Investigation on Similitude Materials with Controlled Strength and Permeability for Physical Model Tests

Abstract

1. Introduction

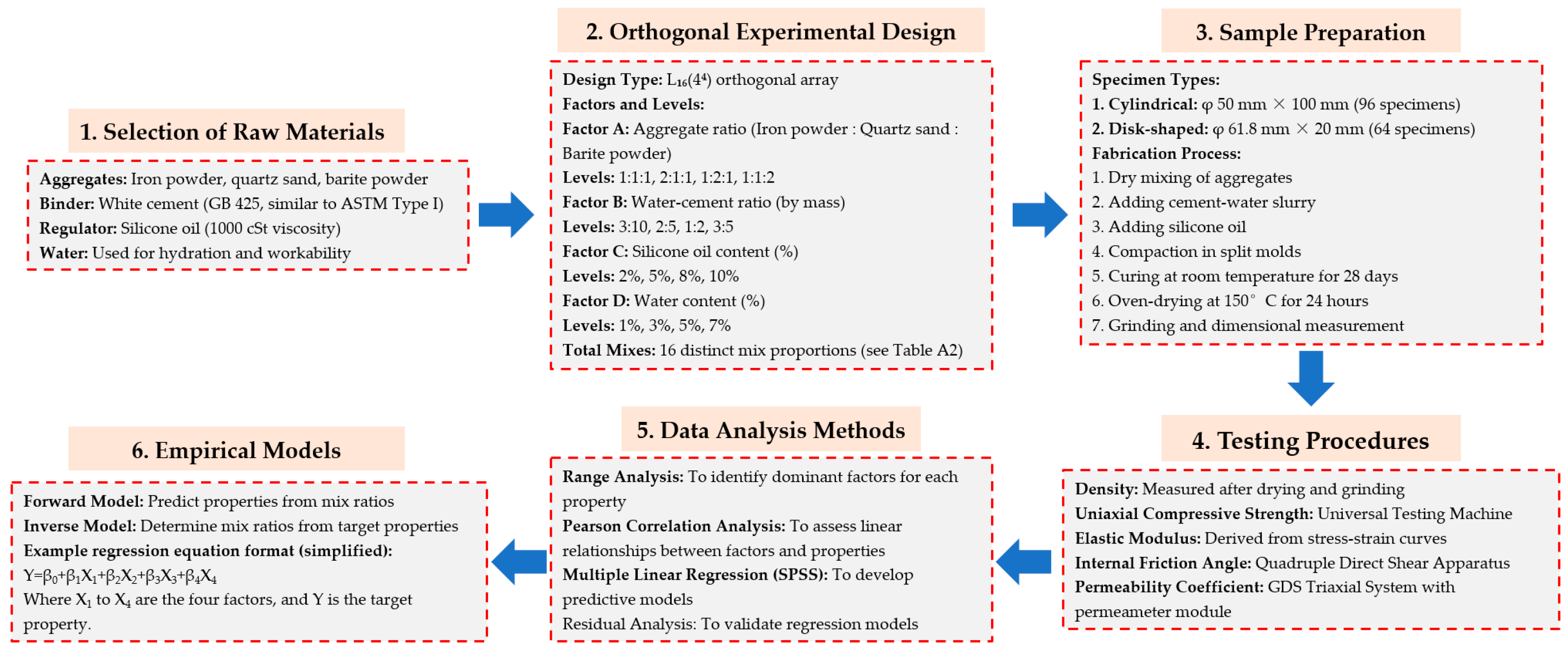

2. Selection of Similar Raw Materials and Orthogonal Experimental Design

2.1. Raw Material Selection

2.2. Orthogonal Experimental Design

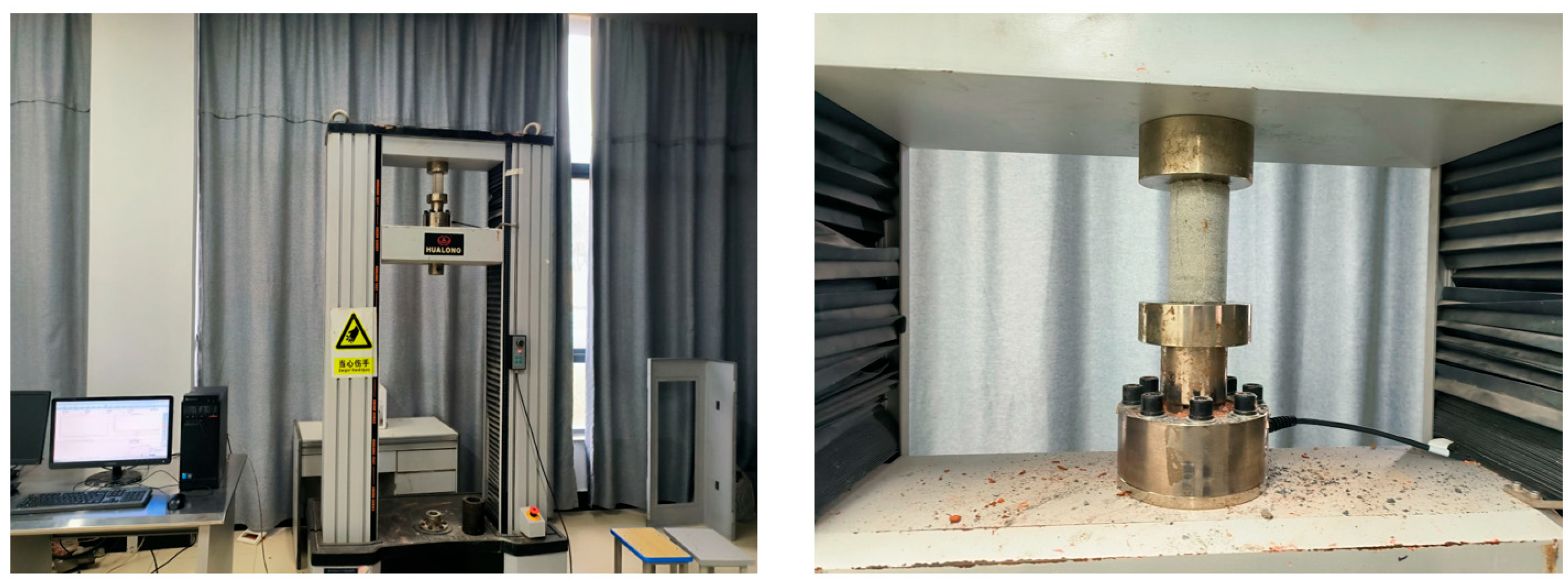

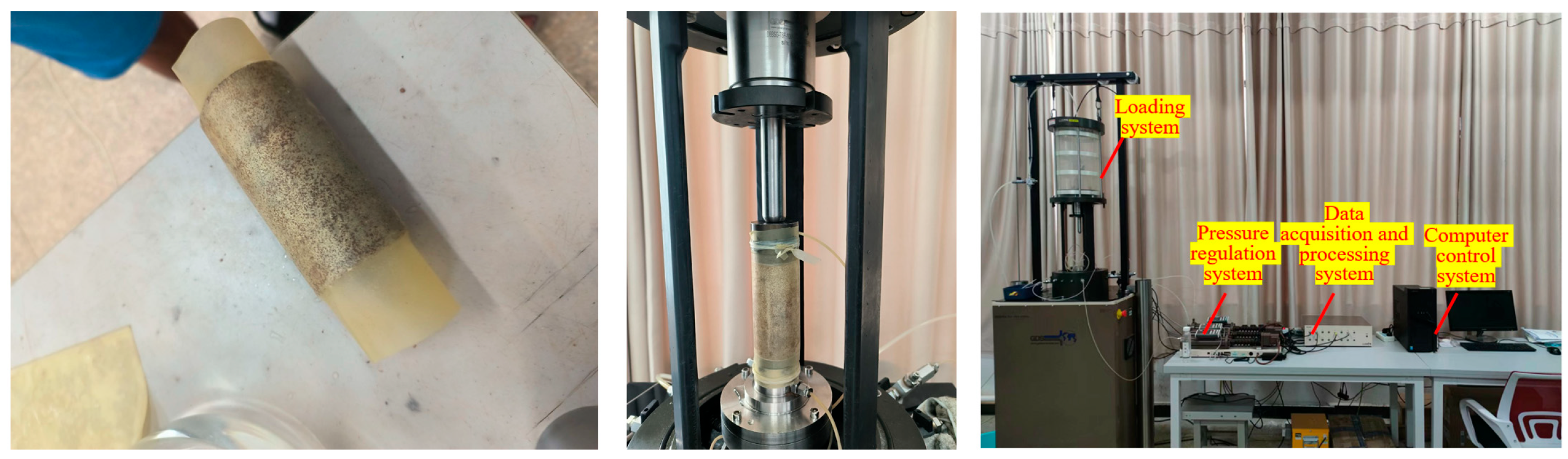

3. Specimen Fabrication and Testing Procedure

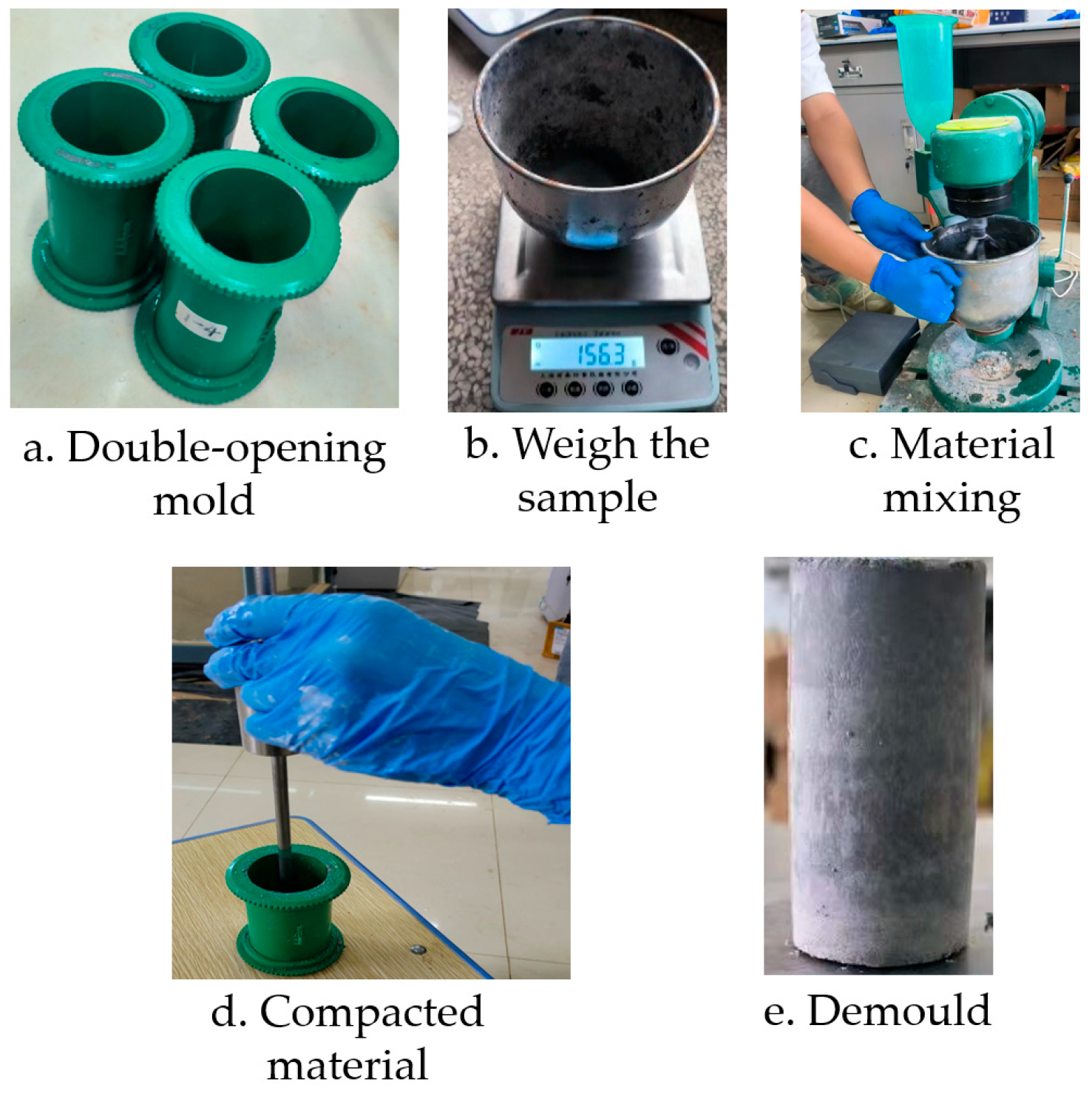

- (1)

- Test Preparation: Necessary tools, including a mixer, electronic balance, trowel, funnel, split mold, hammer, 500 mL beaker, and wide-mouth iron basin, were prepared. Personal protective equipment (PPE) such as gloves and masks was worn.

- (2)

- Raw Material Preparation: Raw materials, namely fine iron powder, quartz sand, barite powder, white cement, silicone oil, and water, were transported to the testing station.

- (3)

- Raw Material Mixing: Iron powder, quartz sand, and barite powder were weighed according to the specified proportions and dry-mixed until homogeneous. White cement and water were weighed, mixed into a slurry, and then poured into the aggregate mixture for thorough blending. Finally, the designated amount of silicone oil was added and mixed uniformly.

- (4)

- Mold Treatment: To facilitate demolding and reduce friction, the inner walls of the mold were wiped with a cloth dampened with barite powder.

- (5)

- Filling and Compaction: The split mold was assembled. The mixture was poured into the mold through a funnel in three separate lifts. Each lift was compacted in layers using the hammer handle.

- (6)

- Press Molding: The top cover of the mold was placed, and pressure was applied to densify the material.

- (7)

- Demolding and Marking: The mold was inverted to remove the outer frame. Subsequently, it was placed upright, and the upper edges were tapped to loosen and remove the semi-cylindrical parts, yielding the specimen. Specimens were then labeled using a marker pen.

- (8)

