Experimental Evaluation of UAV Energy Management Using Solar Panels and Battery Systems

Abstract

1. Introduction

Literature Review

2. Materials and Methods

2.1. Theoretical Background

2.1.1. Lift and Drag for Sustained Flight

2.1.2. Throttle-to-Power Mapping

2.1.3. Solar Contribution

2.2. Hypothetical Model Aircraft

- No-panel version: total mass kg. With-panel version: total mass kg (including a 1.5 kg solar panel assembly).

2.3. Materials

2.3.1. Solar Panel

2.3.2. MPPT Solar Charge Controller

- Bulk, absorption, and float charger voltages;

- Re-bulk voltage offset;

- Duration, time, and tail-current absorption parameters;

- Equalization of current, interval, stop mode, and duration;

- Temperature voltage compensation;

- Low-temperature cut off.

2.3.3. Battery

2.3.4. Brushless Motor and ESC

2.3.5. Arduino Data Logging

2.4. Experimental Procedure

2.4.1. Setup

2.4.2. Mission Profile Script

2.4.3. Data Logging

- The Arduino starts reading I and V on the three channels every 500 ms;

- The mission script varies the throttle command according to the measured data;

- The measured values are printed via serial connection;

- The experiment ends after a predetermined time period.

2.4.4. Post-Processing

2.4.5. Power-Direction Convention and Charging Condition

2.4.6. Statistical Analysis and Replication

3. Results and Discussion

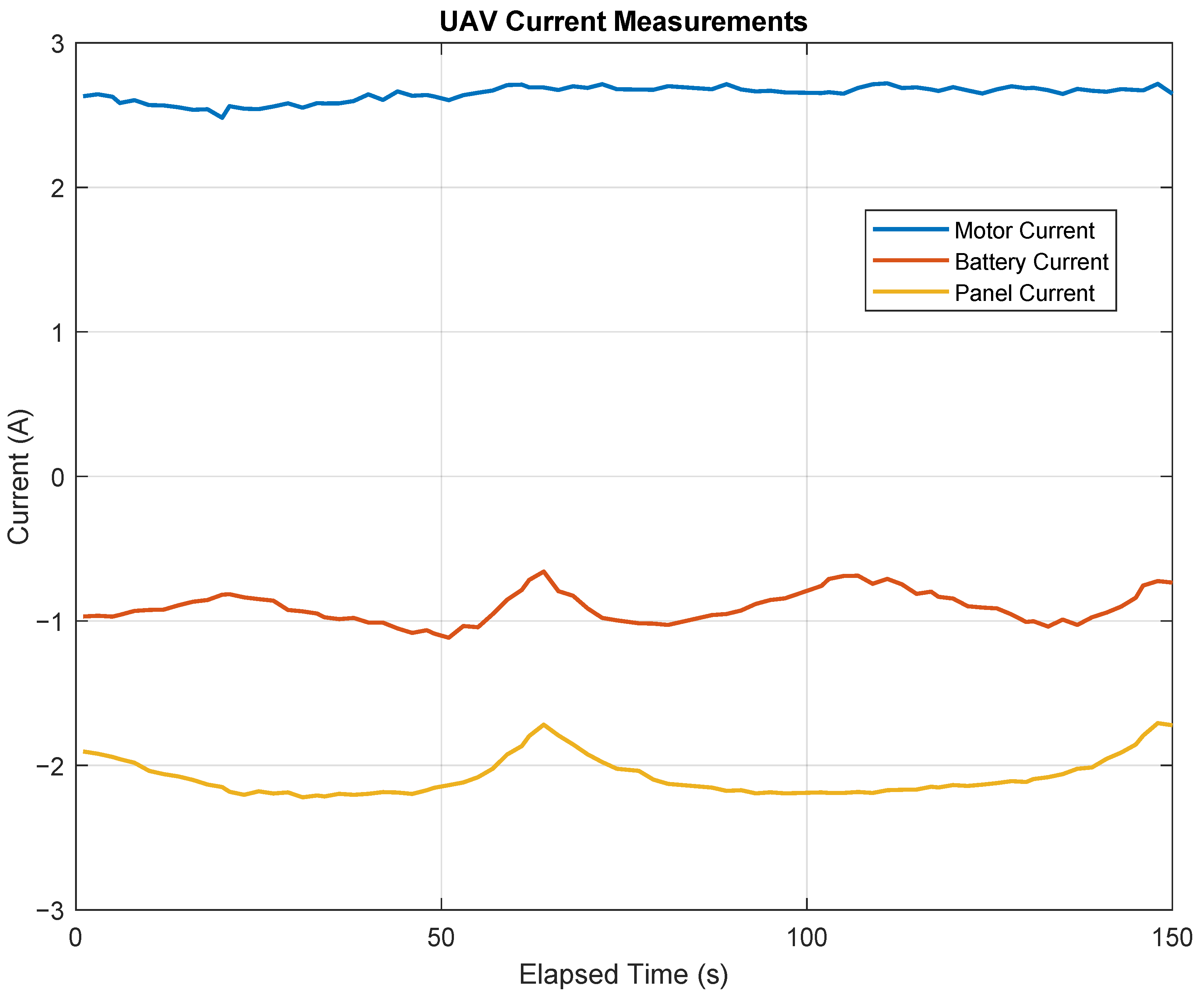

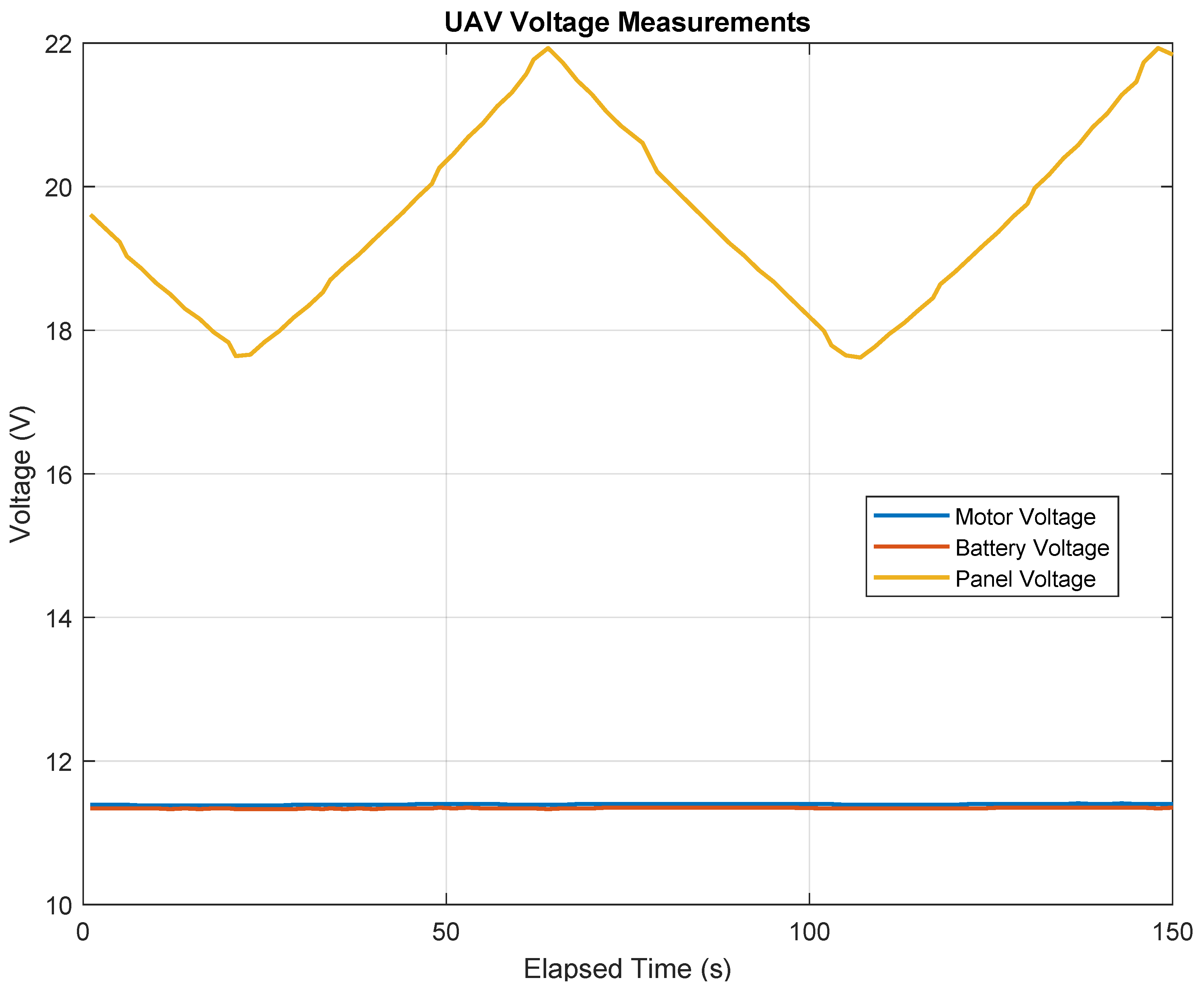

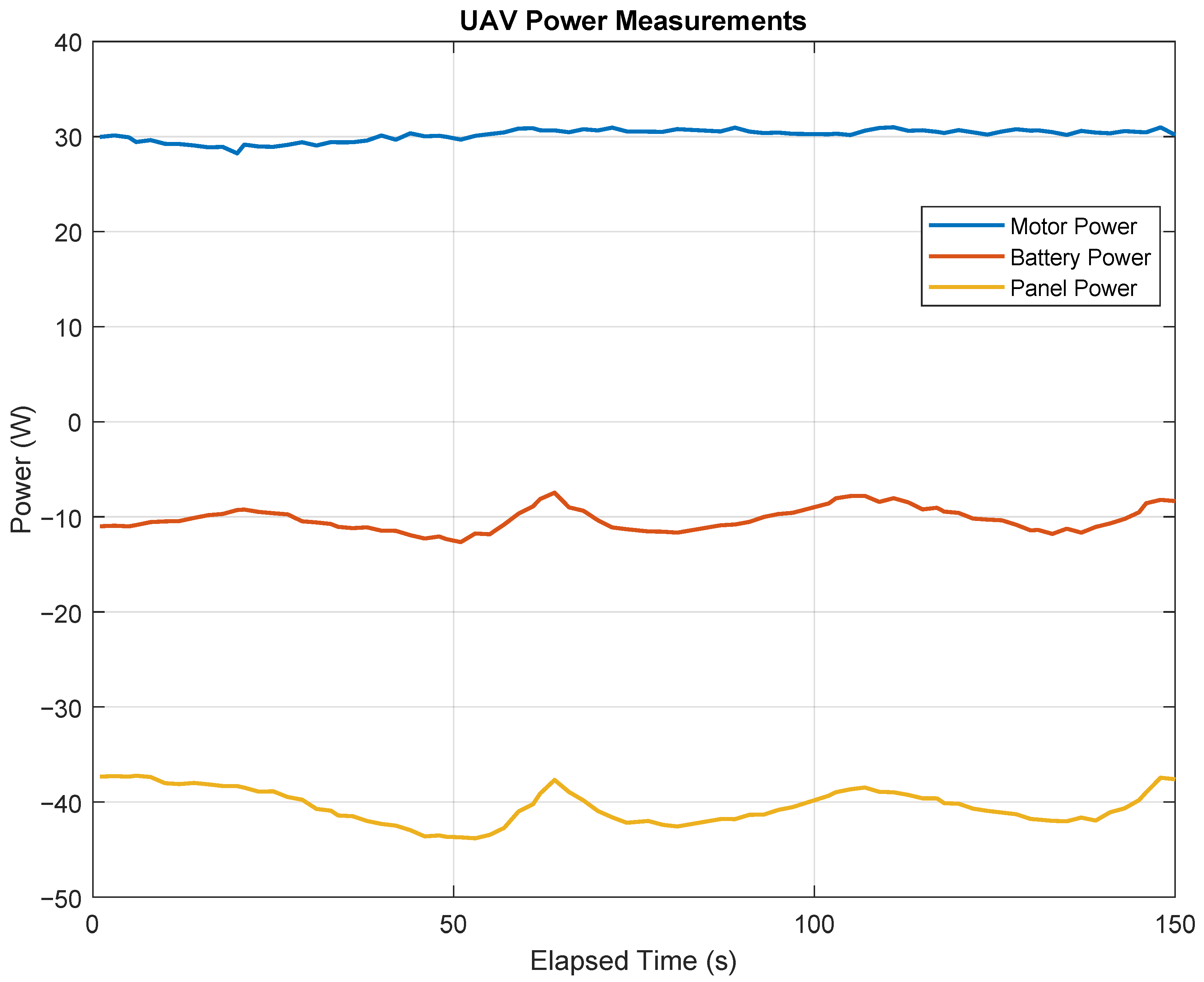

3.1. Solar Panel Power Measurements

3.2. Cruise Power Summary

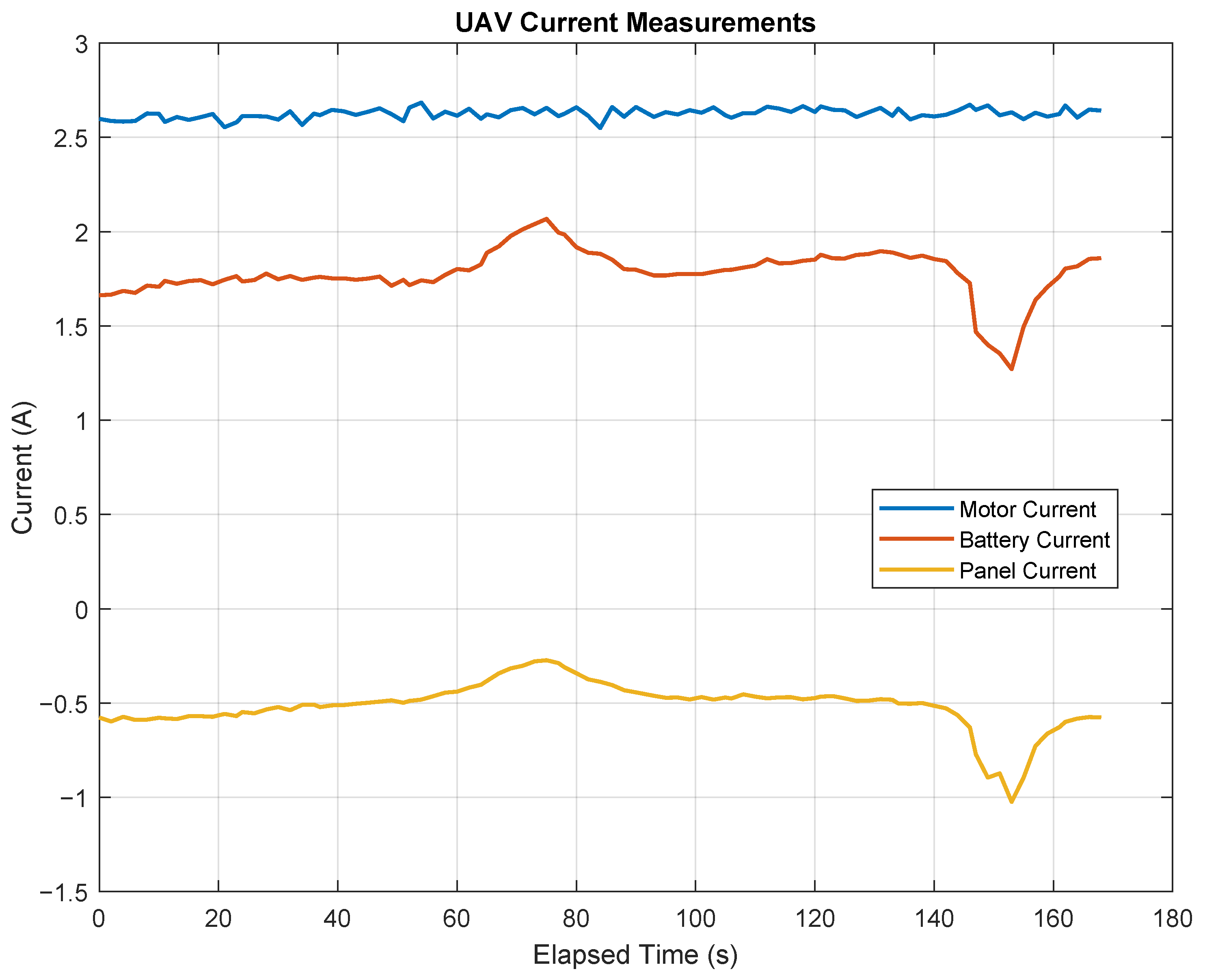

3.3. Replicated Cruise Tests

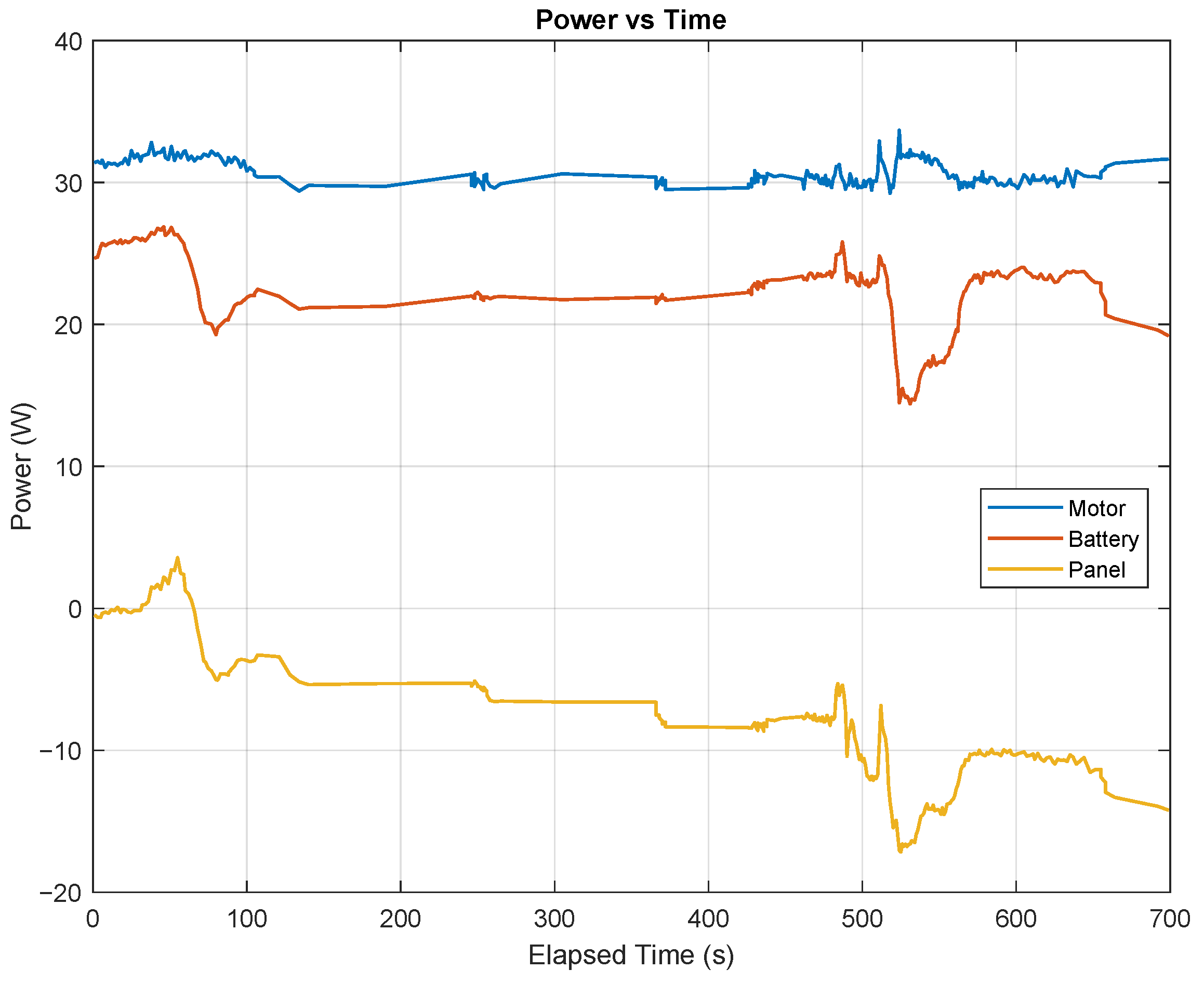

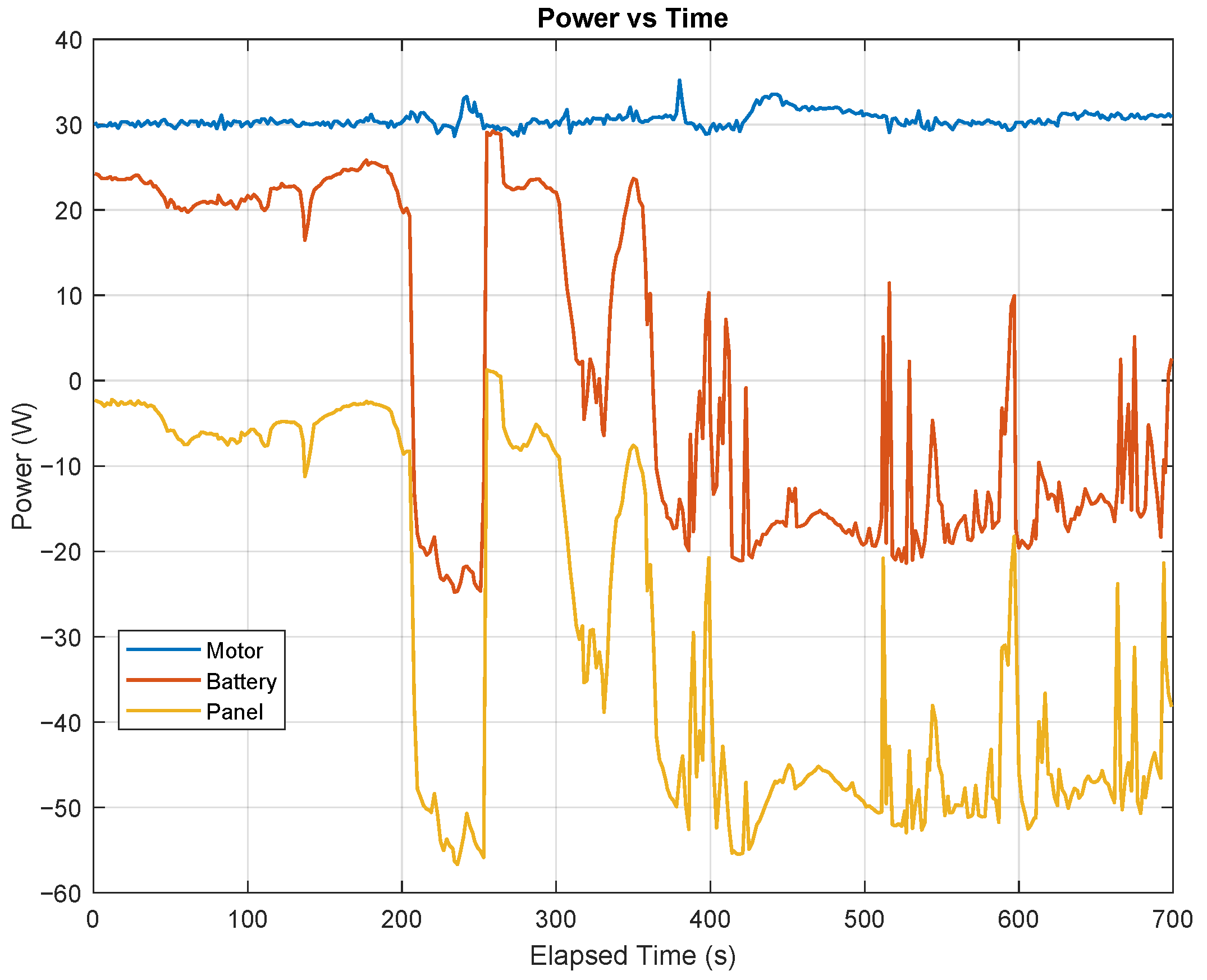

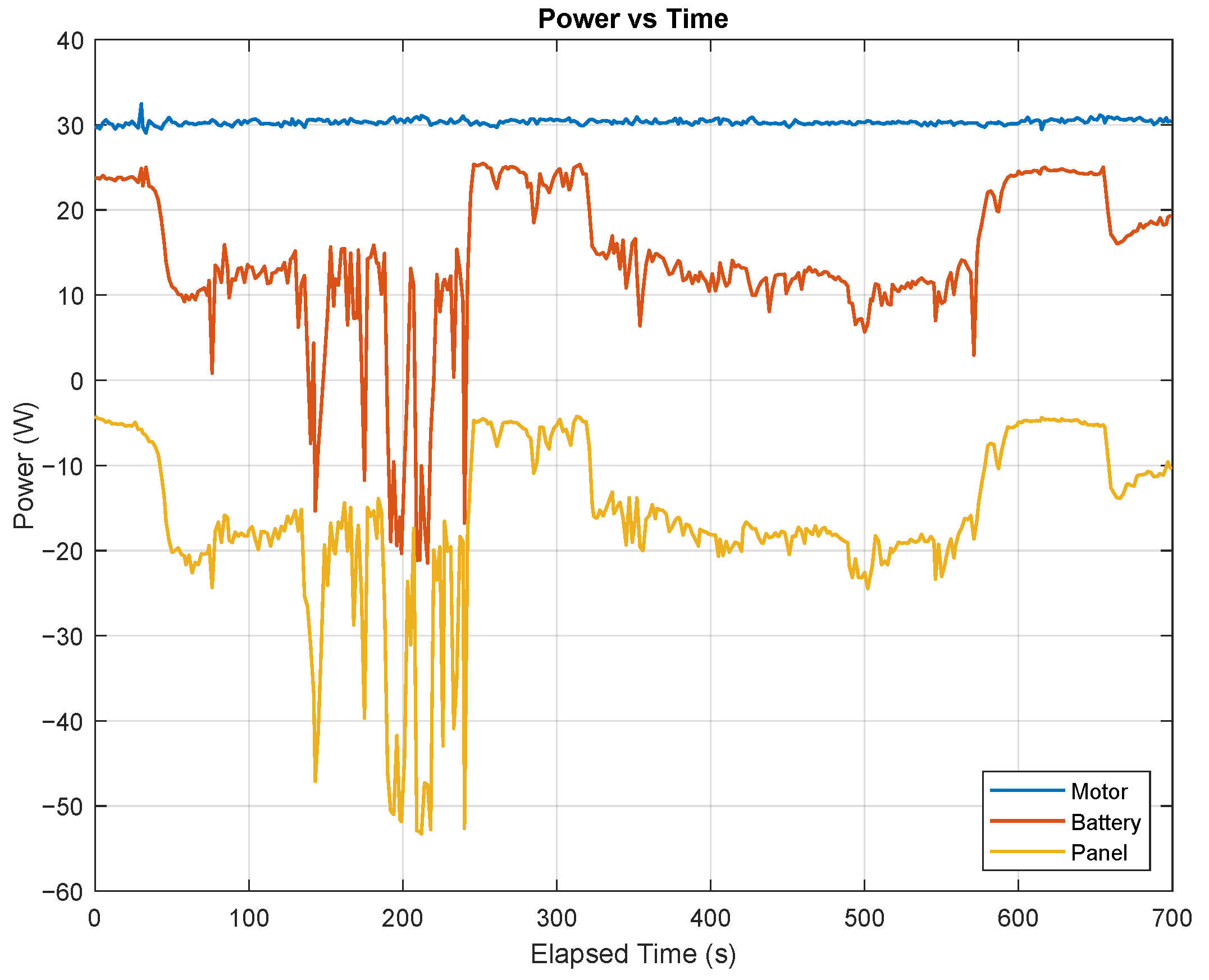

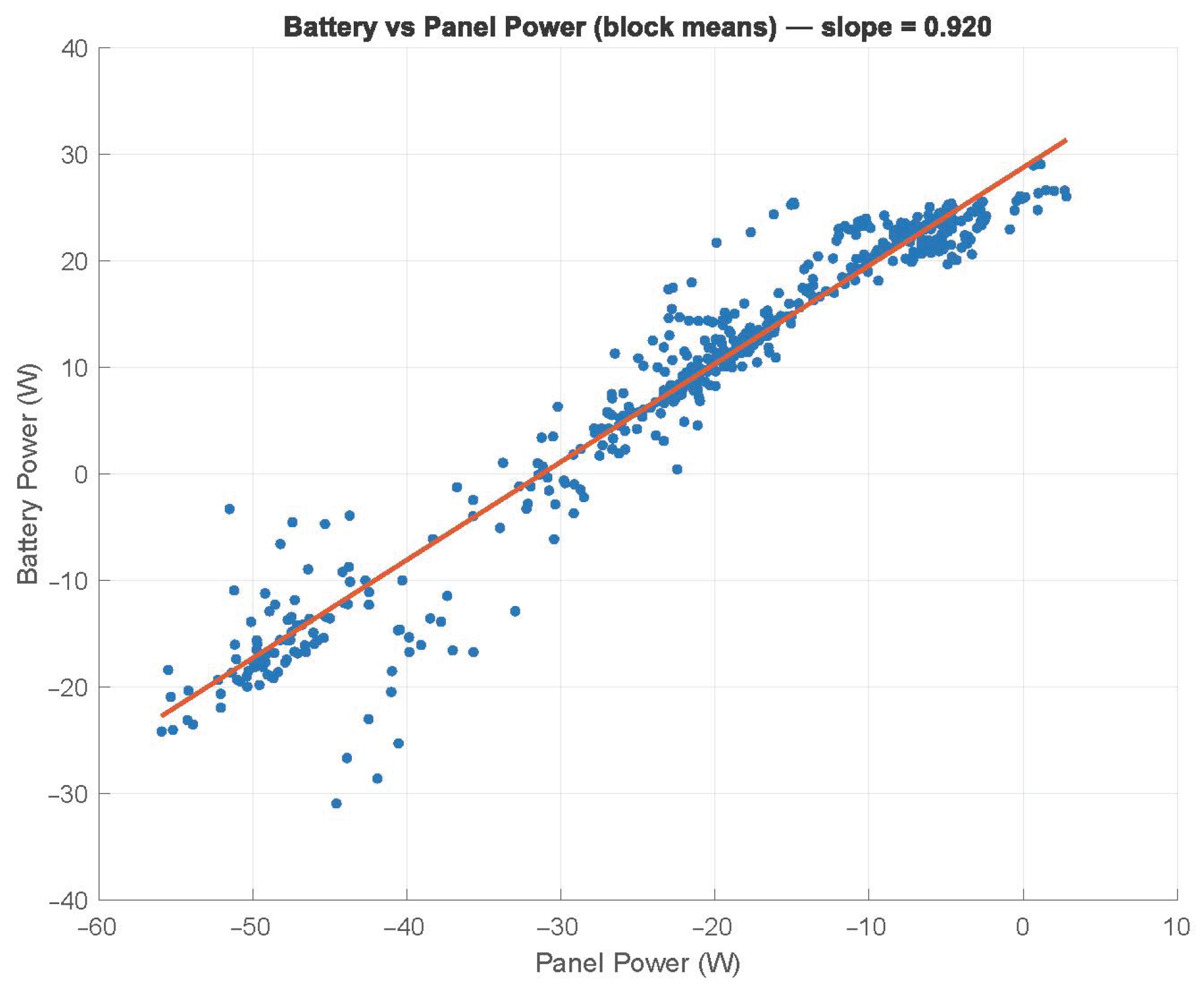

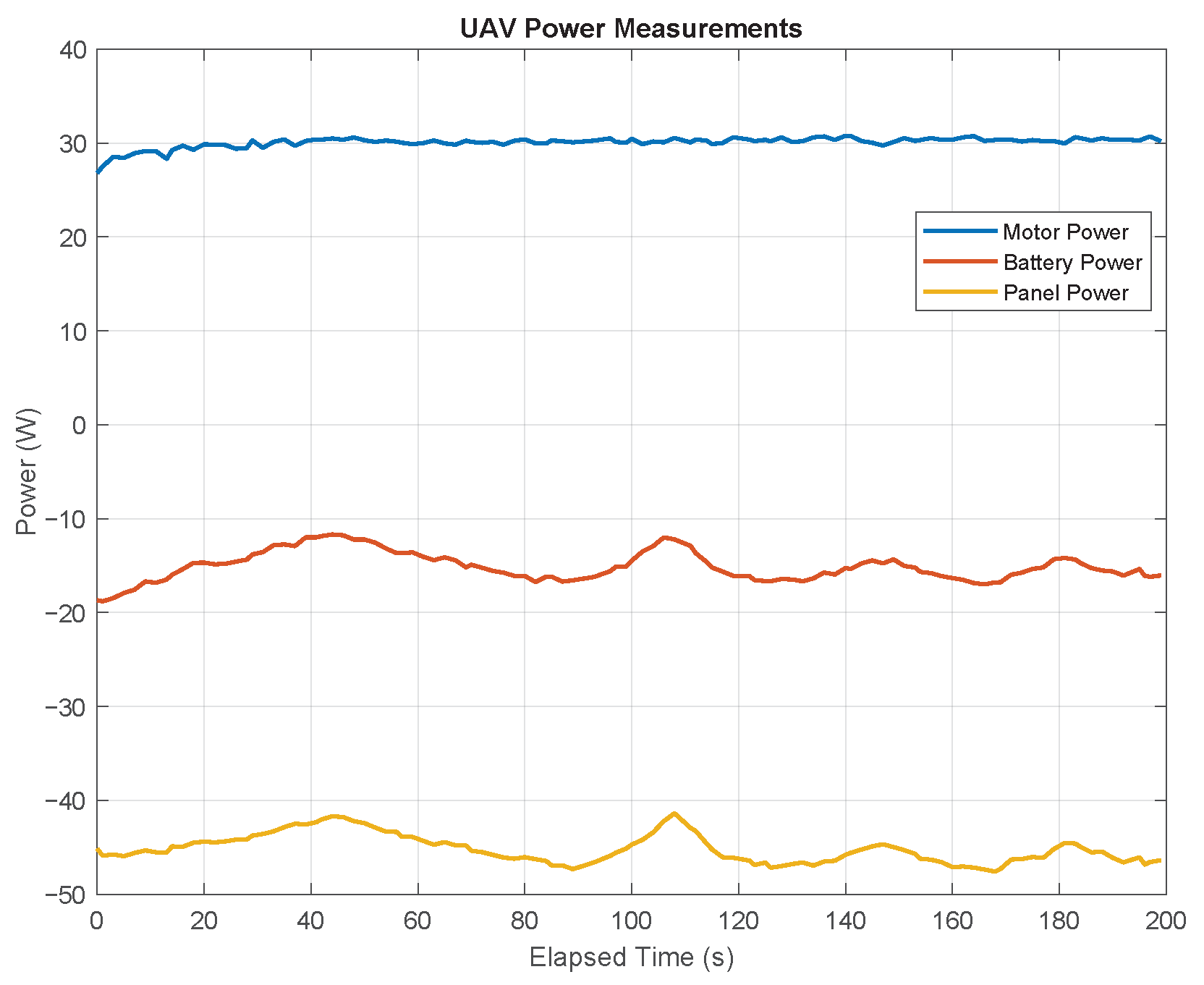

3.4. Per-Run Power Traces

3.5. Aggregate Statistics

3.6. Per-Run Summary

3.7. Significance of Differences

3.8. Discussion of Results

