Evaluation of Deterioration in Cultural Stone Heritage Using Non-Destructive Testing Techniques: The Case of Emir Ali Tomb (Ahlat, Bitlis, Türkiye)

Abstract

1. Introduction

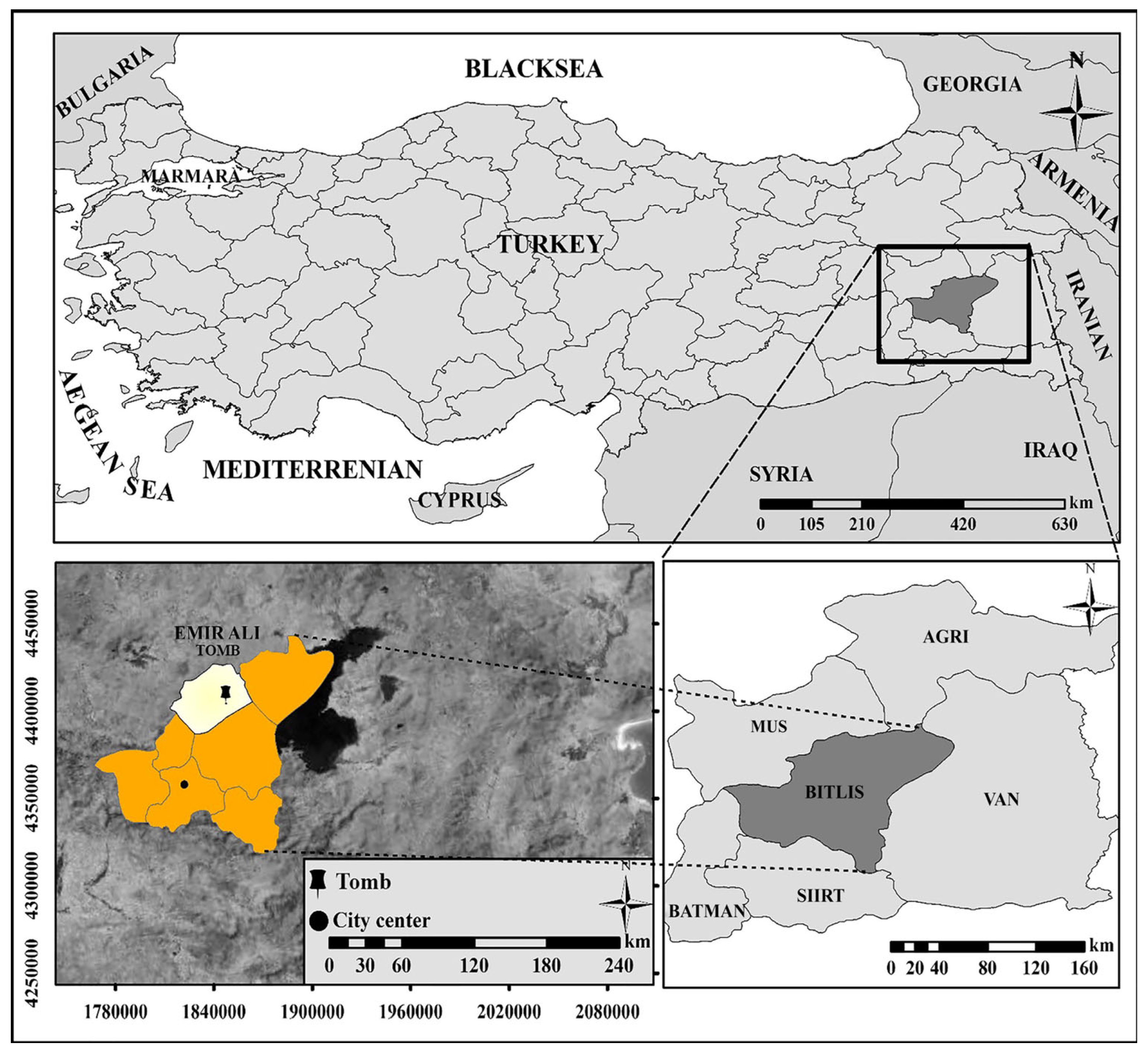

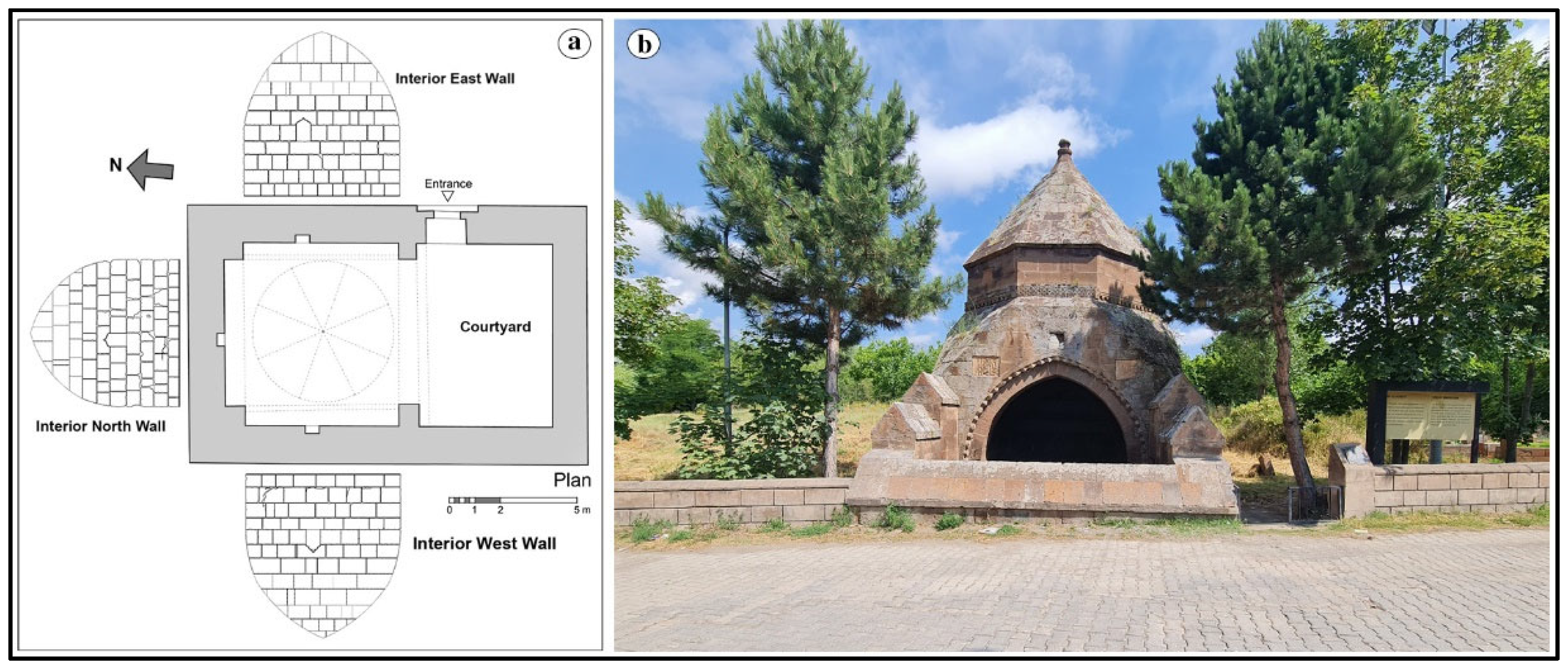

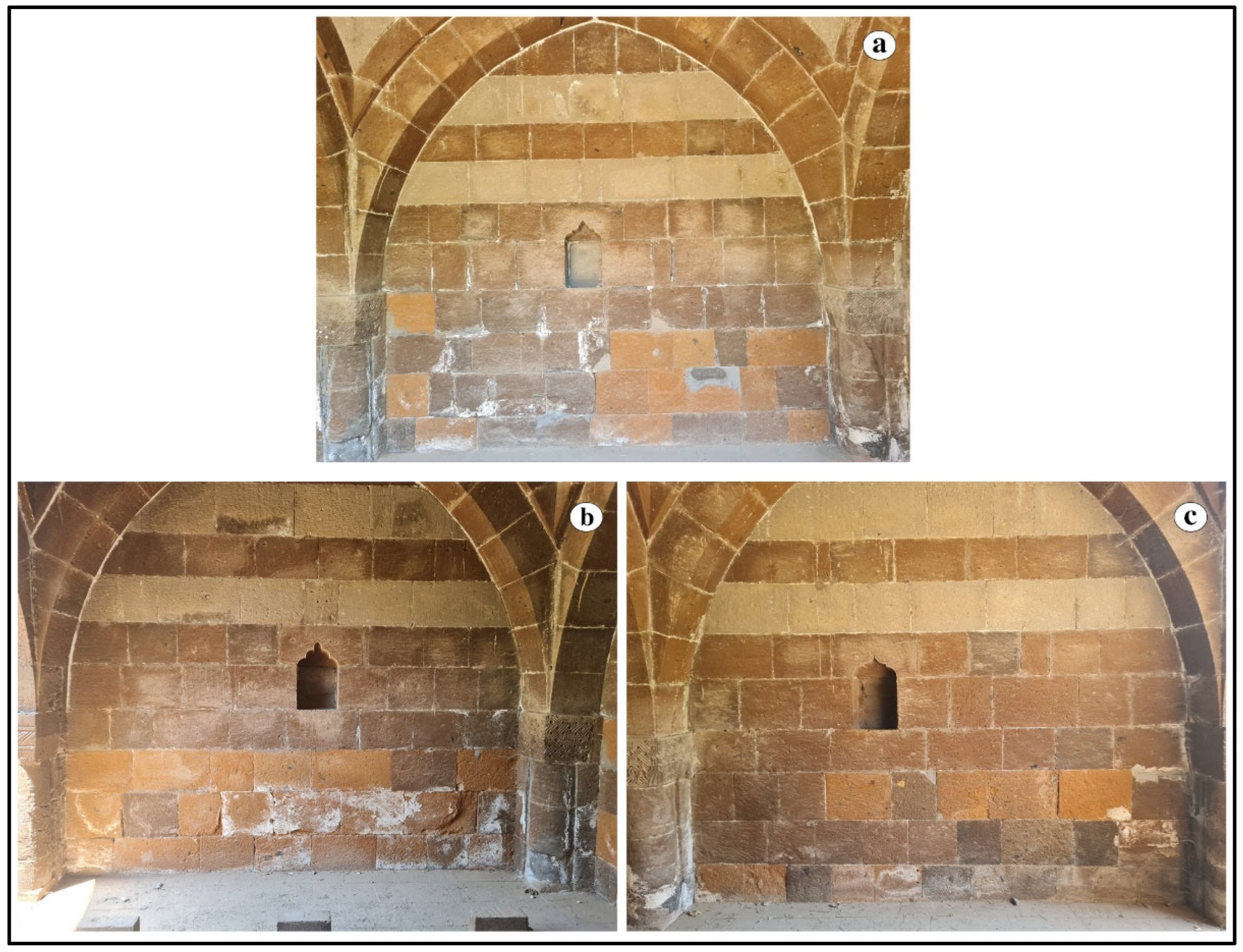

2. Description of the Emir Ali Tomb

