Target Area Selection for Residual Coalbed Methane Drainage in Abandoned Multi-Seam Mines

Abstract

1. Introduction

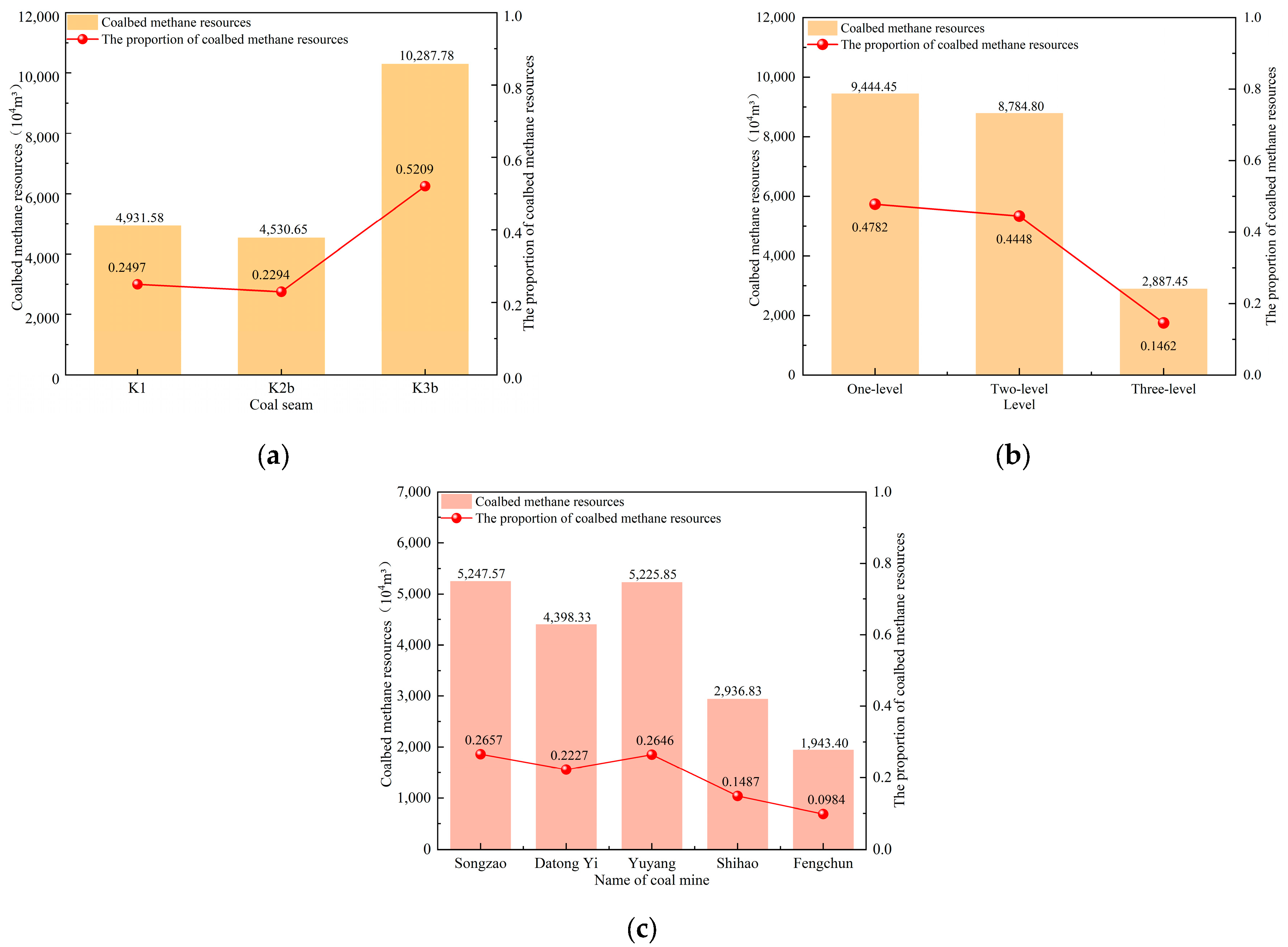

2. Evaluation of CBM Resources in Songzao Mining Area

2.1. Overview of Geological and Hydrological Conditions in Mining Area

2.2. Evaluation of CBM Resources in Mining Area

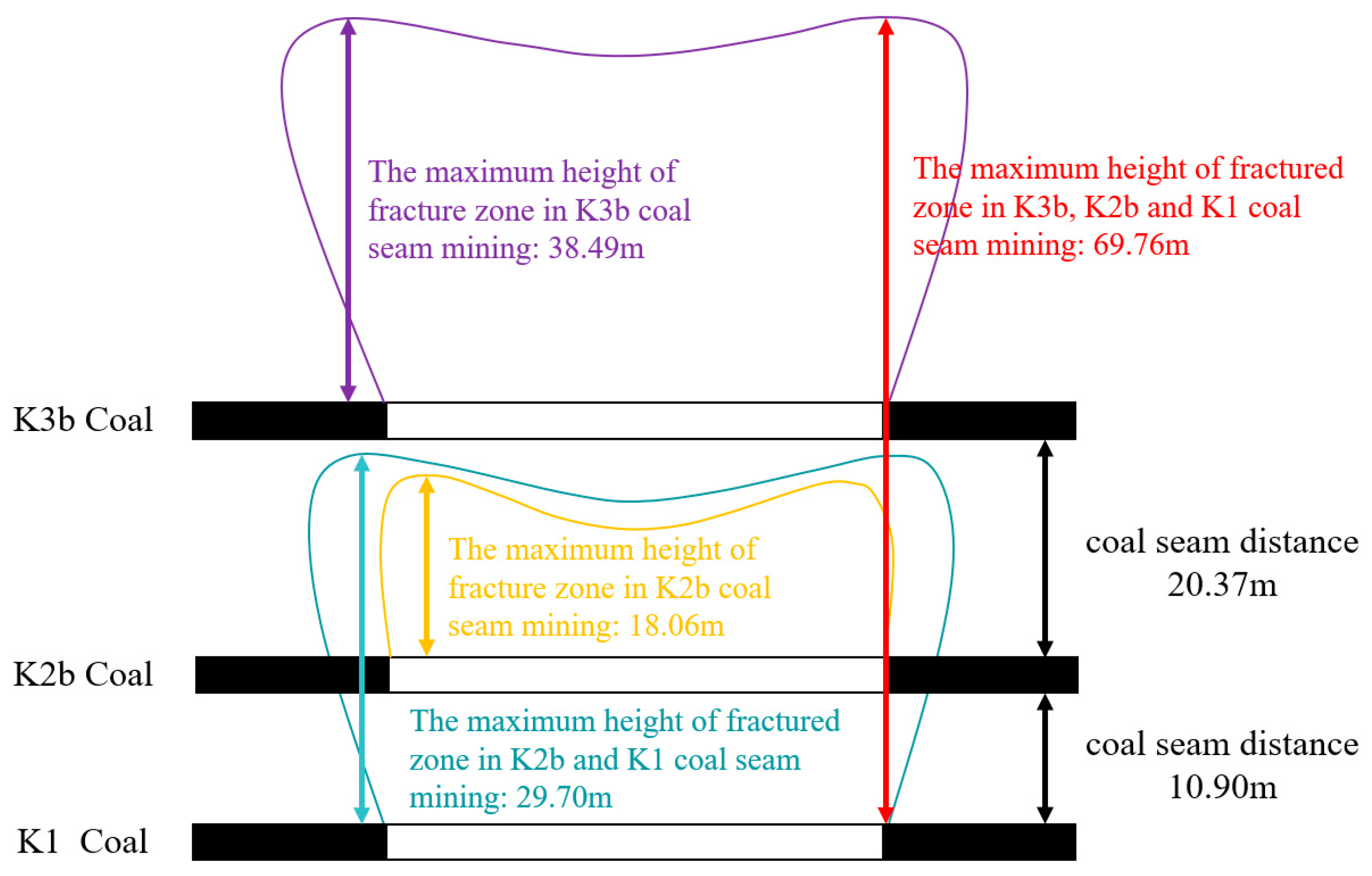

3. Theoretical Calculation of ‘Two Zones’ Height in Songzao Coal Mine

3.1. Project Profile

3.2. Theoretical Calculation of ‘Two-Band’ Height

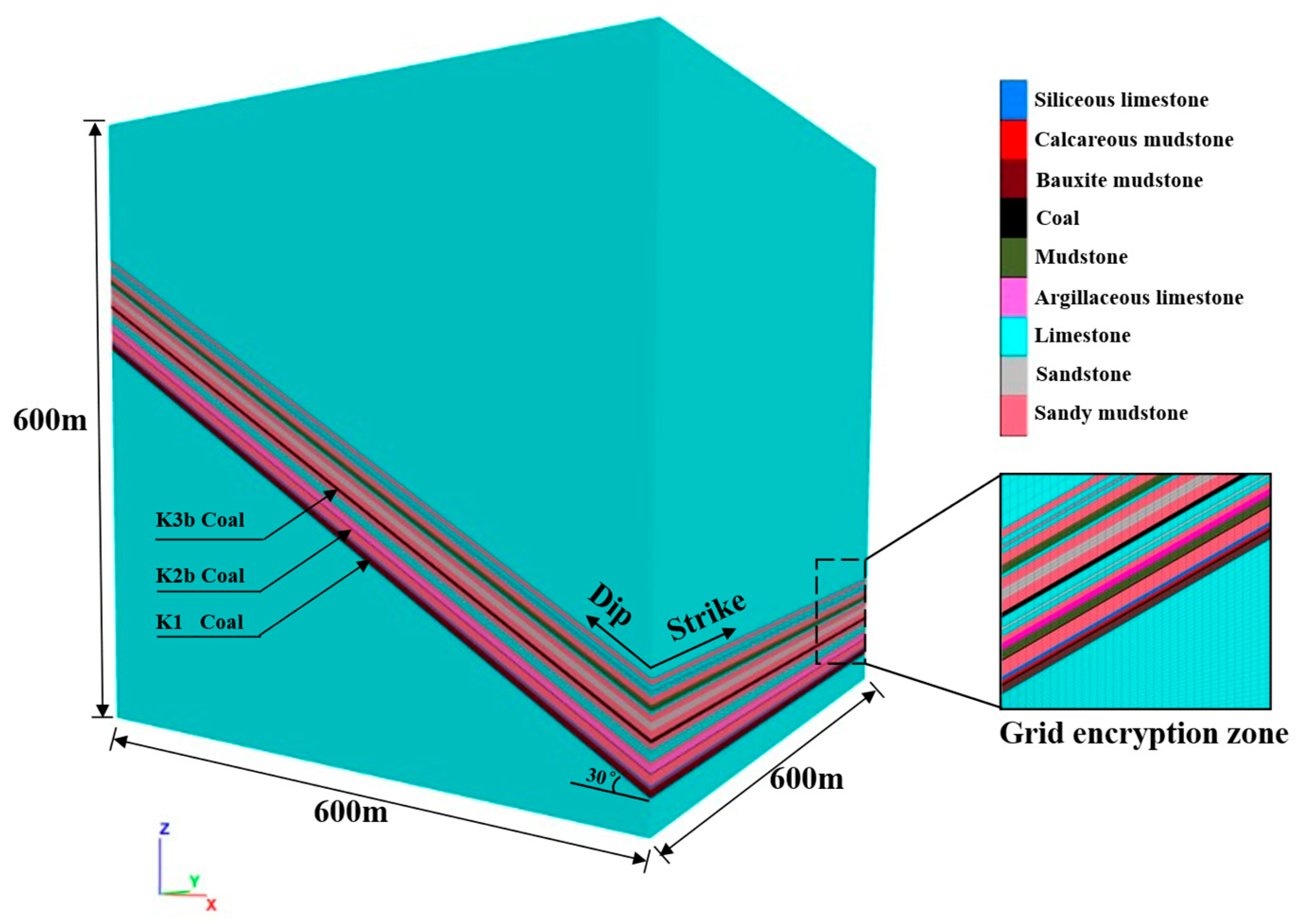

