On Relation Between Fatigue Limit ΔσFL and Threshold ΔKth

Abstract

1. Introduction

2. Background

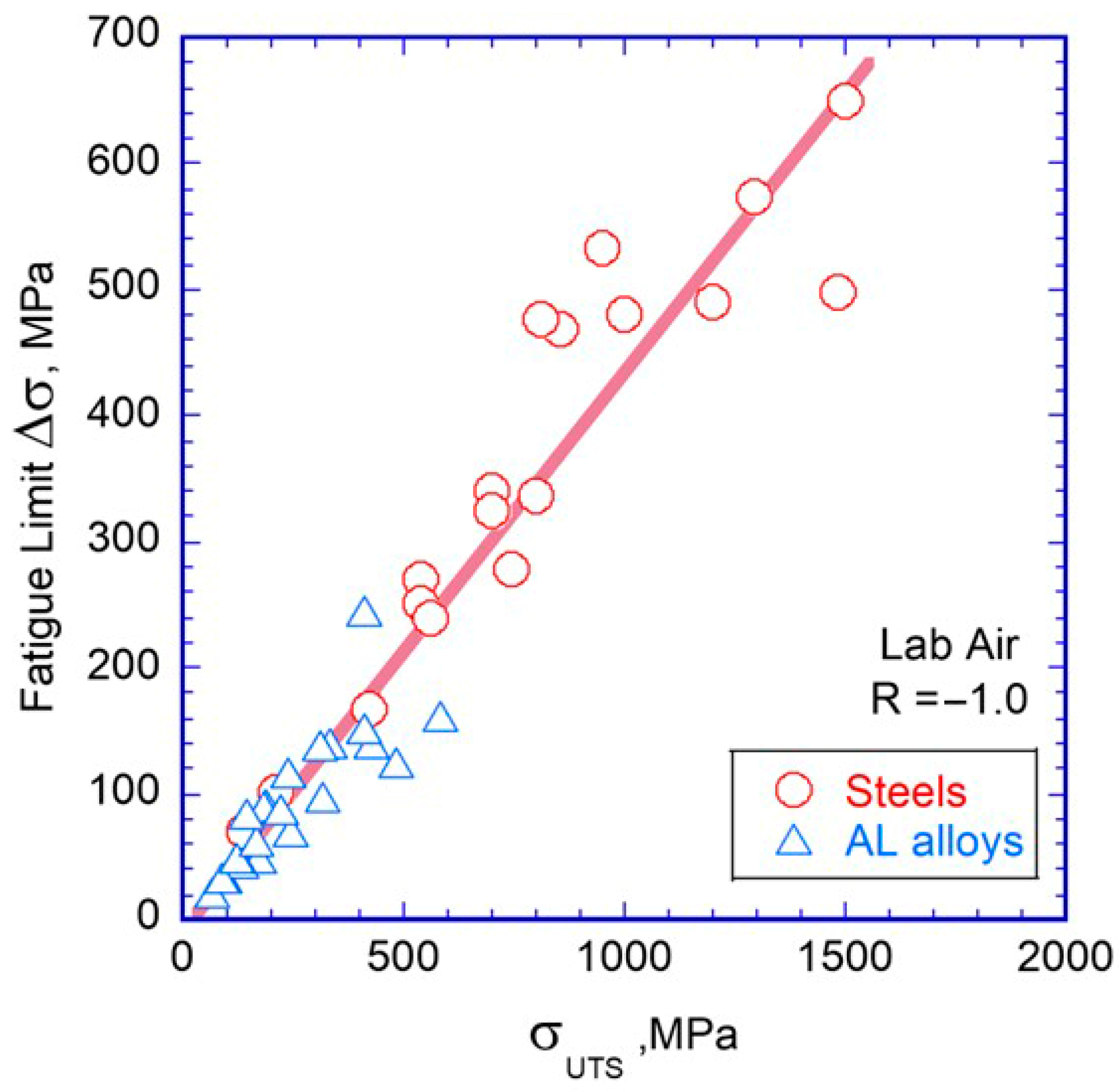

2.1. Stress/Strain Approach to Fatigue

