Variable Dilation Angle Models in Rocks, a Review

Abstract

1. Introduction

- Publications in indexed journals, book chapters, and conference proceedings.

- Studies that explicitly address dilatancy in rocks or models of dilation angle.

- References that include equations related to the dilation angle.

- Publications from the year 2010 onwards.

- Studies applied to other materials (such as concrete, soils, or others).

- Articles on constitutive models without relevant contributions to dilatancy.

- Articles in languages other than English.

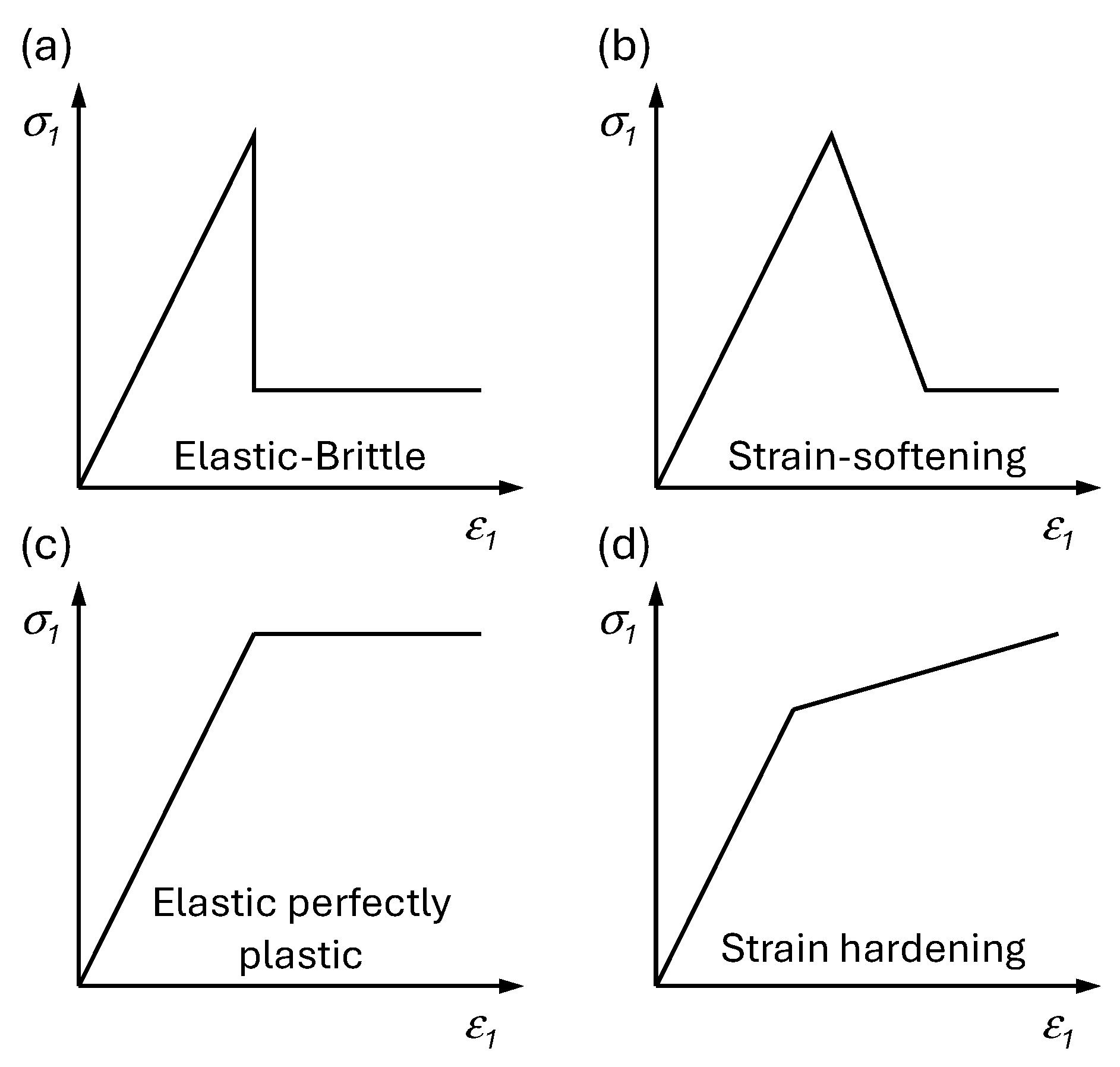

2. Complete Stress–Strain Curves

2.1. Pre-Peak Phase

2.2. Post-Peak Phase

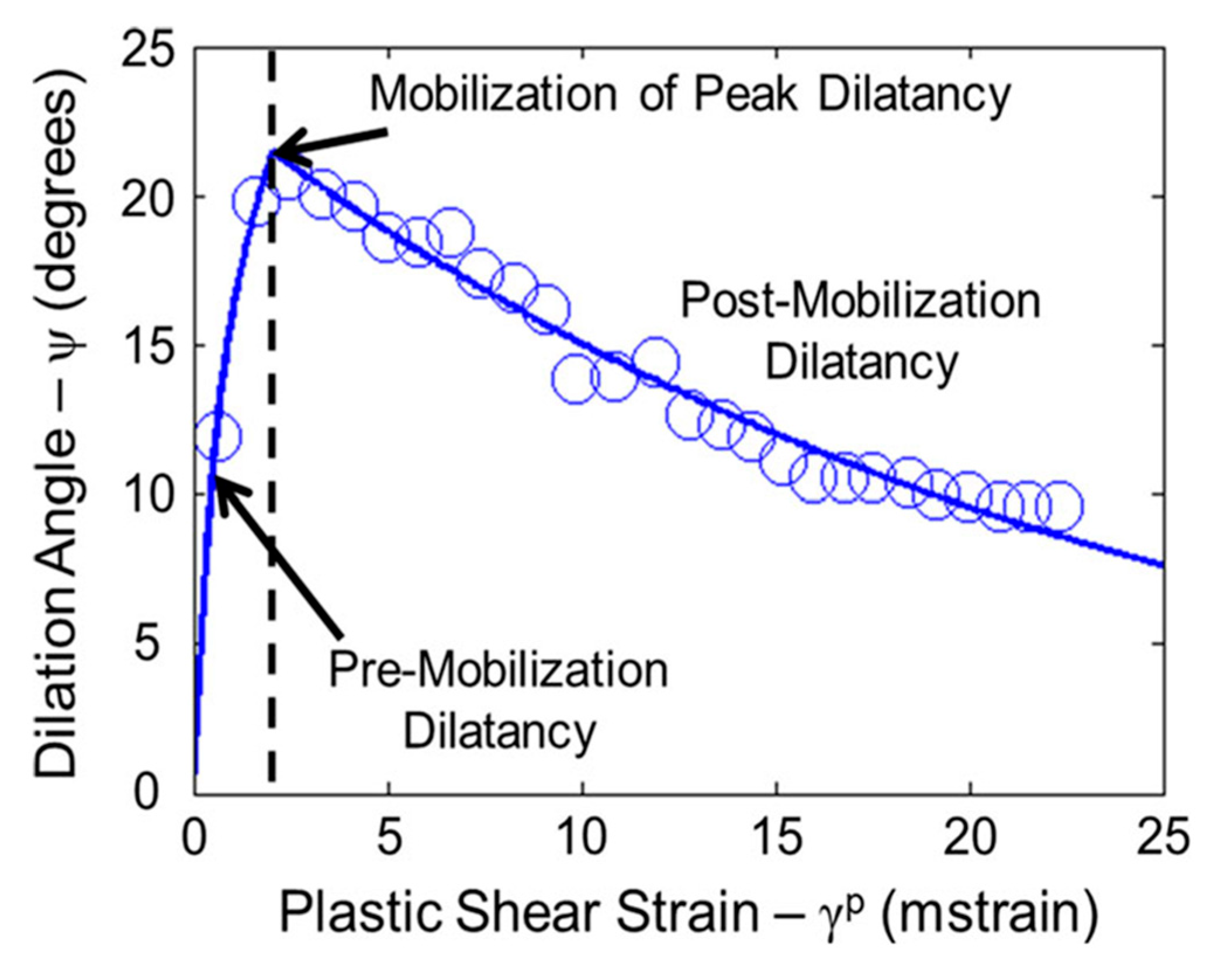

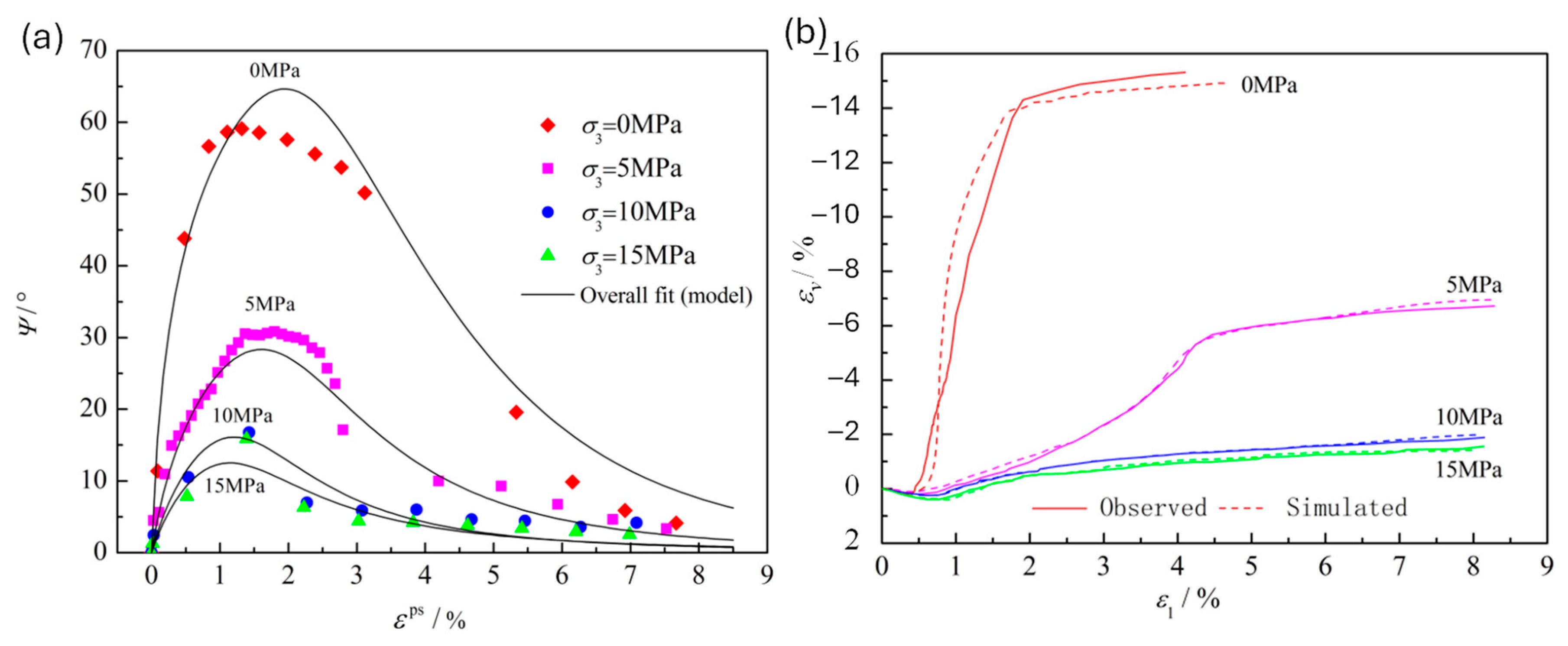

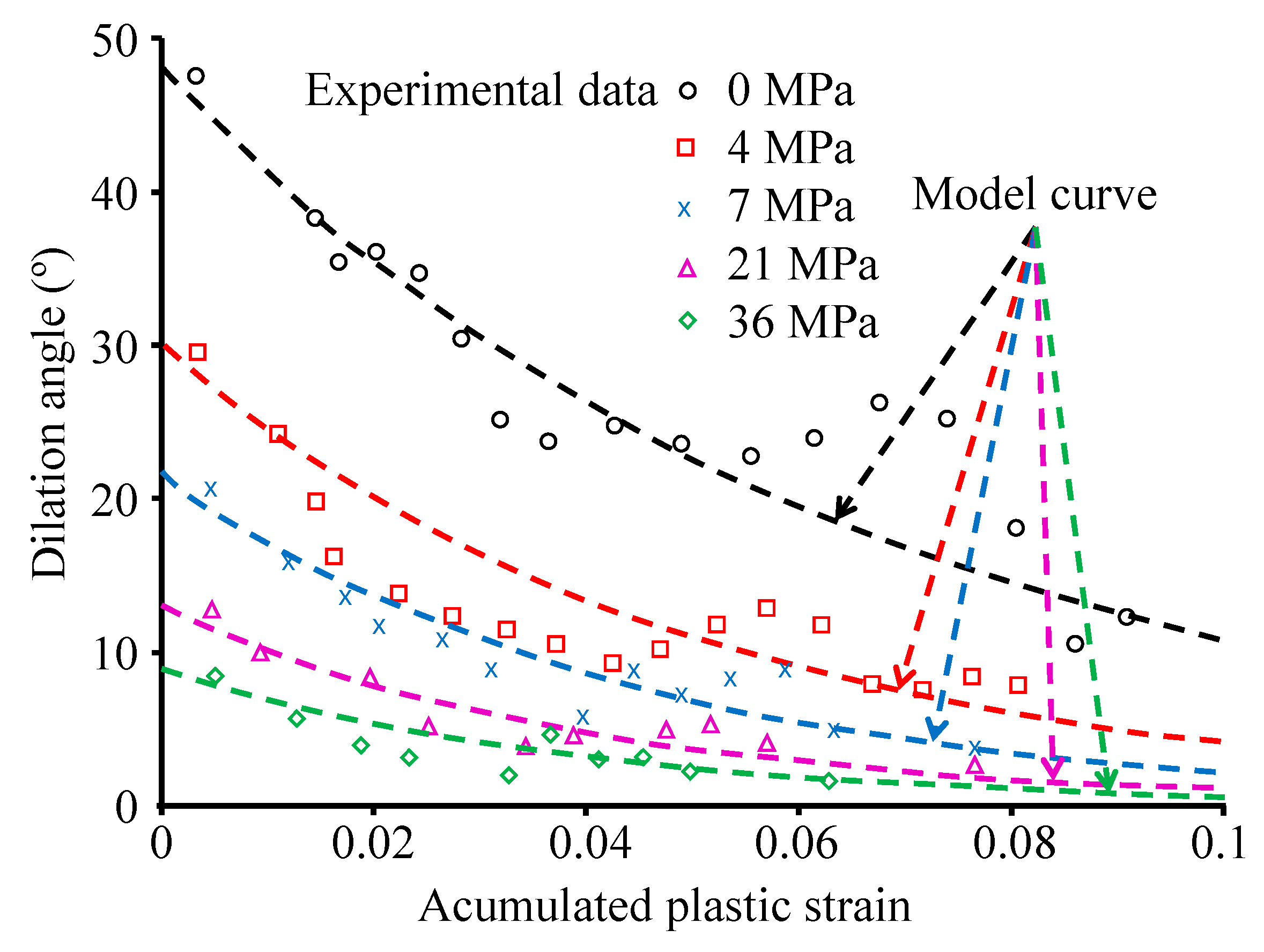

3. Dilatancy Models

- i.

