Tetrahedral Mobile Robots: A Systematic Literature Review

Abstract

1. Introduction

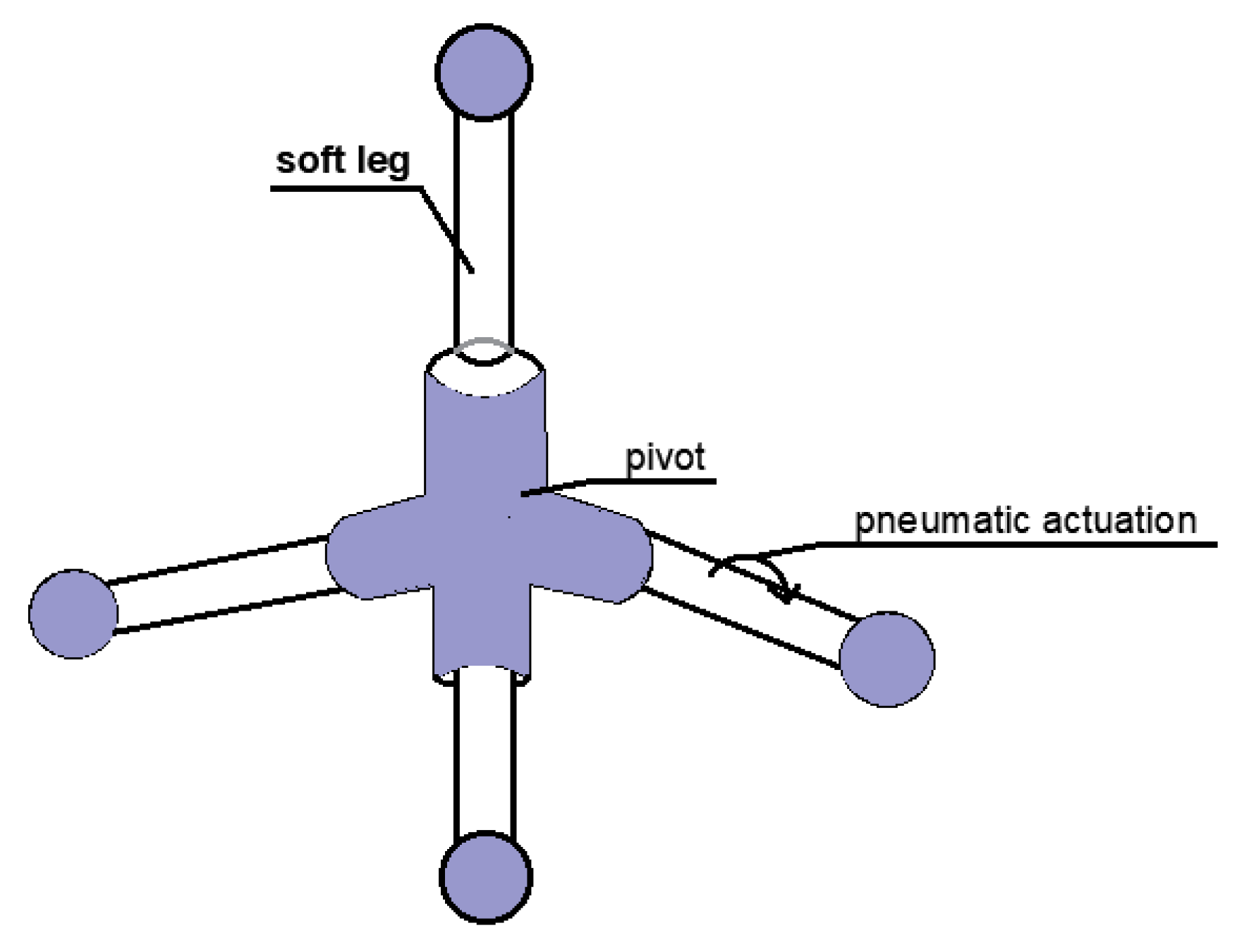

- Soft morphology [1];