4. Numerical Investigation of Mining-Induced Stress-Fracture Field Evolution in Songzao Coal Mine

4.1. Model Development

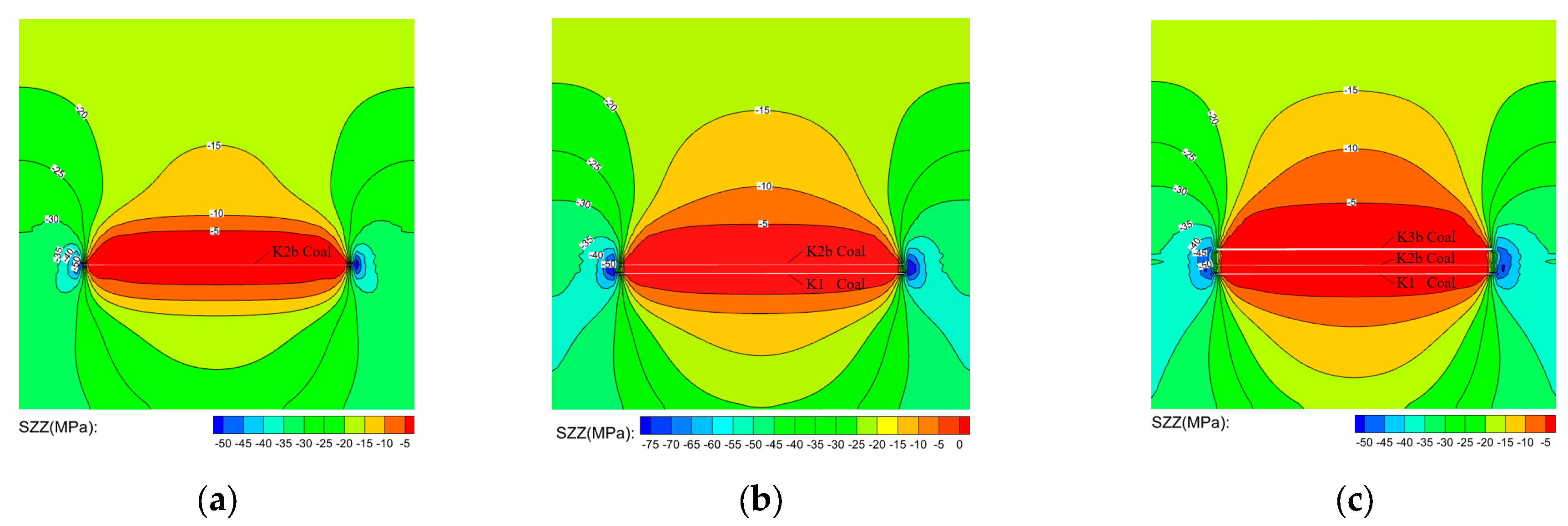

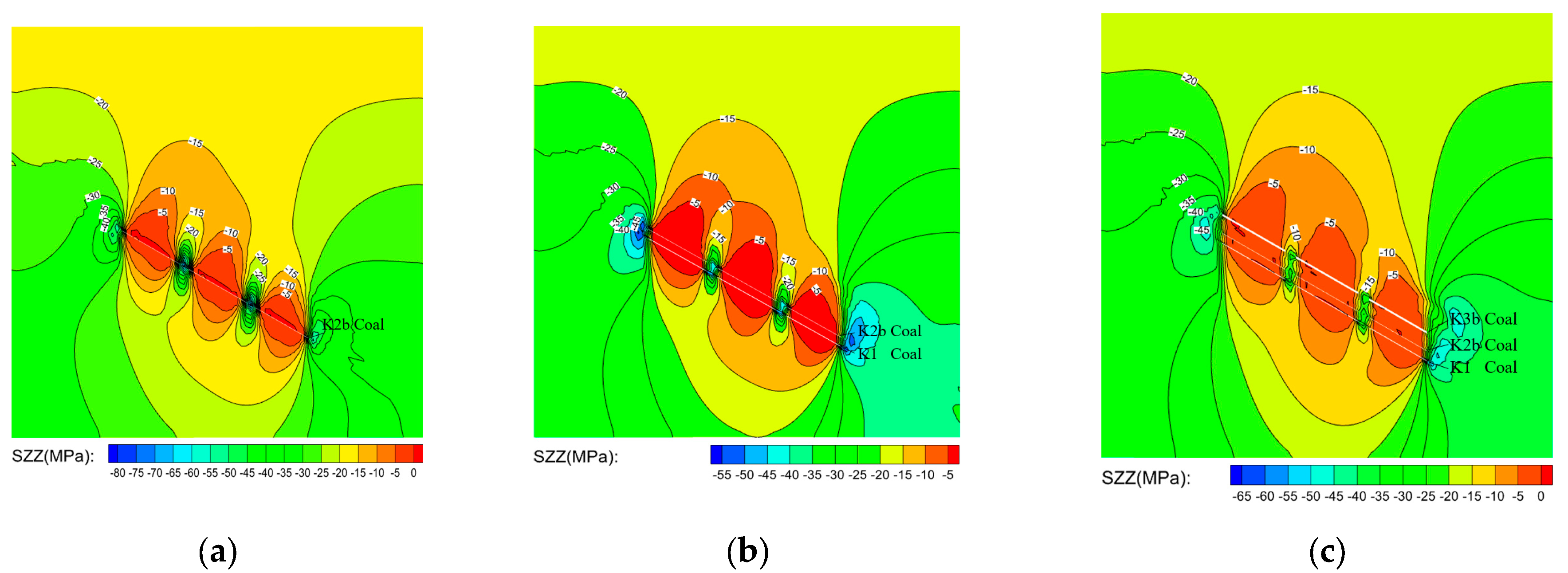

4.2. Stress Evolution Characteristics of Overburden Strata During Multi-Seam Mining

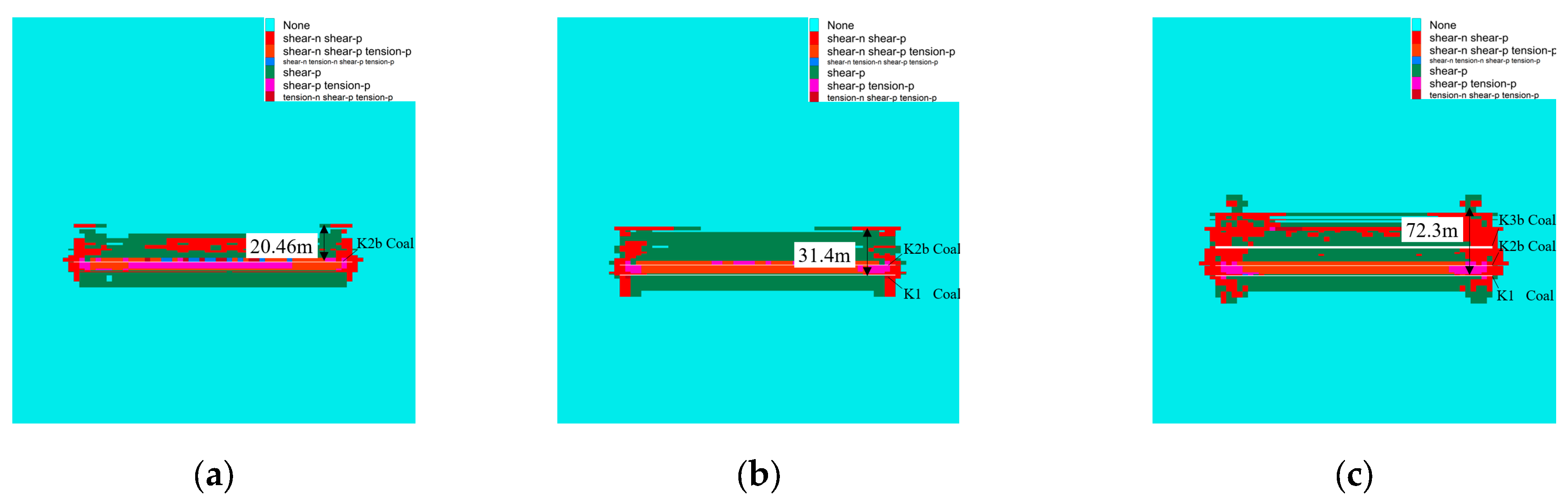

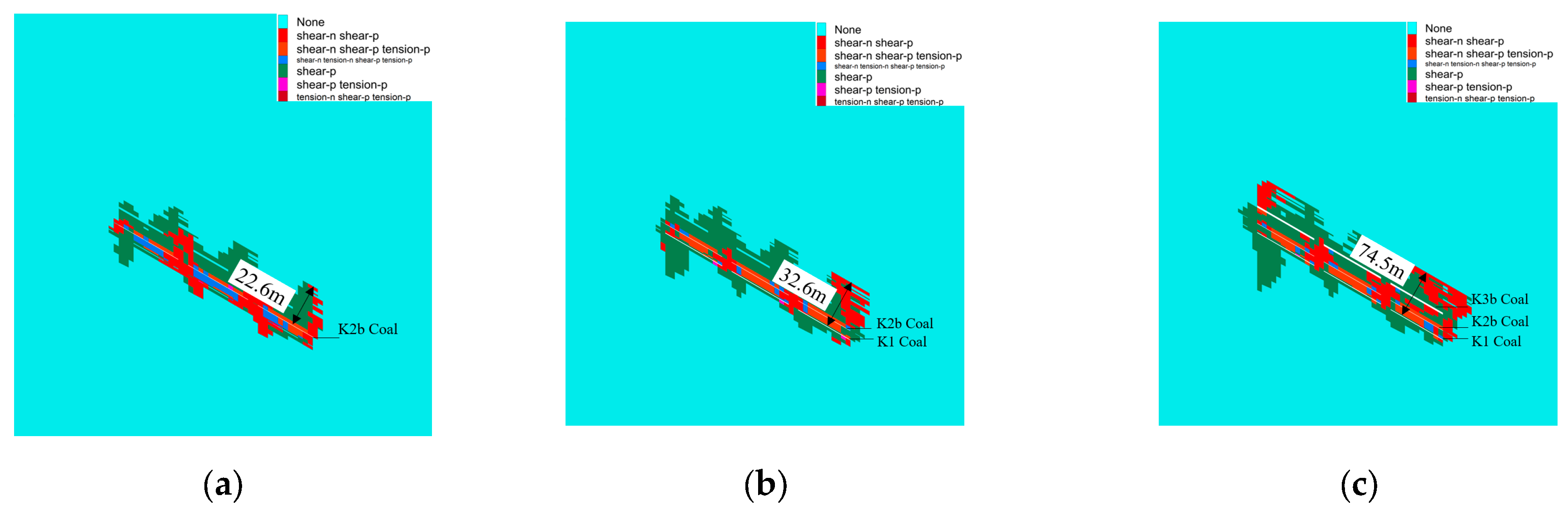

4.3. Fracture Development Characteristics of Overburden Strata During Multi-Seam Mining

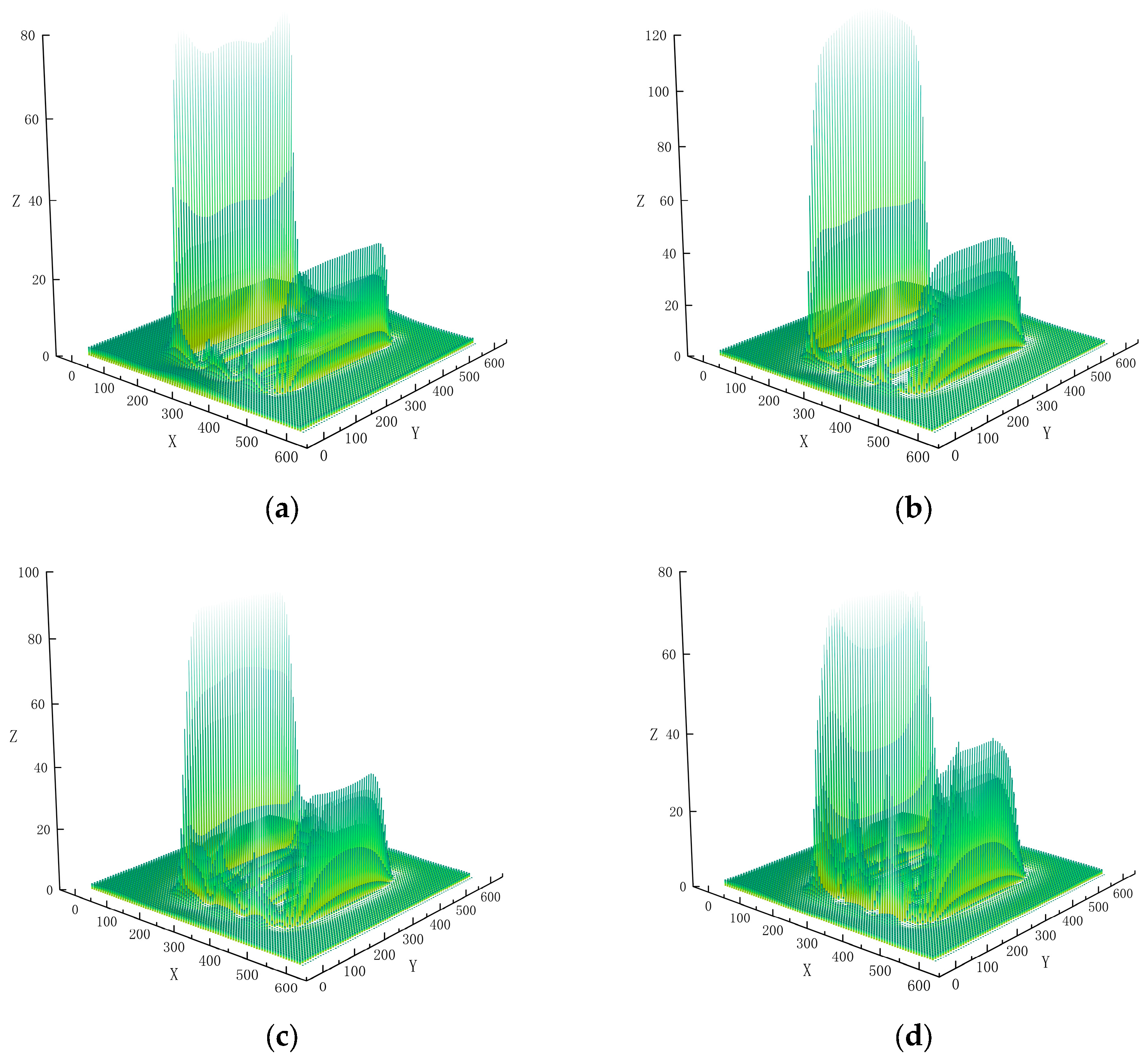

4.4. The Characteristics of Increasing Permeability of Overlying Strata in Multi-Coal Seam Mining