- Pre-mobilization of dilatancy, where the dilation angle increases.

- ii.

- Mobilization of the peak dilatancy, where the dilation angle reaches its maximum value.

- iii.

- Post-mobilization of dilatancy, where the dilation angle decreases to zero.

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Sheng, Q.; Li, N.; Fu, X.; Zhang, Z.; Gao, L. A constitutive model for rock materials subjected to triaxial cyclic compression. Mech. Mater 2020, 144, 103341. [Google Scholar] [CrossRef]

- Zhao, X.G.; Cai, M. A mobilized dilation angle model for rocks. Int. J. Rock Mech. Min. Sci 2010, 47, 368–384. [Google Scholar] [CrossRef]

- Walton, G.; Diederichs, M.S. Dilation and Post-peak Behaviour Inputs for Practical Engineering Analysis. Geotech. Geol. Eng. 2015, 33, 15–34. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A review of experimental and theoretical research on the deformation and failure behavior of rocks subjected to cyclic loading. J. Rock Mech. Geotech. Eng. 2021, 13, 1203–1230. [Google Scholar] [CrossRef]

- Pourhosseini, O.; Shabanimashcool, M. Development of an elasto-plastic constitutive model for intact rocks. Int. J. Rock Mech. Min. Sci 2014, 66, 1–12. [Google Scholar] [CrossRef]

- Sinha, S.; Walton, G. Modeling behaviors of a coal pillar rib using the progressive S-Shaped yield criterion. J. Rock Mech. Geotech. Eng. 2020, 12, 484–492. [Google Scholar] [CrossRef]

- Walton, G.; Diederichs, M.S. A New Model for the Dilation of Brittle Rocks Based on Laboratory Compression Test Data with Separate Treatment of Dilatancy Mobilization and Decay. Geotech. Geol. Eng. 2015, 33, 661–679. [Google Scholar] [CrossRef]

- Eberhardt, E. Numerical modelling of three-dimension stress rotation ahead of an advancing tunnel face. Int. J. Rock Mech. Min. Sci. 2001, 38, 499–518. [Google Scholar] [CrossRef]

- Wu, F.; Deng, Y.; Wu, J.; Li, B.; Sha, P.; Guan, S.; Zhang, K.; He, K.; Liu, H.; Qiu, S. Stress-strain relationship in elastic stage of fractured rock mass. Eng. Geo. 2020, 268, 105498. [Google Scholar] [CrossRef]

- Morris, J.P.; Lomov, I.N.; Glenn, L.A. A constitutive model for stress-induced permeability and porosity evolution of Berea sandstone. J. Geophys. Res. Solid Earth. 2003, 108, 2485. [Google Scholar] [CrossRef]

- Liu, J.; Wu, N.; Si, G.; Zhao, M. Experimental study on mechanical properties and failure behaviour of the pre-cracked coal-rock combination. Bull. Eng. Geol. Environ. 2021, 80, 2307–2321. [Google Scholar] [CrossRef]

- Brown, E.T.; Trollope, D.H. Strength of a model of jointed rock. J. Soil Mech. Found. Div.—Am. Inst. Civ. Engrs. 1970, 96, 685. [Google Scholar] [CrossRef]

- Walton, G.; Alejano, L.R.; Arzúa, J.; Markley, T. Crack Damage parameters and dilatancy of artificially jointed granite samples under triaxial compression. Rock Mech. Rock Eng. 2018, 51, 1637–1656. [Google Scholar] [CrossRef]

- McQuillan, A.; Canbulat, I.; Oh, J. Methods applied in Australian industry to evaluate coal mine slope stability. Int. J. Min. Sci. Technol. 2020, 30, 151–155. [Google Scholar] [CrossRef]

- Gao, F.; Kang, H. Effects of pre-existing discontinuities on the residual strength of rock mass—Insight from a discrete element method simulation. J. Struct. Geol. 2016, 85, 40–50. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Fracture energy-based brittleness index development and brittleness quantification by pre-peak strength parameters in rock uniaxial compression. Rock Mech Rock Eng. 2016, 49, 4587–4606. [Google Scholar] [CrossRef]

- Li, Y.; Jia, D.; Rui, Z.; Peng, J.; Fu, C.; Zhang, J. Evaluation method of rock brittleness based on statistical constitutive relations for rock damage. J. Pet. Sci. Eng. 2017, 153, 123–132. [Google Scholar] [CrossRef]

- Kumar, D.; Gutierrez, M.; Frash, L.P.; Hampton, J.C. Numerical modelling of experimental hydraulic fracture initiation and propagation in enhanced geothermal systems. In Proceedings of the 49th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015. [Google Scholar]

- Zhang, Z.; Liu, X.; Cheng, L.; Wu, S.; Zhang, B. A rheological constitutive model for damaged zone evolution of a tunnel considering strain hardening and softening. Geomech. Geophys. Geo-Energ. Geo-Res. 2020, 6, 56. [Google Scholar] [CrossRef]

- Gadepaka, P.R.; Jaiswal, A. A novel approach for the assessment of caving behaviour in a bord and pillar depillaring panel by using continuum modelling. Int. J. Rock Mech. Min. Sci. 2023, 170, 105476. [Google Scholar] [CrossRef]

- Hudson, J.A.; Crouch, S.L.; Fairhurst, C. Soft, stiff and servo-controlled testing machines: A review with reference to rock failure. Eng. Geo. 1972, 6, 155–189. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, C.; Huang, G. Dilatancy behavior and permeability evolution of sandstone under triaxial compression. R. Soc. Open Sci. 2021, 8, 201792. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. The effect of specimen size on compressive strength of coal. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1968, 5, 325–326. [Google Scholar] [CrossRef]

- Brace, W.F.; Paulding, B.W., Jr.; Scholz, C. Dilatancy in the fracture of crystalline rocks. J. Geophys. Res. 1966, 71, 3939–3953. [Google Scholar] [CrossRef]

- Arzúa, J.; Alejano, L.R. Dilation in granite during servo-controlled triaxial strength tests. I Int. J. Rock Mech. Min. Sci. 2013, 61, 43–56. [Google Scholar] [CrossRef]

- Zheng, Z.; Feng, X.T.; Yang, C.X.; Zhang, X.W.; Li, S.J.; Qiu, S.L. Post-peak deformation and failure behaviour of Jinping marble under true triaxial stresses. Eng. Geol. 2020, 265, 105444. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, W.; Peng, W.; Wang, Y.; Zhou, Y.; Peng, Z. Uniaxial compressive damage evolution and constitutive modelling of fissure-like rocks under different loading rates based on acoustic emission. Sci. Rep. 2025, 15, 2119. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; Hou, P.Y.; Zhang, X.W.; Feng, X.T. Post-peak stress-strain curves of brittle hard rocks under axial-strain-controlled loading. Int. J. Rock Mech. Min. Sci. 2021, 147, 104921. [Google Scholar] [CrossRef]

- Detournay, E. Elastoplastic model of a deep tunnel for a rock with variable dilatancy. Rock Mech. Rock Eng. 1986, 19, 99–108. [Google Scholar] [CrossRef]