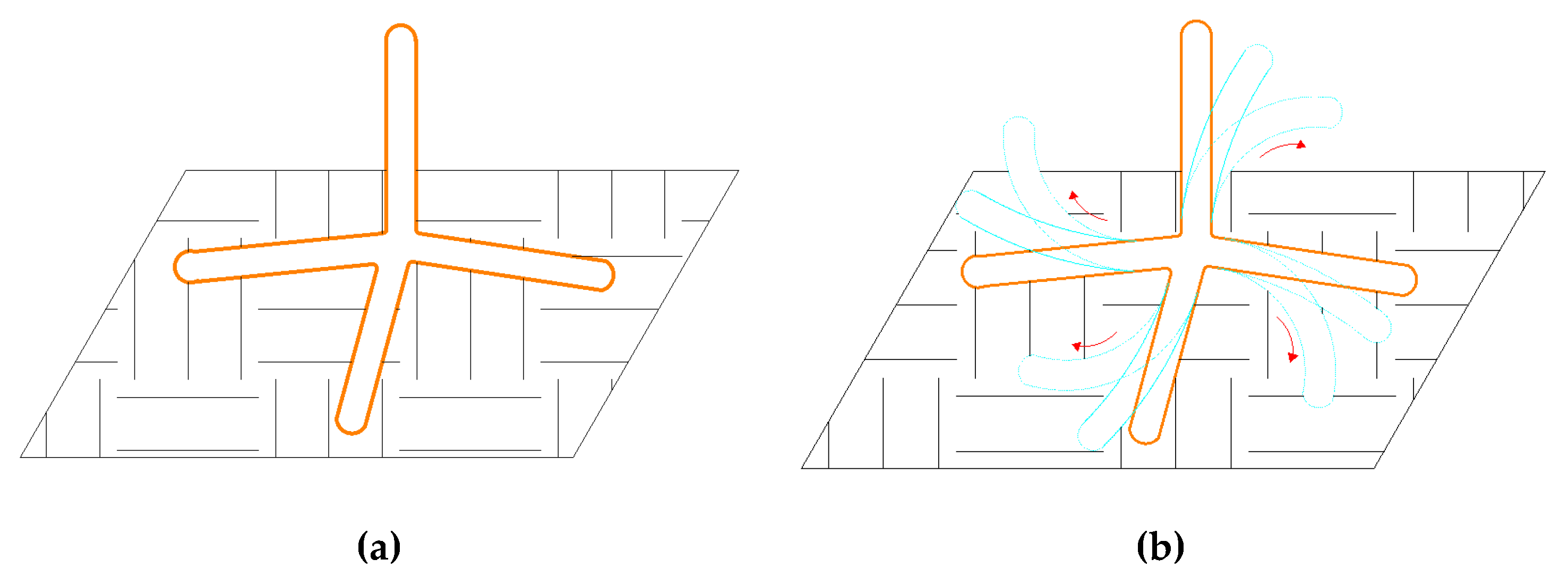

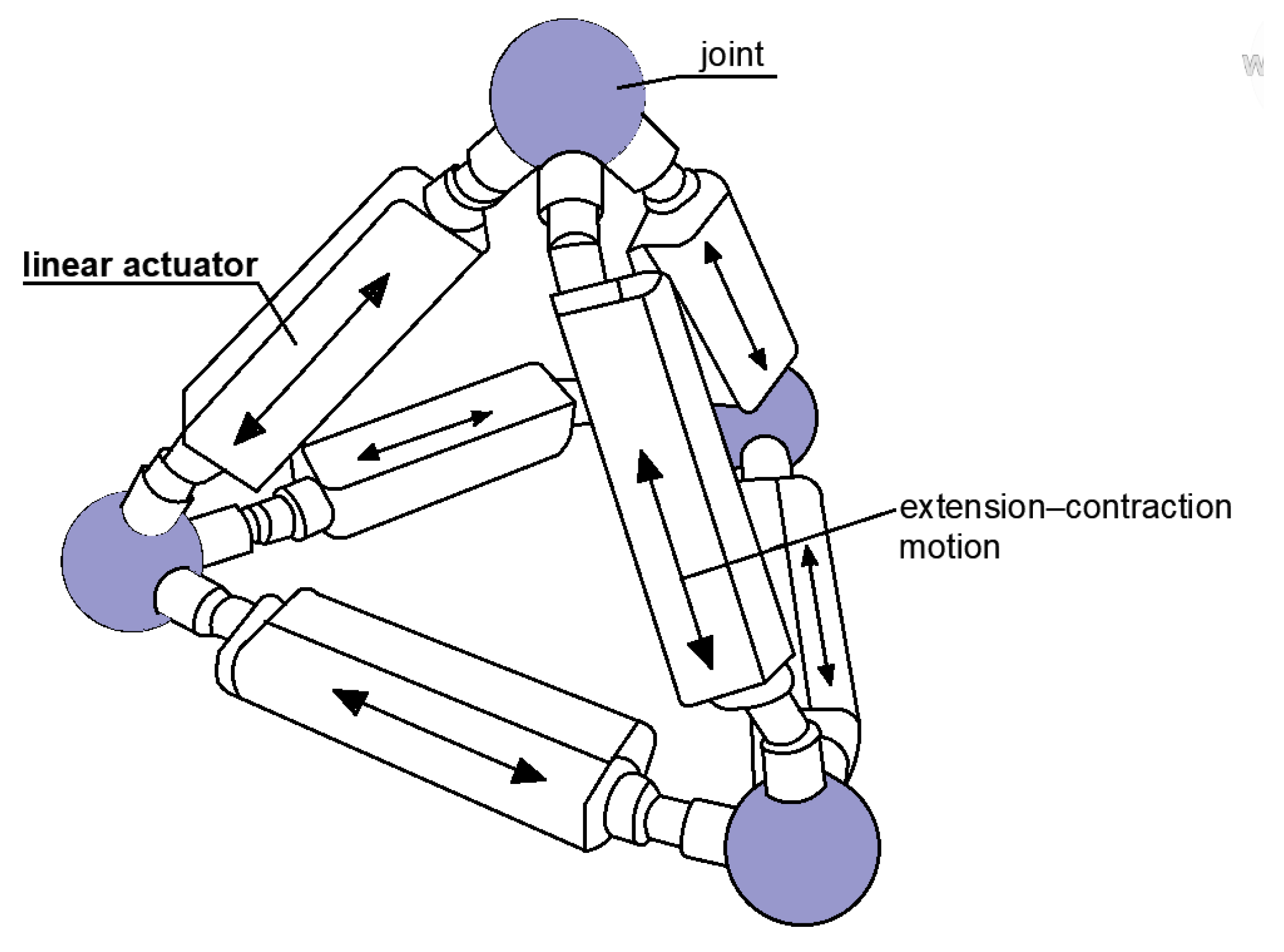

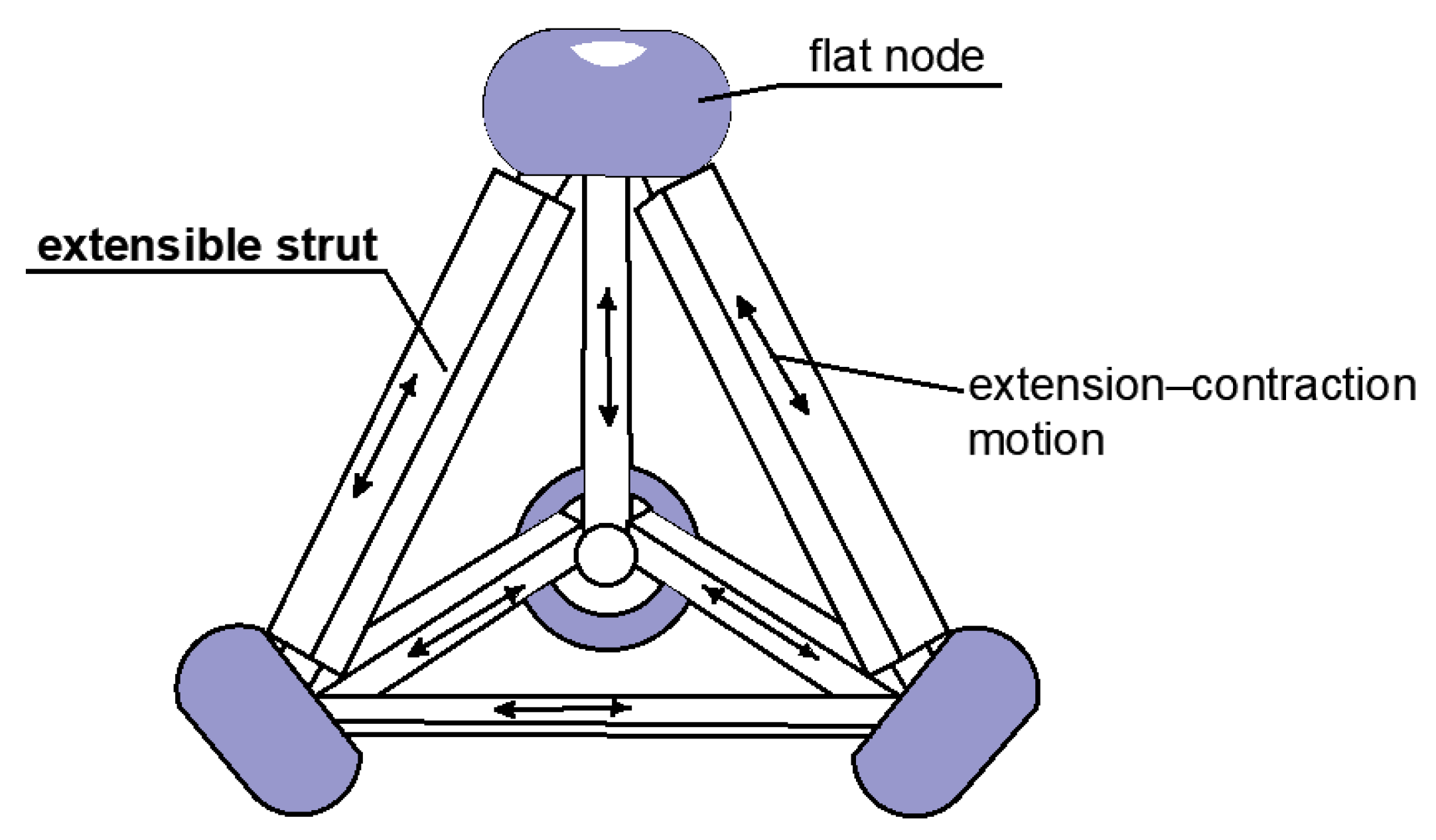

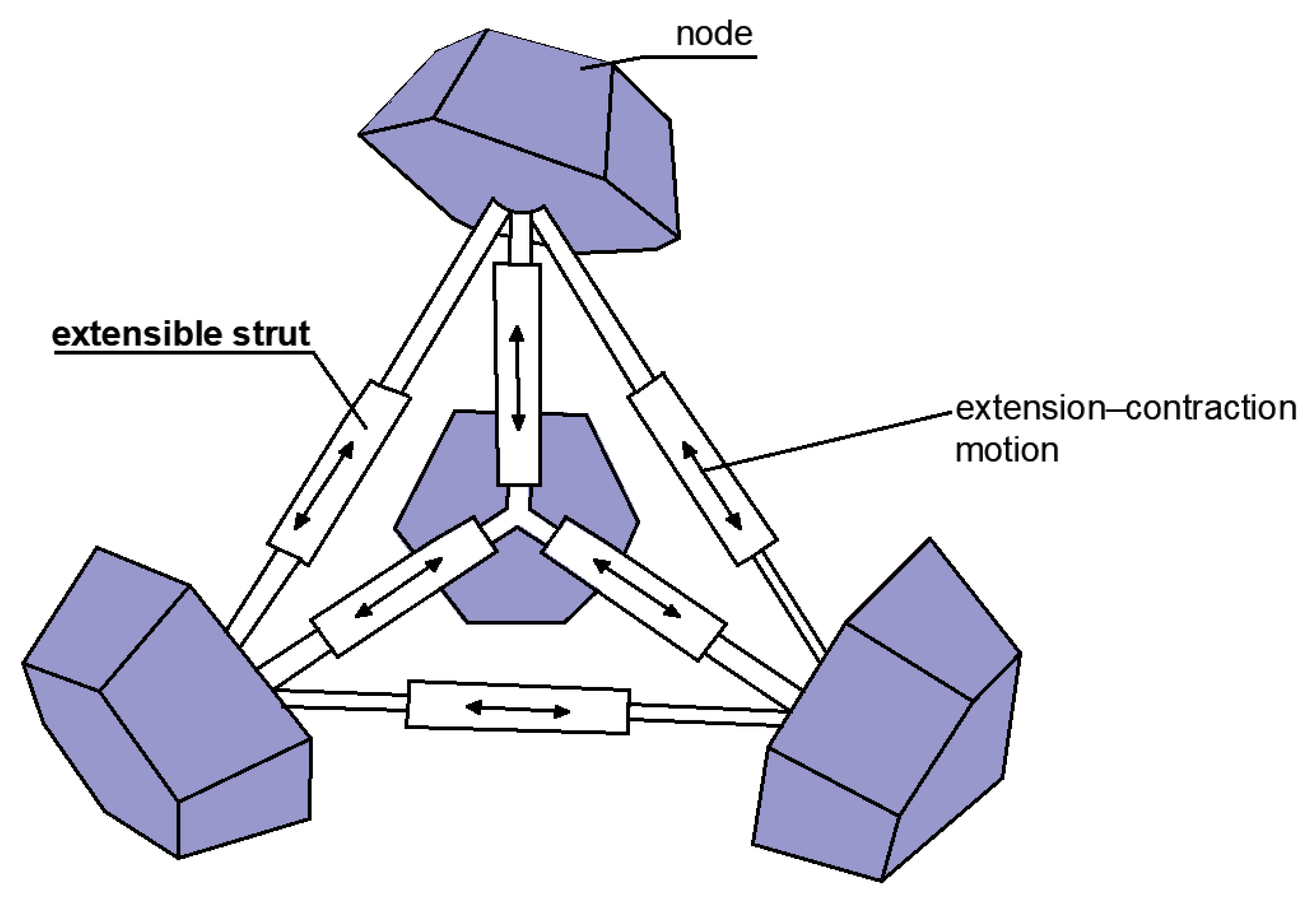

- Crawling; through the actuation of movable elements, the robot can generate forces that move it in different directions [10];

