A Study on the Monitoring and Response Mechanism of Highway Subgrade Structures Based on Ultra-Weak FBG Sensing Array

Abstract

1. Introduction

2. Principle

3. Monitoring Plan

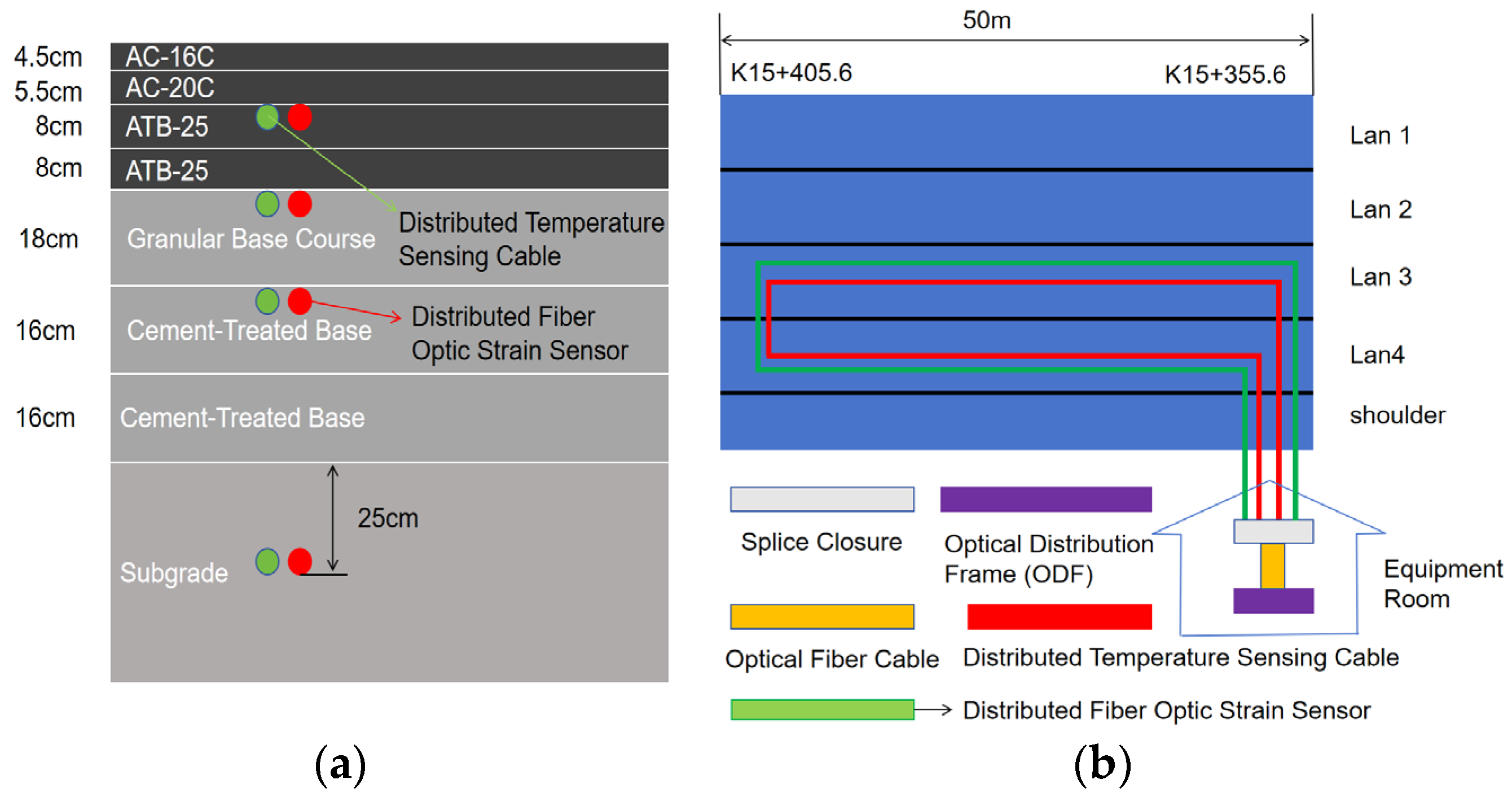

3.1. Typical Flexible Subgrade Structure Composition

3.2. Deployment Plan

- (1)

- High-temperature conditions for ATB-25 upper and lower layers: The paving temperature of the ATB layer can reach 160–180 °C, and traditional epoxy encapsulation is prone to failure due to thermal degradation. To ensure the stability of the sensor optical cable under high-temperature conditions, a high-temperature-resistant slot-cutting process is adopted: after the surface layer has cooled to a constructable temperature, a specialized slot-cutting device is used to excavate a rectangular slot measuring 4 cm (width) × 3 cm (depth). After laying the optical cable, the slot is filled and sealed with asphalt cold patch material.