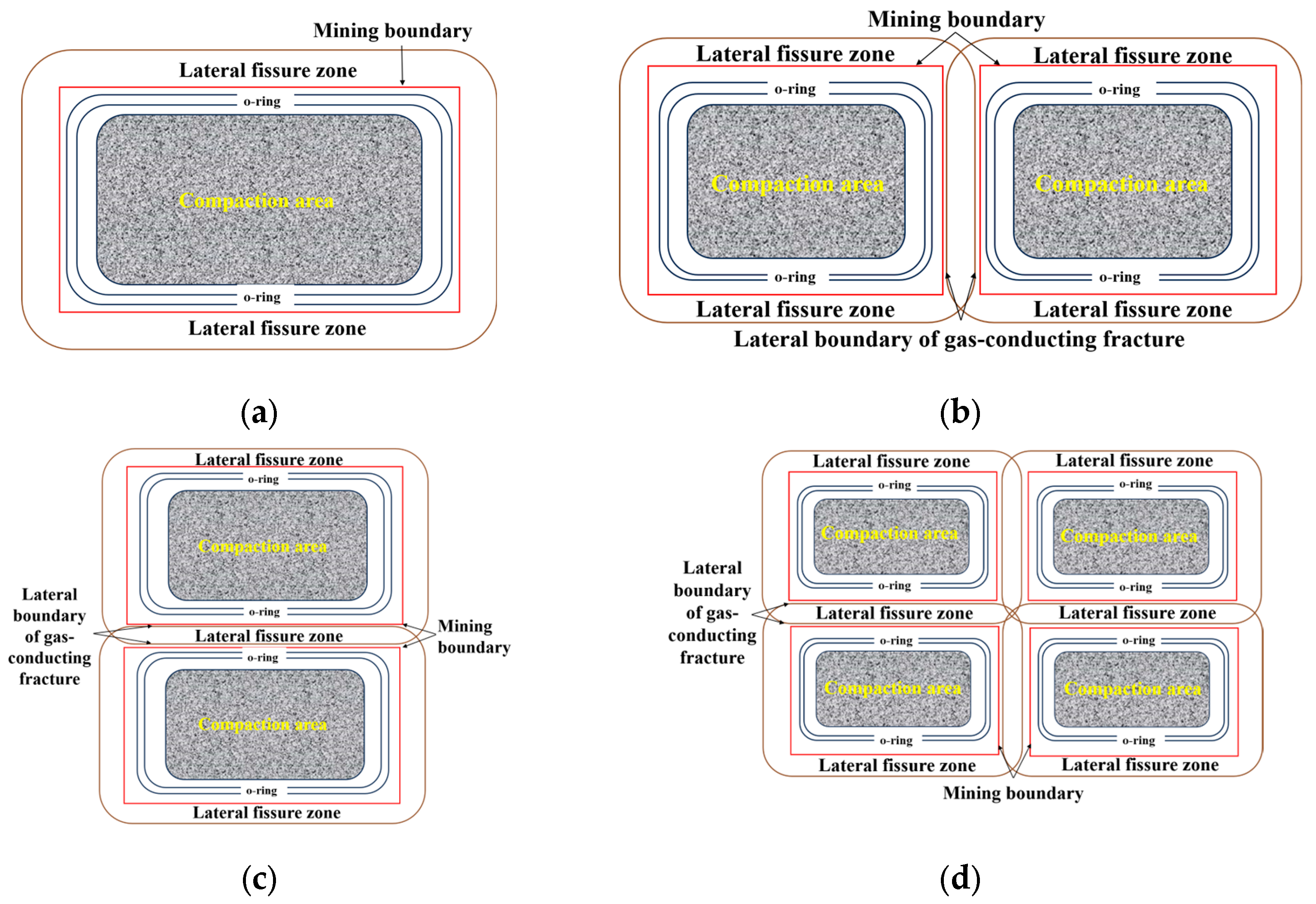

5. Optimization of CBM Extraction Target Area in Fracture Zone

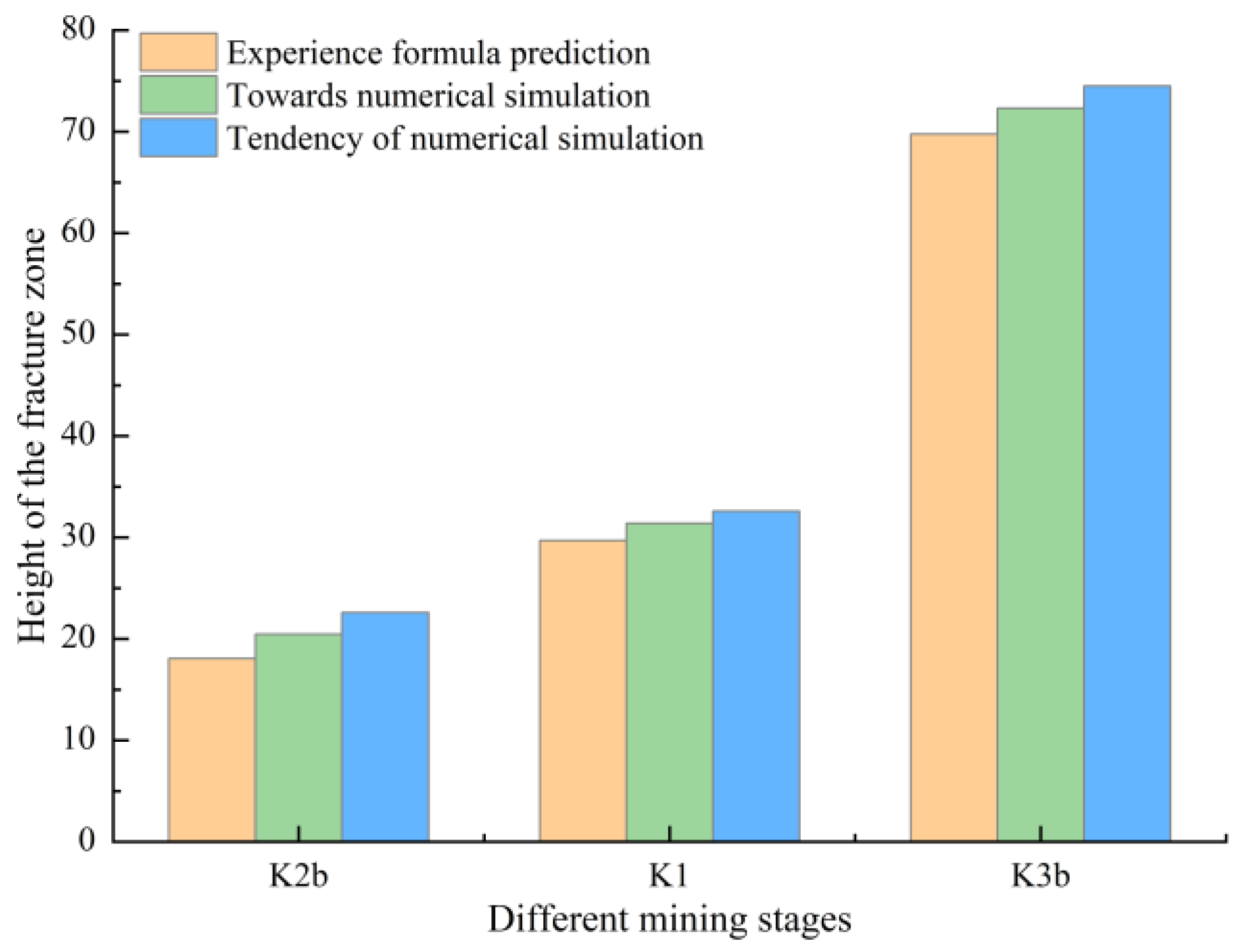

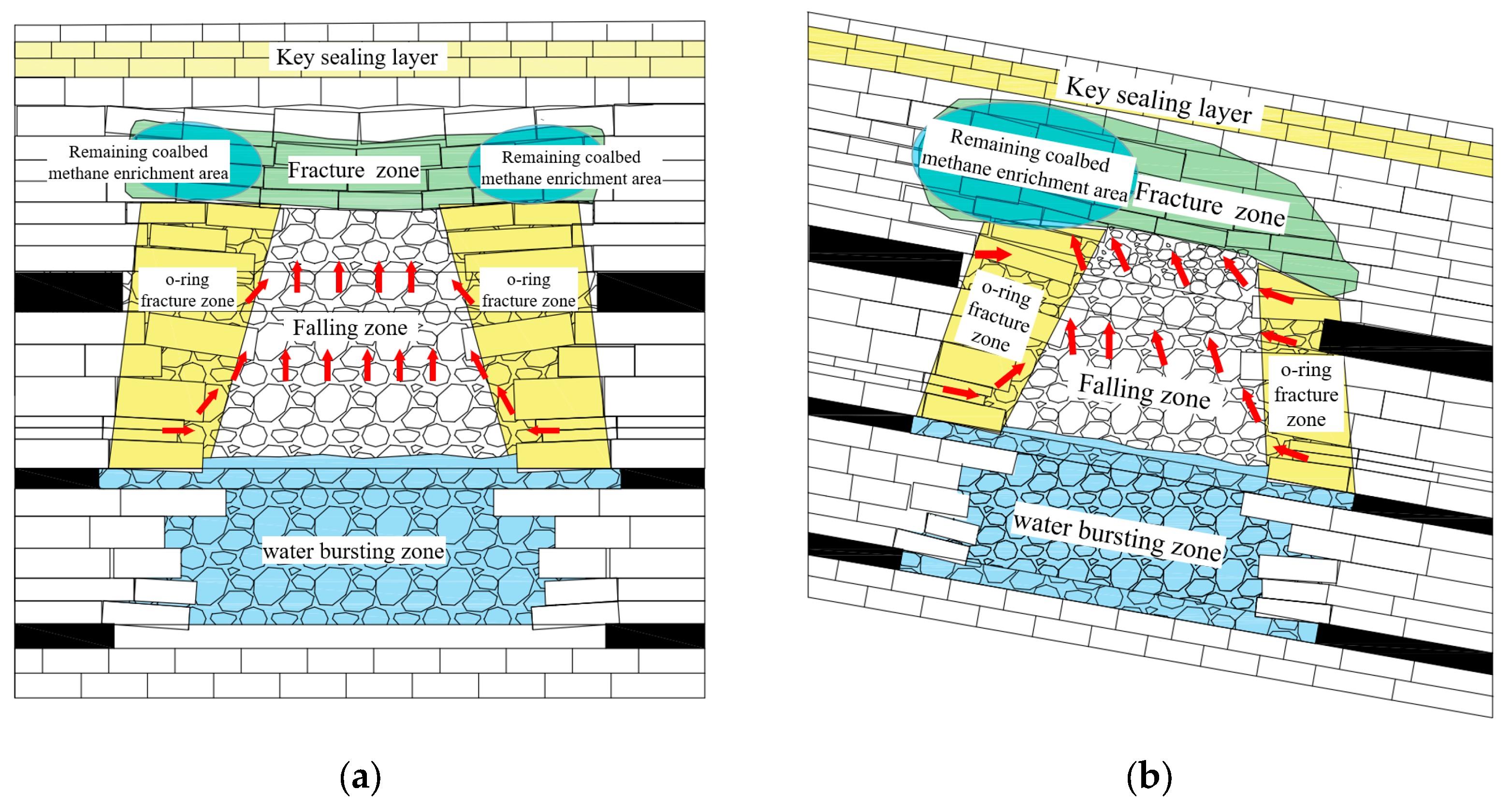

5.1. Height Prediction of Fracture Zone in Abandoned Goaf

5.2. Determination of CBM Extraction Target Area

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variable/Symbol | Description | Units |

| coalbed gas resources | m3 | |

| coal reserves | t | |

| the coal seam average gas content | m3/t | |

