3. Methodology

3.1. Methodology Structure

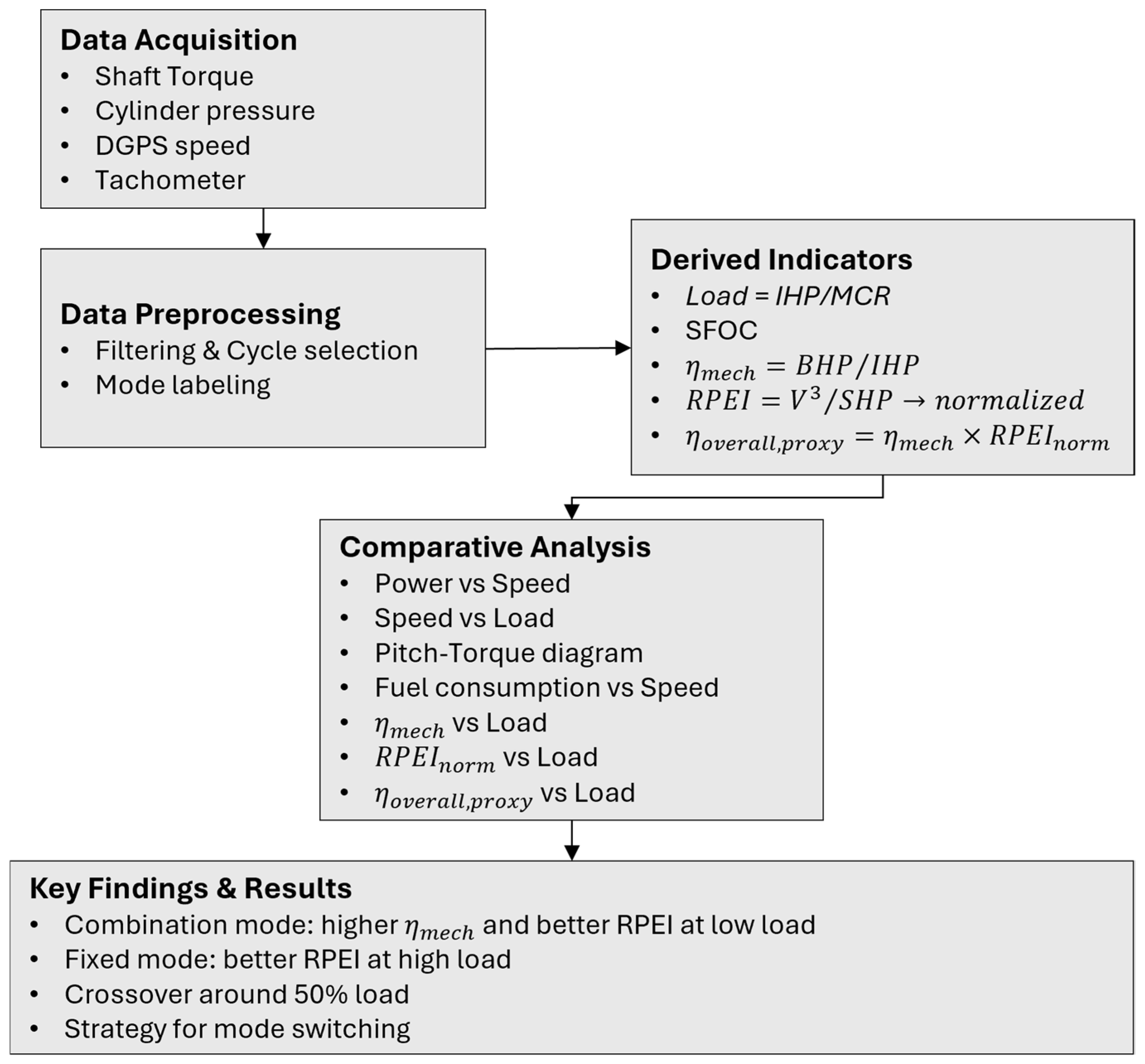

Figure 1 presents the overall research methodology adopted in this study. The process begins with full-scale data acquisition, followed by preprocessing for synchronization and mode labeling. Performance indicators such as load, SFOC, mechanical efficiency, RPEI, and the proxy overall efficiency are then derived. Comparative analyses are conducted across multiple variables, leading to key findings on the efficiency of trade-offs and crossover characteristics between Combination and Fixed modes.

3.2. Data and Methodology

This study investigates the propulsion system with a two-stroke diesel main engine installed on HANNARA training ship of the National Korea Maritime and Ocean University (KMOU). The principal specifications of the system are provided in

Table 2.

