Abstract

In order to investigate the compression damage characteristics of the “interface section coal pillar–backfill body (ICPF)” composite structure formed after coal pillar excavation and gangue material backfill in the key technologies of coal pillar excavation and gangue material backfill replacement in the interface section of thick coal seams, an ICPF single-axis compression damage experiment under different internal dimensions of backfill was conducted using the PFC2D numerical model, with the interface section coal pillar of a working face at a certain mine in northern Shaanxi Province as the research background. In addition, the stress–strain state, peak strength characteristics, damage mode, energy evolution, and damage characteristics of the ICPF composite were analyzed, and models for the evolution of the ICPF elastic modulus and compressive strength were established. The results showed that the stress–strain state of the ICPF changed from brittle to ductile as backfill strength decreased. The distribution of the elastic modulus is primarily influenced by backfill strength, and as the excavation–backfill width increases, the curve exhibits a distinct S-shaped distribution. The compressive strength decreases by up to 63.4% with an increase in excavation–backfill width and by up to 65.1% with a decrease in backfill strength. The sensitivity of compressive strength to backfill strength is greater than that to excavation–backfill width. Based on the established ICPF elastic modulus and compressive strength evolution model, the two mechanical properties were compared using model fitting, and the model fitting results were satisfactory. The ICPF exhibits three types of damage characteristics as the excavation and backfill width increases: oblique shear and tensile damage, edge coal stripping and X-shaped conjugate damage of the backfill body, and large-area plastic damage of the backfill body. By establishing a theoretical damage variable based on linear dissipation energy, damage factors can be quickly obtained from stress–strain curves. The damage curves all exhibit exponential growth, and their growth rates show certain dispersion as the excavation and backfill width increases and backfill strength decreases. Based on the brittleness index analysis of the ICPF composite, as the backfill strength decreases and excavation and backfill width increases, the brittleness index of the composite increases, and the tendency for impact increases. At an excavation and backfill width of 80 mm, rib damage tends to happen.

1. Introduction

In western China, the mining of thick and extra-thick coal seams is influenced by mining height and burial depth, which presents significant challenges for roadway support. To ensure the safety of working face roadways, section coal pillars are often set, with the width of coal pillars typically exceeding 20 m, resulting in the severe waste of coal resources. Based on this, Academician Wang Shuangming proposed an integrated mining technology for interface coal pillars, known as the “excavation–backfill–retention” approach (where interface coal pillars refer to the coal from traditional double-roadway excavation + coal pillars between roadways) with the aim of safely recovering coal resources before mining impacts occur. On the other hand, it calculates the width of large-section roadways and the width of central backfill zones based on the gangue production, achieving complete disposal of gangue in the central backfill zone [1,2]. As part of the interface coal pillar, the section coal pillar can be easily simulated using large-scale “excavation–backfill” operations to approximate the surrounding rock ultimate bearing capacity during the “excavation–backfill–retention” process of the interface coal pillar. By monitoring and analyzing the “excavation–backfill” operations of the section coal pillar, it is possible to accurately determine the damage patterns of the section coal pillar after “excavation–backfill,” providing a theoretical basis for the implementation of the “excavation–backfill–retention” technology for interface coal pillars.

The “excavation–backfill” process in coal pillar sections results in the formation of a composite structure consisting of coal pillars and backfill materials. Previous studies have examined such structures from various perspectives. Extensive research has been conducted on the mechanical behavior and damage mechanisms of coal–backfill composites using both experimental and numerical methods. For instance, Feng et al. elucidated the control mechanism of filled rock layers surrounding pillars [3]; Li et al. investigated thermal damage mechanisms via CT and SEM and developed a constitutive model [4]; Yang et al. evaluated the effect of composite performance through multi-factor experiments [5]; and Zhao et al. established a mechanical model based on elastic theory [6]. Additionally, Wang et al. and Guo et al. utilized PFC simulations to examine interaction characteristics and deformation behavior [7,8]. Several studies have focused on the stability and load-bearing capacity of these composites. Chen et al. and Hu et al. clarified how backfill materials enhance the performance of coal pillars [9,10], while Yu et al. explored the effects of volume fraction and confining pressure [11]. Li et al. examined electromagnetic radiation responses [12], and Zhang et al. analyzed crack propagation using UDEC-Trigon models [13]. Some researchers have addressed specific engineering challenges: FU et al. studied creep properties [14], XU et al. investigated filled body–coal pillar–filled body (FCF) composites [15], An et al. examined surrounding rock mechanics [16], and Jiang et al. developed mechanical models for island mining conditions [17]. Further studies have delved into energy evolution [18], macro-fracture characteristics [19], and applications of Griffith’s criterion [20,21]. While these studies offer valuable insights into horizontally or vertically layered composites, little attention has been paid to hollow structures formed in thick coal seams where the seam height exceeds roadway dimensions [22]. The present study aims to address this research gap by investigating the mechanical behavior and stability of hollow composite structures formed under conditions where coal pillars are not fully replaced.

In this paper, the excavation and backfill width and backfill strength of the interface coal pillar excavation and backfill body (ICPF) were used as variables. PFC2D numerical simulation was used to study the damage evolution, mechanical property evolution, and damage evolution laws of the ICPF under different excavation and backfill dimensions and backfill strengths, revealing the mechanical bearing characteristics of the ICPF under structural and strength parameters. The elastic modulus and compressive strength evolution model was established based on the excavation and backfill dimensions and backfill strength parameters to describe the mechanical properties of the ICPF composite. Finally, the impact tendency of the composite was evaluated using the brittleness index. The research conclusions can provide a theoretical basis for improving the long-term stability of interface excavation and backfill composite and optimizing the mining field structure parameters.

2. Excavation and Backfill Composite Structure

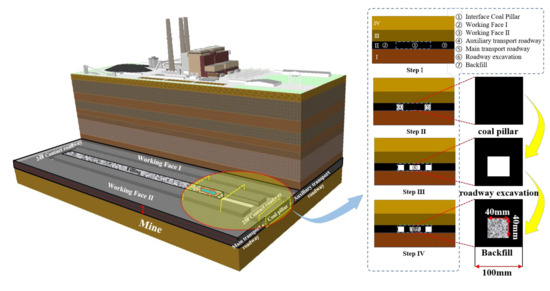

At a certain mine in northern Shaanxi, the actual width of the coal pillar retained between the main and auxiliary transport roadways is 20 m, with an average coal seam thickness of 10.58 m. The actual dimensions of the main and auxiliary transport roadways are 6.5 m × 4.55 m, and a 2 m bottom coal layer is retained at the bottom of the roadways. The layout is shown in Figure 1. Therefore, based on the concept of coal–rock composite [23], the coupled load-bearing structure of the “coal” and “backfill body” after the coal pillar in the section is excavated and backfilled is simplified into a “excavation–backfill” composite model. Considering the curing time and fluidity of the backfill body, the excavation and backfill roadways are separated by a strong backfill body to reduce the fluidity of weak backfill material and improve the roof contact rate. Therefore, the interface coal pillar composite model is influenced not only by the geometric parameters of excavation and backfill but also by the mechanical strength of the backfill material.

Figure 1.

Source of coal pillar excavation and backfilling composite structure in interface section.

