Operational Speed in Skidding Operations by Cable Skidders and Farm Tractors: Results of a Nationwide Assessment

Abstract

1. Introduction

2. Materials and Methods

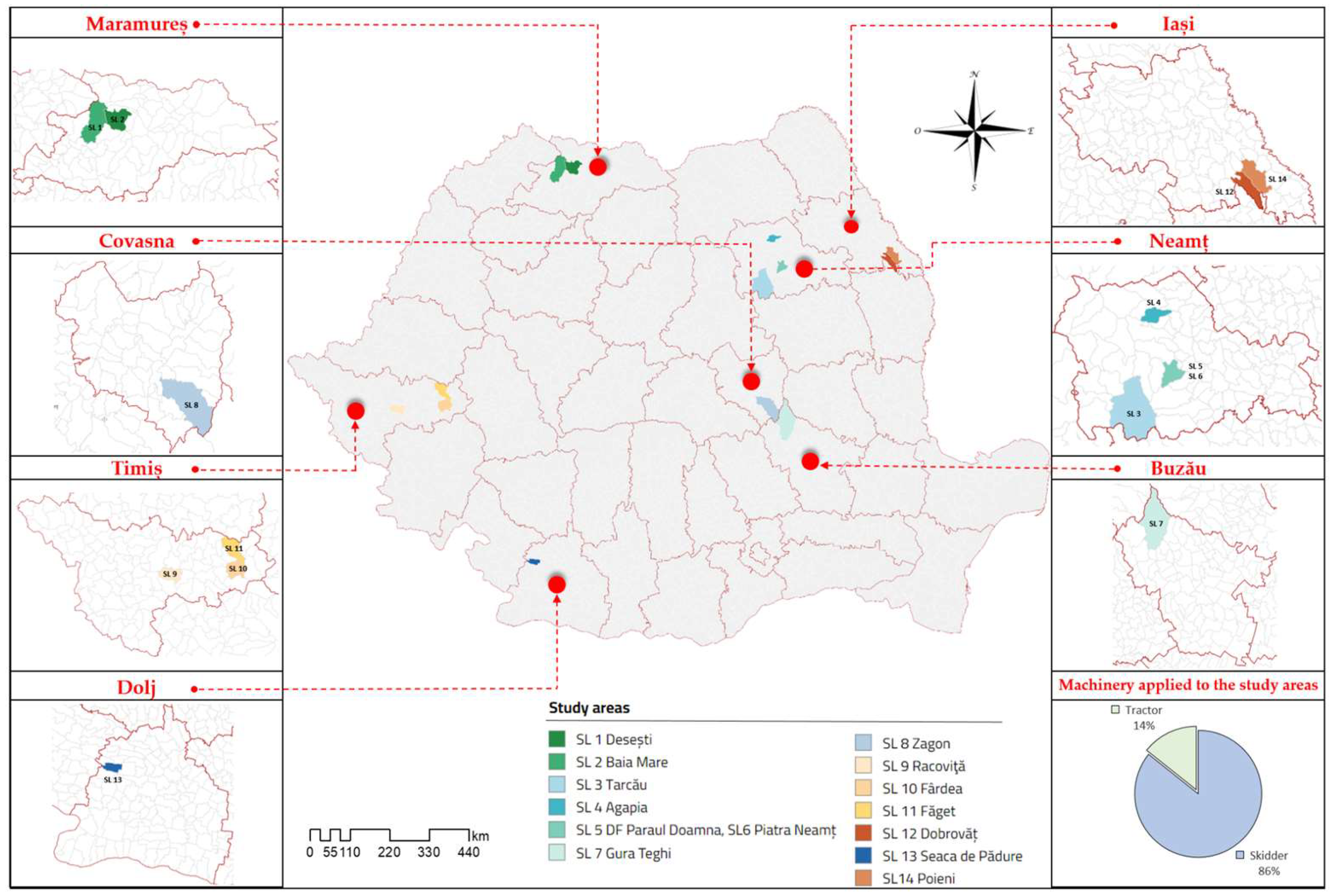

2.1. Data Sourcing

2.2. Data Processing

2.3. Data Analysis

3. Results

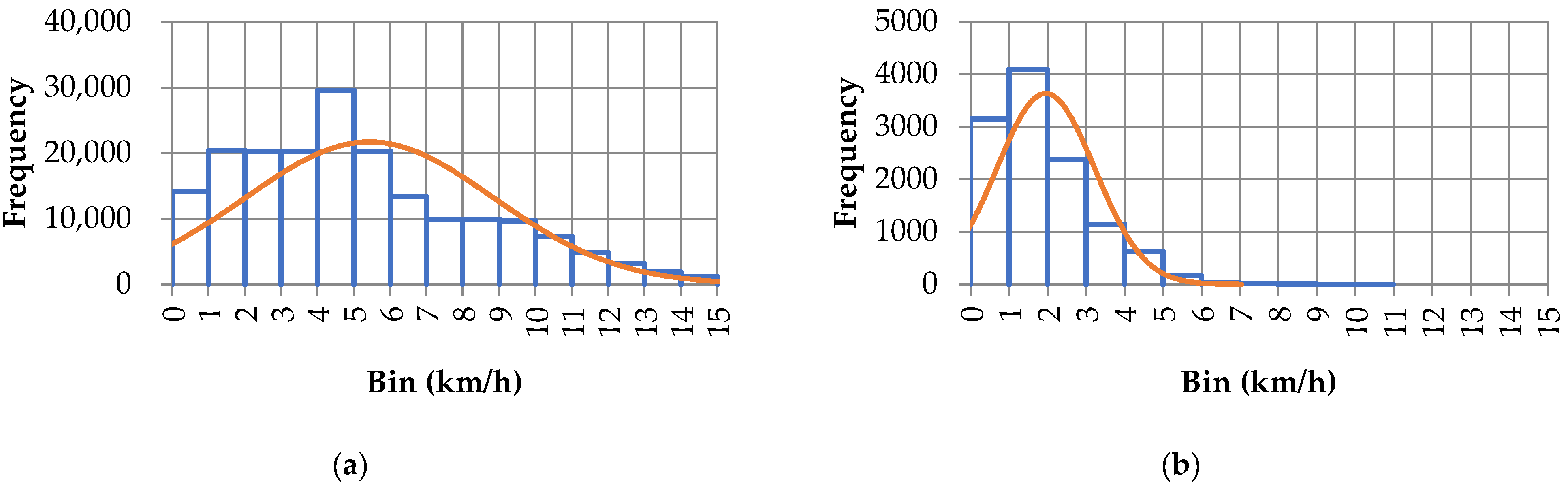

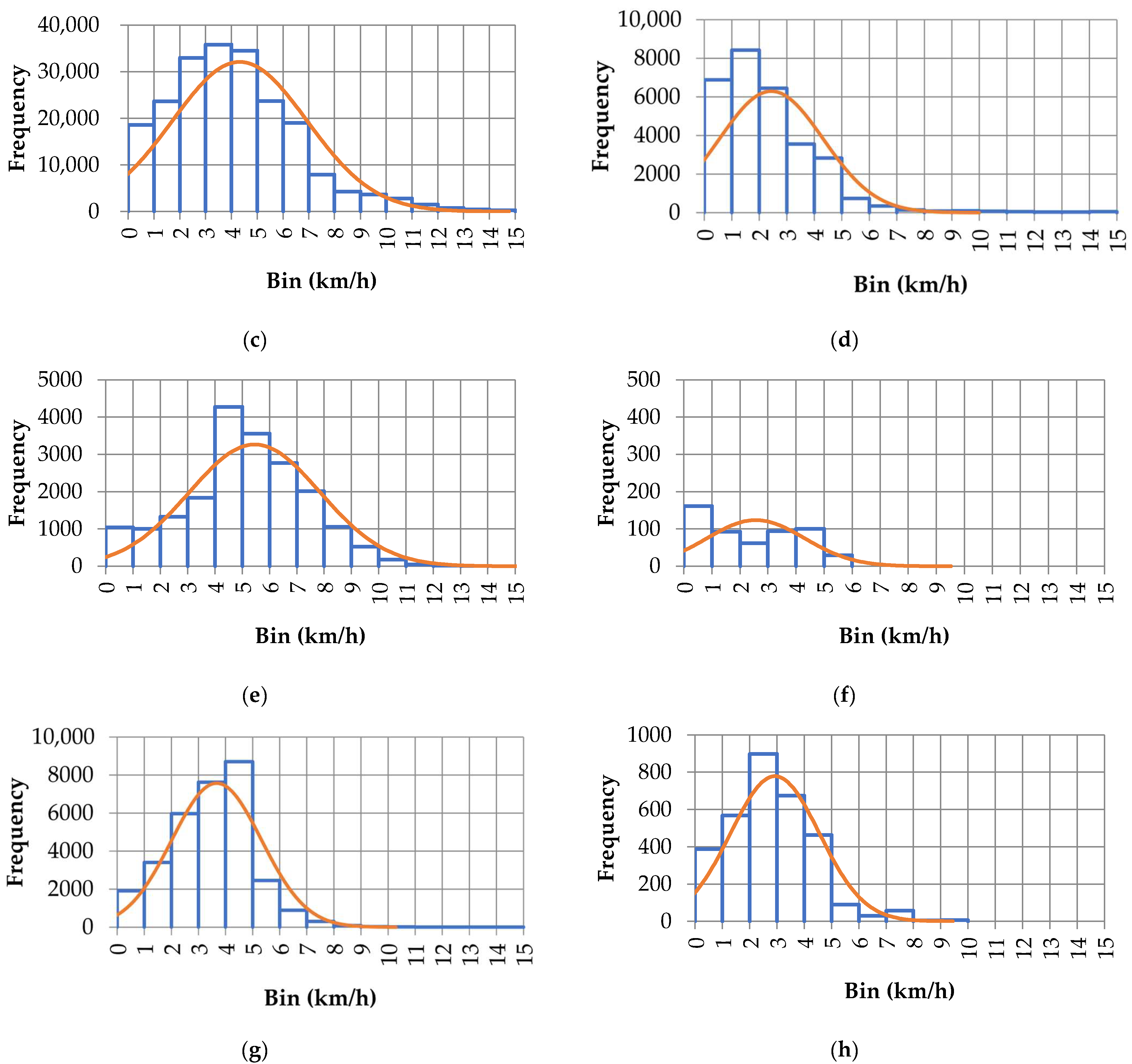

3.1. Data Description

3.2. Comparison of Operational Speed

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| Acronym | Definition |

| GNSS | Global navigation satellite system |

| SK | Skidder |

| FT | Farm tractor |

| U | Mann–Whitney U statistic |

| M | Mean |

| SD | Standard deviation |

| KM | Kilometers |

| H | Hour |

| S | Second |

| SL | Study location |

| IMU | Inertial measurement unit |

| DET | Driving to the pre-skidding site |