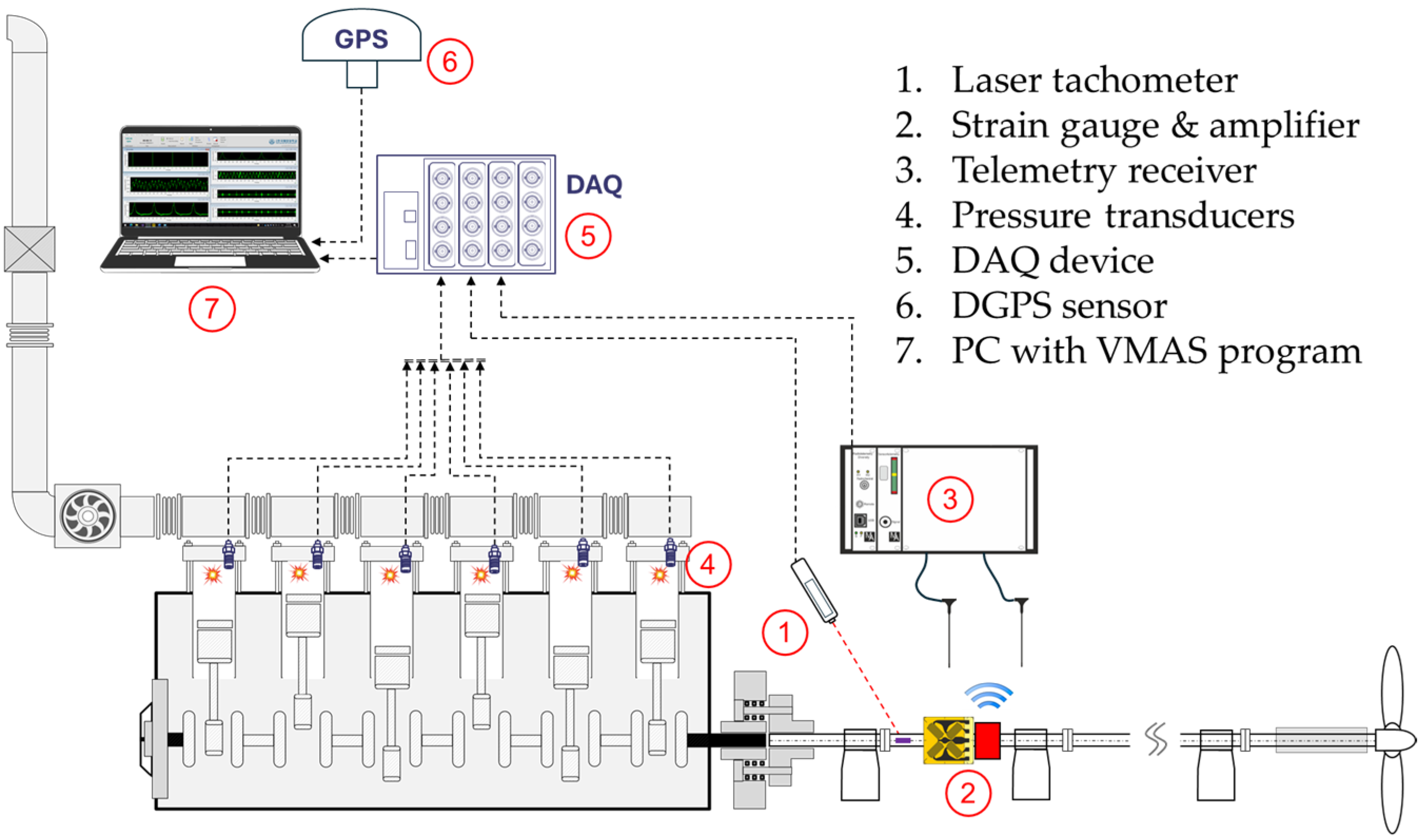

For the purpose of torque and effective power measurements on the intermediate shaft, a full-bridge strain gauge (model CEA-06-250US-350, Micro-Measurements, Wendell, NC, USA) was mounted on the shaft surface. Signal transmission from the strain gauge was achieved using a telemetry system supplied by MANNER Sensortelemetrie(Spaichingen, Germany), consisting of a rotating sensor signal amplifier (model SV_8a) coupled with a stationary receiver unit (model AW_42TE_Fu). The accuracy error is less than . When the uncertainty from strain gauge installation is included, the combined uncertainty is less than 0.36% for a 10 °C temperature variation. To ensure measurement accuracy, the strain gauge system was calibrated using a shunt resistor just before measurements, with the engine in a stopped condition. Cylinder pressure signals were obtained from the main engine’s PMI Controller, which is equipped with an ABB PFPL203 combustion pressure transducer (Zürich, Switzerland) on each cylinder. The transducer calibrated measurement range extends from 0 to 250 bar, with combined measurement errors (including sensitivity drift, linearity deviation, and hysteresis) below .

Ship speed was measured using a DGPS sensor (model JLR-4341, JRC, Tokyo, Japan) installed on the navigation deck. Shaft rotational speed was determined with a laser tachometer (model A2103/LSR/001, Compact Instruments, Lancashire, UK) in conjunction with a reflective tape indicating the top dead center of cylinder No. 1. All measurement signals were synchronously acquired using a data acquisition system (NI-9174 Chassis with NI-9222 modules, National Instruments, Austin, TX, USA), digitized, and processed with VMAS (Vibration Monitoring and Analysis System) program developed by KMOU.

Figure 2 describes the schematic diagram of measurement system. To ensure accurate and reliable detection of all relevant vibration phenomena, a sampling rate of 8192 samples per second was applied.

Using the measured in-cylinder pressure traces, the indicated power (IHP) was computed by evaluating the indicated mean effective pressure (IMEP) for each cylinder, cycle-averaging, and summing across cylinders. Because the propulsion train is a direct-coupled, brake power (BHP) was treated as effectively equal to the shaft horsepower (SHP) obtained from the strain-gauge-derived torque and tachometer RPM, with any minor transmission losses considered negligible within the sensors’ uncertainty.

Cycle-by-cycle measurements were acquired on the training ship under two CPP modes (Combination and Fixed). The dataset analyzed totals 11,378 engine cycles (≈4.10 × 106 crank-angle samples at 360 points per cycle). Operating regimes were classified as LS-LL (<12 kn & <50% load), HS-HL (≥12 kn & ≥50%)

3.3. Performance Indicators

In this study, six performance indicators shown in

Table 3 were established to quantitatively evaluate the operational characteristics of CPP modes. First, the load ratio was defined as the ratio of IHP to the Maximum Continuous Rating (MCR), representing the relative operating condition of the engine. Fuel efficiency was assessed using the Specific Fuel Consumption (SFC), which was estimated based on the reference value of 173.4 g/kWh (at 100% load, Tier II condition) provided in the engine manual, and its variation with load ratio. Accordingly, Fuel Consumption (FC) was calculated by multiplying IHP with the corresponding load-dependent SFC and converting the value into tons per hour.

For efficiency analysis, the mechanical efficiency (ηmech) was defined as the ratio of SHP to IHP, thereby reflecting the actual output efficiency accounting for internal engine losses. Since direct measurement of propulsive efficiency is challenging, a Relative Propulsive Efficiency Index (RPEI) was introduced. Based on the assumption that effective propulsive power is proportional to the cube of ship speed (V3) under identical hull form, draft, and sea conditions, RPEI was defined as V3/SHP, and normalized (RPEInorm) to a median value of one for mode-to-mode comparison. Finally, the proxy overall efficiency (ηoverall,proxy) was defined as the product of ηmech and RPEInorm, and employed as an integrated performance index that simultaneously reflects both engine and propeller efficiencies.

4. Results

4.1. Power vs. Ship Speed

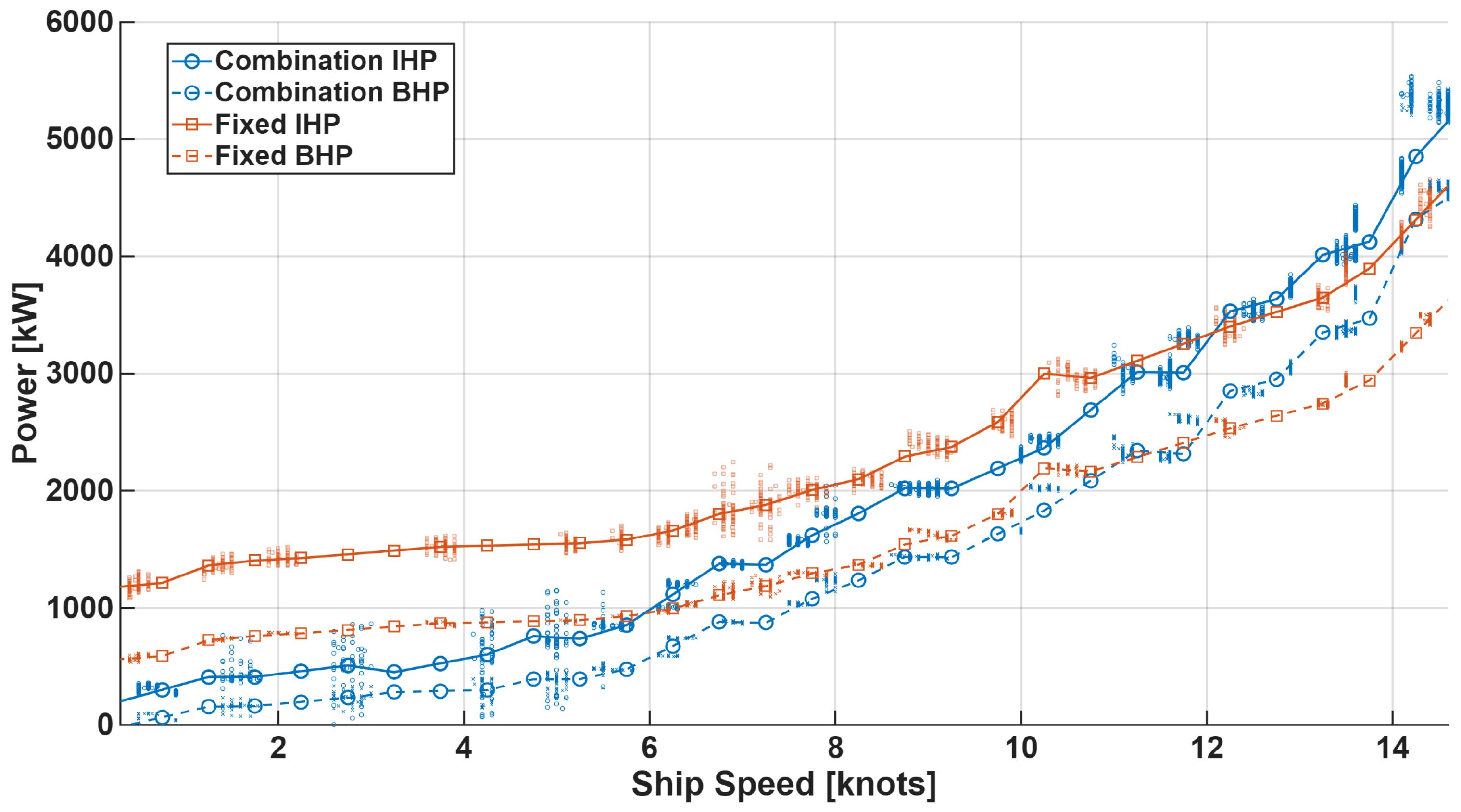

In this study, the IHP and BHP under each operating mode were compared as functions of ship speed.

