Analysis of Failure States of Transportation Vehicles Using the Ishikawa Diagram: A Case Study

Abstract

Featured Application

Abstract

1. Introduction

Ishikawa Diagram

2. Materials and Methods

2.1. Researched Subject Material and Case Study Methods

- Subject of investigation: IVECO, SCANIA, and TATRA road transportation vehicles in real operating conditions.

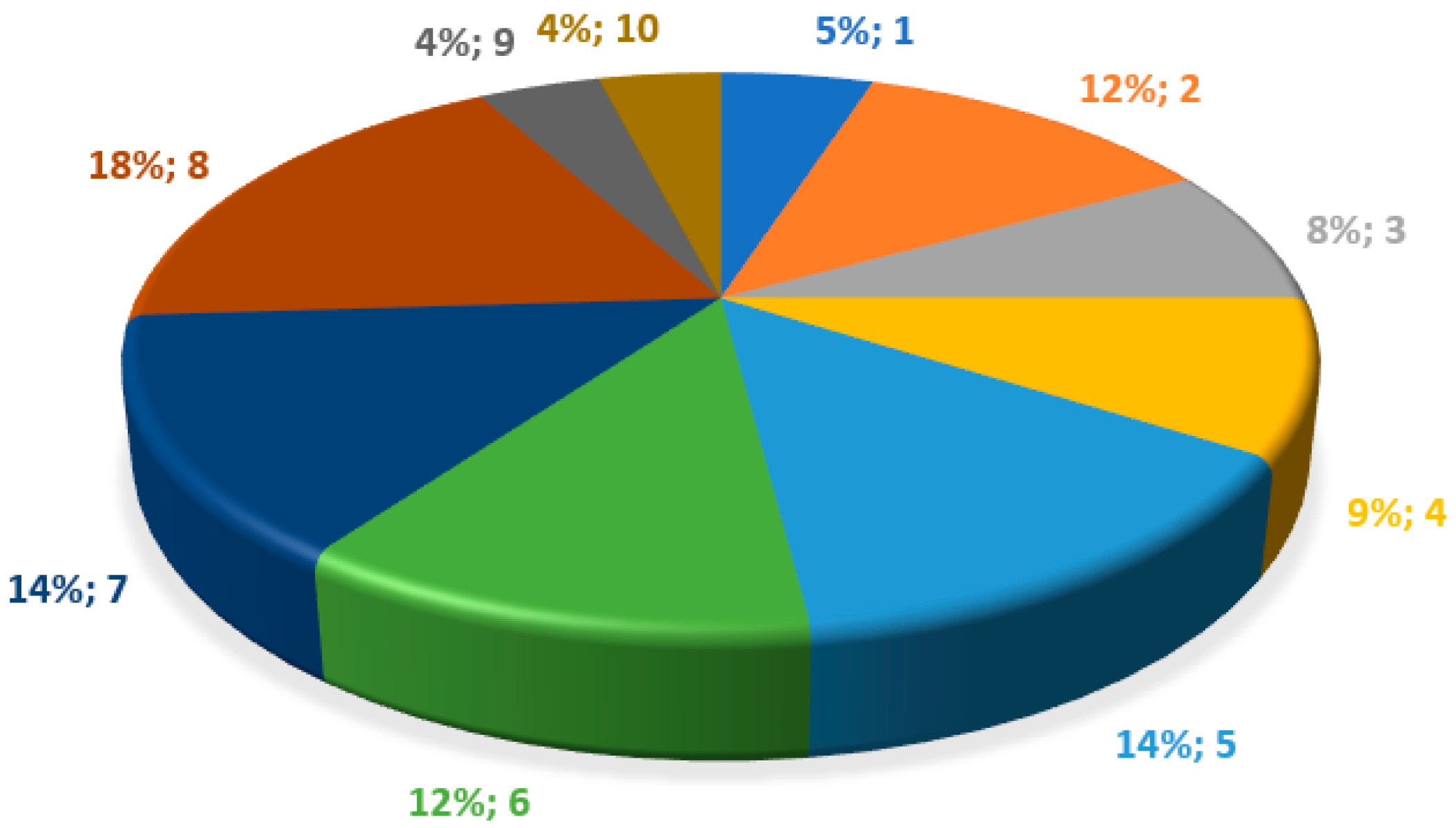

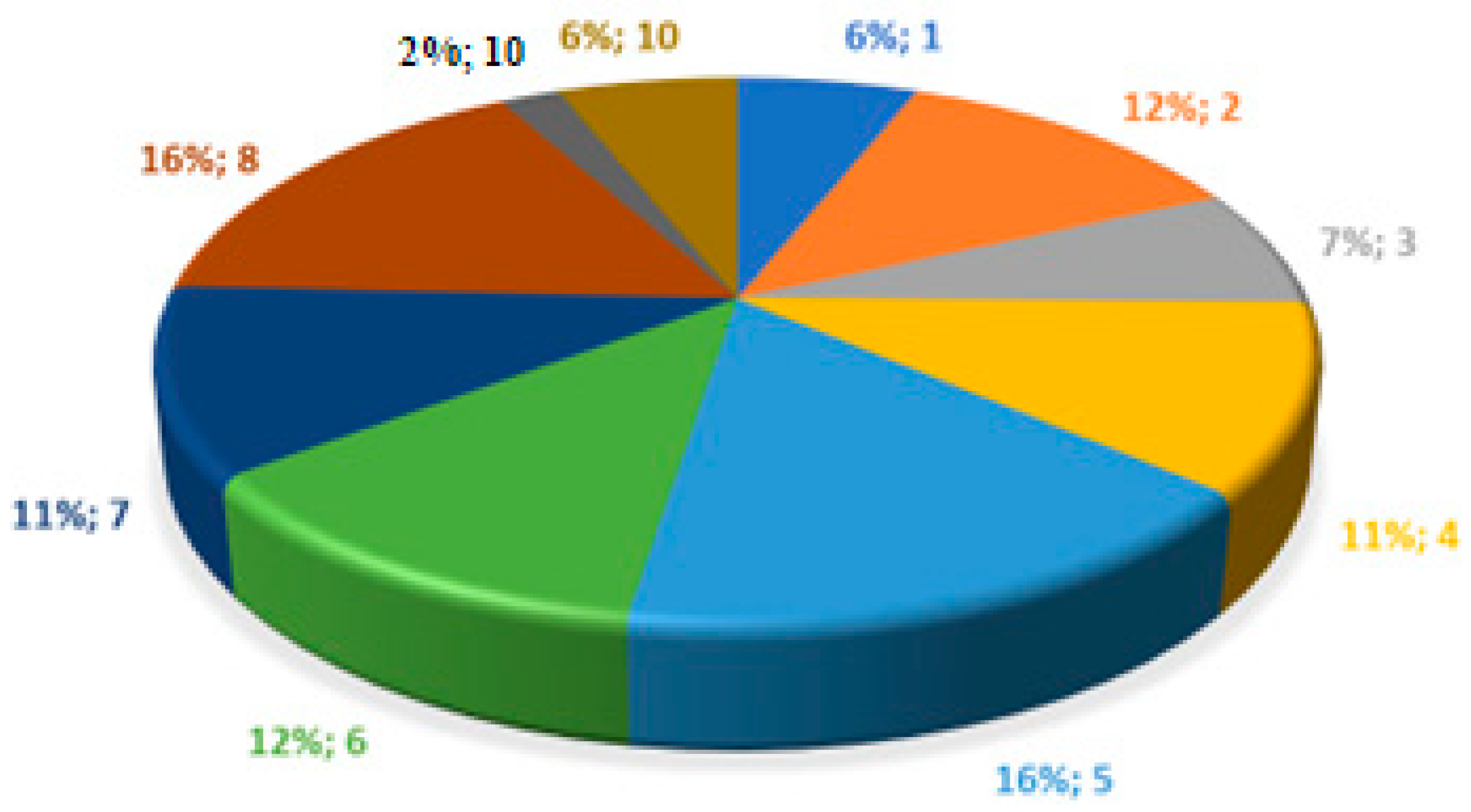

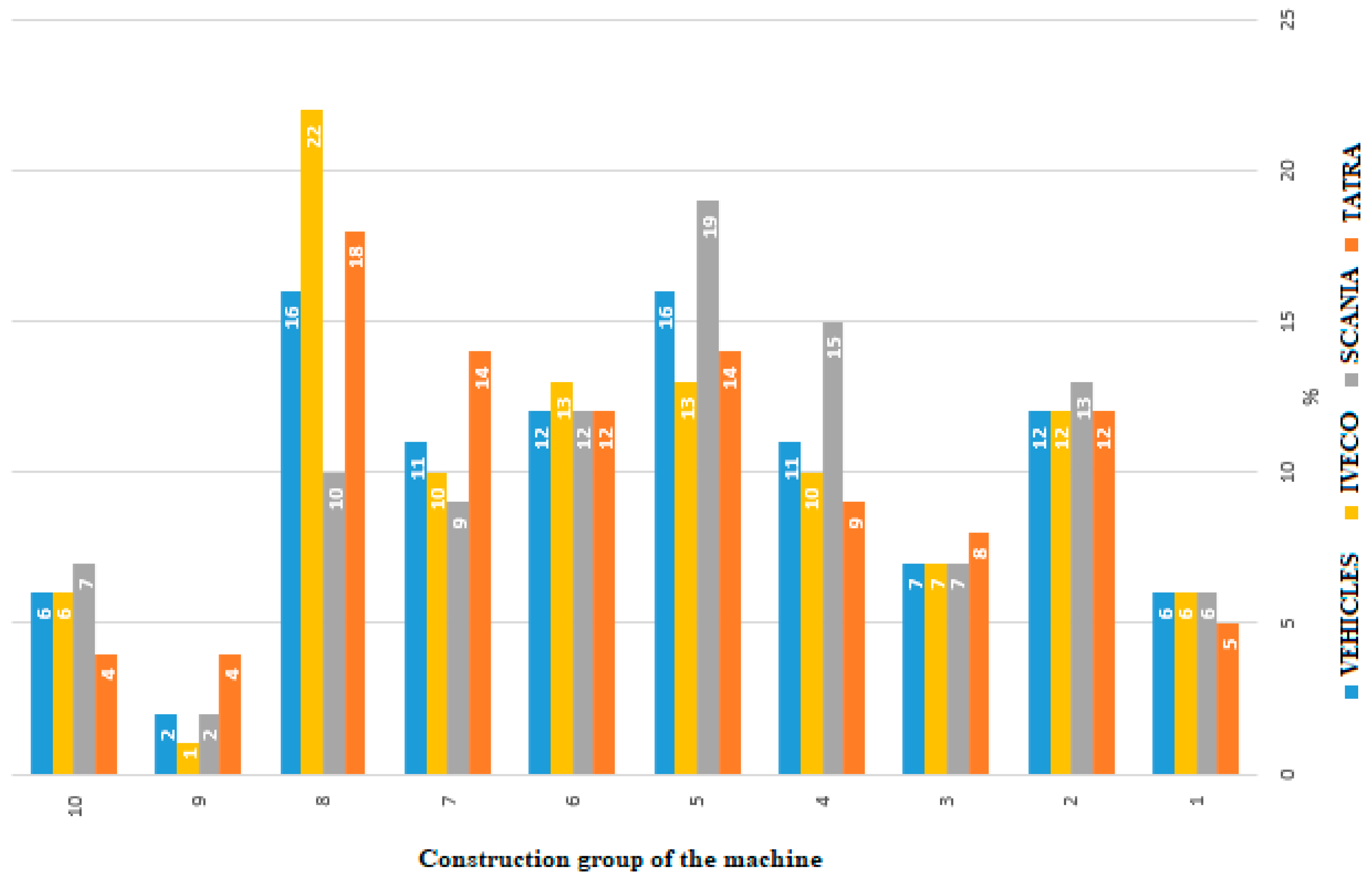

2.2. Design Groups of Monitored Transport Vehicles

- Cabin, controls, instrumentation (on-board computer/control unit, tachograph, outside thermometer);