- (2)

- Granular Base Course and Cement-Treated Base to resist mechanical damage: The middle and lower layers are at risk of being crushed by the tracks of the paver during construction. Longitudinal cable laying can avoid equipment operation paths, while transverse laying requires enhanced protection. This involves excavating a protective trench with dimensions of 5 cm (width) × 4 cm (depth) using a pre-cut slot method and then backfilling with cement mortar after cable laying to enhance mechanical resistance and stability.

- (3)

- Subgrade: In the soil layer, trenches are dug and cables are laid. The trench dimensions are 10 cm (width) × 25 cm (depth). After laying the optical cable, the original soil is used to backfill the trench in layers and compacted to ensure the burial depth, positioning accuracy, and long-term stability.

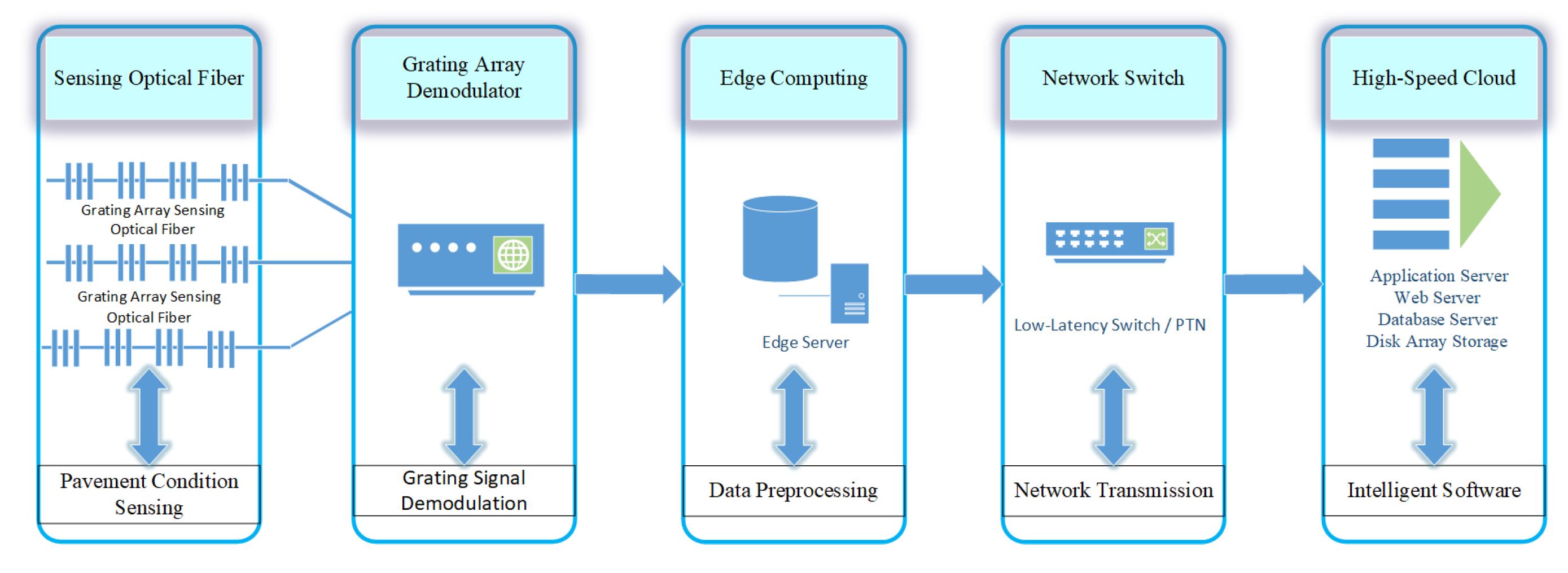

3.3. System Configuration and Data Acquisition Plan

- (1)

