Numerical Simulation and Empirical Validation of Casing Stability in Coalbed Methane Wells Under Mining-Induced Stress: A Case Study of Xiaobaodang Coal Mine in Yulin-Shenmu Mining Area

Abstract

1. Introduction

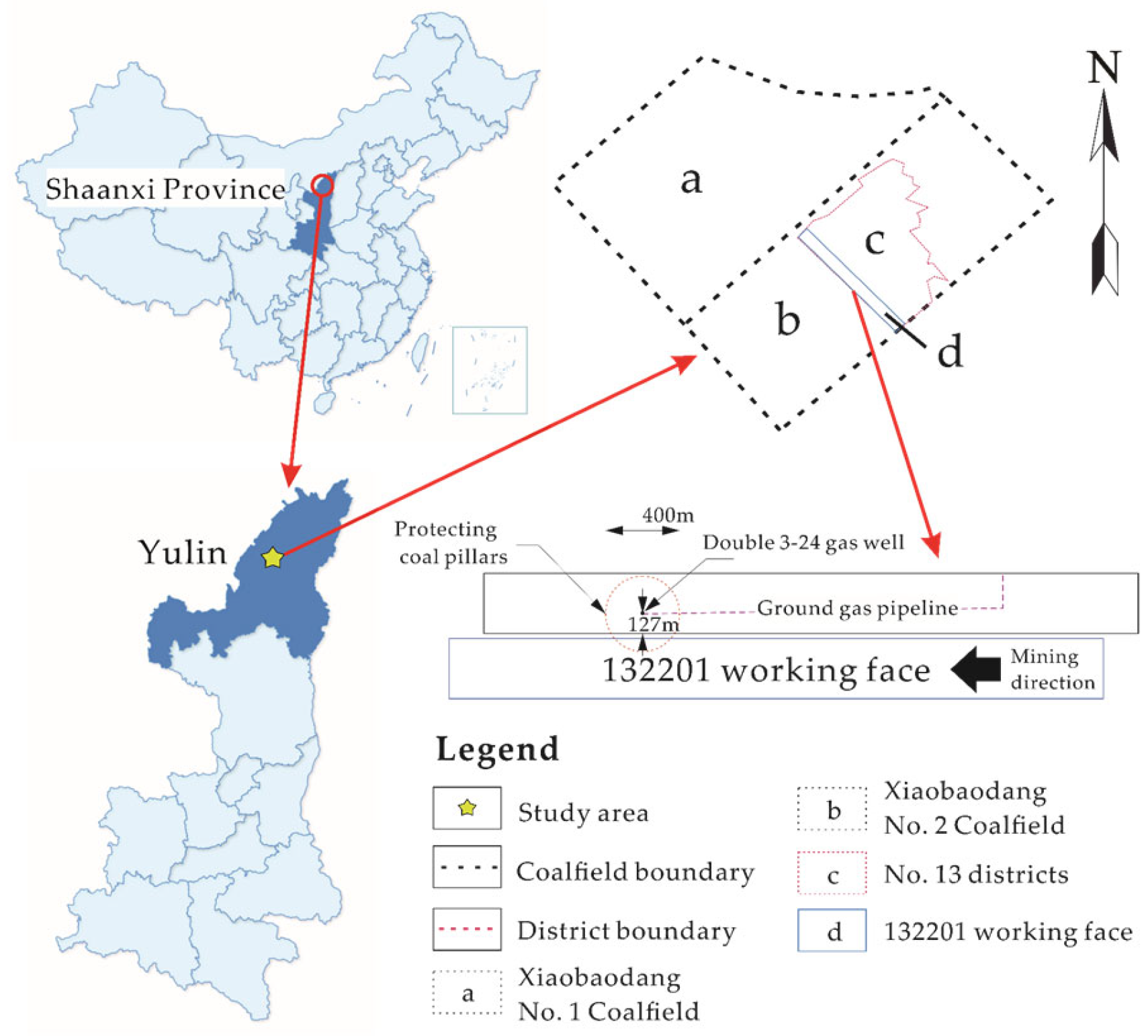

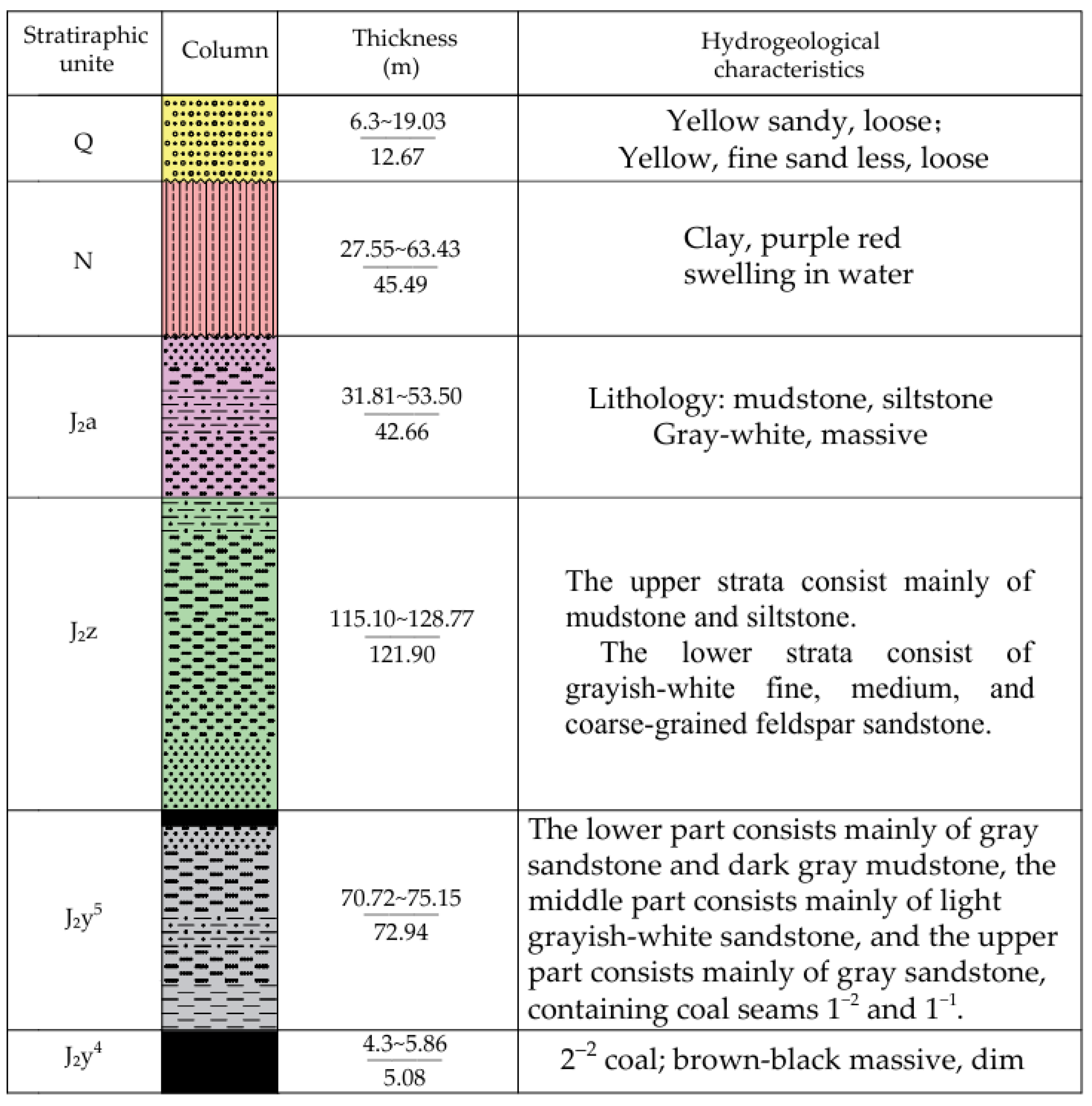

2. Background and Problem Statement

3. Materials and Methods

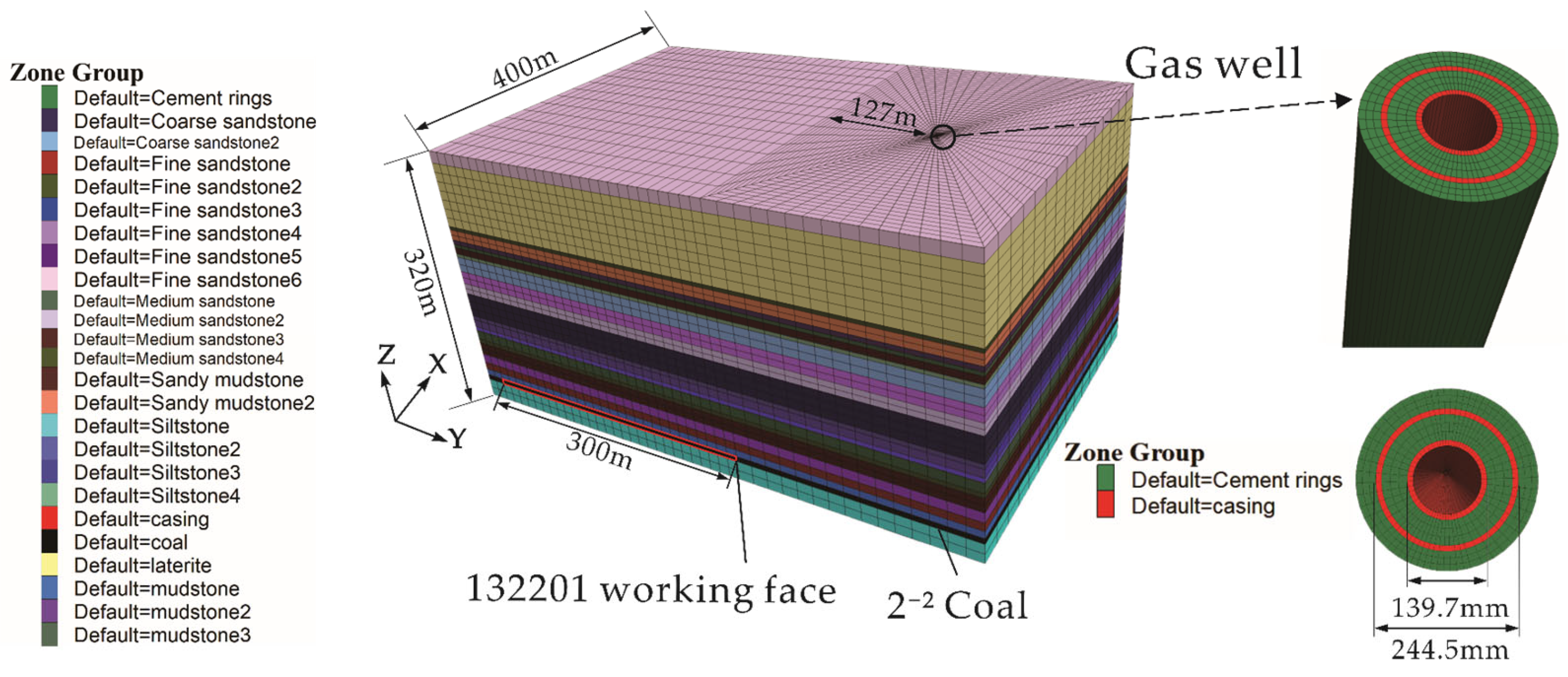

3.1. FLAC3D Model Construction

3.1.1. Model Size

3.1.2. Grid Division

3.1.3. Constitutive Relation

3.2. Setting Model Parameters

3.3. Numerical Boundary Conditions and Excavation Design

- Constraints are applied along the X-axis at both ends of the model’s X-axis, meaning that the displacement in the X-direction at the boundary is 0;

- Constraints are applied along the Y-axis at both ends of the model’s Y-axis boundary, meaning that the displacement in the Y-direction at the boundary is 0;

- The bottom boundary of the model is fixed, i.e., the displacement of the bottom boundary in the X, Y, and Z directions is 0;

- The top of the model is a free boundary.