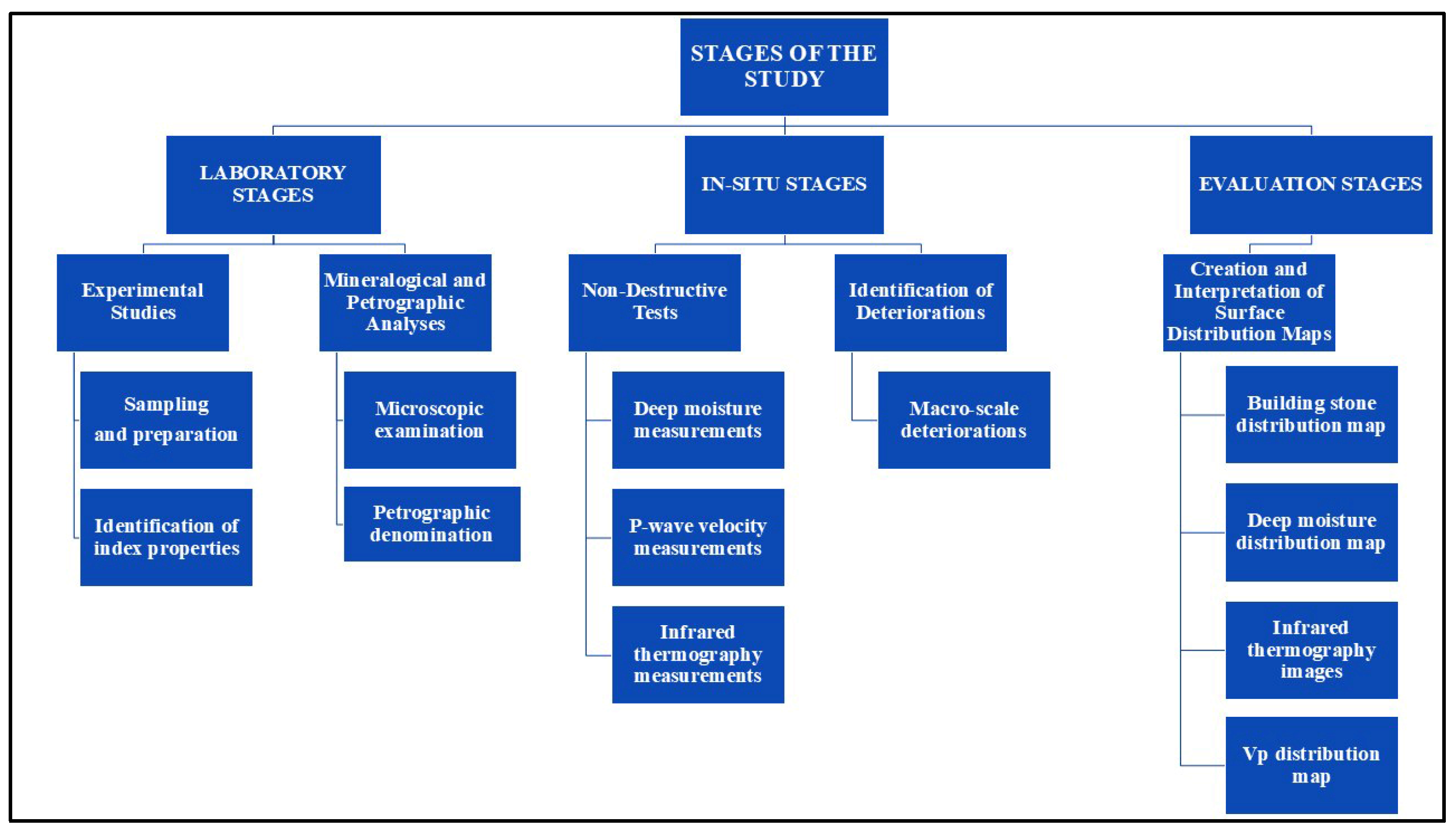

3. Materials and Methods

4. Results and Discussion

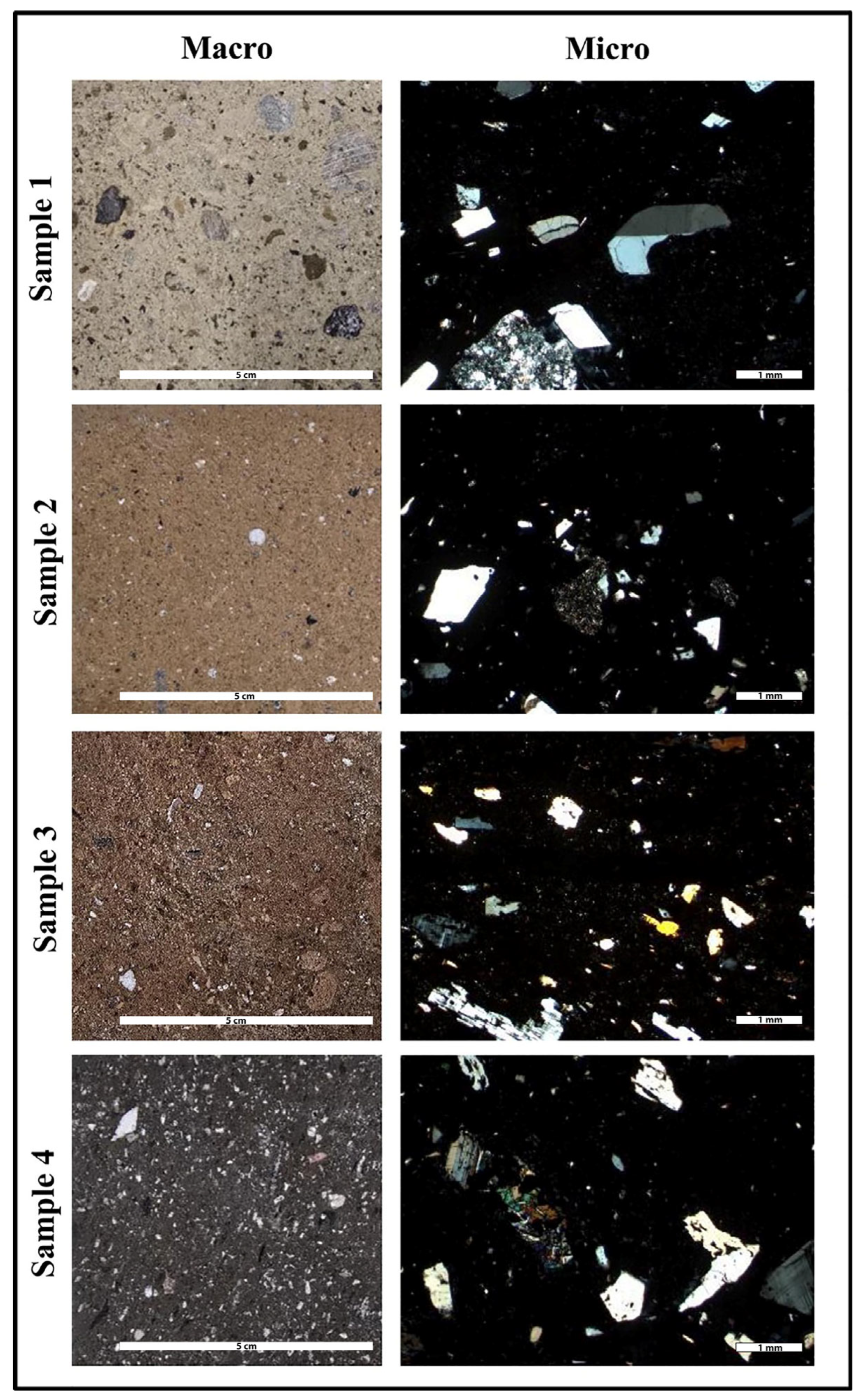

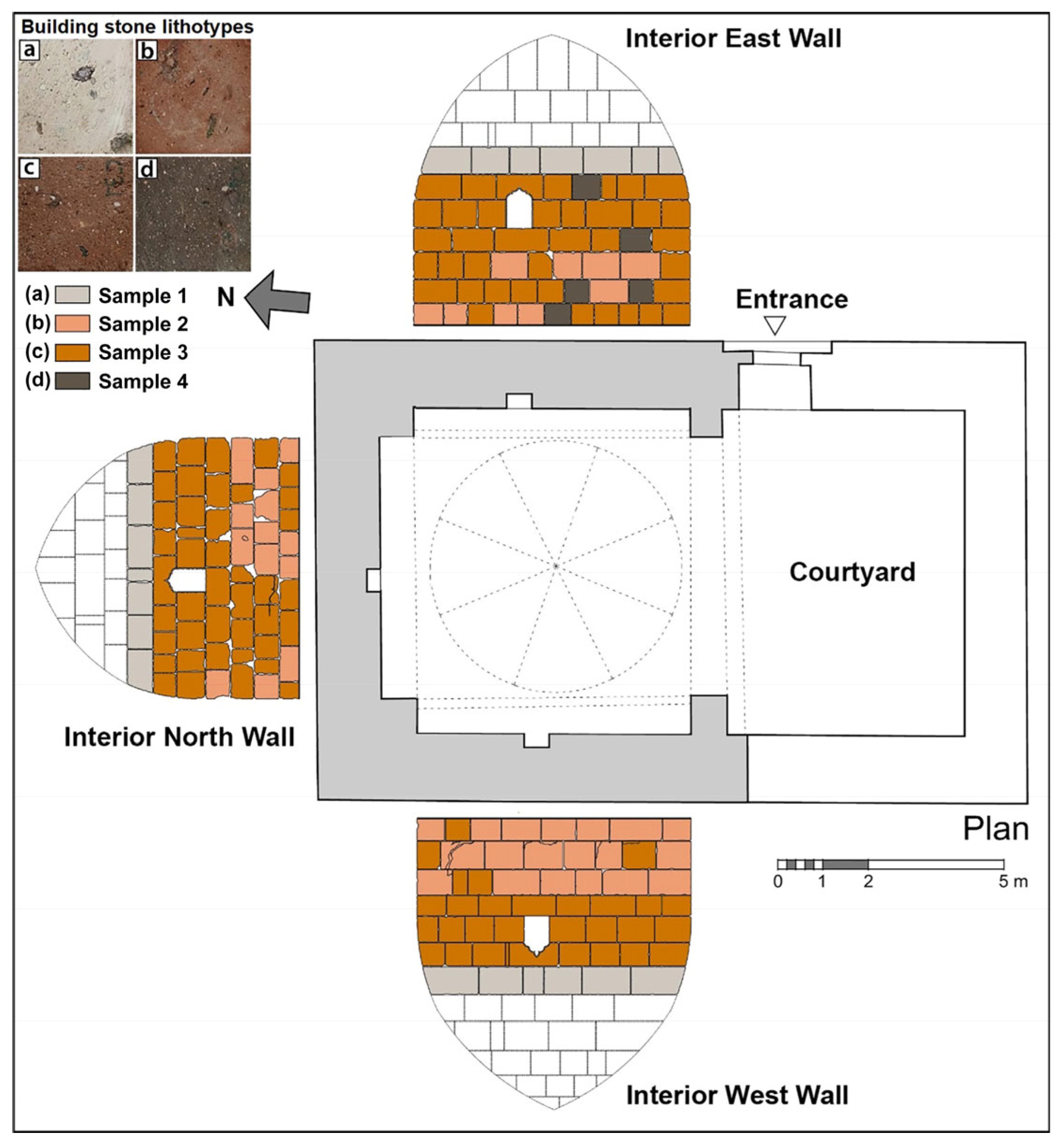

4.1. Petrographic and Physical Properties of Rocks

4.2. NDT Results

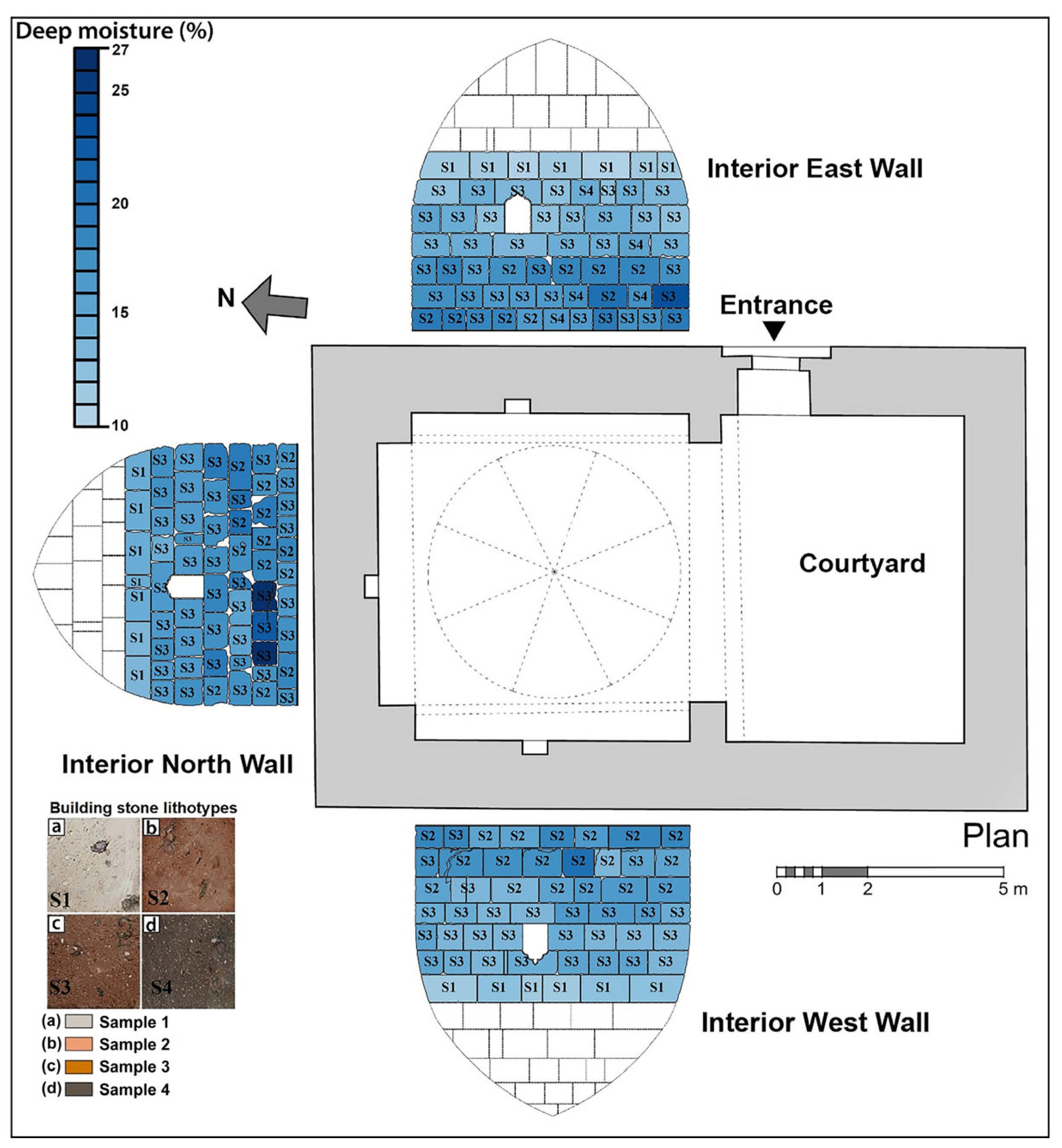

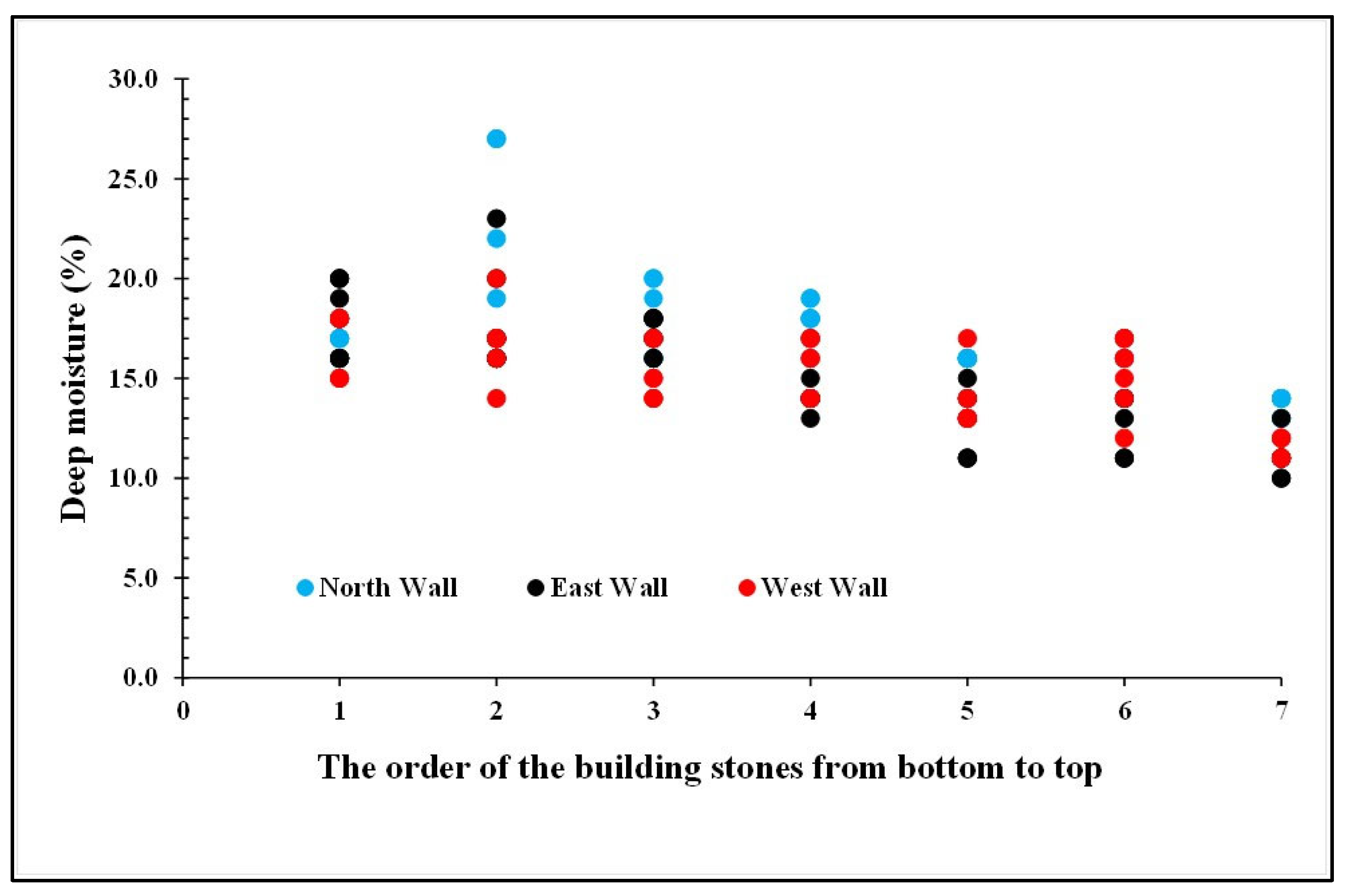

