Experimental and Numerical Study of Damage Evolution and Fracture Characteristics of Three-Layer Composite Rocks Under Dynamic Loading

Abstract

1. Introduction

2. Test Program and Fabrication of Specimens

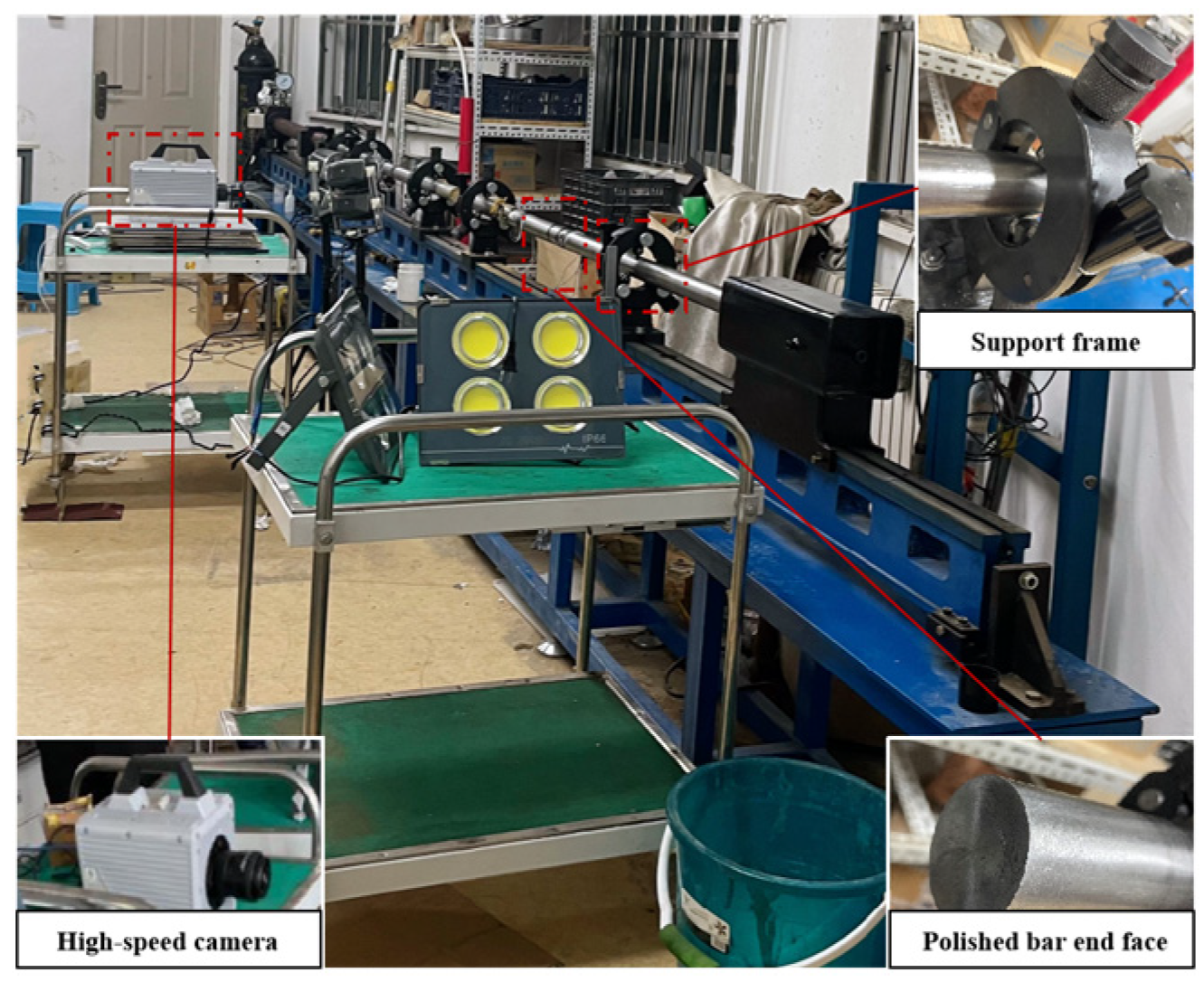

2.1. Test Programand Apparatus

- (1)

- Loading drive system: including launch chamber, high-pressure gas chamber, pressure control valve, high-pressure nitrogen cylinder, etc.

- (2)

- Pressure bar system: composed of impact bar, incident bar, transmission bar, absorption device, etc.

- (3)

- Data acquisition system: composed of strain gauges, junction box, ultra-dynamic strain gauge, oscilloscope, computer, etc.

- (4)

- Image acquisition system: high-speed camera, supplementary lighting device, etc.