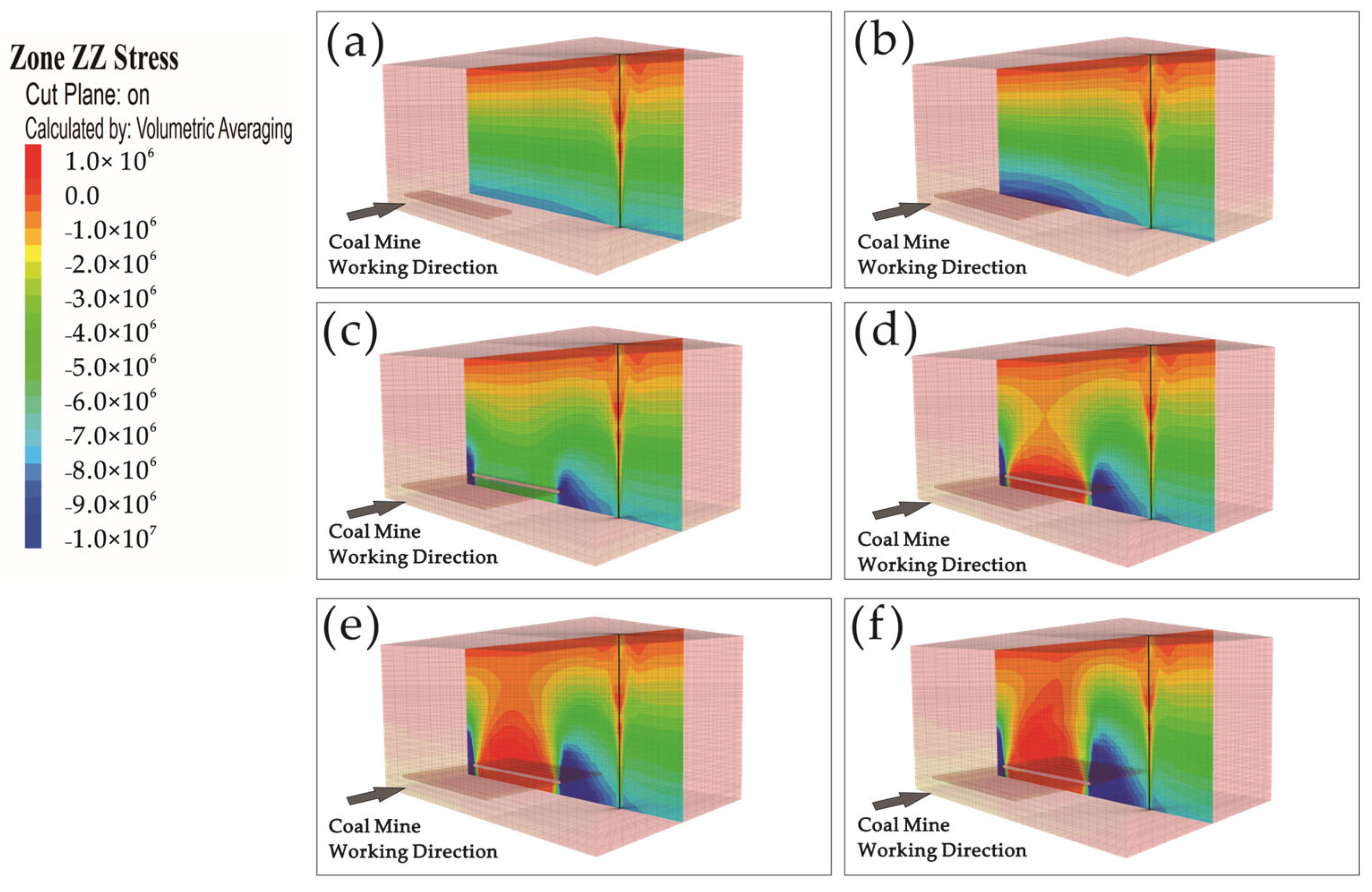

4. Results

4.1. Stress Distribution Characteristics of Overlying Rock (Soil) Layers Affected by Mining Activity Around Gas Wells

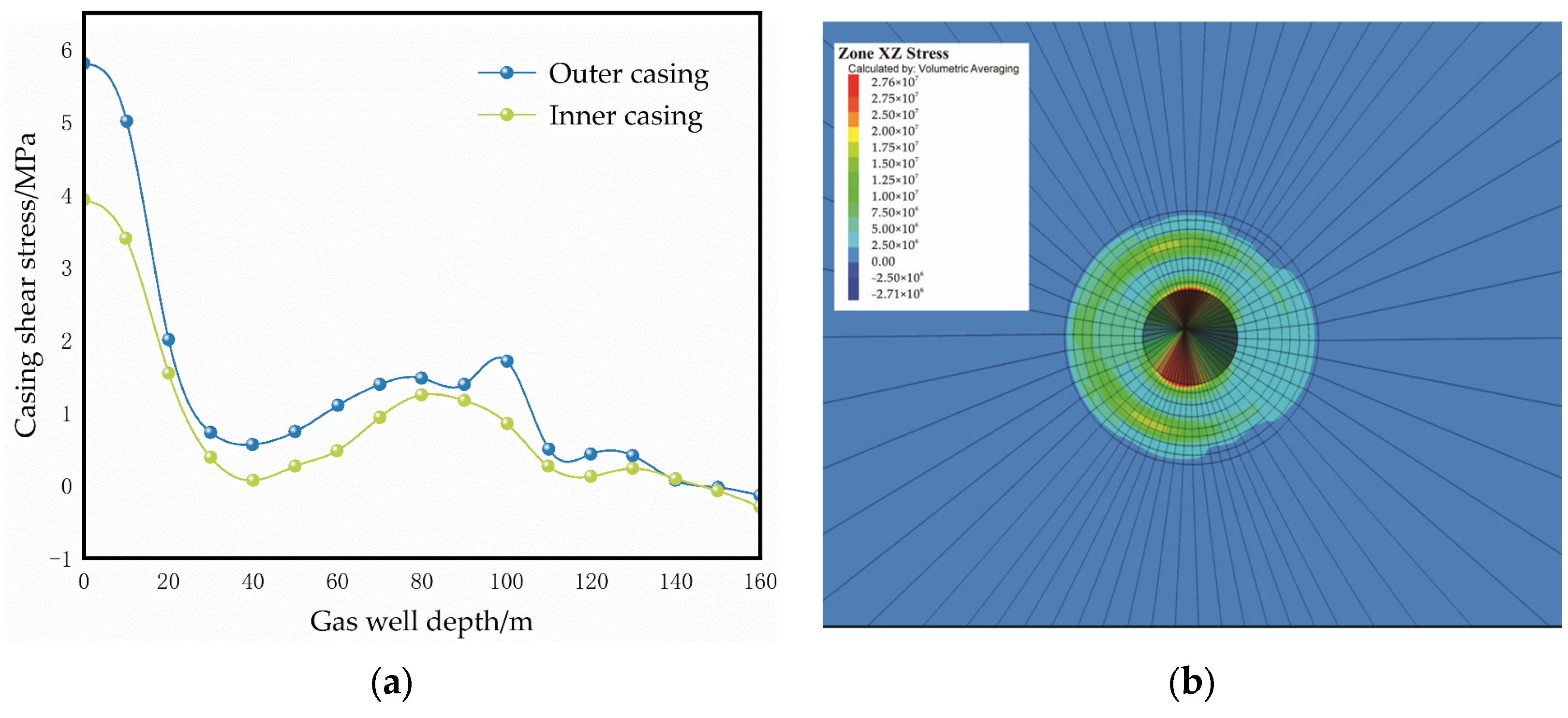

4.2. Shear Stress Distribution Characteristics of Casing in Gas Wells Affected by Production Activities

