Experimental Study on Water Reduction of Grouting Slurry by Ultrasonic

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

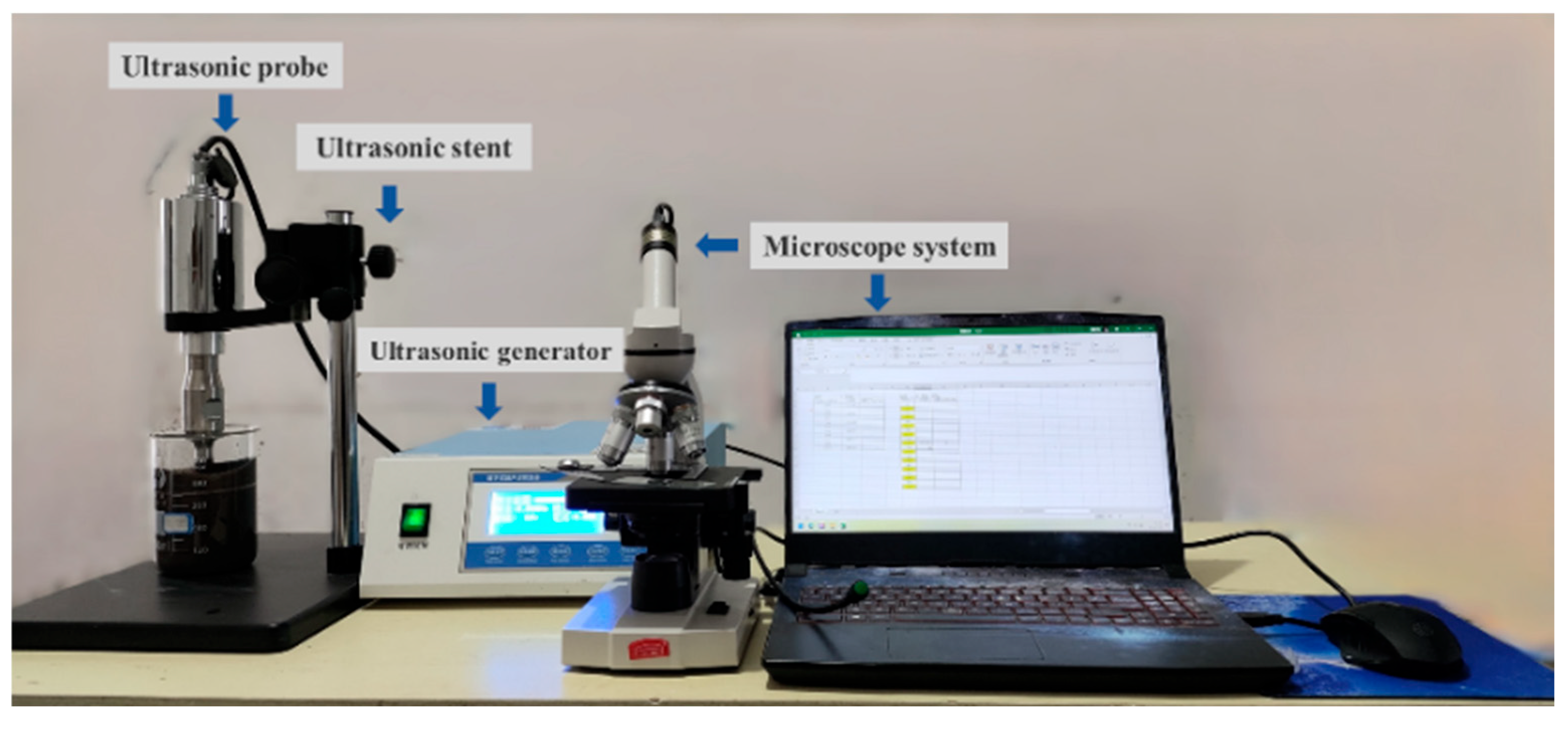

2.2. Equipment

2.3. Experimental Scheme

2.4. Test Method

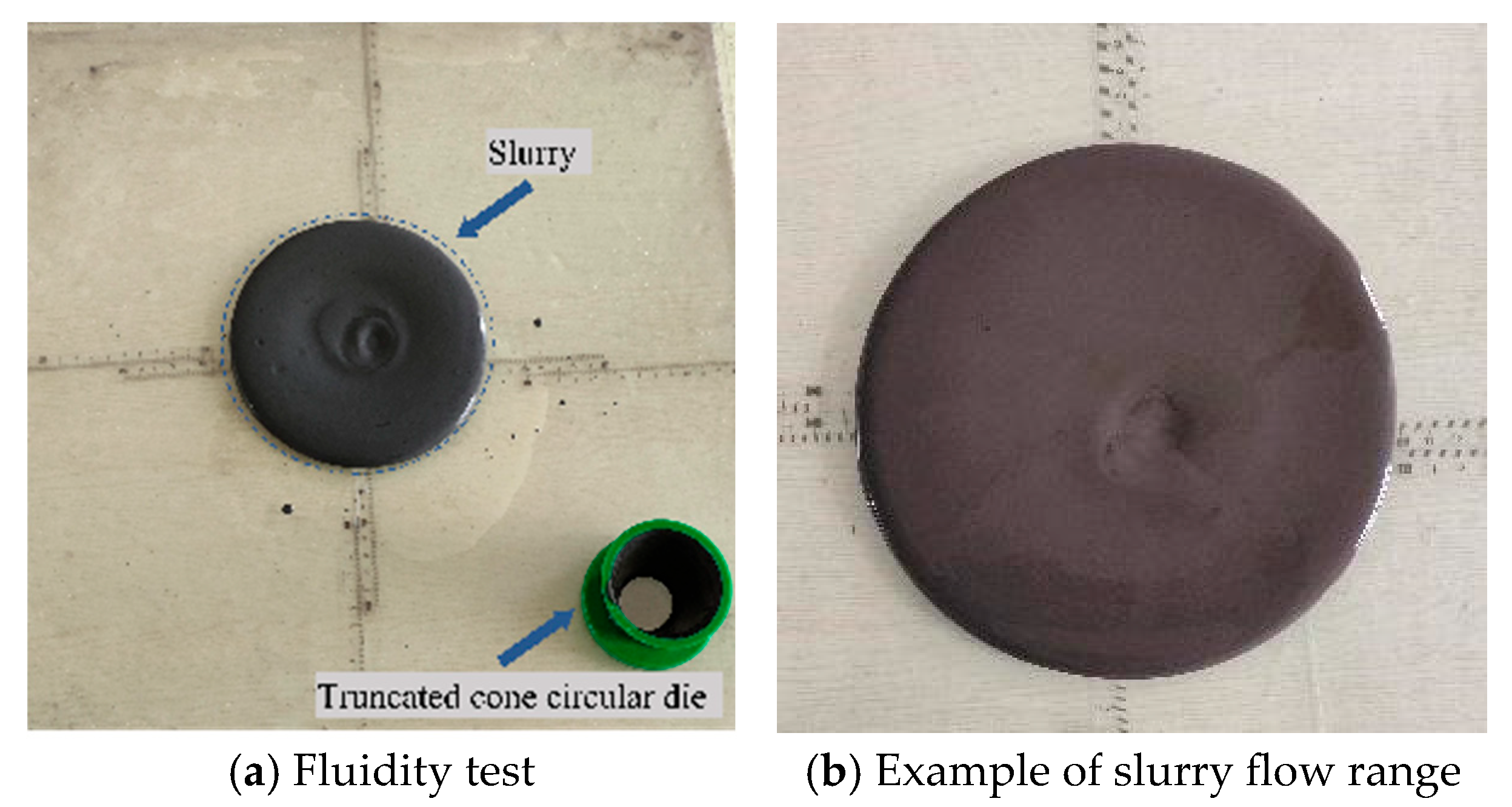

2.4.1. Fluidity Test

2.4.2. Microscopic Imaging Detection

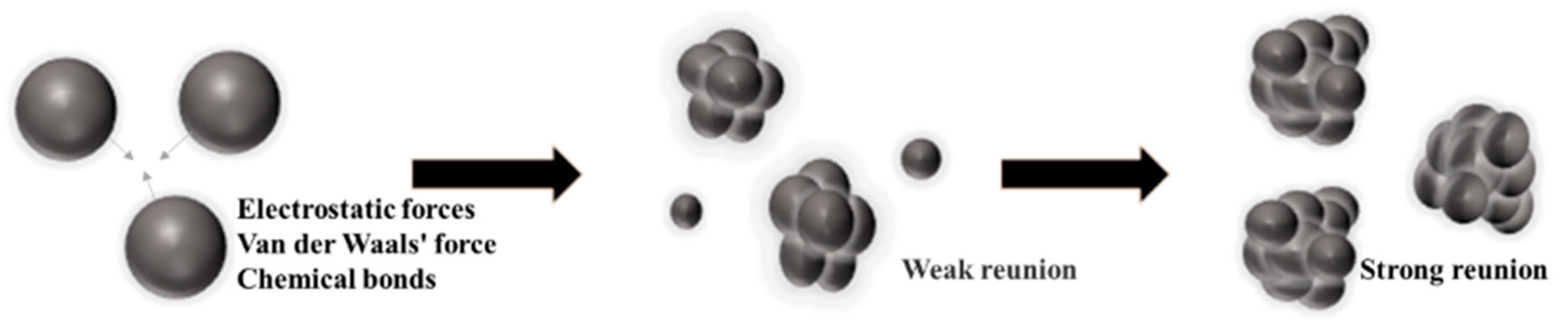

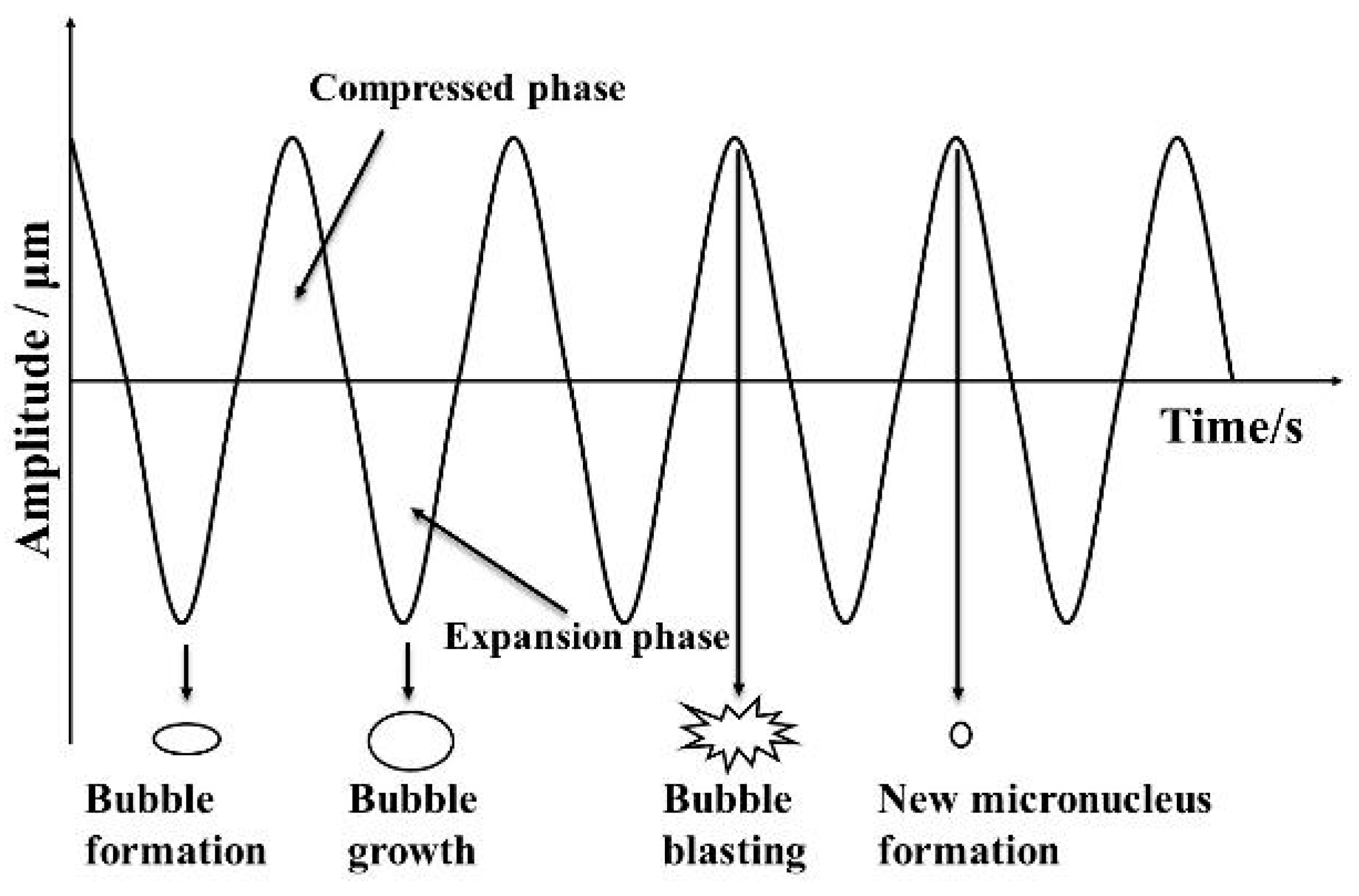

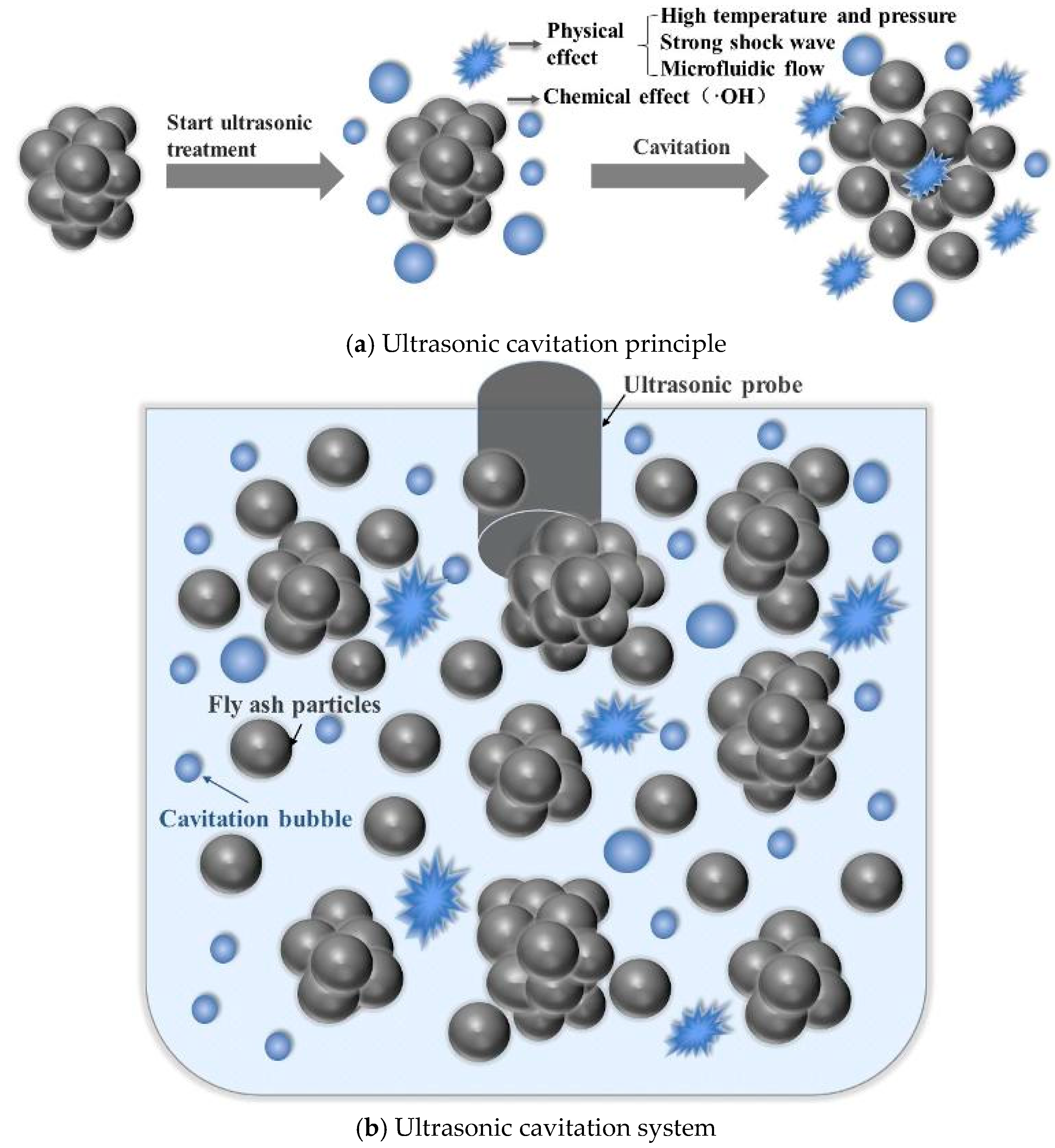

3. Mechanism of Water Reduction by Ultrasonic Pulping

4. Experimental Results and Discussion

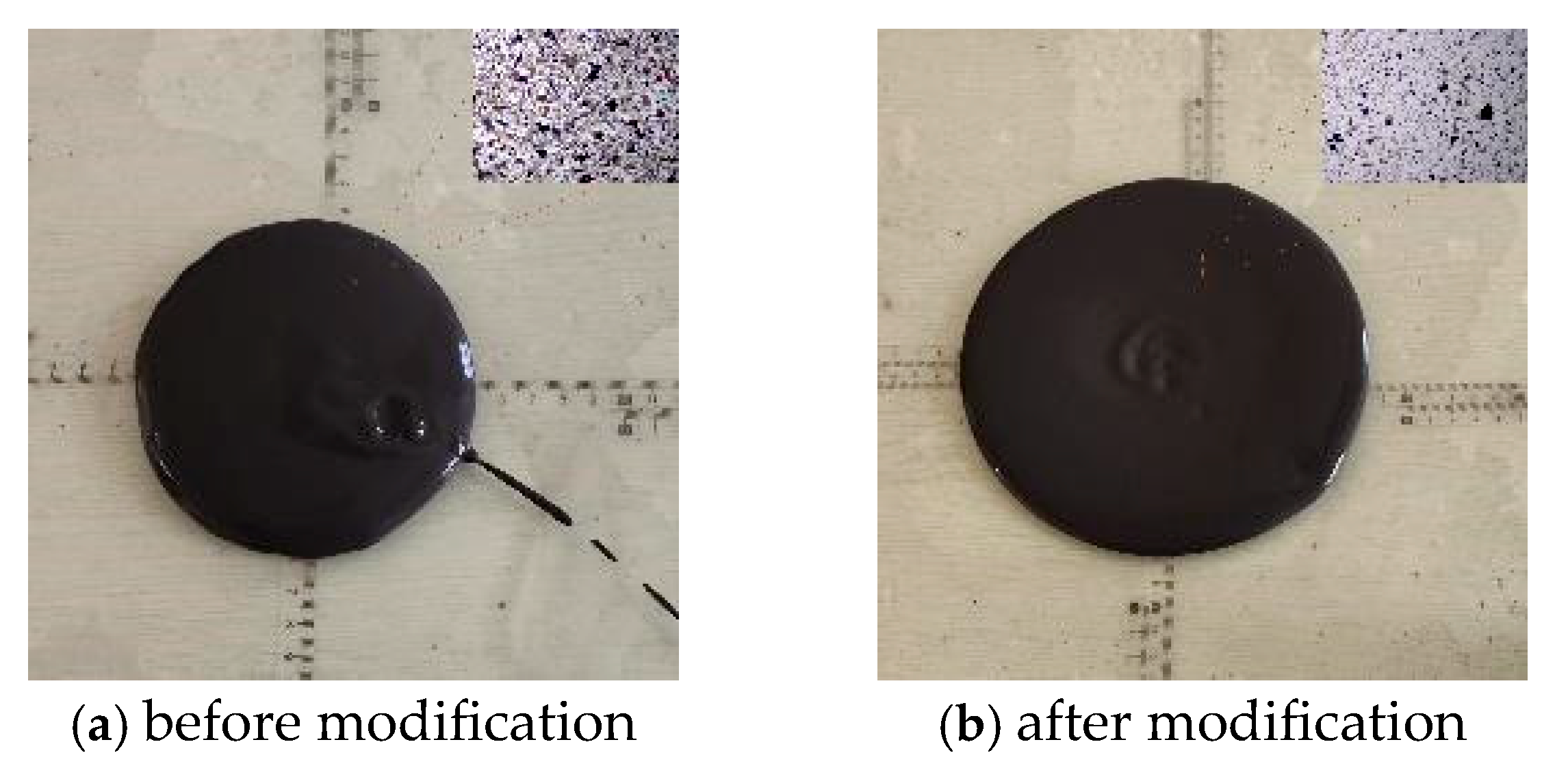

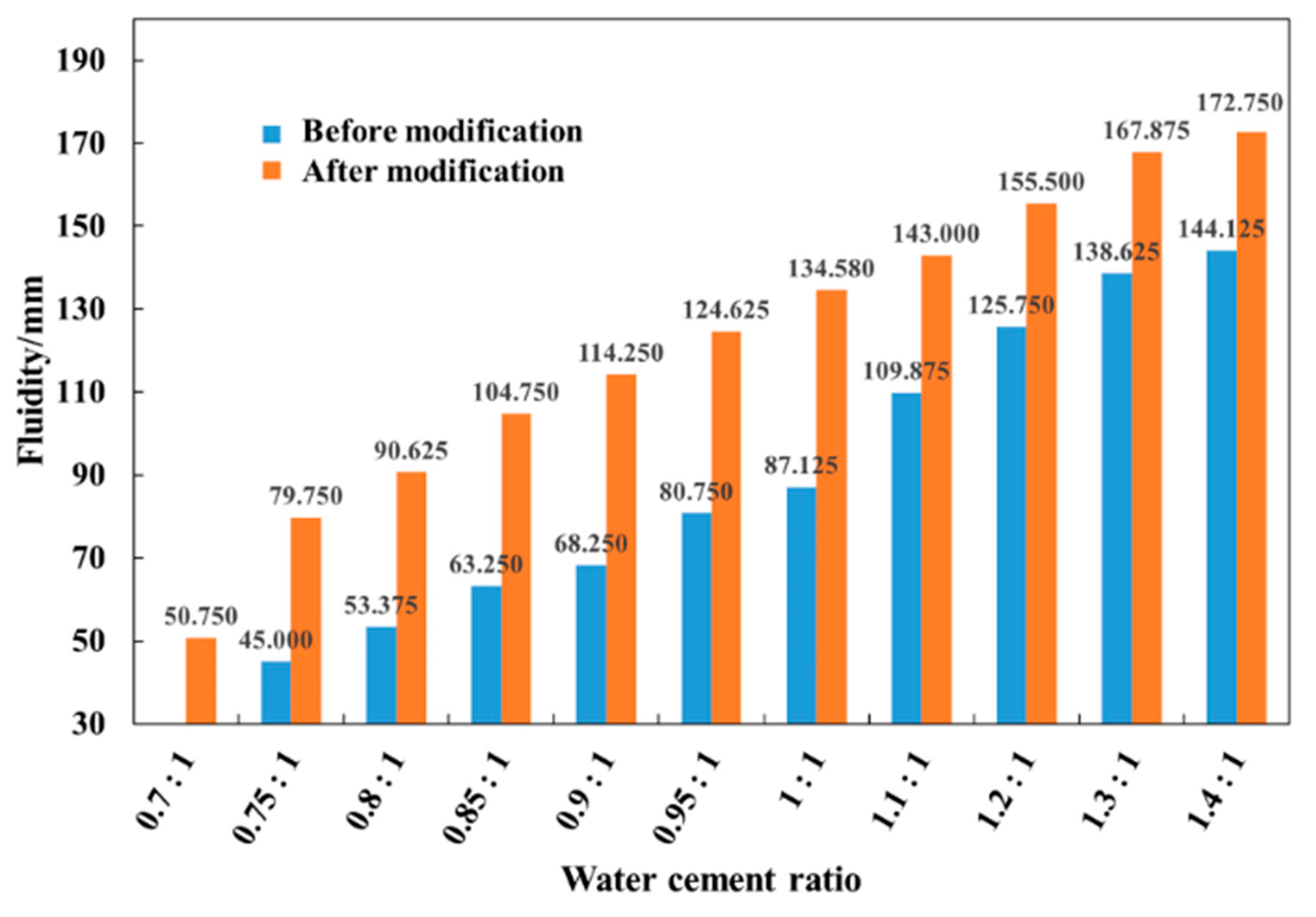

4.1. The Impact of Ultrasonic Action on the Properties of Slurry