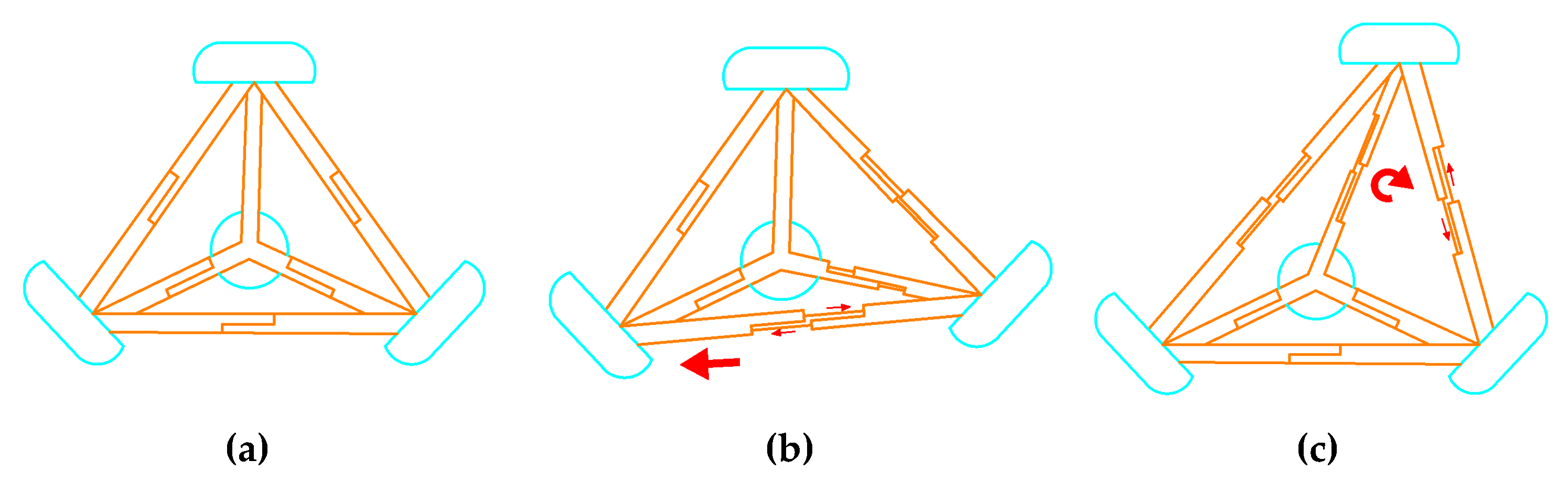

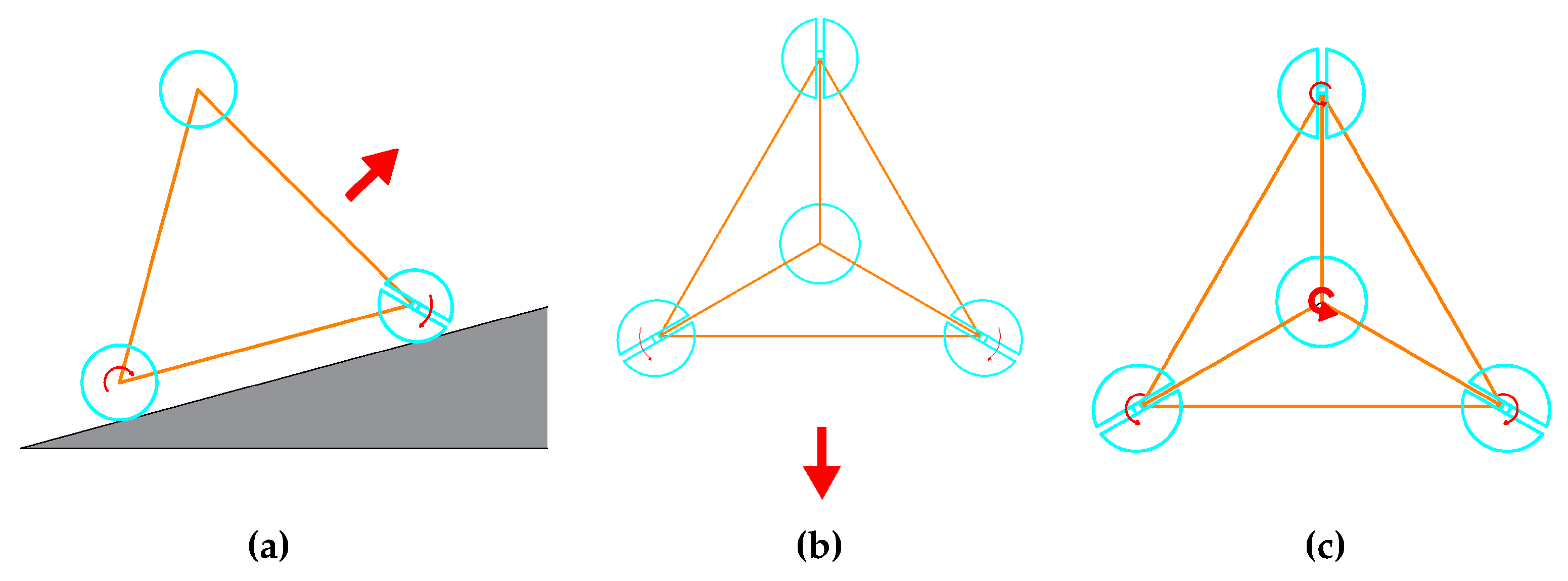

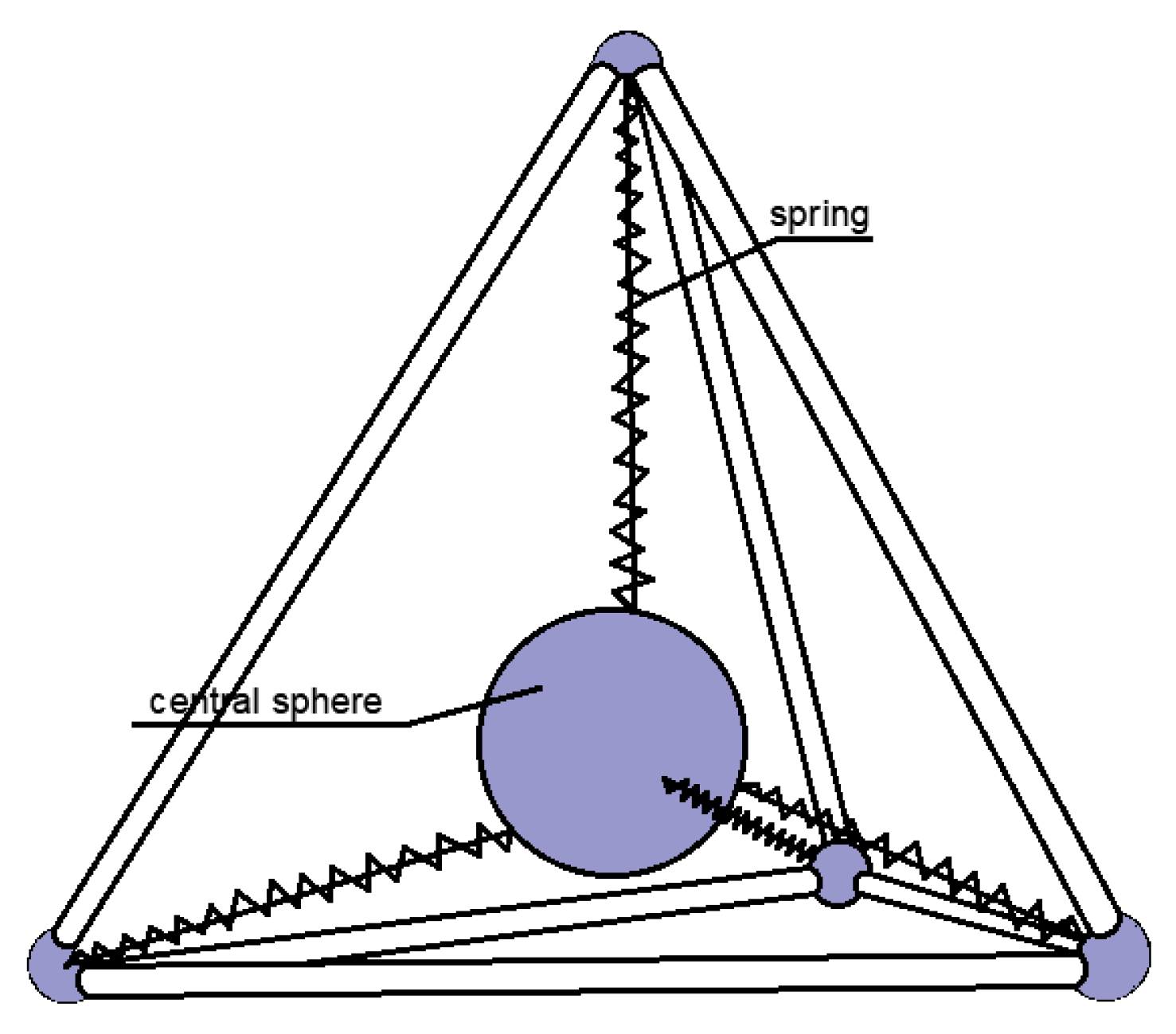

- Rolling, by shifting its center of gravity; the robot can transition from one stable position to another [4];

- Resonance-based movement; by using oscillating mechanisms, the robot can achieve movement across different surfaces [11];

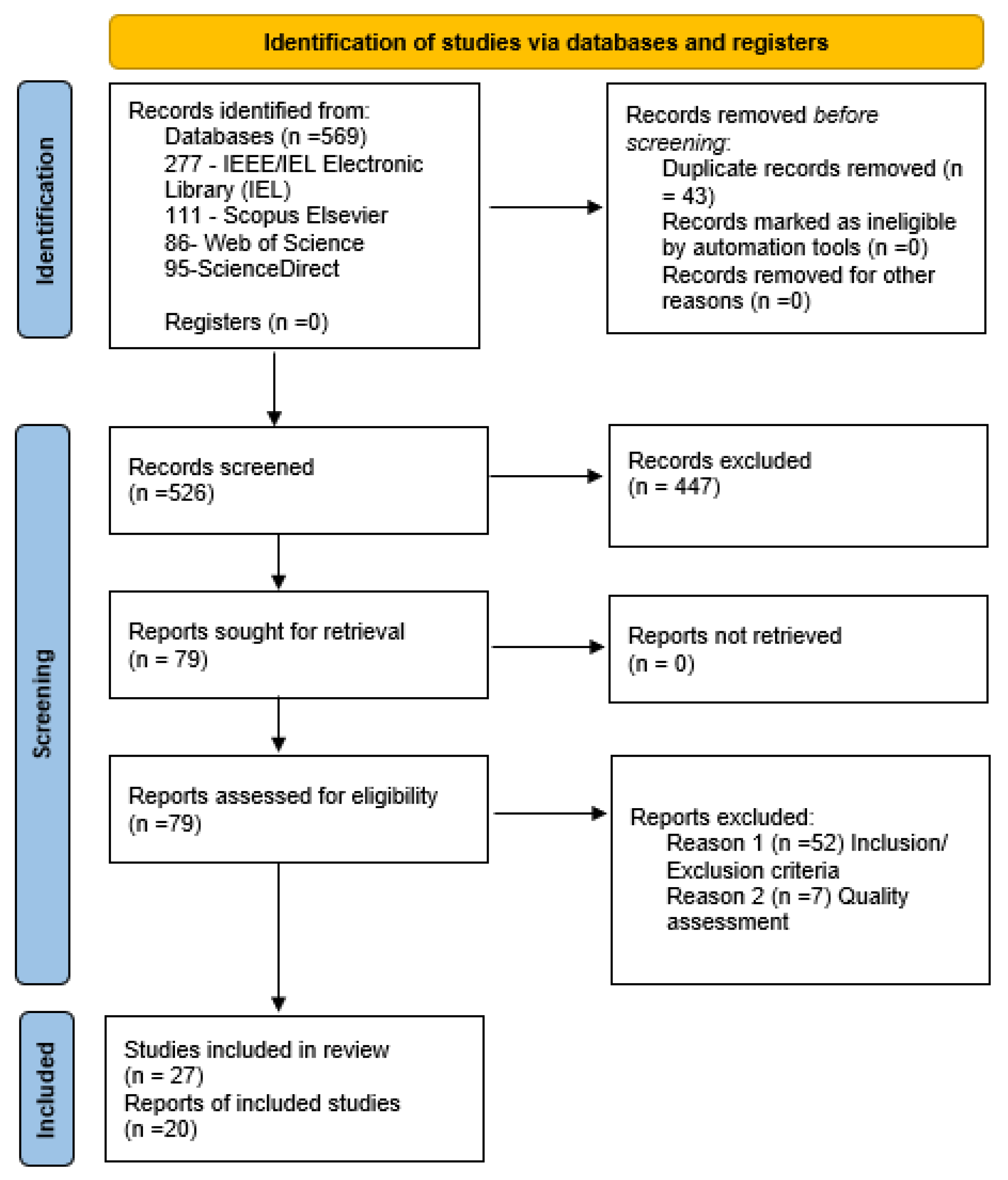

2. Methodology

2.1. Research Questions

2.2. Search Strategy

- IEEE/IEL Electronic Library (IEL)—https://ieeexplore.ieee.org/

- Web of Science—https://www.webofscience.com/

- Scopus Elsevier—https://www.scopus.com/

- ScienceDirect—https://www.sciencedirect.com/

2.3. Inclusion/Exclusion Criteria

- (a)