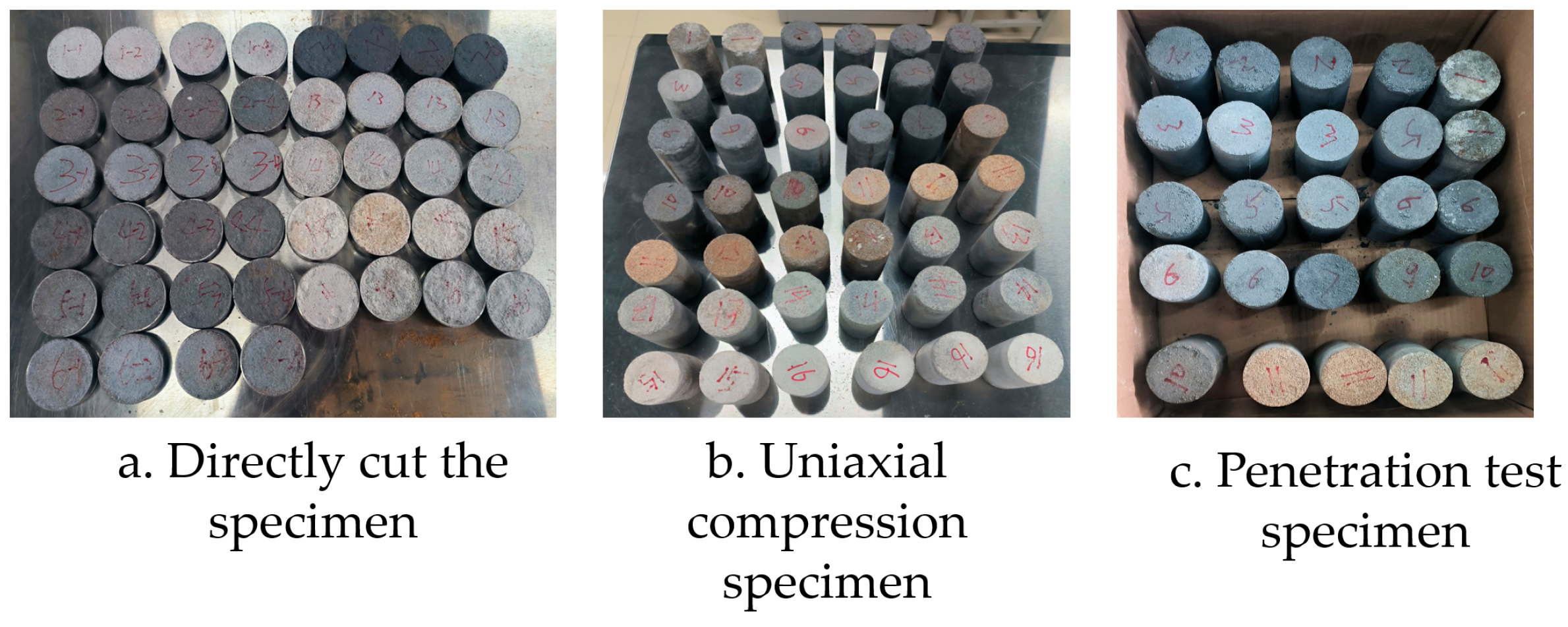

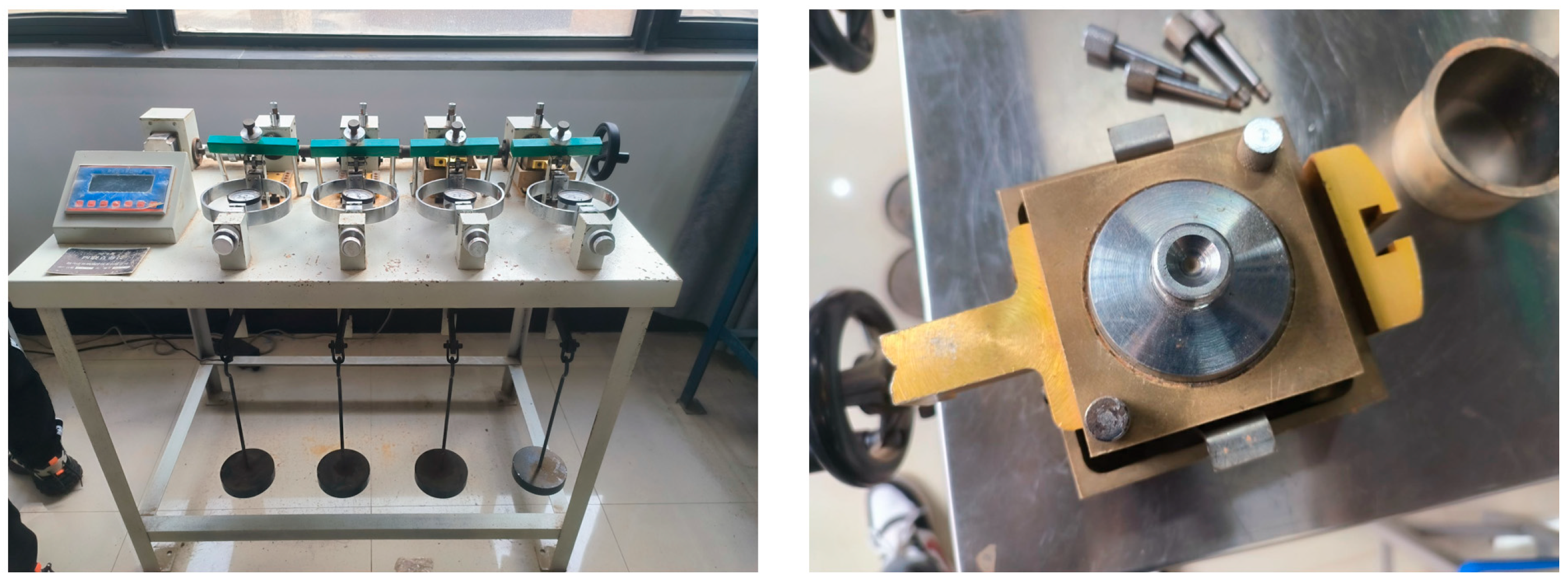

- Curing: Specimens were cured at room temperature for 28 days. A total of 96 cylindrical specimens with dimensions of φ 50 mm × 100 mm and 64 disk-shaped specimens with dimensions of φ 61.8 mm × 20 mm were prepared. As shown in Figure 5.