| Hk | the height of the caving zone | m |

| M | the thickness of the mined coal seam | m |

| Hli | the height of the fracture zone | m |

| the comprehensive mining thickness of the upper and lower coal seams | m | |

| the thickness of the upper coal seam mining | m | |

| the thickness of the lower coal seam mining | m | |

| the normal distance between the upper and lower coal seams | m | |

| the caving ratio of the lower coal seam | / | |

| Kk | the permeability in the k direction | m2 |

| Kk0 | the permeability in the k direction in the initial state | m2 |

| Kni | the stiffness of cracks in i directions | Pa/m |

| Knj | the stiffness of cracks in j directions | Pa/m |

| v | the Poisson ‘s ratio of coal | / |

| ∆σi | the stress variation in i directions | Pa |

| ∆σj | the stress variation in j directions | Pa |

| ∆σk | the stress variation in k directions | Pa |

| bi | the crack openings in the i directions | m |

| bj | the crack openings in the j directions | m |

| the height of the caving zone at the end of the first stage | m | |

| the bulking coefficient of the caved rock in the caving zone at the end of the first stage | / | |

| the bulking coefficient of the caved rock in the caving zone at the end of the second stage | / | |

| the reduction in the unloading height of the fracture zone in the second stage | m | |

| the height of the fracture zone at the end of the first stage | m | |

| the height of the fracture zone at the end of the second stage | m |

References

- Yuan, L. Strategies of High Efficiency Recovery and Energy Saving for Coal Resources in China. J. China Univ. Min. Technol. (Soc. Sci.) 2018, 20, 3–12. [Google Scholar]