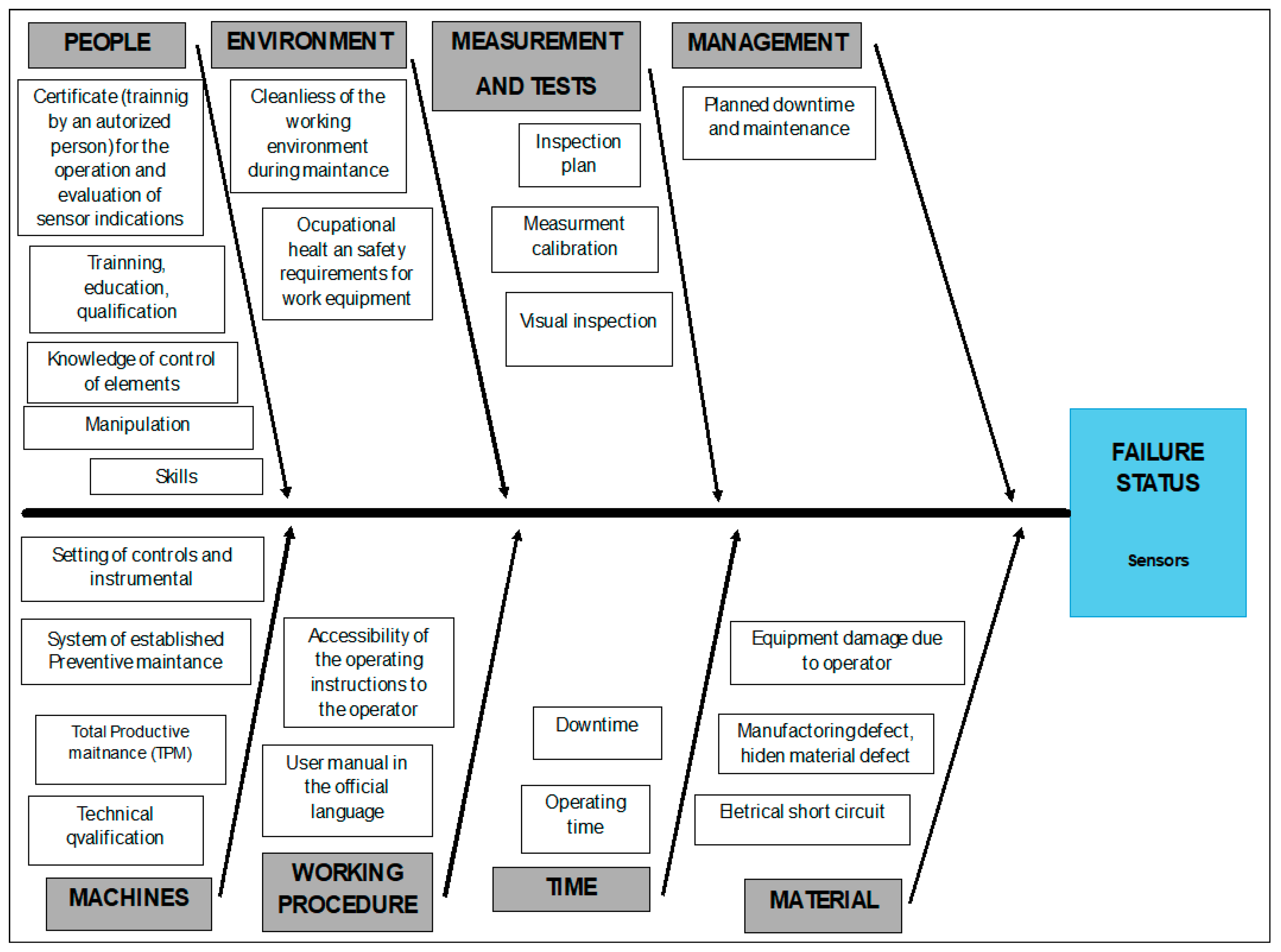

- Sensors—electrical (safety) equipment of the vehicle;