- Alejano, L.R.; Alonso, E. Considerations of the dilatancy angle in rocks and rock masses. Int. J. Rock Mech. Min. Sci. 2005, 42, 481–507. [Google Scholar] [CrossRef]

- Shalev, E.; Lyakhovsky, V.; Ougier-Simonin, A.; Hamiel, Y.; Zhu, W. Inelastic compaction, dilation and hysteresis of sandstones under hydrostatic conditions. Geophys. J. Int. 2014, 197, 920–925. [Google Scholar] [CrossRef]

- Salehnia, F.; Collin, F.; Charlier, R. On the variable dilatancy angle in rocks around underground galleries. Rock Mech. Rock Eng. 2017, 50, 587–601. [Google Scholar] [CrossRef]

- Cieślik, J. Dilatancy as a measure of fracturing development in crystalline rocks. Op. Geosci. 2018, 10, 484–490. [Google Scholar] [CrossRef]

- Rethlefsen, M.L.; Kirtley, S.; Waffenschmidt, S.; Ayala, A.P.; Moher, D.; Page, M.J.; Koffel, J.B. PRISMA-S: An extension to the PRISMA Statement for Reporting Literature Searches in Systematic Reviews. Syst. Rev. 2021, 10, 39. [Google Scholar] [CrossRef]

- Bramer, W.M.; Rethlefsen, M.L.; Kleijnen, J.; Franco, O.H. Optimal database combinations for literature searches in systematic reviews: A prospective exploratory study. Syst. Rev. 2017, 6, 245. [Google Scholar] [CrossRef]

- Booth, A.; Sutton, A.; Clowes, M.; Martyn-St James, M. Systematic Approaches to a Successful Literature Review, 3rd ed.; Sage: Sydney, Australia, 2021; ISBN 978-152-97-1184-4. [Google Scholar]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta-analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synt. Methods 2019, 11, 181–217. [Google Scholar] [CrossRef] [PubMed]

- Bieniawski, Z.T. Mechanism of brittle fracture of rock: Part I—Theory of the fracture process. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 395–406. [Google Scholar] [CrossRef]

- Wawersik, W.R.; Fairhurst, C. A study of brittle rock fracture in laboratory compression experiments. Int. J. Rock Mech. Min. Sci 1970, 7, 561–575. [Google Scholar] [CrossRef]

- Hudson, J.A.; Harrison, J.P. Engineering Rock Mechanics an Introduction to the Principles; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1997; Volume 440. [Google Scholar] [CrossRef]

- ISRM. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006; Ulusay, R., Hudson, J.A., Eds.; Prepared by the commission on testing methods, ISRM; ISRM: Ankara, Turkey, 2007; ISBN 978-9-759-36754-1. [Google Scholar]

- Siratovich, P.A.; Heap, M.J.; Villeneuve, M.C.; Cole, J.W.; Kennedy, B.M.; Davidson, J.; Reuschlé, T. Mechanical behaviour of the Rotokawa Andesites (New Zealand): Insight into permeability evolution and stress-induced behaviour in an actively utilised geothermal reservoir. Geothermics. 2016, 64, 163–179. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Empirical strength criterion for rock masses. J. Geotech. Eng. Div. ASCE. 1980, 106, 1013–1035. [Google Scholar] [CrossRef]

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. & Geomech. Abstr. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Hoek, E.; Carranza-Torres, E.T.; Corkum, B. Hoek-Brown criterion—2002 Edition. In Mining and Tunnelling Innovation and Opportunity, Proceedings of the 5th North American Rock Mechanics Symposium and 17th Tunnelling Association of Canada Conference, Toronto, ON, Canada, 7–10 July 2002; Hammah, R., Bawden, W., Curran, J., Telesnicki, M., Eds.; University of Toronto: Toronto, ON, Canada, 2002; pp. 267–273. [Google Scholar]

- Rafiei Renani, H.; Martin, C.D. Cohesion degradation and friction mobilization in brittle failure of rocks. Int. J. Rock Mech. Min. Sci. 2018, 106, 1–13. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Wang, S.Y. Experimental investigation on the strength, deformability, failure behavior and acoustic emission locations of red sandstone under triaxial compression. Rock Mech. Rock Eng. 2012, 45, 583–606. [Google Scholar] [CrossRef]

- Hashiba, K.; Okubo, S.; Fukui, K. A new testing method for investigating the loading rate dependency of peak and residual rock strength. Int. J. Rock Mech. Min. Sci. 2006, 43, 894–904. [Google Scholar] [CrossRef]

- He, M.; Zhang, Z.; Zheng, J.; Chen, F.; Li, N. A new perspective on the constant mi of the Hoek–Brown failure criterion and a new model for determining the residual strength of rock. Rock Mech. Rock Eng. 2020, 53, 3953–3967. [Google Scholar] [CrossRef]

- Gao, F.; Kang, H. Experimental study on the residual strength of coal under low confinement. Rock Mech. Rock Eng. 2017, 50, 285–296. [Google Scholar] [CrossRef]

- Walton, G.; Gaines, S.; Alejano, L.R. Validity of continuous-failure-state unloading triaxial tests as a means to estimate the residual strength of rocks. J. Rock Mech. Geotech. Eng. 2021, 13, 717–726. [Google Scholar] [CrossRef]

- Walton, G.; Labrie, D.; Alejano, L.R. On the residual strength of rocks and rock masses. Rock Mech. Rock Eng. 2019, 52, 4821–4833. [Google Scholar] [CrossRef]

- Alejano, L.R.; Walton, G.; Gaines, S. Residual strength of granitic rocks. Tunn. Undergr. Space Technol. 2021, 118, 104189. [Google Scholar] [CrossRef]

- Peng, J.; Cai, M.; Rong, G.; Yao, M.D.; Jiang, Q.H.; Zhou, C.B. Determination of confinement and plastic strain dependent post-peak strength of intact rocks. Eng. Geol. 2017, 218, 187–196. [Google Scholar] [CrossRef]

- Lajtai, E.Z. Brittle fracture in compression. Int. J. Fract. 1974, 10, 525–536. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J. The effect of loading rate on the behavior of samples composed of coal and rock. Int. J. Rock Mech. Min. Sci. 2013, 61, 23–30. [Google Scholar] [CrossRef]

- Arzúa, J.; Alejano, L.R.; Clérigo, I.; Pons, B.; Méndez, F.; Prada, F. Stability analysis of a room & pillar hematite mine and techniques to manage local instability problems. In Rock Engineering and Rock Mechanics: Structures in and on Rock Masses, Proceedings of the Eurock 2014, ISRM European Regional Symposium, Vigo, Spain, May 27–29 2014; ISRM: Lisbon, Portugal, 2014. [Google Scholar] [CrossRef]

- Arzúa, J.; Alejano, L.R.; Walton, G. Strength and dilation of jointed granite specimens in servo-controlled triaxial tests. Int. J. Rock Mech. Min. Sci. 2014, 69, 93–104. [Google Scholar] [CrossRef]

- Kuang, Z.; Qiu, S.; Li, S.; Du, S.; Huang, J.; Chen, X. A new brittleness index based on the characteristics of complete stress-strain behaviors. Rock Mech. Rock. Eng. 2021, 54, 1109–1128. [Google Scholar] [CrossRef]

- Fang, Z.; Harrison, J.P. A mechanical degradation index for rock. Int. J. Rock Mech. Min. Sci. 2001, 38, 1193–1199. [Google Scholar] [CrossRef]

- Cai, W.; Zhu, H.; Liang, W.; Wang, X.; Su, C.; Wei, X. A post-peak dilatancy model for soft rock and its application in deep tunnel excavation. J. Rock Mech. Geotech. Eng. 2023, 15, 683–701. [Google Scholar] [CrossRef]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R. Fundamentals of Rock Mechanics, 4th ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2007; ISBN 978-0-632-05759-7. [Google Scholar]

