Analysis of the Interdependence of Surface-Induced Pilling and Electrical Resistance of Cotton Knitwear

Abstract

1. Introduction

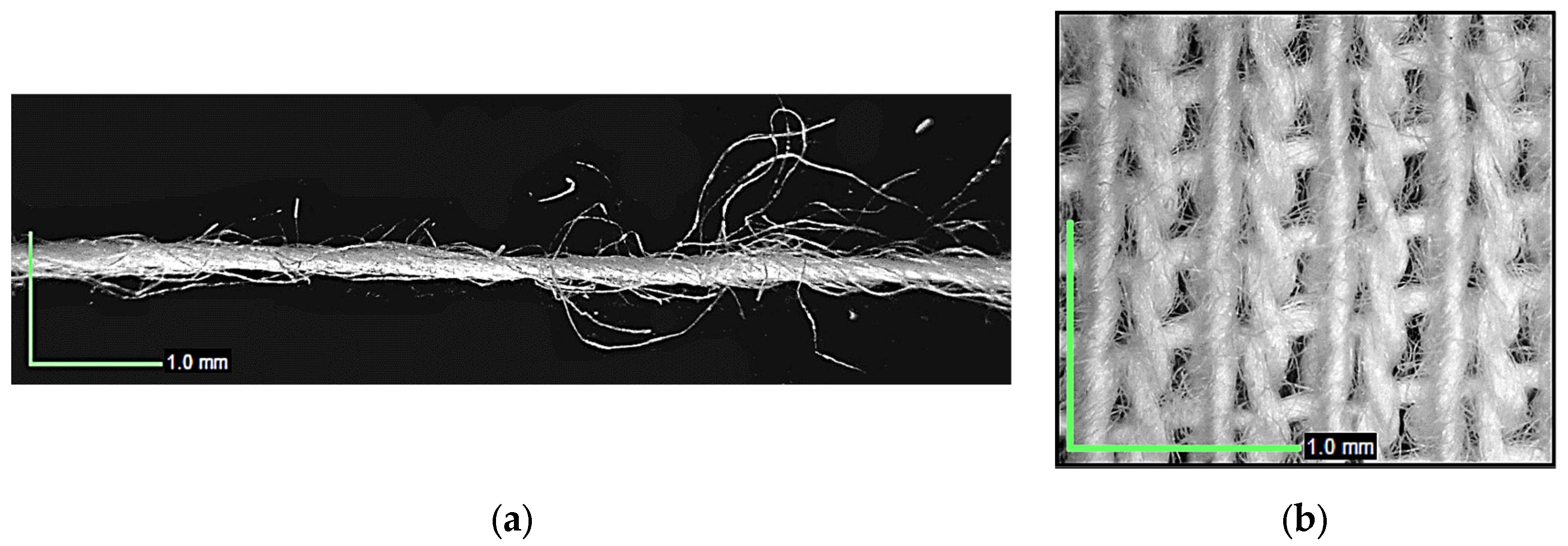

2. Materials and Methods

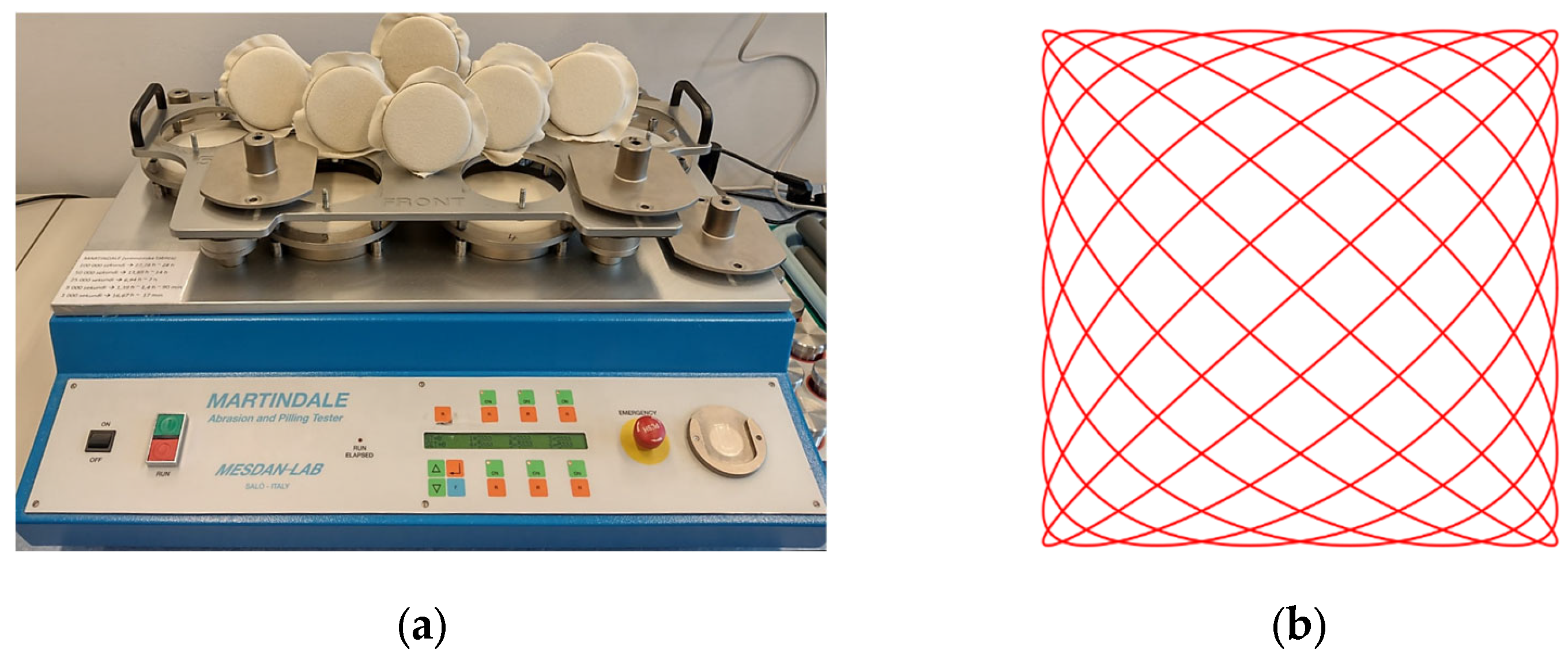

2.1. Induction and Assessment of Pilling of Knitwear Specimens

2.2. Conditioning of Knitwear Specimens Under Different Relative Humidity Conditions

2.3. Electrical Resistance Measurement of Knitwear Specimens

2.4. Physical and Moisture Absorbing Properties Measurement of Knitwear Specimens

- McHRx—moisture content of the specimen determined after a different number of pilling rubs (from 125 to 7000) and under different conditions of relative humidity (HR25, HR40, HR65 and HR80);

- mHRx—mass of the specimen determined after different number of pilling rubs (from 125 to 7000) and under different conditions of relative humidity (HR25, HR40, HR65 and HR80);

- mad—mass of the absolutely dry specimen after a different number of pilling rubs (from 125 to 7000).