- Inclusion criteria:

- IC1—The paper is written in English;

- IC2—The paper presents a tetrahedral, symmetrical structure;

- IC3—The paper is validated through a physical prototype;

- IC4—The paper is validated through publication in a scientific journal or conference;

- IC5—The locomotion system is non-conventional.

- (b)

- Exclusion criteria:

- EC1—The paper is not written in English;

- EC2—The robot’s structure does not exhibit tetrahedral geometry;

- EC3—It does not provide details regarding the physical implementation;

- EC4—It is not published in a validated (peer-reviewed) scientific source;

- EC5—The locomotion system is conventional.

2.4. Quality Assessment of Studies Related to Tetrahedral Robots

- (a)

- Clarity of the purpose and objectives of the research (Criterion 1)The paper provides coherent explanations regarding the purpose and objectives of the research, enhancing the relevance of the scientific approach.

- (b)

- Degree of applicability of the proposed solution (Criterion 2)This criterion assesses whether the proposed solution can be implemented in a real-world context and has practical potential in the targeted environment.

- (c)

- Quality and relevance of the technical data presented (Criterion 3)This criterion assesses whether the study includes concrete, measurable data that support the conclusions drawn.

2.5. Organization and Classification of Results

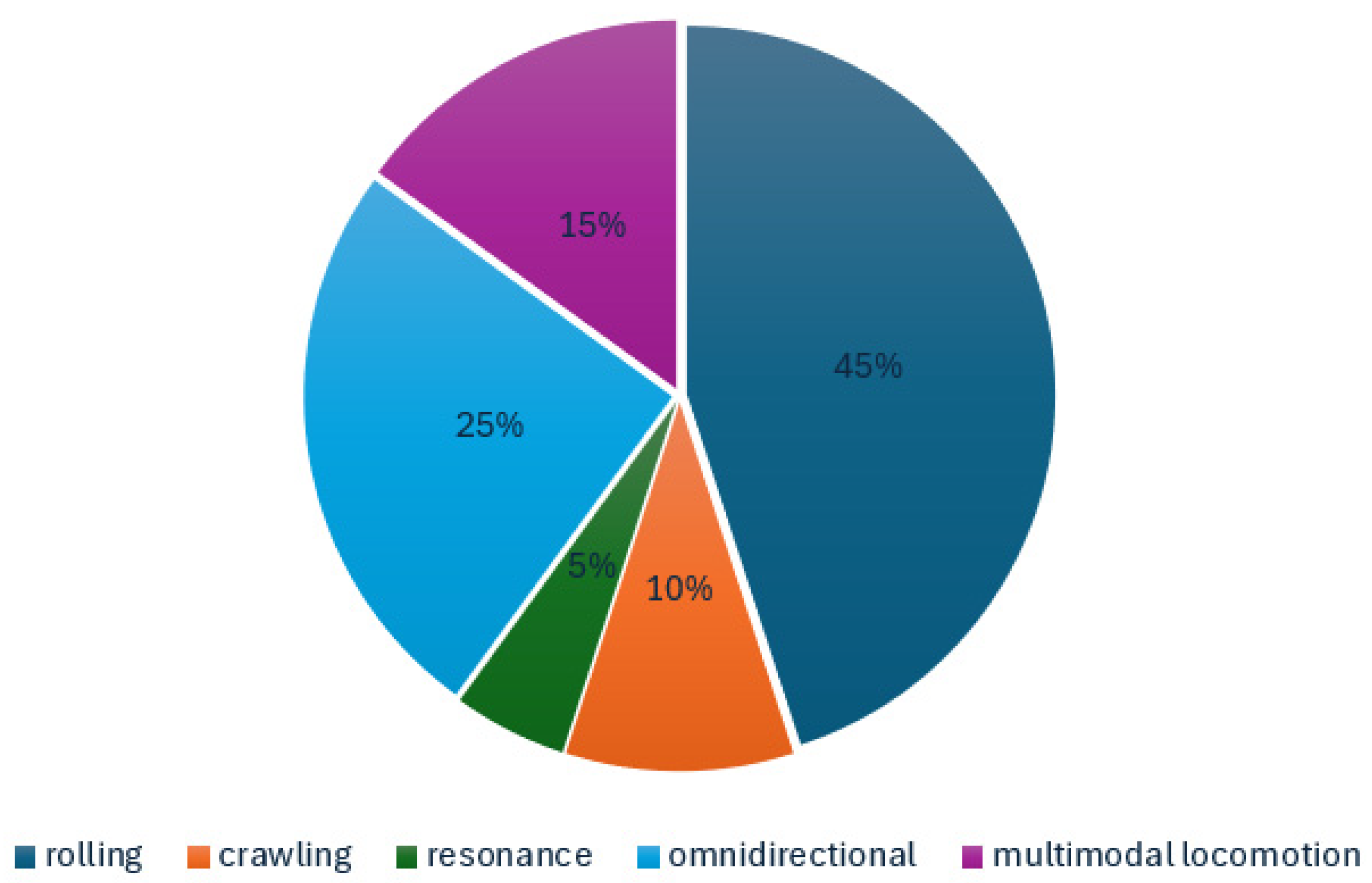

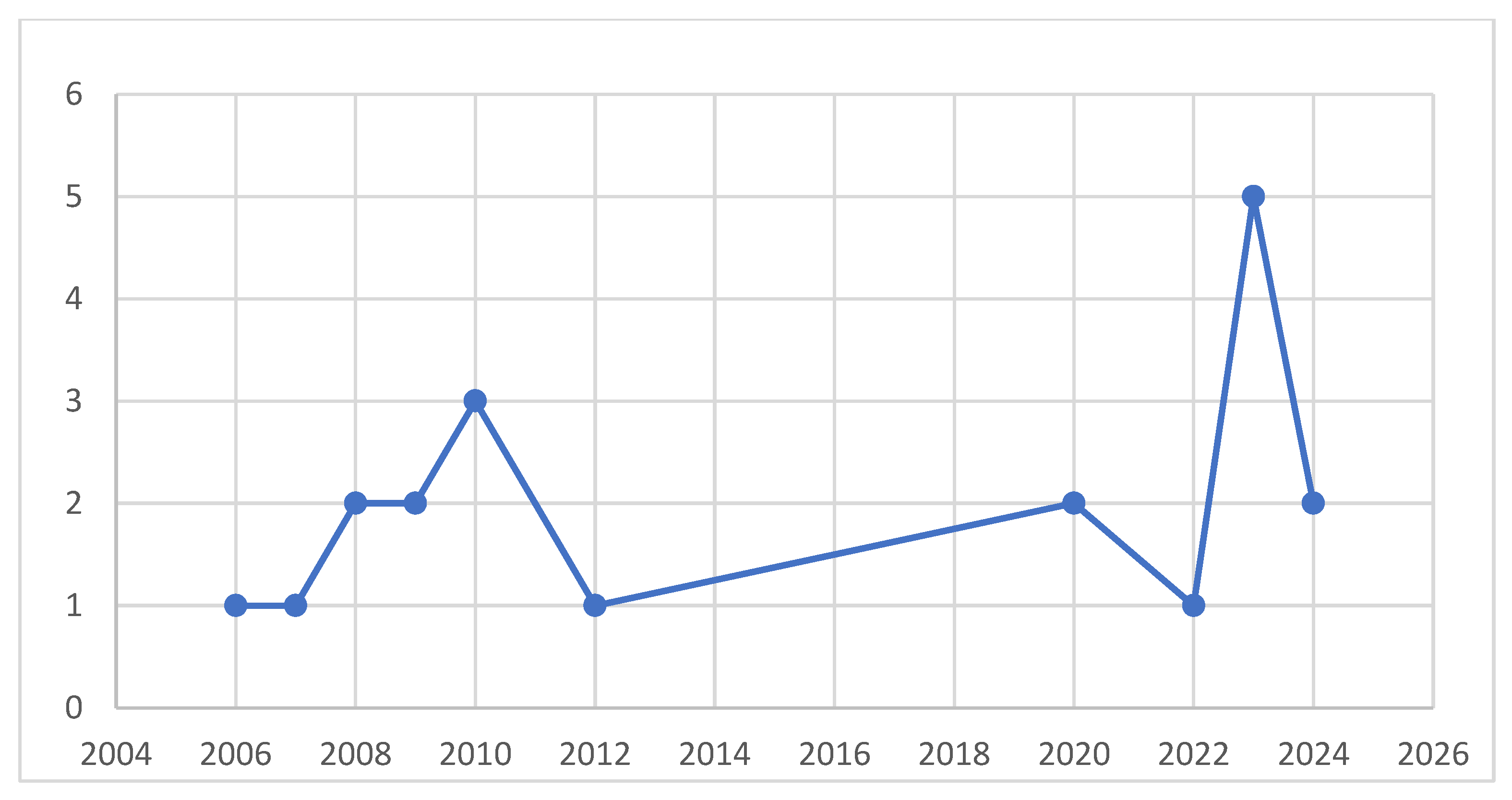

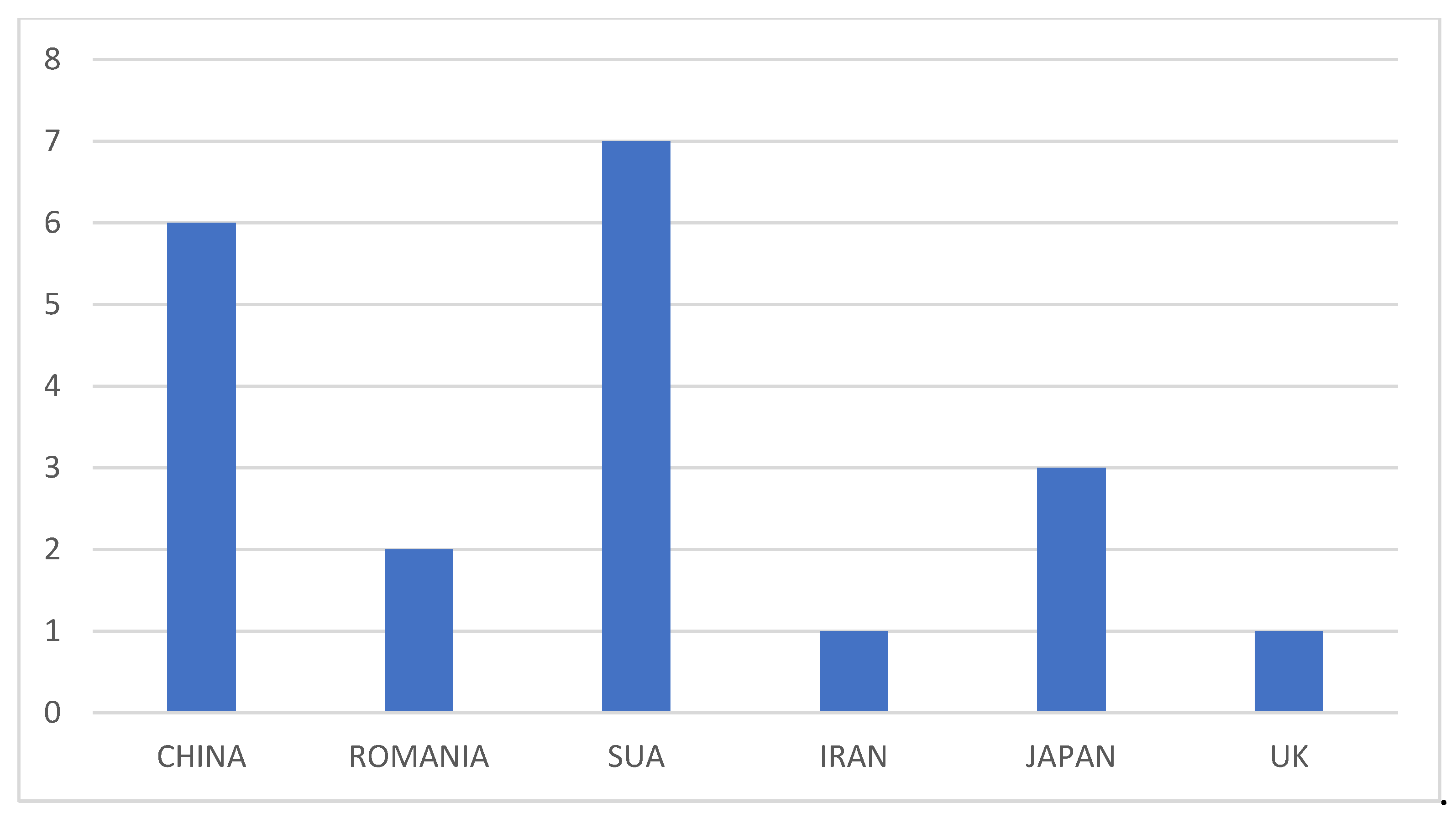

2.6. Literature Analysis

- (a)

- Rolling locomotion

- (b)

- Crawling locomotion

- (c)

- Resonance-based locomotion

- (d)