| MAN | Maneuvering at the pre-skidding site |

| POC | Pulling out the cable |

| APL | Attachment of the payload |

| PIP | Pulling in the payload |

| DPC | Detaching the payload from the cable |

| APE | Attaching the payload for extraction |

| DFR | Driving with the payload to the forest road |

| DPR | Detaching the payload at the forest road |

| MBR | Maneuvering and bunching at the forest road |

| DS | Delays caused by the study |

| DP | Delays caused by personal reasons |

| DM | Delays caused by mechanical reasons |

| DO | Delays caused by operational reasons |

References

- Erler, J.; Spinelli, R.; Borz, S.A.; Mederski, P.S. Technodiversity in Forest Operations; Transilvania University Press: Brașov, Romania, 2023; pp. 4–88. [Google Scholar]

- Oprea, I. Tehnologia Exploatării Lemnului; Transilvania University Press: Brașov, Romania, 2008; pp. 11–17. [Google Scholar]

- Sessions, J. Harvesting Operations in the Tropics; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable forest operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef]

- Heinimann, H.R. Forest operations engineering and management—The ways behind and ahead of a scientific discipline. Croat. J. For. Eng. 2007, 28, 107–121. [Google Scholar]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M. IUFRO Forest Work Study Nomenclature; Swedish University of Agricultural Science: Grapenberg, Sweden, 1995; p. 16. [Google Scholar]

- Acuna, M.; Bigot, M.; Guerra, S.; Hartsough, B.; Kanzian, C.; Kärhä, K.; Lindroos, O.; Magagnotti, N.; Roux, S.; Spinelli, R. Good Practice Guidelines for Biomass Production Studies; CNR IVALSA: Sesto Fiorentino, Italy, 2012; pp. 1–51. ISBN 978-88-901660-4-4. [Google Scholar]