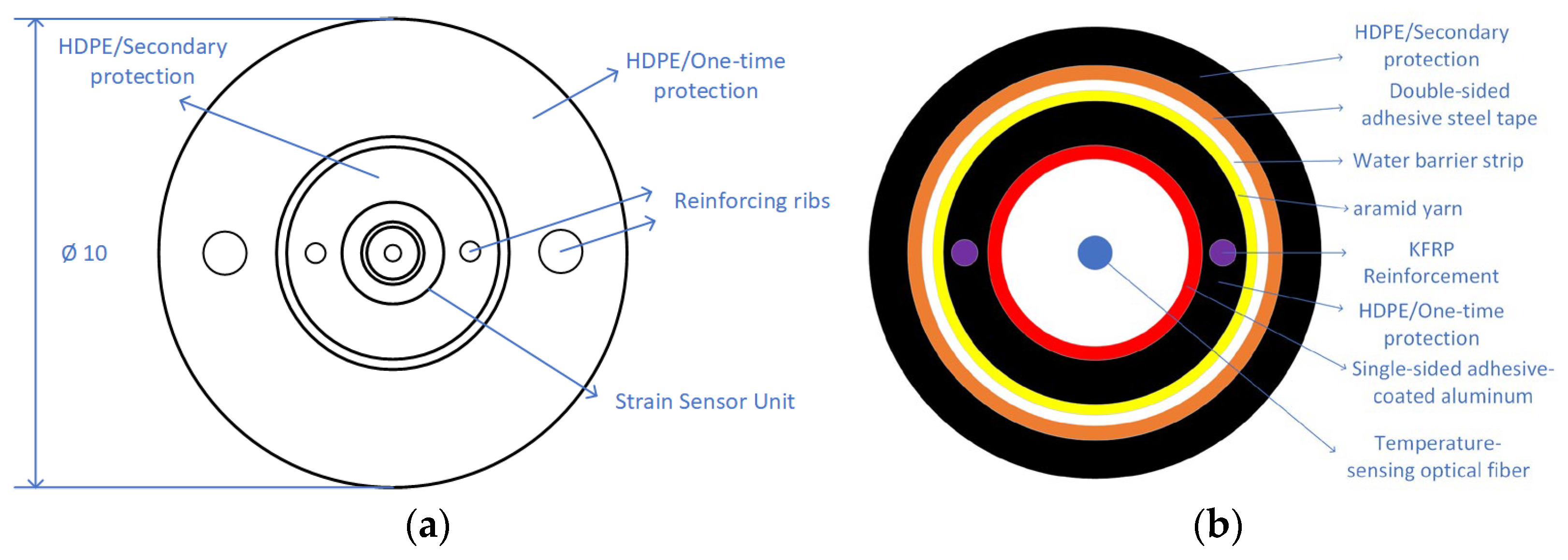

- This section constitutes the system’s primary sensing layer, primarily composed of fiber optic strain sensing cables and temperature sensing cables deployed within various structural layers. The cross-section of the sensing cable is shown in Figure 7. Figure 7a depicts a direct-buried strain sensing cable employing a central tube structure with an internal fixed-point configuration. This design allows for the application of prestress to the sensing fiber, enabling continuous strain monitoring over large gauge lengths. The strain optical cable incorporates dual protective layers. The first layer features a strain unit structure with a stainless steel spiral armor tube design, embedded with two parallel steel wires as reinforcing elements. The second layer employs a steel tape longitudinal wrapping combined with parallel steel wire reinforcement, significantly enhancing the cable’s overall mechanical strength. A structural adhesive is uniformly filled between the two protective layers, improving the overall stiffness and strain transmission performance of the strain-sensing optical cable. Figure 7b shows the direct-burial temperature sensing optical cable, featuring a central tube structure with embedded sensing fibers and accompanying fibers. The excess length of the accompanying fibers is controlled between 2‰ and 3‰ to ensure the sensing fibers remain free from stress. To enhance mechanical performance and accommodate direct burial installation, a dual-armor, dual-sheath structure provides reinforced protection. The inner sheath consists of aluminum cladding and HDPE, while the outer sheath comprises steel tape and HDPE.