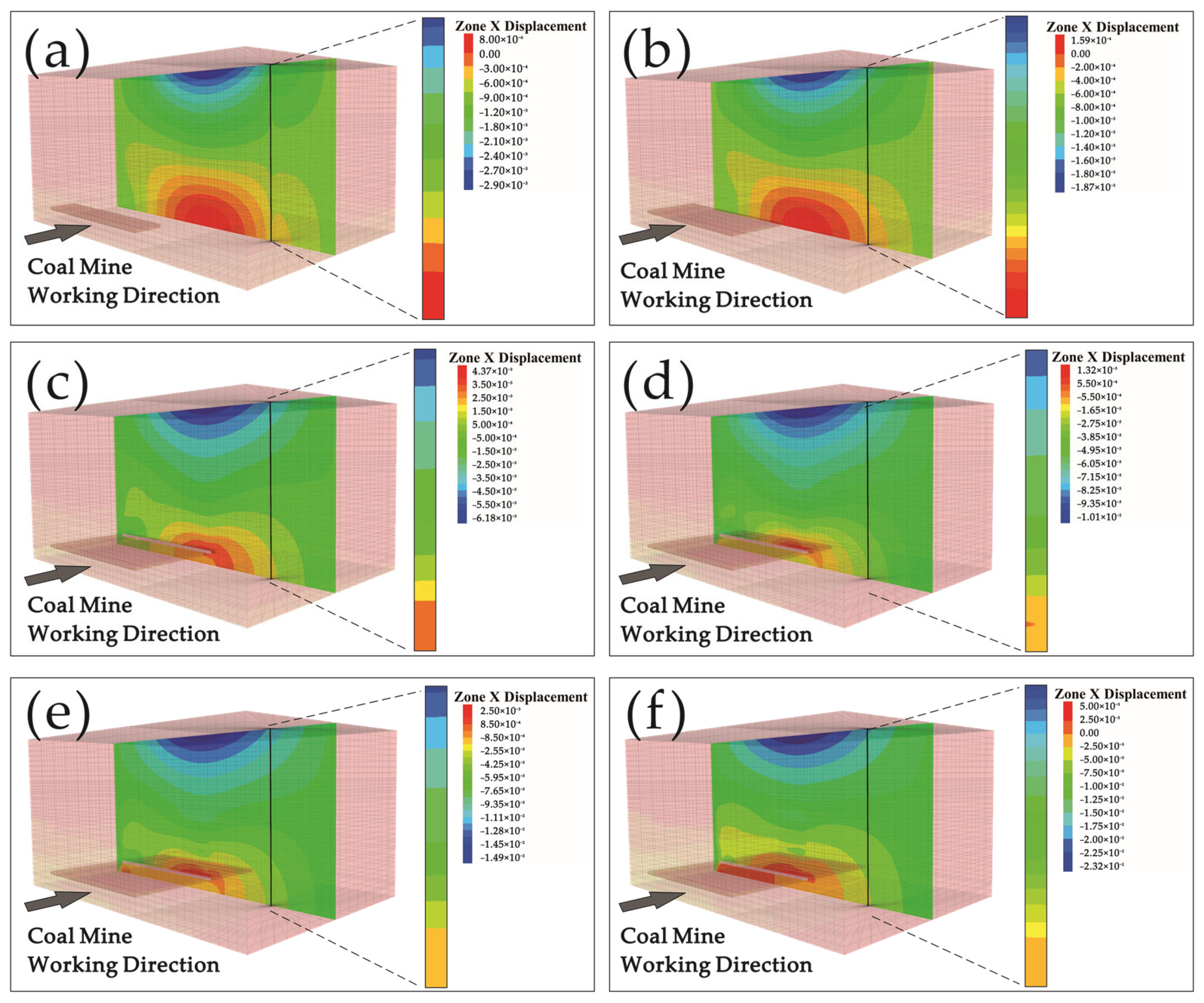

4.3. Characteristics of the Impact of Mining Activity on Gas Well Displacement Distribution

5. Discussion

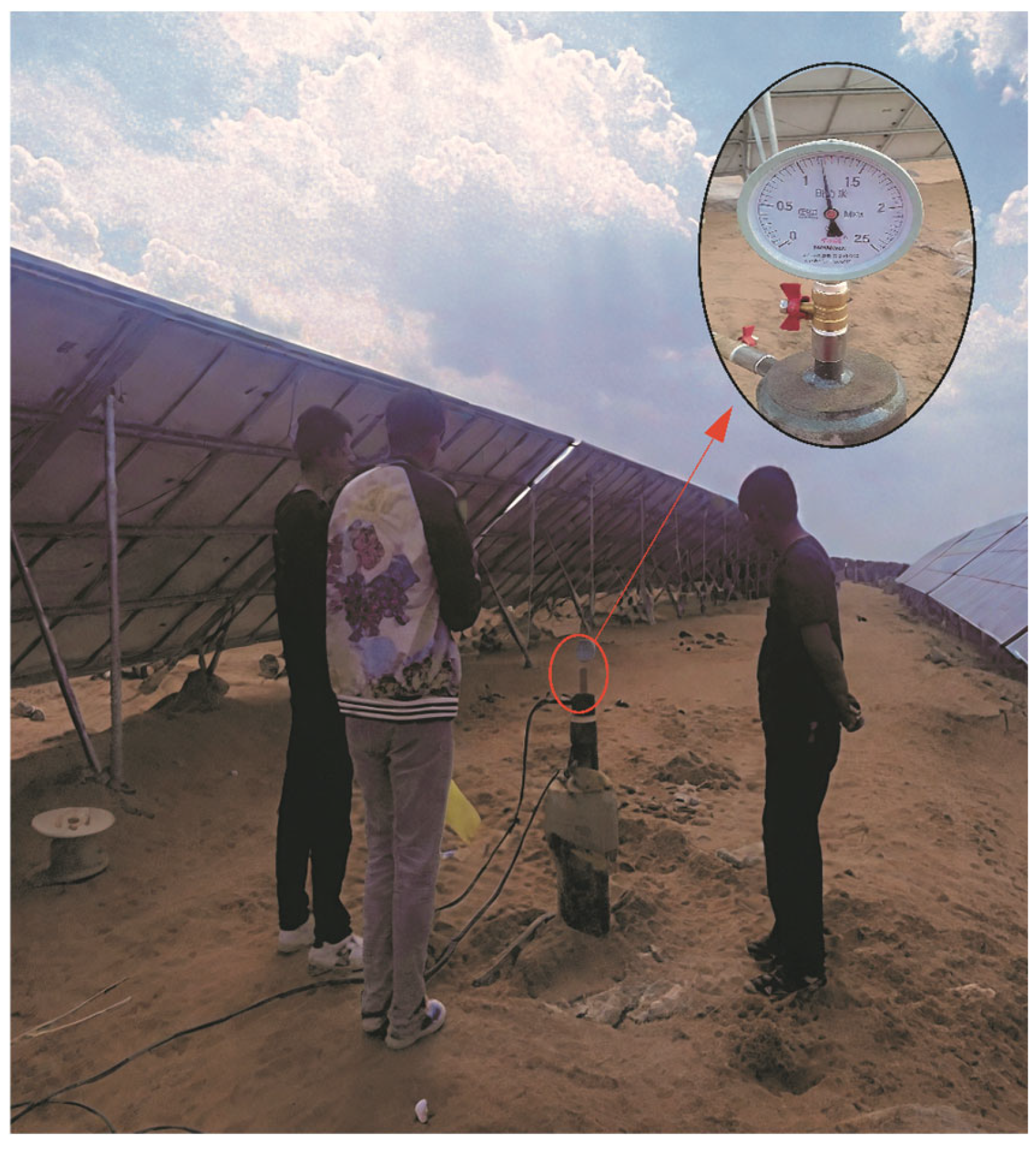

5.1. Gas Well Production Casing Pressure Monitoring

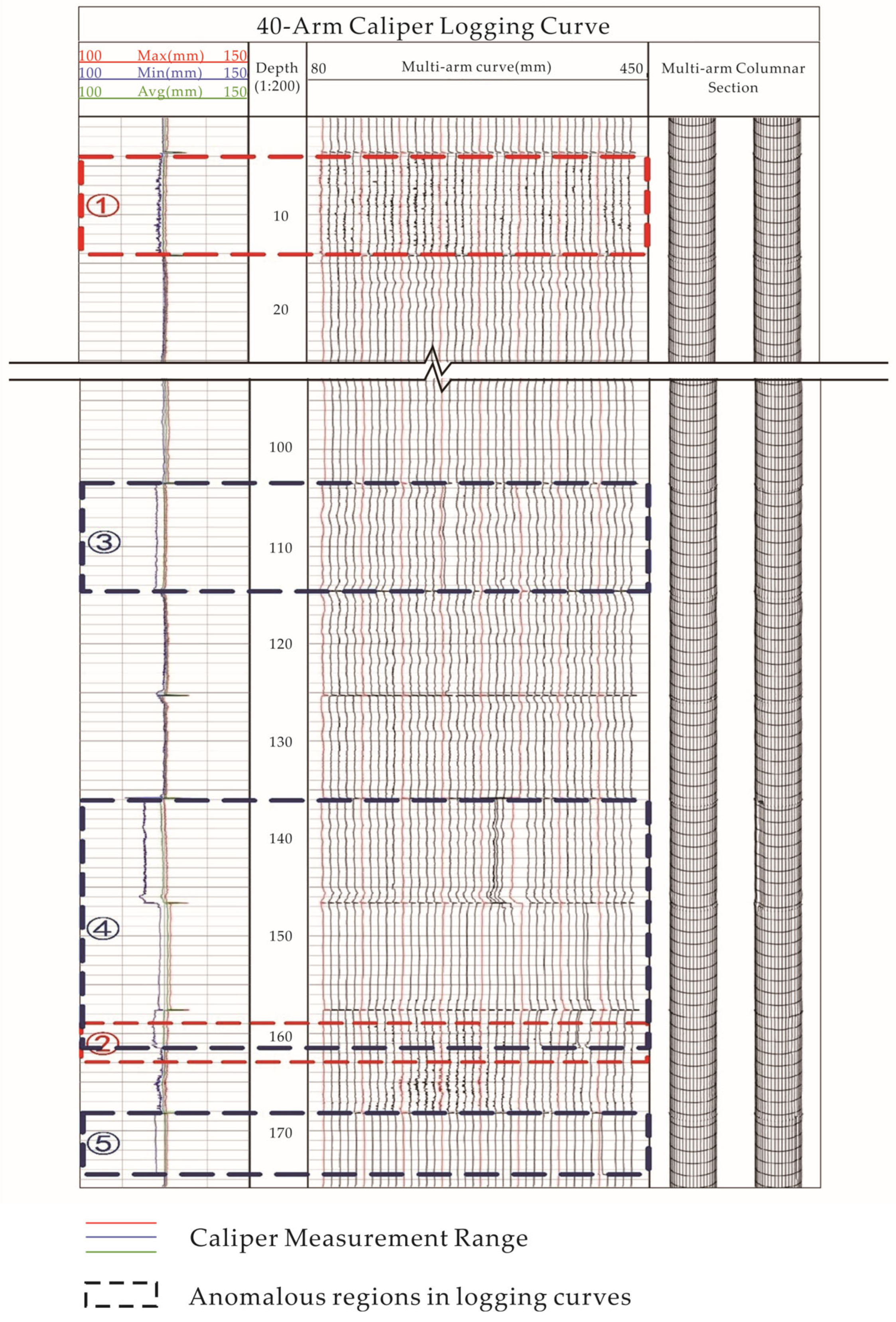

5.2. Multi-Arm Wellbore Diameter Testing of Gas Well Production Casing