- Sabo, A.; Poršinsky, T. Skidding of fir roundwood by Timberjack 240C from selective forests of Groski Kotar. Croat. J. For. Eng. 2005, 26, 13–27. [Google Scholar]

- Gallis, C.; Spyroglou, G. Productivity linear regressions of tree-length harvesting system in natural coastal Aleppo pine (Pinus halepensis L.) forests in the Chalkidiki area of Greece. Croat. J. For. Eng. 2012, 33, 115–123. [Google Scholar]

- Borz, S.A.; Dinulica, F.; Birda, M.; Ignea, G.; Ciobanu, V.D.; Popa, B. Time consumption and productivity of skidding Silver fir (Abies alba Mill.) round wood in reduced accessibility conditions: A case study in windthrow salvage logging from Romanian Carpathians. Ann. For. Res. 2013, 56, 363–375. [Google Scholar]

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding operations in thinning and shelterwood cut of mixed stands—Work productivity, energy inputs and emissions. Ecol. Eng. 2013, 61, 216–223. [Google Scholar] [CrossRef]

- Proto, A.R.; Macri, G.; Visser, R.; Russo, D.; Zimbalatti, G. Comparison of timber extraction productivity between winch and grapple skidding: A case study in Southern Italian Forests. Forests 2018, 9, 61. [Google Scholar] [CrossRef]

- Gilanipoor, N.; Najafi, A.; Heshmat Alvaezin, S.M. Productivity and cost of farm tractor skidding. J. For. Sci. 2012, 58, 21–26. [Google Scholar] [CrossRef]

- Sowa, J.M.; Szewczyk, G. Time consumption of skidding in mature stands performed by winches powered by farm tractor. Croat. J. For. Eng. 2013, 34, 255–264. [Google Scholar]

- Yoshida, M.; Sakai, H. Winch harvesting on flat and steep terrain areas and improvements of its methodology. Croat. J. For. Eng. 2015, 36, 55–61. [Google Scholar]

- Gülci, S.; Büyüksakalli, H.; Taş, I.; Akay, A.E. Productivity analysis of timber skidding operation with farm tractor. Eur. J. For. Eng. 2018, 4, 26–32. [Google Scholar] [CrossRef][Green Version]

- Özturk, T.; Varsak, M.G.; Bilici, E. Evaluating productivity and cycle time of skidding method with farm tractors in Bigadic Forest Enterprise Directorate in Turkey. Eur. J. For. Eng. 2018, 5, 77–82. [Google Scholar] [CrossRef]

- Borz, S.A.; Mititelu, V.-B. Productivity and Fuel Consumption in Skidding Roundwood on Flat Terrains by a Zetor Farm Tractor in Group Shelterwood Cutting of Mixed Oak Forests. Forests 2022, 13, 1294. [Google Scholar] [CrossRef]

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Visser, R.; O’Neal, B. A survey of skidder fleet of Central, Eastern and Southern Europe. Eur. J. For. Res. 2021, 140, 901–911. [Google Scholar] [CrossRef]

- Moskalik, T.; Borz, S.A.; Dvorák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdinš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Ministry of Timber Industrialization and Construction Materials. Norme și Normative de Muncă Unificate în Exploatări Forestiere; Ministry of Timber Industrialization and Construction Materials: Bucharest, Romania, 1989; pp. 1–493. [Google Scholar]

- Marcu, M.V.; Borz, S.A. Effect of Trail Condition, Slope, and Direction of Extraction on Forwarding Performance: Insights from a Controlled Comparative Study. Forests 2024, 15, 1790. [Google Scholar] [CrossRef]

- Borz, S.A.; Mariș, A.-C.; Kaakkurivaara, N. Performance of Skidding Operations in Low-Access and Low-Intensity Timber Removals: A Simulation of Productivity and Fuel Consumption in Mature Forests. Forests 2023, 14, 265. [Google Scholar] [CrossRef]

- Borz, S.A.; Marcu, M.V.; Cataldo, M.F. Evaluation of an HSM 208F 14-ton HVT-R2 forwarder prototype under conditions of steep-terrain low-access forests. Croat. J. For. Eng. 2021, 42, 185–200. [Google Scholar] [CrossRef]