- (2)

- This module serves as the data acquisition hub for the entire system. Utilizing a high-speed spectral demodulator (as shown in Figure 8), it converts optical signals transmitted back from the sensing network into raw electrical signals containing physical quantity information such as strain and temperature. The demodulation process supports wavelength-division/time-division multiplexing demodulation mechanisms and features high-frequency sampling capabilities, ensuring distortion-free capture throughout the entire dynamic response process. This system employs a weak-reflection grating array with a central wavelength of 1550 nm, a grating length of 10 mm, a reflectivity of approximately 0.1%, and a sensor spacing of 1 m. Signal demodulation employs both wavelength-division and time-division multiplexing demodulation techniques. The demodulator features four channels, with each channel capable of supporting up to five kilometers of sensing optical cable. It offers a wavelength resolution of 1 pm, strain measurement accuracy of 2 μm, and temperature measurement accuracy of 0.5 °C.

- (3)

- Edge computing and data preprocessing: The demodulated raw electrical signals will undergo preliminary analysis and preprocessing by the edge computing server to extract key feature indicators, such as peak strain, strain frequency spectrum, and structural response curves. The edge server is deployed in a roadside machine room, supporting local rapid computation and data caching, effectively alleviating transmission pressure and improving response efficiency.

- (4)

- Network transmission channel: The system uses a low-latency, high-reliability industrial communication network to transmit edge preprocessing results back to the upper-level high-speed cloud platform via 4G/5G, dedicated lines, or fiber optic links, ensuring data real-time and integrity, and constructing a structure-communication-computing integrated closed loop.

- (5)

- Intelligent Analysis Software Platform: This module is deployed on a high-speed cloud platform and integrates a variety of intelligent functions, including structural condition sensing, dynamic response analysis, health assessment, early warning and prediction, and service life assessment. The platform enables functional modules such as “multi-layer strain field visualization,” “multi-time-period load-temperature coupling diagnosis,” and “zoned health risk warning,” and provides data support and decision-making basis for operational needs such as smart mobility, smart management, smart maintenance, and smart guidance.

3.4. Load Test Plan

- (1)

- Load test:

- (2)

- Actual Traffic Load Monitoring

- A.