3. ICPF Compression Damage Results and Analysis

3.1. Numerical Models and Calibration

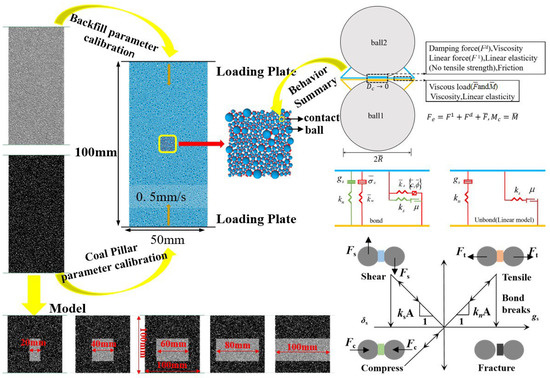

The Discrete Element Method (DEM) enables an in-depth understanding of the microcracking behavior of ICPF composites under uniaxial compression and further facilitates the simulation of complex material responses [24]. As shown in Figure 2, the ICPF model was established using the two-dimensional numerical simulation software PFC2D. The selection of PFC2D over a three-dimensional modeling approach was driven by its superior capability in visualizing and interpreting crack evolution and failure patterns. The two-dimensional framework provides clearer and more intuitive visualization of fracture initiation, propagation, and ultimate failure mechanisms, making it particularly advantageous for qualitative analysis of damage progression.

Figure 2.

Generation and parameter calibration of ICPF (PFC2D) model.

In this model, particles are generated with a spatially random distribution to form bonding bonds, the sizes of which are determined by the minimum contact radius between particles. As a result, the initial bonding state incorporates random weaknesses or omissions, enabling a more accurate representation of the heterogeneous microstructure of natural or engineered materials. These random initial defects and irregular particle arrangements lead to a non-uniform stress distribution within the specimen under applied loads. Consequently, microcracks tend to initiate and propagate preferentially near pre-existing defects or mechanically unfavorable regions. This mechanism enhances the stochastic nature of crack initiation and evolution, contributing to a more realistic simulation of fracture processes. Therefore, it also leads to the formation of an asymmetric damage distribution under loading.

The interparticle bonding is simulated using the Parallel Bond Model (PBM), which describes the mechanical behavior of cement-like materials, such as backfill, connecting adjacent particles. The parallel bond acts similarly to a beam, resisting shear, tensile splitting, and rotational moments within the bonded area. Damage to the bond results in a gradual reduction in and eventual loss of stiffness. However, as long as the particles remain in contact, the contact stiffness continues to function, and the contact points act as potential crack initiation sites. As an anisotropic brittle damage model designed for coal samples and rock-like materials, the PBM captures the progressive deterioration in compressive strength due to bond damage during shearing and tensile failure processes.

As shown in Figure 2, the contact force between particle 1 and particle 2 can be calculated using the following equation:

where Fn and Fs are the normal force and shear force components, respectively, and ni and ti are the unit vectors defining the contact plane. The normal force is

Shear force is calculated using an incremental iterative method and initialized to zero when contact is formed. Subsequently, each relative shear displacement increment (ΔUs) produces an elastic shear force increment (ΔFs), expressed as

where ks is the contact shear stiffness, which is also the shear stiffness of particles 1 and 2.

The total force and torque (Fi, Mi) carried by the parallel keys can be decomposed into normal and shear components, respectively:

where and are the axial force and bending moment, respectively, and and are the shear force and bending moment, respectively. The methods for solving these parameters are similar to those for solving shear stress (Fs):

where A is the particle contact area (two-dimensional for line segment length), and I and J are the moment of inertia and polar moment of inertia of the parallel bond cross section, respectively. These parameters can be calculated as follows:

According to beam theory, the maximum tensile stress (σmax) and shear stress (τmax) acting on the periphery of the parallel bond, respectively, are

If the maximum tensile stress exceeds the tensile strength or the shear stress exceeds the tensile strength, the parallel bond breaks and is removed from the model along with its force, bending moment, and stiffness.

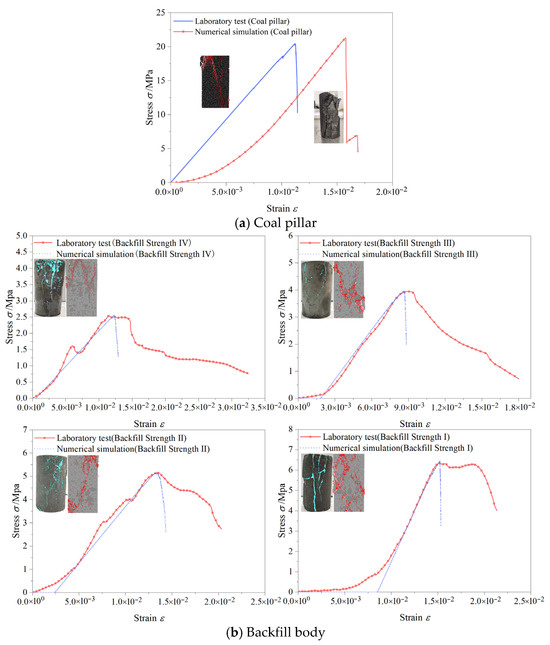

As shown in Figure 3, a numerical model of coal and backfill with dimensions of 50 mm in width and 100 mm in height was established in PFC2D. Through iterative calibration, the microparameters were systematically adjusted until the stress–strain behavior and key mechanical properties matched those of laboratory coal and backfill samples, as summarized in Table 1 and Table 2. It should be noted that, due to the inherent stiffness of particles in PFC2D, the simulation could not reproduce the compaction stage typically observed in physical experiments, a limitation also reported by other researchers in the field. As a result, the numerical curve exhibits a nearly linear response, dominated by elastic deformation, and lacks the initial crack compression phase seen in laboratory curves. This discrepancy arises because the model particles are rigid and uniformly distributed, preventing the representation of pore collapse and progressive crack closure during early loading [25,26]. Consequently, the peak strain in the simulation is lower than that in the experimental results. Nevertheless, the calibrated model using the micromechanical parameters listed in Table 3 exhibited errors in the uniaxial compressive strength (UCS) and elastic modulus (E) within acceptable ranges. Specifically, the UCS errors were 0.2%, 0.9%, 0.6%, 0.5%, and 2.7%, while the E errors were 4.6%, 7%, 1%, 1.8%, and 9.6%. With most errors falling below 5%, the numerical model demonstrates sufficient feasibility for simulating the mechanical behavior of the coal–backfill composite.

Figure 3.

Comparison of coal pillar and backfill body experiments and simulations.

Table 1.

Experimental protocol.

Table 2.

Mechanical parameters of the backfill body obtained by indoor experiments and numerical simulations.

Table 3.

Fine-view parameters of the backfill specimens in the PFC2D model.