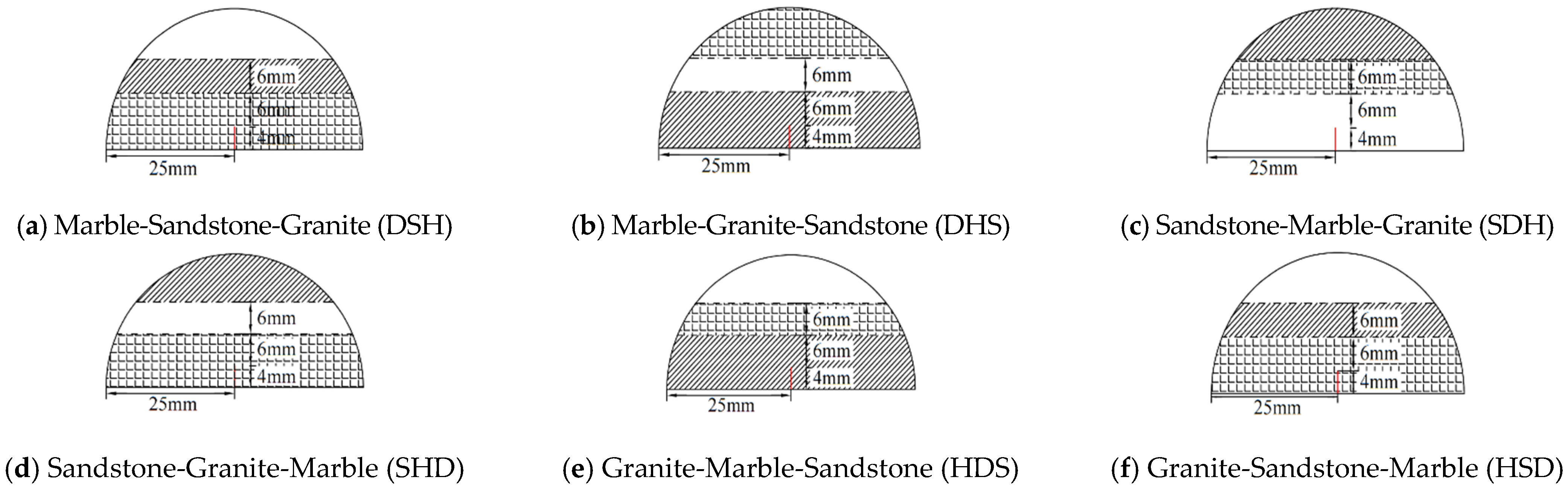

2.2. Fabrication of Specimens

3. Test Results and Analysis

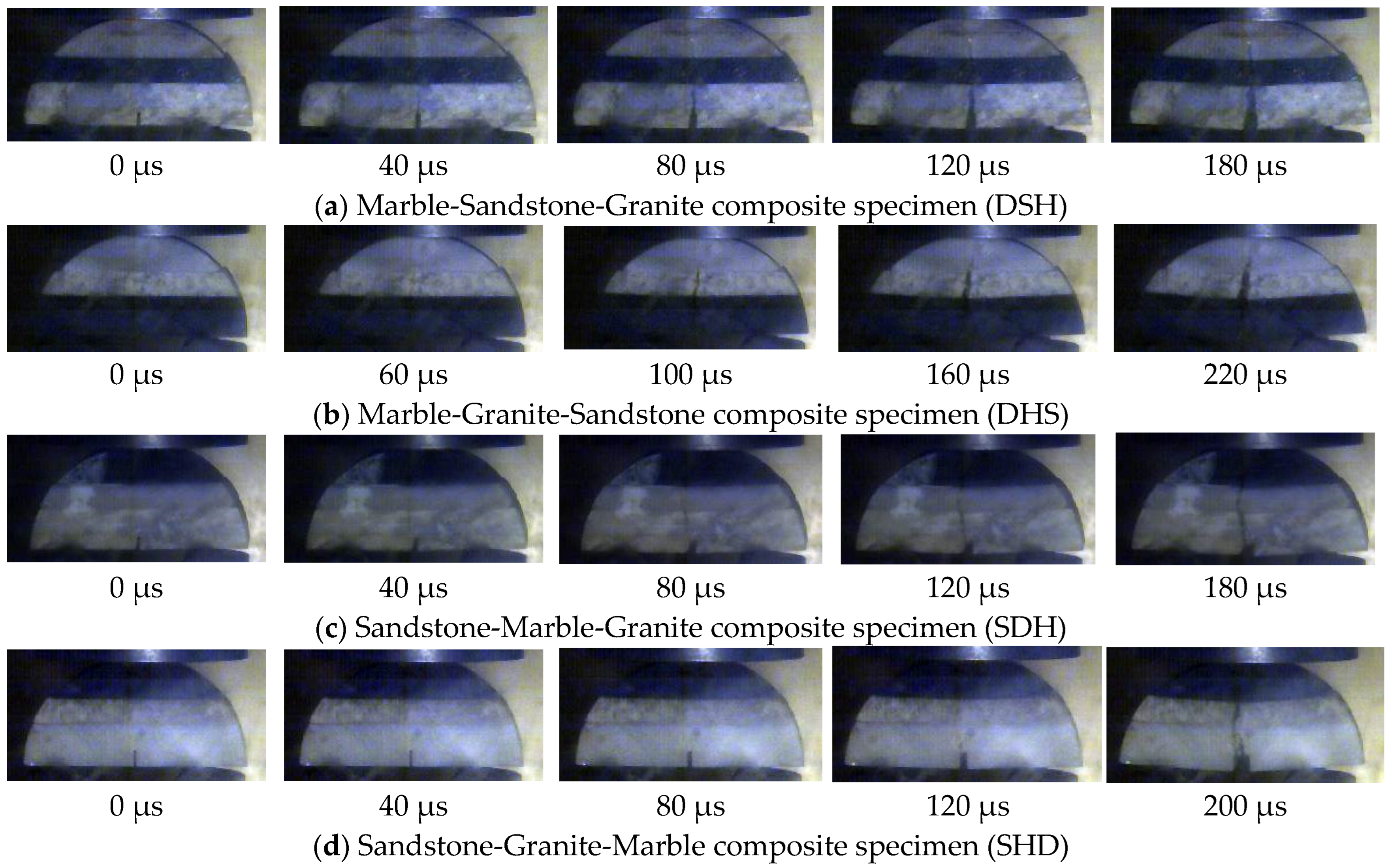

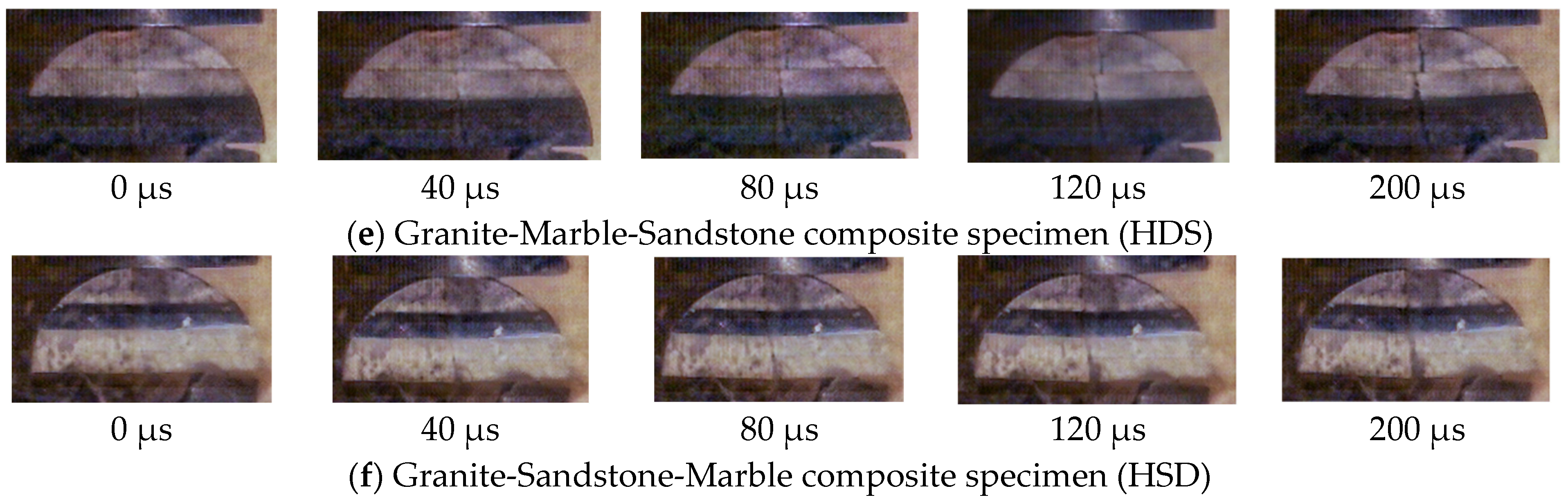

3.1. Analysis of Specimen Damage Process

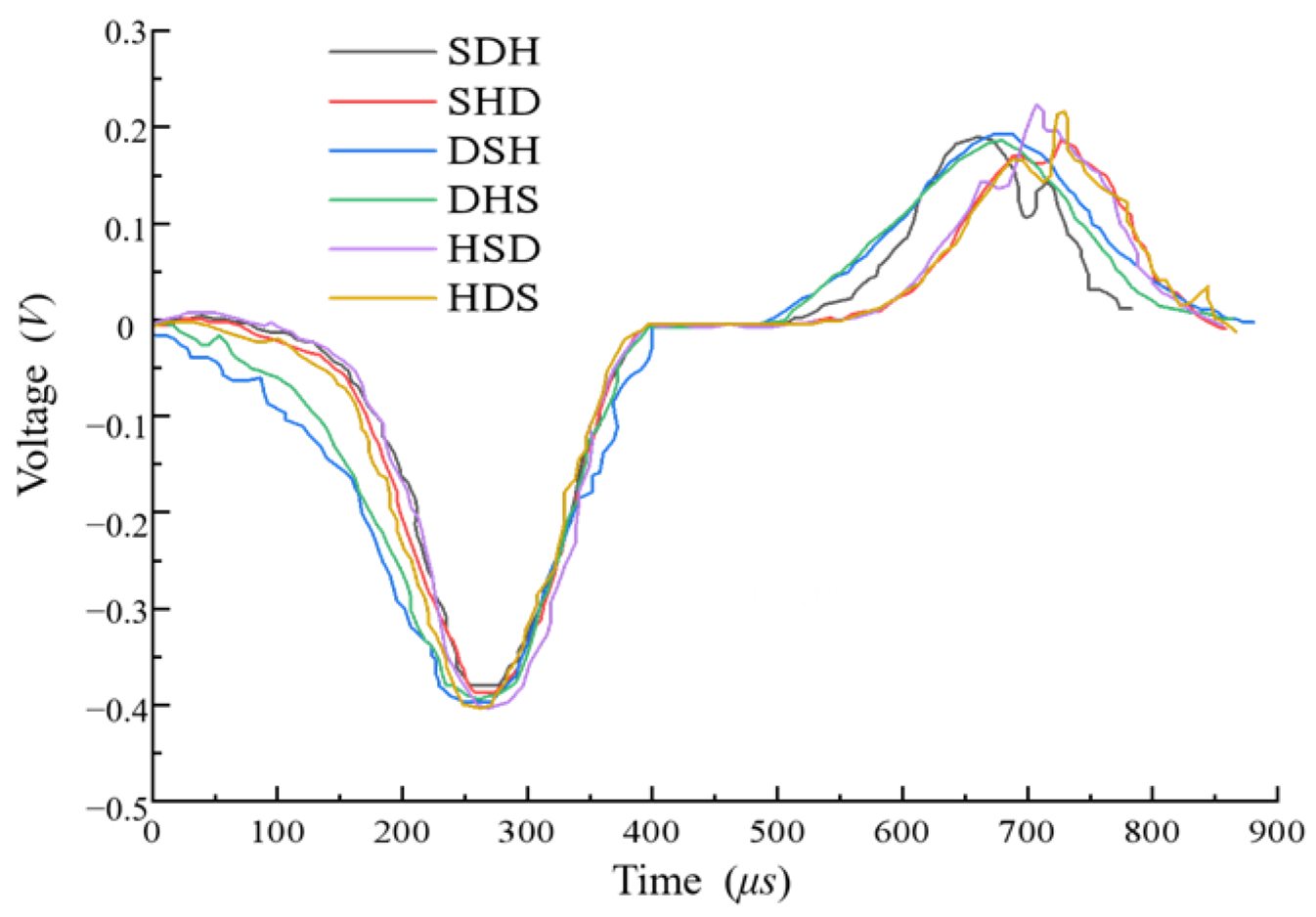