- Meyer, B.R.; Jacot, R.H. Impact of stress-dependent Young’s moduli on hydraulic fracture modelling. In Proceedings of the 38th US Rock Mechanics/Geomechanics Symposium, Washington, DC, USA, 7–10 July 2001. [Google Scholar]

- Hoek, E.; Martin, C.D. Fracture initiation and propagation in intact rock—A review. J. Rock Mech. Geotech. Eng. 2014, 6, 287–300. [Google Scholar] [CrossRef]

- Ramírez-Oyanguren, P.; Alejano, L. Mecánica de Rocas: Fundamentos e Ingeniería de Taludes; Red DESIR: Madrid, Spain, 2008; ISBN 978-8-496-39817-7. (In Spanish) [Google Scholar]

- Ren, C.; Yu, J.; Cai, Y.; Yao, W.; Lai, Y.; Li, B. A novel constitutive model with plastic internal and damage variables for brittle rocks. Eng. Fract. Mech. 2021, 248, 107731. [Google Scholar] [CrossRef]

- Walton, G.; Hedayat, A.; Kim, E.; Labrie, D. Post-yield Strength and Dilatancy Evolution Across the Brittle–Ductile Transition in Indiana Limestone. Rock Mech. Rock Eng. 2017, 50, 1691–1710. [Google Scholar] [CrossRef]

- Al-shayea, N.A. Effects of testing methods and conditions on the elastic properties of limestone rock. Eng. Geol. 2004, 74, 139–156. [Google Scholar] [CrossRef]

- Medhurst, T.P.; Brown, E.T. A study of the mechanical behaviour of coal for pillar design. Int. J. Rock Mech. Min. Sci. 1998, 35, 1087–1105. [Google Scholar] [CrossRef]

- Fossen, H. Structural Geology; Cambridge University Press: New York, NY, USA, 2010; ISBN 978-0-521-51664-8. [Google Scholar]

- Bruning, T.; Karakus, M.; Nguyen, G.D.; Goodchild, D. Experimental study on the damage evolution of brittle rock under triaxial confinement with full circumferential strain control. Rock Mech. Rock Eng. 2018, 51, 3321–3341. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.; Li, Z.; Dou, R. Experimental investigation on the crack propagation behaviors of sandstone under different loading and unloading conditions. Int. J. Rock Mech. Min. Sci. 2020, 130, 104310. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, S.; Li, Z.; Yan, X. Experimental investigation of the strain rate effect on crack initiation and crack damage thresholds of hard rock under quasi-static compression. Acta Geotech. 2023, 18, 903–920. [Google Scholar] [CrossRef]

- Bai, Q.; Friedel, M.; Konietzky, H. Experimental investigation of stress unloading effects on rocl damage and confining pressure-dependent crack initiation stress of porous sandstone under true triaxial stress environments. Rock Mech. Bull. 2024, 3, 100111. [Google Scholar] [CrossRef]

- Lockner, D.A.; Byerlee, J.D.; Kuksenko, V.; Ponomarev, A.; Sidorin, A. Quasi-static fault growth and shear fracture energy in granite. Nature 1991, 6313, 39–42. [Google Scholar] [CrossRef]

- Nicksiar, M.; Martin, C.D. Evaluation of methods for determining crack initiation in compression tests on low-porosity rocks. Rock Mech. Rock Eng. 2012, 45, 607–617. [Google Scholar] [CrossRef]

- Abbas, H.A.; Mohamed, Z.; Kudus, S.A. Deformation behaviour, crack initiation and crack damage of weathered composite sandstone-shale by using the ultrasonic wave and the acoustic emission under uniaxial compressive stress. Int. J. Rock Mech. Min. Sci. 2023, 170, 105497. [Google Scholar] [CrossRef]

- Vermeer, P.A.; de Borst, R. Non-associated plasticity for soils, concrete and rock. Heron 1984, 29, 1–64. [Google Scholar]

- Itasca. User Manual for FLAC, Version 4.0; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2000. [Google Scholar]

- Yi, K.; Kang, H.; Ju, W.; Liu, Y.; Lu, Z. Synergistic effect of strain softening and dilatancy in deep tunnel analysis. Tunn. Undergr. Space Technol. 2020, 97, 103280. [Google Scholar] [CrossRef]

- Walton, G.; Diederichs, M.S.; Arzúa, J. A detailed look at pre-peak dilatancy in a granite—Determining “plastic” strains from laboratory test data. In Rock Engineering and Rock Mechanics: Structures in and on Rock Masses, Proceedings of the Eurock 2014, ISRM European Regional Symposium, Vigo, Spain, 27–29 May 2014; ISRM: Vigo, Spain, 2014. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.; Ju, Y.; Cao, W.; Yuan, S.; Si, G. A plastic strain-based damage model for heterogeneous coal using cohesion and dilation angle. Int. J. Rock Mech. Rock Eng. 2018, 110, 151–160. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, L.; Fan, P.; Yang, X.; Dong, L. Nonlinear Volumetric Deformation Behavior of Rock Salt Using the Concept of Mobilized Dilatancy Angle. Open J. Civ. Eng. 2016, 10, 524–531. [Google Scholar] [CrossRef]

- Rahjoo, M.; Eberhardt, E. A simplified dilation model for modeling the inelastic behavior of rock. In 50th US Rock Mechanics/Geomechanics Symposium; ARMA: Houston, TX, USA, 2016; Volume 3, pp. 1957–1961. [Google Scholar]

- Wang, J.; Wang, Z.; Yang, S. A coupled macro- and meso-mechanical model for heterogeneous coal. Int. J. Rock Mech. Min. Sci. 2017, 94, 64–81. [Google Scholar] [CrossRef]

- Zhao, R.; Li, C. A New Dilation Angle Model for Rocks. Rock Mech. Rock Eng. 2022, 55, 5345–5354. [Google Scholar] [CrossRef]

- Jin, J.; She, C.; Shang, P. Evolution models of the strength parameters and shear dilation angle of rocks considering the plastic internal variable defined by a confining pressure function. Bull. Eng. Geol. Environ. 2021, 80, 2925–2953. [Google Scholar] [CrossRef]

- Yang, F.; Zhou, H.; Zhang, C.; Hu, D.; Lu, J.; Meng, F. An elastoplastic coupling mechanical model for hard and brittle marble with consideration of the first stress invariant effect. Eur. J. Environ. Civ. Eng. 2016, 22, 405–428. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Practical Estimates of Rock Mass Strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Wang, S.; Zheng, H.; Li, C.; Ge, X. A finite element implementation of strain-softening rock mass. Int. J. Rock Mech. Min. Sci. 2011, 48, 67–76. [Google Scholar] [CrossRef]

- Hou, P.Y.; Cai, M. Post-peak stress-strain curves of brittle hard rocks under different loading environment system stiffness. Rock Mech. Rock Eng. 2023, 55, 3837–3857. [Google Scholar] [CrossRef]

- Chen, J.; Wang, W.; Chen, L. A strain hardening and softening constitutive model for hard brittle rocks. Appl. Sci. 2023, 13, 2764. [Google Scholar] [CrossRef]

- Davarpanah, S.M.; Shargi, M.; Narimani, S.; Török, A.; Vásárhelyi, B. Brittle-ductile transition stress of different rock types and its relationship with uniaxial compressive strength and Hoek-Brown material constant (mi). Sci. Rep. 2023, 13, 1186. [Google Scholar] [CrossRef]