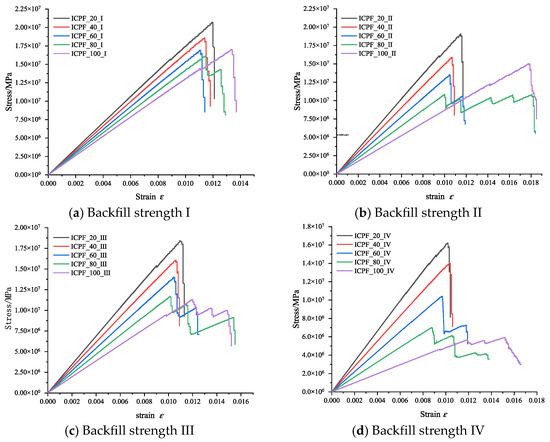

3.2. Stress–Strain Curves

The uniaxial compression stress–strain curves of ICPF specimens are shown in Figure 4. The elastic modulus decreases with increasing excavation and backfill width, and the deformation damage process can be divided into four stages: the pore compaction stage, elastic deformation stage, yield stage, and post-peak damage stage.

Figure 4.

Stress–strain curves.

Pore compaction and elastic deformation stage: As the excavation and backfill width increases, the plastic volume in the ICPF composite increases, and the elastic modulus and peak strength both decrease. However, when the backfill strength is I or II, the peak strength increases when the excavation and backfill width is 100 mm.

Yield stage: The stress–strain curves exhibit nonlinear characteristics. The ICPF composite shows strain softening [27], and the composite exhibits brittle characteristics. As the backfill strength decreases, the composite exhibits a trend toward a transition from brittle to ductile behavior. The volume strain of the non-elastic body increases, and the increase in stress causes the coal wall to peel off. The backfill body undergoes a certain degree of slip along parallel microcracks or interface transition zones, resulting in volume expansion. This is closely related to the dense extension, expansion, and intersection of microcracks during this stage.

Post-peak damage stage: In this stage, stress decreases steadily while strain increases rapidly, resulting in macroscopic damage. However, as the excavation and backfill width increases, the composite structure retains some load-bearing capacity even after damage.

3.3. Elastic Modulus

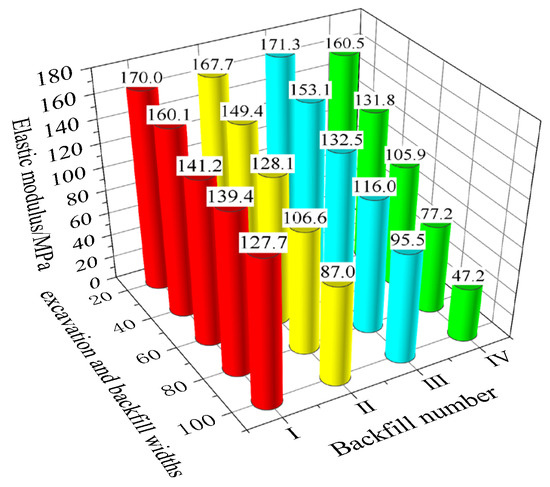

The elastic modulus change process of the ICPF is shown in Figure 5.

Figure 5.

Variation in ICPF elastic modulus under different excavation and backfill widths and backfill strengths.

Figure 5 shows the variation in the ICPF elastic modulus under different excavation and backfill widths and backfill strengths. As shown in Figure 5, with the increase in excavation and backfill width, the elastic modulus of the ICPF specimens shows a linear downward trend, and the rate of decline increases with the decrease in backfill strength. Under high backfill strength (6.26 MPa), the decline in the elastic modulus is relatively small, decreasing from 170.0 MPa at a width of 20 mm to 127.72 MPa at a width of 100 mm, a decrease of approximately 24.7%. However, at lower backfill strengths (2.48 MPa), the elastic modulus decreases significantly with increasing excavation and backfill width, from 160.53 MPa at 20 mm to 47.23 MPa at 100 mm, a decrease of up to 70.5%. This is because the elastic modulus of coal is much greater than that of the central backfill body. The elastic modulus of the ICPF specimens is mainly determined by coal. When the excavation and backfill width increases, the volume proportion of coal decreases, resulting in a decrease in the elastic modulus of the ICPF specimens. The smaller the excavation and backfill width, the smaller the elastic modulus value of the central backfill body and the greater the difference between elastic modulus values inside and outside the ICPF specimen, resulting in more pronounced changes in the elastic modulus value of the ICPF specimen. The volume ratio of the backfill body reflects its effect on the stiffness degradation of coal, which is consistent with the research results of Wang et al. [28].

3.4. Compressive Strength

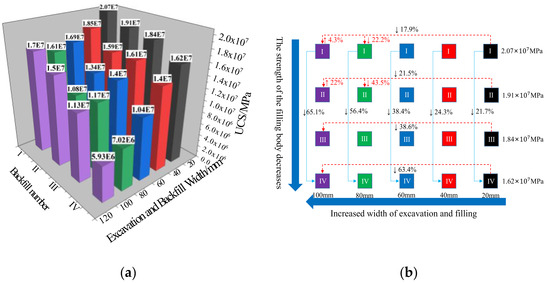

The compressive strength of the ICPF varies with changes in the excavation and backfill width and backfill strength, but the two factors have different sensitivities to the compressive strength. The differences in sensitivity to various factors are shown in Figure 6.

Figure 6.

Compressive strength and sensitivity of ICPF under various backfill strengths: (a) compressive strength and (b) sensitivity.

In Figure 6, when the excavation and backfill width was 20 mm, the backfill strength decreased from 6.26 MPa to 2.48 MPa, resulting in a reduction of approximately 21.7% in the compressive strength. When the excavation and backfill width was 40–100 mm, the compressive strength decreased by 24.3%, 38.4%, 56.4%, and 65.1%, with an average decrease of 41.18%. Similarly, when the backfill strength was 6.26 MPa, 5.15 MPa, 3.98 MPa, and 2.48 MPa, increasing the excavation and backfill width from 20 mm to 100 mm resulted in compressive strength reductions of 17.9%, 21.5%, 38.6%, and 63.4%, respectively, with an average reduction of 35.35%. Comparative analysis indicates that backfill strength is more sensitive to compressive strength. However, when the backfill strength is high, the compressive strength exhibits a certain degree of variability. At compressive strengths of 6.26 MPa and 5.15 MPa, the compressive strength is lowest when the backfill width is 80 mm. This is due to the uneven distribution of overburden loads on the coal pillars and backfill body based on strength distribution theory as the load increases, resulting in the coal pillars on both sides failing to bear the load jointly with the backfill body before becoming unstable.