2.5. Coefficients of Correlation and Determination

3. Results

3.1. Pilling Intensity Ratings of Cotton Knitwear Specimens

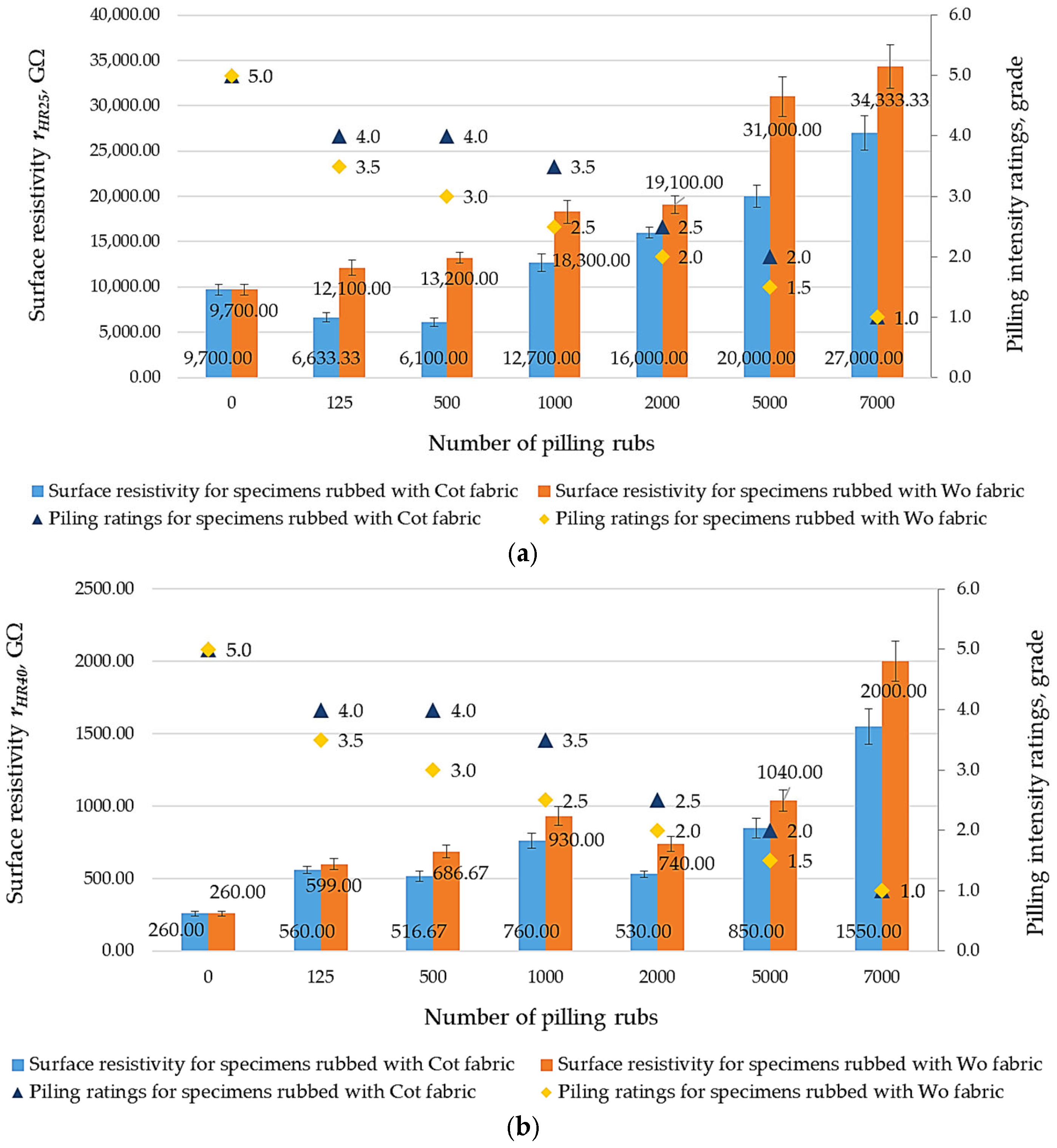

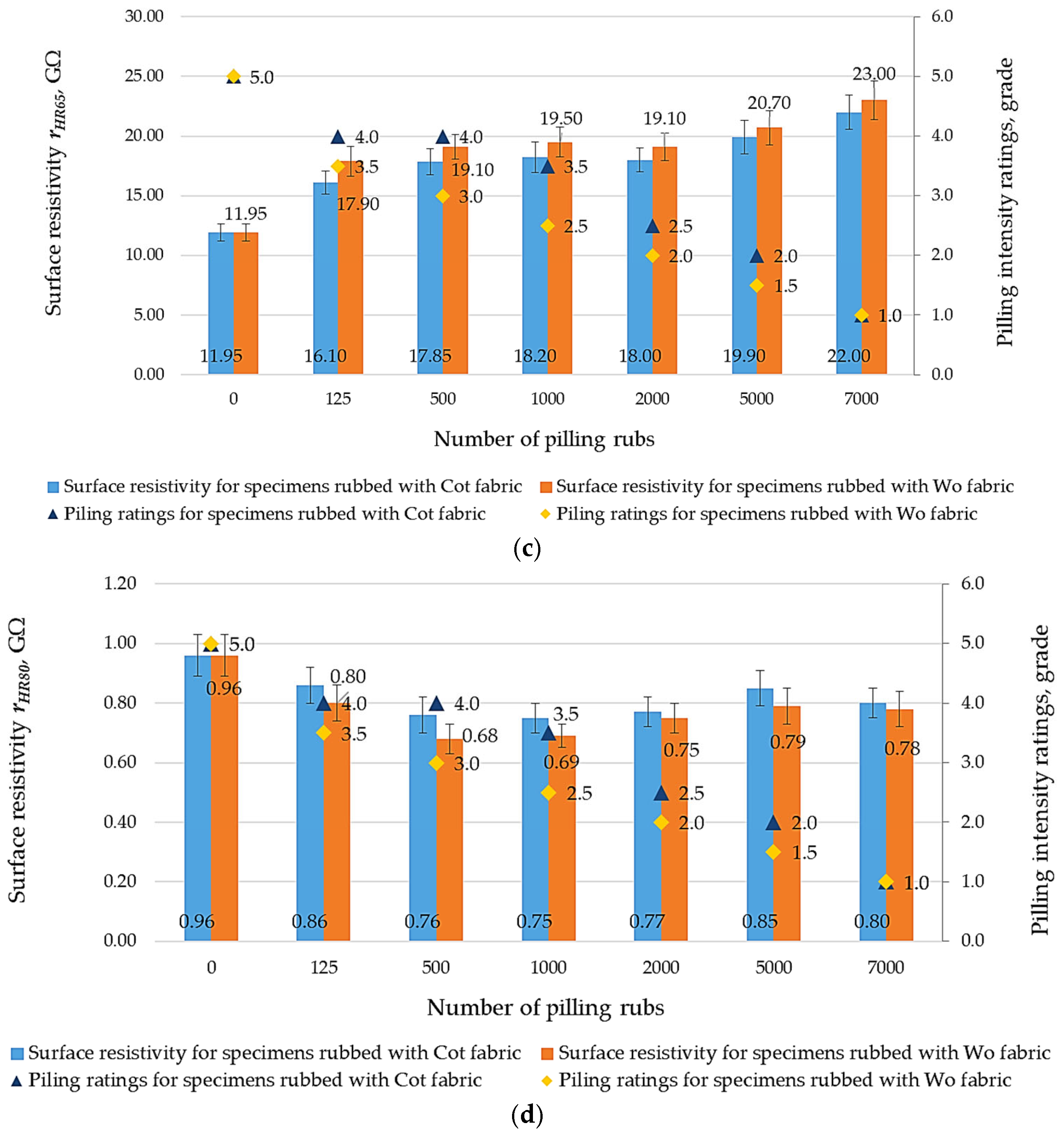

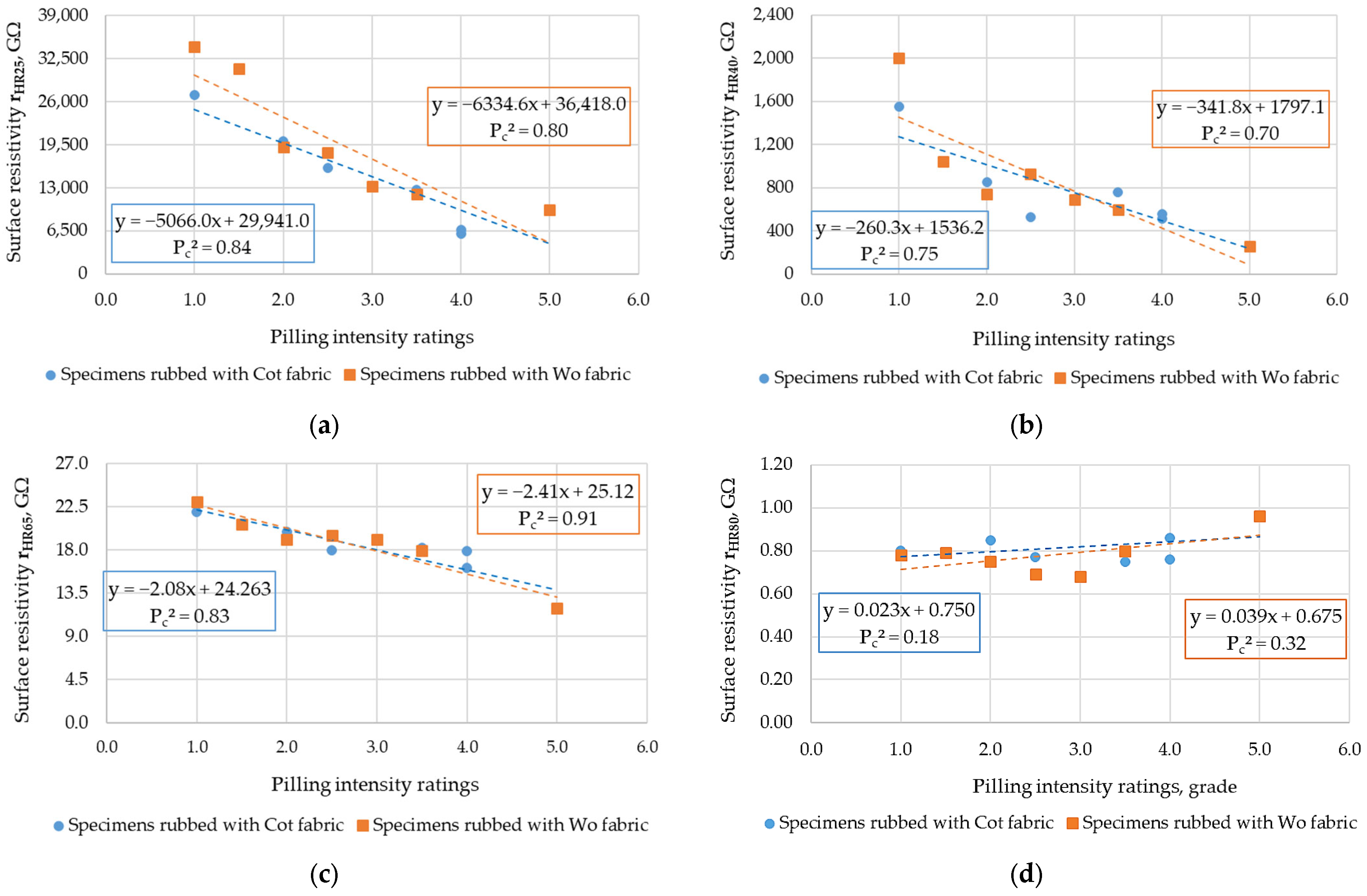

3.2. Interdependence of Surface-Induced Pilling and Surface Resistivity of Cotton Knitwear Specimens

3.3. Interdependence of Surface-Induced Pilling and Vertical Resistance of Cotton Knitwear Specimens

3.4. Interdependence of Physical, Moisture Absorbing and Electrical Properties of Cotton Knitwear Specimens

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| n | Number of replicates |

| Cot | Cotton-based double jersey abrading fabrics |

| Wo | Reference wool abrading fabric |

| HR25 | Atmospheric condition for conditioning of the specimens according to EN 1149-1:2006 and EN 1149-2:1997 with a temperature of 23 ± 1 °C and a relative humidity of 25 ± 5% |

| HR40 | Atmospheric condition for conditioning of the specimens with a temperature of 20 ± 2 °C and a relative humidity of 40 ± 5% |

| HR65 | Standard atmospheric condition used for textile conditioning and testing according to EN ISO 139:2005/A1:2011 with a temperature of 20 ± 2 °C and a relative humidity of 65 ± 5% |

| HR80 | Atmospheric condition for conditioning of the specimens with a temperature of 20 ± 2 °C and a relative humidity of 80 ± 5% |

| r | Surface resistivity geometrical mean of five consecutive measurements |

| R | Vertical resistance average value of five consecutive measurements |

| Pc | Pearson correlation coefficients |

| Pc2 | Coefficient of determination |

| McHRx | Moisture content of specimen after different number of pilling rubs (from 125 to 7000) and under different relative humidity conditions (HR25, HR40, HR65 and HR80) |

| mHRx | Mass of specimen after a different number of pilling rubs (from 125 to 7000) and under different relative humidity conditions (HR25, HR40, HR65 and HR80) |

| mad | Mass of the absolutely dry specimen after a different number of pilling rubs (from 125 to 7000) |

| SE | Standard error |

| a | Coefficient of change due to independent variables |

| b | Coefficient of change due to independent variables |

| p | Significance (p < 0.05) |

References

- Hu, J. Fabric Testing; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 1–424. [Google Scholar]