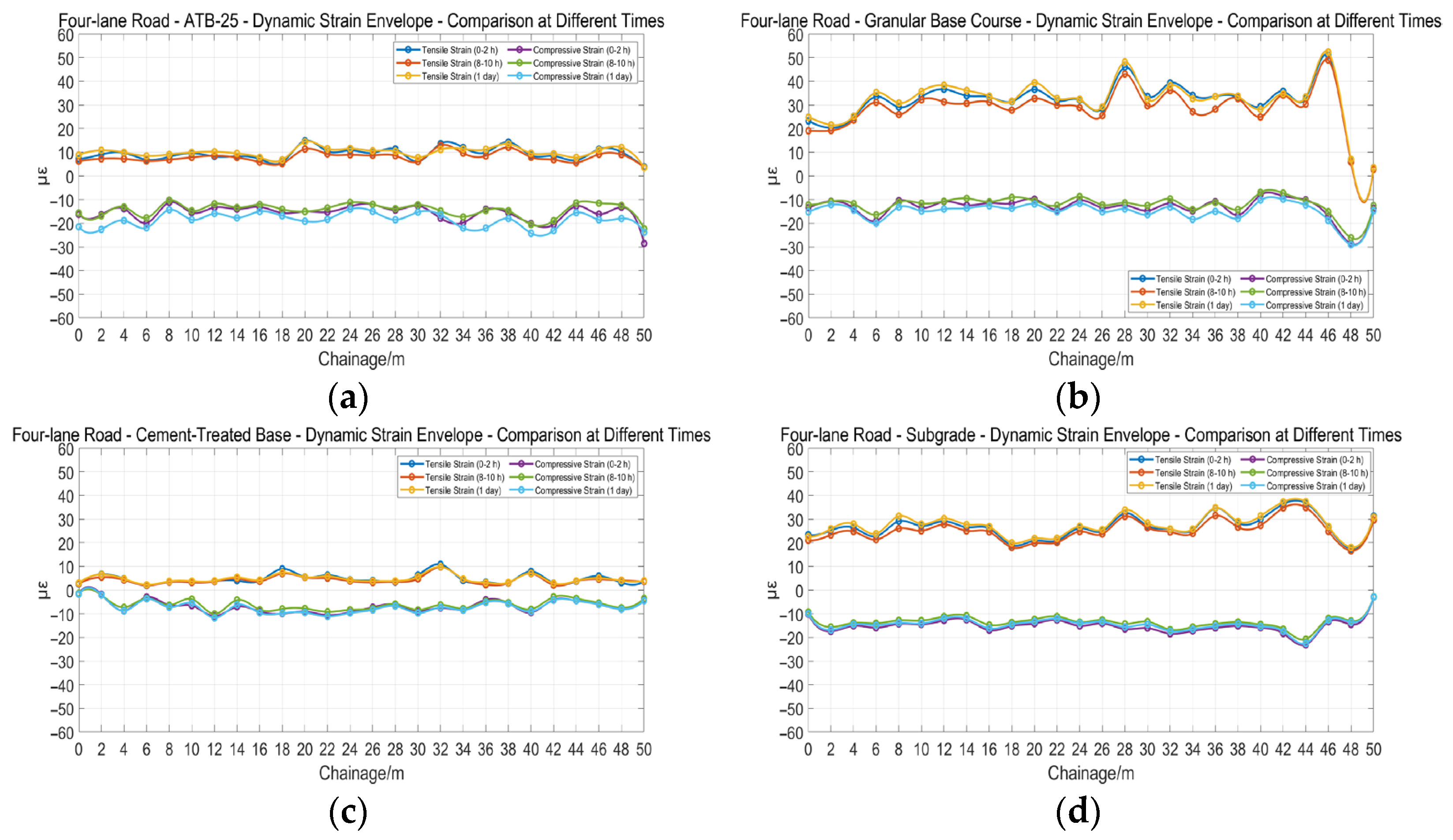

- Stress Field MonitoringAfter the road is opened to traffic, dynamic response data is continuously collected through a buried strain sensor network, and a strain response database is constructed based on long-term monitoring data. To eliminate the impact of vehicle parameter randomness, data screening criteria are set:

- a.

- Vehicle gross weight > 10 tons;

- b.

- Maximum tensile strain of graded crushed stone layer > 5 με

For traffic load events that meet the screening criteria, segmented processing is performed according to the set time window (e.g., 00:00–2:00, 08:00–10:00, and the entire day cycle). For each time segment, the strain time history data recorded by the sensors deployed in each structural layer are extracted. The peak values of tensile strain and compressive strain are calculated, and the average values for that time segment are further determined. Ultimately, a multi-time segment strain response average envelope curve is constructed to describe the typical load transfer characteristics and stress evolution patterns between structural layers under different traffic flow conditions. - B.

