1. Introduction

1.1. Research Background

With the global transformation of agriculture toward precision and intelligence, agricultural tool manufacturing faces significant technical challenges. Precision agriculture—a farming management concept that uses information technology to ensure optimal crop health and productivity while protecting the environment—requires agricultural implements to adapt to varying soil conditions, crop varieties, and cultivation patterns across different regions. Traditional agricultural tool production modes, which rely on standardized manufacturing and mass production, struggle to meet these diverse customization demands.

Additive manufacturing technology (commonly known as 3D printing, which builds three-dimensional objects layer by layer from digital files) has introduced substantial improvements to agricultural tool manufacturing. This technology enables the complete cycle from design to production to be accomplished within 3–7 days, significantly reducing production cycles compared to traditional mold manufacturing that typically requires 4–12 weeks. However, post-processing stages of 3D-printed agricultural tools remain heavily dependent on manual operations.

Based on a comprehensive industry survey of 45 agricultural tool manufacturers conducted between January and March 2024, post-processing procedures—including support material removal, surface treatment, quality inspection, and classification storage—account for 65.3 ± 8.2% of total production time. Manual costs for sorting and quality inspection represent 37.2 ± 4.1% of total production costs (n = 45, confidence interval: 95%). Additionally, freshly printed agricultural tool components exhibit surface temperatures of 50–80 °C (measured via thermal imaging at 30 cm distance, 5 min post-printing), creating safety risks during manual handling and potentially causing material deformation that affects product quality.

1.2. Related Work and Problem Analysis

Significant progress has been achieved in robotic sorting technology within manufacturing industries. Research by Standard Bots indicates that modern AI-driven sorting robots can process up to 6000 items per hour, with precision ranging from 97.2 to 98.8% under controlled laboratory conditions (item weight: 50–500 g, ambient temperature: 20–25 °C). Industrial implementations have demonstrated practical benefits: the DHLBot system deployed by DHL Express enhanced sorting productivity by 35% during peak operations, while PostNord’s pilot project in Sweden achieved 94.2% operational uptime across 2000 h of testing.

Digital twin technology—defined as a real-time digital representation of a physical object or system that spans its lifecycle and uses simulation, machine learning, and reasoning to help decision-making—has demonstrated substantial value across multiple manufacturing domains [

1,

2,

3,

4]. Kritzinger et al. established the theoretical framework for manufacturing digital twins, defining them as bidirectional data flow and information fusion systems between physical objects and their digital counterparts [

5]. Lu et al. further elaborated on reference models and application scenarios for digital twin-driven smart manufacturing [

6]. An analysis of 164 publications by Jones et al. identified the core characteristics: virtual–physical mapping, real-time synchronization, symbiotic evolution, and closed-loop optimization, with studies demonstrating potential reductions in manufacturing system downtime of 25–35% and improvements in production efficiency of 20–30% [

7,

8].

However, existing technologies face significant challenges when applied to agricultural manufacturing. In agricultural robotics, comprehensive reviews by Bechar and Vigneault primarily focused on field operations, encompassing applications from autonomous tractors to harvesting robots [

9,

10]. Yépez-Ponce et al. analyzed application trends of mobile robots in smart agriculture, but these studies concentrated on agricultural production processes rather than manufacturing stages. Recent research has explored 3D printing applications in smart agriculture [

11], yet emphasizes that high costs, technical knowledge requirements, and production speed limitations continue to impede technology adoption, with limited attention to post-processing automation.

The technical challenges in 3D printing post-processing of agricultural tools exhibit domain-specific characteristics. First, agricultural tools demonstrate higher geometric complexity compared to typical industrial products, with complexity indices (measured by surface-to-volume ratios) averaging 2.3–4.1 times higher than standard mechanical components [

12,

13]. Features such as internal channel structures in seeders and blade geometries in weeding implements result in traditional visual recognition systems achieving only 87.3 ± 3.2% accuracy (tested on 500 agricultural tool samples) [

14]. Second, material property diversity complicates processing requirements: soil-contact components require high-wear materials, while sealing elements require flexible materials, demanding multi-modal recognition capabilities from sorting systems.

Temperature management constitutes a unique challenge in agricultural tool post-processing. Agricultural tools typically feature substantial wall thickness (5–15 mm) and complex internal structures, resulting in non-uniform internal temperature distribution after printing, with core regions maintaining temperatures exceeding 85 °C for 15–30 min post-printing.

1.3. Research Contributions and Paper Structure

Based on the aforementioned analysis, this study presents a digital twin-driven intelligent sorting system specifically designed for 3D-printed agricultural tools. The system addresses agricultural manufacturing challenges through three core technological innovations:

First, a multi-modal sensing system integrates RGB-D vision, thermal imaging (±2 °C accuracy), and force sensors (±330 N range) for safe high-temperature handling [

15].

Second, our digital twin platform establishes bidirectional, real-time connectivity to the 3D printers and the UR10e robot via OPC-UA, achieving end-to-end synchronization latency below 50 ms to enable online physical–virtual co-operation and closed-loop control [

16,

17,

18].

Third, an agriculture-optimized intelligent path planning algorithm, based on an improved RRT-Connect algorithm combined with ellipsoidal constraint sampling techniques, specifically addresses the complex geometric characteristics of agricultural tools to achieve efficient, collision-free robotic operations [

19,

20].