- Yuan, X.; Chen, D.; Yin, W.; Yang, M. Study on the chemical agent resistance ability of bamboo pulp fibers. Chem. Eng. Trans. 2015, 46, 25–30. [Google Scholar]

- Machnowski, W.; Was-Gubała, J. Evaluation of selected thermal changes in textile materials arising in the wake of the impact of heat radiation. Appl. Sci. 2021, 11, 6989. [Google Scholar] [CrossRef]

- Cloud, R.M.; Cao, W.; Song, G. Functional finishes to improve the comfort and protection of apparel. In Advances in Dyeing and Finishing Techniques for Textiles; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 258–279. [Google Scholar]

- Coldea, A.M.; Vlad, D. Study regarding the physical-mechanical properties of knits for garments-pilling performance. In Proceedings of the 8th International Conference on Manufacturing Science and Education, Sibiu, Romania, 7–9 June 2017. [Google Scholar]

- Özdil, N.; Zelik, G.; Spren, G. Analysis of abrasion characteristics in textiles. In Abrasion Resistance of Materials; Adamiak, M., Ed.; IntechOpen Limited: London, UK, 2012; pp. 127–154. [Google Scholar]

- Akaydin, M.; Can, Y. Pilling performance and abrasion characteristics of selected basic weft knitted fabrics. Fibres Text. East. Eur. 2010, 18, 51–54. [Google Scholar]

- Textor, T.; Derksen, L.; Bahners, T.; Gutmann, J.S.; Mayer-Gall, T. Abrasion resistance of textiles: Gaining insight into the damaging mechanisms of different test procedures. J. Eng. Fiber Fabr. 2019, 14, 1558925019829481. [Google Scholar] [CrossRef]

- EN ISO 12945-4:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting—Part 4: Assessment of Pilling, Fuzzing or Matting by Visual Analysis. ISO: Geneva, Switzerland, 2020.

- Hoque, M.S.; Hossain, M.J.; Rahman, M.M.; Rashid, M.M. Fiber Types and Fabric Structures Influence on Weft Knitted Fabrics. Heliyon 2022, 8, e09605. [Google Scholar] [CrossRef]

- Hassan, T.; Khan, M.Q.; Salam, A.; Hassan, N.; Raza, A.; Bukhsh, N.; Javed, Z.; Kim, I.S. The assessment of finishing properties on the mass per unit area, pilling, bursting strength, and wicking behavior of polyester weft-knitted jersey fabric. Coatings 2020, 10, 723. [Google Scholar] [CrossRef]

- Elias, K.M.; Rahman, M.O.; Hossain, H.M.Z. Studying the effect of polyester fiber blend ratio and pilling cycle on blended knit fabrics. J. Text. Sci. Technol. 2023, 9, 227–243. [Google Scholar] [CrossRef]

- Tomljenović, A.; Živičnjak, J.; Skenderi, Z. Wearing quality of ribbed knits made from viscose and lyocell fibers for underwear. Fibers 2024, 12, 83. [Google Scholar] [CrossRef]

- Wang, R.; Xiao, Q. Study on pilling performance of polyester-cotton blended woven fabrics. J. Eng. Fibers Fabr. 2020, 15, 1558925020966665. [Google Scholar] [CrossRef]

- Kumpikaitė, E.; Tautkutė-Stankuvienė, I.; Simanavičius, L.; Petraitienė, S. The influence of finishing on the pilling resistance of linen/silk woven fabrics. Materials 2021, 14, 6787. [Google Scholar] [CrossRef]

- Rejali, M.; Hasani, H.; Ajeli, S.; Shanbeh, M. Optimization and prediction of the pilling performance of weft knitted fabrics produced from wool/acrylic blended yarns. Indian J. Fibre Text. Res. 2014, 39, 83–88. [Google Scholar]

- Amin, M.R.; Rana, M.R.I. Analysis of pilling performance of different fabric structures with respect to yarn count and pick density. Ann. Univ. Oradea Fasc. Text. Leatherwork 2015, 16, 9–14. [Google Scholar]

- Değirmenci, Z.; Can, T. Effects of Knitted Structures on the Performance of Cotton Knitted Fabrics. J. Text. Eng. Fash. Technol. 2024, 10, 213–224. [Google Scholar] [CrossRef]

- EN ISO 8388:2003; Knitted Fabrics—Types—Vocabulary. ISO: Geneva, Switzerland, 2003.

- Pasayev, N. Investigation influence of human sweat and moisture on the resistance to abrasion of woolen fabrics. J. Text. Eng. Fash. Technol. 2017, 2, 257–259. [Google Scholar] [CrossRef]

- Textile Exchange. Materials Market Report 2024. Available online: https://textileexchange.org/knowledge-center/reports/materials-market-report-2024/ (accessed on 12 March 2025).

- Grand View Research. Men’s Underwear Market Size, Share & Trends Analysis Report by Type (Briefs, Boxer Brief, Trunks, Boxers), by Fabric, by Region, and Segment Forecasts, 2023–2030. Available online: https://www.grandviewresearch.com/industry-analysis/mens-underwear-market (accessed on 12 March 2025).

- IMARC. Lingerie Market Size, Share, Trends and Forecast by Product Type, Material, Price Range, Distribution Channel, and Region, 2025–2033. Available online: https://www.imarcgroup.com/lingerie-market (accessed on 12 March 2025).

- Hałgas, S.; Wilbik-Hałgas, B.; Sidyk, P. Modeling and testing of ESD protective textiles. Appl. Sci. 2024, 14, 7376. [Google Scholar] [CrossRef]

- Žilinskas, P.J.; Lozovski, T.; Jankauskas, V.; Jurkšus, J. Electrostatic properties and characterization of textile materials affected by ion flux. Mater. Sci. Medzg. 2013, 19, 61–66. [Google Scholar] [CrossRef]

- EN ISO 12945-2:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting—Part 2: Modified Martindale Method. ISO: Geneva, Switzerland, 2020.