- Temperature Field Monitoring

4. Experimental Results and Data Analysis

4.1. Strain Propagation Patterns in Roadbeds Under Dynamic Loads

4.2. Layered Characteristics of Structural Thermal Response to Temperature Gradients

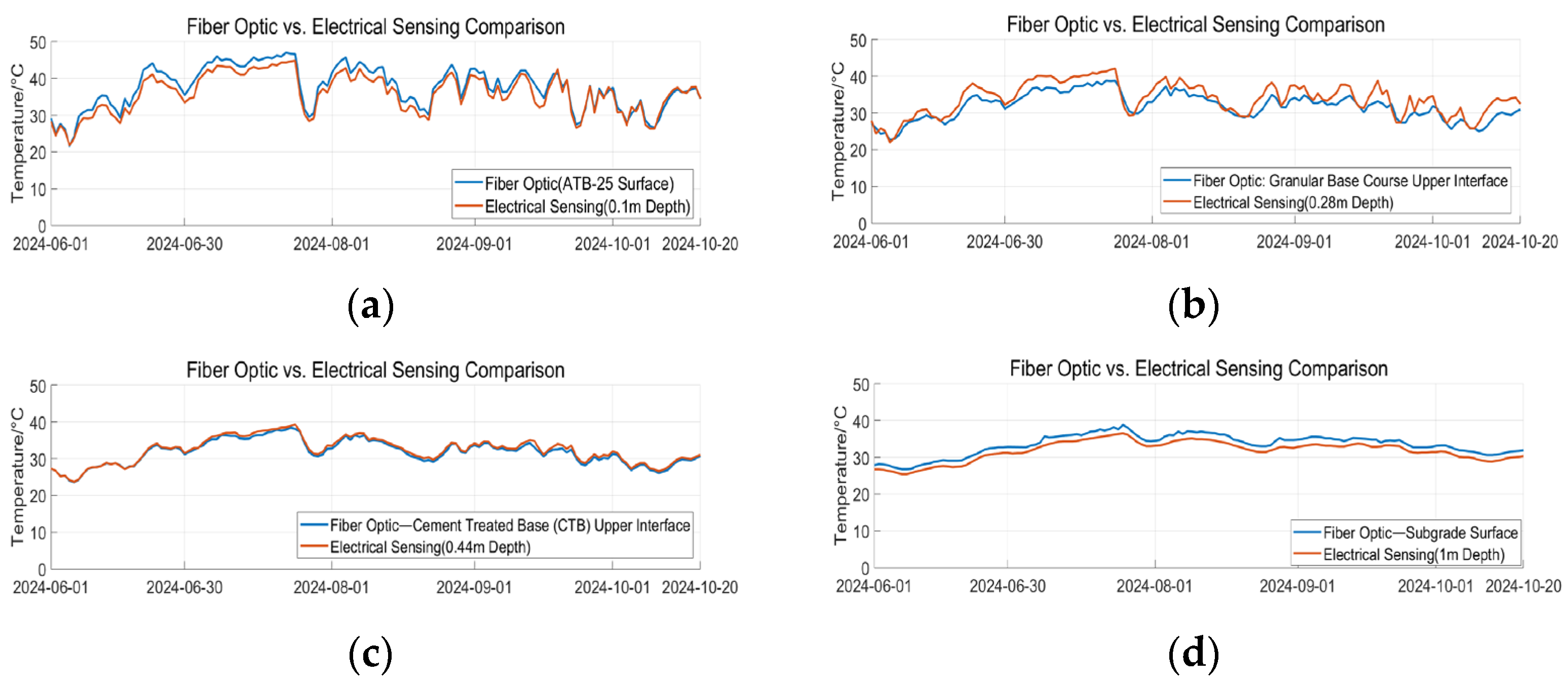

- (1)

- The layering pattern of the temperature field is distinct: temperature variations across layers exhibit consistency in long-term trends and seasonal fluctuations, but the amplitude of short-term daily temperature fluctuations decreases with increasing burial depth. Among these, the ATB layer, as a shallow structural layer, is most significantly influenced by external environmental factors (such as temperature fluctuations and solar radiation), exhibiting the most pronounced temperature fluctuations. Compared to the graded layer, the ATB layer exhibits a wider daily temperature variation range. For example, on 10 June, its daily maximum temperature was significantly higher than that of the graded layer, while its daily minimum temperature was notably lower. This phenomenon clearly reflects the rapid response characteristic of the shallow structural layer to surface thermal conditions.

- (2)

- Consistency at different mileage locations: The thermal response patterns at the 10 m and 30 m measurement points are highly consistent, indicating that the layered differences in the road temperature field can be regarded as a spatially uniform phenomenon, primarily dominated by burial depth and unrelated to the local location of the mileage points.

4.3. Verification of the Stability of Sensor Systems in Long-Term Service

5. Conclusions

- (1)

- Grating array sensors offer convenient installation and deployment, high survival rates, ease of constructing three-dimensional sensing networks and monitoring systems for road infrastructure, and extended service life (the system has been in operation for over two years).

- (2)

- Grating array sensors enable full-field, high-precision distributed measurement of strain and temperature, providing reliable technical support for continuous strain field and temperature field monitoring.

- (3)

- By analyzing data from grating array monitoring, the relationship between structural response and parameters such as modulus, embedment depth, temperature, load, and vehicle speed has been examined. This has provided preliminary insights into the response mechanism of highway subgrade structures.

