Effects of Inulin Supplementation and Electron Beam Irradiation Assisted with Pregelatinization Process on the Quality of Pisang Awak Banana Powder

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Pisang Awak Banana Powder (PABP)

2.1.1. Pisang Awak Banana Puree Preparation

2.1.2. Tray Drying Method

2.1.3. Drum Drying Method

2.2. Electron Beam Irradiation (EBI)

2.3. Physicochemical Properties

2.3.1. Rehydration Time

2.3.2. Pasting Properties

2.3.3. Solubility Index

2.4. Statistical Analysis

3. Results and Discussion

3.1. Effect of Electron Beam Irradiation Dose on Physicochemical Properties of PABP

3.1.1. Rehydration Times

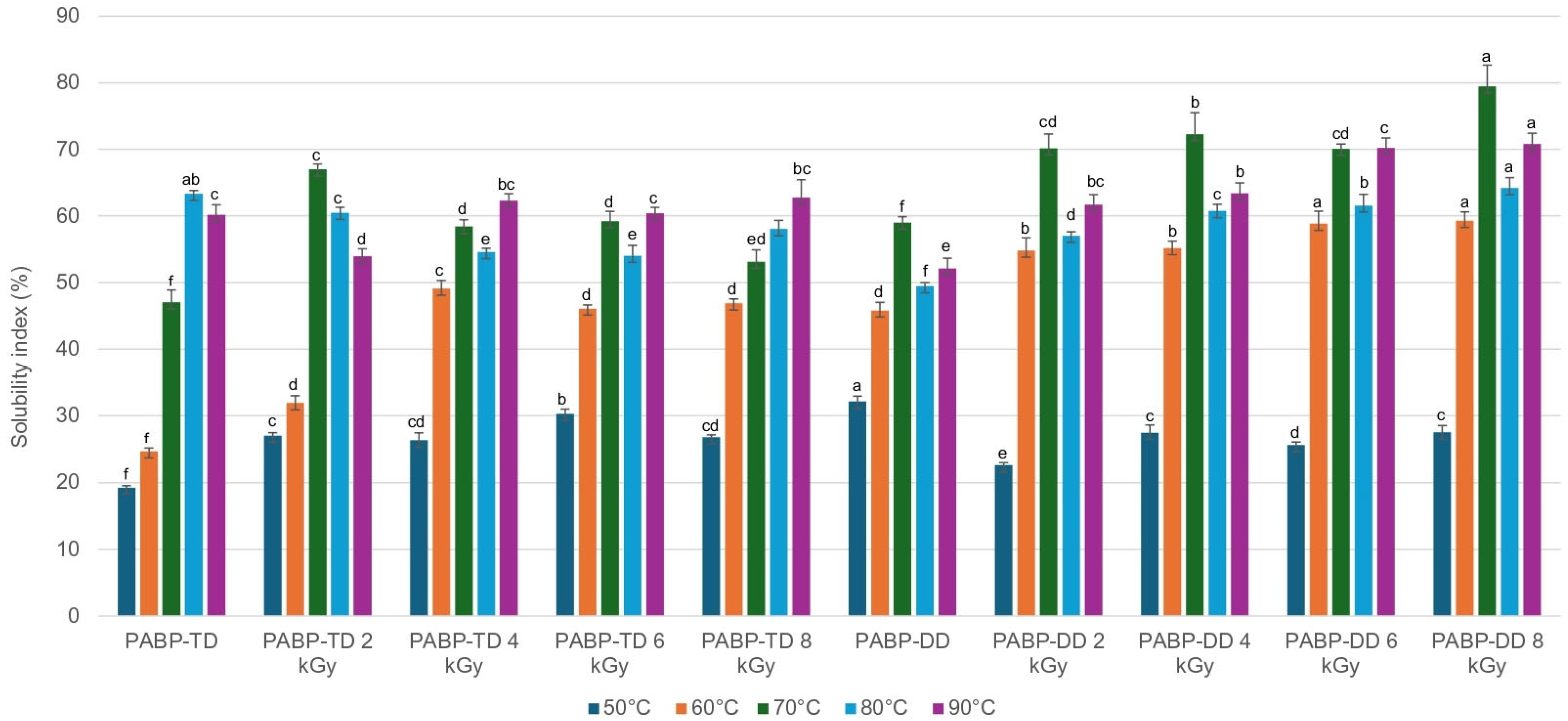

3.1.2. Solubility Index

3.1.3. Pasting Properties

3.2. Effect of Inulin Supplementation Level on Physicochemical Properties of PABP

3.2.1. Rehydration Time and Solubility Index

3.2.2. Pasting Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PABP | Pisang Awak banana powder |

| TD | Tray Drying |

| DD | Drum Drying |

| EBI | Electron Beam Irradiation |

References

- Zhang, S.; Zhao, K.; Xu, F.; Chen, X.; Zhu, K.; Zhang, Y.; Xia, G. Study of Unripe and Inferior Banana Flours Pre-Gelatinized by Four Different Physical Methods. Front. Nutr. 2023, 10, 1201106. [Google Scholar] [CrossRef]

- Moongngarm, A.; Tiboonbun, W.; Sanpong, M.; Sriwong, P.; Phiewtong, L.; Prakitrum, R.; Huychan, N. Resistant Starch and Bioactive Contents of Unripe Banana Flour as Influenced by Harvesting Periods and Its Application. Am. J. Agric. Biol. Sci. 2014, 9, 457–465. [Google Scholar] [CrossRef]

- Brouns, F.; Arrigoni, E.; Langkilde, A.M.; Verkooijen, I.; Fässler, C.; Andersson, H.; Kettlitz, B.; van Nieuwenhoven, M.; Philipsson, H.; Amadò, R. Physiological and Metabolic Properties of a Digestion Resistant Maltodextrin, Classified as Type 3 Retro graded Resistant Starch. J. Agric. Food Chem. 2007, 55, 1574–1581. [Google Scholar] [CrossRef]