4. Analysis of Test Results

5. Sensitivity Analysis

5.1. Density

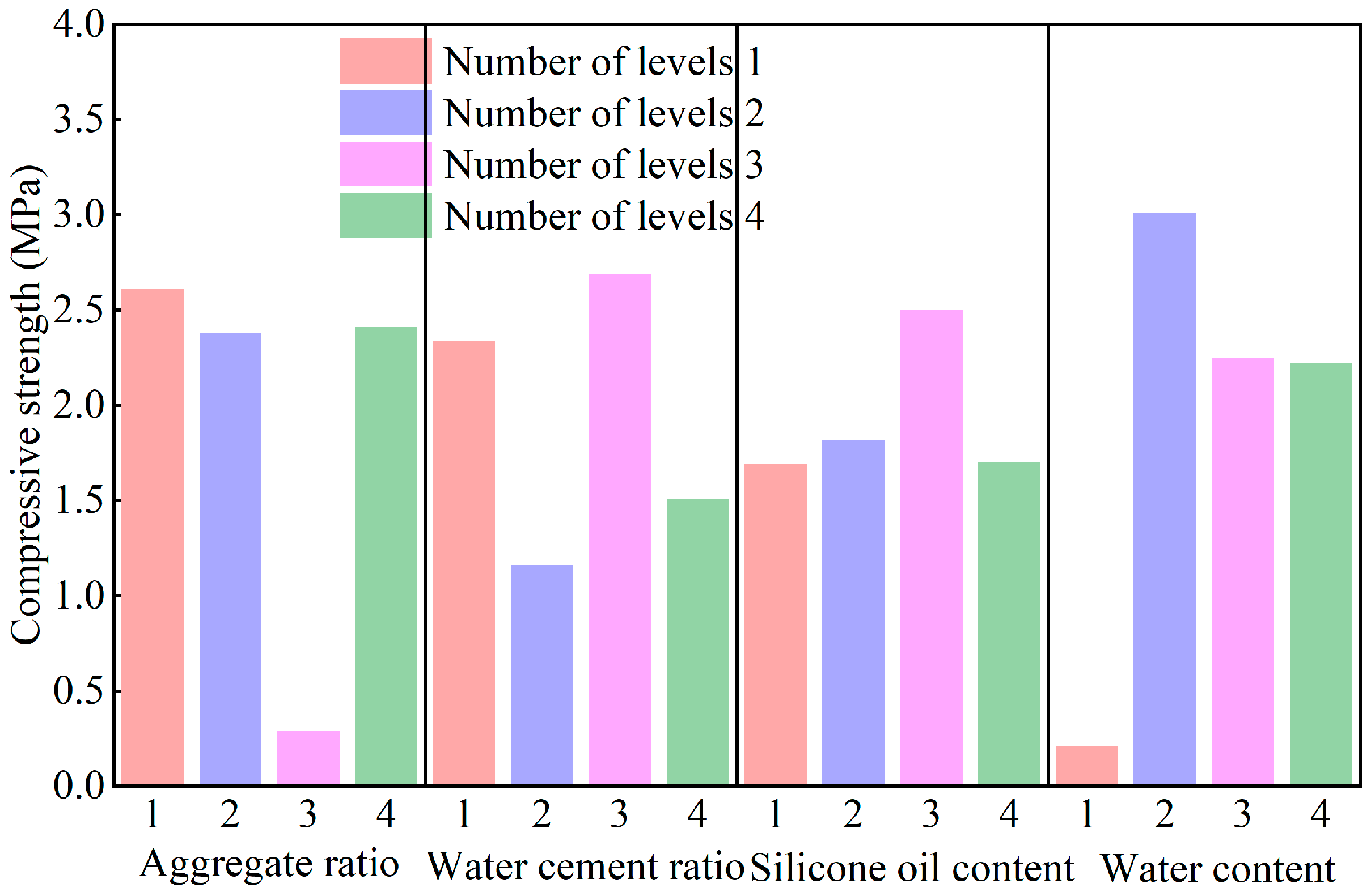

5.2. Compressive Strength

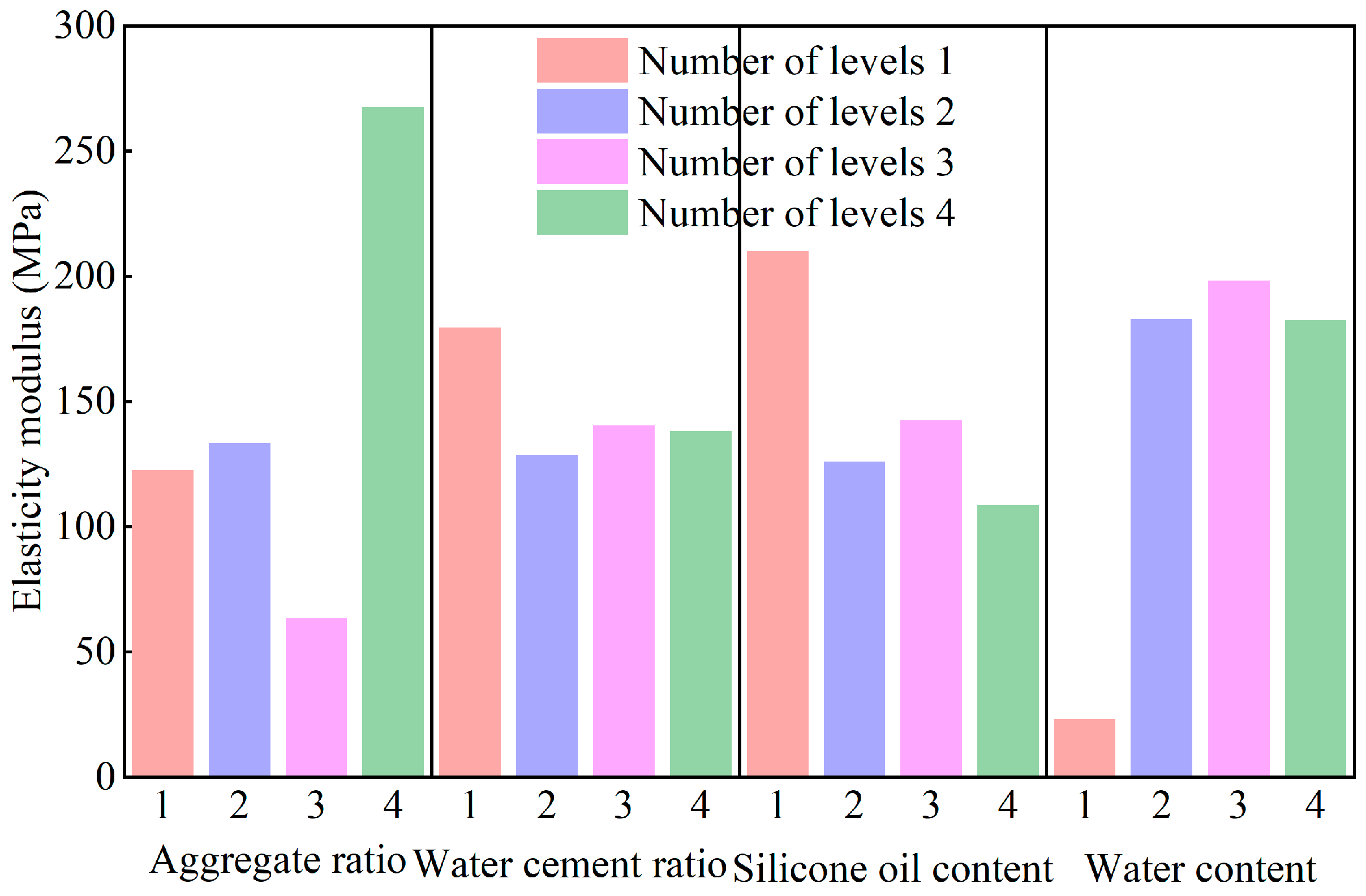

5.3. Elasticity Modulus

5.4. Internal Friction Angle

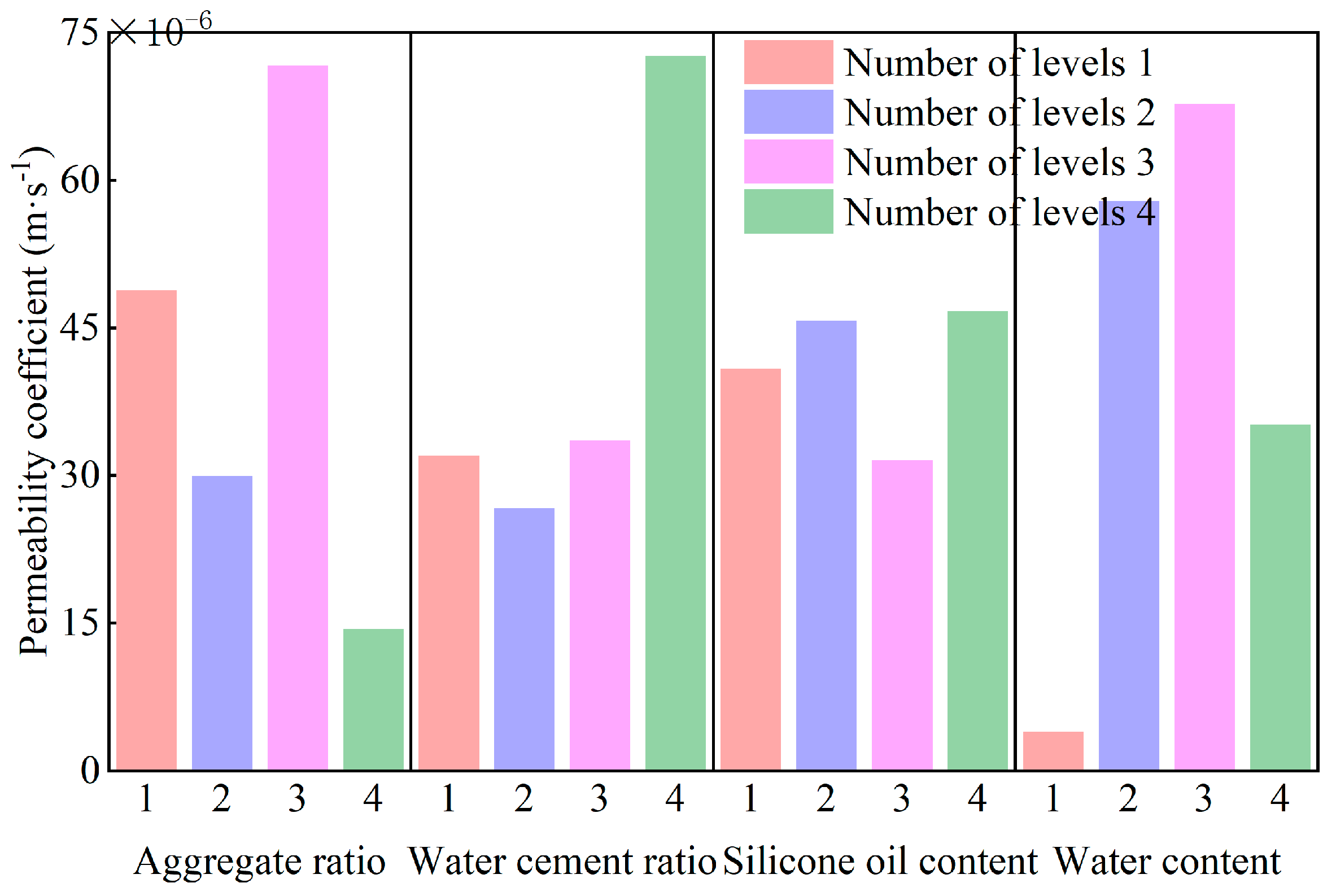

5.5. Permeability Coefficient

- DeepLab is a state-of-the-art semantic segmentation model that excels at assigning a precise label (e.g., “water,” “soil,” “air”) to every pixel in an image. Its use of atrous convolution and atrous spatial pyramid pooling (ASPP) allows for the multi-scale analysis of features, making it ideal for accurately delineating the complex and often diffuse boundaries of a advancing seepage front [46].

- EfficientNet is a family of convolutional neural networks known for achieving superior accuracy with remarkable parameter and computational efficiency. It could be employed as a powerful backbone for feature extraction within a segmentation network (like DeepLab) or used independently for image classification tasks, such as identifying different stages of pore evolution or predicting hydraulic properties from image data alone [47]. The synergy of these models—using EfficientNet for efficient feature encoding and DeepLab for precise pixel-wise decoding—presents a powerful framework for automating the analysis of laboratory experiments and extracting unprecedented quantitative data from visual information.

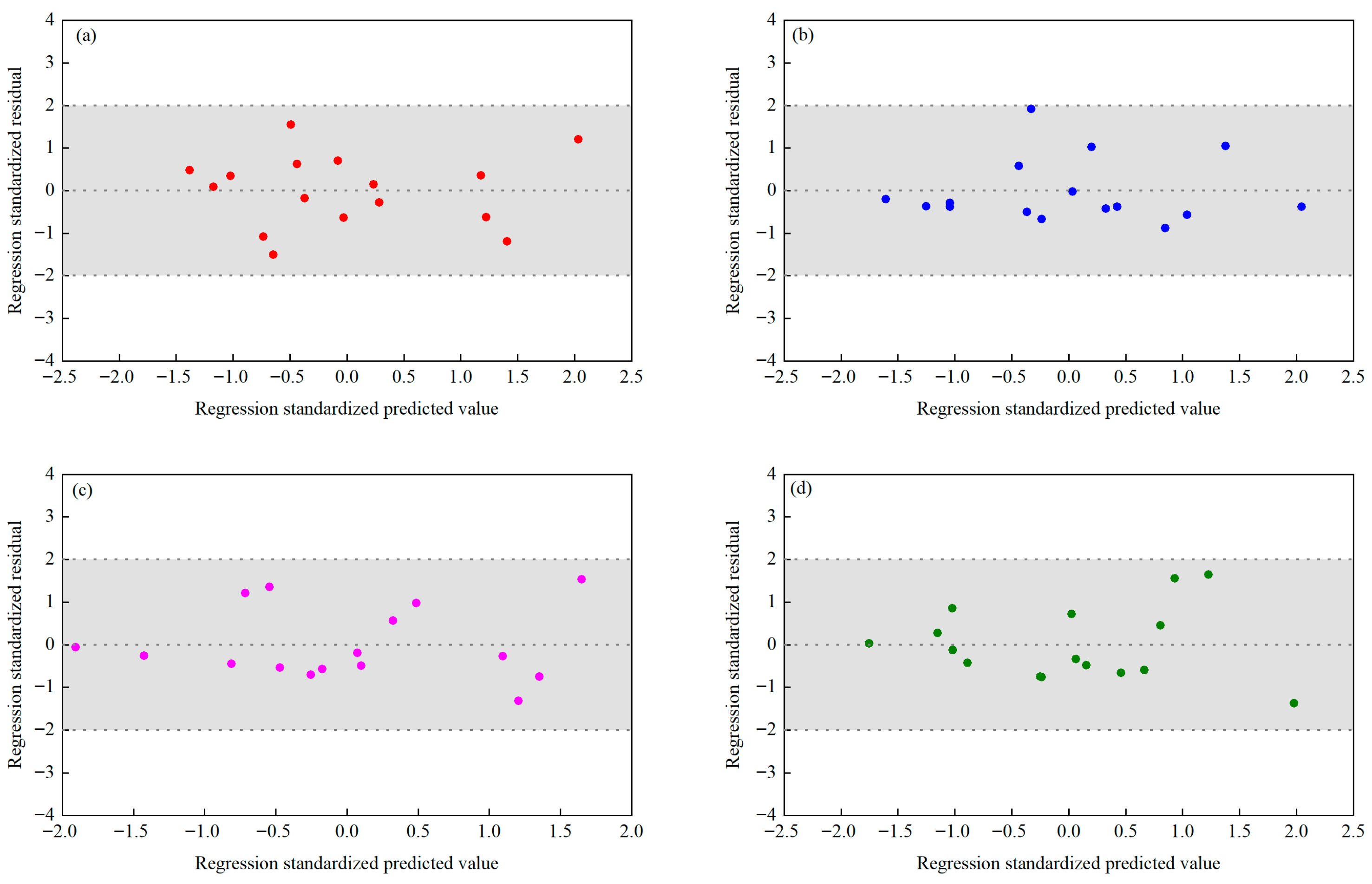