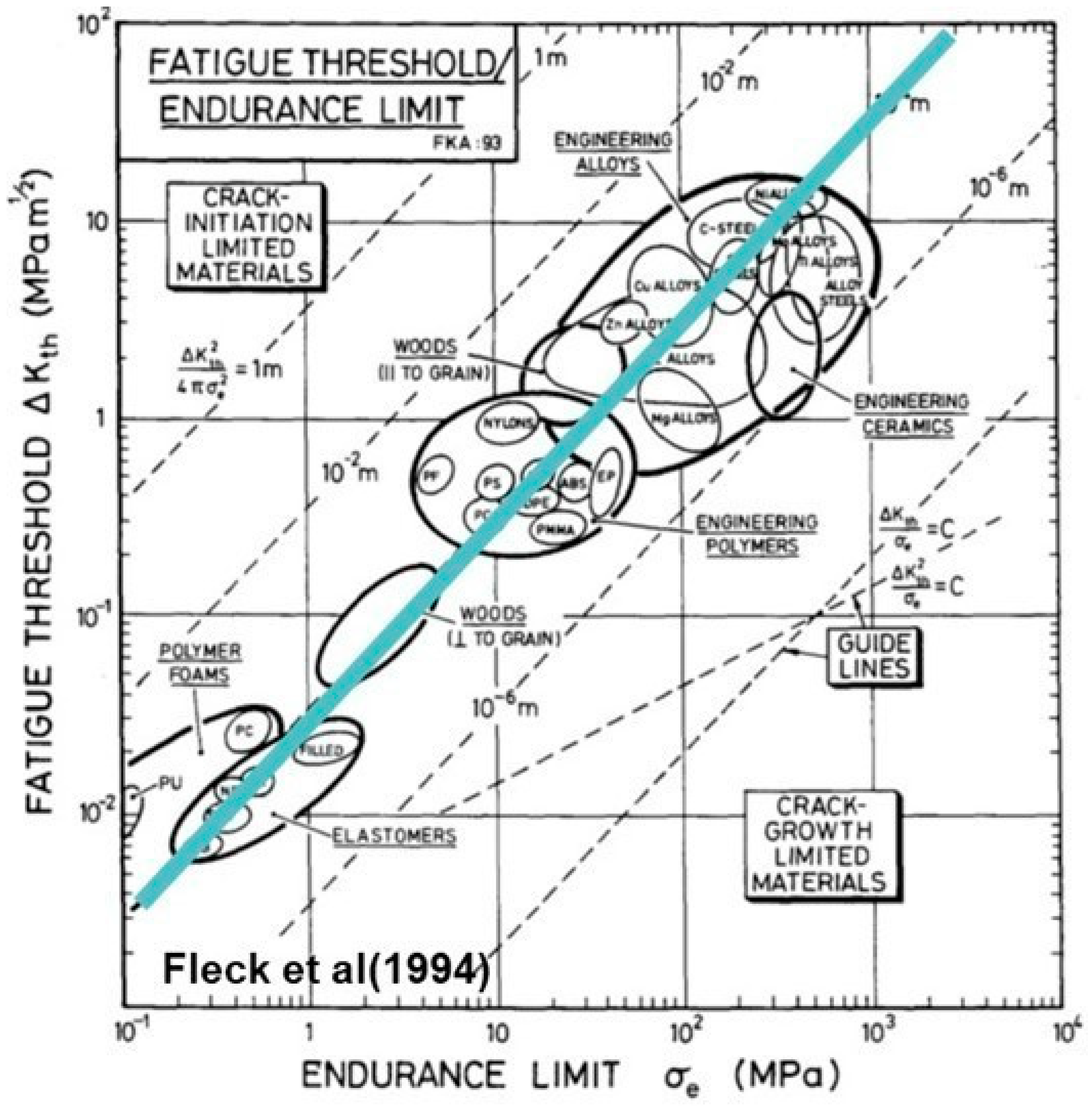

2.2. Fracture Mechanics Approach to Fatigue

2.3. Two Thresholds for Fatigue Crack

- The region below the threshold for crack initiation, where Δσlocal < ΔσFL and ΔKappl < ΔKth.