- Li, P.; Li, M.; Song, Y.; Huang, X.; Wu, T.; Xu, Z.Z.; Lu, H. Green Banana Flour Contributes to Gut Microbiota Recovery and Improves Colonic Barrier Integrity in Mice Following Antibiotic Perturbation. Front. Nutr. 2022, 9, 832848. [Google Scholar] [CrossRef]

- Han, J.; Wu, J.; Liu, X.; Li, Y.; Song, H.; Zhang, Y.; Lin, Q.; Huang, Y. Physiological Effects of Resistant Starch and Its Applications in Food: A Review. Food Prod. Process. Nutr. 2023, 5, 48. [Google Scholar] [CrossRef]

- Jearviriyaboonya, J.; Jirasatthumb, N. The Study of Competition of Cultivated Banana Producers in Isaan Region: The Case of Sangkom District, Nong Khai Province. J. Bus. Innov. Sustain. 2022, 17, 25–42. Available online: https://so02.tci-thaijo.org/index.php/BECJournal/article/view/243499 (accessed on 21 August 2025).

- Chong, C.W.; Liew, M.S.; Ooi, W.; Jamil, H.; Lim, A.; Hooi, S.L.; Tay, C.S.C.; Tan, G. Effect of Green Banana and Pineapple Fibre Powder Consumption on Host Gut Microbiome. Front. Nutr. 2024, 11, 1437645. [Google Scholar] [CrossRef] [PubMed]

- Sani, M.A.; Velayati, N.; Yazdi, N.B.; Khezerlou, A.; Jafari, S.M. Electron Beam Irradiation: A Non-Thermal Technology for Food Safety and Quality Control. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70205. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Safety and Nutritional Adequacy of Irradiated Food; Technical Report Series No. 659; WHO: Geneva, Switzerland, 1991. [Google Scholar]

- Chung, H.J.; Liu, Q. Effect of Gamma Irradiation on Molecular Structure and Physicochemical Properties of Corn Starch. J. Food Sci. 2009, 74, C353–C361. [Google Scholar] [CrossRef]

- Trinh, K.T.; Nguyen, T.L. Electron Beam Irradiated Maize Starch: Changes in Structural, Physico-Chemical Properties, and Digestibility. Int. J. Adv. Appl. Sci. 2020, 7, 119–124. [Google Scholar] [CrossRef]

- Xue, P.; Zhao, Y.; Wen, C.; Cheng, S.; Lin, S. Effects of Electron Beam Irradiation on Physicochemical Properties of Corn Flour and Improvement of the Gelatinization Inhibition. Food Chem. 2017, 233, 369–377. [Google Scholar] [CrossRef]