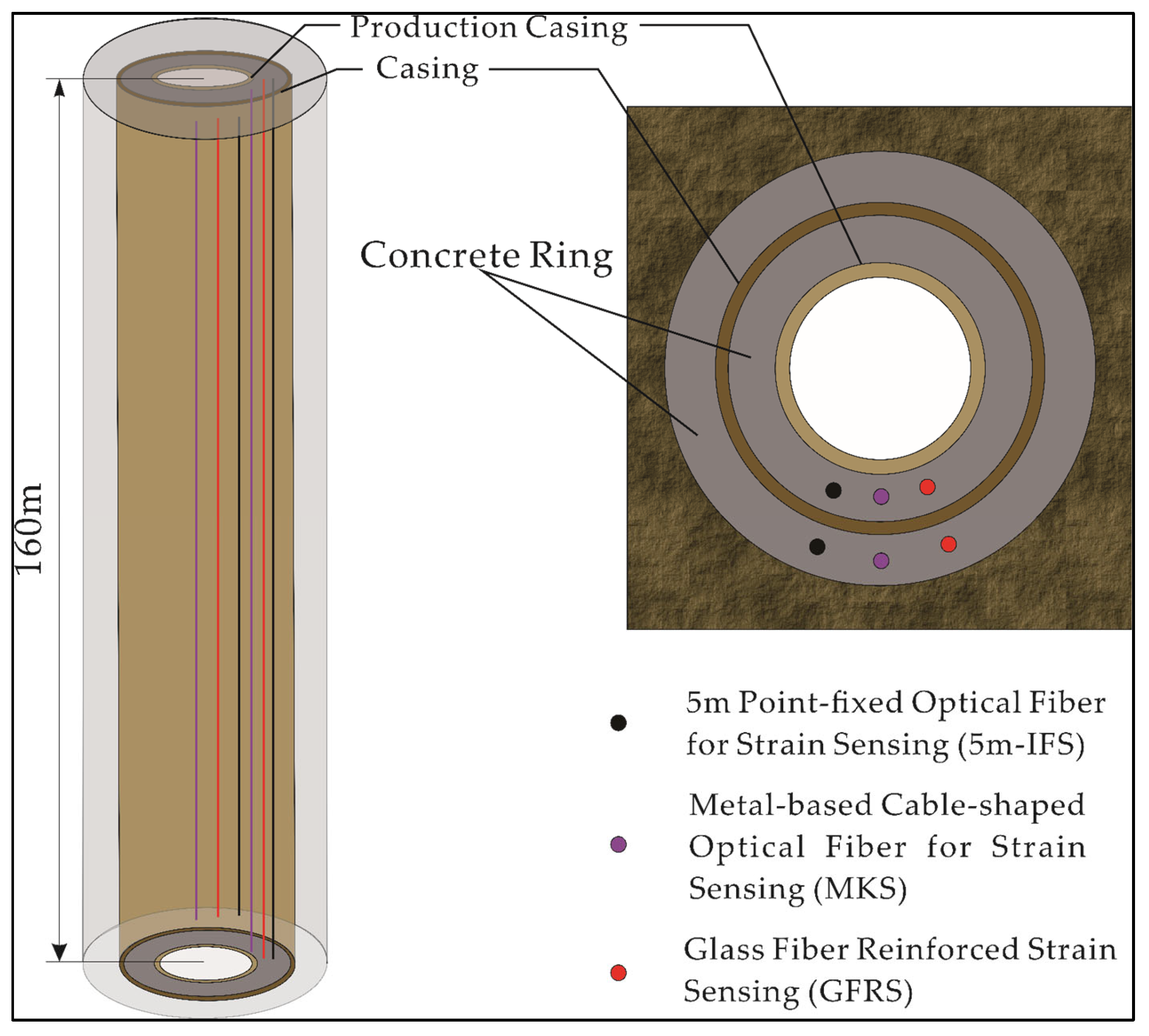

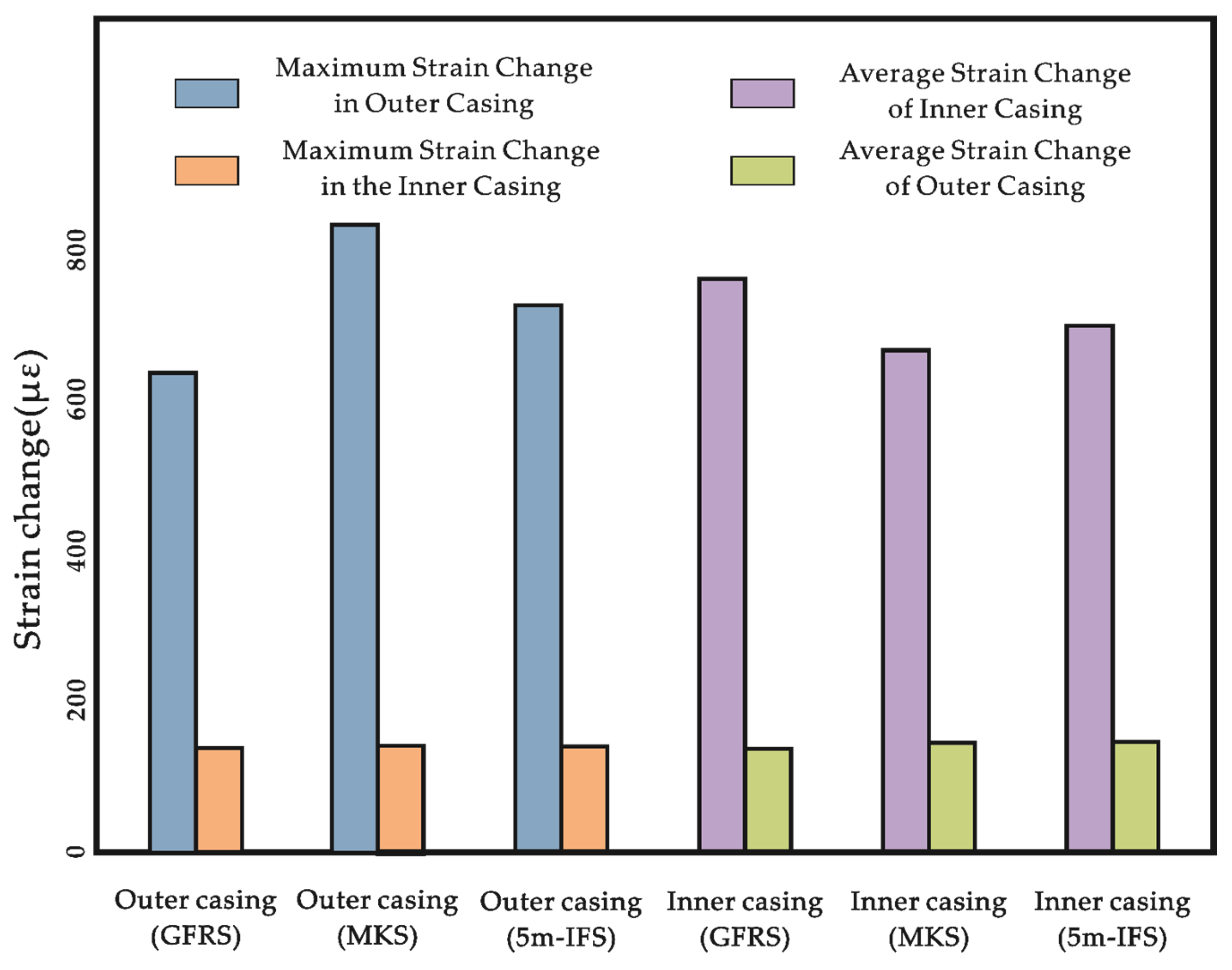

5.3. Distributed Fiber Optic In Situ Dynamic Monitoring

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, D.; Zhang, T.; Yang, Y.; Ren, J. Study on the Disturbance Characteristics and Control Strategies of Coordinated Exploitation of Superimposed Resources of Coal and Oil-Type Gas in Ordos Basin. Energy Sci. Eng 2023, 11, 3964–3978. [Google Scholar] [CrossRef]

- Yuan, L. Scientific problem and countermeasure for precision mining of coal and associated resources. China Coal Soc. 2019, 44, 1–9. [Google Scholar] [CrossRef]