Figure 3 presents the averaged values, illustrating how power varies with ship speed.

Both IHP and BHP in the Combination and Fixed modes exhibited similar increasing trends across the entire speed range. However, in many cases at the same ship speed, the Fixed mode required higher power (IHP and BHP) than the Combination mode. Notably, in the low-speed region below 12 knots, the power demand of the Fixed mode consistently exceeded that of the Combination mode, whereas above 12 knots this relationship was reversed, with the Combination mode showing higher power demand.

These results suggest that in low-speed and low-load conditions, the Combination mode achieves relatively higher efficiency with reduced power loss, while the Fixed mode requires more power to maintain the same speed. In contrast, in the high-speed region (above 12 knots), the characteristics of the propulsion system and the behavior of the propeller efficiency curve lead to a crossover point where the relative advantage between the two operating modes is reversed.

4.2. Ship Speed vs. Load

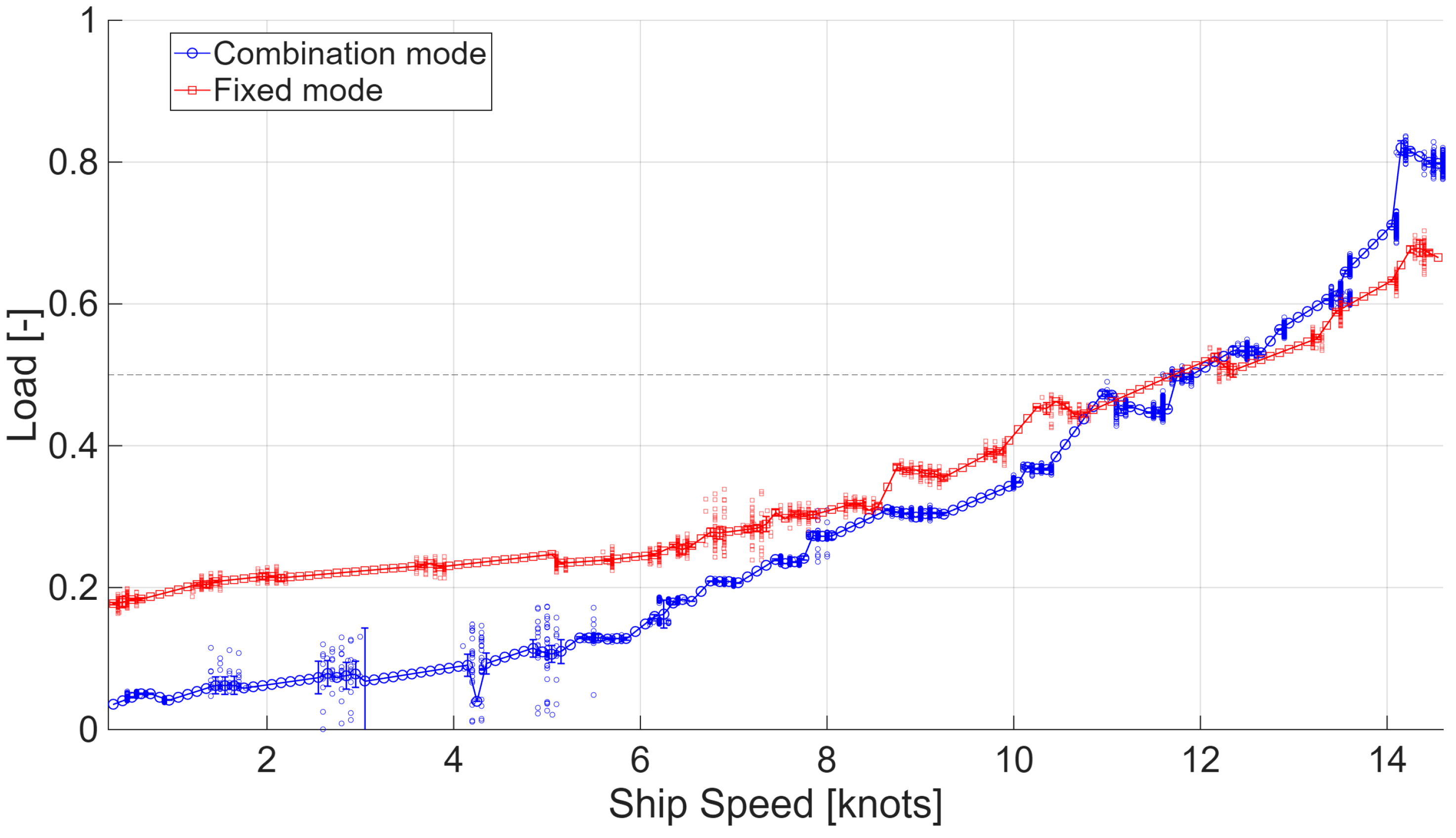

Figure 4 illustrates the relationship between ship speed and engine load under the two operating modes. The analysis revealed a distinct cross-over point between the two modes at approximately 12 knots and 50% load. Below 12 knots, the Combination mode required consistently lower load ratios than the Fixed mode to maintain the same ship speed, indicating an advantage in reducing fuel consumption. For example, at 6 knots, the Combination mode required a load ratio of about 0.15, whereas the Fixed mode demanded approximately 0.25.

In the range of 11–12 knots, the load demands of the two modes converged, forming a cross-over point. Beyond this point (approximately 50% load), as operating conditions shifted toward higher speed and higher load, the Fixed mode exhibited lower load ratios and consequently gained an advantage in terms of fuel efficiency.

This cross-over phenomenon indicates that the Combination mode is more favorable for minimizing fuel consumption in low-speed and low-load conditions, whereas the Fixed mode becomes more economical under high-speed and high-load conditions. Therefore, switching operating modes around 11–12 knots and 50% load could optimize fuel consumption across the entire operating envelope.