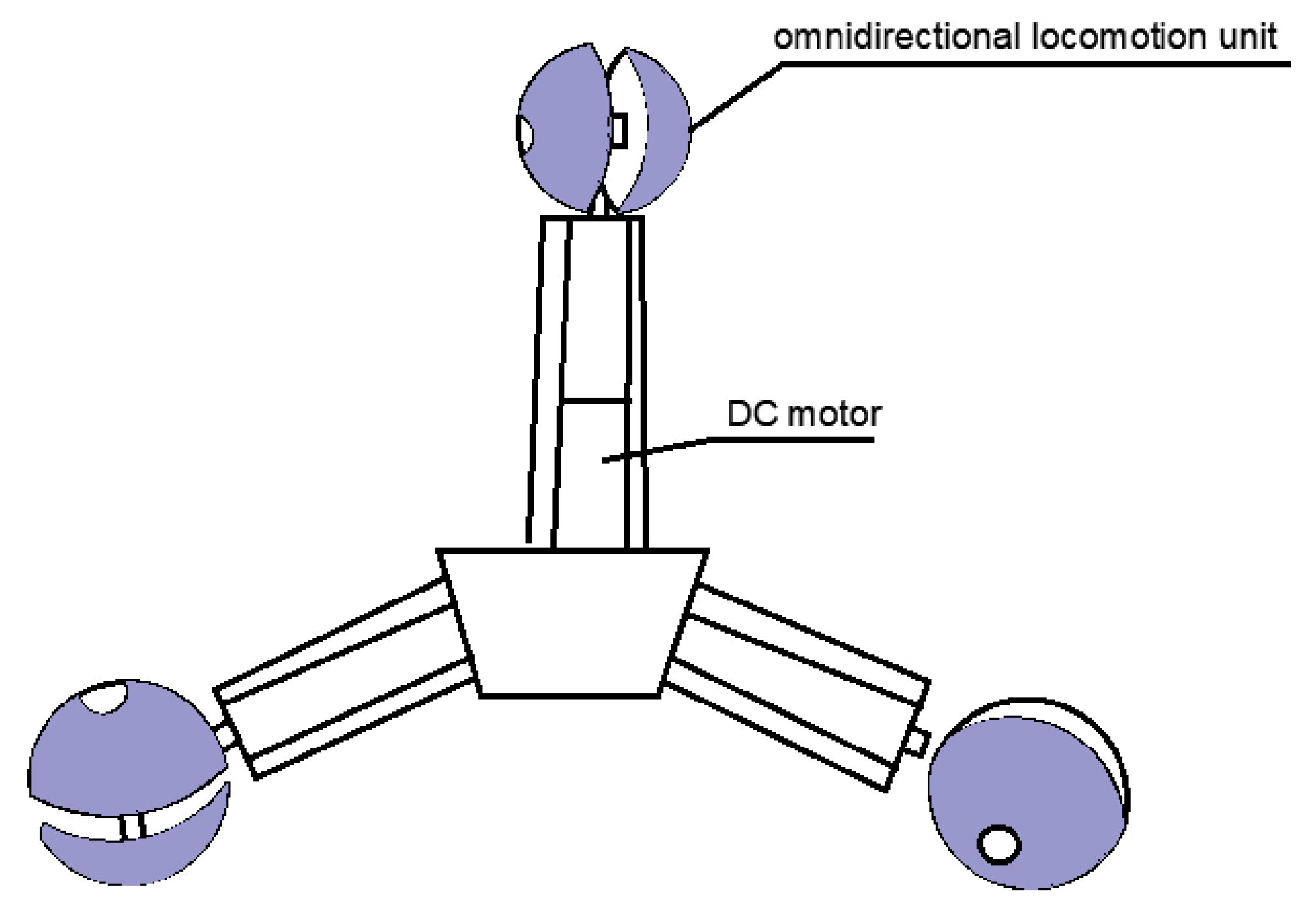

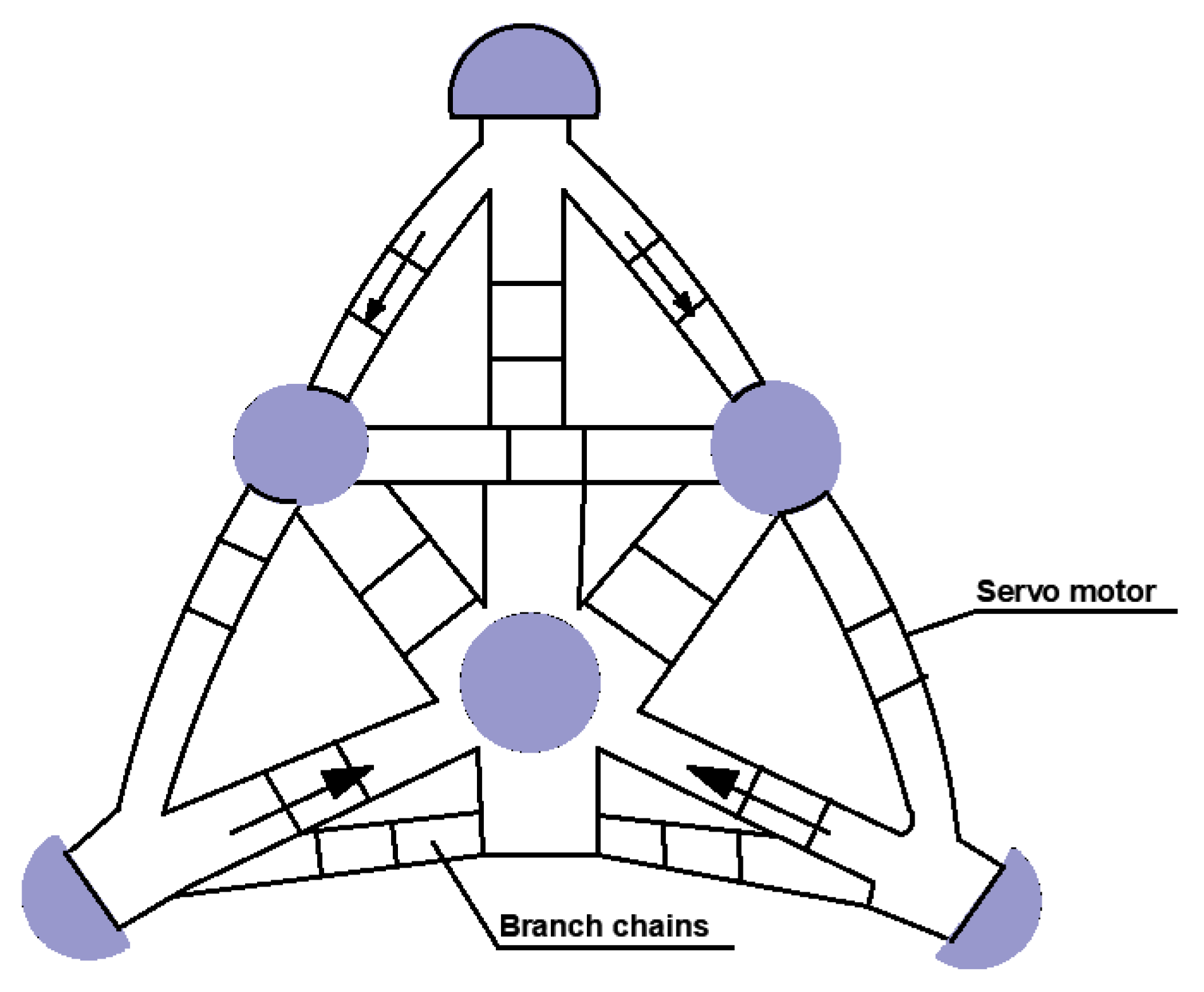

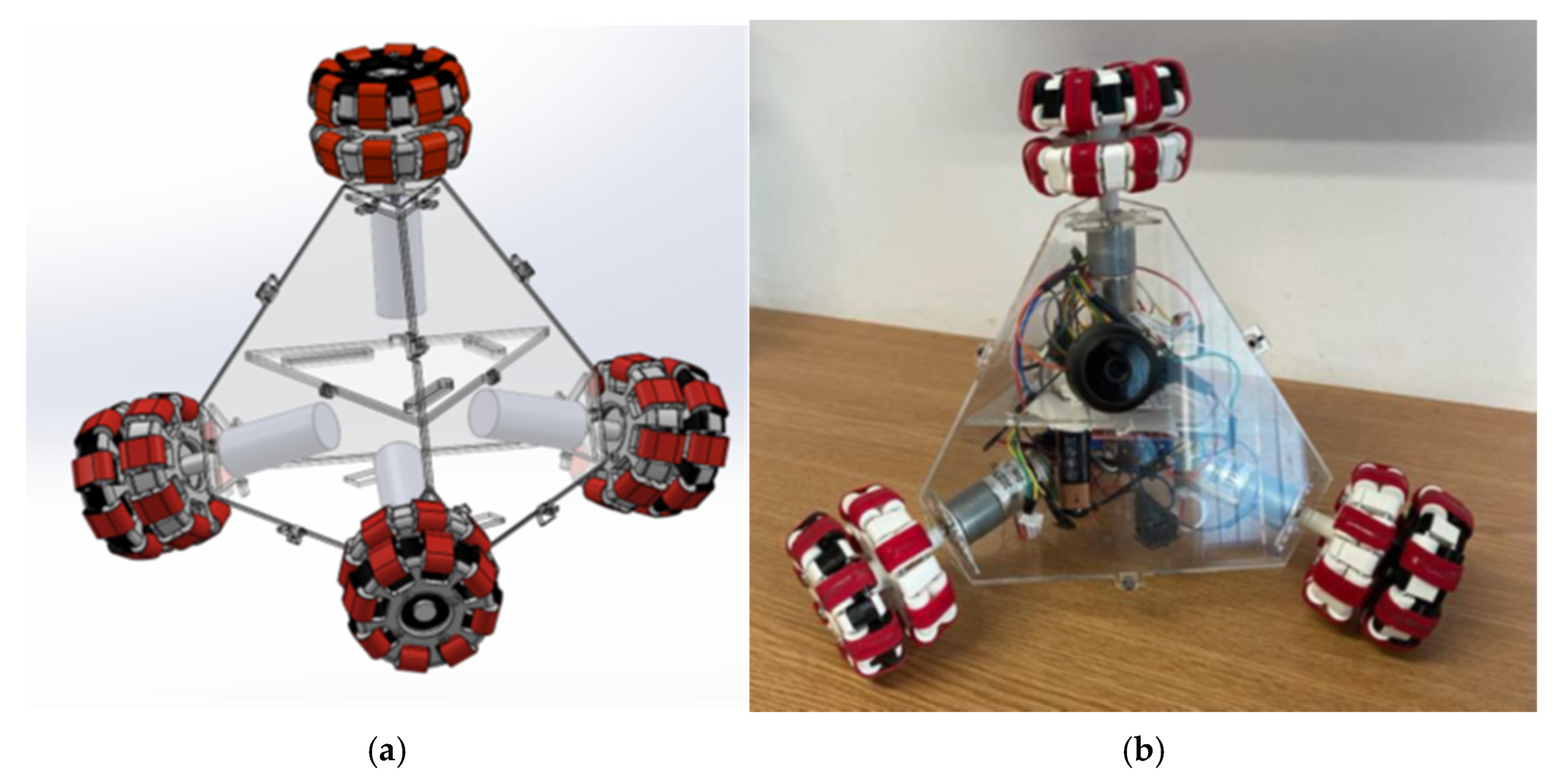

- Omnidirectional locomotion

- (e)

- Multimodal locomotion

3. Discussions, Challenges, and Future Research Directions

- Discussions

- b.

- Challenges

- Low energy efficiency and, consequently, limited autonomy;

- Flexibility;

- Structural complexity and symmetry make it difficult to integrate perception equipment since the robot can roll on any side, thus hindering the acquisition of a complete view of the surrounding environment;

- Maintaining stability during deformation.

- c.

- Future Research Directions

- The use of smart materials such as shape-memory structures, soft actuators, or elastic materials;

- The application of artificial intelligence for trajectory planning or autonomous control, enabling the robot to adapt in real time to different situations;

- Integration of self-learning algorithms to enable robots to control their energy consumption;

- Self-reconfiguration in the case of modular or transformable robots, depending on the operating environment;

- Expansion of experimental testing in uncontrolled environments;

- Development of multimodal mechanisms capable of performing multiple types of locomotion or carrying out several tasks;

- Integration of video cameras and sensors to overcome the limitations imposed by the tetrahedral structure, through the addition of panoramic systems or sensors distributed on all faces.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arachchige, D.D.; Varshney, T.; Huzaifa, U.; Kanj, I.; Nanayakkara, T.; Chen, Y.; Gilbert, H.B.; Godage, I.S. Study on soft robotic pinniped locomotion. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Seattle, WA, USA, 28–30 June 2023; pp. 65–71. [Google Scholar]

- Lyder, A.; Garcia, R.F.M.; Stoy, K. Genderless connection mechanism for modular robots introducing torque transmission between modules. In Proceedings of the ICRA Workshop on Modular Robots, State of the Art, Anchorage, AK, USA, 3 May 2010; pp. 77–81. [Google Scholar]

- Lyder, A.; Petersen, H.G.; Stoy, K. Representation and shape estimation of Odin, a parallel under-actuated modular robot. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), St. Louis, MO, USA, 10–15 October 2009; pp. 5275–5280. [Google Scholar]