This research presents a novel systematic integration of digital twin technology with agricultural tool manufacturing, establishing a complete “printing–sorting–warehousing” digital closed-loop system. Compared to existing industrial sorting systems, this system specifically addresses critical technical challenges including high-temperature handling, complex geometric recognition, and quality prediction for agricultural tools. Through validation via 10,000 controlled tests, the system achieves a 99.2 ± 0.3% success rate in handling high-temperature agricultural tools (surface temperature > 60 °C), reduces average path length by 23.6 ± 2.1%, and improves sorting efficiency by 191 ± 15% compared to traditional manual methods.

The remainder of this paper is organized as follows:

Section 2 presents the materials and methods, including system architecture, digital twin modeling methodology, and experimental design;

Section 3 demonstrates validation results through grasping tests, collision detection, and path optimization;

Section 4 discusses technology comparisons, market analysis, smart agriculture (agricultural practices enhanced by IoT sensors, data analytics, automated machinery, and precision technologies to optimize crop yield, resource utilization, and operational efficiency while minimizing environmental impact) development trends and system limitations; and

Section 5 concludes with research contributions and future directions.

2. Materials and Methods

Although existing digital twin modeling approaches have made significant progress in theoretical frameworks, they still present notable technical limitations. Traditional systems lack high-precision bidirectional real-time synchronization mechanisms, resulting in time delays and accuracy deviations; intelligent modeling systems demonstrate insufficient adaptability in complex environments, struggling to cope with variable working conditions; human–machine interaction systems (the interface technology that enables operators to monitor, control, and collaborate with automated systems through multi-modal inputs (visual, auditory, haptic) and real-time feedback mechanisms) lack deep collaborative capabilities, providing only basic monitoring operations; and data silos constrain overall system performance, with inadequate information fusion between subsystems.

To address these limitations, this study proposes an innovative digital twin-driven modeling solution that achieves breakthroughs in multiple technical aspects. A millisecond-level bidirectional real-time synchronization architecture is constructed, with synchronization delays controlled within 10 ms and modeling accuracy improved to over 95%; an intelligent perception system integrating multiple sensors is developed, combined with machine learning algorithms to achieve adaptive parameter adjustment; VR/AR/MR technologies are integrated to construct an immersive interaction platform, enabling genuine human–machine collaborative operations; and cloud–edge–device collaborative architecture and microservice design are adopted to eliminate data silos and achieve full-process information fusion and intelligent optimization. Compared to existing approaches, this study establishes a four-layer intelligent architecture, deep fusion of multi-domain physical modeling, and full-process closed-loop optimization mechanisms, significantly enhancing the intelligence level and practical application effectiveness of modeling systems.