Author Contributions

Funding

Conflicts of Interest

References

- Girish, S.; Putman, B.J.; Kumar, A.; Nagarajan, S. Evaluation of the sensitivity of the MEPDG to Bottom-Up fatigue cracking in South Carolina. Int. J. Pavement Res. Technol. 2024, 17, 1225–1238. [Google Scholar] [CrossRef]

- Yang, L.; Hu, Y.; Zhang, H. Comparative study on asphalt pavement Rut based on analytical models and test data. Int. J. Pavement Eng. 2020, 21, 781–795. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Xiong, H.; Yang, H. Research on characterization of asphalt pavement performance by acoustic emission Technology. Int. J. Pavement Res. Technol. 2023, 16, 444–473. [Google Scholar] [CrossRef]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K. Continuous health monitoring of pavement systems using smart sensing technology. Constr. Build. Mater. 2016, 114, 719–736. [Google Scholar] [CrossRef]

- Almeida, A.; Picado-Santos, L. Asphalt Road Pavements to Address Climate Change Challenges—An Overview. Appl. Sci. 2022, 12, 12515. [Google Scholar] [CrossRef]

- Dhandapani, B.P.; Mullapudi, R.S. Cement-grouted bituminous mixtures containing reclaimed asphalt pavement material: Design and mechanical properties Road. Mater. Pavement Des. 2024, 26, 1865–1889. [Google Scholar] [CrossRef]

- Shi, Z.; Yue, J.; Xu, L.; Wang, X. Peridynamics for Fracture Analysis of Reflective Cracks in Semi-Rigid Base Asphalt Pavement. Appl. Sci. 2022, 12, 3486. [Google Scholar] [CrossRef]

- Fiandaca, D.; Di Matteo, A.; Patella, B.; Moukri, N.; Inguanta, R.; Llort, D.; Mulone, A.; Mulone, A.; Alsamahi, S.; Pirrotta, A. An Integrated Approach for Structural Health Monitoring and Damage Detection of Bridges: An Experimental Assessment. Appl. Sci. 2022, 12, 13018. [Google Scholar] [CrossRef]

- Braunfelds, J.; Senkans, U.; Skels, P.; Janeliukstis, R.; Porins, J.; Spolitis, S.; Bobrovs, V. Road Pavement Structural Health Monitoring by Embedded Fiber-Bragg-Grating-Based Optical Sensors. Sensors 2022, 22, 4581. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Hu, H.; Ren, C.; Shang, Z.; Ma, X. Evaluation of Grouting Effectiveness on Cracks in Cement-Stabilized Macadam Layer Based on Pavement Mechanical Response Using FBG Sensors. Appl. Sci. 2025, 15, 7312. [Google Scholar] [CrossRef]

- Baba, T.; Saidin, N.; Hasbullah, N.F.; Ahmad, I. Radiation tolerant fiber Bragg gratings: Review of FBG sensing. J. Opt. 2025. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, Z.; Wang, H.; Dong, Y. Distributed optical fiber pressure sensor based on Brillouin scattering. In Optics Frontiers Online 2020: Distributed Optical Fiber Sensing Technology and Applications; SPIE: Bellingham, WA, USA, 2021; Volume 11607, pp. 34–38. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Zhang, N.; Huang, X.; Chen, D. A novel demodulation technique for identical weak fiber Bragg grating array sensing with improved performance. In Optics Frontiers Online 2020: Distributed Optical Fiber Sensing Technology and Applications; SPIE: Bellingham, WA, USA, 2021; Volume 11607, pp. 68–73. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, Y.; Xu, Z.; Zhang, X.; Mou, Q. Brillouin frequency shift error estimation formula for distributed optical fiber sensing technology based on Brillouin scattering. Appl. Opt. 2022, 61, 4354–4362. [Google Scholar] [CrossRef] [PubMed]

- Xinxing, G.; Bo, L. A high-precision bidirectional time-transfer system over a single fiber based on wavelength-division multiplexing and time-division multiplexing. Front. Phys. 2023, 10, 1080966. [Google Scholar] [CrossRef]

- Qin, H.; Li, C.; Luo, B.; Tang, P. Force monitoring in steel-strand anchor cables using quasi-distributed embedded FBG sensors. Constr. Build. Mater. 2024, 438, 137192. [Google Scholar] [CrossRef]

- Kashaganova, G.; Kozbakova, A.; Kartbayev, T.; Togzhanova, K.; Alimseitova, Z.; Sergazin, G. Design of a Fiber Temperature and Strain Sensor Model Using a Fiber Bragg Grating to Monitor Road Surface Conditions. Inventions 2024, 9, 100. [Google Scholar] [CrossRef]

- Jiahui, C.; Haiwei, F.; Miao, C. Temperature Sensing Demodulation System Based on Weakly Reflective Fiber Grating. Opt. Commun. Res. 2025, 3, 82–87. [Google Scholar] [CrossRef]