- Tappiban, P.; Zhao, J.; Zhang, Y.; Gao, Y.; Zhang, L.; Bao, J. Effects of Single and Dual Modifications through Electron Beam Irradiation and Hydroxypropylation on Physicochemical Properties of Potato and Corn Starches. Int. J. Biol. Macromol. 2022, 220, 1579–1588. [Google Scholar] [CrossRef]

- Hu, B.; Huang, M.; Yin, S.-W.; Zi, M.; Wen, Q.-B. Effects of Electron-Beam Irradiation on Physicochemical Properties of Starches Separated from Stored Wheat. Starch-Stärke 2011, 63, 121–127. [Google Scholar] [CrossRef]

- Wang, G.; Wang, D.; Huang, M. Effect of 10 MeV Electron Beam Irradiation on the Structure and Functional Properties of Wheat Starch. Food Biophys. 2023, 18, 470–477. [Google Scholar] [CrossRef]

- Kananurux, N.; Thongngam, M. Effect of Pregelatinization Processes on Functional Properties of Banana Flour. In Proceedings of the 47th Kasetsart University Annual Conference: Agro-Industry, Bangkok, Thailand, 17–20 March 2009; pp. 743–750. [Google Scholar]

- Roberfroid, M.B. Inulin-Type Fructans: Functional Food Ingredients. J. Nutr. 2007, 137 (Suppl. S11), 2493S–2502S. [Google Scholar] [CrossRef] [PubMed]

- Naknaen, P.; Charoenthaikij, P.; Kerdsup, P. Physicochemical Properties and Nutritional Compositions of Foamed Banana Powders (Pisang Awak, Musa sapientum L.) Dehydrated by Various Drying Methods. Walailak J. Sci. Technol. 2016, 13, 177–191. [Google Scholar] [CrossRef]

- Kale, R.; Kumar, A. Effect of Drying Temperature on Preparation and Quality Evaluation of Raw Banana Powder and Shelf Life. Pharma Innov. J. 2022, 11, 1858–1862. [Google Scholar]

- Amer, B.M.A.; Azam, M.M.; Saad, A.G. Monitoring Temperature Profile and Drying Kinetics of Thin-Layer Banana Slices under Controlled Forced Convection Conditions. Processes 2023, 11, 1771. [Google Scholar] [CrossRef]

- Prangpru, N.; Treeamnuk, T.; Jaito, K.; Vanmontree, B.; Treeamnuk, K. Effect of Temperature on the Physicochemical Properties of Tamarind (Tamarindus indica) Powder. Int. J. Food Eng. 2017, 3, 127–131. [Google Scholar] [CrossRef]

- Leelawat, B.; Thongwattananun, S.; Jaroenjun, N.; Sajjabut, S. Quality Improvement of Boba from Sago Flour Supplemented with Inulin Using Electron Beam. Int. J. Agric. Technol. 2023, 19, 2531–2544. [Google Scholar]

- Malyala, P.; Polamarasetty, V.K.J.R.; Rao, B.; Kuna, A.; Babu, G. The Effects of Spray Drying Conditions on Water Absorption Index, Water Solubility Index, Solubility and Water Activity (aw) of Rice Milk Powder. Int. J. Environ. Clim. Change 2022, 12, 517–529. [Google Scholar] [CrossRef]

- AACC International Method 76-21.01; General Pasting Method Using the Rapid Visco Analyser (RVA). AACC International: St. Paul, MN, USA, 1997.

- ICC Standard No. 162; Rapid Pasting Method Using the Newport Rapid Visco Analyser (Standard 1 Profile). International Association for Cereal Science and Technology: Vienna, Austria, 1996.

- Kusumayanti, H.; Handayani, N.A.; Santosa, H. Swelling Power and Water Solubility of Cassava and Sweet Potatoes Flour. Procedia Environ. Sci. 2015, 23, 164–167. [Google Scholar] [CrossRef]

- Anastasiades, A.; Thanou, S.; Loulis, D.; Stapatoris, A.; Karapantsios, T.D. Rheological and Physical Characterization of Pregelatinized Maize Starches. J. Food Eng. 2002, 52, 57–66. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y.-R. Clean Label Starch: Production, Physicochemical Characteristics, and Industrial Applications. Food Sci. Biotechnol. 2021, 30, 1–17. [Google Scholar] [CrossRef]