3.9. Sensitivity Analysis and Correction Directions

3.10. Practical Considerations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned Aerial Vehicle |

| PV | Photovoltaic |

| CIGS | Copper Indium Gallium Selenide |

| MPPT | Maximum Power Point Tracking |

| LiPo | Lithium–Polymer (battery) |

| ESC | Electronic Speed Controller |

| PWM | Pulse Width Modulation |

| PC | Personal Computer |

| DC | Direct Current |

| XFLR5 | Open-Source X-Foil-Based Aerodynamic Analysis Tool |

| Vmp | Voltage at Maximum Power |

References

- Diogo, C.M.A.; Fernandes, E.C. A Mass, Fuel, and Energy Perspective on Fixed-Wing Unmanned Aerial Vehicle Scaling. Drones 2024, 8, 396. [Google Scholar] [CrossRef]

- Mitzi, D.B.; Yuan, M.; Liu, W.; Kellock, A.J.; Chey, S.J.; Gignac, L.; Schrott, A.G. Hydrazine-based deposition route for device-quality CIGS films. Thin Solid Film. 2009, 517, 2158–2162. [Google Scholar] [CrossRef]

- Chawla, R.; Singhal, P.; Garg, A.K. Photovoltaic review of all generations: Environmental impact and its market potential. Trans. Electr. Electron. Mater. 2020, 21, 456–476. [Google Scholar] [CrossRef]

- Yang, D.; Yang, R.; Priya, S.; Liu, S. Recent advances in flexible perovskite solar cells: Fabrication and applications. Angew. Chem. Int. Ed. 2019, 58, 4466–4483. [Google Scholar] [CrossRef] [PubMed]

- Dallaev, R.; Pisarenko, T.; Papež, N.; Holcman, V. Overview of the Current State of Flexible Solar Panels and Photovoltaic Materials. Materials 2023, 16, 5839. [Google Scholar] [CrossRef] [PubMed]

- Dui, H.; Zhang, C.; Bai, G.; Chen, L. Mission reliability modeling of UAV swarm and its structure optimization based on importance measure. Reliab. Eng. Syst. Saf. 2021, 215, 107879. [Google Scholar] [CrossRef]

- Shiau, J.K.; Ma, D.M.; Yang, P.Y.; Wang, G.F.; Gong, J.H. Design of a solar power management system for an experimental UAV. IEEE Trans. Aerosp. Electron. Syst. 2009, 45, 1350–1358. [Google Scholar] [CrossRef]