- Strandgard, M.; Mitchell, R. Automated Time Study of Forwarders using GPS and a vibration sensor. Croat. J. For. Eng. 2015, 36, 175–184. [Google Scholar]

- Hildt, E.; Leszczuk, A.; Mac Donagh, P.; Schlichter, T. Time Consumption Analysis of Forwarder Activities in Thinning. Croat. J. For. Eng. 2020, 41, 13–24. [Google Scholar] [CrossRef]

- Gallo, R.; Grigolato, S.; Cavalli, R.; Mazzetto, F. GNSS-based operational monitoring devices for forest logging operation chains. J. Agric. Eng. 2013, XLIV, e27. [Google Scholar] [CrossRef]

- Mușat, E.C.; Apăfăian, A.I.; Ignea, G.; Ciobanu, V.D.; Iordache, E.; Derczeni, R.A.; Spârchez, G.; Vasilescu, M.M.; Borz, S.A. Time expenditure in computer aided time studies implemented for highly mechanized forest equipment. Ann. For. Res. 2016, 59, 129–144. [Google Scholar] [CrossRef]

- Apăfăian, A.I.; Proto, A.R.; Borz, S.A. Performance of a mid-sized harvester-forwarder system in integrated harvesting of sawmill, pulpwood and firewood. Ann. For. Res. 2017, 60, 227–241. [Google Scholar] [CrossRef]

- Real Statistics Using Excel. Available online: https://real-statistics.com/ (accessed on 18 July 2025).

- D’Agostino, R.; Pearson, E.S. Tests for departure from normality. Empirical results for the distributions of b2 and √b1. Biometrika 1973, 60, 613–622. [Google Scholar] [CrossRef]

- Nichols, A.L.; Edlund, J. The Cambridge Handbook of Research Methods and Statistics for the Social and Behavioral Sciences: Volume 1: Building a Program of Research; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- Mann, H.B.; Whitney, D.R. On a test of whether one of two random variables is stochastically larger than the other. Ann. Math. Statist. 1947, 18, 50–60. [Google Scholar] [CrossRef]

- Simwanda, M.; Wing, M.G.; Sessions, J. Evaluating Global Positioning System accuracy for forest biomass transportation tracking within varying forest canopy. West. J. Appl. For. 2011, 26, 165–173. [Google Scholar] [CrossRef]

- Feng, T.; Chen, S.; Feng, Z.; Shen, C.; Tian, Y. Effects of canopy and multi-epoch observations on single-point positioning errors of a GNSS in coniferous and broadleaved forests. Remote Sens. 2021, 13, 2325. [Google Scholar] [CrossRef]

- Abdi, O.; Uusitalo, J.; Pietarinen, J.; Lajunen, A. Evaluation of forest features determining GNSS positioning accuracy of a novel low-cost, mobile RTK system using LiDAR and TreeNet. Remote Sens. 2022, 14, 2856. [Google Scholar] [CrossRef]

- Moore, A.; Rymer, N.; Glover, J.S.; Ozturk, D. Predicting GPS fidelity in heavily forested areas. In Proceedings of the 2023 IEEE/ION Position, Location and Navigation Symposium (PLANS), Monterey, CA, USA, 24–27 April 2023; pp. 772–780. [Google Scholar]

- Pirti, A. Accuracy analysis of GPS positioning near the forest environment. Croat. J. For. Eng. 2008, 29, 189–199. [Google Scholar]

- Ironside, K.E.; Mattson, D.J.; Arundel, T.R.; Hansen, J.R. Is GPS telemetry location error screening beneficial? Wildl. Biol. 2017, 1–7. [Google Scholar] [CrossRef]

- Keskin, M.; Say, S.M.; Keskin, S.G. Evaluation of a Low-Cost GPS Receiver for Precision Agriculture Use in Adana Province of Turkey. Turk. J. Agric. For. 2009, 33, 79–88. [Google Scholar] [CrossRef]

- Supej, M.; Čuk, I. Comparison of Global Navigation Satellite System Devices on Speed Tracking in Road (Tran) SPORT Applications. Sensors 2014, 14, 23490–23508. [Google Scholar] [CrossRef] [PubMed]

- Suhartana, S.; Yuniawati, Y. Skill of Skidding Equipment Operator in Relation to Productivity, Skidding Cost and Subsidence in Peat Swamp Forest Plantation. Croat. J. For. Eng. 2023, 44, 69–81. [Google Scholar] [CrossRef]