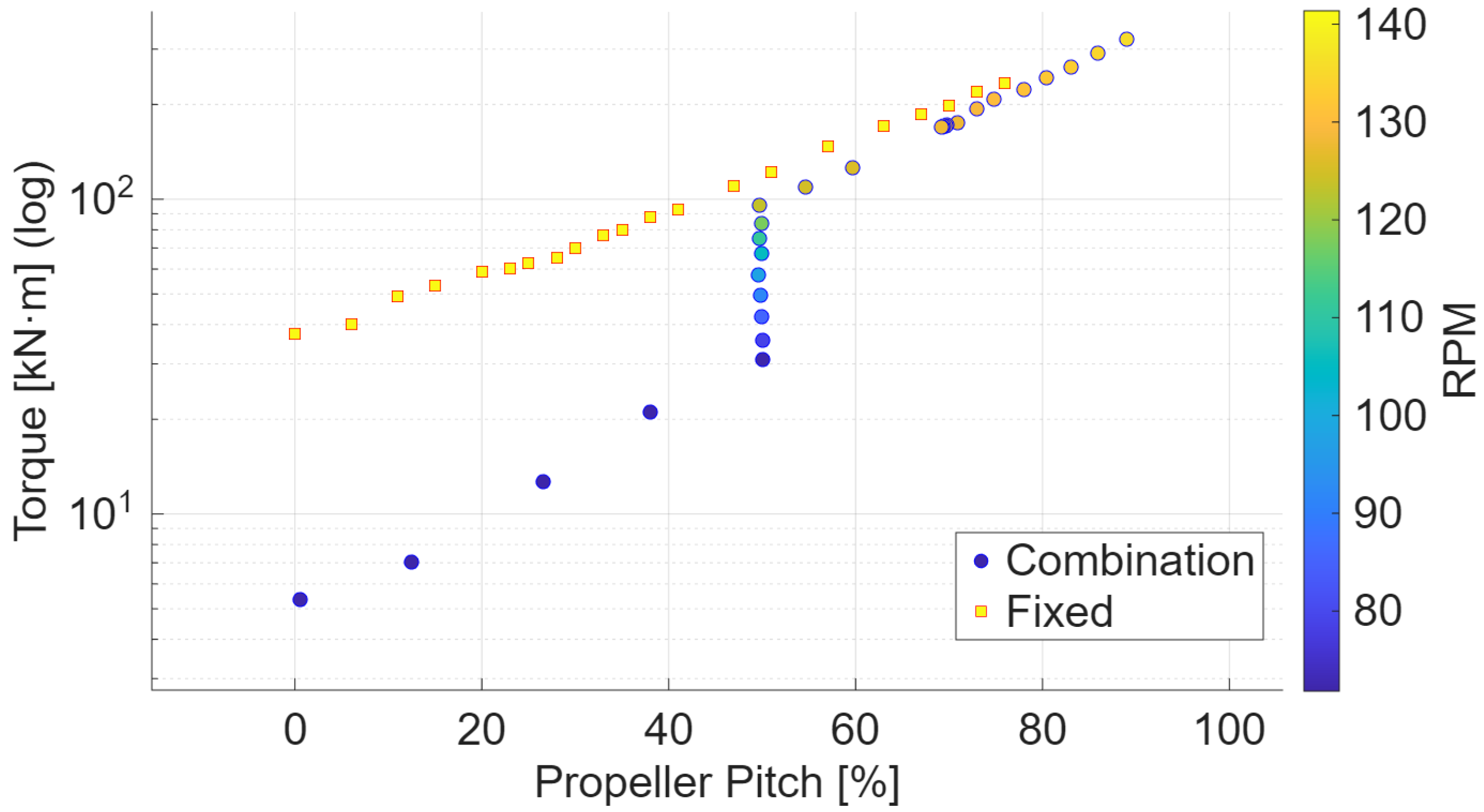

4.3. Pitch–Torque Relationship

Figure 5 presents the relationship between propeller pitch and torque on a logarithmic scale, clearly highlighting the fundamental differences in control characteristics between the two operating modes. The color scale indicates engine RPM, and the analysis confirmed that torque follows a proportional relationship with pitch.

In the Fixed mode, torque was consistently proportional to pitch across the entire range, forming a stable and predictable linear trend. The data distribution was demonstrated the basic principle that torque can be linearly controlled through pitch variation while maintaining a constant engine speed of approximately 140 RPM.

In contrast, the Combination mode exhibited substantial data dispersion in the low-pitch region (20–50%), with a particularly vertical distribution of torque values observed near 50% pitch. This indicates an operating characteristic in which torque is regulated by increasing engine RPM while keeping pitch constant. Specifically, at 50% pitch, torque ranged widely from about 20 kN∙m to 100 kN∙m—more than a fivefold variation—demonstrating the mechanism of adjusting torque and propulsive force by varying engine RPM at a fixed pitch setting. At higher pitch levels (above 50%), the Combination mode converged toward the stable relationship observed in the Fixed mode.

These contrasting control methods distinguish the two modes: the Fixed mode employs a simple and predictable torque control strategy based on constant RPM and pitch variation, whereas the Combination mode allows more flexible control by combining adjustments in both RPM and pitch. The nearly linear trend observed in logarithmic scaling is consistent with the theoretical proportionality law of torque to pitch derived from propeller theory [

18]. This near-proportional pitch–torque trend accords with established propeller open-water characteristics: increasing blade pitch at a given operating condition shifts the operating point toward higher torque/power demand, as documented in standard propeller maps and CPP practice [

25]. The clearer linearity in Fixed mode reflects constant-RPM CPP operation, whereas the wider spread in Combination mode arises from simultaneous changes in RPM and pitch along the combinator schedule, a control behavior reported in CPP literature [

26].

From a practical perspective, the Fixed mode offers predictability and stability, making precise torque management straightforward, while the Combination mode provides superior adaptability to varying operating conditions through its flexible control range. These characteristics help explain the efficiency differences analyzed earlier, illustrating that the multi-variable control of the Combination mode provides opportunities for optimization while simultaneously increasing control complexity.

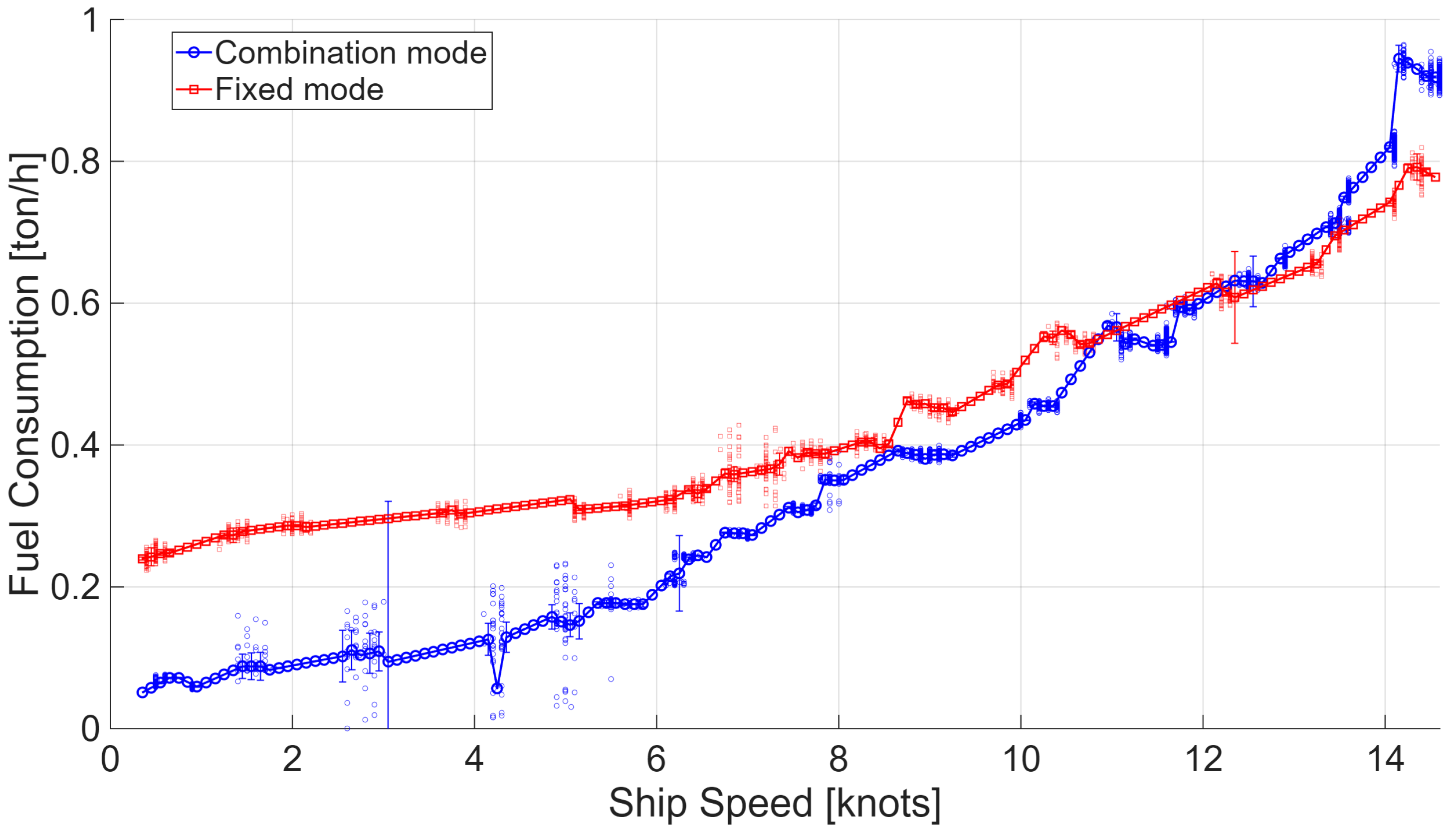

4.4. Relationship Between Ship Speed and Fuel Consumption

To quantify the relationship between ship speed and FC across operating modes, fuel consumption was estimated using the IMO guideline–based SFOC–load correlation. The training ship is equipped with a HYUNDAI–MAN B&W 6S40ME-B9.5-LP SCR two-stroke diesel engine (rated power: 6618 kW at 146 rpm). A baseline SFOC of 173.4 g/kWh at 100% load was adopted and the load-dependent variation was modeled by Equation (1) in accordance with the IMO method [

27,

28]. Because the onboard fuel-flow meter signal could not be time-synchronized with the engine/shaft logs, the resulting FC is interpreted for relative comparisons across modes.