- Telli, A. The relationship between subjective pilling evaluation results and detecting pills and textural features in knitted fabrics. Fibers Polym. 2020, 21, 1841–1848. [Google Scholar] [CrossRef]

- Okubayashi, S.; Campos, R.; Rohrer, C.; Bechtold, T. A piling mechanism for cellulosic knit fabrics-Effects of wet processing. J. Text. Inst. 2005, 96, 37–41. [Google Scholar] [CrossRef]

- Busiliene, G.; Lekeckas, K.; Urbelis, V. Pilling resistance of knitted fabrics. Mater. Sci. Medzg. 2011, 17, 297–301. [Google Scholar] [CrossRef]

- Zhu, L.; Ding, X.; Wu, X. A novel method for improving the anti-pilling property of knitted wool fabric with engineered water nanostructures. J. Mater. Res. Technol. 2020, 9, 3649–3658. [Google Scholar] [CrossRef]

- Wei, Y.; Su, Z.; Wang, Z.; Yuan, H.; Li, C. Mechanism and optimization of pilling propensity of wool fabric drying in dryer. J. Phys. Conf. Ser. 2020, 1626, 012126. [Google Scholar] [CrossRef]

- Naylor, G.R.; Aïssani, N.; Ramsay, D.J. The kinetic model of pilling revisited. Text. Res. J. 2011, 81, 247–253. [Google Scholar] [CrossRef]

- Asanovic, K.A.; Ivanovska, A.M.; Jankoska, M.Z.; Bukhonka, N.; Mihailovic, T.V.; Kostic, M.M. Influence of pilling on the quality of flax single jersey knitted fabrics. J. Eng. Fiber Fabr. 2022, 17, 15589250221091267. [Google Scholar] [CrossRef]

- Peta, K.; Stemp, W.J.; Stocking, T.; Chen, R.; Love, G.; Gleason, M.A.; Houk, B.A.; Brown, C.A. Multiscale Geometric Characterization and Discrimination of Dermatoglyphs (Fingerprints) on Hardened Clay—A Novel Archaeological Application of the GelSight Max. Materials 2025, 18, 2939. [Google Scholar] [CrossRef] [PubMed]

- Canoglu, S.; Sunter Eroglu, N. The electrical and physical effects of yarns containing metal wire on knitted fabric. Ann. Univ. Oradea Fascicle Text. Leatherwork 2019, 20, 2457–4880. [Google Scholar]

- Gamble, G.R. Textile technology: The influence of surface electrolyte and moisture content on the frictional behavior of cotton fiber. J. Cotton Sci. 2006, 10, 61–67. [Google Scholar]

- Asanovic, K.A.; Cerovic, D.D.; Kostic, M.M.; Maletic, S.B.; Ivanovska, A.M. Electro-physical properties of woven clothing fabrics before and after abrasion. J. Nat. Fibers 2022, 19, 6440–6451. [Google Scholar] [CrossRef]

- Doci, D.; Ademi, M.; Tuvshinbayar, K.; Richter, N.; Ehrmann, G.; Spahiu, T.; Ehrmann, A. Washing and Abrasion Resistance of Textile Electrodes for ECG Measurements. Coatings 2023, 13, 1624. [Google Scholar] [CrossRef]

- Xu, B.; Eike, R.J.; Cliett, A.; Ni, L.; Cloud, R.; Li, Y. Durability testing of electronic textile surface resistivity and textile antenna performance. Text. Res. J. 2019, 89, 3708–3721. [Google Scholar] [CrossRef]

- Bogan, K.; Seyam, A.F.M.; Slade, J. Evaluation of the electrical integrity of E-textiles subjected to abrasion. J. Text. Appar. Technol. Manag. 2019, 11, 1–12. [Google Scholar]

- Manasoglu, G.; Celen, R.; Kanik, M.; Ulcay, Y. Electrical Resistivity and Thermal Conductivity Properties of Graphene-Coated Woven Fabrics. J. Appl. Polym. Sci. 2019, 136, 48024. [Google Scholar] [CrossRef]

- Tunáková, V.; Techniková, L.; Militký, J. Influence of washing/drying cycles on fundamental properties of metal fiber-containing fabrics designed for electromagnetic shielding purposes. Text. Res. J. 2017, 87, 175–192. [Google Scholar] [CrossRef]

- Kazani, I.; Hertleer, C.; de Mey, G.; Schwarz, A.; Guxho, G.; van Langenhove, L. Electrical conductive textiles obtained by screen printing. Fibres Text. East. Eur. 2012, 90, 57–63. [Google Scholar]

- Popescu, M.; Ungureanu, C. Green Nanomaterials for Smart Textiles Dedicated to Environmental and Biomedical Applications. Materials 2023, 16, 4075. [Google Scholar] [CrossRef] [PubMed]

- Badawi, N.M.; Batoo, K.M.; Ramesh, S.; Ramesh, K.; Imran, A. SWCNTs/PEDOT: PSS Coated Cotton for Wearable Clothes and Supercapacitor Applications. Sustainability 2023, 15, 889. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E.M.; Sfirloaga, P.; Chirigiu, L.; Gavrilovici, A.M. Hybrid Magneto-Responsive Composites Made from Recyclable Components: Tunable Electrical Properties Under Magnetic and Mechanical Fields. J. Compos. Sci. 2025, 9, 219. [Google Scholar] [CrossRef]

- EN 1149-1:2006; Protective Clothing-Electrostatic Properties-Part 1: Test Method for Measurement of Surface Resistivity. CEN: Brussels, Belgium, 2006.

- EN 1149-2:1997; Protective Clothing-Electrostatic Properties-Part 2: Test Method for Measurement of the Electrical Resistance Through a Material (Vertical Resistance). CEN: Brussels, Belgium, 1997.

- Varnaitė, S.; Vitkauskas, A.; Abraitienė, A.; Rubežienė, V.; Valienė, V. The features of electric charge decay in the polyester fabric containing metal fibres. Mater. Sci. Medzg. 2008, 14, 157–161. [Google Scholar]

- Suh, M.; Seyam, A.M.; Oxenham, W.; Theyson, T. Static generation and dissipation of polyester continuous filament yarn. J. Text. Inst. 2010, 101, 261–269. [Google Scholar] [CrossRef]

- Zhu, R.; Zhang, P.; Nie, F. Overview and correlation study on electrostatic property of different testing standards. Adv. Mater. Res. 2013, 627, 325–328. [Google Scholar] [CrossRef]

- Salvado, R.; Loss, C.; Gonçalves, R.; Pinho, P. Textile materials for the design of wearable antennas: A survey. Sensors 2012, 12, 15841–15857. [Google Scholar] [CrossRef]

- Varnaite-Žuravliova, S.; Stygiene, L.; Čepliauskiene, R.; Krauledas, S.; Sankauskaite, A. The influence of three-layer knitted fabrics’ structure on electrostatic and comfort properties. Mater. Sci. Medzg. 2013, 19, 415–419. [Google Scholar]