- Wiriyawattana, P.; Suwonsichon, S.; Suwonsichon, T. Effects of Drum Drying on Physical and Antioxidant Properties of Riceberry Flour. Agric. Nat. Resour. 2018, 52, 445–450. [Google Scholar] [CrossRef]

- Majzoobi, M.; Radi, M.; Farahnaky, A.; Jamalian, J.; Tongdang, T.; Mesbahi, G. Physicochemical Properties of Pregelatinized Wheat Starch Produced by a Twin Drum Drier. J. Agric. Sci. Technol. 2011, 13, 193–202. [Google Scholar]

- Yadav, A.R.; Guha, M.; Tharanathan, R.N.; Ramteke, R.S. Changes in Characteristics of Sweet Potato Flour Prepared by Different Drying Techniques. LWT–Food Sci. Technol. 2006, 39, 20–26. [Google Scholar] [CrossRef]

- Renjini, A.S.; Subash Chandran, M.P.; Prasobh, G.R.; Akhila, J.B.; Pooja, R.; Sahishna, S.S.A. An Overview on Drying. Int. J. Pharm. Pharm. Res. 2022, 23, 93–108. [Google Scholar]

- Brasoveanu, M.; Nemţanu, M.R.; Duta, D.E. Electron-Beam Processed Corn Starch: Evaluation of Physicochemical and Structural Properties and Technical Economic Aspects of the Processing. Braz. J. Chem. Eng. 2013, 30, 847–856. [Google Scholar] [CrossRef]

- Ma, H.; Liu, M.; Liang, Y.; Zheng, X.; Sun, L.; Dang, W.; Li, J.; Li, L.; Liu, C. Research Progress on Properties of Pre-Gelatinized Starch and Its Application in Wheat Flour Products. Grain Oil Sci. Technol. 2022, 5, 87–97. [Google Scholar] [CrossRef]

- Kocer, E.; Kilic-Akyilmaz, M. Impact of Inulin and Stabilizers on Rehydration, Stability, and Physical Properties after Reconstitution of Yoghurt Powder. J. Food Process. Preserv. 2022, 46, e17001. [Google Scholar] [CrossRef]

- Duangkhamchan, W.; Siriamornpun, S. Improving the Functional and Instantaneous Properties of Pre-Gelatinized Riceberry Powder through Pulsed Fluidized-Bed Agglomeration. Ital. J. Food Sci. 2025, 37, 212–226. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, Health Benefits and Food Applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Xie, Y.; Shao, Y.; Zhang, Y.; Yu, Q.; Yang, X.; Ren, A.; Shang, F. Effects of Inulin Addition on Areca Taro Starch in Terms of Transparency, Freeze–Thaw Stability, Gelatinization Properties, and Rheological Properties. J. Future Foods 2025, in press. [Google Scholar] [CrossRef]

- Ji, X.; Yin, M.; Hao, L.; Shi, M.; Liu, H.; Liu, Y. Effect of Inulin on Pasting, Thermal, Rheological Properties and In Vitro Digestibility of Pea Starch Gel. Int. J. Biol. Macromol. 2021, 193 Pt B, 1669–1675. [Google Scholar] [CrossRef] [PubMed]

- Michalska-Ciechanowska, A.; Majerska, J.; Brzezowska, J.; Wojdyło, A.; Figiel, A. The Influence of Maltodextrin and Inulin on the Physico-Chemical Properties of Cranberry Juice Powders. ChemEngineering 2020, 4, 12. [Google Scholar] [CrossRef]

- González-Tomás, L.; Bayarri, S.; Costell, E. Inulin-Enriched Dairy Desserts: Physicochemical and Sensory Aspects. J. Dairy Sci. 2009, 92, 4188–4199. [Google Scholar] [CrossRef] [PubMed]