Here, SFOCload denotes the specific fuel oil consumption (g/kWh) at a given load, while load represents the relative engine load (0–1).

Figure 6 illustrates the relationship between ship speed and fuel consumption, where the previously identified cross-over phenomenon is again observed. For interpretability,

Figure 4 reports bin means with 95% confidence intervals, CI (bin width = 0.10 kn); per-bin sample sizes were computed (nonzero bins: Combination median 24, range 1–1723; Fixed median 20, range 1–88), and bins with n < 5 were omitted from CI calculation. In the low-speed range (0–6 knots), the Combination mode achieved superior fuel-saving performance, with consumption levels of approximately 0.05–0.2 ton/h, compared with 0.25–0.3 ton/h in the Fixed mode. This indicates that under low-load and low-speed conditions, the optimized engine–propeller matching of the Combination mode contributes significantly to improved fuel efficiency.

In the medium-speed range (6–11 knots), the difference in fuel consumption between the two modes gradually diminished, converging to nearly identical values around 11 knots, where a clear cross-over point was observed.

In the high-speed range (12–15 knots), the relationship was reversed. The Combination mode exhibited a sharp increase in fuel consumption due to its control strategy prioritizing higher speed through greater engine output and RPM, whereas the Fixed mode demonstrated a relatively moderate rate of increase as pitch variation was the primary control mechanism.

Overall, the Combination mode provided an average fuel-saving effect of about 54% in low-load and low-speed operations, demonstrating superior fuel efficiency. In the intermediate load and speed range, the difference between the two modes was marginal, allowing for flexible mode selection based on combined consideration of mechanical and propulsive efficiencies. At high load and high speed, however, the Combination mode’s focus on speed maintenance led to steep increases in fuel consumption, while the Fixed mode secured better economy through its relatively moderate growth in consumption. Based on these results, the Fixed mode is considered more economical for long-distance, high-speed voyages, whereas the Combination mode is more suitable for low-speed cruising and port entry/exit operations where fuel savings are critical. In the 4–5 knot region, the Combination mode curve shows a temporary decrease in fuel consumption, followed by a recovery toward the general trend. This anomaly is more likely associated with transient operating conditions or limited measurements at very low speeds, rather than a true reduction in steady-state fuel consumption. Therefore, this local fluctuation should be interpreted with caution.

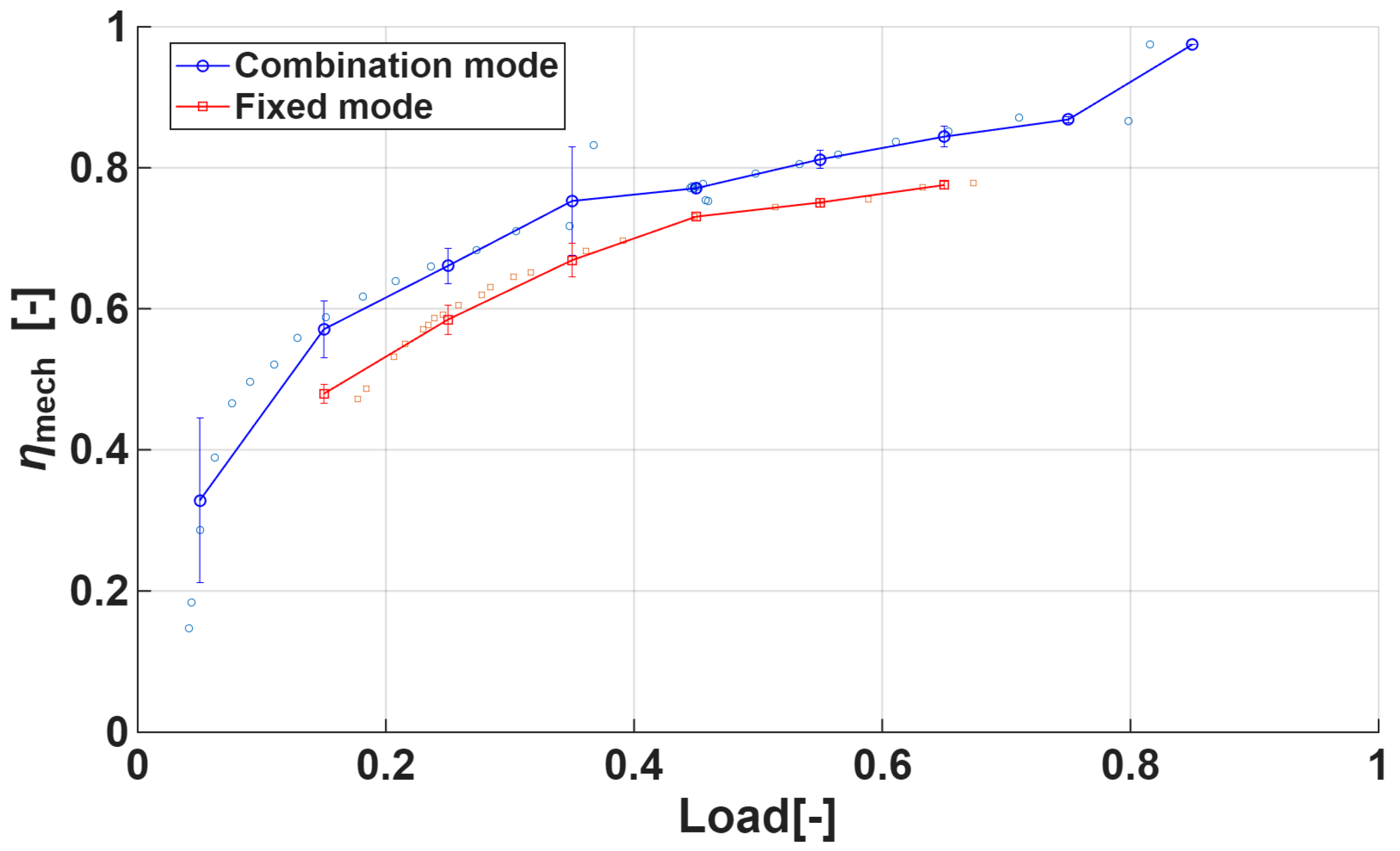

4.5. Mechanical Efficiency vs. Load

The comparison of engine mechanical efficiency (

ηmech) across load ratios revealed that the Combination mode consistently achieved higher efficiency than the Fixed mode over the entire load range, as shown in

Figure 7. On average, the Combination mode exceeded the Fixed mode by about 7–15 percentage points, with the performance gap gradually narrowing at higher loads. Nevertheless, across all operating conditions, the Combination mode demonstrated superior mechanical efficiency.

These findings suggest that the Combination mode is effective in minimizing mechanical losses and enabling the engine to operate closer to its optimal operating points by adjusting both RPM and propeller pitch simultaneously. In contrast, the Fixed mode, with its constant RPM constraint, shows limited adaptability to load variations, resulting in overall lower mechanical efficiency.