- Qin, B.; Shi, Z.; Hao, J.; Ye, D.; Liang, B.; Sun, W. Analysis of the Space–Time Synergy of Coal and Gas Co-Mining. ACS Omega 2022, 7, 13737–13749. [Google Scholar] [CrossRef]

- Liu, J.; Yang, T.; Wang, L.; Chen, X. Research Progress in Coal and Gas Co-mining Modes in China. Energy Sci. Eng. 2020, 8, 3365–3376. [Google Scholar] [CrossRef]

- Dong, M.; Wang, W. Research on coordinated exploitation for resources overlap area of oil-gas and coal in Ordos Basin. Chin. Energy Environ. Prot. 2017, 101–104. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, X.; Zhang, Q. Framework of the theory and technology for simultaneous mining of coal and its associated resources. J. China Univ. Min. Technol. 2016, 45, 653–662. [Google Scholar] [CrossRef]

- Yuan, L.; Zhang, T.; Zhao, Y.; Ren, B.; Hao, X.; Xu, C. Precise coordinated mining of coal and associated resources: A case of environmental coordinated mining of coal and associated rare metal in Ordos basin. China Univ. Min. Technol. 2017, 46, 449–459. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, T.; Ma, C.; Lei, P.; Zhang, X.; Ding, Q. Review on the Evaluation of Casing Damage Level in Oil and Gas Field. MATEC Web Conf. 2019, 256, 02008. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, A. Research Overview of Casing Damage in China’s Oil Fields. In Proceedings of the International Conference on Architectural Engineering and New Materials, Guangzhou, China, 7 October 2015; pp. 409–415. [Google Scholar]

- Yu, X.; Cen, X.; Kan, C.; Hu, Y.; Yang, Y.; Tao, S.; Chen, X.; Chen, X.; Hu, Z. Numerical Simulation Analysis of Wellbore Integrity and Casing Damage in High-Temperature Injection and Production of Shale Oil. Processes 2023, 11, 3053. [Google Scholar] [CrossRef]

- Zhang, J.; Lian, Z.; Zhou, Z.; Song, Z.; Liu, M.; Yang, K.; Liu, Z. Safety and Reliability Assessment of External Corrosion Defects Assessment of Buried Pipelines—Soil Interface: A Mechanisms and FE Study. J. Loss Prevent. Proc. 2023, 82, 105006. [Google Scholar] [CrossRef]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A Study on Casing Deformation Failure during Multi-Stage Hydraulic Fracturing for the Stimulated Reservoir Volume of Horizontal Shale Wells. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Akbarpour, M.; Abdideh, M. Wellbore Stability Analysis Based on Geomechanical Modeling Using Finite Element Method. Model. Earth Syst. Environ. 2020, 6, 617–626. [Google Scholar] [CrossRef]

- Hua, S.; Yao, X. Analysis of the Mechanism by Which High-Toughness Cement Rings Reduce Casing Loss in Oil and Gas Wells. Oil-Gasf. Surf. Eng. 2009, 28, 34–35. [Google Scholar]

- Yang, S.; Han, L.; Feng, C.; Wang, H.; Feng, Y.; Wu, X. Mechanical Performance of Casing in In-Situ Combustion Thermal Recovery. J. Petrol. Sci. Eng. 2018, 168, 32–38. [Google Scholar] [CrossRef]

- Huang, Y.; Li, X.; Dai, K.; Zhang, Z.; Zhang, C.; Lv, C.; Zhang, X. Damage Causes and Solutions for Shale Gas Production Casing. Pet. Tubul. Goods Instrum. 2020, 6, 82–85. [Google Scholar] [CrossRef]

- Alsubaih, A.A.S.; Sepehrnoori, K.; Delshad, M.; Alsaedi, A. A Comprehensive Review of Well Integrity Challenges and Digital Twin Applications Across Conventional, Unconventional, and Storage Wells. Energies 2025, 18, 4757. [Google Scholar] [CrossRef]

- Jiang, M.; Zhou, F.; Liu, Y.; Ye, G.; Wang, F.; Kang, J. Shear Mechanical Behavior and Stress Transfer Characteristics of the Bilayer Casing of Gob Gas Ventholes. Geoenergy Sci. Eng. 2023, 226, 211656. [Google Scholar] [CrossRef]

- Liang, S.; Elsworth, D.; Li, X.; Fu, X.; Sun, B.; Yao, Q. Key Strata Characteristics Controlling the Integrity of Deep Wells in Longwall Mining Areas. Int. J. Coal Geol. 2017, 172, 31–42. [Google Scholar] [CrossRef]

- Liang, S.; Elsworth, D.; Li, X.; Yang, D. Topographic Influence on Stability for Gas Wells Penetrating Longwall Mining Areas. Int. J. Coal Geol. 2014, 132, 23–36. [Google Scholar] [CrossRef]

- Zhang, P.; Dougherty, H.; Su, D.; Trackemas, J.; Tulu, B. Influence of Longwall Mining on the Stability of Gas Wells in Chain Pillars. Int. J. Min. Sci. Technol. 2020, 30, 3–9. [Google Scholar] [CrossRef]

- Ma, Y.; Mu, J.; Xu, P.; Liang, S.; Xu, Y.; Wang, X. Overburden deformation characteristics and gas wellstability under influence of multiple mining. Shaanxi Coal 2025, 44, 15–23+85. [Google Scholar] [CrossRef]

- Su, D.W.H. Effects of Longwall-Induced Stress and Deformation on the Stability and Mechanical Integrity of Shale Gas Wells Drilled through a Longwall Abutment Pillar. Int. J. Min. Sci. Technol. 2017, 27, 115–120. [Google Scholar] [CrossRef]

- Abdollahipour, A.; Soltanian, H.; Pourmazaheri, Y.; Kazemzadeh, E.; Fatehi-Marji, M. Sensitivity Analysis of Geomechanical Parameters Affecting a Wellbore Stability. J. Cent. South Univ. 2019, 26, 768–778. [Google Scholar] [CrossRef]

- Schatzel, S.J.; Karacan, C.Ö.; Dougherty, H.; Goodman, G.V.R. An Analysis of Reservoir Conditions and Responses in Longwall Panel Overburden during Mining and Its Effect on Gob Gas Well Performance. Eng. Geol. 2012, 127, 65–74. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, B.; Wang, Y.; Wang, T.; Liu, Y.; Wang, Y. Anchoring Effect of Abandoned Oil Wells in Coal, Oil, and Gas Co-Production Areas and Its Influence on Overburden Stability. Appl. Sci. 2025, 15, 4223. [Google Scholar] [CrossRef]

- Peng, W. FLAC3D Practical Tutorial; Machinery Industry Press: Beijing, China, 2007. [Google Scholar]

