accounting for over 55% of the total cracks in each case. This suggested that under splitting load conditions, the mixture experiences more damage due to shear failure than to tensile failure. The established DEM model effectively simulated the processes of crack initiation and propagation. Cracks predominantly occurred at three types of locations: fracture at coarse aggregate–coarse aggregate contact interfaces, debonding between asphalt mortar and coarse aggregates, and fracture within the asphalt mortar. Therefore, a uniform distribution of asphalt mortar and coarse aggregates, combined with an effectively interlocked coarse aggregate skeleton, can significantly enhance the crack resistance of asphalt mixtures.

- (5)

- Comprehensive analysis in this study indicated that SMA-20 exhibited the best crack resistance performance, followed by AC-20, while OGFC-20 demonstrated relatively inferior performance. This conclusion is highly consistent with the results obtained from the Voronoi diagram-based meso-structural evaluation method for skeletal contact, which also ranked SMA-20 as having the most favorable skeletal contact conditions, followed by AC-20, with OGFC-20 performing the poorest. These findings confirm a direct correlation between the skeletal contact characteristics of asphalt mixtures and their mechanical properties: when the skeletal contact condition is poor, the key mechanical performance of the mixture deteriorates significantly. Furthermore, this study validated the reliability of the skeletal contact evaluation method for predicting and assessing the performance of asphalt mixtures, providing a new theoretical basis for research on the relationship between meso-structure and macroscopic properties of asphalt mixtures.

6. Limitations and Future Work

This study has limitations that warrant clarification. First, the evaluation metrics of the Voronoi diagram-based skeletal contact meso-structure evaluation method are sensitive to factors such as the clarity of the original image and the accuracy of coarse aggregate identification during image processing. Image quality directly affects the extraction of mesoscopic parameters, potentially introducing uncertainty into the evaluation results. Second, in terms of modeling, the 2D DEM model used in this study inevitably simplifies the actual spatial distribution of aggregates and the 3D transmission paths of contact force chains. Consequently, its physical reality differs from that of a 3D model, which may limit the generalizability of the conclusions. Future research should aim to address these limitations by optimizing the image processing workflow and incorporating more robust algorithms to minimize dependence on image quality. In addition, a 3D discrete element analysis framework should be developed to more accurately simulate aggregate contact behavior and load transfer mechanisms in 3D space, thereby improving the reliability and applicability of the findings.

Author Contributions

H.L.: Writing—Original draft, investigation, formal analysis, and visualization. L.S.: conceptualization, Writing—Review and editing, methodology, supervision and resources. Y.W.: Writing—Original draft, investigation, formal analysis, and software. P.L.: data curation. J.H.: investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by Guangdong Basic and Applied Basic Research Foundation [Grant No. 2021A1515110602 and 2025A1515011019].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to express their sincere appreciation to the financial support provided by the Guangdong Basic and Applied Basic Research Foundation. The technical support from the Xiaoning Institute of Roadway Engineering is also sincerely acknowledged. Special thanks to Xiaoming Sun for providing linguistic assistance during the preparation of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Khorshidi, M.; Goli, A.; Orešković, M.; Khayambashi, K.; Ameri, M. Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability 2023, 15, 13314. [Google Scholar] [CrossRef]

- Xiong, X.; Tan, Y.; Huang, Z.; Chen, B.; Huang, Q. Automatic NDT of semi-rigid base cracks within asphalt pavement based on 3D-GPR and deep learning. Int. J. Pavement Eng. 2025, 26, 2538791. [Google Scholar] [CrossRef]

- Sun, X.; Xu, H.; Qin, X.; Zhu, Y.; Jin, J. Cross-scale study on the interaction behaviour of municipal solid waste incineration fly ash-asphalt mortar: A macro-micro approach. Int. J. Pavement Eng. 2025, 26, 2469114. [Google Scholar] [CrossRef]

- Chen, B.; Wang, X.; Li, Z.; Chen, K.; Li, W.; Chen, Z.; Xiong, X. Spatial distribution characteristics and mechanical properties of artificial coarse aggregates with different morphologies in asphalt mixtures. Case Stud. Constr. Mater. 2025, 22, e04667. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, B.; Hu, H.; Gong, F.; Cheng, X.; Liu, Y. Properties and Microcosmic Mechanism of Coral Powder Modified Asphalt in Offshore Islands and Reefs Construction. Sustainability 2023, 15, 12393. [Google Scholar] [CrossRef]