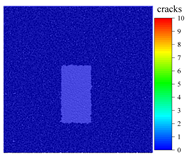

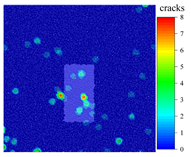

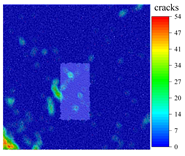

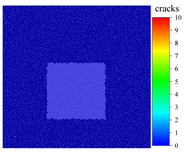

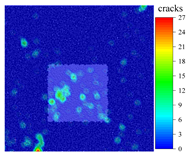

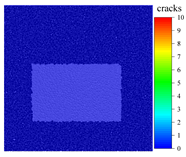

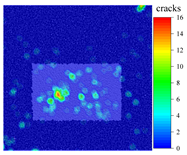

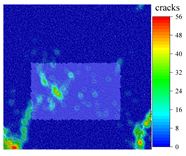

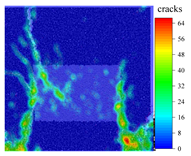

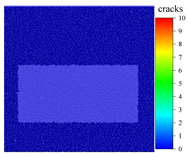

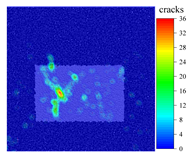

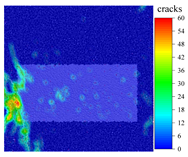

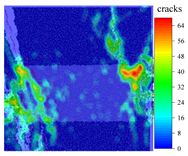

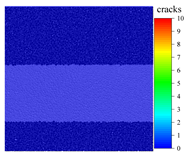

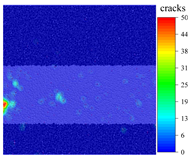

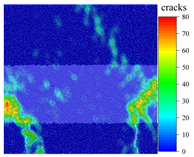

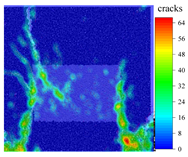

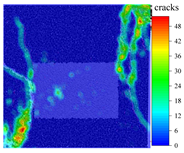

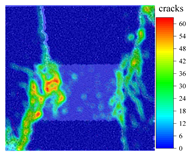

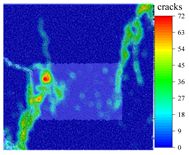

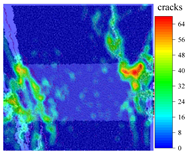

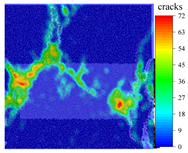

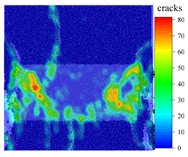

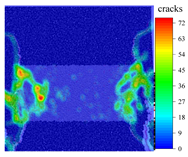

3.5. Failure Process Analysis

The elastic modulus and peak strength are both objective expressions of the load-bearing characteristics of the ICPF composite, but they do not directly reflect the evolution of compression damage in the composite. Therefore, it is also important to analyze the failure process of the ICPF. Due to the significant differences in coal pillar and backfill strength, the failure process of the ICPF composite structure is similar when the backfill strength decreases from 6.26 MPa (backfill strength I) to 2.48 MPa (backfill strength IV). This section only analyzes the failure process of the ICPF composite structure when the backfill strength is 6.26 MPa, as shown in Table 4.

Table 4.

Progressive damage of ICPF with different excavation and backfill widths at backfill strength I.

As shown in Table 4, shear damage of the ICPF composite occurs before peak stress, while tensile shear damage occurs after peak stress. When the stress of the ICPF composite reaches the cracking stress, shear cracks appear in the central backfill body and four corners of the composite with excavation and backfill widths of 20/40/60 mm, while shear cracks appear in the central filled body of the composite with excavation and backfill widths of 80/100 mm. When the stress reaches the peak stress, in the composite with excavation and backfill widths of 20/40/60 mm, the backfill and corner shear cracks gradually expand into a large diagonal shear crack. In the composite with excavation and backfill widths of 80/100 mm, the cracks expand from the middle of the backfill body along the shear direction toward the upper and lower parts of the coal. When the stress reaches residual stress, secondary tensile cracks form at the ends of the shear cracks and propagate from the shear ends to the upper and lower boundaries of the coal. These tensile cracks cause macroscopic displacement and spalling of the ICPF composite, which is particularly evident when the excavation and backfill width is 80 mm. This is due to the brittle characteristics of the coal. For a detailed explanation, see Section 4.3.

4. Discussion

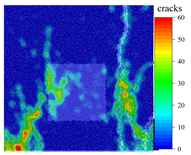

4.1. ICPF Damage Evolution Analysis

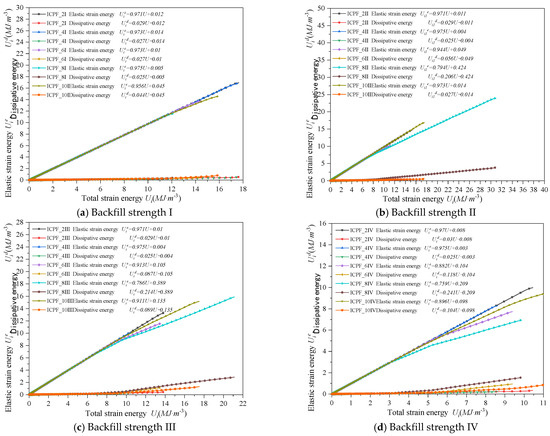

The analysis of the stress–strain curves in Section 3.2 reveals that the damage process of the ICPF can be categorized into four stages. Generally, the majority of damage accumulation in the specimen occurs in the first three stages, and this accumulation is associated with the changes in different forms of energy. Prior research has indicated that rock materials demonstrate a linear pattern of energy storage and dissipation. Elastic strain energy and dissipation energy exhibit a linear relationship with the input strain energy. Dissipation energy is a vital parameter for evaluating rock damage. In the pre-peak phase, the behavior of rock is primarily defined by the accumulation of energy, whereas energy dissipation plays a significant role in the process of rock damage [29]. The relationship between elastic strain energy, dissipation energy, and input strain energy for the ICPF is shown in Figure 7.

Figure 7.

Correlation of energy parameters.

Figure 7 illustrates that the linear equation effectively characterizes the relationships among different energy parameters throughout the loading process of the ICPF specimen. Based on the linear energy dissipation law, it is possible to determine the dissipated energy at any given stress level, with particular emphasis on the peak stress. The magnitude of the dissipated energy reflects the degree of damage of the ICPF composite when loaded to peak stress. Therefore, based on linear dissipated energy, the definition of the damage variable is as follows [29]:

The following complete linear equations are considered:

where DT is the theoretical damage variable; DE is the experimental damage variable; U is the total energy input after ICPF loading is completed; Ui is the energy input when the ICPF reaches any stress level; Uid is energy dissipated and released when the ICPF reaches any stress level; UdP is energy dissipated and released when the ICPF reaches peak stress; a is the energy dissipation factor; and b is a constant.

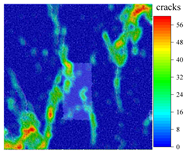

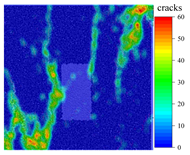

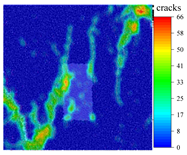

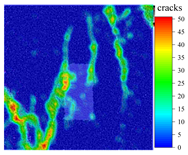

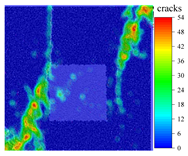

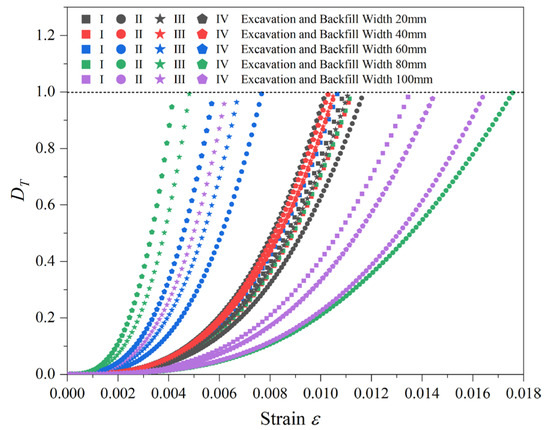

Figure 8 illustrates the relationship between damage variables and strain during a uniaxial compression test. The introduction of a linear dissipation energy law facilitates the calculation of the damage variable from the stress–strain curve, resulting in a damage evolution curve that demonstrates considerable continuity. Notably, as the excavation and backfill width increases to 60 mm, the rate of evolution of the damage variable exhibits considerable variability. Furthermore, a decrease in backfill strength correlates with an initial increase in the damage evolution rate, followed by a subsequent decline. The variation curves of the damage variable across different ICPF composites exhibit similar patterns. During the initial loading phase, the damage variable remains constant, and the corresponding curve is relatively flat. As the rock undergoes further deformation, the curve becomes progressively steeper until it reaches a value of 1, at which point the damage variable escalates until the specimen ultimately fails. In summary, the damage variable demonstrates an exponential growth trend in relation to increasing axial strain, aligning with findings from prior research [30].