6. Linear Regression Analysis

7. Comparative Analysis with Existing Similarity Materials

8. Conclusions

- (1)

- Density is primarily controlled by the aggregate ratio (iron powder–quartz sand–barite powder). Compressive strength and permeability coefficient are most sensitive to water content. Elastic modulus is dominated by aggregate ratio. Internal friction angle is mainly regulated by water–cement ratio.

- (2)

- The similarity materials achieved wide parametric coverage: density (2.20–3.18 g/cm3), compressive strength (0.07–7.53 MPa), elastic modulus (6.98–484.51 MPa), internal friction angle (32.20–49.12°), and permeability coefficient (1.75 × 10−6–140 × 10−6 m/s). This versatility supports model tests under large similarity ratios.

- (3)

- Multivariate linear regression (SPSS 27.0.1) established predictive equations: Forward equations calculate material properties from mix ratios. Inverse equations determine optimal mix ratios for target geomechanical/hydraulic properties. These models facilitate rapid proportioning design for engineering simulations.

- (4)

- The study bridges the gap in quantitative prediction of permeability-stress coupling behavior. The derived formulas enable efficient preparation of similarity materials tailored to specific rock mass simulations (e.g., low–medium strength, variable permeability), advancing reliability in physical model tests for groundwater-related hazards.