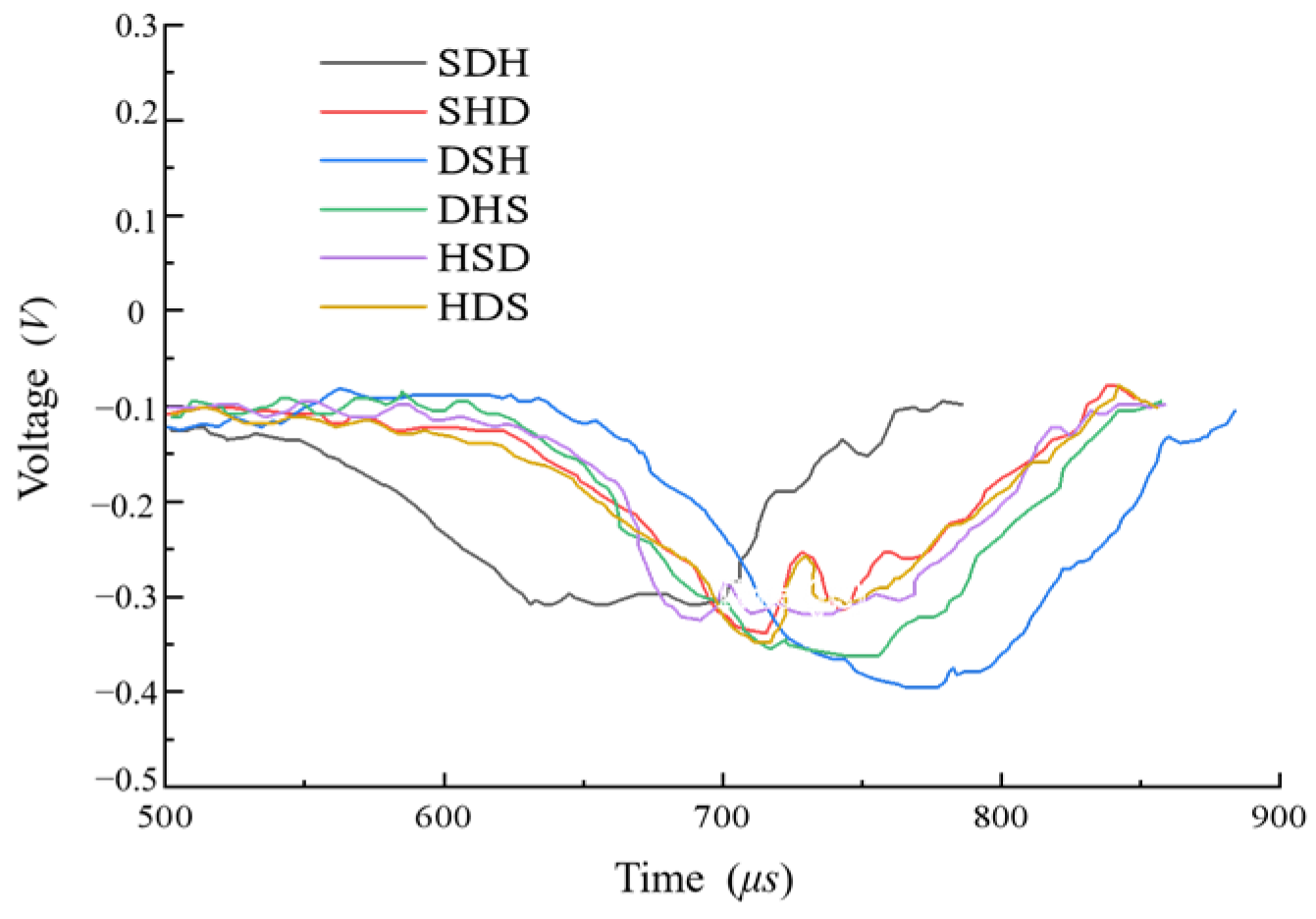

3.2. Stress Wave Characterization

3.3. Analysis of Stress Characteristic Curve and Peak Intensity Change

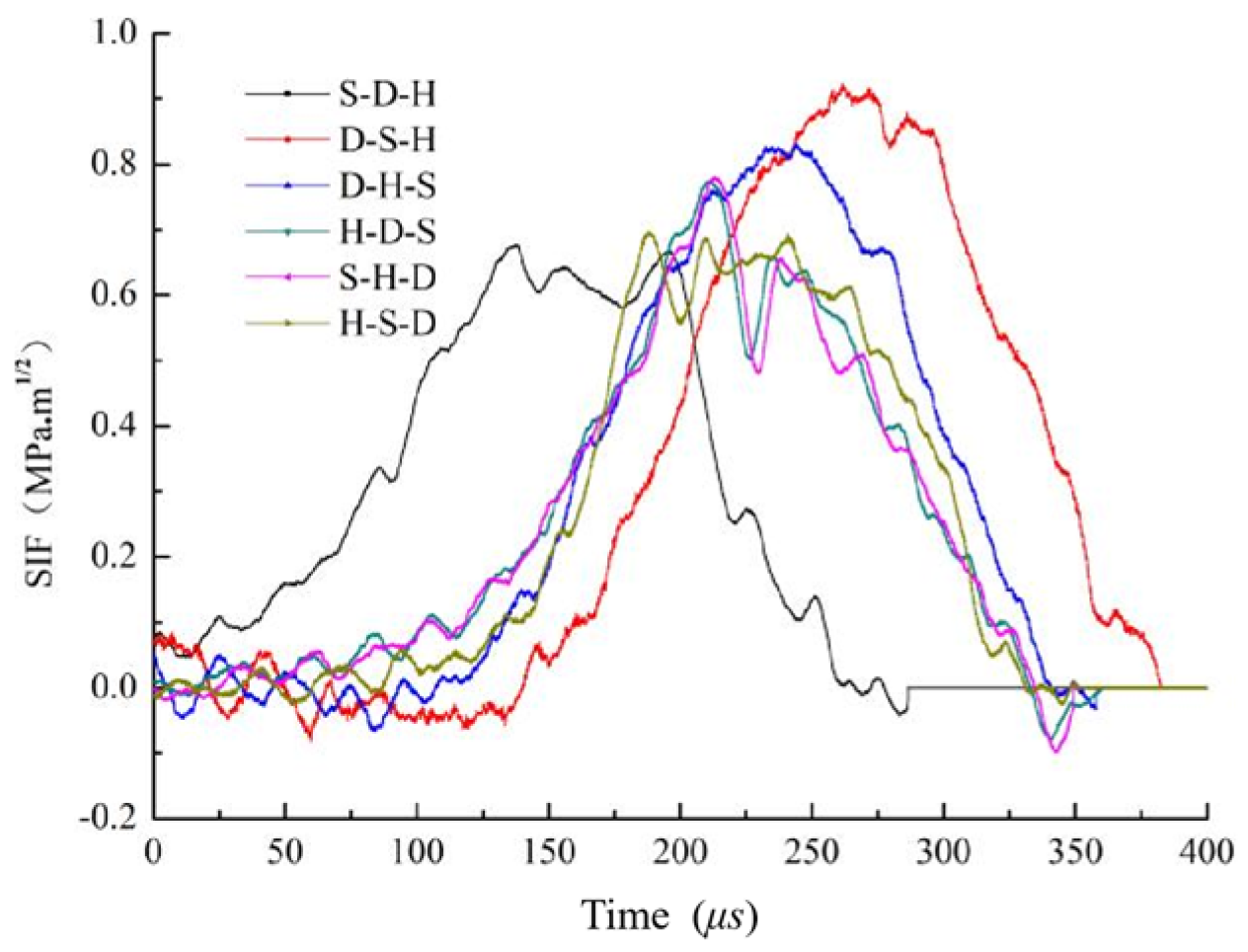

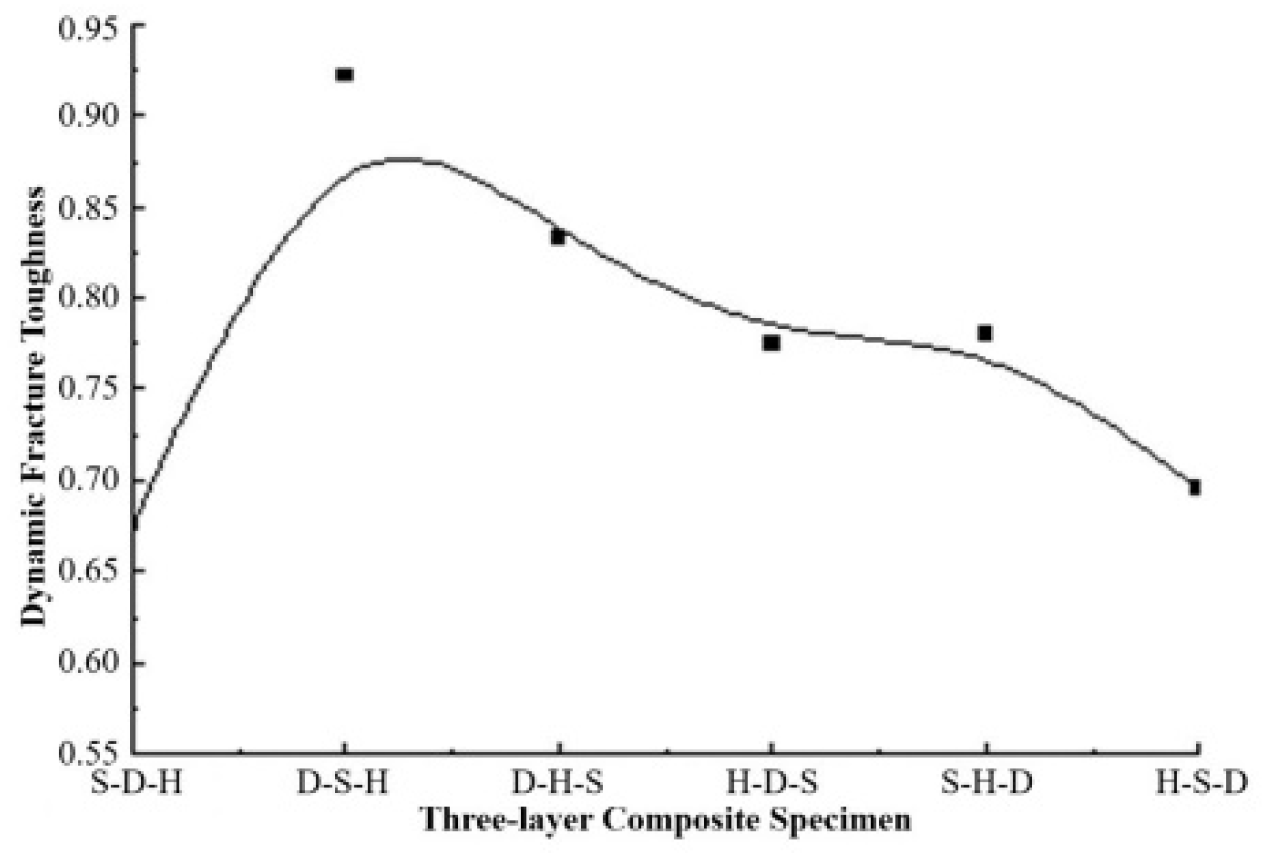