Figure 8.

Evolution of damage variables for ICPF composite under compression loading.

4.2. ICPF Composite Theory Model

4.2.1. ICPF Elastic Modulus Evolution Model

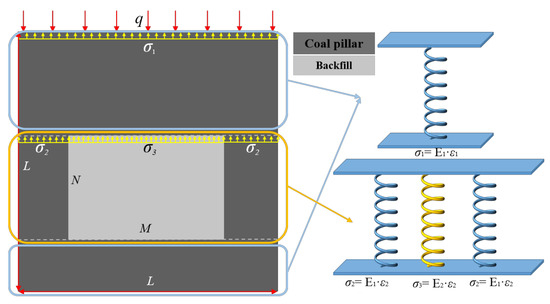

The elastic modulus is one of the basic mechanical properties of ICPF composites. In order to study the changes in the mechanical properties of the ICPF with respect to the excavation and backfill width and backfill strength, it is necessary to establish an evolutionary model for the elastic modulus of the ICPF. For the ICPF composite, the coal and the filled body have different physical and mechanical properties. The harder part of the composite can be regarded as a hard spring, while the softer part, along with its internal microcracks, pores, and coal-filled body interface, can be regarded as a soft spring. That is, the ICPF composite is assumed to be a soft and hard spring model, as shown in Figure 9.

Figure 9.

ICPF composite spring element linear elasticity model.

As shown in Figure 9, there are two sets of linear relationships between the axial stress σ and axial strain ε. These are represented by the coal within the blue frame and the coal sample–backfill body composite within the yellow frame. The linear relationships are expressed as follows:

During the single-axis compression elastic stage, each composite structure undergoes different compression strains ε1 and ε2 and corresponding internal stresses σ1, σ2, and σ3 under the action of external load q. Assuming the average internal stress σ1, the elastic modulus EF of ICPF composite structure can be expressed as

where EI, E1, and E2 are the elastic moduli of the ICPF composite, coal, and backfill body, respectively, in GPa; L, M, and N are the ICPF composite, excavation and backfill width, and excavation and backfill height, respectively, in meters.

ZHAO et al. concluded that composite materials with different elastic moduli exhibit elastic influence coefficients during compression. Under external load q, the average internal stress does not remain constant as the excavation and backfill width increases. Furthermore, the internal backfill body is subjected to triaxial stress, and its elastic modulus exceeds that of the material under uniaxial compression. Therefore, considering the mutual influence factors between the backfill body and the coal during the excavation and backfill process, Equation (14) can be modified as follows [31]:

where c is the elastic interaction coefficient, and d is the stress concentration coefficient of the backfill body.

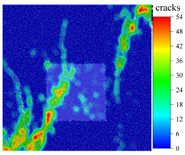

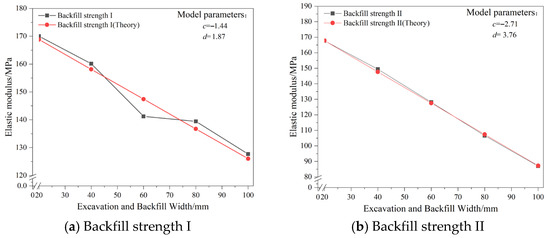

The experimental results corresponding to different backfill strengths in Figure 4 were fitted to the model in Equation (15). The parameters of the ICPF elastic modulus evolution model obtained from the fitting are shown in Figure 10.

Figure 10.

Comparison of calculated elastic modulus of evolutionary model and numerical simulation values.

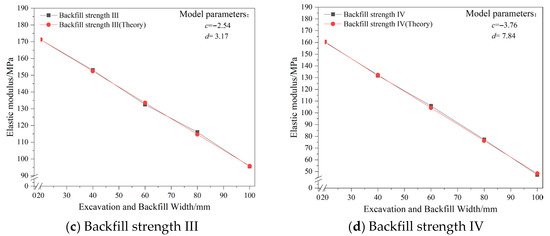

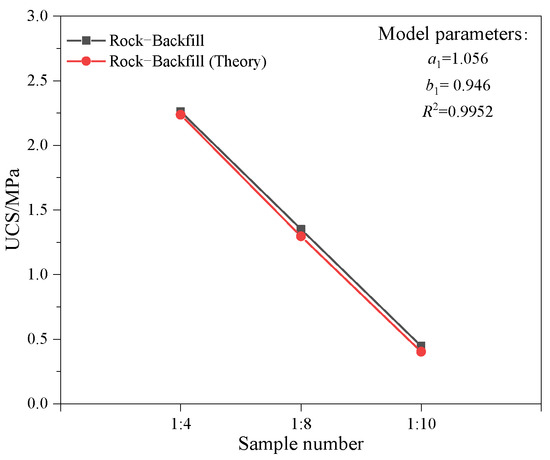

As shown in Figure 10, the numerical simulation curve of the ICPF elastic modulus with respect to the excavation and backfill width is in good agreement with the evolutionary model calculation results, and the fitting parameters of the elastic modulus evolutionary model are all within a reasonable range. The above results indicate that the proposed elastic modulus evolutionary model can well reflect the influence of the excavation and backfill width and backfill strength on the evolution law of the ICPF elastic modulus. To further validate the feasibility of the model, uniaxial compression data of the rock–backfill composite obtained from the study by Zhao et al. were used for comparison [32]. The fundamental mechanical parameters of the composite are summarized in Table 5, and the fitting results, as depicted in Figure 11, show excellent agreement with the experimental data, achieving a fitting accuracy of 0.9952. The close match between the simulated and experimental results demonstrates that the model accurately captures the mechanical behavior of the coal pillar/rock–backfill composite. These findings confirm the strong applicability and reliability of the model for practical engineering applications.

Table 5.

Predicted value [32].

Figure 11.

Comparison of calculated elastic modulus of evolutionary model and predicted value.

4.2.2. ICPF Compressive Strength Evolution Model

The elastic modulus reflects the ability of a composite structure to resist deformation, while compressive strength reflects its load-bearing capacity. Therefore, establishing an ICPF composite structure compressive strength evolution model is also an effective means of studying how the mechanical properties of the ICPF change with excavation and backfill width and backfill strength. Extensive research has shown that the size of coal or rock has a significant impact on the compressive strength of coal–rock composite structures, and the overall strength of the composite is influenced by the individual strengths of the rock and coal components. The dimensions of the backfill portion in the ICPF composite vary with changes in the excavation and backfill width [33]. Therefore, based on the influence of the volume fraction of the backfill body, using the compressive strength σM of the coal test piece as the basis and the volume fraction φF of the backfill body as the independent variable, a power function expression for calculating the compressive strength of the ICPF (σI) was established based on σM and φF:

where a1 is the influence coefficient, and b1 is the influence index.