- Hasan, B. A Survey of MODULAR Self-Reconfigurable (MSR) Robots; KTH Royal Institute of Technology: Stockholm, Sweden, 2012; p. 33. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-178063 (accessed on 27 August 2025).

- Lyder, A.; Garcia, R.F.M.; Stoy, K. Mechanical design of Odin, an extendable heterogeneous deformable modular robot. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Nice, France, 22–26 September 2008; pp. 883–888. [Google Scholar]

- Pieber, M.; Gerstmayr, J. A framework for cellular robots with tetrahedral structure. In Proceedings of the OAGM&ARW Joint Workshop on Vision, Automation and Robotics, Vienna, Austria, 10–12 May 2017; pp. 5–6. [Google Scholar]

- Pieber, M.; Gerstmayr, J. An adaptive robot with tetrahedral cells. In Proceedings of the 4th Joint International Conference on Multibody System Dynamics (IMSD), Montreal, QC, Canada, 29 May–2 June 2016. [Google Scholar]

- Liu, R.; Yao, Y.A.; Li, Y. Design and analysis of a deployable tetrahedron-based mobile robot constructed by Sarrus linkages. Mech. Mach. Theory 2020, 152, 103964. [Google Scholar] [CrossRef]

- Tadakuma, K.; Tadakuma, R.; Nagatani, K.; Yoshida, K.; Aigo, M.; Shimojo, M.; Iagnemma, K. Throwable tetrahedral robot with transformation capability. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), St. Louis, MO, USA, 11–15 October 2009; pp. 2801–2808. [Google Scholar]

- Mărgineanu, D.; Lovasz, E.C.; Modler, K.H.; Perju, D.; Noll, C.; Mandiuc, M. On the 3D crawling mechanical structures. In Proceedings of the 12th IFToMM World Congress, Besançon, France, 17–21 June 2007. [Google Scholar]

- Neubert, J.; Stockton, J.; Blechman, B.; Lipson, H. Tetrabot: Resonance based locomotion for harsh environments. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Taipei, Taiwan, 18–22 October 2010; pp. 2431–2436. [Google Scholar]

- Brunhorn, J.; Tenchio, O.; Rojas, R. A novel omnidirectional wheel based on Reuleaux triangles. In Proceedings of the Robot Soccer World Cup, Atlanta, GA, USA, 9–10 July 2007; pp. 516–522. [Google Scholar]

- Shen, J.; Hong, D. Omburo: A novel unicycle robot with active omnidirectional wheel. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 8237–8243. [Google Scholar]

- Tavakoli, M.; Viegas, C. Analysis and application of dual-row omnidirectional wheels for climbing robots. Mechatronics 2014, 24, 436–448. [Google Scholar] [CrossRef]