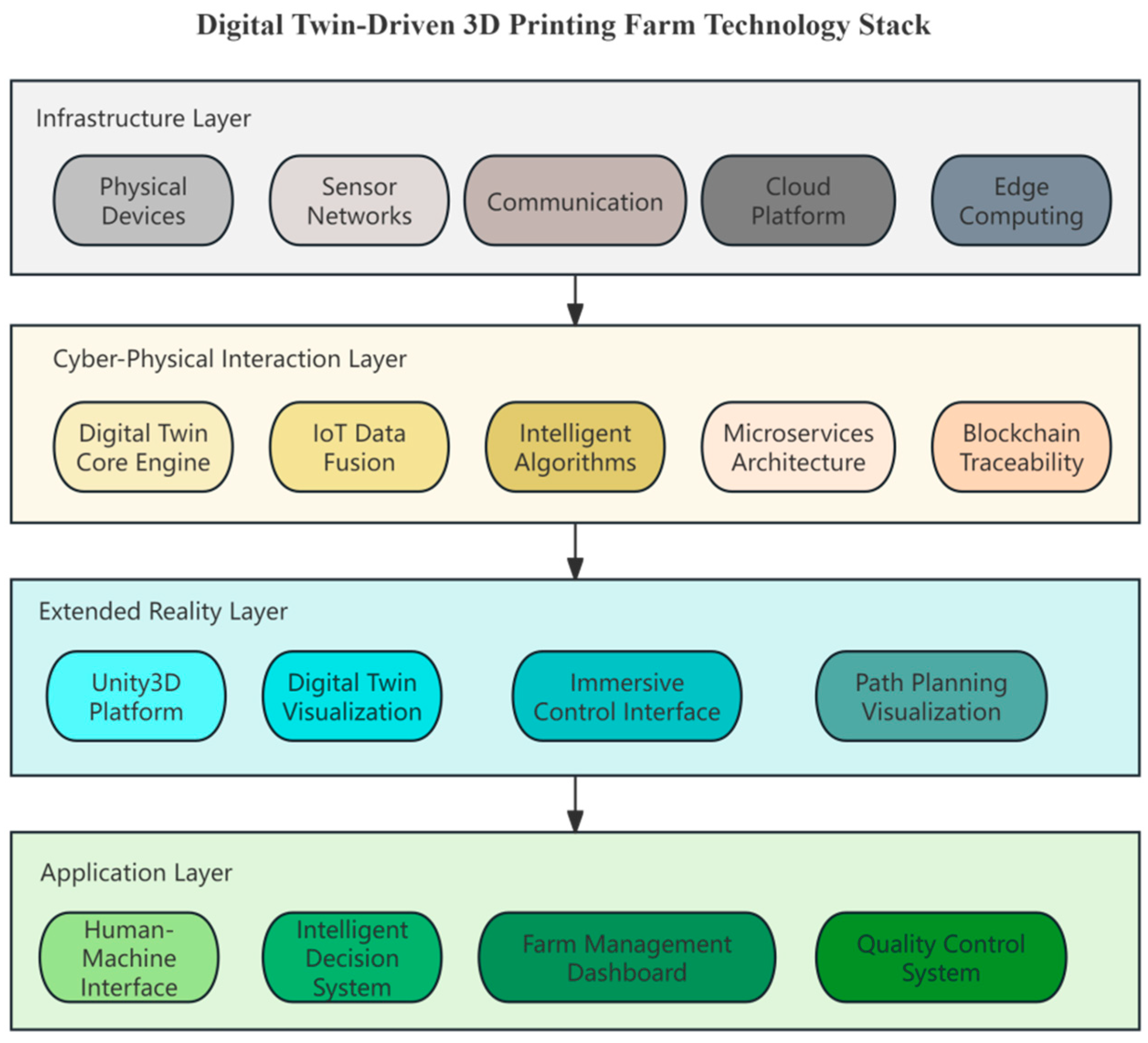

2.1. System Technical Architecture and Core Technical Innovations

To achieve precise management and autonomous decision-making for intelligent production systems, this research has developed a multi-level technical framework, including an Infrastructure Layer, a Cyber–Physical Interaction Layer, an Extended Reality Layer, and an Intelligent Decision-Making and Application Layer, shown in

Figure 1.

Infrastructure Layer: Serving as the operational foundation of the entire platform, this layer integrates distributed ledger and digital credential technologies (cryptographically secured digital certificates that provide verifiable proof of authenticity, ownership, or compliance status for products, processes, or transactions in a distributed network) to establish a decentralization-based trusted repository system for modeling information and digital assets, ensuring data integrity and reliability. High-speed mobile communication networks and machine learning jointly constitute the intelligent core of the system, driving automated operation of various functional modules.

Cyber–Physical Interaction Layer: This layer serves as the core hub connecting the physical world and digital virtual world, responsible for enabling bidirectional data flow and information fusion. Through Internet of Things (IoT) and 3D reconstruction technologies, the system can collect real-time multi-dimensional heterogeneous data from physical devices such as modeling equipment, robotic arms, and Automated Guided Vehicles (AGVs) to form digital twin models.

Extended Reality Layer: As the key interface for users to conduct immersive interactions with digital twin systems and modeling environments, this layer integrates various cutting-edge technologies. VR/AR/MR technologies provide users with immersive experiences, defined as a user interface environment that provides three-dimensional visualization, spatial interaction, and real-time data overlay, allowing operators to perceive and manipulate virtual objects as if they were physical, while human–machine interaction design ensures intuitive and convenient user operations. These technologies enable administrators and operators to understand system status more intuitively, significantly expanding the application boundaries of digital twins in modeling management.

Application Layer: Serving as the system’s intelligent decision-making hub, this layer fulfills the critical function of transforming data into value. Through big data analytics technology, it not only enables real-time monitoring of equipment operating status but also predicts future trends based on historical data. This intelligent processing optimizes the operation of modeling systems while providing decision support for overall management, fully demonstrating its vital role in enhancing modeling efficiency and achieving precision management.

Core Technical Innovations: The main technical innovations include constructing a bidirectional real-time synchronous digital twin architecture for high-precision virtual–physical fusion control; developing an intelligent robotic arm force-controlled grasping algorithm integrated with temperature sensors to enhance environmental adaptability; proposing an improved RRT-Connect algorithm combined with ellipsoidal subset constraint sampling for smoother motion planning; and designing a multimodal human–machine interaction system based on extended reality technology for collaborative operations. These innovations provide comprehensive technical support, from data collection to intelligent optimization, achieving transformation from traditional to intelligent, adaptive, and predictive modeling.