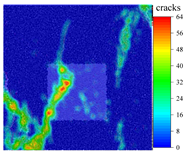

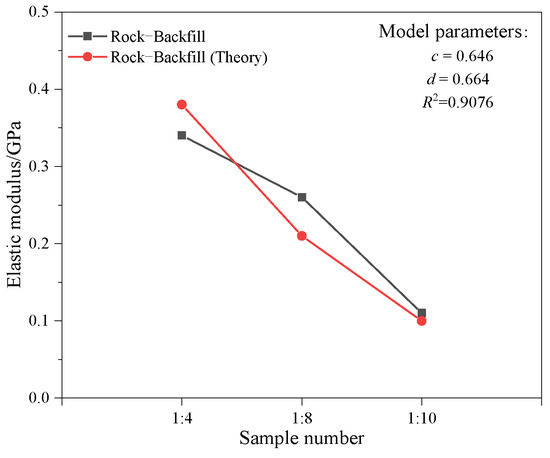

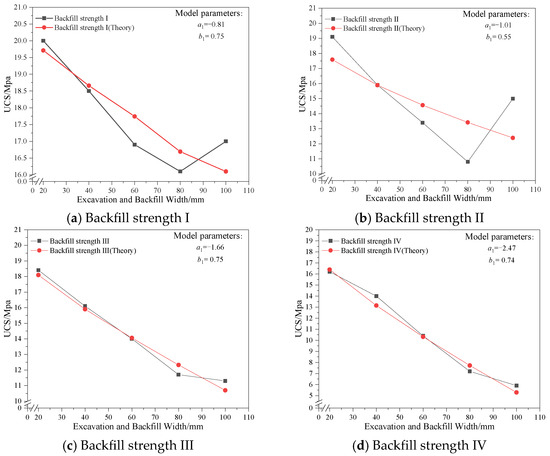

The model parameters in Equation (16) were fitted using the test results corresponding to different backfill strengths in Figure 6. The parameters of the ICPF elastic modulus evolution model obtained from the fitting are shown in Figure 12.

Figure 12.

Comparison of the compressive strength calculated by the evolutionary model with the numerical simulation values.

As shown in Figure 12, the numerical simulation curve of the compressive strength change in the ICPF is in good agreement with the calculated results from the evolution model. At a backfill strength of II, significant variability is observed, and the numerical simulation calculations exhibit substantial fluctuations when the excavation and backfill width is 80 mm. The fitting parameters of the compressive strength evolution model are all within reasonable ranges. The established compressive strength evolution model effectively reflects the influence of the excavation and backfill width and backfill strength on the evolution law of ICPF compressive strength. Similarly, the strength values from Table 5 were fitted, and the fitting results are shown in Figure 13. The fitting accuracy reached 0.9952, indicating good agreement between the simulation and experimental results. This demonstrates that the model can effectively represent the mechanical properties of the coal pillar (rock)–backfill composite, confirming its strong applicability in practical engineering applications.

Figure 13.

Comparison of the compressive strength calculated by the evolutionary model and predicted value.

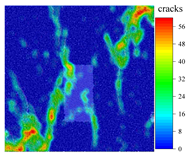

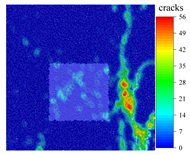

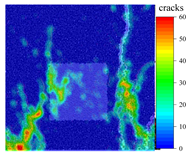

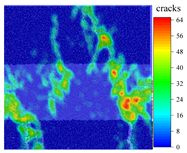

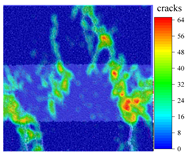

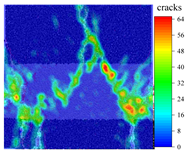

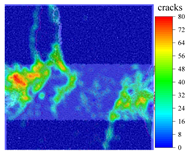

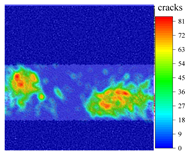

4.3. ICPF Composite Damage Pattern

The final damage pattern of the ICPF composite is the direct basis for studying its damage characteristics. The final damage pattern of the compression damage numerical model is shown in Table 6.

Table 6.

ICPF damage patterns for different excavation and backfill widths and strengths.

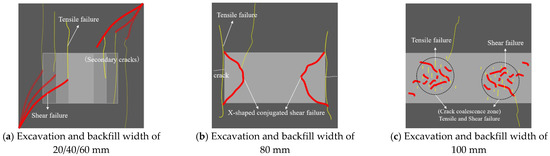

As shown in Table 6, when the excavation and backfill width is 20 mm, a decrease in the backfill strength from Grade I to Grade IV leads to shear cracks propagating from the lower left and upper right corners toward the center, initiating secondary cracks. Tensile cracks occur as adhesive damage at the coal–backfill interface and as secondary cracks during shearing. Under these conditions, the damage mode of the ICPF specimen transitions gradually from shear-dominated to a mixed tensile–shear pattern. Similar damage patterns are observed at widths of 40 mm and 60 mm [34]. When the excavation and backfill width is 80 mm, damage concentrates at the coal–backfill contact surface: the coal pillars experience tensile failure, while the backfill exhibits X-shaped conjugate shear damage, accompanied by secondary cracks extending along the shear plane. The overall failure is primarily tensile–shear. When the width reaches 100 mm, shear-induced damage localizes within the backfill, forming a converging crack zone. For high-strength backfill, secondary cracks extend from this zone to the specimen end, resulting mainly in shear damage.

Notably, when the width exceeds 60 mm, significant damage occurs on both sides of the specimen. In particular, at 80 mm width, increasing overburden load makes the interface coal pillars susceptible to rib damage, which may lead to impact phenomena in the working face.

The macro-scale damage patterns of ICPF specimens under uniaxial compression conditions vary. Overall, the specimens primarily exhibit three damage patterns: shear damage, tensile damage, and combined tensile–shear damage, as shown in Figure 14.

Figure 14.

ICPF uniaxial compression damage pattern.

4.4. ICPF Composite Brittleness Characteristics Analysis

The brittleness of ICPF specimens is closely related to the composite structure and strength of coal pillars and backfill bodies. The brittleness index is an important indicator for predicting rockburst disasters, directly affecting the brittle fracture of coal–rock bodies and the stability of the surrounding rock. The brittleness index is also an important indicator for evaluating the mechanical properties of coal–rock bodies, the stability of surrounding rock in roadways, and the effectiveness of rockburst prevention measures [35,36]. Based on the consideration of both pre-peak and post-peak stress, the brittleness index evaluation is defined as follows [37]:

where Bi1 is the pre-peak brittleness index; Bi2 is the post-peak brittleness index; σi and εi are the initial crack stress and initial crack strain, respectively; σp and εp are the peak stress and peak strain, respectively; and σr and εr are the residual stress and residual strain, respectively.

Based on the stress–strain curves determined in Section 3.2, the stress–strain values for each stage of the ICPF were determined. Using Equation (17), the brittleness indices of ICPF specimens with different excavation and backfill widths and backfill strengths were obtained, as shown in Table 7.