- Paterson, M.S.; Wong, T.F. Experimental Rock Deformation—The Brittle Field, 2nd ed.; Springer: Berlin, Germany, 2005; ISBN 978-3-540-24023-5. [Google Scholar]

- Von Karaman, T. Festigkeitsversuche unter allseitigem druck. Verh. Dtsch. Ing. 1911, 55, 1749–1757. [Google Scholar]

- Peng, S.S. Time-dependent aspects of rock behavior as measured by a servocontrolled hydraulic testing machine. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 235–236, IN212–IN22, 237–246. [Google Scholar] [CrossRef]

- Paraskevopoulou, C.; Perras, M.; Diederichs, M.; Amann, F.; Löw, S.; Lam, T.; Jensen, M. The three stages of stress-relaxation—Observations for the time dependent behaviour of brittle rocks based on laboratory testing. Eng. Geol. 2017, 216, 56–75. [Google Scholar] [CrossRef]

- He, Z.; Wu, G.; Zhu, J. Mechanical properties of rock under uniaxial compression tests of different control modes and loading rates. Sci. Rep. 2024, 14, 2164. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, J.; Jin, Z.; Xu, D.; Zhu, Y.; Guo, Z. Energy dissipation and dilation processes of rock mass under different loading conditions. Sci. Rep. 2025, 15, 17303. [Google Scholar] [CrossRef]

- Cui, G.; Meng, F.; Wang, W.; Liu, P.; Wen, Y.; Yue, Z.; Zhou, H.; Zhang, L. Deformation rate effects in the circumferential strain-controlled post-peak loading tests. Rock Mech. Rock Eng. 2025, 58, 8173–8194. [Google Scholar] [CrossRef]

- Hadizadeh, J.; Rutter, E.H. The low temperature brittle-ductile transition in quartzite and occurrence of cataclastic flow in nature. Geol Rundsch. 1983, 72, 493–503. [Google Scholar] [CrossRef]

- Lazemi, H.A.; Soleiman Dehkordi, M. Application of TBM operational parameters to estimate the drop modulus, case study: Karaj–Tehran water conveyance tunnel of Iran. Int. J. Geo-Eng. 2016, 7, 6. [Google Scholar] [CrossRef][Green Version]

- Bai, Y.; Guan, S.; Tang, Z.; Florez-Lopez, J. Strain-degradation analysis of tunnel structures based on twin-shear unified strength criterion. Lat. Am. J. Solid Struct. 2020, 17, e251. [Google Scholar] [CrossRef]

- Lin, Q.; Cao, P.; Wang, P. Study of post-peak strain-softening mechanical behavior of rock material based on Hoek-Brown criterion. Adv. Civ. Eng. 2018, 2018, 6190376. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, H.; Zhuo, L.; Xiao, M.; Xie, H.; He, J.; Peng, M. Experimental study on the dilatancy and energy evolution behaviors of red-bed rocks under unloading conditions. Materials 2023, 16, 5759. [Google Scholar] [CrossRef]

- Castro-Filgueira, U.; Alejano, L.R.; Ivars, D.M. Particle flow code simulation of intact and fissured granitic rock samples. J. Rock Mech. Geotech. Eng. 2020, 12, 960–974. [Google Scholar] [CrossRef]

- Hansen, B. Line ruptures regarded as narrow rupture zones: Basic equations based on kinematic considerations. Proc. Conf. Earth Press. Probl. 1958, 1, 39–48. [Google Scholar]

- Jaiswal, A.; Shrivastva, B.K. Numerical simulation of coal pillar strength. Int. J. Rock Mech. Min. Sci. 2009, 46, 779–788. [Google Scholar] [CrossRef]

- Brown, E.T.; Bray, J.W.; Ladanyi, B.; Hoek, E. Ground response curves for rock tunnels. J. Geotech. Eng. 1983, 109, 15–39. [Google Scholar] [CrossRef]

- Alejano, L.R.; Alonso, E.; Rodríguez-Dono, A.; Fernández-Manín, G. Application of the convergence-confinement method to tunnels in rock masses exhibiting Hoek-Brown strain-softening behaviour. Int. J. Rock Mech. Min. Sci. 2010, 47, 150–160. [Google Scholar] [CrossRef]

- Rahjoo, M.; Eberhardt, E. Development of a 3-D confinement-dependent dilation model for brittle rocks; part 2, formulation and parameterization based on the Cartesian plastic strain increments ratios approach. Int. J. Rock Mech. Min. Sci. 2021, 148, 104773. [Google Scholar] [CrossRef]

- Crouch, S.L. Experimental determination of volumetric strains in failed rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1970, 7, 589–603. [Google Scholar] [CrossRef]

- Farmer, I. Engineering Behavior of Rocks, 2nd ed.; Chapman and Hall Ltd.: London, UK, 1983; ISBN 978-0-412-13980-2. [Google Scholar]

- Hassani, F.P.; White, M.J.; Branch, D. Behaviour of yielded rock in tunnel design. In Proceedings of the Second International Conference on Stability in Underground Mining, Lexington, KY, USA, 6–8 August 1984. [Google Scholar]

- Zhang, J.C. Experimental and modelling investigations of the coupled elastoplastic damage of a quasi-brittle rock. Rock Mech. Rock Eng. 1970, 51, 465–478. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, K.G.; Varadarajan, A. Post-peak response of some metamorphic rocks of India under high confining pressures. Int. J. Rock Mech. Min. Sci. 2010, 47, 1357–1362. [Google Scholar] [CrossRef]

- Xie, N.; Zhu, Q.Z.; Xu, L.H.; Shao, J.F. A micromechanics-based elastoplastic damage model for quasi-brittle rocks. Comput. Geotech. 2011, 38, 970–977. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.P.; Liu, J.F.; Liu, J.; Wang, J.; Jia, Y.; Shao, J.F. Damage and plastic deformation modeling of Beishan granite under compressive stress conditions. Rock Mech. Rock Eng. 2015, 48, 1623–1633. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, S.G.; Jia, B.X.; Wu, Z.Q. Physical and numerical model tests on post-peak mechanical properties of granite. Chin. J. Geo. Eng. 2015, 37, 847–852. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, S.G.; Liu, J.Q.; Chen, P.P.; Sun, C.A.; Wang, Y.T. Experimental research on mechanical properties of granite under water-rock coupling. Chin. J. Rock Mech. Eng. 2015, 34, 520–527. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, Q.; Zhong, S.; Cui, J.; Feng, X.T.; Song, L. Statistical characterization of the mechanical parameters of intact rock under triaxial compression: An experimental proof of the Jinping marble. Rock Mech. Rock Eng. 2016, 49, 4631–4646. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, B.S.; Lv, H.J. Analytical solution for a circular opening in a rock mass obeying a three-stage stress-strain curve. Int. J. Rock Mech. Min. Sci. 2016, 86, 16–22. [Google Scholar] [CrossRef]

- Yao, M.D.; Rong, G.; Zhou, C.B.; Peng, J. Effects of thermal damage and confining pressure on the mechanical properties of coarse marble. Rock Mech. Rock Eng. 2016, 49, 2043–2054. [Google Scholar] [CrossRef]

- Zhang, H.J.; Li, C.C. Effects of confining stress on the post-peak behaviour and fracture angle of Fauske marble and Iddefjord granite. Rock Mech. Rock Eng. 2019, 52, 1377–1385. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, S.; Wang, Z.; Cong, Y. Analysis of marble failure energy evolution under loading and unloading conditions. Chin. J. Rock Mech. Eng. 2013, 32, 1572–1578. (In Chinese) [Google Scholar]