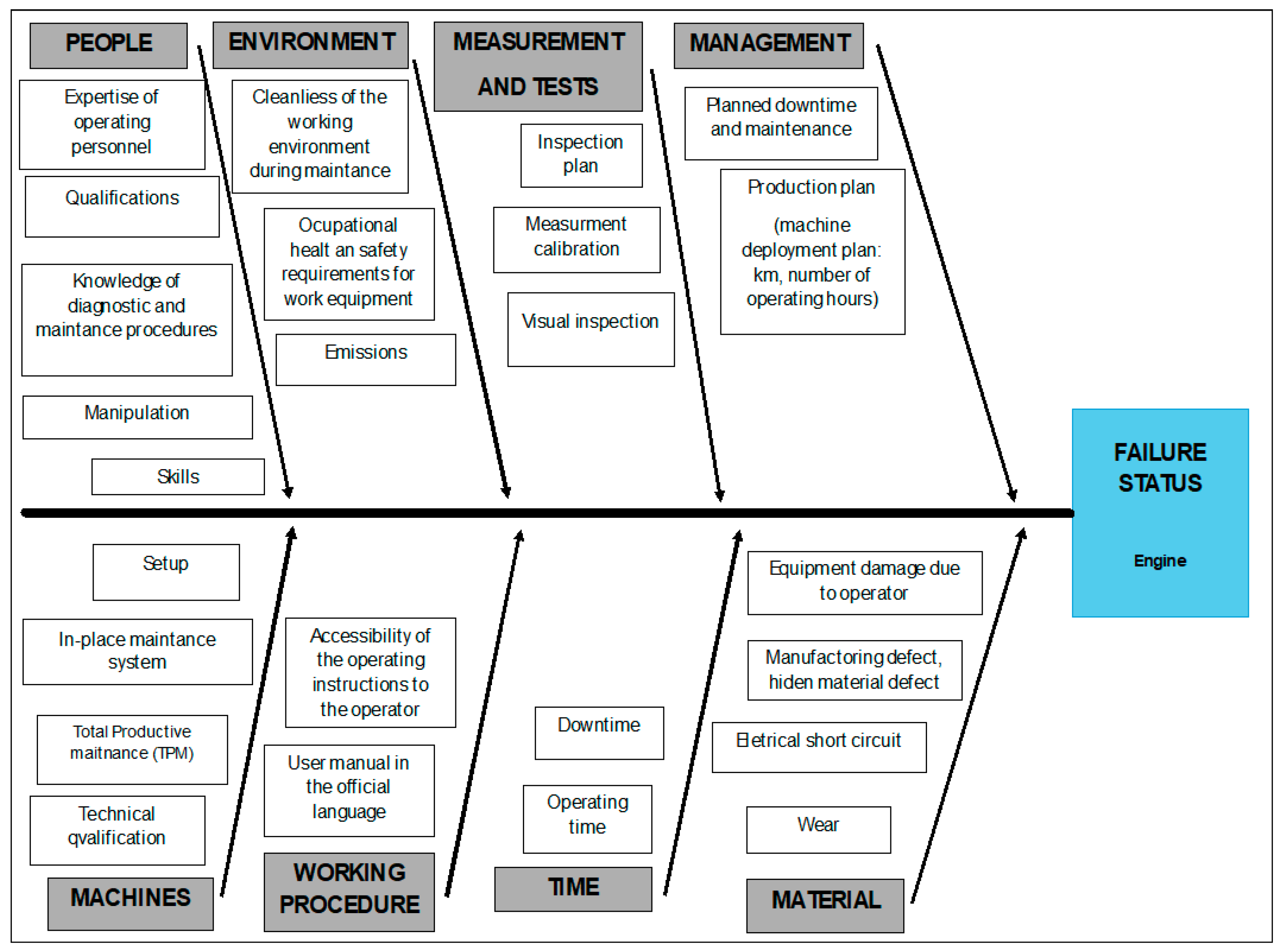

- Engine (fuel system with tank, block, and lower engine cover, cylinders, pistons, pins, connecting rods, bearings, shaft, flywheel, distribution);

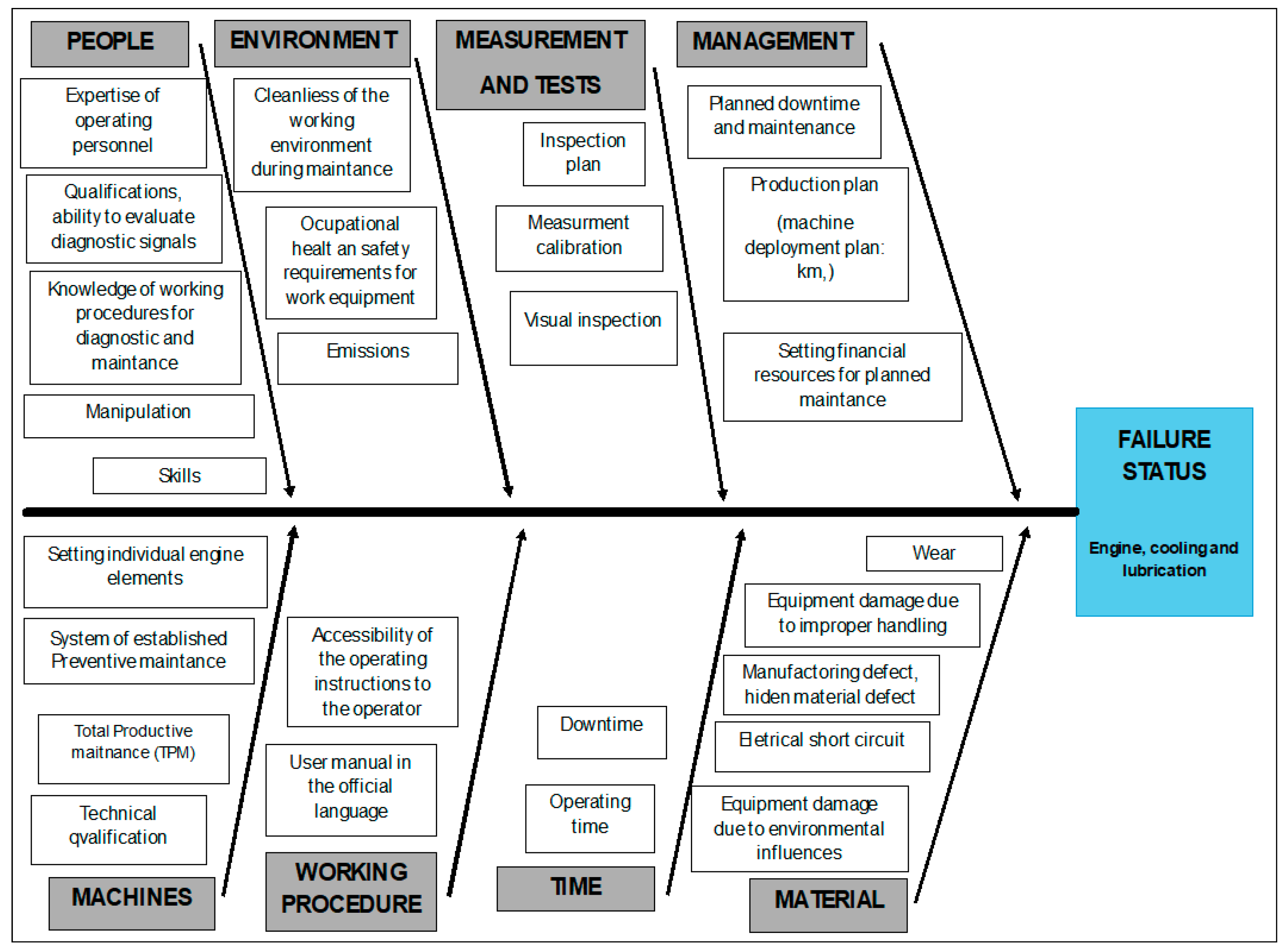

- Engine and its cooling and lubrication;