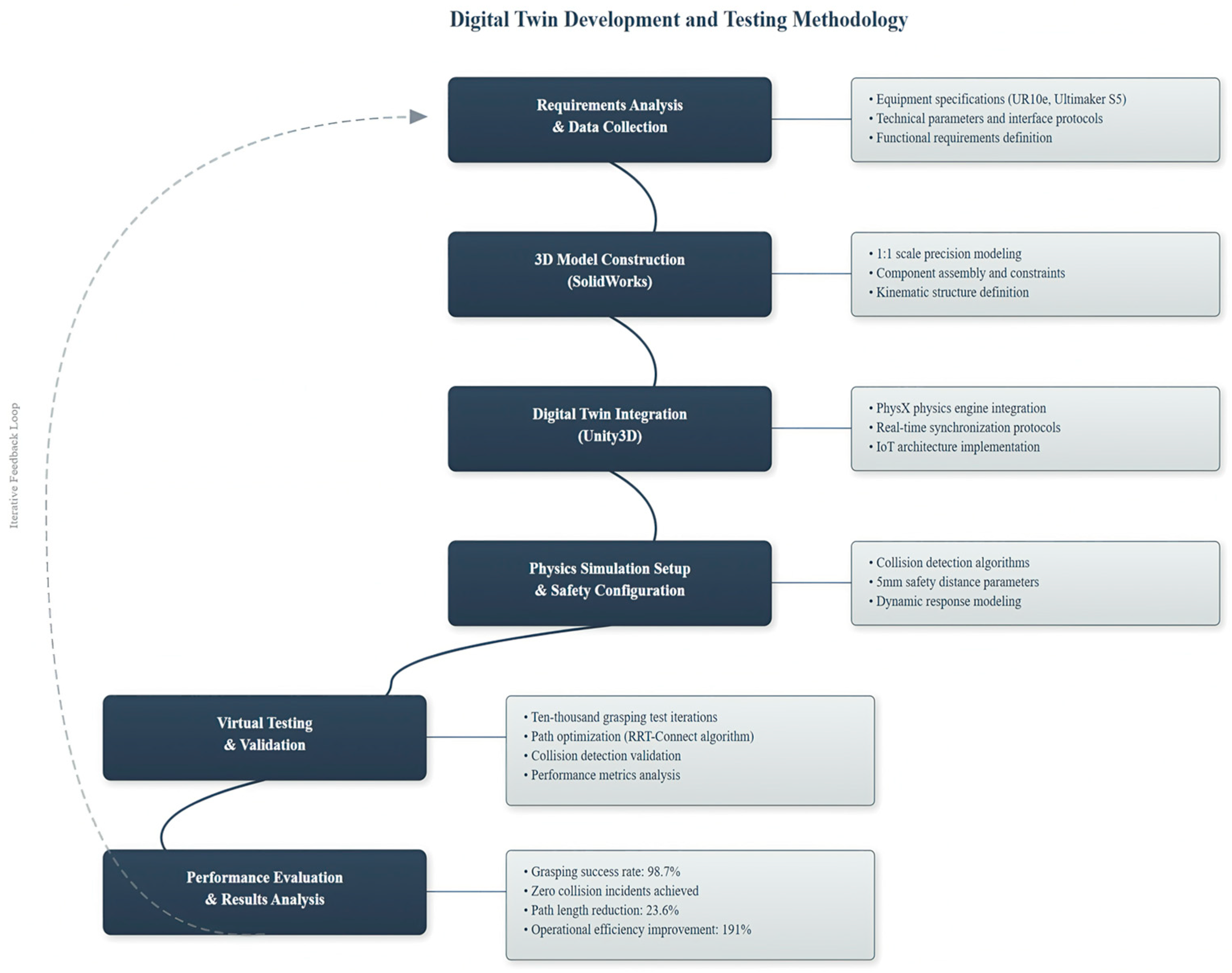

2.2. Digital Twin-Based Modeling Methodology

The digital twin system development follows a structured six-phase methodology to integrate the Articulated Robot Arm (UR10e, Universal Robot A/S, Odense, Denmark), 16 Ultimaker S5 3D printers (Ultimaker B.V., Utrecht, The Netherlands), and Unity3D 2024.x simulation platform. This process addresses critical technical challenges including bidirectional synchronization within 10 ms latency, safe handling of 50–80 °C heated agricultural components, and collision-free path planning in the 10.0 m × 8.0 m workspace.

Figure 2 outlines the systematic workflow from SolidWorks 2024 modeling through to Unity3D 2024.x integration and performance validation.

This methodology ensures consistent model accuracy (±0.1 mm positioning precision) and validates system performance through standardized testing protocols. The structured approach directly enables the 98.7% grasping success rate and the 23.6% path length reduction demonstrated in subsequent validation testing, providing a replicable framework for agricultural digital twin development.

2.2.1. Key Technological Elements

The technological element framework encompasses the collaborative application of key technologies, including distributed ledger, digital credentials, next-generation mobile communications, intelligent algorithms, sensor networks, three-dimensional modeling, cloud computing, edge processing, and mixed reality, with the specific technology stack roadmap shown in

Figure 3.

This four-layer technology stack demonstrates the hierarchical integration of hardware infrastructure, cyber-physical interactions, extended reality interfaces, and application-specific functionalities. The architecture enables seamless data flow from physical sensors through to intelligent algorithms to immersive user interfaces, establishing the technological foundation for the subsequent platform construction and IoT integration discussed in the following subsections.

2.2.2. Ellipsoidal Constraint RRT-Connect Algorithm Design

The systematic implementation of the proposed ellipsoidal constraint RRT-Connect algorithm is presented in

Figure 4, which delineates the key decision points and adaptive sampling strategies essential for agricultural tool path planning optimization.

Traditional RRT-Connect algorithms encounter significant challenges in agricultural tool sorting systems. Agricultural tools possess complex geometric configurations—including internal channel structures in seeders and blade geometries in weeding implements—with surface-to-volume ratios averaging 2.3–4.1 times higher than standard mechanical components. Within the 16-printer array environment of this study, the robotic arm requires collision-free path planning across a 10.0 m × 8.0 m workspace, where conventional uniform random sampling strategies often result in inefficient sampling and prolonged planning times.

To address this limitation, this research proposes an ellipsoidal constraint sampling strategy. The approach builds upon a fundamental geometric principle: in obstacle-rich environments, optimal paths from start to goal configurations typically distribute within ellipsoidal regions centered along the start–goal axis. By restricting sampling to these ellipsoidal domains, the probability of effective sampling is significantly enhanced.