- Delgado, P.; Banón, S. Effects of Replacing Starch by Inulin on the Physicochemical, Texture and Sensory Characteristics of Gummy Jellies. CYTA J. Food 2018, 16, 1–10. [Google Scholar] [CrossRef]

| Samples | Rehydration Time (mins) Mean ± SD (n = 2) | Percentage of Maximum Rehydration Time of Control Sample (%) |

|---|---|---|

| PABP-TD (control) | 2.24 ab ± 0.07 | 100.00 |

| PABP-TD2 | 2.23 a ± 0.02 | 99.55 |

| PABP-TD4 | 2.12 c ± 0.05 | 94.64 |

| PABP-TD6 | 2.04 d ± 0.03 | 91.07 |

| PABP-TD8 | 1.53 e ± 0.03 | 68.30 |

| PABP-DD | 2.19 bc ± 0.01 | 97.77 |

| PABP-DD2 | 1.97 d ± 0.04 | 87.95 |

| PABP-DD4 | 1.49 e ± 0.03 | 66.52 |

| PABP-DD6 | 1.38 f ± 0.05 | 61.61 |

| PABP-DD8 | 1.27 g ± 0.03 | 56.70 |

| Drying Process/ Irradiation Dose | Mean ± SD (n = 2) | |||||

|---|---|---|---|---|---|---|

| Peak Viscosity (cP) | Trough Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback | Final Viscosity (cP) | |

| PABP-TD | 1023.14 a ± 17.24 | 976.13 a ± 17.53 | 45.27 d ± 0.86 | 1161.89 a ± 26.93 | 206.11 b ± 4.24 | 6.46 b ± 0.19 |

| PABP-TD 2 kGy | 630.83 c ± 10.98 | 568.18 c ± 23.01 | 70.95 b ± 2.15 | 674.79 c ± 10.53 | 107.26 d ± 2.36 | 5.68 c ± 0.12 |

| PABP-TD 4 kGy | 501.35 d ± 12.28 | 432.09 d ± 11.89 | 70.65 b ± 1.87 | 517.95 d ± 24.01 | 85.79 f ± 2.20 | 5.21 e ± 0.11 |

| PABP-TD 6 kGy | 453.48 e ± 10.23 | 360.31 e ± 8.90 | 79.70 a ± 1.51 | 381.89 f ± 14.66 | 74.61 g ± 1.68 | 5.42 de ± 0.22 |

| PABP-TD 8 kGy | 388.08 f ± 10.17 | 308.62 f ± 5.28 | 77.65 a ± 2.60 | 383.66 f ± 7.74 | 68.70 h ± 1.71 | 5.24 e ± 0.14 |

| PABP-DD | 759.21 b ± 19.66 | 718.49 b ± 15.16 | 39.36 e ± 0.61 | 1128.68 b ± 18.31 | 387.29 a ± 4.09 | 7.03 a ± 0.09 |

| PABP-DD 2 kGy | 309.45 g ± 10.02 | 294.30 f ± 5.79 | 11.12 g ± 0.24 | 419.07 e ± 9.29 | 128.29 c ± 3.68 | 5.59 cd ± 0.10 |

| PABP-DD 4 kGy | 231.60 h ± 6.69 | 208.03 g ± 1.94 | 25.23 f ± 0.29 | 303.78 g ± 5.75 | 95.71 e ± 2.24 | 3.96 f ± 0.13 |

| PABP-DD 6 kGy | 210.26 i ± 1.75 | 167.34 h ± 2.42 | 44.35 d ± 0.51 | 250.66 h ± 5.43 | 79.00 g ± 2.41 | 3.30 g ± 0.05 |

| PABP-DD 8 kGy | 183.04 j ± 6.78 | 131.07 i ± 3.17 | 55.84 c ± 0.74 | 190.10 i ± 3.73 | 58.31 i ± 2.02 | 2.25 h ± 0.05 |

| Samples | Mean ± S.D. (n = 2) | |

|---|---|---|

| Rehydration Time (Min) | Solubility Index (%) 90 °C | |

| PABP-TD 0% | 1.5567 a ± 0.04 | 61.95 i ± 0.90 |

| PABP-TD 2.5% | 1.5367 a ± 0.04 | 66.12 h ± 1.64 |

| PABP-TD 5% | 1.4300 b ± 0.04 | 69.45 g ± 1.75 |

| PABP-TD 7.5% | 1.3500 c ± 0.04 | 72.20 ef ± 1.81 |

| PABP-TD 10% | 1.3267 cd ± 0.03 | 76.60 c ± 1.43 |

| PABP-DD 0% | 1.3167 cd ± 0.04 | 70.49 fg ± 1.13 |

| PABP-DD 2.5% | 1.3033 cde ± 0.04 | 72.93 de ± 1.53 |

| PABP-DD 5% | 1.2867 de ± 0.02 | 74.94 cd ± 0.42 |

| PABP-DD 7.5% | 1.2533 ef ± 0.02 | 81.44 b ± 2.06 |

| PABP-DD 10% | 1.2067 f ± 0.02 | 84.53 a ± 0.46 |

| Drying Process/ Irradiation Dose/% Inulin | Mean ± S.D. (n = 2) | |||||

|---|---|---|---|---|---|---|

| Peak Viscosity (cP) | Trough Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback | Final Viscosity (cP) | |