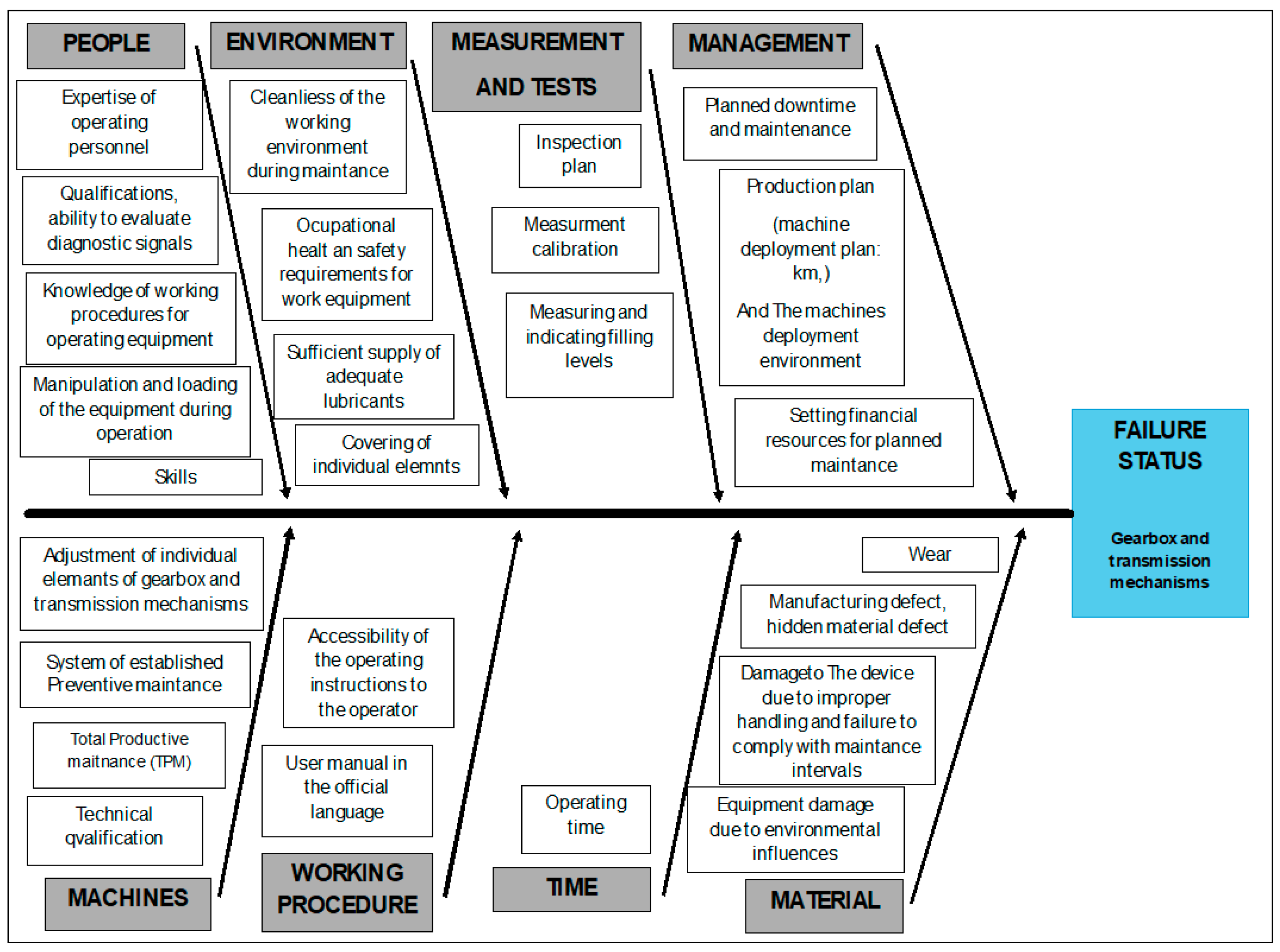

- Transmissions and transmission mechanisms (gearboxes, clutches, shafts, joints, final drives, differentials, distribution);

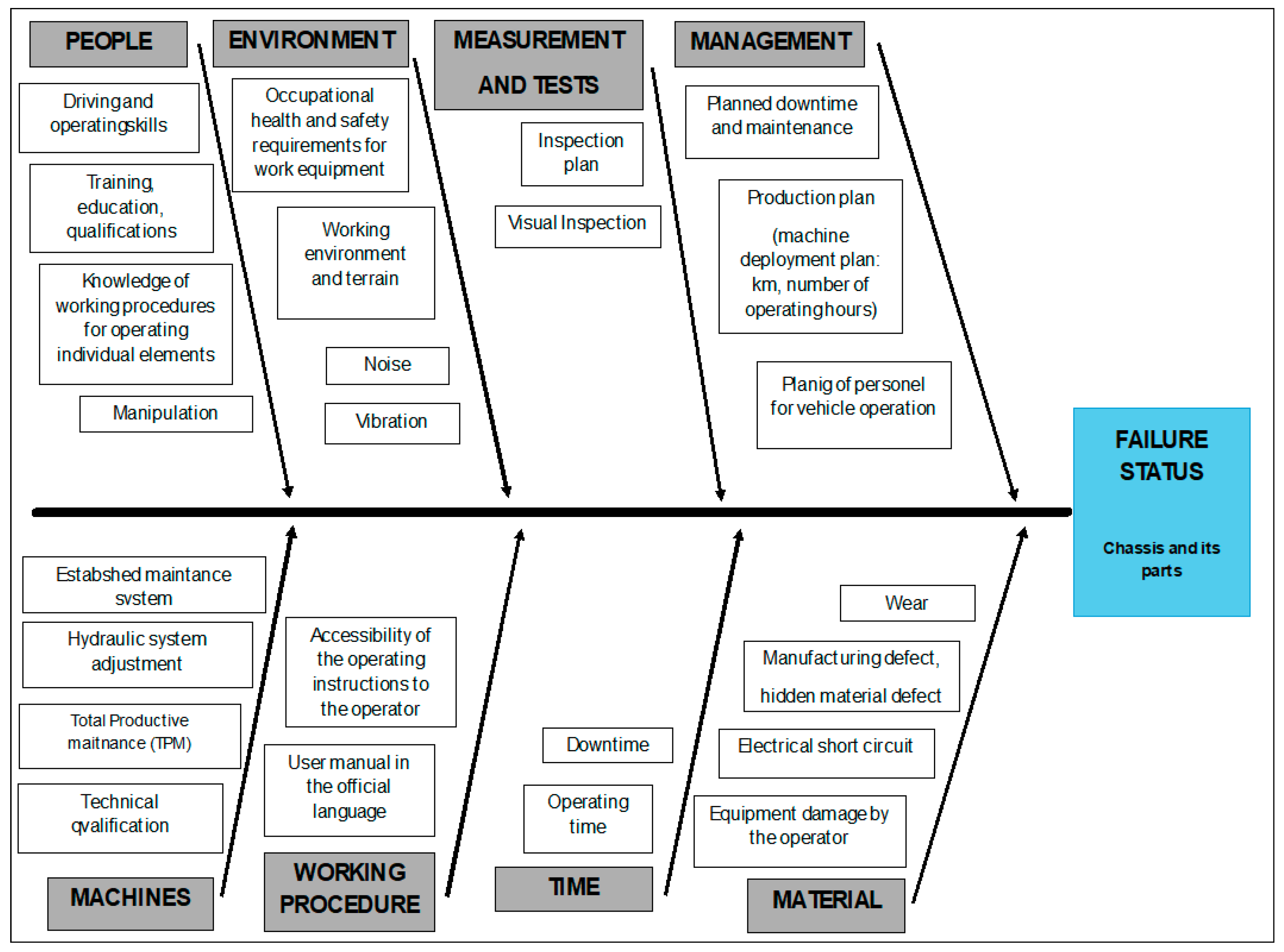

- Chassis (body, frame, shock absorbers, suspension, wheels, tires, axles, steering, brakes);