- Xie, H.; Zhou, H.; Wang, J. Application of FLAC to Predict Ground Surface Displacements Due to Coal Extraction and Its Comparative Analysis. Chin. J. Rock Mech. Eng. 1999, 5, 29–33. [Google Scholar]

- Wang, Y.; Xiang, Y.; Zhang, X.; Liu, S.; Jing, J.; Chen, Y. Study on the Mechanical Behavior and Collapse Resistance of Double-Casing under Gypsum-Salt Layer. J. Phys. Conf. Ser. 2025, 2964, 012006. [Google Scholar] [CrossRef]

- Gholami, R.; Rasouli, V.; Aadnoy, B.; Mohammadnejad, M. Geomechanical and Numerical Studies of Casing Damages in a Reservoir with Solid Production. Rock Mech. Rock Eng. 2016, 49, 1441–1460. [Google Scholar] [CrossRef]

| Rock Type | Density (kg/m3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Poisson Ratio | Cohesive Strength (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|

| sand layer | 1600 (1500–1700) | 0.002 (0.001–0.004) | 0.008 (0.005–0.012) | 0.35 (0.3–0.4) | 0.14 (0.1–0.18) | 15 (12–18) |

| red soil | 1860 (1750–1950) | 0.03 (0.02–0.05) | 0.3 (0.2–0.5) | 0.36 (0.32–0.4) | 0.36 (0.28–0.45) | 23 (20–26) |

| medium-grained sandstone | 2260 (2140–2380) | 5.62 (4.5–6.7) | 9.78 (7.8–11.7) | 0.25 (0.22–0.28) | 4.8 (4.0–5.6) | 41 (38–44) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| coarse-grained sandstone | 2160 (2050–2270) | 1.08 (0.8–1.3) | 2.1 (1.7–2.5) | 0.22 (0.18–0.26) | 4.78 (3.8–5.7) | 51 (48–54) |

| sandy mudstone | 2360 (2260–2460) | 5.47 (4.4–6.6) | 6.08 (4.9–7.3) | 0.2 (0.17–0.23) | 3.9 (3.1–4.7) | 42 (39–45) |

| medium-grained sandstone | 2260 (2140–2380) | 5.62 (4.5–6.7) | 9.78 (7.8–11.7) | 0.25 (0.22–0.28) | 4.8 (4.0–5.6) | 41 (38–44) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| sandy mudstone | 2360 (2260–2460) | 5.47 (4.4–6.6) | 6.08 (4.9–7.3) | 0.2 (0.17–0.23) | 3.9 (3.1–4.7) | 42 (39–45) |

| medium-grained sandstone | 2260 (2140–2380) | 5.62 (4.5–6.7) | 9.78 (7.8–11.7) | 0.25 (0.22–0.28) | 4.8 (3.9–5.9) | 41 (38–44) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| medium-grained sandstone | 2260 (2140–2380) | 5.62 (4.5–6.7) | 9.78 (7.8–11.7) | 0.25 (0.22–0.28) | 4.8 (4.0–5.6) | 41 (38–44) |

| fine-grained sandstone | 2290 (2180–2400) | 6.01 (4.8–7.2) | 15.59 (12.5–18.7) | 0.33 (0.29–0.37) | 4.88 (3.9–5.9) | 42 (39–45) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| fine-grained sandstone | 2290 (2180–2400) | 6.01 (4.8–7.2) | 15.59 (12.5–18.7) | 0.33 (0.29–0.37) | 4.88 (3.9–5.9) | 42 (39–45) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| fine-grained sandstone | 2290 (2180–2400) | 6.01 (4.8–7.2) | 15.59 (12.5–18.7) | 0.33 (0.29–0.37) | 4.88 (3.9–5.9) | 42 (39–45) |

| medium-grained sandstone | 2260 (2140–2380) | 5.62 (4.5–6.7) | 9.78 (7.8–11.7) | 0.25 (0.22–0.28) | 4.8 (4.0–5.6) | 41 (38–44) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| 2−2 coal seam | 1450 (1350–1550) | 1.04 (0.8–1.3) | 7.36 (5.9–8.8) | 0.26 (0.22–0.30) | 2.37 (1.9–2.8) | 33 (30–36) |

| siltstone | 2350 (2250–2450) | 9.26 (7.4–11.1) | 13.97 (11.2–16.7) | 0.24 (0.20–0.28) | 5.15 (4.1–6.2) | 40 (37–43) |

| Type of Casing | Elastic Modulus (E/GPa) | Poisson Ratio | Tensile Strength (MPa) | Density (kg/m3) | Outer Diameter of Casing (mm) | Wall Thickness (mm) |

|---|---|---|---|---|---|---|

| J55 steel grade | 210 | 0.3 | 517 | 7850 | 244.5 | 8.94 |

| N80 steel grade | 210 | 0.3 | 689 | 7850 | 139.7 | 9.17 |

| Joint | Normal Stiffness (Kn/MP) | Tangential Stiffness (Ks/MP) | Friction Angle (°) | Cohesive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Interface between the cement ring and the rock layer | 250 (200–300) | 70 (50–90) | 30 (28–32) | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Li, W.; Li, D.; Ye, Y.; Liu, Y. Numerical Simulation and Empirical Validation of Casing Stability in Coalbed Methane Wells Under Mining-Induced Stress: A Case Study of Xiaobaodang Coal Mine in Yulin-Shenmu Mining Area. Appl. Sci. 2025, 15, 10674. https://doi.org/10.3390/app151910674

Gao Z, Li W, Li D, Ye Y, Liu Y. Numerical Simulation and Empirical Validation of Casing Stability in Coalbed Methane Wells Under Mining-Induced Stress: A Case Study of Xiaobaodang Coal Mine in Yulin-Shenmu Mining Area. Applied Sciences. 2025; 15(19):10674. https://doi.org/10.3390/app151910674

Chicago/Turabian StyleGao, Zeke, Wenping Li, Dongding Li, Yangmin Ye, and Yuchu Liu. 2025. "Numerical Simulation and Empirical Validation of Casing Stability in Coalbed Methane Wells Under Mining-Induced Stress: A Case Study of Xiaobaodang Coal Mine in Yulin-Shenmu Mining Area" Applied Sciences 15, no. 19: 10674. https://doi.org/10.3390/app151910674

APA StyleGao, Z., Li, W., Li, D., Ye, Y., & Liu, Y. (2025). Numerical Simulation and Empirical Validation of Casing Stability in Coalbed Methane Wells Under Mining-Induced Stress: A Case Study of Xiaobaodang Coal Mine in Yulin-Shenmu Mining Area. Applied Sciences, 15(19), 10674. https://doi.org/10.3390/app151910674