4.2. Influence of Ultrasonic Parameters on Slurry Properties

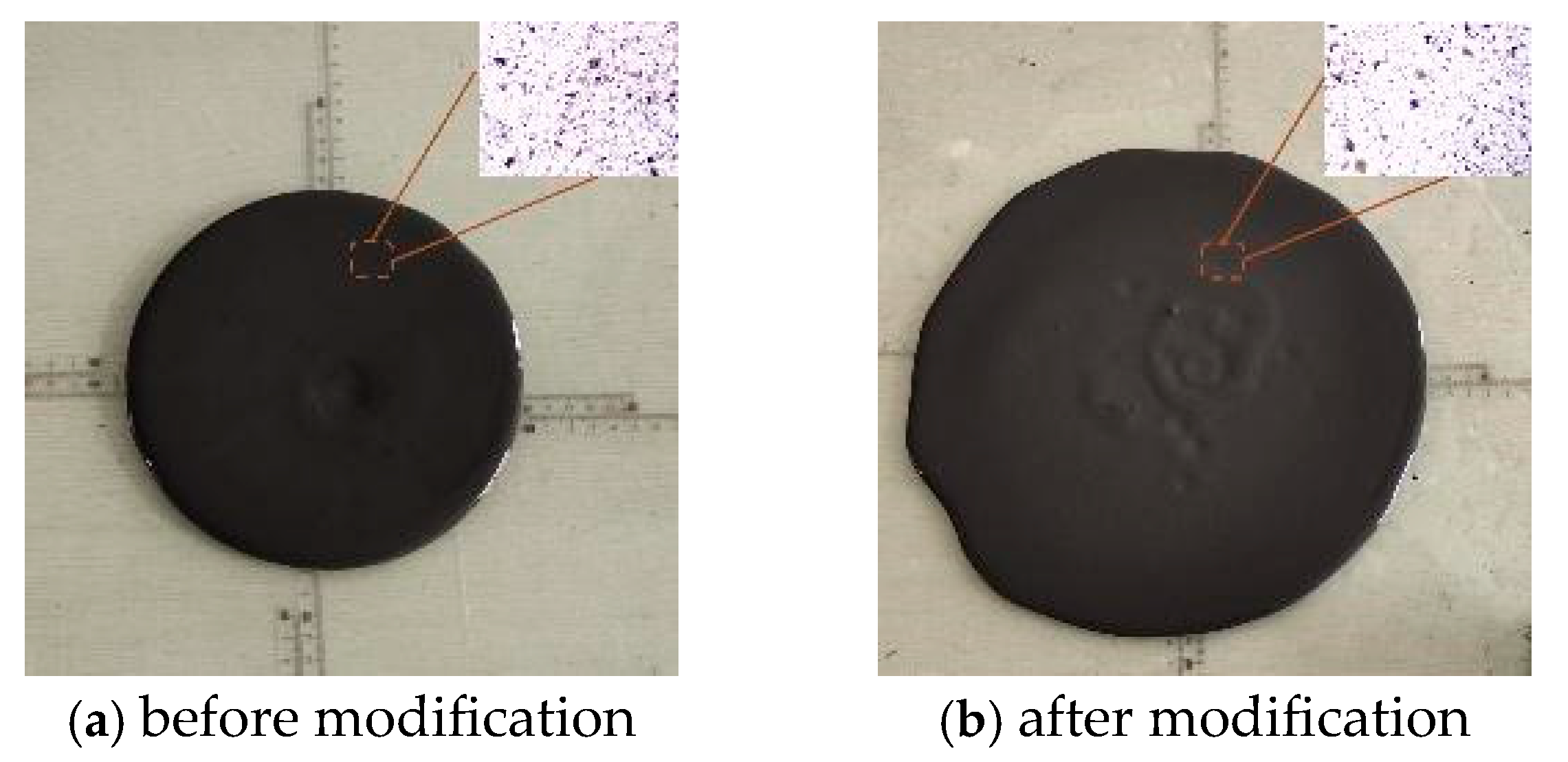

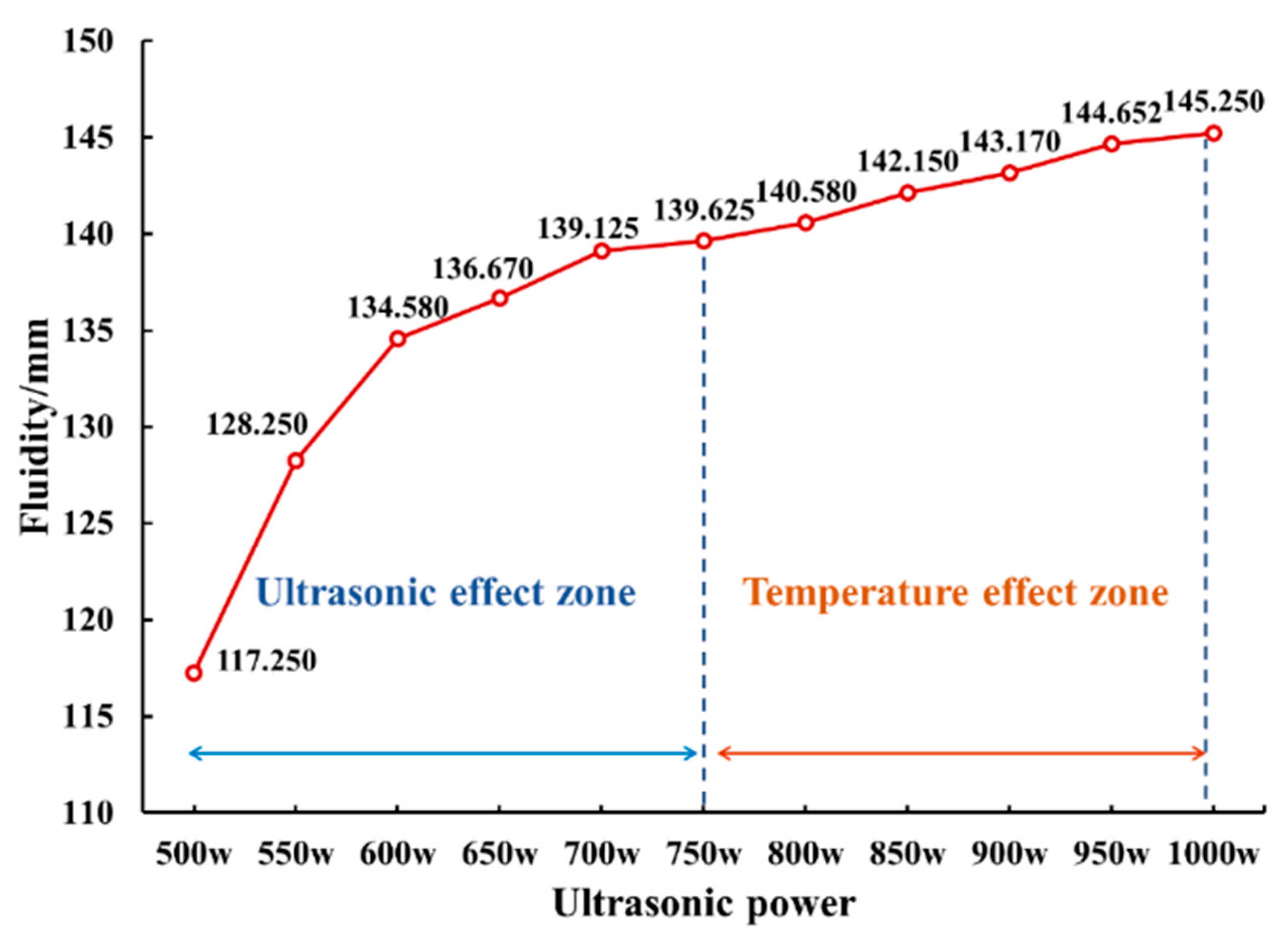

4.2.1. Influence of Ultrasonic Power

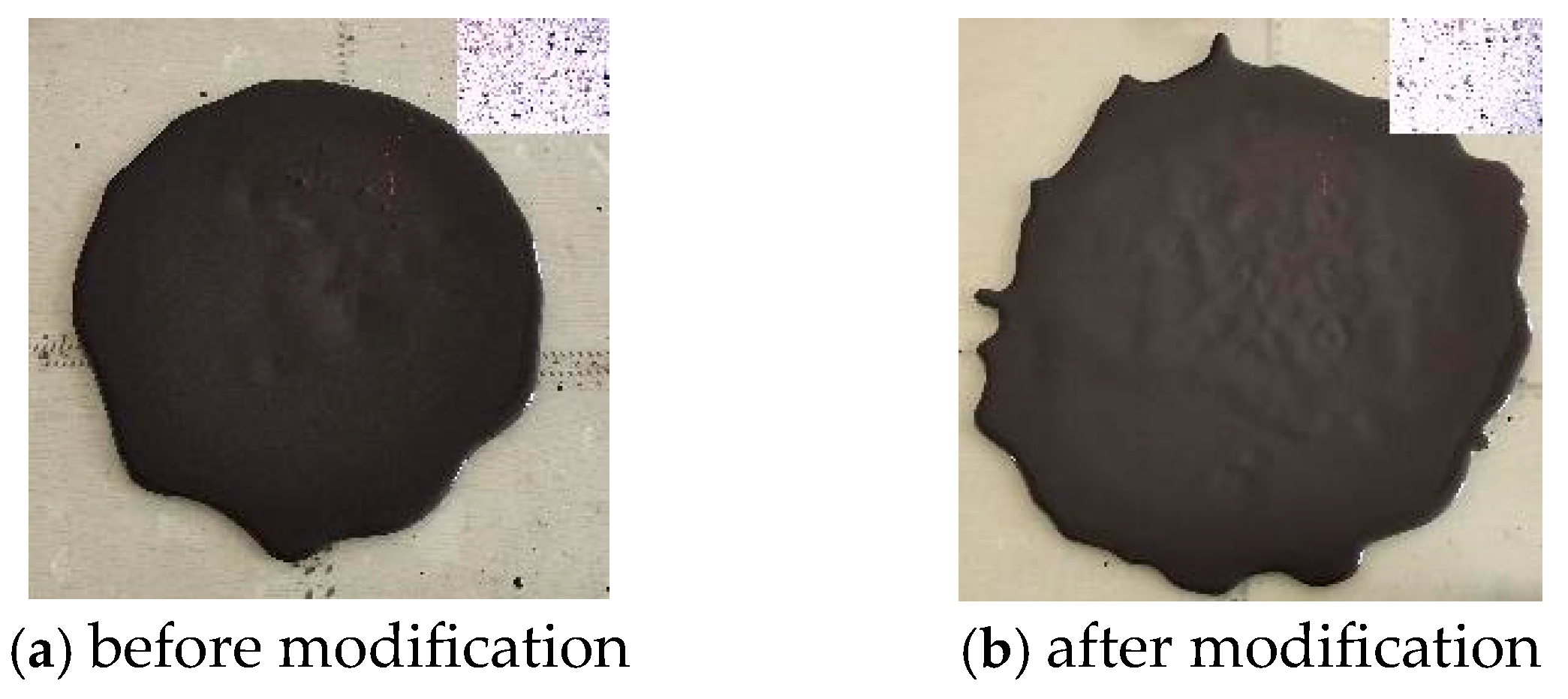

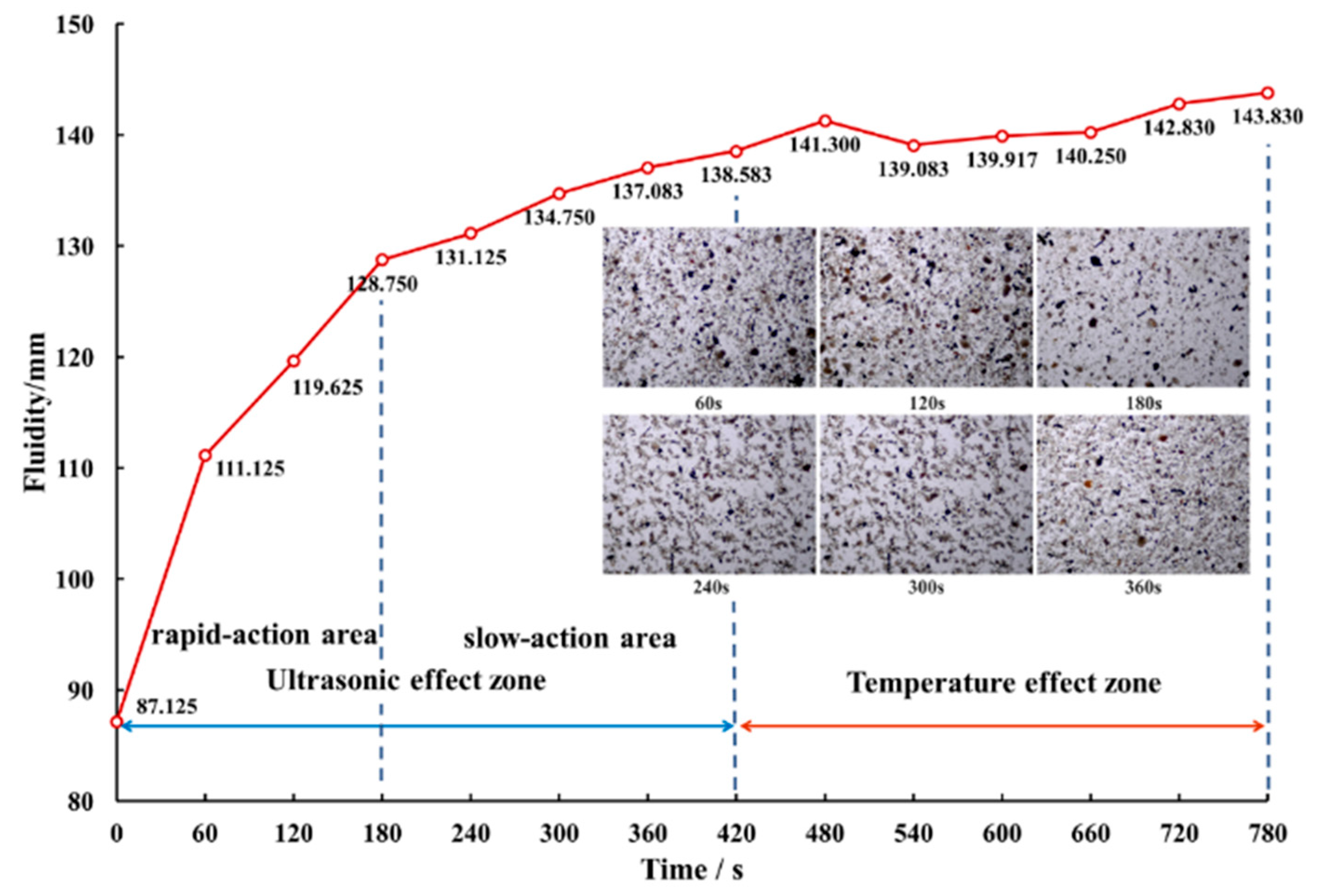

4.2.2. Influence of Ultrasonic Duration

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Ni, J.; Xuan, D. Coal mining technology without village relocation by isolated grout injection into overburden. Coal Sci. Technol. 2015, 43, 8–11. [Google Scholar]

- Xuan, D.; Xu, J. Longwall surface subsidence control by technology of isolated overburden grout injection. Int. J. Min. Sci. Technol. 2017, 27, 813–818. [Google Scholar] [CrossRef]