4.6. Analysis of the Relative Propulsive Efficiency Index (RPEI)

For a given ship, when hull form, draft, and sea conditions are assumed to remain constant, the effective horsepower (EHP) is approximately proportional to the cube of the ship speed, as expressed below [

29]:

where

k is a proportional constant that can be cancelled out when the same resistance conditions are assumed across different operating modes. Accordingly, the propulsive efficiency can be expressed as Equation (3) [

29]:

Since

k is identical under the assumption of equal resistance conditions between operating modes, propulsive efficiency is thus proportional to the cube of ship speed and inversely proportional to shaft power:

Because direct calculation of propulsive efficiency from operational data is difficult, this study introduces the Relative Propulsive Efficiency Index (

RPEI), newly defined as:

For comparability across datasets, the

RPEI was normalized by the overall median value, ensuring that the median equals unity:

Here, the median (RPEI) denotes the cycle-weighted median evaluated on the pooled dataset (Combination and Fixed), using the number of cycles per record as weights to preserve comparability across modes.

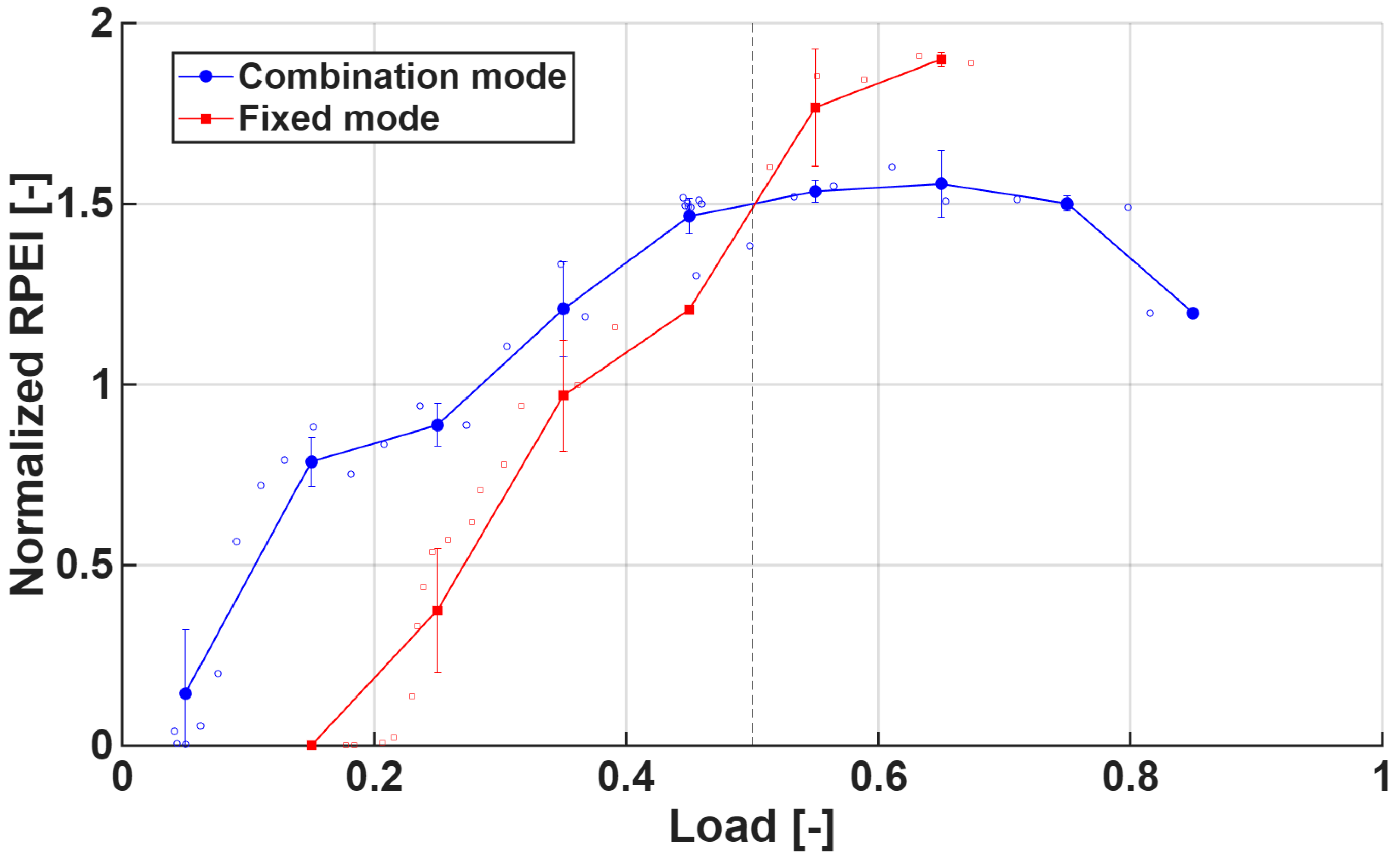

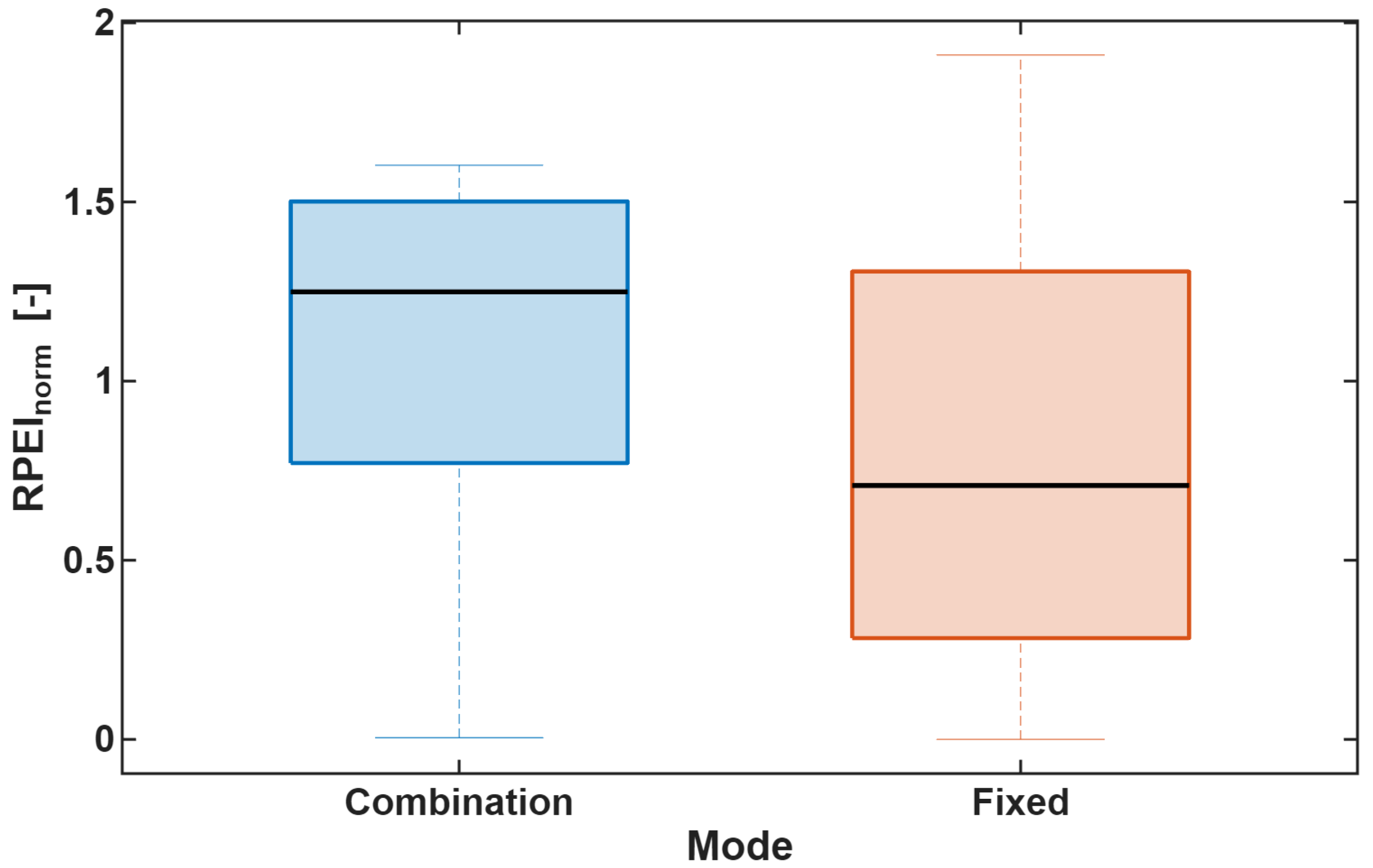

Figure 8 shows that the two operation modes exhibit distinct trends in

RPEInorm as a function of load.