- The failure region above both thresholds, where Δσlocal > ΔσFL and ΔKappl > ΔKth.

- The region of non-propagating cracks, where Δσlocal > ΔσFL but ΔKappl < ΔKth.

3. Analysis

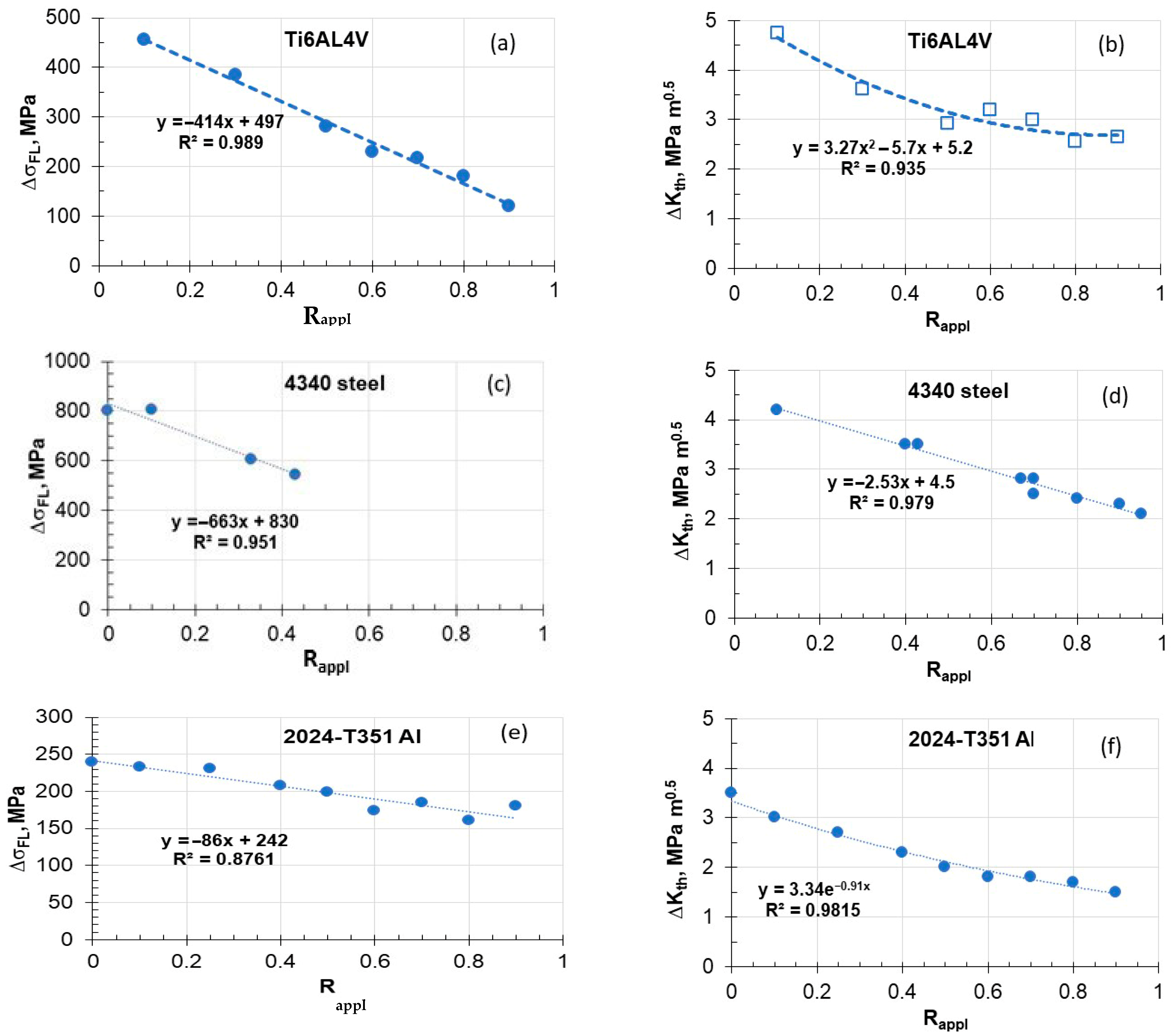

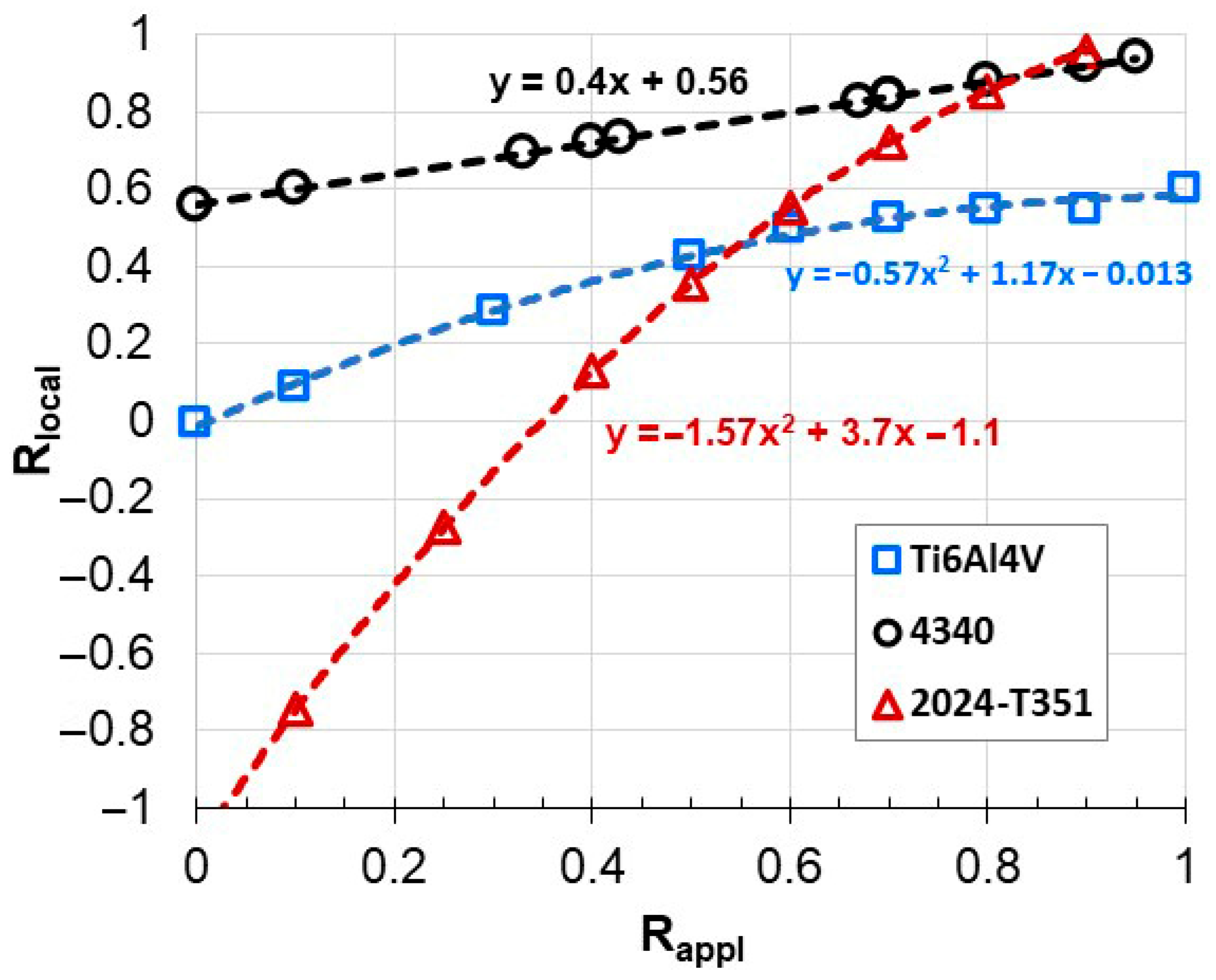

3.1. Relating R-Ratios for Uncracked and Cracked Samples

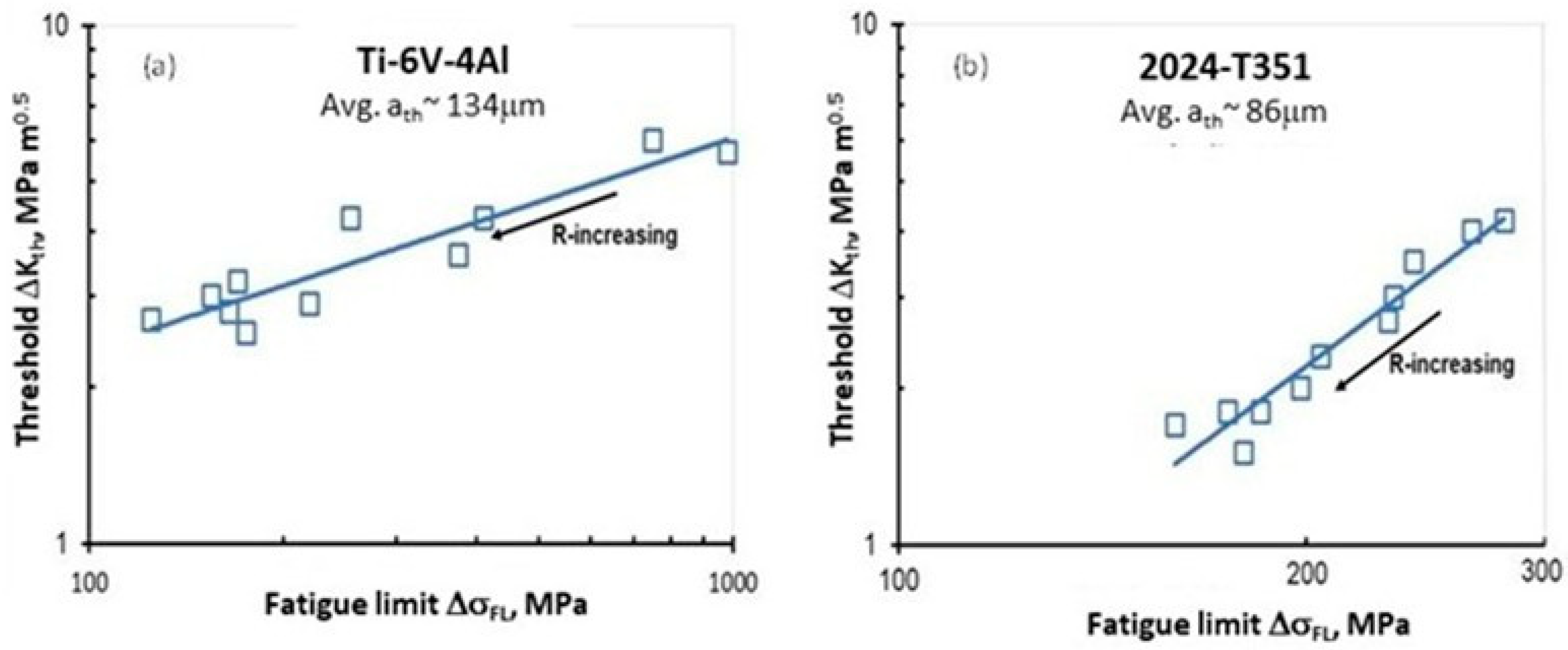

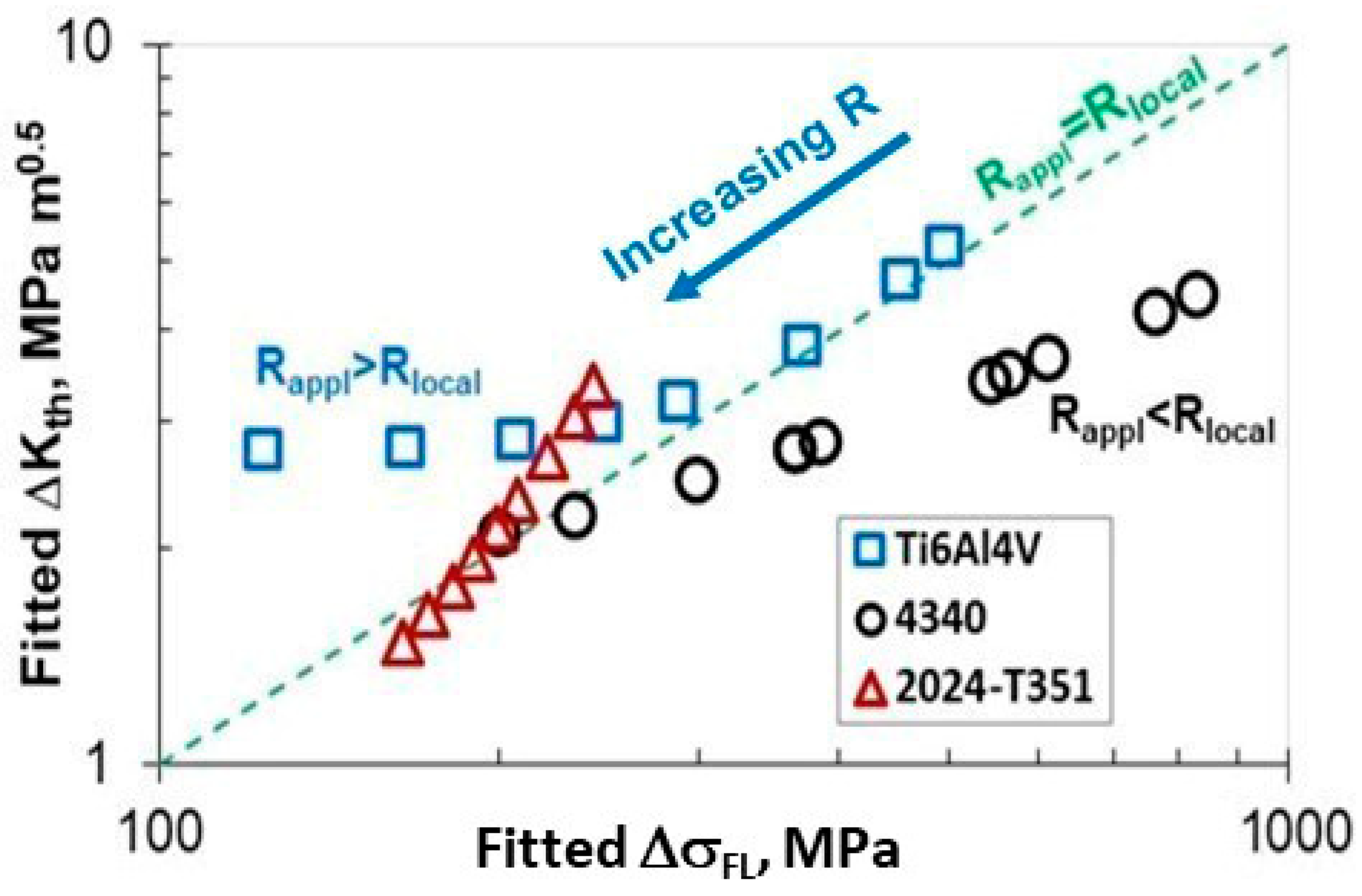

3.2. Approximate Correlation of ΔσFL to ΔKth

3.3. Estimated Relation Between ΔσFL and ΔKth

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ASTM. Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Morrow, J. Fatigue properties of metals, section 3.2. In Fatigue Design Handbook, Pub. No. AE-4; Section 