3.4. Analysis of Dynamic Fracture Toughness

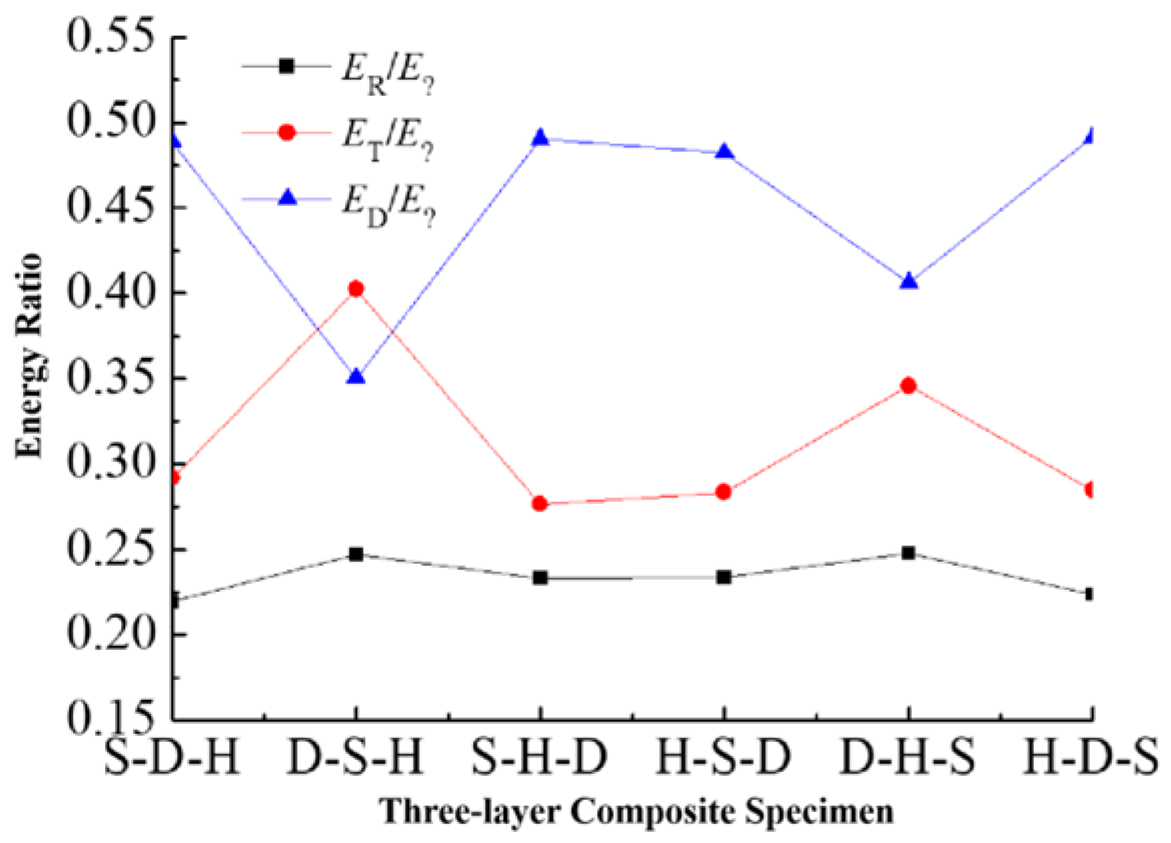

3.5. Characterization of Energy Evolution in the Impact Process

4. DLSM Numerical Simulation Analysis of Stress Wave Transmission and Stress Damage in Three-Layer Composite Rock Materials