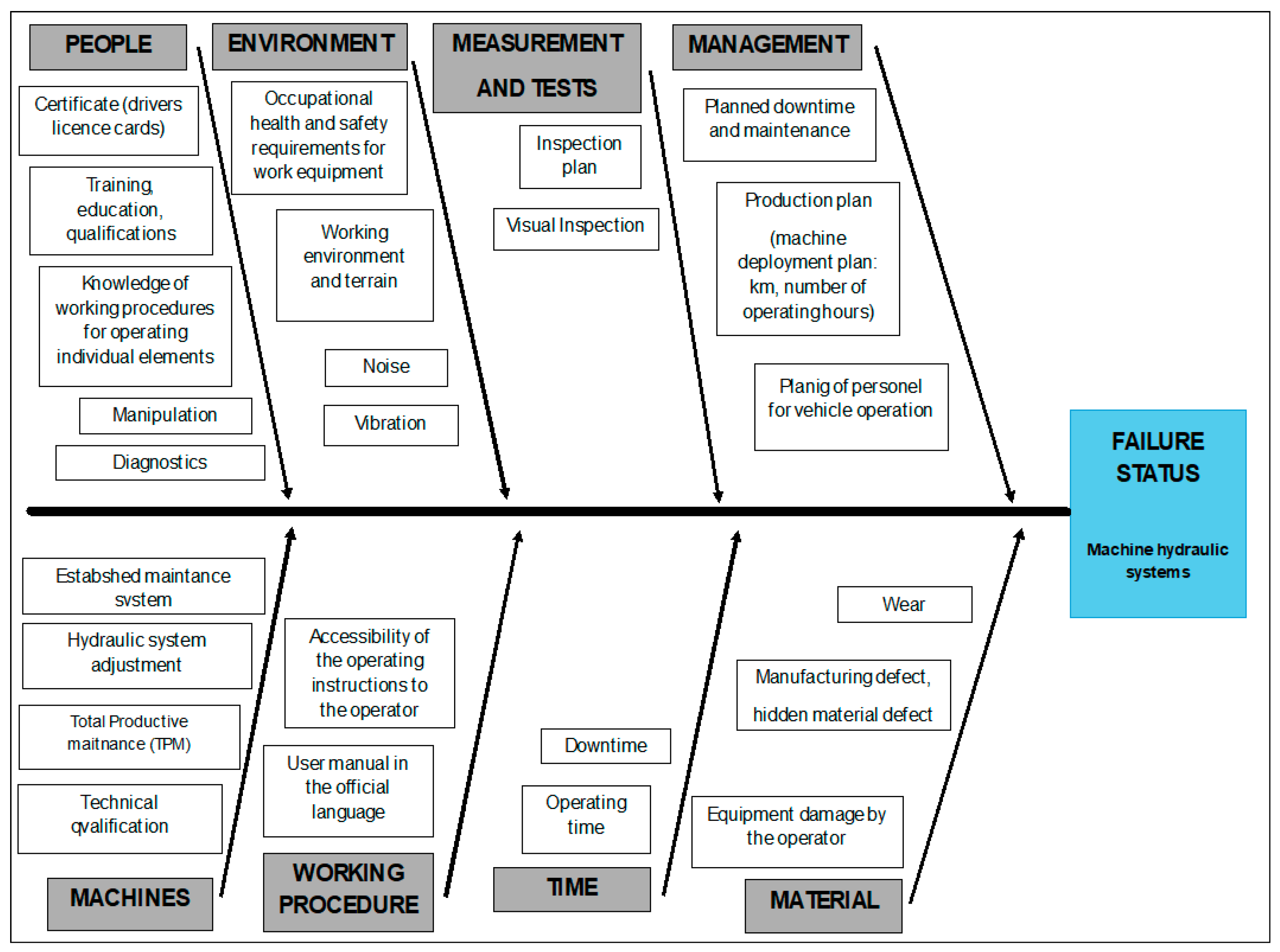

- Machine hydraulic system;