- Hohm, D.; Ropp, M.E. Comparative study of maximum power point tracking algorithms. Prog. Photovoltaics Res. Appl. 2003, 11, 47–62. [Google Scholar] [CrossRef]

- de Carvalho Bertoli, G.; Pacheco, G.M.; Adabo, G.J. Extending flight endurance of electric unmanned aerial vehicles through photovoltaic system integration. In Proceedings of the 2015 International Conference on Renewable Energy Research and Applications (ICRERA), Palermo, Italy, 22–25 November 2015; pp. 143–147. [Google Scholar] [CrossRef]

- Boucher, R.J. History of solar flight. In Proceedings of the AIAA/SAE/ASEE Joint Propulsion Conference, Cincinnati, OH, USA, 11–13 June 1984; pp. 1429–1438. [Google Scholar] [CrossRef]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A review of solar thermal technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- Heutger, M.; Kückelhaus, M. Unmanned Aerial Vehicles in Logistics: A DHL Perspective on Implications and Use for the Logistics Industry, 2014. Available online: https://www.dhl.com/discover/content/dam/dhl/downloads/interim/full/dhl-trend-report-uav.pdf (accessed on 20 September 2025).

- Anderson, M. Amazon Seeks FAA Approval to Test Delivery Drones Outdoors. The Seattle Times, 2014 July 11. [Google Scholar]

- Thiels, C.A.; Aho, J.M.; Zietlow, S.P.; Jenkins, D.H. Use of unmanned aerial vehicles for medical product transport. Air Med. J. 2015, 34, 104–108. [Google Scholar]

- Goodchild, A.; Toy, J. Delivery by drone: An evaluation of unmanned aerial vehicle technology in reducing CO2 emissions in the delivery service industry. Transp. Res. Part D Transp. Environ. 2018, 61, 58–67. [Google Scholar] [CrossRef]

- Wang, X.; Poikonen, S.; Golden, B. The vehicle routing problem with drones: Several worst-case results. Optim. Lett. 2017, 11, 679–697. [Google Scholar] [CrossRef]

- Lei, Z. Development of a Solar-Powered unmanned aerial vehicle. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, ML, USA, 13–17 January 2014; p. 0539. [Google Scholar]

- Choi, Y.; Schonfeld, P.M. Optimization of multi-package drone deliveries considering battery capacity. In Proceedings of the 96th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 8–12 January 2017; pp. 8–12. [Google Scholar]

- Baroutaji, A.; Wilberforce, T.; Ramadan, M.; Olabi, A.G. Comprehensive investigation on hydrogen and fuel cell technology in the aviation and aerospace sectors. Renew. Sustain. Energy Rev. 2019, 106, 31–40. [Google Scholar] [CrossRef]

- Romeo, G.; Frulla, G.; Cestino, E. Design of a high-altitude long-endurance solar-powered unmanned air vehicle for multi-payload and operations. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 199–216. [Google Scholar] [CrossRef]

- Baharozu, E.; Soykan, G.; Ozerdem, M.B. Future aircraft concept in terms of energy efficiency and environmental factors. Energy 2017, 140, 1368–1377. [Google Scholar] [CrossRef]

- Escarti, F. Boeing fuel cell plane in manned aviation first. Fuel Cells Bull. 2008, 4, 70146–70149. [Google Scholar]