Figure 8 displays all raw observations together with bin means and 95% CI (bin width = 0.10). A clear crossover point occurs at approximately 0.5 load, where both modes reach an

RPEInorm of about 1.5. Prior to this point, the Combination mode demonstrates a relatively gradual increase in

RPEInorm, rising from 0.1 to 1.5, whereas the Fixed mode shows a much steeper increase, quickly catching up to the Combination mode. Beyond the crossover, the two modes diverge again: the Combination mode maintains its

RPEInorm near 1.5 and then gradually declines, while the Fixed mode continues to increase, exceeding 1.5 and reaching its peak performance at higher loads.

Therefore, the load ratio of 0.5 can be identified as a turning point: the Combination mode is more economical in low-load conditions, whereas the Fixed mode demonstrates superior propulsive efficiency under high-load conditions. It should be noted, however, that the data density around the 0.48–0.52 load range is relatively sparse, with only a few observations anchoring the crossover region. As such, the exact value of the turning point should be interpreted with caution and regarded as an indicative range rather than a precise threshold.

The box plot of

Figure 9 illustrates the distribution of

RPEInorm under the Combination and Fixed modes. The median value of the Combination mode was approximately 1.25, significantly higher than that of the Fixed mode (about 0.75). This indicates that half of the observations in the Combination mode exceeded 1.25, suggesting superior overall propulsive efficiency compared with the Fixed mode.

In terms of the interquartile range (IQR), the Combination mode exhibited a narrower and more stable spread (0.8–1.5), whereas the Fixed mode showed a wider variability (0.4–1.3). This demonstrates that under similar load conditions, efficiency variations were larger in the Fixed mode than in the Combination mode.

The whiskers also highlight distinct characteristics between the two modes. While the Combination mode had a minimum value close to zero, its maximum extended to about 1.6, reflecting low efficiency under very low load but stable high efficiency at medium to high loads. By contrast, the Fixed mode also had a minimum near zero but extended to a maximum of around 1.9, indicating the potential for achieving higher efficiency at high loads, albeit with greater variability.

In terms of symmetry and variability, the Combination mode displayed relatively balanced quartile distributions and few outliers, reflecting stable operational efficiency. The Fixed mode, however, exhibited an asymmetric distribution with a longer lower-quartile span and multiple outliers, indicating greater efficiency fluctuations with changing operating conditions.

Overall, the Combination mode provides consistently higher and more stable efficiency across the full load range, making it more suitable for low- to mid-load operations where fuel economy is critical. The Fixed mode, on the other hand, can achieve peak efficiency values up to 1.9 but frequently exhibits lower efficiency and larger variability at low loads, suggesting that it is more appropriate for operations under sufficiently high load conditions.

4.7. Overall Efficiency Proxy

By combining mechanical efficiency with the normalized propulsive efficiency, a proxy indicator was defined to approximate the relative overall efficiency of the propulsion system under actual operating conditions, as shown in Equation (7):

The

RPEI introduced in this study serves as a physical indicator for relative comparison of propulsive performance between operating modes when direct thrust measurement is not feasible, using only ship speed and shaft power data. By normalizing RPEI to a median value of unity, differences between modes can be intuitively interpreted as deviations above or below the central reference. When combined with

ηmech, the proxy overall efficiency reflects both engine-side losses and propeller performance, providing a comprehensive measure of propulsion efficiency across a wide range of operating conditions. This composite is interpreted as a first-order separable index; it aggregates engine-side efficiency (

ηmech) with a propulsive proxy (

RPEInorm) without asserting independence beyond the observed range.

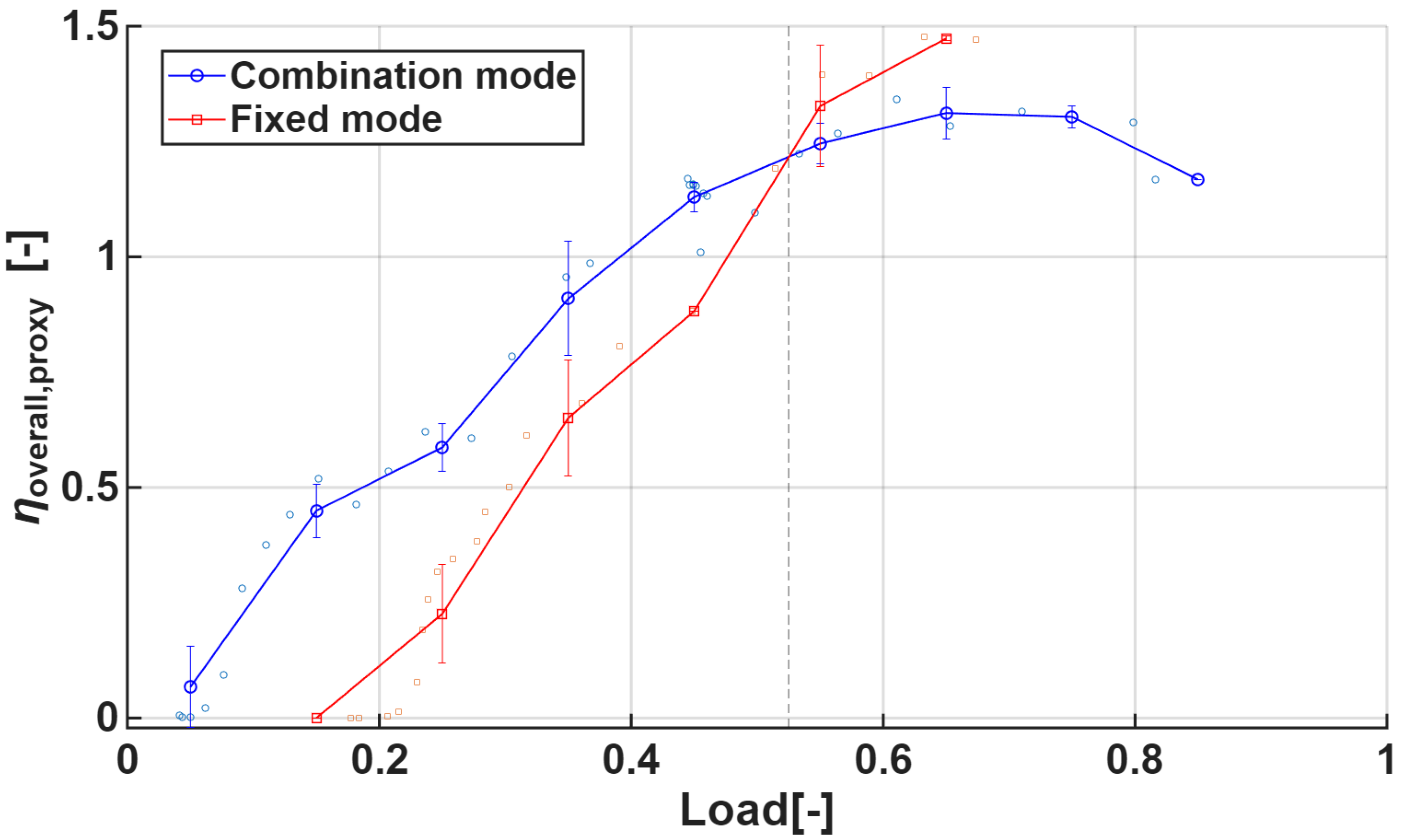

Figure 9 displays all raw observations (faint) together with bin means and 95% confidence intervals (bin width = 0.10); bins with n < 5 were omitted. Accordingly, the mid-load crossover is presented as an indicative range rather than a single point.