4.2.1. Deep Moisture Measurements

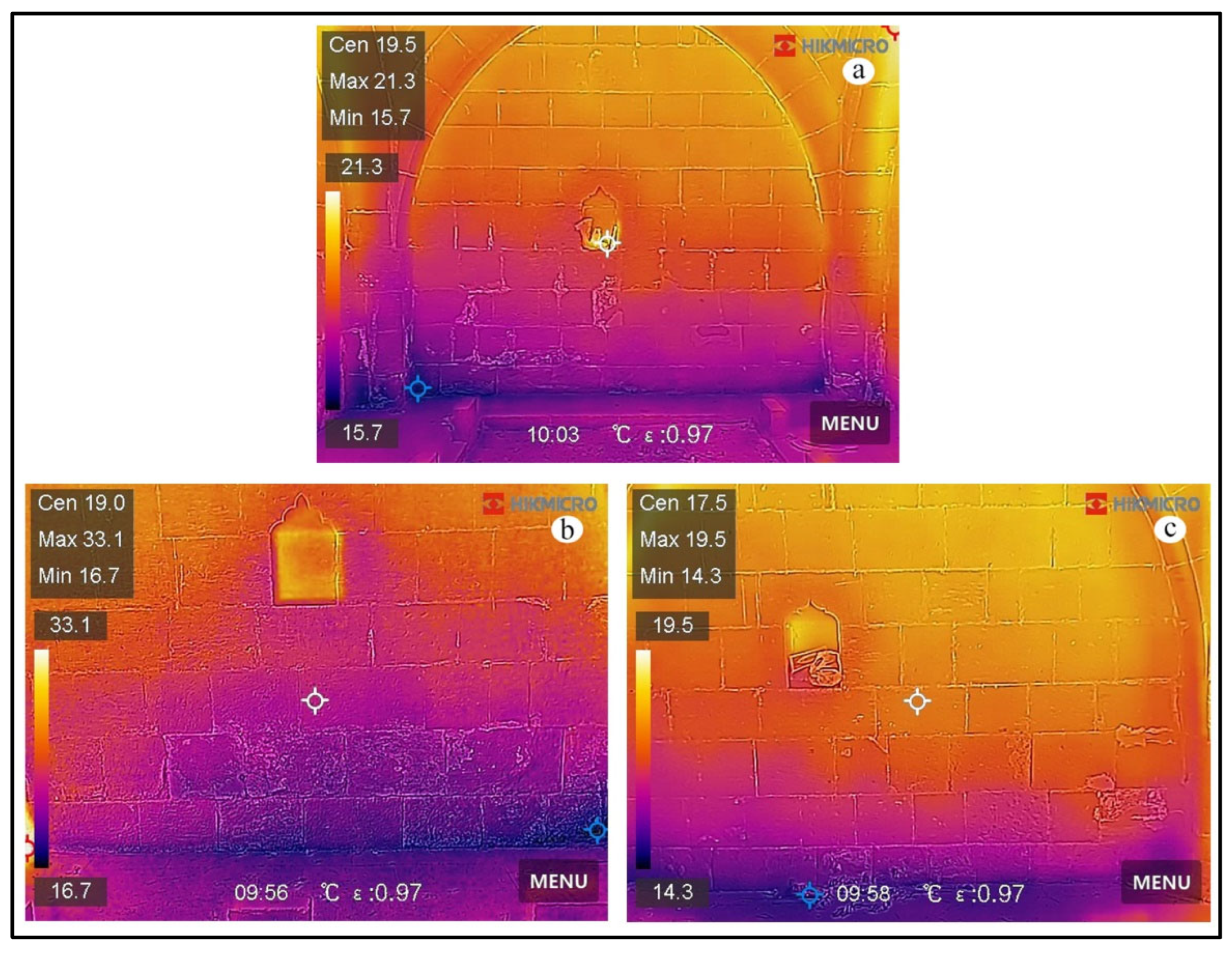

4.2.2. Infrared Thermography Measurement

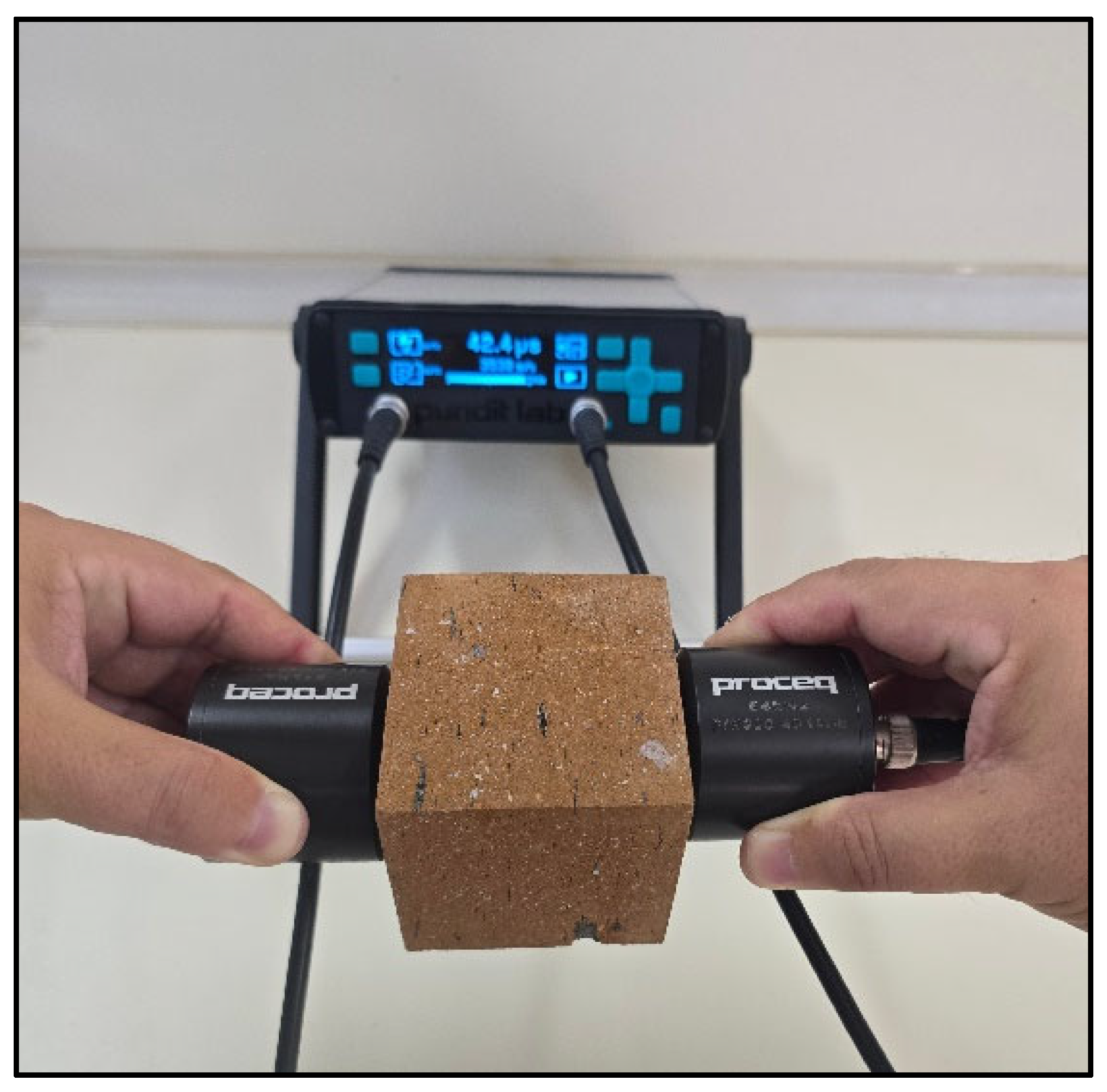

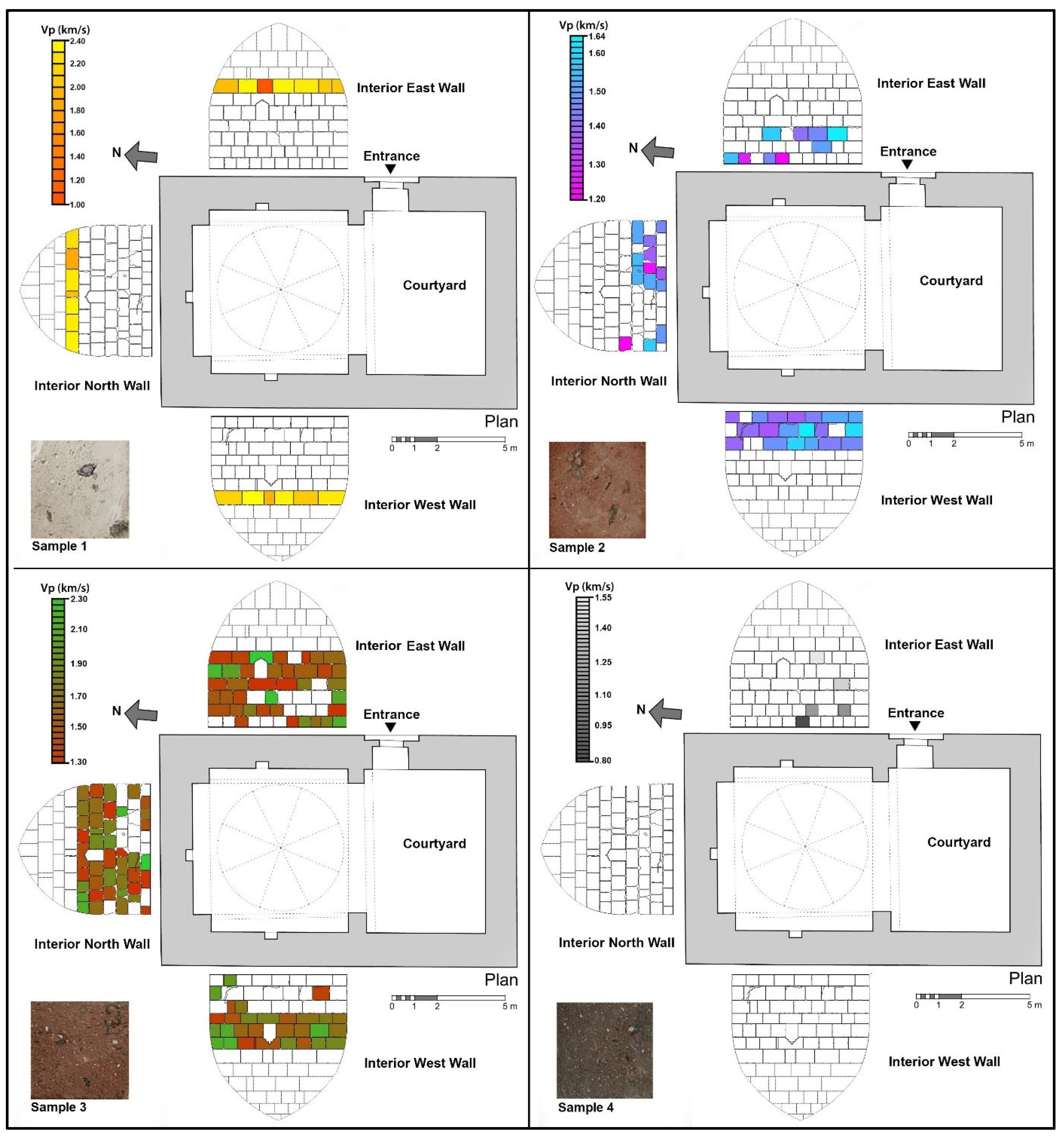

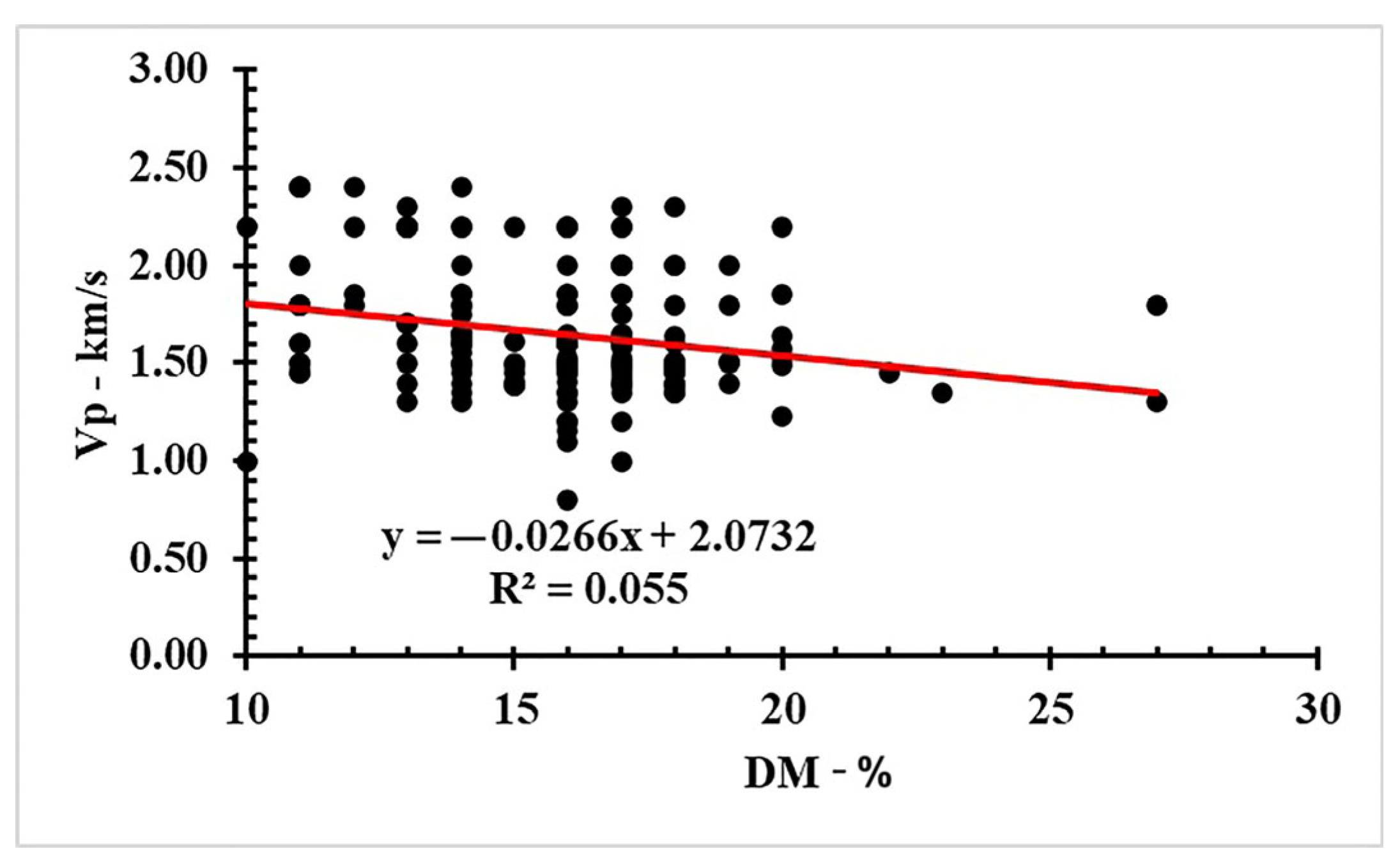

4.2.3. P-Wave Velocity Measurements

5. Conclusions