- (5)

- Future research will focus on two main directions. Scientifically, we plan to integrate computer vision technologies, such as DeepLab and EfficientNet models, for real-time, high-resolution monitoring of seepage fronts and pore evolution during physical tests. This will enable pixel-level analysis of fluid-solid coupling processes. For engineering practice, the derived empirical formulas will be embedded into a user-friendly mix design tool to facilitate rapid optimization of material proportions for specific field conditions, such as tunnels or slopes with varying groundwater pressures. Furthermore, large-scale model tests simulating typical engineering scenarios (e.g., water inrush in tunnels) are planned to validate the predictive models and enhance their practical applicability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Abbreviation | Full Form |

|---|---|

| Factor A | Ratio of iron powder to quartz sand to barite powder |

| Factor B | Water-to-cement ratio |

| Factor C | Silicone oil content |

| Factor D | Water content |

| UTM | Universal Testing Machine |

| GDS | Geotechnical Digital Systems |

| DeepLab | DeepLab series |

| ASPP | Atrous Spatial Pyramid Pooling |

| EfficientNet | Efficient Network |

| SPSS 27.0.1 | Statistical Package for the Social Sciences |

| PPE | Personal protective equipment |

| R | Range |

| UCS | Uniaxial compressive strength |

| E | Elasticity modulus |

| Test Number | Factor A | Factor B | Factor C/% | Factor D/% |

|---|---|---|---|---|

| 1 | 1:1:1 | 3:10 | 2 | 1 |

| 2 | 1:1:1 | 2:5 | 5 | 7 |

| 3 | 1:1:1 | 1:2 | 8 | 3 |

| 4 | 1:1:1 | 3:5 | 10 | 5 |

| 5 | 2:1:1 | 3:10 | 5 | 5 |

| 6 | 2:1:1 | 2:5 | 2 | 3 |

| 7 | 2:1:1 | 1:2 | 10 | 7 |

| 8 | 2:1:1 | 3:5 | 8 | 1 |

| 9 | 1:2:1 | 3:10 | 8 | 7 |

| 10 | 1:2:1 | 2:5 | 10 | 1 |

| 11 | 1:2:1 | 1:2 | 2 | 5 |

| 12 | 1:2:1 | 3:5 | 5 | 3 |

| 13 | 1:1:2 | 3:10 | 10 | 3 |

| 14 | 1:1:2 | 2:5 | 8 | 5 |

| 15 | 1:1:2 | 1:2 | 5 | 1 |

| 16 | 1:1:2 | 3:5 | 2 | 7 |

| Test Number | Density (g·cm−3) | Compressive Strength (MPa) | Elasticity Modulus (MPa) | Internal Friction Angle (°) | Permeability Coefficient (m·s−1) |

|---|---|---|---|---|---|

| 1 | 2.46 | 0.42 | 50.39 | 35.96 | 7.90 × 10−6 |

| 2 | 2.67 | 1.34 | 129.61 | 39.80 | 20.4 × 10−6 |

| 3 | 2.58 | 7.53 | 274.92 | 36.86 | 27.1 × 10−6 |

| 4 | 2.63 | 1.15 | 35.39 | 32.20 | 140 × 10−6 |

| 5 | 2.87 | 5.51 | 323.63 | 34.70 | 30.6 × 10−6 |

| 6 | 2.74 | 1.33 | 122.58 | 33.82 | 59.5 × 10−6 |

| 7 | 2.70 | 2.57 | 80.43 | 49.12 | 27.5 × 10−6 |

| 8 | 3.18 | 0.13 | 6.98 | 39.94 | 2.08 × 10−6 |

| 9 | 2.38 | 0.43 | 35.19 | 36.76 | 74.5 × 10−6 |

| 10 | 2.64 | 0.07 | 10.24 | 41.87 | 4.16 × 10−6 |

| 11 | 2.31 | 0.44 | 181.71 | 40.03 | 77.8 × 10−6 |

| 12 | 2.20 | 0.20 | 25.91 | 32.53 | 130 × 10−6 |

| 13 | 2.45 | 2.99 | 308.69 | 36.34 | 15.0 × 10−6 |

| 14 | 2.24 | 1.89 | 251.98 | 37.74 | 22.5 × 10−6 |

| 15 | 2.55 | 0.22 | 24.99 | 43.83 | 1.75 × 10−6 |

| 16 | 2.32 | 4.55 | 484.51 | 36.68 | 18.3 × 10−6 |

| Influence Factor | Number of Levels | Aggregate Ratio | Water Cement Ratio | Silicone Oil Content | Water Content |

|---|---|---|---|---|---|

| Density (g·cm−3) | 1 | 2.59 | 2.54 | 2.46 | 2.71 |

| 2 | 2.87 | 2.57 | 2.57 | 2.49 | |

| 3 | 2.38 | 2.54 | 2.6 | 2.51 | |

| 4 | 2.39 | 2.58 | 2.61 | 2.52 | |

| Range | 0.49 | 0.04 | 0.15 | 0.22 | |

| Compressive strength (MPa) | 1 | 2.61 | 2.34 | 1.69 | 0.21 |

| 2 | 2.38 | 1.16 | 1.82 | 3.01 | |

| 3 | 0.29 | 2.69 | 2.50 | 2.25 | |

| 4 | 2.41 | 1.51 | 1.70 | 2.22 | |

| Range | 2.32 | 1.53 | 0.81 | 2.8 | |

| Elasticity modulus (MPa) | 1 | 122.58 | 179.48 | 209.8 | 23.15 |

| 2 | 133.41 | 128.6 | 126.04 | 183.02 | |

| 3 | 63.26 | 140.51 | 142.47 | 198.18 | |

| 4 | 267.54 | 138.2 | 108.69 | 182.44 | |

| Range | 204.28 | 50.88 | 101.11 | 175.03 | |

| Internal friction angle (°) | 1 | 36.2 | 35.94 | 36.62 | 40.4 |

| 2 | 39.4 | 38.31 | 37.72 | 34.89 | |

| 3 | 37.8 | 42.46 | 37.83 | 36.17 | |

| 4 | 38.65 | 35.34 | 39.88 | 40.59 | |

| Range | 3.2 | 10.12 | 3.26 | 5.7 | |

| Permeability coefficient (m·s−1) | 1 | 48.85 × 10−6 | 32.00 × 10−6 | 40.88 × 10−6 | 3.97 × 10−6 |

| 2 | 29.92 × 10−6 | 26.64 × 10−6 | 45.69 × 10−6 | 57.9 × 10−6 | |

| 3 | 71.62 × 10−6 | 33.54 × 10−6 | 31.55 × 10−6 | 67.73 × 10−6 | |

| 4 | 14.39 × 10−6 | 72.6 × 10−6 | 46.67 × 10−6 | 35.18 × 10−6 | |

| Range | 57.23 × 10−6 | 45.96 × 10−6 | 15.12 × 10−6 | 63.76 × 10−6 |

References

- Sun, L.; Wang, W.-X.; Xu, J.-S. Study on Proportioning Scheme of Coal System Rocky Similar Material Based on Orthogonal Test. Materials 2023, 16, 7113. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W. Experimental Development Process of a New Fluid–Solid Coupling Similar-Material Based on the Orthogonal Test. Processes 2018, 6, 211. [Google Scholar] [CrossRef]

- Lin, Z.; Jiang, Y.; Xiong, Y.; Xu, C.; Guo, Y.; Wang, C.; Fang, T. Analytical Solution for Displacement-Dependent Active Earth Pressure Considering the Stiffness of Cantilever Retaining Structure in Cohesionless Soil. Comput. Geotech. 2024, 170, 106258. [Google Scholar] [CrossRef]

- Yang, H.; Zhao, Z.; Li, Y. Experimental Study on Ratio of High Strength Similar Materials. Saf. Coal Mines 2018, 49, 59–62+67. [Google Scholar] [CrossRef]