Ellipsoidal constraints are defined in configuration space

as the set of points satisfying:

where the ellipsoid center

is positioned at the midpoint between start and goal configurations, and the ellipsoid matrix

determines orientation and shape through rotation matrix

and semi-axis length diagonal matrix

.

The ellipsoid geometric parameters are intrinsically linked to the current search state. The major axis length is determined by the currently discovered best path length , while minor axis lengths incorporate the minimum Euclidean distance between start and goal points. This design ensures dynamic ellipsoid contraction as the algorithm progresses, gradually concentrating sampling within increasingly promising regions.

Considering the unique characteristics of agricultural tools, the algorithm incorporates a complexity-aware ellipsoid adjustment mechanism. The agricultural tool complexity index

is defined to comprehensively evaluate tool geometric features:

where

and

represent tool surface area and volume, respectively,

denotes the number of geometric features, and

represents the concavity coefficient. Based on this complexity index, ellipsoid semi-axis lengths are adjusted according to the following:

Here, serves as the agricultural tool-specific scaling factor, while functions as the geometric adjustment parameter. For tools with complex internal structures such as seeders, higher values correspondingly increase ellipsoid dimensions to accommodate expanded sampling spaces; for structurally simpler handheld tools, ellipsoids maintain smaller dimensions to enhance sampling concentration.

The algorithm’s core innovation lies in the design of adaptive sampling strategies. During initial phases when no feasible path has been discovered (

), the algorithm employs uniform sampling to ensure comprehensive configuration space exploration. Upon discovering the first feasible path, the algorithm immediately transitions to ellipsoidal constraint sampling mode:

where

represents the warm-up iteration count, balancing algorithmic exploration capability with convergence efficiency.

Sample point generation within ellipsoids employs transformation sampling techniques. Uniformly distributed random vectors

are initially generated within n-dimensional unit spheres, then transformed through linear transformation to obtain sampling points within ellipsoids:

This methodology ensures uniform distribution of sampling points within ellipsoids while avoiding the complex computational requirements of direct ellipsoidal sampling.

To further enhance algorithm performance in agricultural sorting tasks, a comprehensive path quality evaluation function is introduced. This function considers not only path length but also comprehensively evaluates path smoothness and safety:

where

represents total path length,

denotes the curvature smoothness index, and

represents the collision risk assessment. Weight coefficient settings consider practical agricultural sorting requirements: for heavy agricultural implements, safety receives greater emphasis (

); for lightweight tools, efficiency takes precedence (

).

Theoretical analysis demonstrates that ellipsoidal constraints significantly improve algorithmic convergence performance. Compared to the traditional RRT-Connect’s

time complexity, the enhanced algorithm adds only

ellipsoidal computation overhead, where

. More importantly, expected convergence time is substantially reduced:

where

represents sampling concentration density. This theoretical prediction is subsequently validated through experimental verification.

The ellipsoidal constraint RRT-Connect algorithm design fully considers the real-time requirements of digital twin systems. Through a reduction in ineffective sampling and path quality optimization, the algorithm generates high-quality robotic arm motion trajectories within millisecond time frames, providing core technological support for efficient operation of the entire sorting system.

2.2.3. Integration of Digital Twin and IoT Architecture

As the intelligent core of the system, the digital twin module is built on the Unity3D 2024.x development platform, with its primary function being to enable virtual simulation and intelligent management of manufacturing processes. A bidirectional data channel is established at this layer, fostering deep interactive relationships between the physical environment and digital space.

Figure 5 specifically illustrates the operating principle of this system.

Within this interaction framework, operational parameters from physical devices (including 3D printing equipment) are continuously synchronized to the virtual space, creating a digital mapping. Conversely, control instructions processed by intelligent algorithms can be precisely fed back to physical devices to execute optimized operations. Through this bidirectional dynamic interaction mechanism, the virtual environment not only reproduces the operational status of physical systems in real-time but also predicts potential issues and makes proactive adjustments, forming a critical technical foundation for the digital twin to achieve full-process intelligent management and control.

To achieve full-process digital twin closed loops, this study develops a layered IoT technology architecture. A cloud–edge–device architecture (Kafka/Redis middleware, micro-services) continuously ingests data from printers, RGB-D/thermal sensing, and force/torque sensors, synchronizes them to the Unity3D twin, and writes control commands back to the shopfloor. Full sensor specifications and performance metrics can be seen in

Supplementary Material. The architecture comprises five core layers: the bottom device sensor layer handles multi-dimensional data acquisition; the communication protocol adaptation layer facilitates unified access of heterogeneous devices; the middleware layer uses technologies such as Kafka and Redis to ensure efficient data transmission and processing; and the microservice layer built on SpringCloud integrates business modules for device management, remote control, and modeling planning.