- The building material of the monument is Ahlat stone, widely used in the region, and four different rock types were identified based on their color and geomechanical properties.

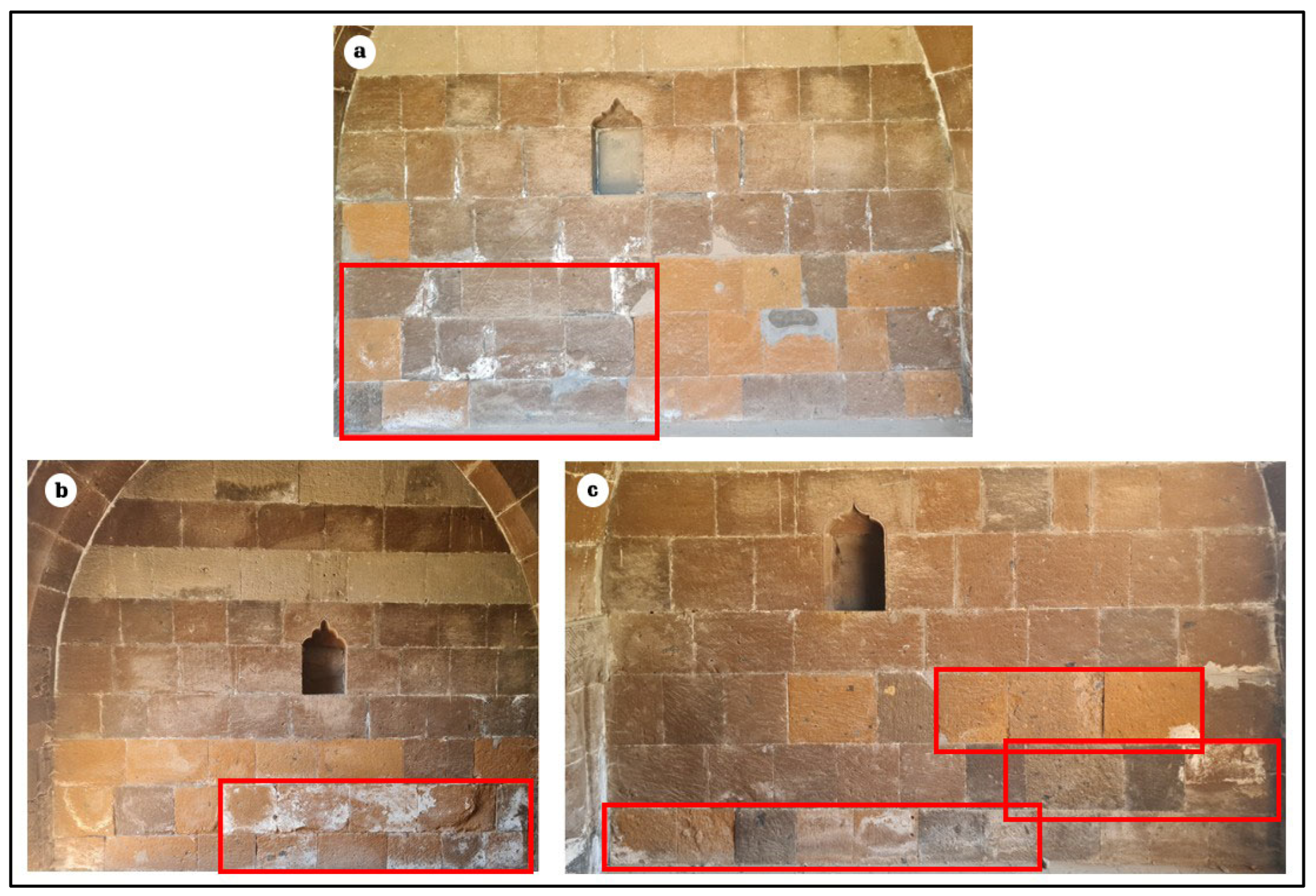

- On the interior and exterior surfaces of the monument, deterioration types such as differential erosion, contour scaling, cracks, black crust, efflorescence, graffiti, lichens, moss, and higher plants were identified. The most prominent type of deterioration is efflorescence, which is widespread in the capillary zone of the monument.

- Deep moisture distributions in the interior walls range from 10% to 27%, with the capillary zone being the most significant factor controlling this distribution.

- In infrared thermography images, the lowest temperature was measured on the east interior wall (14.3 °C), and the highest on the west interior wall (33.1 °C). This temperature variation is related to the monument’s exterior topographic elevation and capillary water rise.