Table 7.

ICPF specimen brittleness index.

As shown in Table 7, when the excavation and backfill width is 20 mm and backfill strength is 6.15 MPa, the brittleness index of the ICPF specimen is 1.01. When the excavation and backfill width increases to 100 mm, the brittleness index reaches maximum at 80 mm, increasing by 18.8%. When the excavation and backfill width remains constant, reducing the backfill strength to 2.14 MPa results in an 18.8% increase in the brittleness index. Analysis of the remaining ICPF specimens showed similar patterns in the brittleness index, which first increased and then decreased with an increase in the excavation and backfill width and increased with a decrease in the backfill strength. When the excavation and backfill width was 80 mm and backfill strength was 2.14 MPa, the brittleness index reached its maximum value of 2.16, representing an increase of 114% compared to the minimum value. The ICPF impact tendency increased, consistent with the results of the damage pattern analysis. The coal pillars on both sides are prone to rib damage, which can cause impacts on the headgate.

The notable increase in the brittleness index under specific geometric and mechanical conditions provides important insights into potential rockburst risks and roadway stability. A higher brittleness index often corresponds to a greater tendency for sudden, violent failure, which is a critical indicator for rockburst prediction. Moreover, the variations in brittleness highlight its value in assessing the stability of underground excavations, particularly in coal mines where dynamic failure poses serious safety threats. In future work, we aim to further investigate the quantitative relationship between the brittleness index and rockburst potential, as well as its integration into early warning systems and support design guidelines for safer mining operations.

5. Conclusions

The conclusions of this study are as follows:

(1) The deformation and damage process of the ICPF composite can be divided into four distinct stages: pore compaction, elastic deformation, yield, and post-peak damage. With increasing excavation width and decreasing backfill strength, the composite exhibits a transition from brittle to more ductile behavior during the yield stage.

(2) The elastic modulus distribution is primarily influenced by backfill strength, while excavation width acts as a shape parameter in the distribution function. Compressive strength shows higher sensitivity to backfill strength than to excavation width. These findings led to the development of evolution models for both the elastic modulus and compressive strength, which effectively capture the mechanical behavior of the ICPF under various conditions. These models offer practical tools for designing backfill systems in coal mines.

(3) A damage variable model based on the linear energy dissipation law was established to quantify damage progression in the ICPF. When the excavation width exceeds 60 mm, the damage evolution rate becomes notably discrete. Across all configurations, the damage variable follows an exponential growth trend with axial strain, providing a valuable metric for stability assessment in field applications.

(4) Numerical simulations revealed three characteristic failure modes dependent on the excavation width: at small widths, coal serves as the main load-bearing component, failing through oblique shear and tensile damage with minimal backfill involvement; at larger widths, edge coal exhibits extensive spalling, and the backfill shows X-shaped conjugate failure; and under full excavation and backfilling conditions, the backfill undergoes widespread plastic damage.

(5) Brittleness analysis indicates that the brittleness index increases with larger excavation width and lower backfill strength, suggesting elevated risk of dynamic failure such as rockburst. The maximum brittleness occurs at an 80 mm excavation width, where coal ribs are highly susceptible to damage—consistent with observed failure patterns. This highlights the value of the brittleness index as an early warning indicator for engineering instability.

Author Contributions

Conceptualization, B.Z., D.Z.; methodology, D.Z.; software, D.Z.; validation, D.Z., P.C. and S.C.; formal analysis, P.C.; investigation, S.C.; resources, D.Z.; data curation, D.Z.; writing—original draft preparation, D.Z.; writing—review and editing, P.C. and S.C.; visualization, D.Z.; supervision, B.Z.; project administration, B.Z.; funding acquisition, B.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by (1) “Two Chains” Integration Key Projects—Joint Key Projects of Enterprise Institutes—Industrial Field Program (No. 2023-LL-QY-02) and the (2) National Natural Science Foundation of China (No. 52074208).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that there are no conflicts of interest concerning the publication of this paper.

Correction Statement

This article has been republished with a minor correction to the Data Availability Statement. This change does not affect the scientific content of the article.

References

- Wang, S.M.; Shen, Y.J.; Song, S.J.; Liu, L.; Gu, L.J.; Wei, J.B. The changing status of coal energy and green low-carbon development under the “double carbon” target. J. China Coal Soc. 2023, 48, 2599–2612. [Google Scholar]

- Wang, S.M.; Liu, L.; Zhao, Y.J.; Zhang, B.; Wang, J.Y.; Zhu, M.B.; Wang, M.; Zhang, X.Y. New energy development in coal-fired areas under the goal of “double carbon”—A new path for future coal mine transformation and upgrading. Coal Sci. Technol. 2023, 51, 59–79. [Google Scholar]

- Feng, G.R.; Bai, J.W.; Shi, X.D.; Qi, T.Y.; Wang, P.F.; Guo, J.; Wang, S.Y.; Kang, L.X. Key column theory for chain destabilization of legacy coal column group and its application prospect. J. China Coal Soc. 2021, 46, 164–179. [Google Scholar]

- Li, J.; Feng, G.; Bai, J.; Yilmaz, E.; Zhao, H.; Li, H.; Ma, J. Thermal effect on bearing behavior and instability of coal-backfill composites. Compos. Struct. 2025, 371, 119447. [Google Scholar] [CrossRef]

- Yang, K.; Lv, X.; Liu, Q.J.; Yang, Y.Q.; Chi, X.L.; Fang, J.J.; Fu, Q.; Wang, Y.; Zhang, Z.N. Experimental study on the instability characteristics of coal pillar-artificial dam adhesions left in abandoned mines. J. Min. Saf. Eng. 2022, 39, 1071–1083. [Google Scholar]

- Zhao, B.Z.; Zhai, D.; Yang, X.; Guo, Y.X.; Liu, C.G.; Sun, H. Study on filling body-coal column bearing effect and reasonable mining parameters. Min. Res. Dev. 2020, 40, 15–21. [Google Scholar]

- Wang, F.T.; Li, G.; Ban, J.G.; Peng, X.Y.; Li, S.T.; Liu, S.F. Study on the synergistic bearing effect of deep mining filler and coal column. J. Min. Saf. Eng. 2020, 37, 311–318. [Google Scholar]

- Zhu, X.J.; Guo, G.L.; Liu, H.; Peng, X.N.; Yang, X.Y. Stability analysis of the composite support pillar in backfill-strip mining using particle flow simulation method. Environ. Earth Sci. 2022, 81, 124. [Google Scholar] [CrossRef]

- Chen, S.J.; Zhang, J.W.; Yin, D.W.; Liu, Y.; Shen, B.T.; Ren, K.Q.; Cheng, W.M. Mechanism and numerical simulation study on the performance of coal column lifting by filling wall. J. Min. Saf. Eng. 2017, 34, 268–275. [Google Scholar]

- Hu, B.N.; Li, H.Y. Numerical simulation study of coal mine filler action and its mechanism analysis. Coal Sci. Technol. 2010, 38, 13–16. [Google Scholar]

- Yu, X.; Tan, Y.Y.; Song, W.D.; Wang, J. Study on the strength and damage mechanism of filler-encapsulated rock assemblages. J. China Univ. Min. Technol. 2023, 52, 30–42. [Google Scholar]