- Li, T. Mining Practice of Isolated Grouting and Filling Under Railway Tunnel in Yangquan Mining Area. Saf. Coal Mines 2020, 51, 155–158. [Google Scholar]

- Xu, J.; Xuan, D.; Zhu, W. Partial backfilling coal mining technology based on key strata control. J. Min. Strat. Control Eng. 2019, 1, 69–76. [Google Scholar]

- Ni, J. Study on mechanism of disaster reduction under extremely-thick igneous rock by isolated grouting in Huaibei Mining Area. Coal Sci. Technol. 2017, 45, 55–59. [Google Scholar]

- Xu, J.; Qin, W.; Xuan, D. Accumulative effect of overburden strata expansion induced by stress relief. J. China Coal Soc. 2020, 45, 35–43. [Google Scholar]

- Guan, X.; Zhong, Q. Research on the Performance of Micro-fine Cement-based Grouting Material and Its Engineering Application. Saf. Coal Mines 2013, 44, 142–145. [Google Scholar]

- Zhang, L.; Xu, J.; Xuan, D. Experimental research on slurry bleeding properties of isolated grouting filling for overburden. China Coal 2017, 43, 121–124, 129. [Google Scholar]

- Zhang, L.; Xu, J.; Xuan, D. Experimental and applied research on compression properties of slurry used for isolated overburden grout injection. J. China Coal Soc. 2017, 42, 1117–1122. [Google Scholar]