- P-wave velocity values vary widely depending on the atmospheric processes to which the monument is exposed. The geomechanical properties (water absorption value by weight, porosity, P-wave velocity, etc.), location (geographical direction, height from the base, duration of sunlight exposure, etc.), and size of the building stones are important factors in this variation.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bozdağ, A.; Bayram, A.F.; İnce, İ.; Asan, K. The relationship between weathering and welding degree of pyroclastic rocks in the Kilistra ancient city, Konya (Central Anatolia, Turkey). J. Afr. Earth Sci. 2016, 123, 1–9. [Google Scholar] [CrossRef]

- İnce, İ.; Bozdağ, A.; Korkanç, M. Leeb Hardness Approach in the Determination of Strength after Accelerated Weathering Tests. Stud. Conserv. 2025, 70, 332–342. [Google Scholar] [CrossRef]

- Tuğrul, A. Niksar Yöresindeki Bazaltların Mühendislik Özelliklerine Ayrışmanın Etkileri. Ph.D. Thesis, İstanbul Üniversitesi, Fen Bilimleri Enstitüsü, İstanbul, Turkey, 1995. [Google Scholar]

- Mol, L.; Preston, P.R. The writing’s in the wall: A review of new preliminary applications of electrical resistivity tomography within archaeology. Archaeometry 2010, 52, 1079–1095. [Google Scholar] [CrossRef]

- Fort, R.; de Buergo, M.A.; Perez-Monserrat, E.M. Non-destructive testing for the assessment of granite decay in heritage structures compared to quarry stone. Int. J. Rock Mech. Min. Sci. 2013, 61, 296–305. [Google Scholar] [CrossRef]

- Jo, Y.H.; Lee, C.H. Quantitative modeling and mapping of blistering zone of the Magoksa Temple stone pagoda (13th century, Republic of Korea) by graduated heating thermography. Infrared Phys. Technol. 2014, 65, 43–50. [Google Scholar] [CrossRef]

- Kilic, G. Using advanced NDT for historic buildings: Towards an integrated multidisciplinary health assessment strategy. J. Cult. Herit. 2015, 16, 526–535. [Google Scholar] [CrossRef]

- Fais, S.; Cuccuru, F.; Ligas, P.; Casula, G.; Bianchi, M.G. Integrated ultrasonic, laser scanning and petrographical characterisation of carbonate building materials on an architectural structure of a historic building. Bull. Eng. Geol. Environ. 2017, 76, 71–84. [Google Scholar] [CrossRef]

- İnce, İ.; Bozdağ, A.; Tosunlar, M.B.; Hatır, M.E.; Korkanç, M. Determination of deterioration of the main facade of the Ferit Paşa Cistern by non-destructive techniques (Konya, Turkey). Environ. Earth Sci. 2018, 77, 420. [Google Scholar] [CrossRef]

- Korkanç, M.; Hüseyinca, M.Y.; Hatır, M.E.; Tosunlar, M.B.; Bozdağ, A.; Özen, L.; İnce, İ. Interpreting sulfated crusts on natural building stones using sulfur contour maps and infrared thermography. Environ. Earth Sci. 2019, 78, 378. [Google Scholar] [CrossRef]

- Valero, L.R.; Sasso, V.F.; Vicioso, E.P. In situ assessment of superficial moisture condition in façades of historic building using non-destructive techniques. Case Stud. Constr. Mater. 2019, 10, e00228. [Google Scholar] [CrossRef]

- Bozdağ, A.; İnce, İ.; Bozdağ, A.; Hatır, M.E.; Tosunlar, M.B.; Korkanç, M. An assessment of deterioration in cultural heritage: The unique case of Eflatunpınar Hittite Water Monument in Konya, Turkey. Bull. Eng. Geol. Environ. 2020, 79, 1185–1197. [Google Scholar] [CrossRef]

- Tosunlar, M.B.; Beycan, A.D.O.; Korkanç, M. Non-destructive test investigations on the deterioration of roman mausoleum in Karadağ central anatolia, Turkey. Mediterr. Archaeol. Archaeom. 2020, 20, 199. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Q.; Tong, H.; He, Z.; Qu, J.; Zhang, B. Monitoring the deterioration of masonry relics at a UNESCO World Heritage site. KSCE J. Civ. Eng. 2021, 25, 3097–3106. [Google Scholar] [CrossRef]

- Hatir, M.E.; Barstuğan, M.; İnce, İ. Deep learning-based weathering type recognition in historical stone monuments. J. Cult. Herit. 2020, 45, 193–203. [Google Scholar] [CrossRef]

- Hatır, M.E.; Ince, I.; Bozkurt, F. Investigation of the effect of microclimatic environment in historical buildings via infrared thermography. J. Build. Eng. 2022, 57, 104916. [Google Scholar] [CrossRef]

- Özer, F.; Söylemez, M.; İnce, İ.; Günaydin, O. Detection of deteriorations in cultural structures created by carving into low-strength rocks by the non-destructive test (NDT) method. Front. Archit. Res. 2023, 12, 788–802. [Google Scholar] [CrossRef]

- Korkanç, M.; İnce, İ.; Hüseyinca, M.Y.; Tosunlar, M.B.; Hatır, M.E. The effect of case hardening on the natural preservation of stone monuments, Fraktin monument, Türkiye. Bull. Eng. Geol. Environ. 2025, 84, 258. [Google Scholar] [CrossRef]

- Yılmaz, V. İç göçün nedenleri ve değerlendirilmesi: Bitlis ili örneği. OPUS Int. J. Soc. Res. 2019, 11, 1709–1735. [Google Scholar] [CrossRef]

- Güleryüz, U. Bitlis in İnanç Turizmi Potansiyeli Üzerinde Ohin Norşin ve Hizan Medreselerinin Etkileri. In Proceedings of the 6th Uluslararası Marmara Bilimsel Araştırmalar ve İnovasyon Kongresi, İstanbul, Turkey, 7–8 October 2023. [Google Scholar]

- Bektaşoğlu, M. Anadolu’da Türk İslam Sanatı; Diyanet İşleri Başkanlığı: Ankara, Turkey, 2009. [Google Scholar]

- Biran, M. Il-Khanate Empire. In The Encyclopedia of Empire; John, M.M., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2016. [Google Scholar] [CrossRef]

- Available online: https://www.mgm.gov.tr/veridegerlendirme/il-ve-ilceler-istatistik.aspx?k=undefined&m=BITLIS (accessed on 29 July 2025).

- Akın, M.; Dinçer, İ.; Özvan, A.; Oyan, V.; Tapan, M. İgnimbiritlerdeki kılcal su emme özelliğinin Ahlat Selçuklu mezar taşlarının bozunmasındaki rolü. Jeol. Mühendisliği Derg. 2016, 40, 149–166. [Google Scholar] [CrossRef]

- Özvan, A.; Dinçer, İ.; Akın, M.; Oyan, V.; Tapan, M. Experimental studies on ignimbrite and the effect of lichens and capillarity on the deterioration of Seljuk Gravestones. Eng. Geol. 2015, 185, 81–95. [Google Scholar] [CrossRef]

- Ötüken, S.Y. Türkiyeʼde Vakıf Abideler ve Eski Eserler: Balıkesir. Bilecik. Bingöl. Bitlis. Bolu. Burdur; Vakıflar Genel Müdürlüğü: Kizilay, Turkey, 1977; Volume 2. [Google Scholar]

- TS EN-1936: 2010; Natural Stone Test Methods—Determination of Real Density and Apparent Density and of Total and Open Porosity. Turkish Standards Institution: Ankara, Turkey, 2010.

- ASTM E494; Standard Practice for Measuring Ultrasonic Velocity in Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D5873; Standard Test Method for Determination of Rock Hardness by Rebound Hammer Method. ASTM International: West Conshohocken, PA, USA, 2014.

- TS EN-12407; Natural Stone Test Methods—Petrographic Examination. Turkish Standards Institution: Ankara, Turkey, 2019.

- İnce, İ.; Korkanç, M.; Hatır, M.E. Evaluation of weathering effects due to surface and deep moisture in a Roman rock tomb: Lukianos Monument Konya (Turkey). Mediterr. Archaeol. Archaeom. 2020, 20, 121. [Google Scholar] [CrossRef]

- International Council on Monument and Sites International Scientific Committee for Stone (ICOMOS-ISCS). Illustrated Glossary on Stone Deterioration Patterns; Ateliers 30 Impresión; International Council on Monument and Sites International Scientific Committee for Stone: Champigny-sur-Marne, France, 2008. [Google Scholar]

- Golden Software. Environmental Services: Accurately Assess Your Site and Confidently Advise Stakeholders; Golden Software, LLC.: Golden, CO, USA, 2025; Available online: https://www.goldensoftware.com (accessed on 23 August 2025).