- Stygienė, L.; Krauledas, S.; Abraitienė, A.; Varnaitė-Žuravliova, S.; Dubinskaitė, K. Thermal comfort and electrostatic properties of socks containing fibers with bio-ceramic, silver, and carbon additives. Materials 2022, 15, 2908. [Google Scholar] [CrossRef] [PubMed]

- Gulbinienė, A.; Valatkienė, L. Influence of Relative Humidity on Electrical Properties of Textile Laminates. Mater. Sci. Medzg. 2023, 29, 525–530. [Google Scholar] [CrossRef]

- Nurmi, S.; Hammi, T.; Demoulin, B. Protection Against Electrostatic and Electromagnetic Phenomena. In Multifunctional Barriers for Flexible Structure; Duquesne, S., Magniez, C., Camino, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 97, pp. 63–83. [Google Scholar]

- Groop, E.E.; Nowicki, A.W.; Calle, C.I.; Buhler, C.R.; Mantovani, J.G. Comparison of surface resistivity and triboelectric charge generation characteristics of materials. In Proceedings of the 40th Space congress-Linking the Past to the Future-A Celebration of Space, Cape Canaveral, FL, USA, 29 April–2 May 2003. [Google Scholar]

- Paasi, J.; Coletti, G.; Fast, L.; Lemaire, P.; Vogel, C.; Peltoniemi, T.; Reina, G.; Smallwood, J. ESD-Protective Clothing for Electronics Industry–A New European Research Project ESTAT-Garments. In Proceedings of the 6th Dresden Textile Conference, Dresden, Germany, 19–20 June 2002. [Google Scholar]

- Asanovic, K.A.; Mihajlidi, T.A.; Milosavljevic, S.V.; Cerovic, D.D.; Dojcilovic, J.R. Investigation of the electrical behavior of some textile materials. J. Electrost. 2007, 65, 162–167. [Google Scholar] [CrossRef]

- Hong, H.; Hu, J.; Yan, X. Effect of the basic surface properties of woven lining fabric on printing precision and electrical performance of screen-printed conductive lines. Text. Res. J. 2020, 90, 1212–1223. [Google Scholar] [CrossRef]

- Wang, X.; Xu, W.; Li, W.; Cui, W. Study on the Electrical Resistance of Textiles under Wet Conditions. Text. Res. J. 2009, 79, 753–760. [Google Scholar] [CrossRef]

- Sereda, P.J.; Feldman, R.F. Electrostatic charging on fabrics at various humidities. J. Text. Inst. Trans. 1964, 55, T288–T298. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Ye, X.; Ma, K.; Li, H. Correlation Analysis and Prediction Model of Thermal Protection Performance of Aramid 1414 Fabric. Polymers 2023, 15, 1188. [Google Scholar] [CrossRef]

- Hasan, M.S.M.; Chowdhury, M.K.H.; Smriti, S.A.; Khalil, E.; Akter, M.; Farhana, K. Predicting the Effect of Thread Density on the Physical and Thermal Properties of Plain-Woven Fabric by Using a Soft Computing System. J. Eng. Fibers Fabr. 2024, 19, 15589250241308553. [Google Scholar] [CrossRef]

- Schober, P.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- EN ISO 139:2005/A1:2011; Textiles—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2005.

- EN ISO 12947-1:1998+AC:2006; Textiles-Determination of the Abrasion Resistance of Fabrics by the Martindale Method-Part 1: Martindale Abrasion Testing Apparatus. ISO: Geneva, Switzerland, 1998.

- Wilson, R.E. Humidity Control by Means of Sulfuric Acid Solutions, with Critical Compilation of Vapour Pressure Data. J. Ind. Eng. Chem. 1921, 13, 326–331. [Google Scholar] [CrossRef]

- EN ISO 5084:2003; Textiles—Determination of Thickness of Textiles and Textile Products. ISO: Geneva, Switzerland, 2003.

- EN 14971:2008; Textiles—Knitted Fabrics—Determination of Number of Stitches per Unit Length and Unit Area. ISO: Geneva, Switzerland, 2008.

- ASTM D 2654-89a; Standard Test Methods for Moisture in Textiles. ASTM: West Conshohocken, PA, USA, 2021.

| Property | Cotton Knitted Fabric |

|---|---|

| Thickness, mm | 0.70 ± 0.02 |

| Bulk Density, g/m3 | 0.26 |

| Overall Porosity, % | 83.04 |

| Areal Density, g/m2 | 167.2 ± 1.1 |

| Wale/Course Density, cm−1 | 21.5 ± 0.5/12.5 ± 0.5 |

| Stitch Density, cm−2 | 268.8 ± 10.2 |

| Lengthwise/Widthwise Tensile Strength, N | 415.7 ± 42.3/121.2 ± 11.6 |

| Lengthwise/Widthwise Elongation at Break, % | 50.6 ± 2.2/142.4 ± 3.1 |

| Abradant Fabrics | Number of Pilling Rubs | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 125 | 500 | 1000 | 2000 | 5000 | 7000 | |

| Surface-Induced Pilling Intensity Ratings | |||||||

| Cot | 5.0 | 4.0 | 4.0 | 3.5 | 2.5 | 2.0 | 1.0 |

| Wo | 5.0 | 3.5 | 3.0 | 2.5 | 2.0 | 1.5 | 1.0 |

| Number of Pilling Rubs | Abradant Fabric | |||

|---|---|---|---|---|

| Cot | Wo | |||

| 125 |  |  |  |  |

| Pilling Intensity Rating | 4.0 | 3.5 | ||

| 1000 |  |  |  |  |

| Pilling Intensity Rating | 3.5 | 2.5 | ||

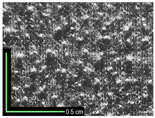

| 7000 |  |  |  |  |

| Pilling Intensity Rating | 1.0 | 1.0 | ||

| Surface Resistivity, GΩ | 0 | 125 | 500 | 1000 | 2000 | 5000 | 7000 | |

|---|---|---|---|---|---|---|---|---|

| Cot | HR25 | 9700.00 ± 582.00 | 6633.33 ± 506.13 | 6100.00 ± 457.60 | 12,700.00 ± 952.10 | 16,000.00 ± 576.00 | 20,000.00 ± 1200.00 | 27,000.00 ± 1890.00 |

| HR40 | 260.00 ± 16.64 | 560.00 ± 26.88 | 516.67 ± 36.17 | 760.00 ± 53.20 | 530.00 ± 20.14 | 850.00 ± 68.00 | 1550.00 ± 124.00 | |