- Ma, C.; Xuan, D.; Xu, J. Experimental study on water reduction and modification of filling slurry by isolated grouting in overlying strata. J. Min. Saf. Eng. 2023, 40, 1122–1128. [Google Scholar]

- Fan, L. Scientific connotation of water-preserved mining. J. China Coal Soc. 2017, 42, 27–35. [Google Scholar]

- Che, Q.; Du, S.; Zhang, D. Advancements in end treatment techniques and applications of acid mine drainage in coal mines. Coal Sci. Technol. 2024, 52, 339–351. [Google Scholar]

- Qin, W.; Xu, J.; Xuan, D. Research on technology and economic evaluation of coal mine green mining. J. Min. Saf. Eng. 2023, 40, 1092–1101. [Google Scholar]

- Wang, S.; Duan, Z.; Ma, L. Research status and future trends of geological assurance technology for coal green development in Western China. Coal Sci. Technol. 2019, 47, 1–6. [Google Scholar]

- Chen, L.; Lu, D.; Wang, Y. Research and application of ultrasonic technology in mineral flotation and development trend. Chin. J. Nonferrous Met. 2021, 31, 1042–1056. [Google Scholar]

- Chen, X. Design of multipoint coal flow monitoring system of belt conveyor based on ultrasonic. Ind. Mine Autom. 2017, 43, 75–78. [Google Scholar]

- Wang, X.; Niu, Z.; Zhang, L. Research progress and prospects of ultrasonic vibration in coal rock fracturing. Coal Sci. Technol. 2024, 52, 232–243. [Google Scholar]

- Xu, C.; Ma, J.; Mao, Y. Research on Motion Characteristics of Jig Buoy Based on High Precision Sensor Design. Coal Sci. Technol. 2024, 43, 259–263. [Google Scholar]

- Shi, Q.; Qin, B.; Sun, Y. Ultrasound-assisted leaching of calcium ions from fly ash to mineralize CO2 and fire extinguishing characteristics of products. J. China Coal Soc. 2025, 50, 1034–1046. [Google Scholar]

- Chen, J.; Guo, Z.; Liu, G. Rheological properties of cassava starch treated by ultrasonic. J. Fujian Agric. For. Univ. (Nat. Sci. Ed.) 2013, 42, 86–92. [Google Scholar]

- Li, W.; Zheng, J.; Chen, Y. Effect of ultrasound treatment on pasting, rheological and textural properties of pea starch. Food Mach. 2018, 34, 32–37. [Google Scholar]