- StataCorp. Stata Statistical Software: Release 15; StataCorp LLC.: College Station, TX, USA, 2017. [Google Scholar]

- NBG. Engineering Geology and Rock Engineering; Norwegian Group of Rock Mechanics: Fornebu, Norway, 1985. [Google Scholar]

- Chen, T.C.; Yeung, M.R.; Mori, N. Effect of water saturation on deterioration of welded tuff due to freeze-thaw action. Cold Reg. Sci. Technol. 2004, 38, 127–136. [Google Scholar] [CrossRef]

- Korkanç, M.; İnce, İ.; Hatır, M.E.; Tosunlar, M.B. Atmospheric and anthropogenic deterioration of the İvriz rock monument: Ereğli-Konya, Central Anatolia, Turkey. Bull. Eng. Geol. Environ. 2021, 80, 3053–3063. [Google Scholar] [CrossRef]

- Hatır, M.E.; İnce, İ.; Korkanç, M. The effect of wind and solar radiation on deterioration developments in historic buildings: Şeyh Osman Rumi Tomb, Central Turkey. Environ. Earth Sci. 2024, 83, 617. [Google Scholar] [CrossRef]

- Fener, M. The effect of rock sample dimension on the P-wave velocity. J. Nondestruct. Eval. 2011, 30, 99–105. [Google Scholar] [CrossRef]

- Liao, Z.; Xu, J.; Zhang, K.; Zhou, C. Exploring wave propagation behaviors in rock: A grain-based perspective on mineral structures. Deep Undergr. Sci. Eng. 2025, 1–15. [Google Scholar] [CrossRef]

- İnce, İ.; Karakaya, E.; Balci, M.C.; Tosunlar, M.B. Investigation of the relationships between direct and semi-direct P-wave velocity measurement techniques in igneous rocks. Sādhanā 2025, 50, 145. [Google Scholar] [CrossRef]

- Karakul, H.; Ulusay, R. Empirical correlations for predicting strength properties of rocks from P-wave velocity under different degrees of saturation. Rock Mech. Rock Eng. 2013, 46, 981–999. [Google Scholar] [CrossRef]

- Kahraman, S.; Fener, M.; Kilic, C.O. Estimating the wet-rock P-wave velocity from the dry-rock P-wave velocity for pyroclastic rocks. Pure Appl. Geophys. 2017, 174, 2621–2629. [Google Scholar] [CrossRef]

- Fener, M.; Ince, I. Effects of the freeze–thaw (F–T) cycle on the andesitic rocks (Sille-Konya/Turkey) used in construction building. J. Afr. Earth Sci. 2015, 109, 96–106. [Google Scholar] [CrossRef]

- Gökçe, M.V.; İnce, İ.; Fener, M.; Taşkıran, T.; Kayabali, K. The effects of freeze–thaw (F–T) cycles on the Gödene travertine used in historical structures in Konya (Turkey). Cold Reg. Sci. Technol. 2016, 127, 65–75. [Google Scholar] [CrossRef]

| Measurement Period (2011–2024) | ||||||

|---|---|---|---|---|---|---|

| Months | Average Temperature (°C) | Average Maximum Temperature (°C) | Average Minimum Temperature (°C) | Monthly Average Total Precipitation (mm) | Maximum Temperature (°C) | Minimum Temperature (°C) |

| January | −4.2 | −0.4 | −7.9 | 157.0 | 10.1 | −24.1 |

| February | −3.2 | 1.1 | −7.1 | 110.2 | 21.9 | −21.3 |

| March | 0.9 | 5 | −2.8 | 205.8 | 16.7 | −20.3 |

| April | 7.5 | 12.5 | 2.9 | 124.4 | 22.9 | −10.0 |

| May | 12.3 | 17.6 | 7.1 | 107.5 | 27.4 | 0.0 |

| June | 18.4 | 24.4 | 11.7 | 15.8 | 31.5 | 5.2 |

| July | 22.7 | 29.0 | 15.8 | 8.6 | 34.6 | 8.1 |

| August | 23.0 | 29.6 | 16.2 | 7.3 | 34.3 | 9.9 |

| September | 18.3 | 24.6 | 11.7 | 26.9 | 32.2 | 2.7 |

| October | 11.2 | 16.6 | 6.3 | 89.2 | 26.4 | −1.7 |

| November | 4.2 | 8.7 | 0.6 | 90.9 | 21.7 | −12.5 |

| December | −1.5 | 2.4 | −4.9 | 128.1 | 13.3 | −24.4 |

| Annual | 9.1 | 14.3 | 4.1 | 1071.7 | 34.6 | −24.4 |

| Samples | Reddish Brown Ignimbrite | Dark Brown Ignimbrite | Yellowish Gray Ignimbrite | Black Ignimbrite |

|---|---|---|---|---|

| SiO2 | 66.25 | 66.80 | 72.43 | 66.04 |

| Al2O3 | 16.03 | 15.53 | 12.44 | 16.24 |

| Fe2O3 | 4.47 | 4.49 | 4.28 | 4.62 |

| MgO | 0.21 | 0.20 | 0.04 | 0.23 |

| CaO | 1.45 | 1.46 | 0.45 | 1.55 |

| Na2O | 5.90 | 5.85 | 4.96 | 5.73 |

| K2O | 5.11 | 5.11 | 5.10 | 5.01 |

| TiO2 | 0.40 | 0.38 | 0.26 | 0.40 |

| P2O5 | 0.06 | 0.07 | 0.01 | 0.06 |

| MnO | 0.14 | 0.14 | 0.11 | 0.14 |

| * Dry unit weight (kN/m3) | 15.13 | 15.77 | 16.82 | 14.85 |

| * Uniaxial compressive strength (MPa) | 15.78 | 12.10 | 28.92 | 12.43 |

| Sample No. | Color | Mineralogical Composition | Texture | Rock Name |

|---|---|---|---|---|

| 1 | Beige | MS 43%, Q 22%, Rf 18%, P 12%, B 3%, Py 2% | Fiamme | Ignimbrite |

| 2 | Brown | MS 49%, Q 23%, Rf 13%, P 13%, Py 2% | Fiamme | Ignimbrite |

| 3 | Dark brown | MS 41%, Q 33%, Rf 12%, P 11%, Py 3% | Fiamme | Ignimbrite |

| 4 | Black | MS 52%, Q 21%, Rf 13%, P 12%, Py 2% | Fiamme | Ignimbrite |

| Sample No | ρd—g/cm3 | n—% | Wa—% | Vp—km/s | SHR |

|---|---|---|---|---|---|

| 1 | 1.71 ± 0.01 | 22.59 ± 0.60 | 13.42 ± 0.28 | 2.40 ± 0.02 | 21.40 ± 1.02 |

| 2 | 1.63 ± 0.01 | 30.75 ± 0.95 | 19.80 ± 0.34 | 1.64 ± 0.05 | 15.50 ± 0.75 |

| 3 | 1.66 ± 0.01 | 29.13 ± 0.82 | 18.83 ± 0.29 | 2.30 ± 0.06 | 14.30 ± 0.85 |

| 4 | 1.52 ± 0.01 | 31.70 ± 0.73 | 20.55 ± 0.37 | 1.55 ± 0.05 | 13.50 ± 0.78 |

| NST | 5 | 5 | 5 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balci, M.C. Evaluation of Deterioration in Cultural Stone Heritage Using Non-Destructive Testing Techniques: The Case of Emir Ali Tomb (Ahlat, Bitlis, Türkiye). Appl. Sci. 2025, 15, 10404. https://doi.org/10.3390/app151910404

Balci MC. Evaluation of Deterioration in Cultural Stone Heritage Using Non-Destructive Testing Techniques: The Case of Emir Ali Tomb (Ahlat, Bitlis, Türkiye). Applied Sciences. 2025; 15(19):10404. https://doi.org/10.3390/app151910404

Chicago/Turabian StyleBalci, Mehmet Can. 2025. "Evaluation of Deterioration in Cultural Stone Heritage Using Non-Destructive Testing Techniques: The Case of Emir Ali Tomb (Ahlat, Bitlis, Türkiye)" Applied Sciences 15, no. 19: 10404. https://doi.org/10.3390/app151910404

APA StyleBalci, M. C. (2025). Evaluation of Deterioration in Cultural Stone Heritage Using Non-Destructive Testing Techniques: The Case of Emir Ali Tomb (Ahlat, Bitlis, Türkiye). Applied Sciences, 15(19), 10404. https://doi.org/10.3390/app151910404