| HR65 | 11.95 ± 0.72 | 16.10 ± 0.97 | 17.85 ± 1.07 | 18.20 ± 1.28 | 18.00 ± 0.99 | 19.90 ± 1.39 | 22.00 ± 1.43 | |

| HR80 | 0.96 ± 0.07 | 0.86 ± 0.06 | 0.76 ± 0.06 | 0.75 ± 0.05 | 0.77 ± 0.05 | 0.85 ± 0.06 | 0.80 ± 0.05 | |

| Wo | HR25 | 9700.00 ± 582.00 | 12,100.00 ± 847.00 | 13,200.00 ± 594.00 | 18,300.00 ± 1281.00 | 19,100.00 ± 954.30 | 31,000.00 ± 2170.00 | 34,333.33 ± 2396.67 |

| HR40 | 260.00 ± 16.64 | 599.00 ± 38.94 | 686.67 ± 44.47 | 930.00 ± 65.10 | 740.00 ± 51.80 | 1040.00 ± 72.80 | 2000.00 ± 140.00 | |

| HR65 | 11.95 ± 0.72 | 17.90 ± 1.25 | 19.10 ± 1.06 | 19.50 ± 1.27 | 19.10 ± 1.15 | 20.70 ± 1.45 | 23.00 ± 1.61 | |

| HR80 | 0.96 ± 0.07 | 0.80 ± 0.06 | 0.68 ± 0.05 | 0.69 ± 0.04 | 0.75 ± 0.05 | 0.79 ± 0.06 | 0.78 ± 0.06 | |

| Abradant Fabric | Pc | Pc2 | SE * | a ** | b ** | p *** | |

|---|---|---|---|---|---|---|---|

| Cot | HR25 | −0.92 | 0.84 | 3297.79 | −5066.0 | 29,941.0 | 0.004 |

| HR40 | −0.87 | 0.75 | 224.69 | −260.3 | 1536.2 | 0.011 | |

| HR65 | −0.91 | 0.83 | 1.41 | −2.08 | 24.263 | 0.004 | |

| HR80 | 0.42 | 0.18 | 0.074 | 0.023 | 0.750 | 0.349 | |

| Wo | HR25 | −0.89 | 0.80 | 4657.84 | −6334.6 | 36,418.0 | 0.007 |

| HR40 | −0.84 | 0.70 | 326.46 | −341.8 | 1797.1 | 0.018 | |

| HR65 | −0.95 | 0.91 | 1.14 | −2.41 | 25.12 | 0.001 | |

| HR80 | 0.57 | 0.32 | 0.084 | 0.039 | 0.675 | 0.183 | |

| Vertical Resistance, MΩ | 0 | 125 | 500 | 1000 | 2000 | 5000 | 7000 | |

|---|---|---|---|---|---|---|---|---|

| Cot | HR25 | 5430.00 ± 352.95 | 3780.00 ± 204.12 | 7583.33 ± 531.25 | 8313.33 ± 598.56 | 6706.67 ± 402.40 | 4960.00 ± 347.20 | 1930.00 ± 123.52 |

| HR40 | 1035.00 ± 72.45 | 800.00 ± 56.00 | 1650.00 ± 124.58 | 649.00 ± 42.79 | 1230.00 ± 73.80 | 843.50 ± 60.73 | 607.50 ± 42.53 | |

| HR65 | 9.25 ± 0.56 | 16.45 ± 1.03 | 19.17 ± 1.34 | 18.95 ± 1.23 | 16.10 ± 0.97 | 21.00 ± 1.33 | 22.20 ± 1.33 | |

| HR80 | 1.13 ± 0.07 | 1.21 ± 0.06 | 1.33 ± 0.09 | 1.63 ± 0.10 | 1.37 ± 0.09 | 1.83 ± 0.12 | 1.21 ± 0.08 | |

| Wo | HR25 | 5430.00 ± 352.95 | 4877.78 ± 342.78 | 10,411.11 ± 583.02 | 11,133.33 ± 758.27 | 9600.00 ± 643.20 | 7600.00 ± 486.40 | 7533.33 ± 467.00 |

| HR40 | 1035.00 ± 72.45 | 833.00 ± 61.04 | 1696.67 ± 128.57 | 803.33 ± 57.04 | 1073.33 ± 70.84 | 1320.00 ± 92.40 | 1866.67 ± 130.67 | |

| HR65 | 9.25 ± 0.56 | 15.70 ± 1.02 | 16.40 ± 1.15 | 20.20 ± 1.31 | 17.55 ± 1.10 | 19.90 ± 1.39 | 27.35 ± 1.91 | |

| HR80 | 1.13 ± 0.07 | 1.23 ± 0.08 | 1.60 ± 0.10 | 1.51 ± 0.10 | 1.27 ± 0.08 | 1.55 ± 0.10 | 1.31 ± 0.09 | |

| Abradant Fabric | Pc | Pc2 | |

|---|---|---|---|

| Cot | HR25 | 0.47 | 0.22 |

| HR40 | 0.39 | 0.16 | |

| HR65 | −0.78 | 0.60 | |

| HR80 | −0.34 | 0.11 | |

| Wo | HR25 | −0.42 | 0.17 |

| HR40 | −0.48 | 0.23 | |

| HR65 | −0.92 | 0.85 | |

| HR80 | −0.46 | 0.21 | |

| Mass of Specimen, g | Number of Pilling Rubs | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 125 | 500 | 1000 | 2000 | 5000 | 7000 | ||

| Cot | HR25 | 2.5624 ± 0.06 | 2.5808 ± 0.07 | 2.5816 ± 0.03 | 2.5783 ± 0.03 | 2.5821 ± 0.03 | 2.5812 ± 0.05 | 2.5815 ± 0.06 |

| HR40 | 2.7002 ± 0.08 | 2.6638 ± 0.04 | 2.6683 ± 0.03 | 2.6673 ± 0.08 | 2.6705 ± 0.04 | 2.6692 ± 0.07 | 2.6684 ± 0.06 | |

| HR65 | 2.7360 ± 0.05 | 2.7314 ± 0.08 | 2.7334 ± 0.03 | 2.7343 ± 0.05 | 2.7346 ± 0.08 | 2.7291 ± 0.06 | 2.7268 ± 0.07 | |

| HR80 | 2.7712 ± 0.08 | 2.7725 ± 0.04 | 2.7734 ± 0.07 | 2.7738 ± 0.03 | 2.7772 ± 0.05 | 2.7746 ± 0.05 | 2.7755 ± 0.03 | |

| Wo | HR25 | 2.5624 ± 0.06 | 2.5674 ± 0.03 | 2.5638 ± 0.03 | 2.5738 ± 0.06 | 2.5772 ± 0.06 | 2.5764 ± 0.06 | 2.5745 ± 0.04 |

| HR40 | 2.7002 ± 0.08 | 2.6440 ± 0.07 | 2.6408 ± 0.06 | 2.6466 ± 0.03 | 2.6451 ± 0.03 | 2.6455 ± 0.07 | 2.6436 ± 0.04 | |