- Gfrerrer, A. Geometry and kinematics of the Mecanum wheel. Comput. Aided Geom. Des. 2008, 25, 784–791. [Google Scholar] [CrossRef]

- Adăscăliţei, F.; Doroftei, I. Practical applications for mobile robots based on Mecanum wheels—A systematic survey. Rom. Rev. Precis. Mech. Opt. Mechatron. 2011, 40, 21–29. [Google Scholar]

- Taheri, H.; Zhao, C.X. Omnidirectional mobile robots, mechanisms and navigation approaches. Mech. Mach. Theory 2020, 153, 103958. [Google Scholar] [CrossRef]

- Byun, K.S.; Song, J.B. Design and construction of continuous alternate wheels for an omnidirectional mobile robot. J. Robot. Syst. 2003, 20, 569–579. [Google Scholar] [CrossRef]

- Park, Y.K.; Lee, P.; Choi, J.K.; Byun, K.S. Analysis of factors related to vertical vibration of continuous alternate wheels for omnidirectional mobile robots. Intell. Serv. Robot. 2016, 9, 207–216. [Google Scholar] [CrossRef]

- Ignatiev, K.V.; Kopichev, M.M.; Putov, A.V. Autonomous omni-wheeled mobile robots. In Proceedings of the 2016 2nd International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Chelyabinsk, Russia, 19–20 May 2016; pp. 1–4. [Google Scholar]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Keele, UK, 2004; Volume 33, pp. 1–26. [Google Scholar]

- Gomes, D.F.; Pinto, V.H. Systematic literature review on hybrid robotic vehicles. Robotics 2024, 13, 34. [Google Scholar] [CrossRef]

- Izadi, M.; Mahjoob, M.J.; Soheilypour, M.; Vahid-Alizadeh, H. A motion planning for toppling-motion of a TET walker. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO), Singapore, 26–28 February 2010; pp. 34–39. [Google Scholar]

- Belisle, R.; Yu, C.-H.; Nagpal, R. Mechanical design and locomotion of modular-expanding robots. In Proceedings of the IEEE 2010 International Conference on Robotics and Automation Workshop, Modular Robotics: State of the Art, Anchorage, AK, USA, 3 May 2010; pp. 17–23. [Google Scholar]

- Abrahantes, M.; Silvert, A.; Wendtt, L.; Littiot, D. Construction and Control of a 4-Tetrahedron Walker Robot. In Proceedings of the 40th Southeastern Symposium on System Theory (SSST), New Orleans, LA, USA, 16–18 March 2008; pp. 343–346. [Google Scholar]

- Wang, Y.; Wang, J.; Fei, Y. Design and modeling of tetrahedral soft-legged robot for multigait locomotion. IEEE/ASME Trans. Mechatron. 2022, 27, 1288–1298. [Google Scholar] [CrossRef]

- Zhang, L.; Bi, S.; Cai, Y. Design and motion analysis of tetrahedral rolling robot. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Taipei, Taiwan, 18–22 October 2010; pp. 502–507. [Google Scholar]

- Swett, J.; Abrahantes, M. Distributed control system implementation for tetrahedral walker robots. In Proceedings of the IEEE International Electro/Information Technology Conference (EIT), Milwaukee, WI, USA, 5–7 June 2014; pp. 231–235. [Google Scholar]

- Yu, C.-H.; Nagpal, R. Engineering self-adaptive modular robotics: A bio-inspired approach. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), St. Louis, MO, USA, 11–15 October 2009; pp. 414–420. [Google Scholar]

- Zhao, Z.; Li, Y.; Wu, J.; Yao, Y. Envelop-Climbing Locomotion Planning and Capability Analysis of a Deformable Tetrahedron Rolling Robot. IEEE Robot. Autom. Lett. 2023, 8, 4625–4632. [Google Scholar] [CrossRef]

- Abrahantes, M.; Smits, C. Implementation and control of a reconfigurable 8-Tetrahedral robot. In Proceedings of the 2012 IEEE Aerospace Conference, Indianapolis, IN, USA, 6–8 May 2012; pp. 1–10. [Google Scholar]

- Abrahantes, M.; Doorn, P.; Richard, J.; Barbachyn, S. Implementation and control of a reconfigureable 4-tetrahedral robot. In Proceedings of the 41st Southeastern Symposium on System Theory (SSST), University of Tennessee Space Institute, Tullahoma, TN, USA, 15–17 March 2009; pp. 344–348. [Google Scholar]

- Gifford, C.M.; Agah, A.; Carmichael, B.L.; Wade, U.B.; Ruiz-Carrión, I. Seismic TETwalker mobile robot design and modeling. In Proceedings of the 2008 IEEE Aerospace Conference, Woburn, MA, USA, 10–11 November 2008; pp. 1–11. [Google Scholar]

- Yu, C.-H.; Nagpal, R. Self-adapting modular robotics: A generalized distributed consensus framework. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation (ICRA), Kobe, Japan, 12–17 May 2009; pp. 1881–1888. [Google Scholar]

- Motahari-Bidgoli, S.M.; Mahjoob, M.J.; Davaria, S. Simulation and analysis of a TET-walker robot motion. In Proceedings of the 2nd RSI/ISM International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 15–17 October 2014; pp. 914–919. [Google Scholar]

- Perera, D.M.; Arachchige, D.D.K.; Mallikarachchi, S.; Ghafoor, T.; Kanj, I.; Chen, Y.; Godage, I.S. Teleoperation of soft modular robots: Study on real-time stability and gait control. In Proceedings of the 2023 IEEE International Conference on Soft Robotics (RoboSoft), Singapore, 3–7 April 2023; pp. 183–190. [Google Scholar]

- Wharton, P.; You, T.L.; Jenkinson, G.P.; Diteesawat, R.S.; Le, N.H.; Hall, E.-C.; Garrad, M.; Conn, A.T.; Rossiter, J. Tetraflex: A multigait soft robot for object transportation in confined environments. IEEE Robot. Autom. Lett. 2023, 8, 5007–5014. [Google Scholar] [CrossRef]

- Tadakuma, K. Tetrahedral mobile robot with novel ball shape wheel. In Proceedings of the First IEEE/RAS-EMBS International Conference on Biomedical Robotics and Biomechatronics, BioRob 2006, Pisa, Italy, 20–22 February 2006; pp. 946–952. [Google Scholar]

- Curtis, S.; Brandt, M.; Bowers, G.; Brown, G.; Cheung, C.; Cooperider, C.; Desch, M.; Desch, N.; Dorband, J.; Gregory, K.; et al. Tetrahedral robotics for space exploration. IEEE Aerosp. Electron. Syst. Mag. 2007, 22, 20–30. [Google Scholar] [CrossRef]

- Arachchige, D.D.K.; Perera, D.M.; Huzaifa, U.; Kanj, I.; Godage, I.S. Tumbling locomotion of tetrahedral soft-limbed robots. IEEE Robot. Autom. Lett. 2024, 9, 4337–4344. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Xu, Y.; Dai, J.S.; Zhao, Z.; Yao, Y. A deformable tetrahedron rolling mechanism (DTRM) based on URU branch. Mech. Mach. Theory 2020, 153, 104000. [Google Scholar] [CrossRef]

- Teutan, E.; Bara, M.; Ardelean, I. Generating of digitised with the aid of Tetrobot module. Mechanika 2012, 18, 666–670. [Google Scholar] [CrossRef][Green Version]

- Tadakuma, K.; Tadakuma, R.; Berengueres, J. Tetrahedral mobile robot with spherical omnidirectional wheel. J. Robot. Mechatron. 2008, 20, 125–134. [Google Scholar][Green Version]