- Diniz, C.C.C.; Nakajima, N.Y.; Robert, R.C.G.; Dolácio, C.J.F.; Silva, F.D.; Balensiefer, D.F. Performance of grapple skidder in different ground inclinations. Floresta 2019, 49, 87–94. [Google Scholar]

- Simões, D.; da Silva, R.B.G.; Miyajima, R.H.; Avelino, L.T.; Barreiros, R.M. Impact of skidding and slope on grapple skidder productivity and costs: A Monte Carlo simulation in Eucalyptus plantations. Forests 2024, 15, 1890. [Google Scholar] [CrossRef]

- Higgins, G. Factors affecting skidder performance. In Proceedings of the LIRO Ground-Based Logging Seminar, Rotorua, New Zealand, June 1986; Logging Industry Research Organisation: Rotorua, New Zealand, 1986; pp. 1–14. Available online: https://forestengineering.org/wp-content/uploads/2020/11/LIRA_CONF_1986_3A_AFFECTING_SKIDDER_PERFORMANCE_HIGGINS.pdf (accessed on 22 August 2025).

- Contreras, M.; Parra, C.; Cárdenas, C.; Hermosilla, C.; Pastén, R.; Aedo, D. Skid trail network visualizer: A computational tool to generate skid trails created by ground-based timber harvesting machines and facilitate soil disturbance monitoring. Comput. Electron. Agric. 2024, 225, 109282. [Google Scholar] [CrossRef]

- McDonald, T.P.; Fulton, J.P. Automated time study of skidders using global positioning system data. Comput. Electron. Agric. 2005, 48, 19–37. [Google Scholar] [CrossRef]

- Barrile, V.; Simonetti, S.; Citroni, R.; Fotia, A.; Bilotta, G. Experimenting Agriculture 4.0 with sensors: A data fusion approach between remote sensing, UAVs and self-driving tractors. Sensors 2022, 22, 7910. [Google Scholar] [CrossRef]

| Study Site | Type of Forest | Season | Machine Type | Skid Trail Slope | Collection Dates |

|---|---|---|---|---|---|

| S 1 | Mixed | Winter | Skidder | Moderate | 10 November 2020–13 November 2020 |

| S 2 | Mixed | Autumn | Skidder | Flat | 21 September 2021–23 September 2021 |

| S 3 | Coniferous | Winter | Skidder | Moderate | 22 November 2021–25 November 2021 |

| S 4 | Mixed | Winter | Skidder | Steep | 24 November 2021–26 November 2021 |

| S 5 | Mixed | Winter | Skidder | Moderate | 22 November 2021 |

| S 6 | Mixed | Winter | Skidder | Steep | 23 November 2021–26 November 2021 |

| S 7 | Mixed | Spring | Skidder | Moderate | 15 March 2022–24 March 2022, 3 May 2022 |

| S 8 | Mixed | Spring | Skidder | Moderate | 15 March 2022–25 March 2022, 3 May 2022–6 May 2022 |

| S 9 | Broadleaved | Summer | Skidder | Flat | 1 August 2022–5 August 2022 |

| S 10 | Broadleaved | Summer | Skidder | Flat | 19 July 2022–29 July 2022 |

| S 11 | Broadleaved | Summer | Skidder | Steep | 18 July 2022–29 July 2022 |

| S 12 | Broadleaved | Summer | Skidder | Moderate | 16 August 2022–26 June 2022 |

| S 13 | Broadleaved | Autumn | Farm tractor | Flat | 27 September 2021–30 September 2021, 1 October 2021 |

| S 14 | Broadleaved | Summer | Farm tractor | Moderate | 16 August 2022–24 August 2022 |

| Event | Abbreviation | Definition |

|---|---|---|

| Driving to the pre-skidding site | DET | Begins when the machine departs from the landing area and concludes upon arrival at the pre-skidding site, excluding any unrelated pauses. |

| Maneuvering at the pre-skidding site | MAN | Starts upon reaching the pre-skidding site and ends when the machine is positioned for pre-skidding. It excludes unrelated interruptions. |

| Pulling out the cable | POC | Begins when the operator deploys the winch cables and concludes when the worker managing the cable reaches the site of the logs to be secured. This step may occur multiple times within a complete skidding cycle and excludes any unrelated interruptions. |