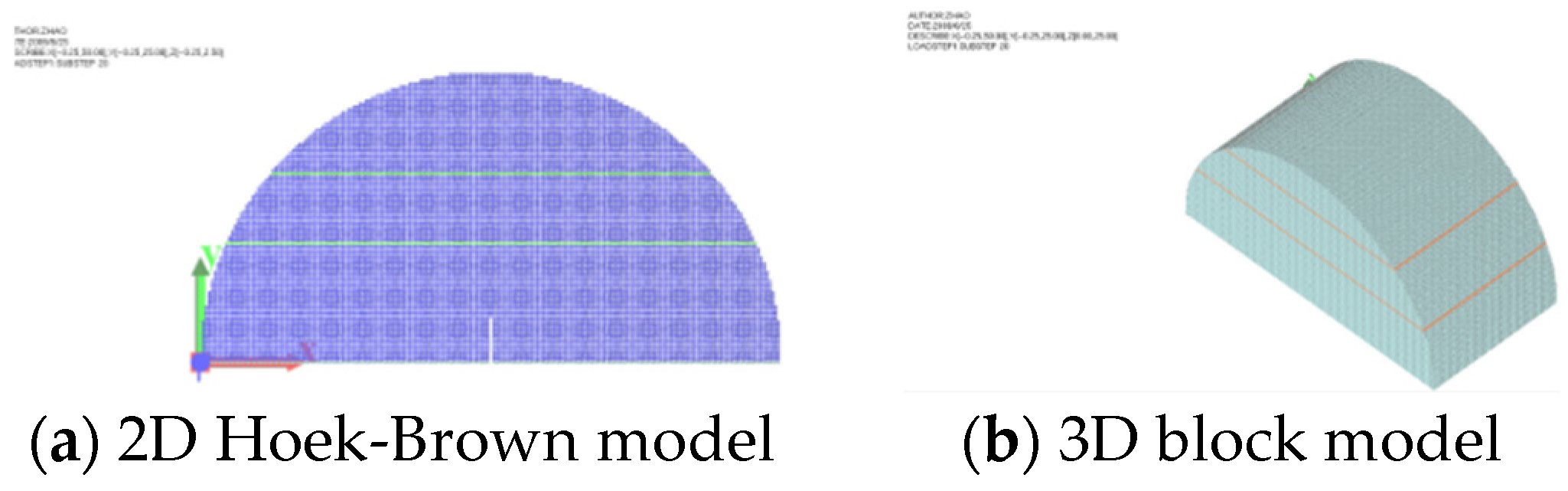

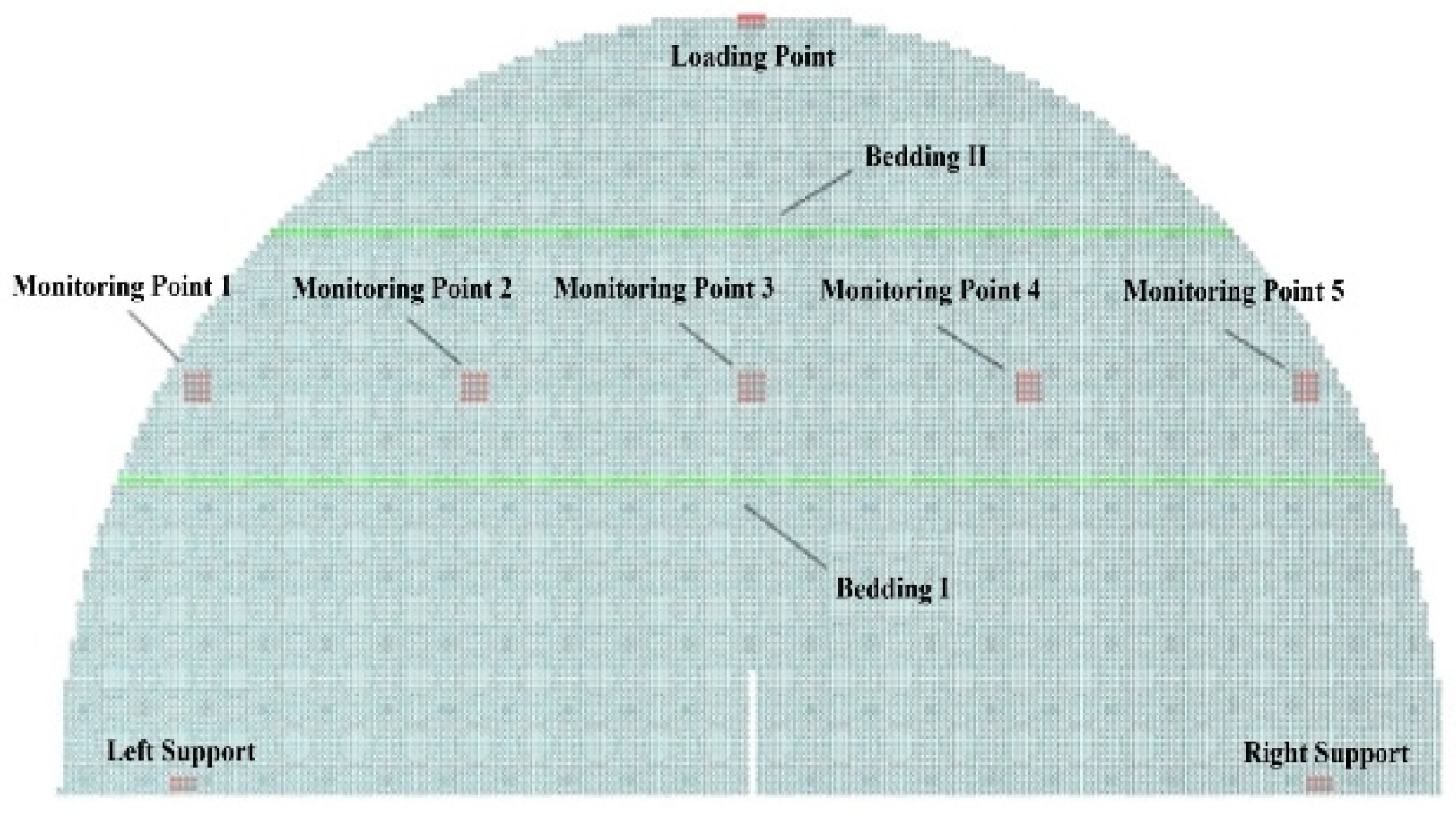

4.1. Modeling

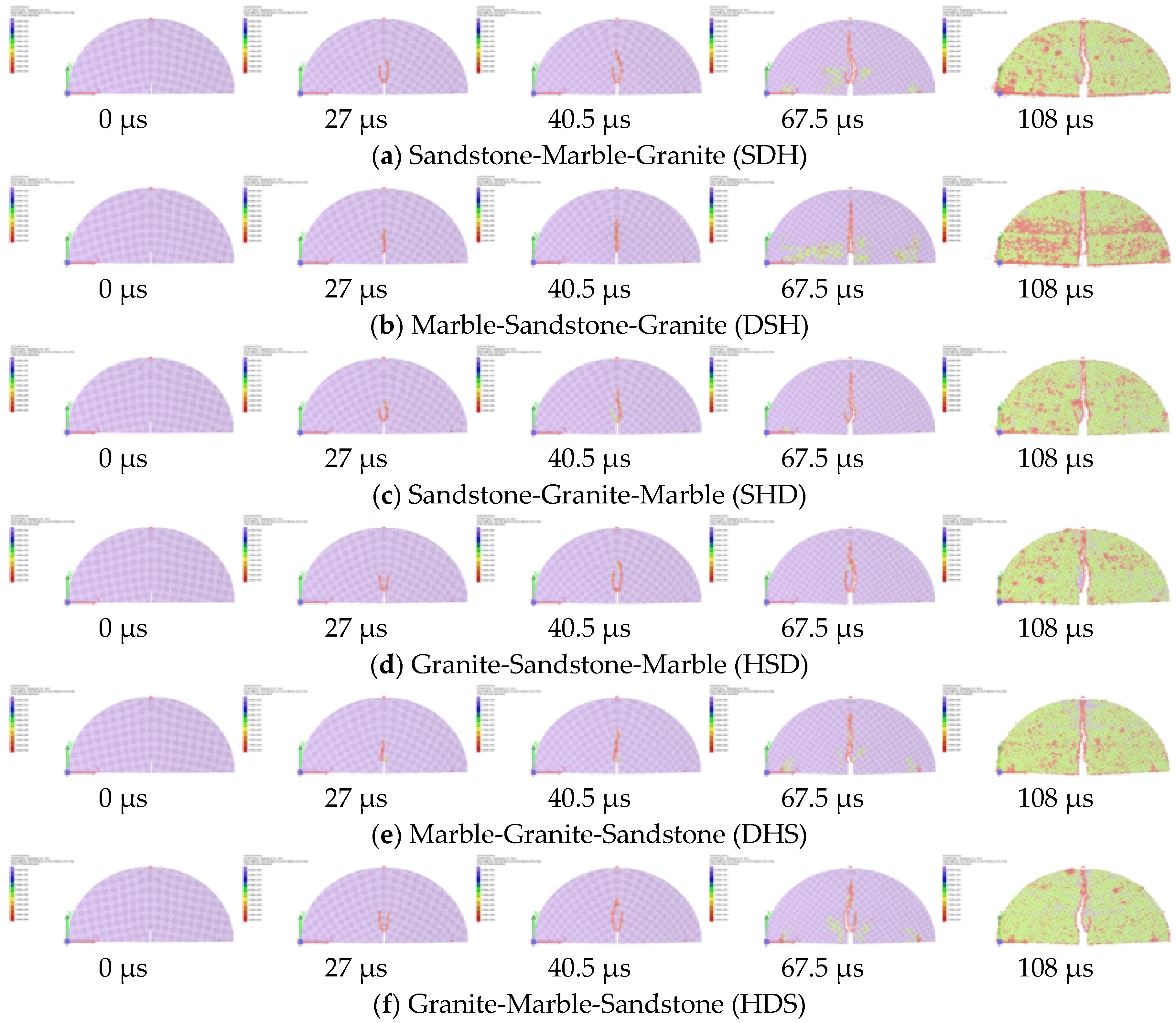

4.2. Dynamic Fracture Process Analysis

4.3. Analysis of Crack Propagation Displacement Fitting Curve

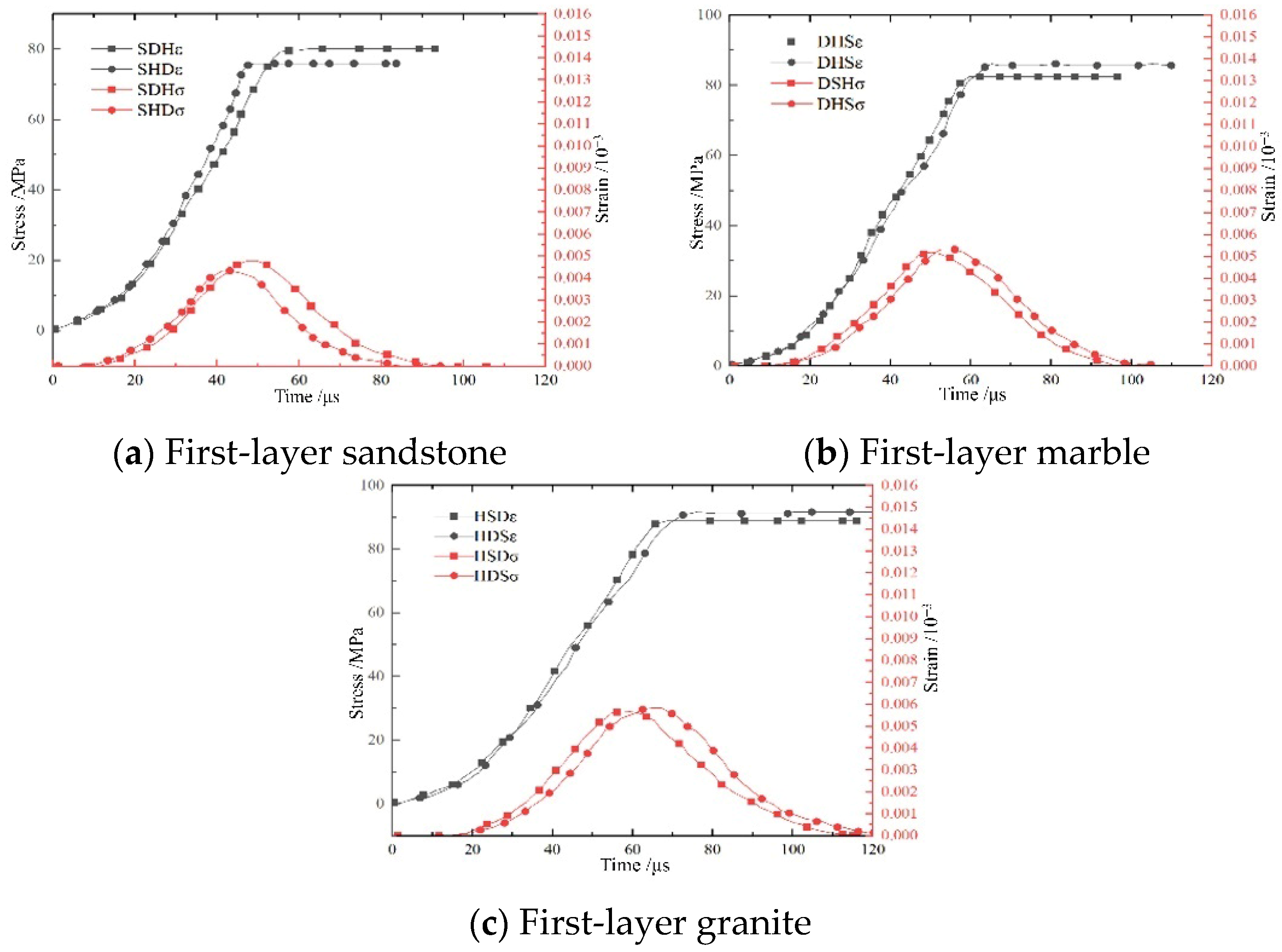

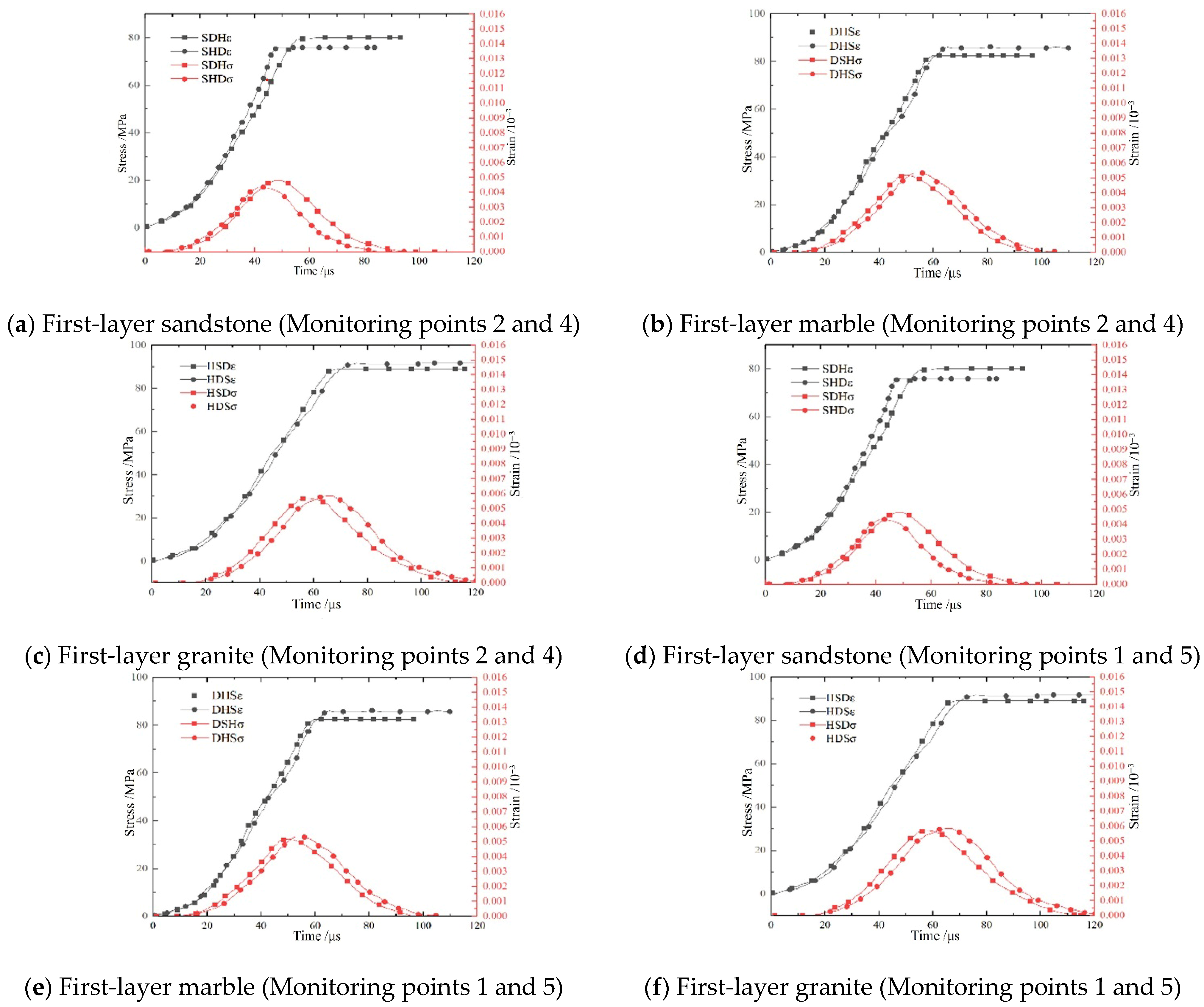

4.4. Analysis of Stress–Strain Characteristics at Monitoring Points

5. Conclusions

- (1)

- The fracture mechanism of the composite specimen primarily initiates at the tip of cut seam, subsequently propagating along the upper surface and penetrating the bedding structure. When marble is utilized as the impact end material, it tends to generate secondary cracks due to stress concentration rather than originating from the tip of cut seam. Furthermore, the fracture morphology observed in the three-layer composite specimens exhibits a notable similarity, without significant distinctions.

- (2)

- When subjected to identical impact conditions, the incident wave forms across various composite specimens are nearly identical. However, the peak value of the transmitted wave varies with the position switch of each layer. It has been observed that marble demonstrates superior wave impedance matching when utilized as the material subjected to the impact. The ratio of reflected energy in the three-layer composite specimens remains relatively constant, while the transmitted energy ratio indicates that when marble serves as the upper material, the energy transmission ratio is greater. In contrast, the transmitted energy ratios for sandstone and granite are largely comparable due to their substantial hardness differences.

- (3)

- When the integrated hardness of a specimen remains constant, a lower hardness at the crack initiation site leads to a more rapid onset of crack initiation. If the crack initiation site is identical, a reduced hardness in the second layer of the specimen results in quicker crack propagation. Regarding dynamic fracture toughness, specimens exhibiting minimal hardness variation demonstrate that when the impact material is sandstone, the dynamic fracture peak value is diminished, causing these