- Li, X.; Zhou, J.; Yang, Z.; Li, H.; Bu, J.R.; Liu, Z.Y.; Wang, Y.R. Time-frequency evolution of electromagnetic radiation in deformation and fracture of composite coal-rock under different loading rates. Constr. Build. Mater. 2024, 453, 139030. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, C.P.; Liu, B.; Liu, Y.; Zhang, N.; Wang, H.Y. Numerical investigation on crack development and energy evolution of stressed coal-rock combination. Int. J. Rock Mech. Min. 2020, 133, 104417. [Google Scholar] [CrossRef]

- Fu, J.X.; Zhang, B.Y.; Tan, Y.Y.; Wang, J.; Song, W.D. Study on creep characteristics and damage evolution of surrounding rock and filling body (SR-FB) composite specimens. J. Mater. Res. Technol. 2023, 23, 5382–5399. [Google Scholar] [CrossRef]

- Xu, B.; Li, Y.L.; Wang, S.S.; Luo, H.H.; Lu, B. Study on the strength characteristics and failure characteristics of the composite load-bearing structure in the cemented filling field. Constr. Build. Mater. 2022, 330, 127242. [Google Scholar] [CrossRef]

- An, B.F.; Zhang, J.X.; Li, M.; Huang, P. Stability of pillars in backfilling mining working face to recover room mining standing pillars. J. Min. Saf. Eng. 2016, 33, 238–243. [Google Scholar]

- Jiang, F.X.; Chen, Y.; Li, D.; Wang, C.W.; Gai, D.C.; Zhu, S.T. Study on mechanical mechanism of rock burst at isolated backfilling working face during primary mining. J. China Coal Soc. 2019, 44, 151–159. [Google Scholar]

- Yang, L.; Gao, F.Q.; Wang, X.Q.; Li, J.Z. Energy evolution law and failure mechanism of coal-rock combined specimen. J. China Coal Soc. 2019, 44, 3894–3902. [Google Scholar]

- Wang, X.L.; Li, Z.F.; Guo, J.P.; Lu, C.W.; Jiang, H.Q.; Mei, J.W. Experimental and numerical investigations on damage mechanical behaviors of surrounding rock-backfill composite under uniaxial compression. Constr. Build. Mater. 2024, 417, 135210. [Google Scholar] [CrossRef]

- Song, H.Q.; Zuo, J.P.; Liu, H.Y.; Zuo, S.H. The strength characteristics and progressive failure mechanism of soft rock-coal combination samples with consideration given to interface effects. Int. J. Rock Mech. Min. 2021, 138, 104593. [Google Scholar] [CrossRef]

- Zuo, J.P.; Song, H.Q. Energy evolution law and differential energy destabilization model of coal-rock assemblage. J. China Coal Soc. 2022, 47, 3037–3051. [Google Scholar]

- Zhai, W.L.; He, F.L.; Song, J.Y.; Wu, Y.H.; Xu, X.H.; Wang, D.Q.; Zhang, J.L.; Li, L. Strong strata behavior mechanism and roof cutting control of small pillar gob-side roadway in extra-thick coal seam. Bull. Eng. Geol. Environ. 2024, 83, 77. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.P.; Song, H.Q.; Feng, L.L.; Shao, G.Y. Study on cyclic plus and minus deformation and crack evolution law of coal-rock assemblage. J. Min. Saf. Eng. 2018, 35, 26–833. [Google Scholar]

- Ma, S.Z.; Liu, K.W.; Guo, T.F.; Yang, J.C.; Li, X.D.; Yan, Z.X. Experimental and numerical investigation on the mechanical characteristics and failure mechanism of cracked coal & rock-like combined sample under uniaxial compression. Theor. Appl. Fract. Mec. 2022, 122, 103583. [Google Scholar]

- Su, G.S.; Huang, J.W.; Liu, Y.N. Crack propagation mechanism of fissured sandstone subjected to uniaxial cyclic compression test. Theor. Appl. Fract. Mec. 2025, 139, 105049. [Google Scholar] [CrossRef]

- Jiang, Q.; Xin, J.; Xu, D.P.; Liu, Q. Shear failure process of rectangular tunnel: Physical experimental test and numerical back-analysis. Theor. Appl. Fract. Mec. 2022, 120, 103384. [Google Scholar] [CrossRef]

- Alam, S.Y.; Loukili, A. Effect of micro-macro crack interaction on softening behaviour of concrete fracture. Int. J. Solids Struct. 2020, 182, 34–45. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.X.; Song, W.D.; Zhang, Y.F. Mechanical properties, damage evolution, and constitutive model of rock-encased backfill under uniaxial compression. Constr. Build. Mater. 2021, 285, 122898. [Google Scholar] [CrossRef]

- Gong, F.Q.; Zhang, P.L.; Luo, S.; Li, J.C.; Huang, D. Theoretical damage characterisation and damage evolution process of intact rocks based on linear energy dissipation law under uniaxial compression. Int. J. Rock Mech. Min. 2021, 146, 104858. [Google Scholar] [CrossRef]

- Chen, Z.Q.; He, C.; Ma, G.Y.; Xu, G.W.; Ma, C.C. Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock Mech. Rock Eng. 2019, 52, 1265–1274. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, G.Y.; Xu, L.; Zhou, J.; Huang, X.L. Mechanical property evolution model of cemented tailings-rock backfill considering strengthening and weakening effects. Constr. Build. Mater. 2023, 377, 131081. [Google Scholar] [CrossRef]

- Zhao, K.; He, Z.W.; Zhou, Y.; Yan, Y.J.; Wan, W.L.; Ning, F.J.; Huang, M.; Wang, J.Q. Synergistic deformation in a combination of cemented paste backfill and rocks. Constr. Build. Mater 2022, 317, 125943. [Google Scholar] [CrossRef]

- Li, C.J.; Xu, Y.; Feng, M.M.; Pan, B. Deformation law and damage mechanism of coal-like rock assemblages under uniaxial loading. J. China Coal Soc. 2020, 45, 1773–1782. [Google Scholar]

- Zhao, B.C.; Zhai, D.; Chen, P.; Wei, Q.M.; Wang, R.F. Damage evolution law and crack expansion characteristics of gangue cemented filler. J. Xi’an Univ. Sci. Technol. 2023, 43, 18–27. [Google Scholar]

- Wang, Y.; Li, X.; Wu, Y.F.; Ben, Y.X.; Li, S.D.; He, J.M.; Zhang, B. Research on relationship between crack initiation stress level and brittleness indices for brittle rocks. Chin. J. Rock Mech. Eng. 2014, 33, 264–275. [Google Scholar]

- Zhou, H.; Meng, F.Z.; Zhang, C.Q.; Xu, R.C.; Lu, J.J. Quantitative evaluation of rock brittleness based on stress-strain curves. Chin. J. Rock Mech. Eng. 2014, 33, 1114–1122. [Google Scholar]

- Chen, G.Q.; Zhang, Y.; Xu, Q.; Wu, X.Z.; Meng, K.; Fan, H.Z. A novel brittle evaluation method considering the difference in energy evolution during rock failure process. Eng. Fail. Anal. 2025, 170, 109280. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).