| Attachment of the payload | APL | It begins when the worker handling the cable arrives at the pieces of wood to be attached and ends when the payload is attached to the cable. It can occur multiple times in a full skidding work cycle and excludes unrelated interruptions. |

| Pulling in the payload | PIP | Begins when the operator engages the winch and concludes once the payload arrives at the machine’s rear part. This may occur multiple times within a complete skidding cycle, excluding any interruptions unrelated to the task. |

| Detaching the payload from the cable | DPC | It begins when actions to release the load are initiated and ends when the payload is detached from the cable. It can be repeated several times in a full skidding work cycle and excludes unrelated interruptions. |

| Attaching the payload for extraction | APE | Starts when the cables are released and ends when the payload is secured for extraction. It excludes unrelated interruptions. |

| Driving with the payload toward the forest access road | DFR | Starts when leaving the pre-skidding location and ends when reaching the landing. It excludes unrelated interruptions. |

| Detaching the payload toward the main forest haul road | DPR | Starts when operating the winch to release the cables and ends when the cables are free. It may involve a manual worker and excludes unrelated interruptions. |

| Maneuvering and bunching at the forest road | MBR | Starts with the first maneuver to bunch the wood and ends when the wood is bunched. It can be repeated several times in a full skidding work cycle and excludes unrelated interruptions. |

| Delays produced by the study | DS | Delays attributable to the study, such as the time spent to place and take down the dataloggers from the machines. |

| Delays produced by personal motives | DP | Delays caused by personal activities of workers. |

| Delays caused by mechanical reasons | DM | Delays due to mechanical problems with the machine. |

| Delays caused by operational reasons | DO | Delays due to operational organization problems, including waiting and performing other tasks not related to the skidding operations. |

| Machine | Study Site | Useful Data (s) | Deleted Data (s) | Total Observed Data (s) | Useful Data (h) | Deleted Data (h) | Total Observed Data (h) |

|---|---|---|---|---|---|---|---|

| Skidder | SL1 | 84,561 | 3446 | 88,007 | 23:29:21 | 0:57:26 | 24:26:47 |

| SL2 | 25,251 | 50,547 | 75,798 | 7:00:51 | 14:02:27 | 21:03:18 | |

| SL3 | 54,926 | 33,078 | 88,004 | 15:15:26 | 9:11:18 | 24:26:44 | |

| SL4 | 26,497 | 42,256 | 68,753 | 7:21:37 | 11:44:16 | 19:05:53 | |

| SL5 | 7716 | 7834 | 15,550 | 2:08:36 | 2:10:34 | 4:19:10 | |

| SL6 | 58,793 | 27,547 | 86,340 | 16:19:53 | 7:39:07 | 23:59:00 | |

| SL7 | 75,695 | 113,862 | 189,557 | 21:01:35 | 31:37:42 | 52:39:17 | |

| SL8 | 170,790 | 94,478 | 265,268 | 47:26:30 | 26:14:38 | 73:41:08 | |

| SL9 | 96,289 | 103 | 96,392 | 26:44:49 | 0:01:43 | 26:46:32 | |

| SL10 | 122,324 | 20,819 | 143,143 | 33:58:44 | 5:46:59 | 39:45:43 | |

| SL11 | 162,337 | 12,935 | 175,272 | 45:05:37 | 3:35:35 | 48:41:12 | |

| SL12 | 163,178 | 4485 | 167,663 | 45:19:38 | 1:14:45 | 46:34:23 | |

| Farm tractor | SL13 | 22,770 | 120,102 | 142,872 | 6:19:30 | 33:21:42 | 39:41:12 |

| SL14 | 129,782 | 8615 | 138,397 | 36:03:02 | 2:23:35 | 38:26:37 | |

| Total | 1,200,909 | 540,107 | 1,741,016 | 333:35:09 | 150:01:47 | 483:36:56 | |

| Dataset | Operational Event | Mean Value (km/h) | Median Value (km/h) | Standard Deviation (km/h) | Number of Observations | Result of the Normality Test |

|---|---|---|---|---|---|---|

| SK | Driving to the pre-skidding site (SK-DET) | 5.40 | 5.00 | 3.42 | 185,950 | No p < 0.05 α = 0.05 |