- Yang, L.; Lifan, L.; Qiuyang, H. Rayleigh Scattering Crosstalk Suppression Technology for Quasi-Distributed Acoustic Wave Sensing Systems. Acta Opt. Sin. 2024, 44, 450–458. [Google Scholar]

- Hou, Z.; Cao, D.; Peng, P.; Ding, X.; Ma, T.; Cheng, J. Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring. Materials 2025, 18, 3489. [Google Scholar] [CrossRef] [PubMed]

- Alhussein, A.N.D.; Qaid, M.R.T.M.; Agliullin, T.; Valeev, B.; Morozov, O.; Sakhabutdinov, A. Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies. Sensors 2025, 25, 2289. [Google Scholar] [CrossRef] [PubMed]

- Amaya, A.; Sierra-Pérez, J. Toward a Structural Health Monitoring Methodology for Concrete Structures under Dynamic Loads Using Embedded FBG Sensors and Strain Mapping Techniques. Sensors 2022, 22, 4569. [Google Scholar] [CrossRef] [PubMed]

| Material Name | Design Modulus (MPa) | Pavement Thickness (cm) | Tensile Splitting Strength (MPa) | |

|---|---|---|---|---|

| 20 °C | 15 °C | |||

| AC-16C Modified Asphalt Concrete (Anti-skid Wearing Course) | 1300 | 1900 | 4.5 | 1.1 |

| AC-20C Medium-graded Modified Asphalt Concrete (Binder Course) | 1200 | 1800 | 5.5 | 1.0 |

| ATB-25 Dense Graded Asphalt Treated Base (Upper Base) | 1200 | 1400 | 16 | 0.8 |

| Graded Crushed Stone (Lower Base) | 400 | 18 | — | |

| 3% Cement Stabilized Gravel (Subbase) | 1000 (Deflection Calculation) | 32 | 0.8 | |

| 2400 (Tensile Stress Calculation) | ||||

| Earthwork Subgrade | 40.5 | — | — | |

| Structural Layer | Dominant Strain Type | Characteristic Value (με @10 km/h) |

|---|---|---|

| ATB-25 | Compressive | −48.07 |

| Granular Base Course | Tensile | 80.50 |

| Cement-Treated Base | Compressive | −25.71 |

| Subgrade | Tensile | 87.45 |

| Structural Layer | Tensile Strain Reduction | Compressive Strain Reduction | Sensitivity Ranking | Similarity Coefficient | p |

|---|---|---|---|---|---|

| ATB-25 | 10.8% | 32.7% | 2 | 0.9654 | 2.385 × 10−9 |

| Granular Base Course | 27.9% | 44.6% | 1 | 0.9660 | 5.264 × 10−8 |

| Cement-Treated Base | 12.8% | 18.2% | 3 | 0.9815 | 0.004 |

| Subgrade | 14.8% | 11.3% | 4 | 0.9625 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, Q.; Yin, S.; Kang, Y.; Zeng, J.; Li, S.; Yue, L.; Yang, Y. A Study on the Monitoring and Response Mechanism of Highway Subgrade Structures Based on Ultra-Weak FBG Sensing Array. Appl. Sci. 2025, 15, 9930. https://doi.org/10.3390/app15189930

Nan Q, Yin S, Kang Y, Zeng J, Li S, Yue L, Yang Y. A Study on the Monitoring and Response Mechanism of Highway Subgrade Structures Based on Ultra-Weak FBG Sensing Array. Applied Sciences. 2025; 15(18):9930. https://doi.org/10.3390/app15189930

Chicago/Turabian StyleNan, Qiuming, Suhao Yin, Yinglong Kang, Juncheng Zeng, Sheng Li, Lina Yue, and Yan Yang. 2025. "A Study on the Monitoring and Response Mechanism of Highway Subgrade Structures Based on Ultra-Weak FBG Sensing Array" Applied Sciences 15, no. 18: 9930. https://doi.org/10.3390/app15189930

APA StyleNan, Q., Yin, S., Kang, Y., Zeng, J., Li, S., Yue, L., & Yang, Y. (2025). A Study on the Monitoring and Response Mechanism of Highway Subgrade Structures Based on Ultra-Weak FBG Sensing Array. Applied Sciences, 15(18), 9930. https://doi.org/10.3390/app15189930