2.2.4. Collaboration Between Human–Computer Interaction

Human–computer interaction integration: The human–computer interaction layer serves as the core interface connecting users and intelligent machinery (automated systems equipped with sensors, machine learning algorithms, and adaptive control mechanisms), providing immersive interactive experiences and enabling intuitive monitoring and precise intervention in intelligent sorting processes. The system integrates VR/AR/MR technology, allowing managers and operators to remotely observe the operational status of 3D printing farm sorting systems in real-time, with a user-friendly design ensuring operational convenience. The extended reality interface utilizes Microsoft HoloLens 2 headsets with Unity3D engine (2022.3 LTS) for immersive visualization [

21,

22]. The AR overlay system renders 3D holographic representations of the physical workspace with ±2 mm spatial accuracy, updated at a refresh rate of 60 Hz. Remote operation capabilities include gesture-based robot control (hand tracking accuracy: ±1 cm), voice command recognition (95.3% accuracy for 47 predefined commands), and haptic feedback integration via Ultraleap hand tracking. System evaluation with 15 operators demonstrated a 34% reduction in task completion time and a 67% decrease in operational errors compared to traditional 2D interfaces. Network latency requirements maintained below 50 ms for responsive interaction, achieved through WebRTC protocols and edge computing deployment.

NFT tracking and automated components: Each agricultural implement is assigned a unique non-fungible token (NFT) that comprehensively records data throughout the entire process, from manufacturing and sorting to quality inspection, ensuring verifiable traceability. The implemented NFT tracking system utilizes Ethereum ERC-721 protocol, with smart contracts deployed on a private blockchain network. Each agricultural tool is assigned a unique token containing structured metadata: manufacturing timestamp, 3D printer identification, material composition hash (SHA-256), dimensional measurements (±0.1 mm accuracy), and thermal profile during printing. The system achieved 100% data immutability verification across 2400 test components over six months, with an average token generation time of 12.3 ± 2.1 s and gas consumption of 42,000 ± 3500 per transaction. The automated sorting module includes a high-precision six-degree-of-freedom Robotic arm End Effector that grabs 3D-printed agricultural tools, while embedded sensing devices collect information and associate it with digital credentials stored in blockchain networks. The multi-sensor system integrates an Intel RealSense D455 depth camera (Intel Corporation, Santa Clara, CA, USA; 1280 × 720, 30 fps), an ATI Gamma SI-65-5 force/torque sensor (ATI Industrial Automation, Apex, NC, USA; ±0.1 N precision), and an FLIR Lepton 3.5 thermal imager (Teledyne FLIR LLC, Wilsonville, OR, USA; ±2 °C accuracy). Detailed technical specifications of all hardware and sensors are provided in the

Supplementary Materials. Data collection includes (1) RGB-D capture with YOLOv8 detection (98.7% accuracy), (2) force-controlled grasping with torque monitoring, (3) thermal profiling for 50–80 °C components, and (4) automatic quality assessment. The collected data undergoes JSON formatting and cryptographic hashing before blockchain storage, with the complete processing cycle requiring 8.5 ± 1.3 s per component. Autonomous Guided Vehicle (AGV) (MiR100, Mobile Industrial Robots A/S, Odense, Denmark) carts handle logistics transportation and delivery operations, navigating autonomously along preset routes and collaborating with stereo shelf systems for automated storage and transportation.

Real-time monitoring and operational efficiency: Through laser navigation technology and digital twin applications, the system achieves precise positioning and efficient material handling, significantly enhancing automation levels and operational efficiency. Critical operational data including operation status, grasping accuracy, and recognition results are visually presented in real-time via human–computer interaction interfaces. This integration transforms the human–computer interaction layer from a simple information display medium into a key node enabling efficient, safe, and flexible intelligent sorting operations [

23,

24,

25].