| HR65 | 2.7360 ± 0.05 | 2.7309 ± 0.08 | 2.7327 ± 0.05 | 2.7327 ± 0.07 | 2.7315 ± 0.04 | 2.7290 ± 0.07 | 2.7226 ± 0.08 | |

| HR80 | 2.7712 ± 0.08 | 2.7697 ± 0.06 | 2.7686 ± 0.08 | 2.7695 ± 0.05 | 2.7728 ± 0.03 | 2.7755 ± 0.05 | 2.7705 ± 0.06 | |

| Abradant Fabric | Number of Pilling Rubs | ||

|---|---|---|---|

| 0–7000 | 0–7000 | ||

| Number Wales/Courses, cm−1 | Stich Density, cm−2 | ||

| Cot and Wo | HR25 | 22.5 ± 0.5/13.5 ± 0.5 | 303.75 ± 7.6 |

| HR40 | 21.5 ± 0.0/12.5 ± 0.0 | 268.75 ± 0.0 | |

| HR65 | 21.5 ± 0.0/12.5 ± 0.0 | 268.75 ± 0.0 | |

| HR80 | 22.5 ± 0.5/13.5 ± 0.5 | 303.75 ± 7.6 | |

| Moisture Content, % | Number of Pilling Rubs | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 125 | 500 | 1000 | 2000 | 5000 | 7000 | ||

| Cot | HR25 | 1.2 ± 0.03 | 1.3 ± 0.01 | 1.3 ± 0.02 | 1.3 ± 0.02 | 1.3 ± 0.03 | 1.3 ± 0.03 | 1.3 ± 0.04 |

| HR40 | 4.2 ± 0.05 | 4.6 ± 0.08 | 4.8 ± 0.05 | 4.9 ± 0.07 | 4.8 ± 0.10 | 4.8 ± 0.05 | 4.8 ± 0.07 | |

| HR65 | 6.8 ± 0.16 | 7.2 ± 0.15 | 7.3 ± 0.11 | 7.5 ± 0.16 | 7.3 ± 0.19 | 7.1 ± 0.07 | 7.0 ± 0.18 | |

| HR80 | 8.1 ± 0.19 | 8.8 ± 0.15 | 8.9 ± 0.12 | 9.0 ± 0.26 | 9.0 ± 0.15 | 8.9 ± 0.11 | 9.0 ± 0.11 | |

| Wo | HR25 | 1.2 ± 0.03 | 1.3 ± 0.03 | 1.4 ± 0.04 | 1.3 ± 0.03 | 1.3 ± 0.03 | 1.3 ± 0.04 | 1.3 ± 0.02 |

| HR40 | 4.2 ± 0.05 | 4.5 ± 0.12 | 4.5 ± 0.10 | 4.3 ± 0.12 | 4.1 ± 0.09 | 4.2 ± 0.10 | 4.1 ± 0.04 | |

| HR65 | 6.8 ± 0.16 | 7.8 ± 0.12 | 7.9 ± 0.09 | 7.6 ± 0.11 | 7.4 ± 0.09 | 7.4 ± 0.12 | 7.2 ± 0.16 | |

| HR80 | 8.1 ± 0.19 | 9.4 ± 0.16 | 9.5 ± 0.13 | 9.0 ± 0.14 | 9.0 ± 0.26 | 9.2 ± 0.21 | 9.1 ± 0.20 | |

| Abradant Fabric | Measured Property of the Specimens | ||||||

|---|---|---|---|---|---|---|---|

| Mass | Thickness | Moisture Content | |||||

| Pc | Pc2 | Pc | Pc2 | Pc | Pc2 | ||

| Cot | HR25 | 0.28 | 0.08 | 0.57 | 0.32 | 0.36 | 0.13 |

| HR40 | −0.46 | 0.21 | 0.60 | 0.36 | 0.51 | 0.26 | |

| HR65 | −0.78 | 0.61 | 0.46 | 0.21 | 0.42 | 0.18 | |

| HR80 | −0.65 | 0.43 | −0.69 | 0.47 | −0.86 | 0.74 | |

| Wo | HR25 | 0.75 | 0.57 | 0.47 | 0.22 | 0.23 | 0.06 |

| HR40 | −0.50 | 0.25 | 0.73 | 0.53 | −0.32 | 0.10 | |

| HR65 | −0.84 | 0.70 | 0.56 | 0.32 | 0.40 | 0.16 | |

| HR80 | 0.29 | 0.08 | −0.81 | 0.65 | −0.82 | 0.67 | |

| Abradant Fabric | Measured Property of the Specimens | ||||||

|---|---|---|---|---|---|---|---|

| Mass | Thickness | Moisture Content | |||||

| Pc | Pc2 | Pc | Pc2 | Pc | Pc2 | ||

| Cot | HR25 | −0.05 | 0.00 | 0.08 | 0.01 | 0.08 | 0.01 |

| HR40 | 0.13 | 0.02 | −0.08 | 0.01 | 0.05 | 0.00 | |

| HR65 | −0.77 | 0.59 | 0.50 | 0.25 | 0.36 | 0.13 | |

| HR80 | 0.31 | 0.09 | 0.51 | 0.26 | 0.64 | 0.41 | |

| Wo | HR25 | 0.35 | 0.12 | 0.37 | 0.13 | 0.36 | 0.13 |

| HR40 | −0.26 | 0.07 | −0.04 | 0.00 | 0.26 | 0.07 | |

| HR65 | −0.91 | 0.83 | 0.15 | 0.02 | 0.54 | 0.29 | |

| HR80 | 0.01 | 0.00 | 0.64 | 0.41 | 0.52 | 0.27 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Živičnjak, J.; Tomljenović, A. Analysis of the Interdependence of Surface-Induced Pilling and Electrical Resistance of Cotton Knitwear. Appl. Sci. 2025, 15, 10419. https://doi.org/10.3390/app151910419

Živičnjak J, Tomljenović A. Analysis of the Interdependence of Surface-Induced Pilling and Electrical Resistance of Cotton Knitwear. Applied Sciences. 2025; 15(19):10419. https://doi.org/10.3390/app151910419

Chicago/Turabian StyleŽivičnjak, Juro, and Antoneta Tomljenović. 2025. "Analysis of the Interdependence of Surface-Induced Pilling and Electrical Resistance of Cotton Knitwear" Applied Sciences 15, no. 19: 10419. https://doi.org/10.3390/app151910419

APA StyleŽivičnjak, J., & Tomljenović, A. (2025). Analysis of the Interdependence of Surface-Induced Pilling and Electrical Resistance of Cotton Knitwear. Applied Sciences, 15(19), 10419. https://doi.org/10.3390/app151910419