- Yang, X.; Dong, J.; Yang, J.; Han, X. Similar Material Proportioning Tests and Mechanical Properties Based on Orthogonal Design. Materials 2023, 16, 6439. [Google Scholar] [CrossRef]

- Li, J.; Zou, H.; Sun, G.; Zhou, Z.; Zeng, L. Experimental Study on Similar Materials in Model Test Based on Orthogonal Design. IOP Conf. Ser. Earth Environ. Sci. 2021, 692, 042014. [Google Scholar] [CrossRef]

- Lin, Z.; Jiang, Y.; Xu, C.; Chi, M.; Fang, T.; Guan, L.; Feng, G.; Lin, G. Performance of Adjacent Metro Tunnels during Deep Excavation: A Case Study in Hangzhou. Transp. Geotech. 2025, 53, 101585. [Google Scholar] [CrossRef]

- Kong, C.; Gao, X.; Ren, S.; Gu, S.; Gu, Y. Physical Model Test of Tunnel Complex Surrounding Rock Progressive Failure Based on Strength-Reduction Similar Materials. Eng. Fail. Anal. 2023, 149, 107255. [Google Scholar] [CrossRef]

- Xu, Z.; Luo, Y.; Chen, J.; Su, Z.; Zhu, T.; Yuan, J. Mechanical Properties and Reasonable Proportioning of Similar Materials in Physical Model Test of Tunnel Lining Cracking. Constr. Build. Mater. 2021, 300, 123960. [Google Scholar] [CrossRef]

- Sun, B.; Chen, R.; Ping, Y.; Zhu, Z.; Wu, N.; He, Y. Dynamic Response of Rock-like Materials Based on SHPB Pulse Waveform Characteristics. Materials 2021, 15, 210. [Google Scholar] [CrossRef]

- Wang, Q.; Ye, H.; Li, N.; Ren, G.; Lei, T.; Chen, D.; Chen, W. Proportioning experiment and strength variation law of similar simulation materials for soft rock of coal measures. Exp. Technol. Manag. 2021, 38, 77–82. [Google Scholar] [CrossRef]

- Li, S.C.; Wang, H.P.; Zhang, Q.Y.; Li, Y. New Type Geo-Mechanical Similar Material Experiments Research and Its Application. Key Eng. Mater. 2006, 326–328, 1801–1804. [Google Scholar] [CrossRef]

- Qiu, J.; Lu, Y.; Lai, J.; Zhang, Y.; Yang, T.; Wang, K. Experimental Study on the Effect of Water Gushing on Loess Metro Tunnel. Environ. Earth Sci. 2020, 79, 261. [Google Scholar] [CrossRef]

- Liu, M.; Fan, Q.; Han, J.; Li, W. Research on Mix Proportion of Similar Materials in Limestone. HongShui Rive 2020, 39, 85–89. [Google Scholar]

- Diao, X.H.; Wang, K.; Fu, P.Y. Study on Proportioning of Similar Material to Swelling Rock. Appl. Mech. Mater. 2014, 501–504, 439–443. [Google Scholar] [CrossRef]

- Fu, H.-Y.; Qi, S.-X.; Shi, Z.-N.; Zeng, L. Mixing Ratios and Cementing Mechanism of Similar Silty Mudstone Materials for Model Tests. Adv. Civ. Eng. 2021, 2021, 2426130. [Google Scholar] [CrossRef]

- Yang, M.; Yang, Y.; Zhao, B. Study on the Proportion of Conglomerate Similar Materials Based on the Orthogonal Test. Shock Vib. 2021, 2021, 6657323. [Google Scholar] [CrossRef]

- Tang, F.; Qin, Y.; Sun, J.; Yan, L.; Chu, C.; Xu, Y. Study on Similar Simulation Experiment of Stopped Working Face Gob Spontaneous Combustion Based on Coal Similar Material. Combust. Sci. Technol. 2025, 1–23. [Google Scholar] [CrossRef]

- Wen, C.; Jia, S.; Fu, X.; Meng, L.; Zhao, Z. Experimental Research and Sensitivity Analysis of Mudstone Similar Materials Based on Orthogonal Desig. Adv. Mater. Sci. Eng. 2020, 2020, 2031276. [Google Scholar] [CrossRef]

- Xu, C.; Cui, Y.; Xue, L.; Chen, H.; Dong, J.; Zhao, H. Experimental Study on Mechanical Properties and Failure Behaviours of New Materials for Modeling Rock Bridges. J. Mater. Res. Technol. 2023, 23, 1696–1711. [Google Scholar] [CrossRef]

- Shi, W.; Zhang, J.; Xin, C.; Song, D.; Hu, N.; Li, B. Proportioning Test on the Similar Materials of the Rock Mass Physical Model Test Considering Seepage and Dynamic Characteristics. J. Mar. Sci. Eng. 2023, 11, 1815. [Google Scholar] [CrossRef]

- Nie, X.; Yin, Q.; He, M.; Wang, Q.; Jing, H.; Zheng, B.; Meng, B.; Deng, T.; Jiang, Z.; Wu, J. Shear Mechanical Properties and Fracturing Responses of Layered Rough Jointed Rock-like Materials. Int. J. Min. Met. Mater. 2024, 31, 2417–2434. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Wang, K.; Li, L.; Cheng, S.; Sun, S. Development of Similar Materials with Different Tension-Compression Ratios and Evaluation of TBM Excavation. Bull. Eng. Geol. Environ. 2024, 83, 190. [Google Scholar] [CrossRef]

- Kumar, S.; Tiwari, G.; Parameswaran, V.; Das, A. Dynamic Mechanical Behaviour of Rock-like Materials with a Flaw Under Different Orientation and Infill Conditions. Bull. Eng. Geol. Environ. 2023, 82, 345. [Google Scholar] [CrossRef]

- Huang, D.; Gu, D.M. Influence of Filling-Drawdown Cycles of the Three Gorges Reservoir on Deformation and Failure Behaviors of Anaclinal Rock Slopes in the Wu Gorge. Geomorphology 2017, 295, 489–506. [Google Scholar] [CrossRef]

- Macfarlane, D.F. Observations and Predictions of the Behaviour of Large, Slow-Moving Landslides in Schist, Clyde Dam Reservoir, New Zealand. Eng. Geol. 2009, 109, 5–15. [Google Scholar] [CrossRef]

- Jiao, Y.-Y.; Zhang, H.-Q.; Tang, H.-M.; Zhang, X.-L.; Adoko, A.C.; Tian, H.-N. Simulating the Process of Reservoir-Impoundment-Induced Landslide Using the Extended DDA Method. Eng. Geol. 2014, 182, 37–48. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, S.; Guo, W.; Liu, W. Physical Simulation of High-Pressure Water Inrush Through the Floor of a Deep Mine. Mine Water Environ. 2017, 36, 542–549. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhao, J.; Shen, J. Deformation and Stability in Coal Seam Mining Under Fluid–Solid Coupling. Geotech. Geol. Eng. 2024, 42, 4333–4348. [Google Scholar] [CrossRef]

- Zhai, C.; Zheng, Y.; Yu, X.; Xu, J.; Sun, Y.; Cong, Y.; Tang, W.; Li, Y.; Zhu, X.; Chen, A. Experimental study on the mechanical properties of coal-like materials for hydraulic fracturing simulation. Coal Geol. Explor. 2022, 50, 16–28. [Google Scholar] [CrossRef]

- Li, S.; Liu, H.; Li, L.; Zhang, Q.; Wang, K.; Wang, K. Large Scale Three-Dimensional Seepage Analysis Model Test and Numerical Simulation Research on Undersea Tunnel. Appl. Ocean Res. 2016, 59, 510–520. [Google Scholar] [CrossRef]

- Song, C.; Xu, X.; Wang, L. Development and Characterisation of Novel Fluid–Solid Coupled Similar Materials Under Dry–Wet Cycling Conditions. Buildings 2025, 15, 1794. [Google Scholar] [CrossRef]