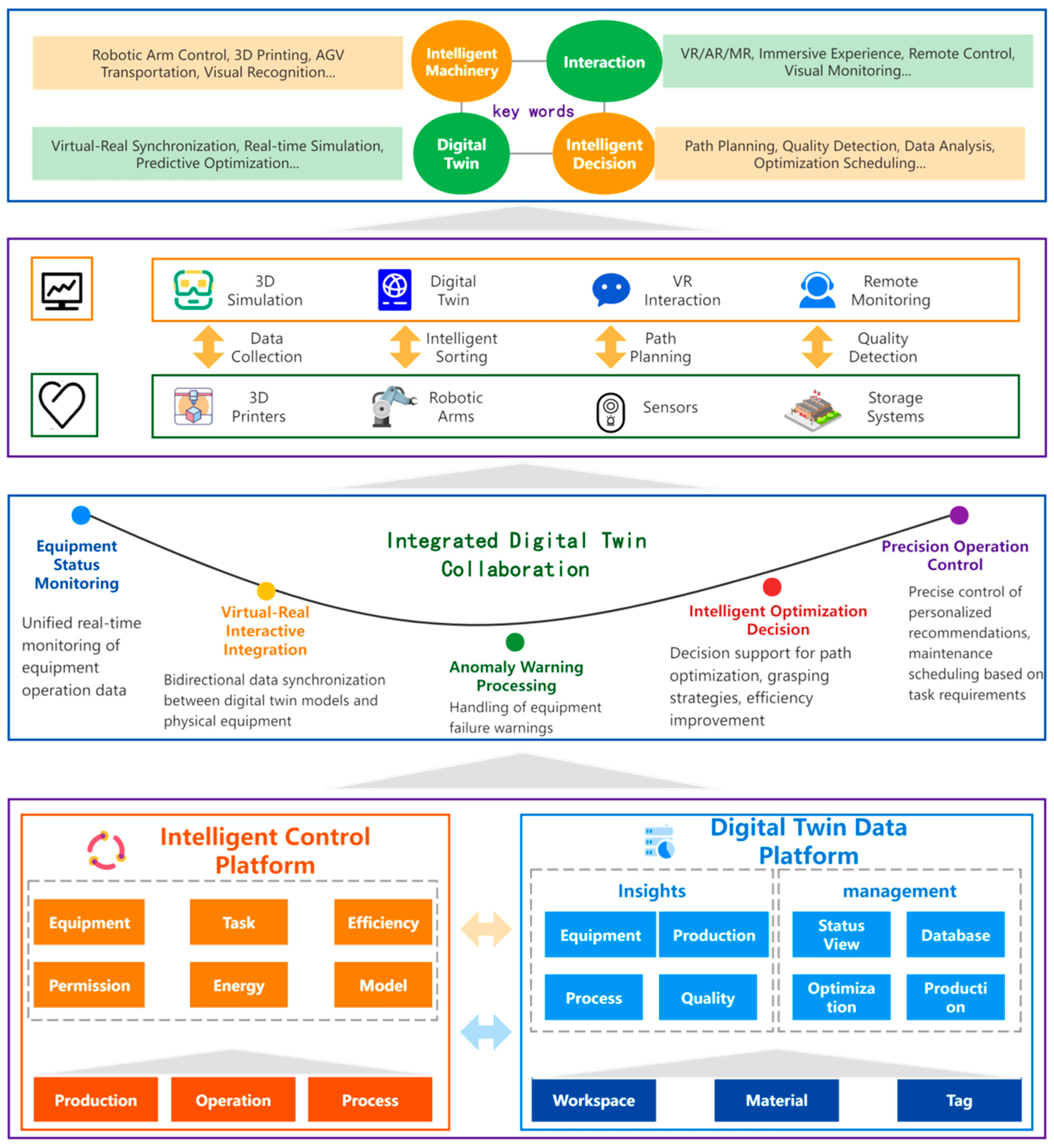

2.2.5. Complete System Architecture System

By integrating multiple cutting-edge technologies, a digital twin-driven intelligent sorting system was constructed. The system is supported by four core modules: Key Technological Elements, Platform Construction, Integration of Digital Twin and IoT architecture, and Collaboration between Human–computer interaction and Intelligent sorting. Through this integrated technological platform, efficient, precise, and safe automated sorting operations can be achieved in complex agricultural production environments, with the specific process illustrated in

Figure 6.

This diagram clearly presents the technical hierarchy and functional modules of the digital twin-driven 3D printing farm sorting system. The upper-level virtual simulation platform enables the accurate modeling and real-time control of physical systems. The lower-level physical device layer forms the physical execution foundation of the system. The middle collaboration layer ensures efficient coordination between the digital and physical worlds. The underlying dual-platform architecture provides robust technical support for the stable operation of the entire system. Overall, they constitute the design of a digital twin-driven 3D printing farm sorting system.