- Zhang, C.Q.; Feng, X.T.; Zhou, H.; Qiu, S.; Yang, Y.S. Rock mass damage induced by rockbursts occurring on tunnel floors: A case study of two tunnels at the Jinping II Hydropower Station. Environ. Earth Sci. 2014, 71, 441. [Google Scholar] [CrossRef]

- Liu, Z.B.; Shao, J.F. Strength behavior, creep failure and permeability change of a tight marble under triaxial compression. Rock Mech. Rock Eng. 2017, 50, 529–541. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.P. Experimental research on sandstone pre-peak unloading process under high confining pressure. Chin. J. Rock Mech. Eng. 2011, 30, 473–479. (In Chinese) [Google Scholar]

- Yang, S.Q. Experimental study on deformation, peak strength and crack damage behavior of hollow sandstone under conventional triaxial compression. Eng. Geol. 2016, 213, 11–24. [Google Scholar] [CrossRef]

- Zong, Y.J.; Han, L.J.; Wei, J.J.; Wen, S.Y. Mechanical and damage evolution properties of sandstone under triaxial compression. Int. J. Min. Sci. Technol. 2016, 26, 601–607. [Google Scholar] [CrossRef]

- Xia, Y.J.; Li, L.C.; Tang, C.A.; Li, X.Y.; Mas, S.; Li, M. A new method to evaluate rock mass brittleness based on stress-strain curves of class I. Rock Mech. Rock Eng. 2017, 50, 1123–1139. [Google Scholar] [CrossRef]

- Chen, Z.Q.; He, C.; Ma, G.Y.; Xu, G.W.; Ma, C.C. Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock Mech. Rock Eng. 2019, 52, 1265–1274. [Google Scholar] [CrossRef]

- Lu, Y.L.; Wang, L.G.; Yang, F.; Li, Y.J.; Chen, H.M. Post-peak strain softening mechanical properties of weak rock. Chin. J. Rock Mech. Eng. 2010, 29, 640–648. (In Chinese) [Google Scholar]

- Yu, H.C.; Zhang, X.S.; Liu, H.D.; Huang, Z.Q.; Shi, G.C. Stress relaxation behavior of silty mudstone considering the effect of confining pressure. Environ. Earth Sci. 2016, 75, 1001. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Jing, H.W.; Huang, Y.H.; Yang, X.X.; Meng, B. Deformation and damage failure behavior of mudstone specimens under single-stage and multi-stage triaxial compression. Rock Mech. Rock Eng. 2019, 52, 673–689. [Google Scholar] [CrossRef]

- Zhang, J.; Ai, C.; Li, Y.W.; Che, M.G.; Gao, R.; Zeng, J. Energy-based brittleness index and acoustic emission characteristics of anisotropic coal under triaxial stress condition. Rock Mech. Rock Eng. 2018, 51, 3343–3360. [Google Scholar] [CrossRef]

- Jia, C.J.; Xu, W.Y.; Wang, S.S.; Wang, R.; Yu, J. Experimental analysis and modeling of the mechanical behavior of breccia lava in the dam foundation of the Baihetan Hydropower Project. Bull. Eng. Geol. Environ. 2019, 78, 2681–2695. [Google Scholar] [CrossRef]

- Fairhurst, C.E.; Hudson, J.A. Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int. J. Rock Mech. Min Sci. 1999, 36, 279–289. [Google Scholar] [CrossRef]

- Hou, P.Y.; Cai, M. A modified Hoek-Brown model for determining plastic strain-dependent post-peak strength of brittle rock. Rock Mech. Rock Eng. 2023, 56, 2375–2393. [Google Scholar] [CrossRef]

- Hajiabdolmajid, V.; Kaiser, P.K.; Martin, C.D. Mobilised strength components in brittle failure of rock. Geotechnique. 2003, 53, 327–336. [Google Scholar] [CrossRef]

- Hajiabdolmajid, V.; Kaiser, P.K.; Martin, C.D. Modelling brittle failure of rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 731–741. [Google Scholar] [CrossRef]

- Arzúa, J.; Alejano, L.R. Study of the mechanical behavior of intact and jointed rocks in laboratory with particular emphasis on dilatancy. In Proceedings of the 10th Asian Rock Mechanics Symposium (ARMS10) and the 2018 ISRM International Symposium, Singapore, 29 October–3 November 2018; Zhao, Z., Zhou, Y., Shang, J., Eds.; ISRM: Singapore, 2018; ISBN 978-981-11-9003-2. [Google Scholar]

| Model | Equations | Main Features |

|---|---|---|

| Alejano and Alonso [30] | The A&A model estimates the angle of maximum dilatancy and how it decays from that value with just one parameter. It considers plastic deformations from the peak strength. Useful for sedimentary rocks. | |

| Zhao and Cai [2] | Z&C developed a mathematical model with good agreement with experimental results. Based on 9 coefficients that lack physical meaning. The fitting of the 9 coefficients may give non-univocal results. It considers plastic deformations from the CD stress. It may fit any type of rock. | |