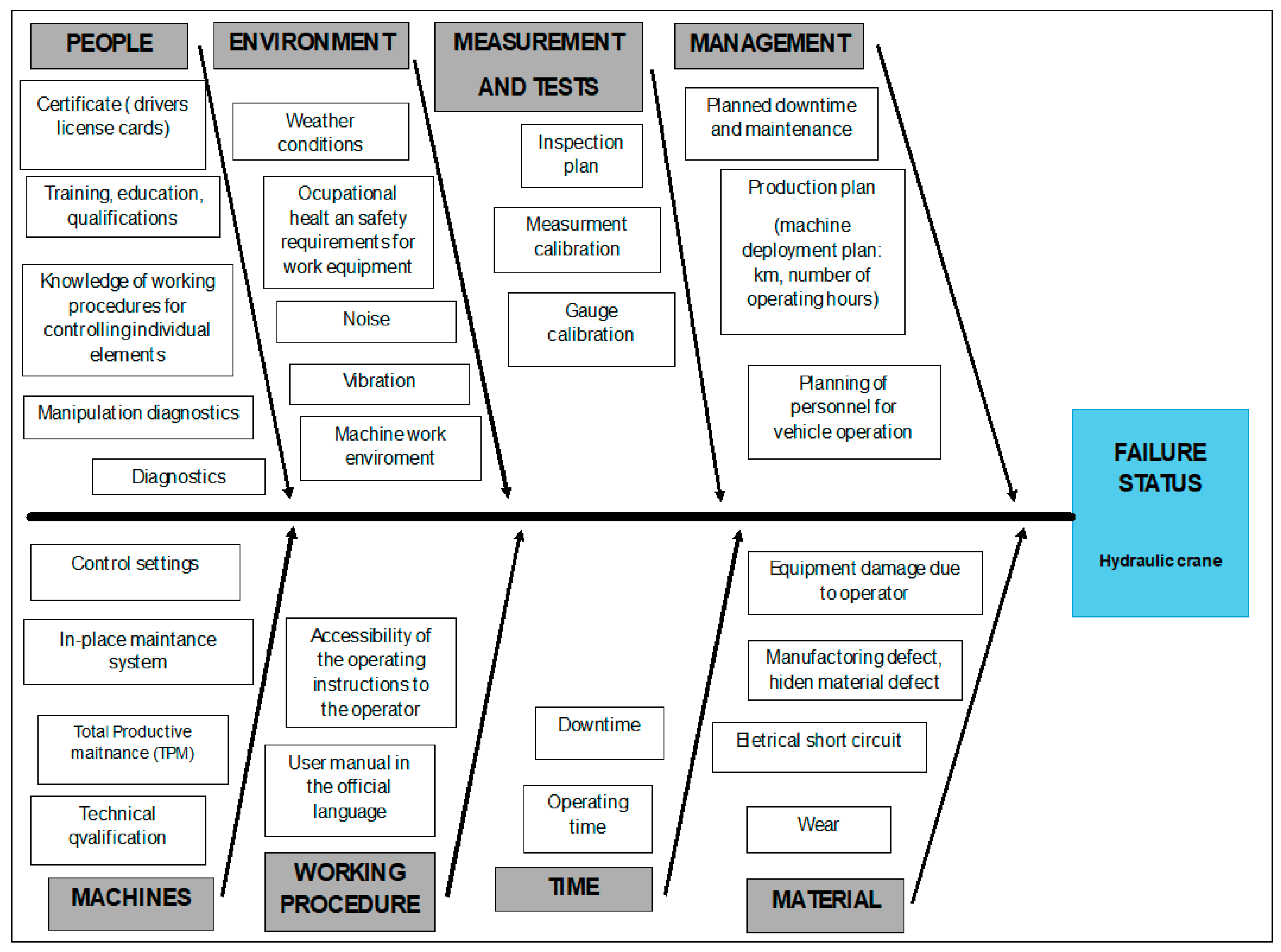

- Hydraulic crane with log grab;

- Trailer/semi-trailer;

- Crossbars.

2.3. Procedure for Using the Ishikawa Diagram

- Problem definition

- 2.

- Drawing the backbone of the diagram and Identification of the main categories of causes

- 3.

- Brainstorming and discussion

- 4.

- Revision and analysis of the diagram

- 5.

- Identification of root causes and action plan

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kováč, J. Technika a Mechanizácia v Lesníctve; (Vysokoškolská Učebnica) 1. vyd; Technická Univerzita vo Zvolene: Zvolen, Slovakia, 2017; 345p, ISBN 978-80-228-3021-8. [Google Scholar]

- Kováčová, K.; Marko, J. Metóda RCM a jej Implementácia pri Údržbe a Prevádzke LKT. In COYOUS 2008: Konference Mladých Vědeckých Pracovníků, 2.4.2008; Česká Zemědělská Univerzita v Praze: Praha, Czech Republic, 2008; pp. 126–134. ISBN 978-80-213-1778-9. [Google Scholar]

- Kováč, J. Teória Mobilných Strojov: Riešené Úlohy a Príklady, 1st ed.; Elektronické Dokumenty (listy, články, Monografie); TU vo Zvolene: Zvolen, Slovakia, 2013; 175p, ISBN 978-80-228-2589-4. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences, Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Migdalski, J.; Bartoszewicz, J.; Bobrowski, D.; Ciechanowicz, K.; Dwilinski, L.; Jazwinski, J.; Kalinowska, H.; Kilinski, A. Probabilistic Methods in Reliability. In Reliability Handbook: Mathematical Basics; Migdalski, J., Ed.; Wema: Warsaw, Poland, 1982; p. 68. [Google Scholar]

- Neruda, J.; Simanov, V.; Klvač, R.; Skoupý, A.; Kadlec, J.; Zemánek, T.; Nevrkla, P. Technika a Technologie v Lesnictví—Díl První; Mendelova Univerzita v Brně: Brno, Czech Republic, 2013; 364p, ISBN 978-80-7375-839-4. [Google Scholar]

- Dal’skii, A.M. Tekhnologicheskoe Obespechenie Nadezhnosti Vysokotochnykh Detalei Mashin; Mashinostroenie: Moskva, Rusko, 1975. [Google Scholar]

- Samoilenko, D.; Marčenko, A.; Cho, H.M. Zlepšenie krútiacich a výkonových charakteristík dieselového motora typu V použitím novej konštrukcie turbodúchadla s variabilnou geometriou (VGT). J. Mech. Sci. Technol. 2017, 31, 5021–5027. [Google Scholar] [CrossRef]

- Al-Duais, F.S.; Mohamed, A.; Jawa, T.M.; Sayed-Ahmed, N. Optimal Periods of Conducting Preventive Maintenance to Reduce Expected Downtime and Its Impact on Improving Reliability. Comput. Intell. Neurosci. 2022, 2022, 7105526. [Google Scholar] [CrossRef] [PubMed]

- Basri, E.I.; Razak, I.H.A.; Ab-Samat, H.; Kamaruddin, S. Preventive maintenance (PM) planning: A review. J. Qual. Maint. Eng. 2017, 23, 114–143. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Zennaro, I.; Florian, E.; Calzavara, M. Age replacement policy in the case of no data: The effect of Weibull parameter estimation. Int. J. Prod. Res. 2020, 58, 5851–5869. [Google Scholar] [CrossRef]

- Gao, W.; Ji, H.; Wang, Y.; Yang, T. A nonlinear preventive maintenance model with an environmental factor-based Weibull distribution. IOP Conf. Ser. Mater. Sci. Eng. 2019, 521, 012009. [Google Scholar] [CrossRef]

- Zhu, L.; Shan, M.; Hwang, B.G. Overview of design for maintainability in building and construction research. J. Perform. Constr. Facil. 2018, 32, 04017116. [Google Scholar] [CrossRef]

- Chew, Y.L.M.; Asmone, A.; Conejos, S. Design for Maintainability: Benchmarks for Quality Buildings; World Scientific Publishing: Singapore, 2018; ISBN 978-981-323-059-0. [Google Scholar] [CrossRef]

- Khalek, I.A.; Chalhoub, J.; Ayer, S.K. Indicators of effective design for maintainability in conceptual design. In AEI 2019: Integrated Building Solutions—The National Agenda; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 309–315. [Google Scholar]