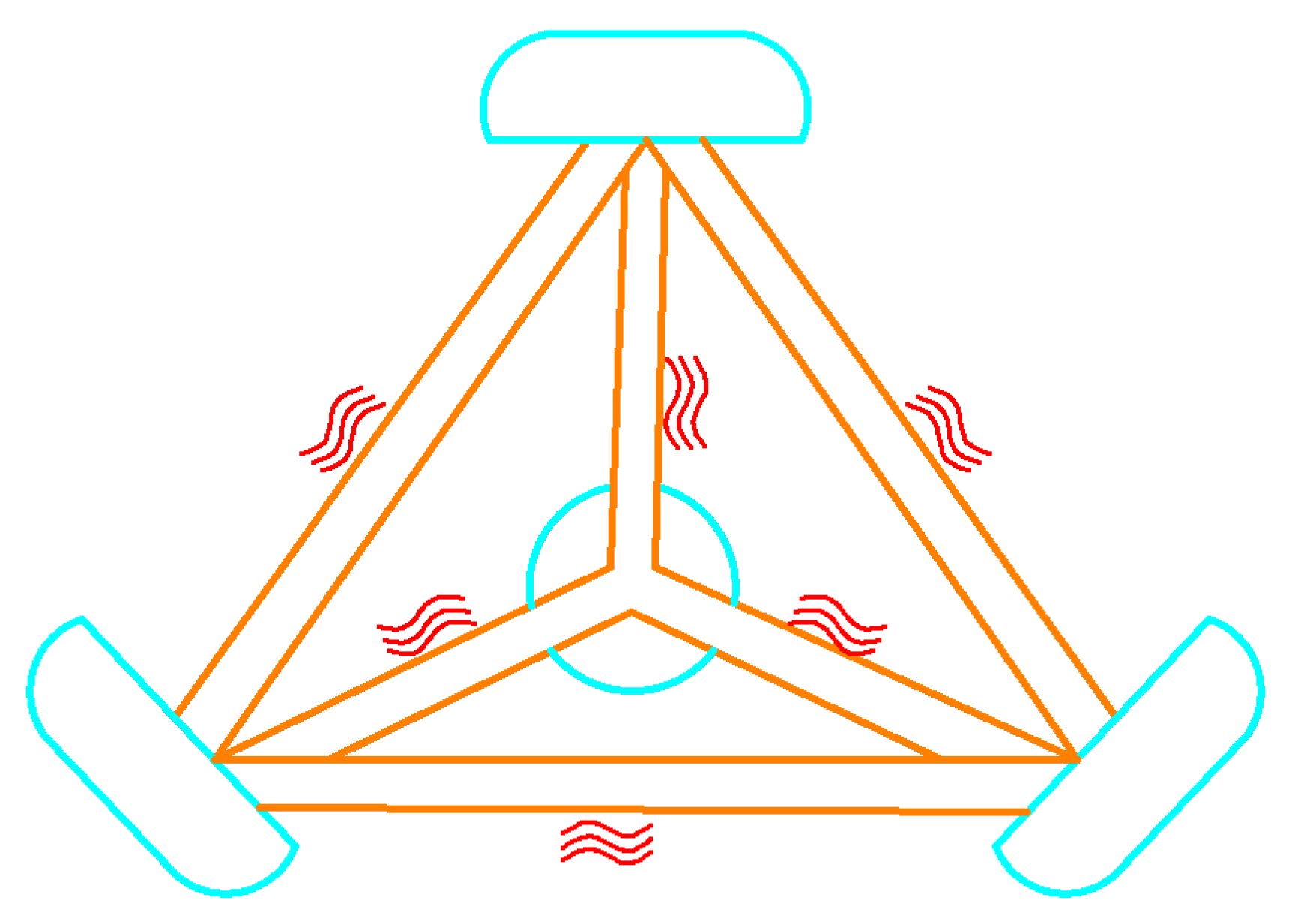

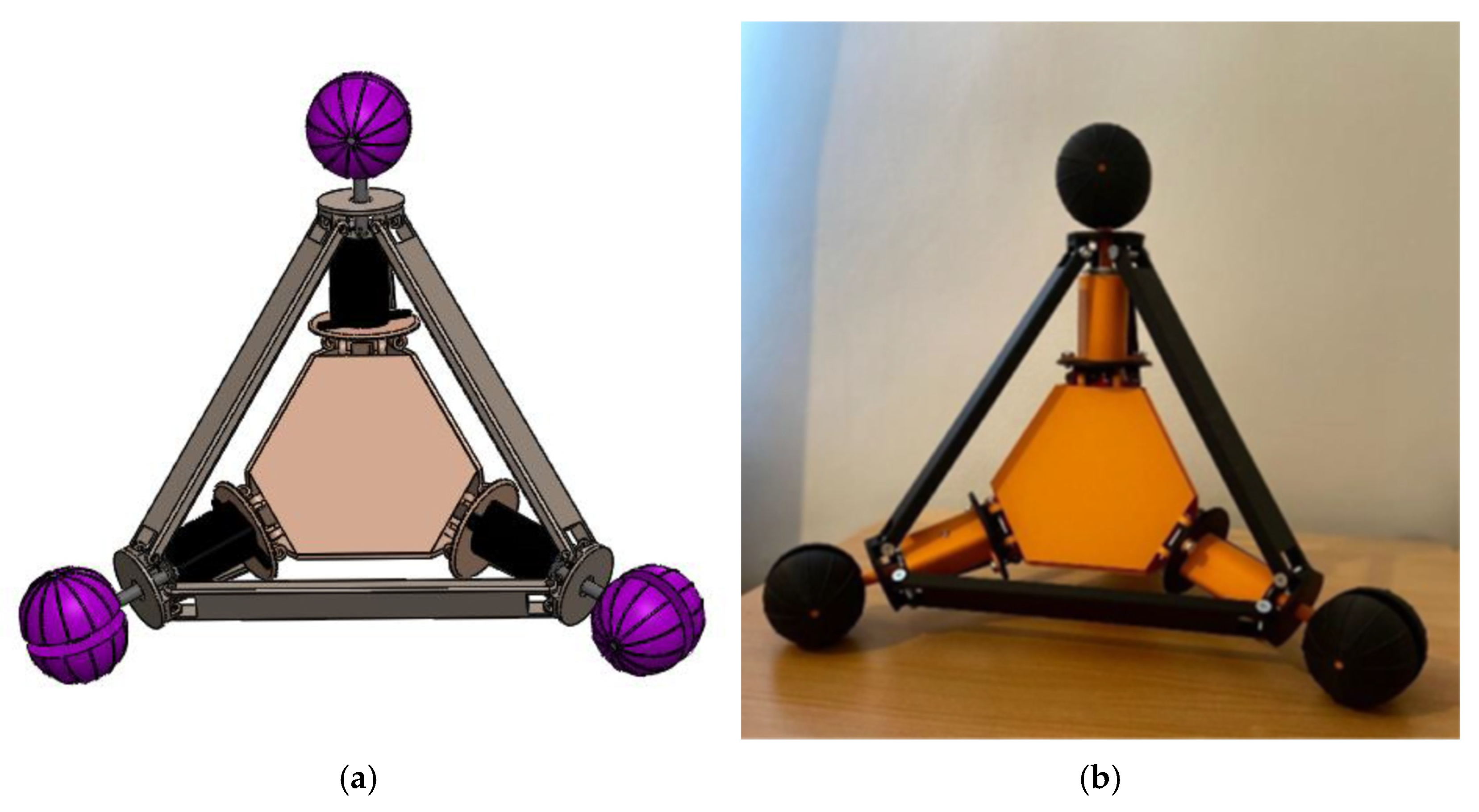

- Simerean, A.-C.; Tătar, M.O. Contributions to the development of tetrahedral mobile robots with omnidirectional locomotion units. Machines 2024, 12, 852. [Google Scholar] [CrossRef]

- Simerean, A.-C.; Tătar, M.O. Studies regarding tetrahedral robots with omnidirectional locomotion units. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2023, 66, 421–428. [Google Scholar][Green Version]

- Hu, S.; Liu, R.; Li, R.; Huang, T.; Li, Y.; Yao, Y. Design and analysis of a size-tunable tetrahedron rolling mechanism based on deployable RRR chains. Mech. Mach. Theory 2023, 183, 105284. [Google Scholar] [CrossRef]

- Bi, S.; Zhang, L. Tetrahedral Rolling Robot with Parallel Mechanism. CN Patent 101664926A, 10 March 2010. [Google Scholar]

- Yao, Y.; Liu, R. Combined Tetrahedral Movable Robot. CN Patent 110696007A, 17 January 2020. [Google Scholar]

- Huang, H.; Pang, C.; Dong, X.; Zheng, L.; Wu, D.; Meng, C.; Lin, Z. Multi-Mode Reconstruction Method for Soft Robot. CN Patent 116423544A, 14 July 2023. [Google Scholar]

- Huang, H.; Meng, C.; Ouyang, J.; Wu, D.; Lin, Z.; Pang, C.; Wang, Y. Reconstructed Tetrahedron Soft Robot and Multi-Gait Motion Control Method Thereof. CN Patent 116476098A, 25 July 2023. [Google Scholar]

- Shen, Z.; Wang, Y.; Chen, D.; Kong, D.; Lv, P.; Shi, W. Tetrahedron Rolling Robot and Motion Joint Parameter Optimization Method Thereof. CN Patent 116079785A, 21 March 2023. [Google Scholar]

- Su, K.; Liu, J. Tetrahedral Rolling Robot Mechanism. CN Patent 120057139A, 30 May 2025. [Google Scholar]

| No. | Research Questions |

|---|---|

| RQ1 | What type of locomotion is used? |

| RQ2 | What practical applications are targeted by this category of robots? |

| RQ3 | What are the most common challenges in their design and implementation? |

| No. | Paper | C1 | C2 | C3 | Final Rating |

|---|---|---|---|---|---|

| 1. | [23] | Yes | No | Yes | Average |

| 2. | [24] | Yes | Yes | Yes | High |

| 3. | [25] | Yes | Yes | Yes | High |

| 4. | [26] | Yes | Yes | Yes | High |

| 5. | [27] | Yes | Yes | Yes | High |

| 6. | [28] | Yes | No | Yes | Average |

| 7. | [29] | Yes | No | No | Low |

| 8. | [30] | Yes | Yes | Yes | High |

| 9. | [31] | Yes | Yes | Yes | High |

| 10. | [32] | Yes | Yes | Yes | High |

| 11. | [33] | Yes | No | Yes | Average |

| 12. | [34] | Yes | Yes | Partial | Average |

| 13. | [35] | Yes | No | Yes | Average |

| 14. | [36] | Yes | Yes | Yes | High |

| 15. | [11] | Yes | Yes | Yes | High |

| 16. | [37] | Yes | Yes | Yes | High |

| 17. | [38] | Yes | Yes | Yes | High |

| 18. | [39] | Yes | Yes | Yes | High |

| 19. | [9] | Yes | Yes | Yes | High |

| 20. | [40] | Yes | Yes | Yes | High |

| 21. | [41] | Yes | Yes | Yes | High |

| 22. | [42] | Yes | No | Yes | Average |

| 23. | [43] | Yes | Yes | Yes | High |

| 24. | [44] | Yes | Yes | Yes | High |

| 25. | [45] | Yes | Yes | Yes | High |

| 26. | [8] | Yes | Yes | Yes | High |

| 27. | [46] | Yes | Yes | Yes | High |

| No. | Research Questions | Selected Papers |

|---|---|---|

| RQ1 | What type of locomotion is used? | [8,9,11,24,25,26,27,30,31,32,36,37,38,39,40,41,43,44,45,46] |

| RQ2 | What practical applications are targeted by this category of robots? | [8,9,11,24,25,26,27,30,31,32,36,37,38,39,40,41,43,44,45,46] |

| RQ3 | What are the most common challenges in their design and implementation? | [8,9,11,24,25,26,27,30,31,32,36,37,38,39,40,41,43,44,45,46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simerean, A.-C.; Tătar, M.O. Tetrahedral Mobile Robots: A Systematic Literature Review. Appl. Sci. 2025, 15, 9979. https://doi.org/10.3390/app15189979

Simerean A-C, Tătar MO. Tetrahedral Mobile Robots: A Systematic Literature Review. Applied Sciences. 2025; 15(18):9979. https://doi.org/10.3390/app15189979

Chicago/Turabian StyleSimerean, Anca-Corina, and Mihai Olimpiu Tătar. 2025. "Tetrahedral Mobile Robots: A Systematic Literature Review" Applied Sciences 15, no. 18: 9979. https://doi.org/10.3390/app15189979

APA StyleSimerean, A.-C., & Tătar, M. O. (2025). Tetrahedral Mobile Robots: A Systematic Literature Review. Applied Sciences, 15(18), 9979. https://doi.org/10.3390/app15189979