- Barrett, S. First flight of DLR’s HY4 fuel cell light aircraft. Fuel Cells Bull. 2016, 2016, 1. [Google Scholar] [CrossRef]

- Meyer, J.; Du Plessis, J.; Ellis, P.; Clark, W. Design considerations for a low altitude long endurance solar powered unmanned aerial vehicle. In Proceedings of the AFRICON 2007, Windhoek, South Africa, 26–28 September 2007; pp. 1–7. [Google Scholar]

- Montgomery, S.; Mourtos, N. Design of a 5 kilogram solar-powered unmanned airplane for perpetual solar endurance flight. In Proceedings of the 49th AIAA/ASME/SAE/ASEE, San Jose, CA, USA, 15–17 July 2013; p. 3875. [Google Scholar]

- Cui, Y.; Chen, J.; Lin, H.; Shu, Z.; Huang, T. Cooperative Multi-AAV Path Planning for Discovering and Tracking Multiple Radio-Tagged Targets. IEEE Trans. Syst. Man Cybern. Syst. 2025, 55, 2463–2475. [Google Scholar] [CrossRef]

- Cui, Y.; Cheng, L.; Basin, M.; Wu, Z. Distributed Byzantine-resilient learning of multi-UAV systems via filter-based centerpoint aggregation rules. IEEE/CAA J. Autom. Sin. 2025, 12, 1056–1058. [Google Scholar] [CrossRef]

- Al Dhafari, L.S.; Afzal, A.; Al Abri, O.K.; Khan, A. Solar-powered UAVs: A systematic literature review. In Proceedings of the 2024 2nd International Conference on Unmanned Vehicle Systems-Oman (UVS), Muscat, Oman, 12–14 March 2024; pp. 1–8. [Google Scholar]

- Hariharan, R.; Saxena, A.; Dhote, V.; Srisathirapathy, S.; Almusawi, M.; Kumar, J.R.R. Advancements in solar-powered UAV design leveraging machine learning: A comprehensive review. In Proceedings of the E3S Web of Conferences, EDP Sciences, Dushanbe, Tajikistan, 22–24 April 2024; Volume 540, p. 02024. [Google Scholar]

- İlhan, C.; Çalık, Z. Solar-powered UAV: A novel approach to conceptual design. Konya J. Eng. Sci. 2024, 12, 396–409. [Google Scholar] [CrossRef]

- Salazar, F.; Martinez-Garcia, M.S.; de Castro, A.; Logroño, N.; Cazorla-Logroño, M.F.; Guamán-Molina, J.; Gómez, C. Optimization of the solar energy storage capacity for a monitoring UAV. Sustain. Futur. 2024, 7, 100146. [Google Scholar] [CrossRef]

- Zhao, L. Solar-Powered High-Altitude Drone Makes Maiden Flight. China Daily (Global Edition), 5 September 2022. Available online: https://global.chinadaily.com.cn/a/202209/05/WS63154be7a310fd2b29e75e19.html (accessed on 20 September 2025).

- de Brederode, V. Fundamentos de Aerodinâmica Incompressível; IST Press: Lisbon, Portugal, 1997. [Google Scholar]

- Instituto Português do Mar e da Atmosfera. IPMA Climate and Meteorological Data Portal, 2025. Available online: https://www.ipma.pt/ (accessed on 1 September 2025).

| Run | Number of Blocks | Approx. Duration (min) |

|---|---|---|

| Run 1 | 83 | 6.92 |

| Run 2 | 59 | 4.92 |

| Run 3 | 140 | 11.67 |

| Run 4 | 140 | 11.67 |

| Run 5 | 140 | 11.67 |

| Total | 562 | 46.85 |

| Configuration | Battery Power (W) | Panel Power (W) | Total Power (W) | Irradiance (W/m2) | Temperature (°C) |

|---|---|---|---|---|---|

| No panel (baseline) | 19.2 | 0.0 | 19.2 | - | - |

| With panel, sunny | −10.2 | 40.4 | 30.2 | 930 | 36 |

| With panel, cloudy | 20.5 | 9.8 | 30.3 | 360 | 21 |

| Run | Irradiance (W/m2) | Temp (°C) |

|---|---|---|

| Run 1, Run 2 | 702 | 25 |

| Run 3, Run 4 | 751 | 24 |

| Run 5 | 791 | 24 |

| Run | (W) ± CI95 | (W) ± CI95 |

|---|---|---|

| Run 1 | 22.41 ± 0.56 | 7.51 ± 1.07 |

| Run 2 | 4.10 ± 4.17 | 26.80 ± 2.25 |

| Run 3 | 1.11 ± 3.06 | 29.48 ± 3.42 |

| Run 4 | 14.28 ± 1.38 | 16.05 ± 1.54 |

| Run 5 | 11.01 ± 1.44 | 19.33 ± 1.52 |

| Run | Endurance (h) |

|---|---|

| Run 1 | 4.46 |

| Run 2 | 24.36 |

| Run 3 | 90.42 |

| Run 4 | 7.00 |

| Run 5 | 9.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, P.; Santos, R.; Rego, F. Experimental Evaluation of UAV Energy Management Using Solar Panels and Battery Systems. Appl. Sci. 2025, 15, 10689. https://doi.org/10.3390/app151910689

Fernandes P, Santos R, Rego F. Experimental Evaluation of UAV Energy Management Using Solar Panels and Battery Systems. Applied Sciences. 2025; 15(19):10689. https://doi.org/10.3390/app151910689

Chicago/Turabian StyleFernandes, Pedro, Ricardo Santos, and Francisco Rego. 2025. "Experimental Evaluation of UAV Energy Management Using Solar Panels and Battery Systems" Applied Sciences 15, no. 19: 10689. https://doi.org/10.3390/app151910689

APA StyleFernandes, P., Santos, R., & Rego, F. (2025). Experimental Evaluation of UAV Energy Management Using Solar Panels and Battery Systems. Applied Sciences, 15(19), 10689. https://doi.org/10.3390/app151910689