specimens more susceptible to cracking. For specimens where the first layer material is uniform, those with a softer second layer material exhibit lower dynamic fracture toughness, facilitating crack expansion. Conversely, specimens with a significant hardness disparity experience faster damage, which deviates from this observed trend.

- (4)

- The dynamic fracture behavior simulated by DLSM aligns closely with experimental findings. The load–displacement curve indicates that the peak load for specimens with granite as the upper layer is significantly greater than that of other specimens. Among specimens sharing the same upper material, variations in peak load are evident. Specifically, when the lower material is marble or granite, the peak load surpasses that of specimens with sandstone as the lower layer. However, when the upper material is either marble or granite, no substantial difference is observed between these specimens and those with sandstone as the lower layer. Notably, the three-layer composite specimen exhibiting the highest peak load is HSD, followed closely by HDS, while DSH exhibits a slight increase over DHS.

- (5)

- The stress–strain characteristics of the three-layer composite laminated specimen are influenced by the overall hardness of the material. Specifically, a lower hardness in the material composition located near the impact end results in a reduced overall hardness of the specimen, which in turn leads to a diminished peak stress–strain value and a delayed time to achieve peak stress and strain. The time to reach peak strain and peak stress is also contingent upon the differences in material hardness. Where the first layer is composed of granite, followed by marble, the aforementioned trend is followed. However, when the first layer consists of sandstone, the significant hardness disparity between sandstone and granite, along with the brittleness of granite, alters this dynamic. Consequently, the time to reach the peak for the sandstone layer occurs prior to that of the granite layer.

- (6)