- Zhang, J.Q.; Liu, Z.; Shen, B.J.; Zhao, S.H.; Chen, X.J.; Ye, J.C. Progress and insights from worldwide deep coalbed methane exploration and development. Pet. Geol. Exp. 2025, 47, 1–8. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, K. Further discussion on the scientific problems and countermeasures in the utilization of abandoned mines. J. China Coal Soc. 2021, 46, 16–24. [Google Scholar] [CrossRef]

- Yang, K.; Fu, Q.; Yuan, L.; Chen, N.; Liu, Q.J.; Yang, Q.G. Development strategy of pumped storage in underground space of closed/abandoned mines. J. Min. Sci. Technol. 2023, 8, 283–292. [Google Scholar] [CrossRef]

- Liu, Q.J.; Yang, Q.G.; Yang, K.; Fu, Q.; Xie, Q.; Han, Y. Case study of pumped storage hydropower based on multi-energy complementary utilization mode in abandoned coal mines. J. Min. Saf. Eng. 2023, 40, 578–586. [Google Scholar] [CrossRef]

- Wang, J.C.; Yang, Z.B.; Qin, Y.; Yang, Y.Q.; Dong, Z.Y.; Meng, X.H. Research status and prospects of secondary enrichment and accumulation of residual coalbed methane resources in abandoned mines. Coal Geol. Explor. 2022, 52, 35–44. [Google Scholar] [CrossRef]

- Kędzior, S.; Dreger, M. Methane occurrence, emissions and hazards in the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2019, 211, 103226. [Google Scholar] [CrossRef]

- Xiu, Y.; Liu, Q.; Fu, Q.; Yang, K.; Zhang, M.; Wu, B.N. Optimization of residual coalbed methane extraction wells and analysis of development and emission reduction benefits in the Songzao mining area. Sci. Rep. 2025, 15, 13731. [Google Scholar] [CrossRef]

- Xie, Y.H.; Hua, X.Z. Study on the development laws of overburden rock fracture in double-seam mining of abandoned mine. China Min. Mag. 2025, 34, 137–145. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Wang, Y. Key technologies and bottleneck problems of multi-energy complementary DC microgrid for residual coalbed methane mining in abandoned mines. J. China Coal Soc. 2023, 48, 179. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, B.; Zhang, C.L.; Zhao, J.J.; Liu, J.K.; Zhang, S. Study of dynamic evolution rules and distribution pattern of mining-induced fractures of thick coal seam. J. China Univ. Min. Technol. 2013, 42, 935–940. [Google Scholar] [CrossRef]

- Li, R.F. Study on the Reservoir and Resource Evaluation Technique of CBM in the Stabilization Region After Mining. Ph.D. Thesis, Chongqing University, Chongqing, China, 2014. [Google Scholar]

- Wang, H.B.; Zhang, Y.; Pang, Y.H.; Jia, W. Prediction model of the height of fractured zone in abandoned goaf and its application. Rock Soil Mech. 2022, 43, 1073–1082. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Y.Q.; Peng Syd, S.; Cheng, H.Z.; Wang, N.; Luo, J.B. Measurement of overburden failure zones in close-multiple coal seams mining. Int. J. Min. Sci. Technol. 2021, 31, 43–50. [Google Scholar] [CrossRef]

- Qian, M.G.; Xu, J.L. Study on the “O-shape” circle distribution characteristics of mining-induced fractures in the overlaying strata. J. China Coal Soc. 1998, 23, 20–23. [Google Scholar]

- Liu, Z.G.; Yuan, L.; Dai, G.L.; Shi, B.M.; Lu, P.; Tu, M. Study on Coal Seam Roof Gas Drainage from the Strike of Annular Fracture Areas by the Long Drill Method. Strateg. Study CAE 2004, 6, 32–38. [Google Scholar]

- Yang, K.; Xie, G.X. Caving thickness effects on distribution and evolution characteristics of mining induced fracture. J. China Coal Soc. 2008, 33, 1092–1096. [Google Scholar]

- Guo, W.B.; Zhao, G.B.; Lou, G.Z.; Wang, S. A new method of predicting the height of the fractured water-conducting zone due to high-intensity longwall coal mining in China. Rock Mech. Rock Eng. 2019, 52, 2789–2802. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Z.; Zhu, D.L.; Yang, W.Z.; Zhao, D.W.; Wang, W.D. Study on the fractal characteristics of coal body fissure development and the law of coalbed methane migration of around the stope. Geofluids 2020, 2020, 9856904. [Google Scholar] [CrossRef]

- Zhang, L.; Kan, Z.H.; Xue, J.H.; Li, M.X.; Zhang, C. Study on permeability law of intact and fractured coals under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2021, 40, 2487–2499. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.Q.; Li, M.X.; Liu, S.; Yuan, X.C.; Li, J.H. Experimental study on evolution of fracture network and permeability characteristics of bituminous coal Under repeated mining effect. Nat. Resour. Res. 2022, 31, 463–486. [Google Scholar] [CrossRef]

- Ma, W.X.; Zhang, L.; Ding, H.L.; Guo, M.J.; Zhang, X.J. Numerical simulation study on fracture evolution of overburden rock in extra-thick coal seam mining. China Energy Environ. Prot. 2024, 46, 275–280. [Google Scholar] [CrossRef]

- Xie, H.G.; Li, X.J.; Cai, J.J.; Wang, S.W.; Feng, C. Evolution of fissures and pressure discharge of gas caused by mining of the upper protective layer of a coal seam. Sci. Rep. 2023, 13, 2561. [Google Scholar] [CrossRef]

- Xu, A.; Sang, S.X.; Zhou, X.Z.; Han, S.J.; Chen, J.; Feng, Y.F.; Lou, Y.; Yan, Z.H.; Gao, W. Optimal design of coalbed methane wells in mining area with thin to medium thick coal seam group. Coal Sci. Technol. 2025, 53, 385–399. [Google Scholar] [CrossRef]

- Zhao, P.X.; Zhuo, R.S.; Li, S.G.; Lin, H.F.; Chang, Z.C. Research on the evolution mechanism of the topological relationship of the property parameters of the mining overburden rock pressure relief gas migration channel. Coal Sci. Technol. 2024, 52, 135–149. [Google Scholar] [CrossRef]

- Wu, R.L.; Wang, Y.F.; Xu, D.L.; She, Z.L.; Meng, L. Effects of working face width on the scope of the “three zones” of gas pressure relief and migration in coal seam group mining. J. Min. Saf. Eng. 2017, 34, 192–198. [Google Scholar] [CrossRef]

- Wu, R.L. Effects of key stratum on the scope of the “three zones” of gas pressure relief and migration in coal seam group mining. J. China Coal Soc. 2013, 38, 924–929. [Google Scholar] [CrossRef]

- Xie, P.S.; Huang, B.F.; Wu, Y.P.; Yang, H.; Lin, W.D.; Tian, S.Q.; Wang, Z.; Wan, X.; Bai, R.X. Study on the interaction between strata movement and support in pitching oblique mining area of steeply dipping seam. J. China Univ. Min. Technol. 2024, 53, 664–679. [Google Scholar] [CrossRef]