3.2 is a summary of a paper presented at division 4 of the SAE Iron and Steel Technical Committee, Nov. 4, 1964; Society of Automotive Engineers: Warrendale, PA, USA, 1968. [Google Scholar]

- ASTM. E647-23b: Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2024. [Google Scholar]

- Dowling, N.E.; Kampe, S.L.; Kral, M.V. Mechanical Behavior of Material, 5th ed.; Pearson: London, UK, 2019. [Google Scholar]

- Boyce, B.L.; Ritchie, R.O. Effect of load ratio and maximum stress intensity on the fatigue threshold in Ti-6Al-4V. Eng. Fract. Mech. 2001, 68, 129–147. [Google Scholar] [CrossRef]

- Ravichandran, K.S. Near threshold fatigue crack growth behavior of a Titanium alloy: Ti-6Al-4V. Acta Metall. Et Mater. 1991, 39, 401–410. [Google Scholar] [CrossRef]

- Peters, J.O.; Boyce, B.L.; Chen, X.; McNaney, J.M.; Hutchinson, J.W.; Ritchie, R.O. On the application of the Kitagawa–Takahashi diagram to foreign-object damage and high-cycle fatigue. Eng. Fract. Mech. 2002, 69, 1425–1446. [Google Scholar] [CrossRef]

- Groves, H.J. Fatigue of Aircraft Structures, NAVAIR 01-1A-13; Supt. of Docs., U. S. Govt. Print. Off.: Washington, DC, USA, 1966. [Google Scholar]

- Newman, J.C.; Vizzini, A.J.; Yamada, Y. Fatigue Crack Growth Data Bases and Analysis for Threshold Behavior in Rotorcraft Materials, DOT/FAA/AR/103; Department of Transportation: Washington, DC, USA, 2010. [Google