- Sun, X.; Qin, X.; Liu, Z.; Yin, Y. Damaging effect of fine grinding treatment on the microstructure of polyurea elastomer modifier used in asphalt binder. Measurement 2025, 242, 115984. [Google Scholar] [CrossRef]

- Coenen, A.R.; Kutay, M.E.; Sefidmazgi, N.R.; Bahia, H.U. Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis. Road Mater. Pavement Des. 2012, 13, 433–454. [Google Scholar] [CrossRef]

- Sefidmazgi, N.R.; Tashman, L.; Bahia, H. Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis. Road Mater. Pavement Des. 2012, 13, 21–37. [Google Scholar] [CrossRef]

- Sun, P.; Zhang, K.; Han, S.; Liang, Z.; Kong, W.; Zhan, X. Method for the Evaluation of the Homogeneity of Asphalt Mixtures by 2-Dimensional Image Analysis. Materials 2022, 15, 4265. [Google Scholar] [CrossRef]

- Shi, L.; Guo, H.; Zeng, G.; Zhou, R.; Li, X.; Lin, B.; Liang, H. Key parameters and effects in image processing and aggregate–aggregate contact calculation of asphalt mixtures. Measurement 2025, 239, 115439. [Google Scholar] [CrossRef]

- Busang, S.; Maina, J. Influence of aggregates properties on microstructural properties and mechanical performance of asphalt mixtures. Constr. Build. Mater. 2022, 318, 126002. [Google Scholar] [CrossRef]

- Hassan, H.M.Z.; Wu, K.; Huang, W.; Chen, S.; Zhang, Q.; Xie, J.; Cai, X. Study on the influence of aggregate strength and shape on the performance of asphalt mixture. Constr. Build. Mater. 2021, 294, 123599. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Liu, B.; Tan, Y. Meso-Structural Modeling of Asphalt Mixtures Using Computed Tomography and Discrete Element Method with Indirect Tensile Testing. Materials 2025, 18, 2566. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Gao, Y.; Huang, X.; Li, L. Investigation of motion of coarse aggregates in asphalt mixture based on virtual simulation of compaction test. Int. J. Pavement Eng. 2020, 21, 144–156. [Google Scholar] [CrossRef]

- Yao, H.; Xu, M.; Liu, J.; Liu, Y.; Ji, J.; You, Z. Literature review on the discrete element method in asphalt mixtures. Front. Mater. 2022, 9, 879245. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; You, W. Microstructural behavior of the low-temperature cracking and self-healing of asphalt mixtures based on the discrete element method. Mater. Struct. 2022, 55, 18. [Google Scholar] [CrossRef]

- Du, J.; Dai, X.; Liu, Q.; Fu, Z. Toughening Effect of Micro-Cracks on Low-Temperature Crack Propagation in Asphalt Concrete. Materials 2025, 18, 2429. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Luo, X. Real-Time Optimization of Discrete Element Models for Studying Asphalt Mixture Compaction Characteristics at the Meso-Scale. Sensors 2025, 25, 638. [Google Scholar] [CrossRef] [PubMed]

- Ai, X.; Yi, J.; Pei, Z.; Zhou, W.; Feng, D. Advances in discrete element modeling of asphalt mixture: A literature review. Arch. Comput. Methods Eng. 2024, 31, 4003–4029. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Wang, J.; Xu, J.; Miao, Y.; Ma, Q.; Wang, L.; Liu, T. Characterization of Force Distribution and Force Chain Topology in Asphalt Mixtures Using the Discrete Element Method. Materials 2025, 18, 2347. [Google Scholar] [CrossRef]

- Zhu, X.; Qian, G.; Yu, H.; Yao, D.; Shi, C.; Zhang, C. Evaluation of coarse aggregate movement and contact unbalanced force during asphalt mixture compaction process based on discrete element method. Constr. Build. Mater. 2022, 328, 127004. [Google Scholar] [CrossRef]

- Liu, G.; Han, D.; Zhao, Y. Quantitative investigation of aggregate skeleton force chains of asphalt mixtures based on computational granular mechanics. Adv. Civ. Eng. 2020, 2020, 2196503. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, G.; Jiang, N. Characterization of Three-Dimensional Strong Force Chain Properties of Mineral Aggregate Mixtures Based on the Discrete Element Method. Buildings 2024, 14, 3289. [Google Scholar] [CrossRef]