| PABP-TD 0% | 377.37 a ± 5.74 | 305.68 a ± 4.39 | 75.77 a ± 3.00 | 370.22 a ± 7.63 | 64.69 a ± 4.45 | 5.07 c ± 0.31 |

| PABP-TD 2.5% | 292.52 b ± 1.27 | 251.53 b ± 1.30 | 40.35 c ± 2.33 | 314.28 b ± 5.85 | 64.13 a ± 1.37 | 5.23 c ± 0.14 |

| PABP-TD 5% | 269.11 c ± 3.25 | 239.78 c ± 6.60 | 28.95 d ± 2.64 | 295.12 c ± 3.57 | 61.11 a ± 0.98 | 5.53 b ± 0.07 |

| PABP-TD 7.5% | 249.88 d ± 3.86 | 214.43 d ± 3.68 | 30.32 d ± 1.03 | 270.72 d ± 0.73 | 54.59 b ± 1.44 | 5.74 b ± 0.13 |

| PABP-TD 10% | 221.96 e ± 1.41 | 198.61 e ± 3.63 | 21.82 e ± 3.00 | 251.14 e ± 6.23 | 51.45 b ± 2.51 | 6.00 a ± 0.19 |

| PABP-DD 0% | 177.93 f ± 8.33 | 117.11 f ± 15.00 | 59.96 b ± 7.35 | 173.99 f ± 20.78 | 54.92 b ± 3.96 | 2.19 d ± 0.09 |

| PABP-DD 2.5% | 153.61 g ± 3.93 | 102.60 g ± 4.79 | 55.52 b ± 3.76 | 148.79 g ± 1.61 | 49.89 bc ± 1.61 | 1.79 e ± 0.03 |

| PABP-DD 5% | 139.70 h ± 6.11 | 91.45 h ± 2.32 | 45.86 c ± 1.49 | 140.65 gh ± 2.83 | 46.38 cd ± 1.05 | 1.77 e ± 0.08 |

| PABP-DD 7.5% | 121.44 i ± 3.84 | 85.96 h ± 3.24 | 32.28 d ± 1.06 | 129.30 hi ± 3.96 | 44.24 d ± 3.96 | 2.35 d ± 0.03 |

| PABP-DD 10% | 111.27 j ± 3.07 | 82.94 h ± 3.44 | 21.19 d ± 3.61 | 125.00 i ± 3.84 | 37.46 e ± 3.49 | 1.65 e ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leelawat, B.; Thongwattananun, S.; Jaroenjun, N.; Sajjabut, S. Effects of Inulin Supplementation and Electron Beam Irradiation Assisted with Pregelatinization Process on the Quality of Pisang Awak Banana Powder. Appl. Sci. 2025, 15, 10517. https://doi.org/10.3390/app151910517

Leelawat B, Thongwattananun S, Jaroenjun N, Sajjabut S. Effects of Inulin Supplementation and Electron Beam Irradiation Assisted with Pregelatinization Process on the Quality of Pisang Awak Banana Powder. Applied Sciences. 2025; 15(19):10517. https://doi.org/10.3390/app151910517

Chicago/Turabian StyleLeelawat, Bootsrapa, Samatarn Thongwattananun, Nutwasa Jaroenjun, and Surasak Sajjabut. 2025. "Effects of Inulin Supplementation and Electron Beam Irradiation Assisted with Pregelatinization Process on the Quality of Pisang Awak Banana Powder" Applied Sciences 15, no. 19: 10517. https://doi.org/10.3390/app151910517

APA StyleLeelawat, B., Thongwattananun, S., Jaroenjun, N., & Sajjabut, S. (2025). Effects of Inulin Supplementation and Electron Beam Irradiation Assisted with Pregelatinization Process on the Quality of Pisang Awak Banana Powder. Applied Sciences, 15(19), 10517. https://doi.org/10.3390/app151910517