Scholar]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Paris, P.C.; Gomez, M.P.; Anderson, W.E. A rational analytic theory of fatigue. Trend Eng. 1961, 13, 9–14. [Google Scholar]

- Paris, P.; Erdogan, F. A critical analysis of crack propagation laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Paris, P.C. Fracture mechanics and fatigue: A historical perspective. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 535–540. [Google Scholar] [CrossRef]

- Elber, W. Fatigue crack closure under cyclic tension loading. Eng. Fract. Mech. 1970, 2, 37–45. [Google Scholar]

- Miller, K.J. The two thresholds of fatigue behavior. Fatigue Fract. Eng. Mater. Struct. 1993, 16, 931–939. [Google Scholar] [CrossRef]

- Fleck, N.A.; Kang, K.J.; Ashby, M.F. The cyclic properties of engineering materials, Overview No. 112. Acta Met. Mater. 1994, 42, 365–381. [Google Scholar] [CrossRef]

- Frost, N.E.; Dugdale, S.D. Fatigue tests on notched mild steel plates with measurements of fatigue cracks. J. Mech. Phys. Solids 1957, 5, 182–192. Available online: https://www.sciencedirect.com/science/article/abs/pii/0022509657900042 (accessed on 1 September 2025). [CrossRef]

- Nisitani, H. Effects of size on the fatigue limit and the branch point in rotary bending tests of carbon steel specimens. Bull. JSME 1968, 11, 947–957. [Google Scholar] [CrossRef]

- Lukáš, P.; Klesnil, M. Fatigue limit of notched bodies. Mater. Sci. Eng. 1978, 34, 61–66. [Google Scholar] [CrossRef]