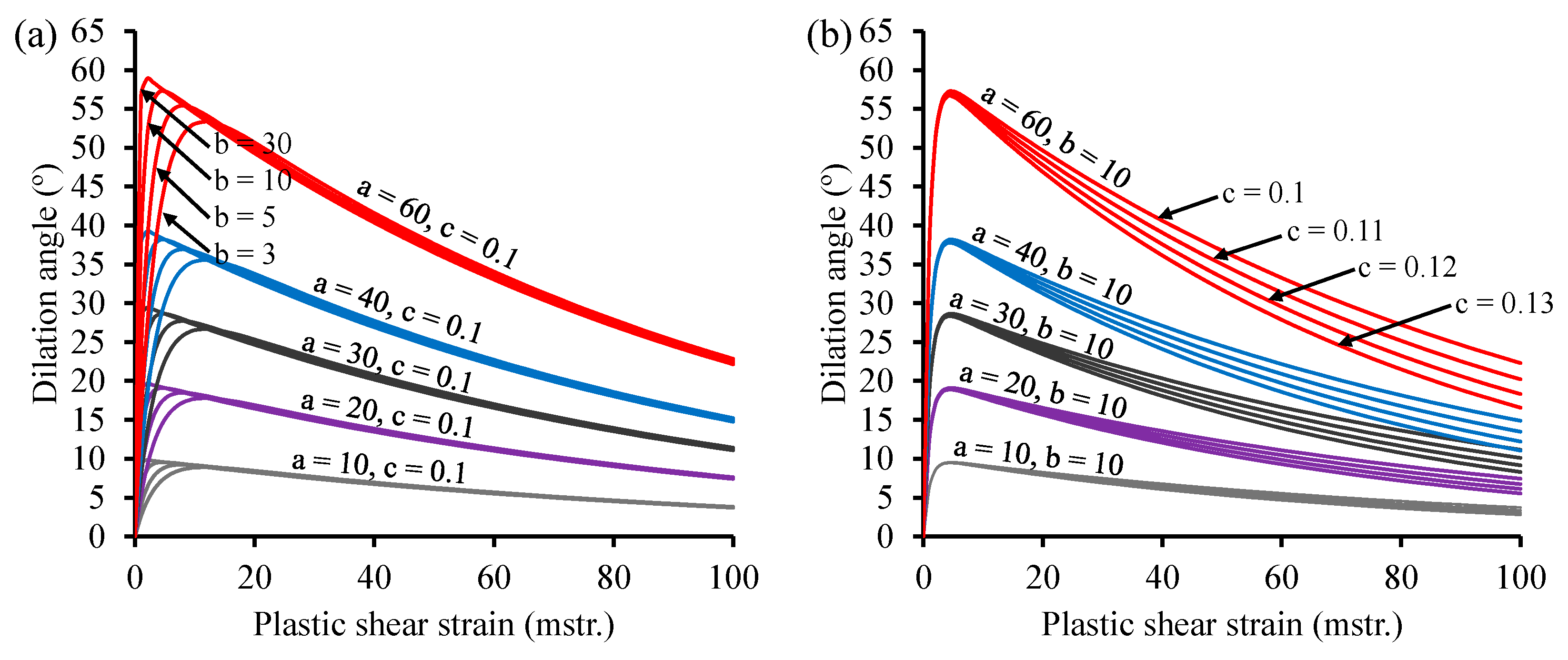

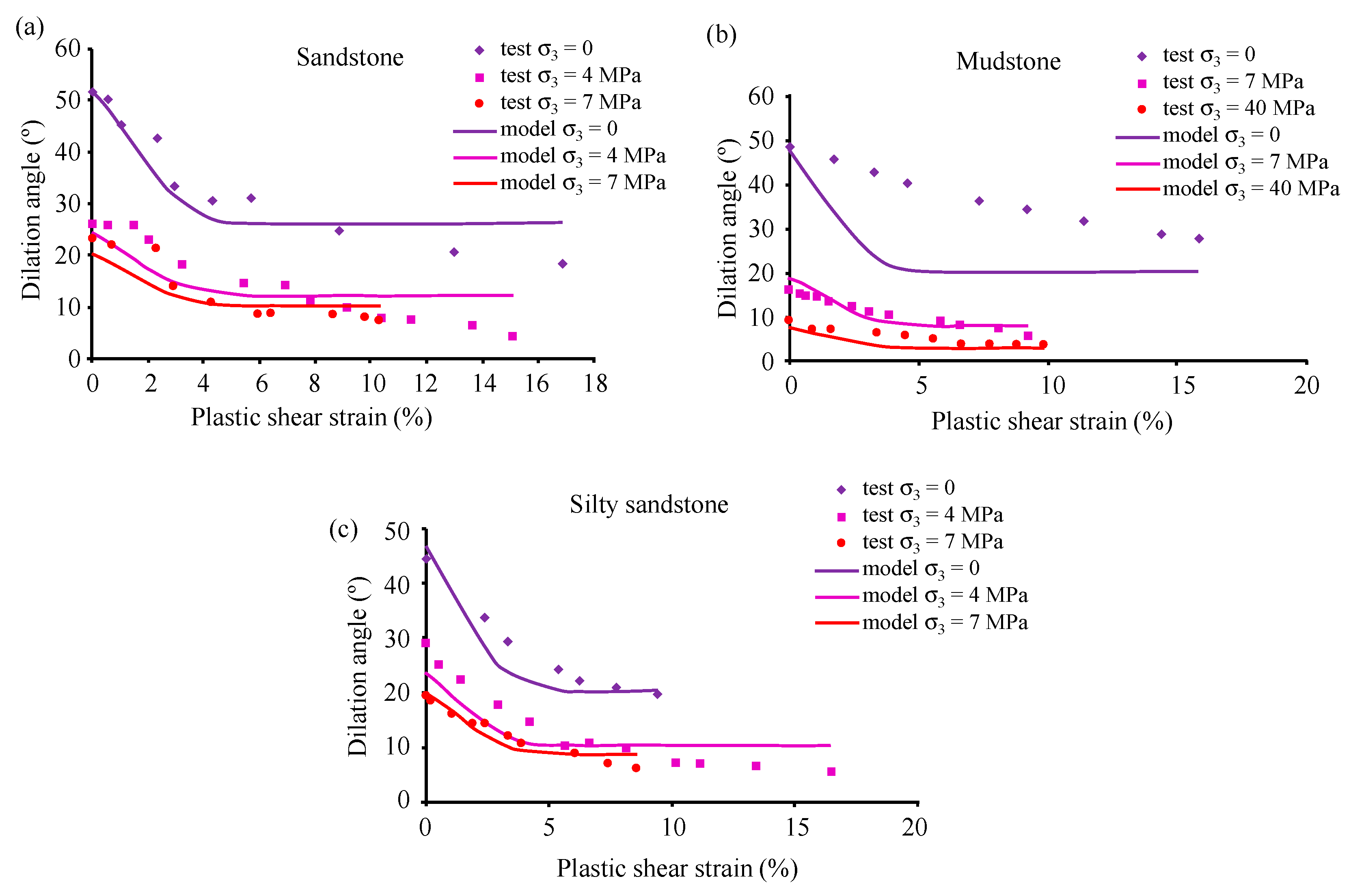

| Pourhosseini and Shabanismashcool [5] | The P&S model describes the maximum dilation angle and how it descends from that value with only three parameters. The authors considered 3 types of rock for their study (sandstones, silty sandstones and mudstones). | |

| Walton and Diederichs [7] | The W&D model describes the behavior of the dilation angle through a piecewise function, simplifying its study. It makes a distinction between the maximum dilation angle for sedimentary and crystalline rocks. It requires adjusting 4 to 7 parameters depending on the available information. The model considers plastic deformations starting from the CD. | |

| Chen et al. [83] | Chen et al. model is a 12-parameter model that can be implemented in FLAC3D. The model considers the plastic deformations starting from the CD. It was only validated in specimens of salt rock. | |

| Rahjoo and Eberhardt [84] | The R&E model considers a normalized space (ψ⁄ψpeak, γp⁄γppeak) of the Zhao and Cai [2] model, simplifying the number of required parameters from 9 to 5. Since it is based on the Z&C model, it should be applicable to any type of rock. | |

| Wang et al. [85] | W et al. model is a 6-parameter model that considers the plastic deformations starting from the CD. It was only validated in one type of coal. | |

| Jin et al. [87]) | J et al. model is a 6-parameter model that considers plastic deformations from the peak strength. It defines an internal variable (κ) as a nonlinear function of confinement and plastic deformations. Validated in 30 different rock types collected from the literature. | |

| Zhao and Li [86] | Z&L model is a piecewise simple model that uses 5 fitting parameters with a clear physical meaning. It can consider the plastic deformations starting from the peak strength or from the CD. They fitted the model to 13 types of rock collected from the literature. | |

| Cai et al. [61] | The Cai et al. model is based on the model of Alejano and Alonso [30]. It depends solely on two parameters (k and γp*). The authors fitted the model to 11 different rock types. | |

| Wang et al. [99] | Wang et al. model is based on an energetic approach. It depends on two parameters but has no dependence on confining stress. They fitted four test results of a granite gneiss. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arzúa, J.; Ibarra-González, D.; Martínez-Bautista, E. Variable Dilation Angle Models in Rocks, a Review. Appl. Sci. 2025, 15, 9872. https://doi.org/10.3390/app15189872

Arzúa J, Ibarra-González D, Martínez-Bautista E. Variable Dilation Angle Models in Rocks, a Review. Applied Sciences. 2025; 15(18):9872. https://doi.org/10.3390/app15189872

Chicago/Turabian StyleArzúa, Javier, Daniel Ibarra-González, and Edison Martínez-Bautista. 2025. "Variable Dilation Angle Models in Rocks, a Review" Applied Sciences 15, no. 18: 9872. https://doi.org/10.3390/app15189872

APA StyleArzúa, J., Ibarra-González, D., & Martínez-Bautista, E. (2025). Variable Dilation Angle Models in Rocks, a Review. Applied Sciences, 15(18), 9872. https://doi.org/10.3390/app15189872