- He, S.; Chen, G.; Zhong, Z. Effect of ultrasonic dispersion on evenness and properties of aramid 1313 paper. Pap. Pap. Mak. 2015, 34, 38–42. [Google Scholar]

- Hou, J.; Zhu, X.; Long, J. Research on Property of Near-spherical Silver-coated Copper Powder Prepared by Ultrasonic Dispersion. Hot Work. Technol. 2017, 46, 126–129. [Google Scholar]

- Shao, X. The Experimental Research for Micro Movement Characteristics of Cement Grout in Sandy Soil. Master’s Thesis, Hua Qiao University, Xiamen, China, 2018. [Google Scholar]

- Zhang, Y.; Chen, L.; Chun, H. Effect of ultrasonic pretreatment on flotation saparation of spodumene ore. Chin. J. Nonferrous Met. 2024, 34, 586–597. [Google Scholar]

- GB 18599-2020; Standard for Pollution Control on the Non-Hazardous Industrial Solid Waste Storage and Landfill. Ministry of Ecology and Environment of the People’s Republic of China and State Administration for Market Regulation: Beijing, China, 2020.

- Xu, J. Experimental Study on Characteristics of Gangue Powder Grouting Filling Material. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- GB/T 8077-2023; Methods for Testing Uniformity of Concrete Admixture. State Administration for Market Regulation and National Standardization Administration: Beijing, China, 2023.

- Zhu, J.; Hui, J.; Luo, H. Effects of polycarboxylate superplasticizer on rheological properties and early hydration of natural hydraulic lime. Cem. Concr. Compos. 2021, 122, 104052. [Google Scholar] [CrossRef]

- Cheng, C.; Li, Y.; Zhang, Z. Study on agglomeration phenomenon and regulation method of lithium carbonate crystal prepared from potassium carbonate. Inorg. Chem. Ind. 2024, 56, 47–54. [Google Scholar]

- Sen, T.K.; Mesfin, Y.A.; Jafary, T. Municipal sewage sludge dewatering performance enhancement by ultrasonic cavitation and advanced oxidation: A case study. Water Sci. Technol. 2024, 89, 2593–2604. [Google Scholar] [CrossRef]

- He, W.; Lu, B.; Shi, W. Enhanced permeation effect of fine-grained tailings by ultrasound cavitation. China Saf. Sci. J. 2024, 34, 91–100. [Google Scholar]

- Li, T.; Liu, J. Dynamic Behavior of Ultrasonic Cavitation Bubble in Silver Melt. Spec. Cast. Nonferrous Alloys 2024, 44, 776–781. [Google Scholar]

- Kannoto, S.; Yoshizawa, S. Effect of intended shift in propagation direction of cavitation generation position on coagulation position in bubble-enhanced ultrasonic heating. Jpn. J. Appl. Phys. 2024, 63, 3. [Google Scholar] [CrossRef]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Zou, S.; Zhou, W.; Huang, Y.; Shao, L.; Yuan, J.; Gou, X.; Jin, W.; Wang, Z.; Chen, X.; et al. Clinically applicable histopathological diagnosis system for gastric cancer detection using deep learning. Nat. Commun. 2020, 11, 4294. [Google Scholar] [CrossRef] [PubMed]

| Number | Water Cement Ratio | Ultrasonic Power/w | Ultrasonic Time/min |

|---|---|---|---|

| 1 | 0.7:1 | 600 | 5 |

| 2 | 0.75:1 | 600 | 5 |

| 3 | 0.8:1 | 600 | 5 |

| 4 | 0.85:1 | 600 | 5 |

| 5 | 0.9:1 | 600 | 5 |

| 6 | 0.95:1 | 600 | 5 |

| 7 | 1:1 | 600 | 5 |

| 8 | 1.1:1 | 600 | 5 |

| 9 | 1.2:1 | 600 | 5 |

| 10 | 1.3:1 | 600 | 5 |

| 11 | 1.4:1 | 600 | 5 |

| Number | Ultrasonic Time/min | Water Cement Ratio | Ultrasonic Power/w |

|---|---|---|---|

| 1 | 1 | 1:1 | 600 |

| 2 | 2 | 1:1 | 600 |

| 3 | 3 | 1:1 | 600 |

| 4 | 4 | 1:1 | 600 |

| 5 | 5 | 1:1 | 600 |

| 6 | 6 | 1:1 | 600 |

| 7 | 7 | 1:1 | 600 |

| 8 | 8 | 1:1 | 600 |

| 9 | 9 | 1:1 | 600 |

| 10 | 10 | 1:1 | 600 |

| 11 | 11 | 1:1 | 600 |

| 12 | 12 | 1:1 | 600 |

| 13 | 13 | 1:1 | 600 |

| Number | Ultrasonic Power/w | Water Cement Ratio | Ultrasonic Time/min |

|---|---|---|---|

| 1 | 500 | 1:1 | 5 |

| 2 | 550 | 1:1 | 5 |

| 3 | 600 | 1:1 | 5 |

| 4 | 650 | 1:1 | 5 |

| 5 | 700 | 1:1 | 5 |

| 6 | 750 | 1:1 | 5 |

| 7 | 800 | 1:1 | 5 |

| 8 | 850 | 1:1 | 5 |

| 9 | 900 | 1:1 | 5 |

| 10 | 950 | 1:1 | 5 |

| 11 | 1000 | 1:1 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, R.; Xuan, D.; Xu, J.; Li, J.; Ma, C. Experimental Study on Water Reduction of Grouting Slurry by Ultrasonic. Appl. Sci. 2025, 15, 10425. https://doi.org/10.3390/app151910425

Yao R, Xuan D, Xu J, Li J, Ma C. Experimental Study on Water Reduction of Grouting Slurry by Ultrasonic. Applied Sciences. 2025; 15(19):10425. https://doi.org/10.3390/app151910425

Chicago/Turabian StyleYao, Ruilin, Dayang Xuan, Jialin Xu, Jian Li, and Chengwei Ma. 2025. "Experimental Study on Water Reduction of Grouting Slurry by Ultrasonic" Applied Sciences 15, no. 19: 10425. https://doi.org/10.3390/app151910425

APA StyleYao, R., Xuan, D., Xu, J., Li, J., & Ma, C. (2025). Experimental Study on Water Reduction of Grouting Slurry by Ultrasonic. Applied Sciences, 15(19), 10425. https://doi.org/10.3390/app151910425