The graph in

Figure 10 reveals a critical cross-over point at a load ratio of 0.525, which carries significant implications for ship propulsion system design and operational optimization. Below this threshold, the Combination mode demonstrates clear superiority. In this region, its overall proxy efficiency rises steeply from about 0.05 to 1.25, while the Fixed mode begins near zero and increases only gradually. This indicates that engine–propeller matching is more effectively optimized in the low-load range under the Combination mode.

The advantage of the Combination mode at low loads arises from its ability to adjust both engine RPM and propeller pitch simultaneously. This dual adjustment enables the engine to maintain an optimal RPM–torque balance while the propeller is set to an appropriate pitch angle, collectively achieving high mechanical and propulsive efficiency.

The cross-over point at a load ratio of 0.525 represents a critical threshold where the efficiency characteristics of the two operating modes fundamentally shift. At this point, both modes converge to an overall efficiency of approximately 1.25, reflecting a balance between their distinct optimization mechanisms. The convergence near this threshold highlights the interplay of trade-offs: in the Combination mode, mechanical efficiency remains high but its slope begins to decline, whereas in the Fixed mode, mechanical efficiency remains relatively lower but the RPEI slope rises sharply, offsetting the difference.

Beyond the 0.525 load ratio, the Fixed mode surpasses the Combination mode and sustains higher efficiency. The Fixed mode continues to rise, reaching a peak of about 1.5, while the Combination mode attains a maximum of around 1.3 before declining beyond a load ratio of 0.8. Consistent with these conventions, the crossover near ~0.5 load should be interpreted as an indicative range due to limited samples.

This reversal phenomenon is attributed to the propeller optimization effect in the high-load region. In the fixed mode, the engine speed remains constant, and as the load increases, the propeller pitch also increases, allowing the propeller to operate closer to its optimum operating condition, thereby maximizing propulsive efficiency under high-load conditions. In contrast, the combination mode is primarily focused on engine optimization, which leads to a gradual decline in propeller–engine matching efficiency in the high-load range.

5. Discussion and Conclusions

This study compared and analyzed the combination mode and fixed mode of CPP using actual ship operating data, focusing on mechanical efficiency (ηmech), propulsive efficiency (RPEInorm), and fuel consumption. The findings shed light on the dual optimization challenge in marine propulsion system design.

First, the combination mode consistently maintained higher ηmech across all load ranges by following an “engine-prioritized optimization” strategy. Particularly under low-load and low-speed conditions (ship speed < 12 knots, load < 50%), it achieved superior RPEInorm and reduced fuel consumption. This demonstrates that combination mode can enhance both economic and environmental performance in coastal navigation, port entry/exit, and low-speed cruising, where simultaneous adjustment of engine RPM and propeller pitch minimizes internal engine losses and secures favorable speed-to-power ratios.

Second, the fixed mode, following a “propeller-prioritized optimization” strategy, outperformed the combination mode in high-load and high-speed conditions. By keeping engine RPM constant and adjusting only the pitch, the fixed mode secured better RPEInorm and fuel efficiency once the load exceeded ~50% (corresponding to ~12 knots). Beyond this crossover point, the system gains more from optimizing propeller performance, even if engine efficiency is partially sacrificed. Thus, fixed mode proves more advantageous for long-distance voyages or sustained high-speed cruising. At high loads, the Fixed mode appears to operate closer to a favorable region of the propeller’s open-water characteristics; however, without open-water curves or direct thrust measurements we cannot quantify the optimal advance or thrust coefficients. We therefore treat this as indicative and plan to obtain thrust data to derive these coefficients at the crossover.

Although the analysis is based on a two-stroke diesel paired with a four-bladed CPP, the qualitative pattern—combination favored at low-speed/low-load and fixed favored at high-speed/high-load—is expected to hold for other CPP-equipped ships, while the critical speed point (crossover) is parameter-dependent. Variations in CPP geometry and control law (e.g., pitch-to-diameter ratio, expanded area ratio, blade number) and in ship condition (e.g., draft/displacement and cargo capacity) can shift the operating point and thereby shift the crossover without overturning the overall trend.

Third, the efficiency patterns of the two modes highlight the trade-off between engine and propeller optimization in propulsion system design. Combination mode ensures consistently higher mechanical efficiency but sacrifices propeller efficiency at high loads, whereas fixed mode maximizes propeller performance in heavy-load conditions at the expense of engine efficiency. This finding underscores that no single efficiency indicator is sufficient to determine the optimal design point; rather, operating profiles must guide a context-dependent optimization strategy.

Fourth, the proposed proxy overall efficiency (

ηoverall,proxy), defined as the product of

ηmech and

RPEInorm, offers a useful integrated metric for evaluating propulsion performance. This indicator can support real-time optimization and control algorithms, enabling adaptive switching between modes based on operating conditions. Using 50% load and 12 knots as a reference point, operators could dynamically choose between combination and fixed mode to maximize overall voyage efficiency. The formulation of the RPEI in this study assumes constant hull form, draft, and sea conditions, applying the conventional relation EHP∝

V3 that is widely used in efficiency analyses and preliminary power prediction methods [

9,

21]. In practice, however, propulsion power typically scales with

V3∼4 [

29], and factors such as biofouling, hull roughness, trim or draft variation, and added resistance in waves are known to increase effective resistance and required power [

22,

23,

24]. These nonlinear effects are especially pronounced at low speeds, where viscous and wave-making components may deviate from ideal scaling. Although hull-cleaning records and sea-state logs were unavailable in the present dataset, future work should integrate such auxiliary information to conduct sensitivity analyses, thereby strengthening the robustness and real-time applicability of the

RPEI.

Furthermore, we acknowledge that the proxy overall efficiency index (ηoverall,proxy) has not been directly validated against thrust-based propulsion efficiency due to the absence of propeller thrust measurements in the present dataset. While this indicator is useful as a relative measure when only engine and shaft data are available, the lack of empirical validation remains a limitation.

Finally, several limitations and directions for future research are noted. Incorporating draft, sea state, and thrust measurements will allow a more precise evaluation of true propulsive efficiency. since this analysis was limited to a single vessel and CPP system, broader studies across diverse ship types and propeller designs are necessary. To validate the applicability of the proposed real-time mode-switching strategy, follow-up studies should include simulation-based verification and full-scale sea trials.

Quantitative assessment of the crossover’s sensitivity to draft/displacement and cargo capacity—and its dependence on CPP specifications—remains a key next step for external validation across different ship types and propeller designs.

In conclusion, this study emphasizes the importance of mission- and profile-specific optimization in marine propulsion system design. By quantifying the trade-off between combination and fixed mode, it provides practical insights for enhancing both fuel economy and compliance with environmental regulations. Furthermore, the findings lay a foundation for the development of intelligent control and automation technologies for future propulsion systems. Building on these results, we now outline the principal limitations of the present work and the corresponding directions for future research.

This study adopts the constant-resistance assumption in the RPEI formulation and lacks direct thrust and open-water propeller data, so propeller operating coefficients could not be quantified. The mid-load transition (~0.5–0.525 load) is supported by relatively few observations and should be interpreted as an indicative range. The analysis is limited to a single vessel and CPP configuration. Future work will incorporate thrust sensing and open-water/CFD characterization to benchmark the proxy metric, collect denser measurements around the transition, log fouling, draft/trim, sea state and wave-added resistance for corrections, extend the analysis to multiple ship types and CPP designs, and validate a closed-loop mode-switching controller in sea trials with fuel and emissions tracking.