- Ren, X.; Xu, G.; Chen, Z.; Ran, S.; Zhang, J. Development of Similar Materials for Fluid–Solid Coupling Model Testing and Application in Damage Constitutive Models. Sci. Rep. 2024, 14, 14786. [Google Scholar] [CrossRef]

- Liang, D.; Jiang, Z.; Zhu, S.; Sun, Q.; Qian, Z. Experimental Research on Water Inrush in Tunnel Construction. Nat. Hazards 2016, 81, 467–480. [Google Scholar] [CrossRef]

- Li, S.; Pan, D.; Xu, Z.; Li, L.; Lin, P.; Yuan, Y.; Gao, C.; Lu, W. A model test on catastrophic evolution process of water inrush of a concealed karst cave filled with confined water. Rock Soil Mech. 2018, 39, 3164–3173. [Google Scholar] [CrossRef]

- Li, S.; Gao, C.; Zhou, Z.; Li, L.; Wang, M.; Yuan, Y.; Wang, J. Analysis on the Precursor Information of Water Inrush in Karst Tunnels: A True Triaxial Model Test Study|Rock Mechanics and Rock Engineering. Rock Mech. Rock Eng. 2019, 52, 373–384. [Google Scholar] [CrossRef]

- Li, L.; Sun, S.; Wang, J.; Yang, W.; Song, S.; Fang, Z. Experimental Study of the Precursor Information of the Water Inrush in Shield Tunnels Due to the Proximity of a Water-Filled Cave. Int. J. Rock Mech. Min. Sci. 2020, 130, 104320. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Xiang, W.; Yin, X.; Xue, T.; Lin, H.; Cheng, L.; Guo, X. Development and application of new-style hydro-mechanical coupling similar materials in complex environment. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 4168–4180. [Google Scholar] [CrossRef]

- Wu, B.; Li, P.; Wang, Y.; Zhang, B.; Chi, M. Mechanical properties analysis of materials for similar simulationtest of coal-water co-mining. China Coal 2022, 48, 64–73. [Google Scholar] [CrossRef]

- Shi, X.; Liu, B.; Qi, Y. Applicability of similar materials bonded by cement and plaster in solid-liquid coupling tests. Rock Soil Mech. 2015, 36, 2624–2630+2638. [Google Scholar] [CrossRef]

- Shi, X.; Liu, B.; Xiao, J. Amethod for determining the ratio of similar materials with cement and plaster as bonding agents. Rock Soil Mech. 2015, 36, 1357–1362. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, Y.; Yang, D. Simulation theory & method of 3D solid-liquid coupling. J. Liaoning Tech. Univ. 2007, 2, 204–206. [Google Scholar]

- Wei, L.; Jing, H.; Xu, B.; Wang, Y. Solid-fluid coupling analogous material test for subsea tunnel. J. Cent. South Univ. (Sci. Technol.) 2015, 46, 983–990. [Google Scholar] [CrossRef]

- Zan, W.; Lai, J.; Zhang, W.; Yang, Q.; Qin, Y.; Su, X. Experimental and Applied Research on Similar Materials to Granular Mixtures for Solid-Liquid Coupling Model Test of an Underwater Tunnel. Constr. Build. Mater. 2024, 416, 135170. [Google Scholar] [CrossRef]

- Xu, S.; Yang, K.; Xiong, W.; Li, Z.; Hao, L. Permeability and Porosity of Artificial-Similar Material for Biomimetic Geotechnical Engineering via Direct Ink Writing for Sustainability. 3D Print. Addit. Manuf. 2024, 11, 1758–1767. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Zou, S.; Zhou, W.; Huang, Y.; Shao, L.; Yuan, J.; Gou, X.; Jin, W.; Wang, Z.; Chen, X.; et al. Clinically Applicable Histopathological Diagnosis System for Gastric Cancer Detection Using Deep Learning. Nat. Commun. 2020, 11, 4294. [Google Scholar] [CrossRef] [PubMed]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated Estimation of Cementitious Sorptivity via Computer Vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef]

- Zhan, X.; Gao, L.; Zhao, F.; Wang, Y.; Liu, P.; Han, S. Experimental study on the proportioning of ultra-high strength similar materials for large similarity ratio model tests. Coal Geol. Explor. 2023, 51, 109–118. [Google Scholar] [CrossRef]

- He, C.; Chen, J.; Ren, C.; Li, L. Similar Material Proportioning and Sensitivity Analysis for Similar Modeling Tests of Rock Contact Zones. Mater. Rep. 2025, 1–17. Available online: https://link.cnki.net/urlid/50.1078.TB.20250814.0952.002 (accessed on 25 August 2025).

| Level | Factor A | Factor B | Factor C/% | Factor D/% |

|---|---|---|---|---|

| 1 | 1:1:1 | 3:10 | 2 | 1 |

| 2 | 2:1:1 | 2:5 | 5 | 3 |

| 3 | 1:2:1 | 1:2 | 8 | 5 |

| 4 | 1:1:2 | 3:5 | 10 | 7 |

| Category | Aggregate Ratio | Water Cement Ratio | Silicone Oil Content | Water Content |

|---|---|---|---|---|

| Density | 0.809 ** | 0.041 | 0.219 * | −0.251 * |

| Compressive strength | 0.198 * | −0.05 | 0.05 | 0.275 * |

| Elasticity modulus | −0.094 | −0.09 | −0.234 * | 0.398 * |

| Permeability coefficient | −0.127 * | 0.341 * | −0.001 | 0.274 * |

| Aspect | Material Composition | Performance Range | Advantages | Disadvantages | Risks | Considerations |

|---|---|---|---|---|---|---|

| This Study | Iron powder, quartz sand, barite powder, cement, silicone oil, water. | ρ: 2.20–3.18 g/cm3; UCS: 0.07–7.53 MPa; E: 6.98–484.51 MPa; φ: 32.2–49.12°; k: 1.75–140 × 10−6 m/s. | Wide prop. range; predictive models; permeability control. | Multi-factor control; higher cost; complex prep. | Oil dispersion; curing sensitivity; perm. calibration. | For controlled strength; inverse design. |

| Literature [49] | River sand, barite powder, cement, gypsum, paraffin oil, water. | ρ: 1.78–2.19 g/cm3; UCS: 1.79–5.67 MPa; E: 21.4–134.6 MPa; c: 60.7–117.9 kPa; φ: 32.1–42.8°. | Low cost; validated strength models; good for contact zones. | Narrow range; not for hydr. Coupling. | Not for fluid-solid; limited strength/perm. accuracy. | Mechanical only; simple; economical. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, Y.; Wang, Y.; Yu, Y.; Sun, Y.; Dong, J. Investigation on Similitude Materials with Controlled Strength and Permeability for Physical Model Tests. Appl. Sci. 2025, 15, 10278. https://doi.org/10.3390/app151810278

Rong Y, Wang Y, Yu Y, Sun Y, Dong J. Investigation on Similitude Materials with Controlled Strength and Permeability for Physical Model Tests. Applied Sciences. 2025; 15(18):10278. https://doi.org/10.3390/app151810278

Chicago/Turabian StyleRong, Yao, Yangchen Wang, Yitian Yu, Yang Sun, and Jingliang Dong. 2025. "Investigation on Similitude Materials with Controlled Strength and Permeability for Physical Model Tests" Applied Sciences 15, no. 18: 10278. https://doi.org/10.3390/app151810278

APA StyleRong, Y., Wang, Y., Yu, Y., Sun, Y., & Dong, J. (2025). Investigation on Similitude Materials with Controlled Strength and Permeability for Physical Model Tests. Applied Sciences, 15(18), 10278. https://doi.org/10.3390/app151810278