- The findings of this study hold significant application prospects for practical engineering. In geotechnical engineering involving dynamic loading such as tunnel excavation, mine blasting, and hydraulic engineering, for composite rock masses composed of multiple layers of different rocks, their damage evolution and fracture characteristics under impact loading can be predicted based on the properties (e.g., hardness, elastic modulus) of each layer of rock. This provides a theoretical basis for optimizing engineering design and formulating reasonable construction schemes.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hopkinson, J. On the rupture of iron wire by a blow. Proc. Manch. Lit. Philos. Soc. 1872, 11, 40–45. [Google Scholar]

- Hopkinson, J. Further experiments on the rupture of iron wire. Proc. Manch. Lit. Philos. Soc. 1872, 1, 119–121. [Google Scholar]

- Al-aasm, I.S.; Mrad, C.; Packard, J. Fluid compartmentalization of Devonian and Mississippian dolostones, western Canada sedimentary basin: Petrologic and geochemical evidence from fracture mineralization. Can. J. Earth Sci. 2019, 56, 265–305. [Google Scholar] [CrossRef]

- Lenton, A.; Mcinnes, K.L.; O’grady, J.G. Marine projections of warming and ocean acidification in the australasian region. Aust. Meteorol. Oceanogr. J. 2015, 65, S1–S28. [Google Scholar] [CrossRef]

- Lei, Q.H.; Gao, K. A numerical study of stress variability in heterogeneous fractured rocks. Int. J. Rock Mech. Min. Sci. 2019, 113, 121–133. [Google Scholar] [CrossRef]

- Odling, N.E. Scaling and connectivity of joint systems in sandstones from western Norway. J. Struct. Geol. 1997, 19, 1257–1271. [Google Scholar] [CrossRef]

- Shi, H.; Song, L.; Wang, D. Strength model for damaged sandstone based on power-law distribution of crack length. J. China Univ. Min. Technol. 2022, 51, 263–272. [Google Scholar]

- Shi, H.; Zhang, H.; Song, L.; Wu, Y. Variation of strata pressure and axial bolt load at a coal mine face under the effect of a fault. Arch. Min. Sci. 2019, 64, 351–374. [Google Scholar]

- Li, D.; Wan, Q.; Zhu, Q.; Hu, C. Experimental study on mechanical properties and failure behaviour of fractured rocks under different loading methods. J. Min. Saf. Eng. 2021, 38, 1025–1035. [Google Scholar]