- Câmara, G.; Azevedo, N.M.; Micaelo, R. Impact of Rejuvenator-Modified Mastic on Asphalt Mixture Stiffness: Meso-Scale Discrete Element Method Approach. Buildings 2023, 13, 3023. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, Q.; Chen, X.; Ni, F. Meso-cracking characteristics of rubberized cement-stabilized aggregate by discrete element method. J. Clean. Prod. 2021, 316, 128374. [Google Scholar] [CrossRef]

- Li, X.; Shi, L.; Liao, W.; Wang, Y.; Nie, W. Study on the influence of coarse aggregate morphology on the meso-mechanical properties of asphalt mixtures using discrete element method. Constr. Build. Mater. 2024, 426, 136252. [Google Scholar] [CrossRef]

- Quezada, J.C.; Chazallon, C. Discrete element modelling of hot mix asphalt complex modulus using realistic aggregate shapes. Road Mater. Pavement Des. 2022, 23, 178–195. [Google Scholar] [CrossRef]

- Shi, L.; Liang, H.; Wang, D.; Liu, T. Mesogenetic evaluation and design of coarse aggregate contact within asphalt mixture. J. Mater. Civ. Eng. 2022, 34, 04022187. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.; Huang, W. Study on the optimal compaction effort of asphalt mixture based on the distribution of contact points of coarse aggregates. Road Mater. Pavement Des. 2021, 22, 1594–1615. [Google Scholar] [CrossRef]

- Jin, C.; Wan, X.; Yang, X.; Liu, P.; Oeser, M. Three-dimensional characterization and evaluation of aggregate skeleton of asphalt mixture based on force-chain analysis. J. Eng. Mech. 2021, 147, 04020147. [Google Scholar] [CrossRef]

- Liu, G.; Han, D.; Zhao, Y.; Zhang, J. Effects of asphalt mixture structure types on force chains characteristics based on computational granular mechanics. Int. J. Pavement Eng. 2022, 23, 1008–1024. [Google Scholar] [CrossRef]

- Hamzehkolaei, N.S.; Kadkhoda, N. An efficient ranked Voronoi diagram-based hybrid method for reliability-based structural analysis and design optimization. Soft Comput. 2023, 27, 13889–13910. [Google Scholar] [CrossRef]

- Niu, H.; Savvaris, A.; Tsourdos, A.; Ji, Z. Voronoi-visibility roadmap-based path planning algorithm for unmanned surface vehicles. J. Navig. 2019, 72, 850–874. [Google Scholar] [CrossRef]

- Figurska, M.; Dawidowicz, A.; Zysk, E. Voronoi Diagrams for Senior-Friendly Cities. Int. J. Environ. Res. Public Health 2022, 19, 7447. [Google Scholar] [CrossRef]

- Aurenhammer, F. Voronoi diagrams—A survey of a fundamental geometric data structure. ACM Comput. Surv. (CSUR) 1991, 23, 345–405. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, L.; Li, X.; Liu, T.; Xu, R.; Wang, D. Meso-structural evaluation of asphalt mixture skeleton contact based on Voronoi diagram. Case Stud. Constr. Mater. 2023, 19, e02494. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Aliha, M.R.M. Comparison of testing method effects on cracking resistance of asphalt concrete mixtures. Appl. Sci. 2021, 11, 5094. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Liu, J.; Yang, C.; Wang, F. A Methodological Review on Development of Crack Healing Technologies of Asphalt Pavement. Sustainability 2023, 15, 9659. [Google Scholar] [CrossRef]

- Shan, J.; Du, Y.; Fan, D.; Guo, L. Determination of parameters of the discrete element bond model for asphalt mixture based on splitting test. Adv. Civ. Eng. 2019, 2019, 5047214. [Google Scholar] [CrossRef]

- Xing, C.; Liu, B.; Sun, Z.; Tan, Y.; Liu, X.; Zhou, C. DEM-based stress transmission in asphalt mixture skeleton filling system. Constr. Build. Mater. 2022, 351, 128956. [Google Scholar] [CrossRef]

- Peng, Y.; Sun, L.-j. Aggregate distribution influence on the indirect tensile test of asphalt mixtures using the discrete element method. Int. J. Pavement Eng. 2017, 18, 668–681. [Google Scholar] [CrossRef]

- Shi, L.; Wang, D.; Cai, X.; Wu, Z. Distribution characteristics of coarse aggregate contacts based on digital image processing technique. China J. Highw. Transp. 2014, 27, 23–31. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).