- Xie, P.S.; Duan, D.J.; Huangfu, J.Y.; Tian, S.Q. Experiment study on roof movement and its filling in multi-section mining of steeply dipping seam. J. Xi'an Univ. Sci. Technol. 2020, 40, 212–220. [Google Scholar] [CrossRef]

- Meng, X.J.; Zhao, P.X.; Wang, X.Y.; Liu, L.D.; Yang, J.S. “Three zones” microseismic monitoring and analysis of gas drainage effect of overlying strata in gob of high dip high gas seam. Coal Sci. Technol. 2022, 50, 177–185. [Google Scholar]

- Yang, Z.B.; Wang, J.C.; Yang, Y.Q.; Qin, Y.; Li, G.F. Spatial division of coalbed methane disturbed reservoir left over from abandoned working face-Taking 12501 working face of Tunlan Coal Mine as an example. Coal Sci. Technol. 2023, 51, 243–255. [Google Scholar] [CrossRef]

- AQ/T 1018-2006; Prediction Method of Mine Gas Emission Rate. State Administration of Work Safety: Beijing, China, 2006.

- Li, S.G.; Liu, L.D.; Zhao, P.X.; Lin, H.F.; Xu, P.Y. Analysis and application of fracture evolution law of over burden compacted area on fully-mechanized mining face under multiple factors. Coal Sci. Technol. 2022, 50, 95–104. [Google Scholar]

- Huang, Q.M.; Wu, B.; Cheng, W.M.; Lei, B.W.; Shi, H.H.; Chen, L. Investigation of permeability evolution in the lower slice during thick seam slicing mining and gas drainage: A case study from the Dahuangshan coalmine in China. J. Nat. Gas Sci. Eng. 2018, 52, 141–154. [Google Scholar] [CrossRef]

- Li, S.G.; Qian, M.G.; Shi, P.W. Methane migration and accumulation state after seam mining. Coal Geol. Explor. 2000, 28, 31–33. [Google Scholar]

- Yin, Z.S.; Sang, S.X.; Zhou, X.Z. Study on Migration and Enrichment Regularities of CBM in Exhausted Coal Resource Wells. Spec. Oil Gas Reserv. 2014, 21, 48–51+153. [Google Scholar] [CrossRef]

| Name of Indicator | Songzao | Fengchun | Datong Yi | Shihao | Yuyang |

|---|---|---|---|---|---|

| Geological structure complexity | Medium | Complex | Medium | Medium | Medium |

| Average buried depth (m) | 298 | 302 | 466 | 485 | 351 |

| Inclination degree of coal seam | Inclined | Steep inclined | Gentle inclined | Gentle inclined | Gentle inclined |

| Height of water outlet point (m) | +333 | +523 | +460 | +480 | +470 |

| Water accumulation in the goaf (104 m3) | 981 | 127 | 3384 | 2510 | 2000 |

| Goaf area (km2) | 12.55 | 3.36 | 18.36 | 3.84 | 6.31 |

| Water-free space in the goaf (104 m3) | 1426 | 333.5 | 0 | 132 | 0 |

| CBM emission (m3/min) | 114.37 | 54.02 | 267.27 | 202.18 | 137.4 |

| Maximum CBM content (m3/t) | 28.51 | 26.87 | 24.03 | 29.45 | 29.44 |

| Remaining coal resources (104 t) | 4786.6 | 4484.8 | 8418.2 | 7860.6 | 3391.9 |

| Name of Indicator | Songzao | Fengchun | Datong Yi | Shihao | Yuyang |

|---|---|---|---|---|---|

| Coal consumption (104 t) | 5242.1 | 1940.27 | 4392.91 | 2752.7 | 3303.6 |

| Rate of recovery | 80% | 80% | 80% | 78.69% | 68.40% |

| Coal Seam | Mining Thickness/m | Caving Zone/m |

|---|---|---|

| K2b | 0.56 | 0.58–4.98 |

| K1 | 0.97 | 2.41–6.81 |

| K3b | 2.50 | 8.11–12.51 |

| Lithologic Characteristics | Density (kg·m−3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Angle of Internal Friction (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Sandy mudstone | 2558 | 2.69 | 2.15 | 33 | 4.43 | 1.68 |

| Limestone | 2600 | 9.32 | 6.54 | 31 | 6.67 | 4.57 |

| Coal | 1400 | 2.31 | 1.63 | 18 | 1.88 | 0.52 |

| Mudstone | 2330 | 3.12 | 2.56 | 23 | 3.89 | 1.17 |

| Sandstone | 2752 | 8.86 | 5.26 | 33 | 5.72 | 3.53 |

| Argillaceous limestone | 2559 | 5.85 | 2.40 | 42 | 3.51 | 1.65 |

| Siliceous limestone | 2320 | 4.38 | 3.32 | 30 | 3.32 | 2.45 |

| Calcareous mudstone | 2550 | 2.45 | 1.86 | 33 | 2.15 | 1.53 |

| Bauxite mudstone | 2620 | 2.33 | 1.54 | 35 | 2.07 | 1.12 |

| Mining Stage | Fracture Zone Development Height/m | ||

|---|---|---|---|

| Empirical Formula Prediction | Numerical Simulation Results | ||

| Toward | Dip | ||

| K2b coal seam | 18.06 m | 20.46 m | 22.60 |

| K1 coal seam | 29.70 m | 31.40 m | 32.60 |

| K3b coal seam | 69.76 m | 72.30 m | 74.50 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Xiu, Y.; Liu, Q.; Zhang, B.; Duan, M.; Yang, Y.; Guo, C. Target Area Selection for Residual Coalbed Methane Drainage in Abandoned Multi-Seam Mines. Appl. Sci. 2025, 15, 10619. https://doi.org/10.3390/app151910619

Li G, Xiu Y, Liu Q, Zhang B, Duan M, Yang Y, Guo C. Target Area Selection for Residual Coalbed Methane Drainage in Abandoned Multi-Seam Mines. Applied Sciences. 2025; 15(19):10619. https://doi.org/10.3390/app151910619

Chicago/Turabian StyleLi, Gen, Yaxin Xiu, Qinjie Liu, Bin Zhang, Minke Duan, Youxing Yang, and Chenye Guo. 2025. "Target Area Selection for Residual Coalbed Methane Drainage in Abandoned Multi-Seam Mines" Applied Sciences 15, no. 19: 10619. https://doi.org/10.3390/app151910619

APA StyleLi, G., Xiu, Y., Liu, Q., Zhang, B., Duan, M., Yang, Y., & Guo, C. (2025). Target Area Selection for Residual Coalbed Methane Drainage in Abandoned Multi-Seam Mines. Applied Sciences, 15(19), 10619. https://doi.org/10.3390/app151910619