- Zhang, M.; Wang, W.; Wang, Q.; Zhang, S. Dynamic failure process and strain-damage evolution law of sandstone based on SHPB experiments. Explos. Shock Waves 2021, 41, 37–50. [Google Scholar]

- Guo, D.M.; Yan, P.Y.; Zhang, Y.S.; Zhang, W.; Ding, Y.Y.; Zhao, L.M. Experimental research on the sprayed concrete-surrounding rock combined body subjected to cyclic impact loadings. J. Vib. Shock 2019, 38, 105–111. [Google Scholar]

- Xie, B.J.; Wang, X.Y.; Lv, P.Y. Dynamic properties of bedding coal and rock and the SHPB testing for its impact damage. J. Vib. Shock 2017, 36, 117–124. [Google Scholar]

- Ding, X.; Yang, Y.; Zhou, W.; An, W.; Li, J.; Ebelia, M. The law of blast stress wave propagation and fracture development in soft and hard composite rock. Sci. Rep. 2022, 12, 17120. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Xiao, T.L.; Zhao, Y.F.; Shen, H.C. Effect of fracture location on mechanical properties of composite rock samples under different surrounding pressure. Min. R D 2023, 43, 67–75. [Google Scholar]

- Dong, T.; Cao, P.; Lin, Q.; Liu, Z.; Xiao, F.; Zhang, Z. Fracture evolution of artificial composite rocks containing interface flaws under uniaxial compression. Theor. Appl. Fract. Mech. 2022, 120, 103401. [Google Scholar] [CrossRef]

- Park, C.H.; Bobet, A. Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng. Fract. Mech. 2010, 77, 2727–2748. [Google Scholar] [CrossRef]

- Sagong, M.; Bobet, A. Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int. J. Rock Mech. Min. Sci. 2002, 39, 229–241. [Google Scholar] [CrossRef]

- Li, J. Study on Mechanical Properties and Failure Characteristics of Layered Composite Rock Under Acid Environment. Ph.D. Thesis, East China Jiaotong University, Nanchang, China, 2018. [Google Scholar]

- Zhao, G.Y.; Li, Z.Y.; Wu, H.; Wang, E.J.; Liu, L.L. Dynamic failure characteristics of sandstone with non-penetrating cracks. Rock Soil Mech. 2019, 40, 73–81. [Google Scholar]

- Li, D.J.; Qi, H.; Li, C.X.; Feng, J.L. Brazilian disc splitting tests and numerical simulations on coal samples containing bedding planes. J. Min. Sci. Technol. 2020, 5, 150–159. [Google Scholar]

- Guéry, A.A.C.; Cormery, F.; Shao, J.F.; Kondo, D. A micromechanical model of elastoplastic and damage behavior of a cohesive geomaterial. Int. J. Solids Struct. 2008, 45, 1406–1429. [Google Scholar] [CrossRef]

- Bikong, C.; Hoxha, D.; Shao, J.F. A micro-macro model for time-dependent behavior of clayey rocks due to anisotropic propagation of microcracks. Int. J. Plast. 2015, 69, 73–88. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Li, D.Y.; Ma, G.W.; Li, J.C. Failure of rock under dynamic compressive loading. J. Cent. South Univ. 2008, 15, 339–343. [Google Scholar] [CrossRef]

- Zhang, M.T.; Wang, W.; Zhang, S.Y. Numerical Simulation of Failure Process and Damage of Gray Sandstone under Impact Loading. Blasting 2020, 37, 46–54. [Google Scholar]

- Yang, S.Q.; Li, Y.; Huang, Y.H.; Tang, W.L. Particle flow analysis of macroscopic and microscopic mechanical properties of Brazilian disc containing a hole under splitting test. J. China Univ. Min. Technol. 2019, 48, 984–992. [Google Scholar]

- Xie, L.; Zhu, W.; Wang, S.H.; Niu, L.L. Three-Dimensional parallel computing on failure process of rock specimen with a pre-existing circular opening. Chin. J. Geotech. Eng. 2011, 33, 1447–1455. [Google Scholar]

- Yang, S.Q.; Lu, C.H.; Qu, T. Investigations of Crack Expansion in Marble Having a Single Pre-existing Hole: Experiment and Simulations. J. China Univ. Min. Technol. 2009, 38, 774–781. [Google Scholar]

- Sha, R.D.; Liang, Z.Z.; Qian, X.Q. Numerical Simulation of Rock Specimens Failure Mode with a Single Hole Under Dynamic Loading. J. Water Resour. Archit. Eng. 2019, 17, 65–70+92. [Google Scholar]

| Rock Material | Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (GPa) | Protodyakonov’s Hardness | UCS (MPa) |

|---|---|---|---|---|---|

| Marble | 2500 | 0.3 | 3.0 | 8 | 90.5 |

| Sandstone | 2600 | 0.24 | 4.6 | 6 | 62.3 |

| Granite | 3000 | 0.2 | 18.4 | 12 | 150.1 |

| Test Specimen | Dynamic Fracture Toughness/MPa·m1/2 |

|---|---|

| SDH | 0.67605 |

| DSH | 0.92144 |

| DHS | 0.83249 |

| HDS | 0.77472 |

| SHD | 0.78014 |

| HSD | 0.69563 |

| Specimen Type | Incident Energy EI/J | Reflected Energy ER/J | Transmitted Energy ET/J | Dissipated Energy ED/J | ER/EI | ET/EI | ED/EI | |

| Three-layer composite | SDH | 30.79 | 6.75 | 8.99 | 15.04 | 21.93% | 29.19% | 48.86% |

| DSH | 40.08 | 9.90 | 16.13 | 14.04 | 24.71% | 40.23% | 35.04% | |

| SHD | 31.03 | 7.23 | 8.58 | 15.22 | 23.30% | 27.64% | 49.04% | |

| HSD | 33.04 | 7.73 | 9.36 | 15.94 | 23.40% | 28.35% | 48.24% | |

| DHS | 36.57 | 9.06 | 12.65 | 14.86 | 24.77% | 34.58% | 40.63% | |

| HDS | 31.12 | 6.97 | 8.86 | 15.29 | 22.39% | 28.47% | 49.13% | |

| Coordinate | X | Y | Z |

|---|---|---|---|

| Monitoring Point 1 | 5 | 13 | 12.5 |

| Monitoring Point 2 | 15 | 13 | 12.5 |

| Monitoring Point 3 | 25 | 13 | 12.5 |

| Monitoring Point 4 | 35 | 13 | 12.5 |

| Monitoring Point 5 | 45 | 13 | 12.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, H.; Wang, Y.; Yang, W.; Zhang, P.; Xiao, H.; Zhang, Y.; Zhang, Y. Experimental and Numerical Study of Damage Evolution and Fracture Characteristics of Three-Layer Composite Rocks Under Dynamic Loading. Appl. Sci. 2025, 15, 10369. https://doi.org/10.3390/app151910369

Xue H, Wang Y, Yang W, Zhang P, Xiao H, Zhang Y, Zhang Y. Experimental and Numerical Study of Damage Evolution and Fracture Characteristics of Three-Layer Composite Rocks Under Dynamic Loading. Applied Sciences. 2025; 15(19):10369. https://doi.org/10.3390/app151910369

Chicago/Turabian StyleXue, Huajun, Yanbing Wang, Weihong Yang, Pengda Zhang, Hui Xiao, Yaoyao Zhang, and Yuanjian Zhang. 2025. "Experimental and Numerical Study of Damage Evolution and Fracture Characteristics of Three-Layer Composite Rocks Under Dynamic Loading" Applied Sciences 15, no. 19: 10369. https://doi.org/10.3390/app151910369

APA StyleXue, H., Wang, Y., Yang, W., Zhang, P., Xiao, H., Zhang, Y., & Zhang, Y. (2025). Experimental and Numerical Study of Damage Evolution and Fracture Characteristics of Three-Layer Composite Rocks Under Dynamic Loading. Applied Sciences, 15(19), 10369. https://doi.org/10.3390/app151910369