- de Castro, J.T.P.; Meggiolaro, M.A.; Miranda, A.C.d.O.; Wu, H.; Imad, A.; Benseddiq, N. Prediction of fatigue crack initiation lives at elongated notch roots using short crack concepts. Int. J. Fatigue 2012, 42, 172–182. [Google Scholar] [CrossRef]

- Chapetti, M.D. Non-propagating cracks at the fatigue limit of notches: An Analysis of notch sensitivity and size effect. Materials 2024, 17, 4632. [Google Scholar] [CrossRef]

- Neuber, H. Theory of Notch Stresses: Principles for Exact Calculation of Strength with Reference to Structural Form and Material, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1958. [Google Scholar]

- Peterson, R.E. Notch sensitivity. In Metal Fatigue; Sines, G., Waisman, J.L., Eds.; McGraw-Hill: New York, NY, USA, 1959; pp. 293–306. [Google Scholar]

- Ince, A. Novel computational method for modeling elastic–plastic stress–strain fields near cracks under cyclic loadings. Int. J. Fatigue 2025, 193, 108792. [Google Scholar] [CrossRef]

- Taylor, D. The Theory of Critical Distance; Elsevier: Oxford, UK, 2007. [Google Scholar]

- US Military. MIL-HandBook-5 Metallic Materials & Aircraft Structures; DoD: Washington, DC, USA, 2006. [Google Scholar]

- Stein, T.; Wicke, M.; Brueckner-Foit, A.; Kirsten, T.; Zimmermann, M.; Buelbuel, F.; Christ, H.-J. Crack growth behavior in an aluminum alloy under very low stress amplitudes. J. Mater. Res. 2017, 32, 4354–4361. [Google Scholar] [CrossRef]

- Wicke, M.; Brueckner-Foit, A.; Kirsten, T.; Zimmermann, M.; Buelbuel, F.; Christ, H.J. Near-threshold crack extension mechanisms in an aluminum alloy studied by SEM and X-ray tomography. Int. J. Fatigue 2019, 119, 102–111. [Google Scholar] [CrossRef]

- Tanaka, Y.; Park, S.; Okazaki, S.; Matsunaga, H. Criteria for determining the fatigue limit of Ni-based superalloy 718 considering the competition between opening- and shear-mode fatigue crack-growth. Eng. Fract. Mech. 2023, 290, 109500. [Google Scholar] [CrossRef]

- Cappelli, M.; Carlson, R.; Kardomateas, G. The transition between small and long fatigue crack behavior and its relation to microstructure. Int. J. Fatigue 2008, 30, 1473–1478. [Google Scholar] [CrossRef]

- Wei, X.; Li, C.; McCarthy, C.; Kolinski, J.M. Complexity of crack front geometry enhances toughness of brittle solids. Nat. Phys. 2024, 20, 1009–1014. [Google Scholar] [CrossRef]

- Meia, J.; Xinga, S.; Vasua, A.; Chunga, J.; Desaia, R.; Dong, P. The fatigue limit prediction of notched components—A critical review and modified stress gradient based approach. Int. J. Fatigue 2010, 135, 10553. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kujawski, D.; Vasudevan, A.K. On Relation Between Fatigue Limit ΔσFL and Threshold ΔKth. Appl. Sci. 2025, 15, 10405. https://doi.org/10.3390/app151910405

Kujawski D, Vasudevan AK. On Relation Between Fatigue Limit ΔσFL and Threshold ΔKth. Applied Sciences. 2025; 15(19):10405. https://doi.org/10.3390/app151910405

Chicago/Turabian StyleKujawski, Daniel, and Asuri K. Vasudevan. 2025. "On Relation Between Fatigue Limit ΔσFL and Threshold ΔKth" Applied Sciences 15, no. 19: 10405. https://doi.org/10.3390/app151910405

APA StyleKujawski, D., & Vasudevan, A. K. (2025). On Relation Between Fatigue Limit ΔσFL and Threshold ΔKth. Applied Sciences, 15(19), 10405. https://doi.org/10.3390/app151910405