| SK | Maneuvering at the pre-skidding site (SK-MAN) | 2.00 | 1.60 | 1.27 | 11,606 | No p < 0.05 α = 0.05 |

| SK | Driving with the payload to the forest road (SK-DFR) | 4.30 | 3.90 | 2.61 | 209,838 | No p < 0.05 α = 0.05 |

| SK | Maneuvering and bunching at the forest road (SK-MBR) | 2.40 | 2.00 | 1.89 | 29,809 | No p < 0.05 α = 0.05 |

| FT | Driving to the pre-skidding site (SK-DET) | 5.50 | 6.00 | 2.40 | 19,962 | No p < 0.05 α = 0.05 |

| FT | Maneuvering at the pre-skidding site (SK-MAN) | 2.60 | 2.20 | 1.74 | 539 | No p < 0.05 α = 0.05 |

| FT | Driving with the payload to the forest road (SK-DFR) | 3.70 | 3.60 | 1.65 | 31,400 | No p < 0.05 α = 0.05 |

| FT | Maneuvering and bunching at the forest road (SK-MBR) | 2.90 | 2.80 | 1.63 | 3175 | No p < 0.05 α = 0.05 |

| Reference Operational Event | Compared Operational Event | p-Value | Diagnostic of the Comparison Test |

|---|---|---|---|

| Driving to the pre-skidding site (DET) | Maneuvering at the pre-skidding site (MAN) | <0.05 | Significant differences |

| Driving to the pre-skidding site (DET) | Driving with the payload to the forest road (DFR) | <0.05 | Significant differences |

| Driving to the pre-skidding site (DET) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Maneuvering at the pre-skidding site (MAN) | Driving with the payload to the forest road (DFR) | <0.05 | Significant differences |

| Maneuvering at the pre-skidding site (MAN) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Driving with the payload to the forest road (DFR) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Reference Operational Event | Compared Operational Event | p-Value | Diagnostic of the Comparison Test |

|---|---|---|---|

| Driving to the pre-skidding site (DET) | Maneuvering at the pre-skidding site (MAN) | <0.05 | Significant differences |

| Driving to the pre-skidding site (DET) | Driving with the payload to the forest road (DFR) | <0.05 | Significant differences |

| Driving to the pre-skidding site (DET) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Maneuvering at the pre-skidding site (MAN) | Driving with the payload to the forest road (DFR) | <0.05 | Significant differences |

| Maneuvering at the pre-skidding site (MAN) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Driving with the payload to the forest road (DFR) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Reference Operational Event for the Skidder Dataset | Compared Operational Event for the Farm Tractor Dataset | p-Value | Diagnostic of the Comparison Test |

|---|---|---|---|

| Driving to the pre-skidding site (DET) | Driving to the pre-skidding site (DET) | <0.05 | Significant differences |

| Maneuvering at the pre-skidding site (MAN) | Maneuvering at the pre-skidding site (MAN) | <0.05 | Significant differences |

| Maneuvering and bunching at the forest road (MBR) | Maneuvering and bunching at the forest road (MBR) | <0.05 | Significant differences |

| Driving with the payload to the forest road (DFR) | Driving with the payload to the forest road (DFR) | <0.05 | Significant differences |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zurita Vintimilla, M.C.; Borz, S.A. Operational Speed in Skidding Operations by Cable Skidders and Farm Tractors: Results of a Nationwide Assessment. Appl. Sci. 2025, 15, 9921. https://doi.org/10.3390/app15189921

Zurita Vintimilla MC, Borz SA. Operational Speed in Skidding Operations by Cable Skidders and Farm Tractors: Results of a Nationwide Assessment. Applied Sciences. 2025; 15(18):9921. https://doi.org/10.3390/app15189921

Chicago/Turabian StyleZurita Vintimilla, Monica Cecilia, and Stelian Alexandru Borz. 2025. "Operational Speed in Skidding Operations by Cable Skidders and Farm Tractors: Results of a Nationwide Assessment" Applied Sciences 15, no. 18: 9921. https://doi.org/10.3390/app15189921

APA StyleZurita Vintimilla, M. C., & Borz, S. A. (2025). Operational Speed in Skidding Operations by Cable Skidders and Farm Tractors: Results of a Nationwide Assessment. Applied Sciences, 15(18), 9921. https://doi.org/10.3390/app15189921