- Stejskal, T. Modely Vzniku Porúch vo Výrobných a Robotických Systémoch. Acta Mech. Slovaca 2008, 12, 601–606. [Google Scholar]

- Moubray, J. Reliability-Focused Maintenance; Butterworth-Heinemann Oxford: Oxford, UK, 1997. [Google Scholar]

- Drożyner, P.A.; Mikołajczak, P. Údržba vozidiel, strojov a zariadení z hľadiska požiadaviek ISO9001. Udržiavať. Reliab. Reliab. 2007, 4, 55–598. [Google Scholar]

- Biban, L.K.; Dhounchak, D.; Shakti. 8D Methodology: From Concept to Application Across Manufacturing Indus tries. Int. J. Sci. Res. Sci. Eng. Technol. 2017, 3, 558–563. [Google Scholar]

- Müller, M. Maintenance Success Control (Key Figures and Controlling in Maintenance); Eksploatacja i Niezawodność–Maintenance and Reliability. No. 4/2007; Polish Maintenance Society: Warsaw, Poland, 2007. [Google Scholar]

- American Society for Quality, Fishbone Diagram. Available online: https://asq.org/quality-resources/fishbone (accessed on 2 June 2025).

- Ishikawa, K.; Loftus, J.H. (Eds.) Introduction to Quality Control; 3A Corporation: Tokyo, Japan, 1990. [Google Scholar]

- Dai, W.; Sun, J.; Chi, Y.; Lu, Z.; Xu, D.; Jiang, N. Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology. Appl. Sci. 2019, 9, 2786. [Google Scholar] [CrossRef]

- STN 01 0606:1980; Spoľahlivosť v Technike, Postup voľby Nomenklatúry Normovaných Ukazovateľov Spoľahlivosti. UNMS SR: Bratislava, Slovakia, 1980.

- Pacaiova, H.; Izarikova, G. Base Principles and Practices for Implementation of Total Productive Maintenance in Automotive Industry. Qual. Innov. Prosper. 2019, 23, 45–59. [Google Scholar] [CrossRef]

- Manshin, Y.P.; Manshina, E.Y. Problems of Parts Reliability in the Design of Mechanical System. State Tech. Univ. Ser. Mech. Eng. 2019, 5, 56. [Google Scholar] [CrossRef]

- Paraschivescu, A.O. Managementul Calitatii; Tehnopress Publishing: Iasi, Romania, 2006; pp. 155–156. [Google Scholar]

| Vehicle | Product Class | Operational Regime | Reliability Group | Limitation of Usage Time |

|---|---|---|---|---|

| IVECO | Code 3: Refurbished products | General: The periods of activity and waiting alternate randomly. The regularity of the alternation cannot be determined either because of the operating conditions or because the operating conditions vary for different specimens of the same type of product | II: Material damage from unfulfilled task or downtime, equal to the value of the product | Planned: The use of most objects of a given type is interrupted (the object is decommissioned, comes in for repair, or is written off) at a certain operating time or after a specified period of time has passed following the task’s completion. Forced: The use of all objects of a given type is interrupted in connection with a failure of the object or if the assessment of the technical condition indicates that a failure will soon occur, or that the object has reached a limit state, or everything indicates that the object is not fulfilling certain tasks. |

| SCANIA | Code 3: Refurbished products | General: The periods of activity and waiting alternate randomly. The regularity of the alternation cannot be determined either because of the operating conditions or because the operating conditions vary for different specimens of the same type of product | II: Material damage from unfulfilled task or downtime, equal to the value of the product | Planned: The use of most objects of the given type is interrupted (the object is decommissioned or comes for repair or is written off) at a certain operating time or after a certain period of time has passed after the task has been completed. Forced: The use of all objects of a given type is interrupted in connection with a failure of the object or if the assessment of the technical condition indicates that a failure will soon occur, or that the object has reached a limit state, or everything indicates that the object is not fulfilling certain tasks. |

| TATRA | Code 3: Refurbished products | General: the periods of activity and waiting alternate randomly. The regularity of the alternation cannot be determined either because of the operating conditions or because the operating conditions vary for different specimens of the same type of product | II: Material damage from unfulfilled task or downtime, equal to the value of the product | Planned: The use of most objects of a given type is interrupted (the object is decommissioned or comes for repair or is written off) at a certain operating time or after a certain period of time has passed after the task has been completed. Forced: The use of all objects of a given type is interrupted in connection with a failure of the object or if the assessment of the technical condition indicates that a failure will soon occur, or that the object has reached a limit state, or everything indicates that the object is not fulfilling certain tasks. |

| Trailers, semi-trailers | Code 3: Refurbished products | Cyclical: Periods of activity and waiting alternate with constant cyclicality | III: Material damage from unfulfilled task or downtime, equal to the value of the product | Planned: The use of most objects of a given type is interrupted (the object is decommissioned or comes for repair or is written off) at a certain operating time or after a certain period of time has passed after the task has been completed. Forced: The use of all objects of a given type is interrupted in connection with a failure of the object or if the assessment of the technical condition indicates that a failure will soon occur, or that the object has reached a limit state, or everything indicates that the object is not fulfilling certain tasks. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kováč, J.; Kuvik, T.; Mancel, V.; Krilek, J. Analysis of Failure States of Transportation Vehicles Using the Ishikawa Diagram: A Case Study. Appl. Sci. 2025, 15, 10221. https://doi.org/10.3390/app151810221

Kováč J, Kuvik T, Mancel V, Krilek J. Analysis of Failure States of Transportation Vehicles Using the Ishikawa Diagram: A Case Study. Applied Sciences. 2025; 15(18):10221. https://doi.org/10.3390/app151810221

Chicago/Turabian StyleKováč, Ján, Tomáš Kuvik, Vladimír Mancel, and Jozef Krilek. 2025. "Analysis of Failure States of Transportation Vehicles Using the Ishikawa Diagram: A Case Study" Applied Sciences 15, no. 18: 10221. https://doi.org/10.3390/app151810221

APA StyleKováč, J., Kuvik, T., Mancel, V., & Krilek, J. (2025). Analysis of Failure States of Transportation Vehicles Using the Ishikawa Diagram: A Case Study. Applied Sciences, 15(18), 10221. https://doi.org/10.3390/app151810221