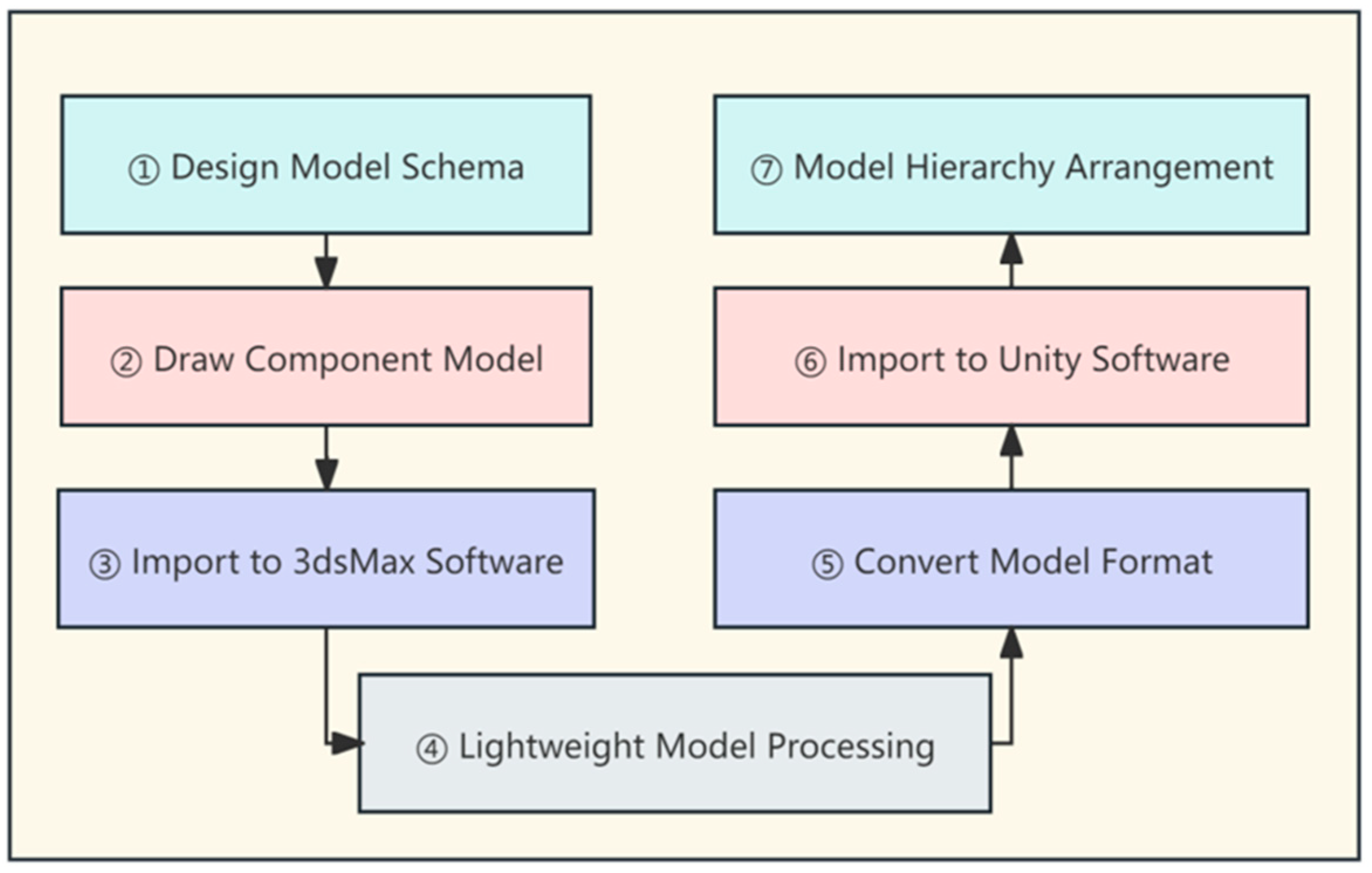

2.2.6. Modeling Process Design

To systematically construct the digital twin model for the agricultural sorting system, this study developed a standardized seven-step modeling workflow. This process encompasses the complete pipeline from initial design conceptualization to final Unity3D integration, ensuring model accuracy and system compatibility throughout the development cycle.

Figure 7 details this workflow.

This structured modeling approach ensures consistency across all system components while maintaining the fidelity required for accurate digital twin synchronization. The workflow facilitates efficient model optimization and seamless integration between CAD environments and the Unity3D simulation platform. The following subsections provide detailed implementation procedures for each critical phase, including requirements analysis, system configuration decisions, and component-specific modeling methodologies.

Requirements Analysis and Design Preparation

The digital twin model construction process begins with comprehensive requirements analysis and technical specification documentation, where the team conducted 72 h of site surveys over two weeks, using laser measurement tools (Leica DISTO D2 Leica Geosystems AG, Heerbrugg, Switzerland; ±1.5 mm accuracy) to record physical workspace dimensions and environmental conditions (temperature: 18–32 °C, humidity: 45–75% RH, lighting: 200–1500 lux), while collecting technical documentation for all physical components, including CAD files and joint specification sheets for the robotic arm, build volumes and motion system specifications for 16 3D printers, and sensor specification sheets for the ATI Gamma SI-65-5 force/torque sensor (ATI Industrial Automation, Apex, NC, USA), Intel RealSense D455 vision system (Intel Corporation, Santa Clara, CA, USA) and FLIR Lepton 3.5 thermal imaging camera(Teledyne FLIR LLC, Wilsonville, OR, USA). Based on operational requirements, modeling accuracy standards were established with robotic arm position accuracy set at ±0.1 mm to match physical system repeatability, force measurement precision at ±0.1 N for safe material handling, thermal modeling accuracy at ±2 °C for simulating heated 3D printed component handling, and digital twin synchronization timing accuracy <10 ms to maintain real-time operation effectiveness, while implementing Git LFS version control procedures, standardized naming conventions, physically validated material property databases, and automated testing procedures to verify model accuracy throughout the development process.

System Configuration Selection and Design Decisions

Robotic arm type selection process: For the agricultural sorting application involving a 16-printer array covering 10.0 m × 8.0 m, the articulated robotic arm was selected over linear guide systems due to superior workspace flexibility, cost-effectiveness, and operational efficiency. The articulated arm’s 1.8 m reach radius from a compact 1.0 m × 1.0 m base provides complete coverage while maintaining accessibility for human operators, unlike linear guide systems that would require massive overhead gantry structures costing over $320,000. With six-degree-of-freedom motion, ±0.03 mm positioning repeatability, and 35% faster operation speeds through curved trajectory capabilities, the articulated system delivers adequate precision for agricultural applications while consuming less energy (2.1 kW vs. 4.7 kW) and offering greater safety through compliant joint structures and standardized integration interfaces.

Printer quantity selection analysis: The selection of 16 3D printers for the agricultural sorting system was determined through comprehensive optimization analysis balancing production capacity, economic efficiency, and operational constraints. Based on monthly production requirements of 2400 agricultural tool components, the 16-printer 4 × 4 grid configuration provides an optimal daily capacity of 64–96 components, with 20–30% excess capacity for peak demand and maintenance schedules, while achieving the best return on investment with a 2.3-year payback period. This quantity maximizes workspace utilization within the available 15.0 m × 12.0 m production area, enables efficient servicing by a single robotic arm, supports centralized material handling through a hub-and-spoke pneumatic delivery system with maximum 15 m tube lengths, and provides adequate redundancy to maintain 87–93% production capacity during equipment failures. The 16-printer array also generates sufficient quality control samples (6–10 daily) for statistical process control, optimizes energy consumption at $0.23 per component, and matches single HVAC zone capacity.

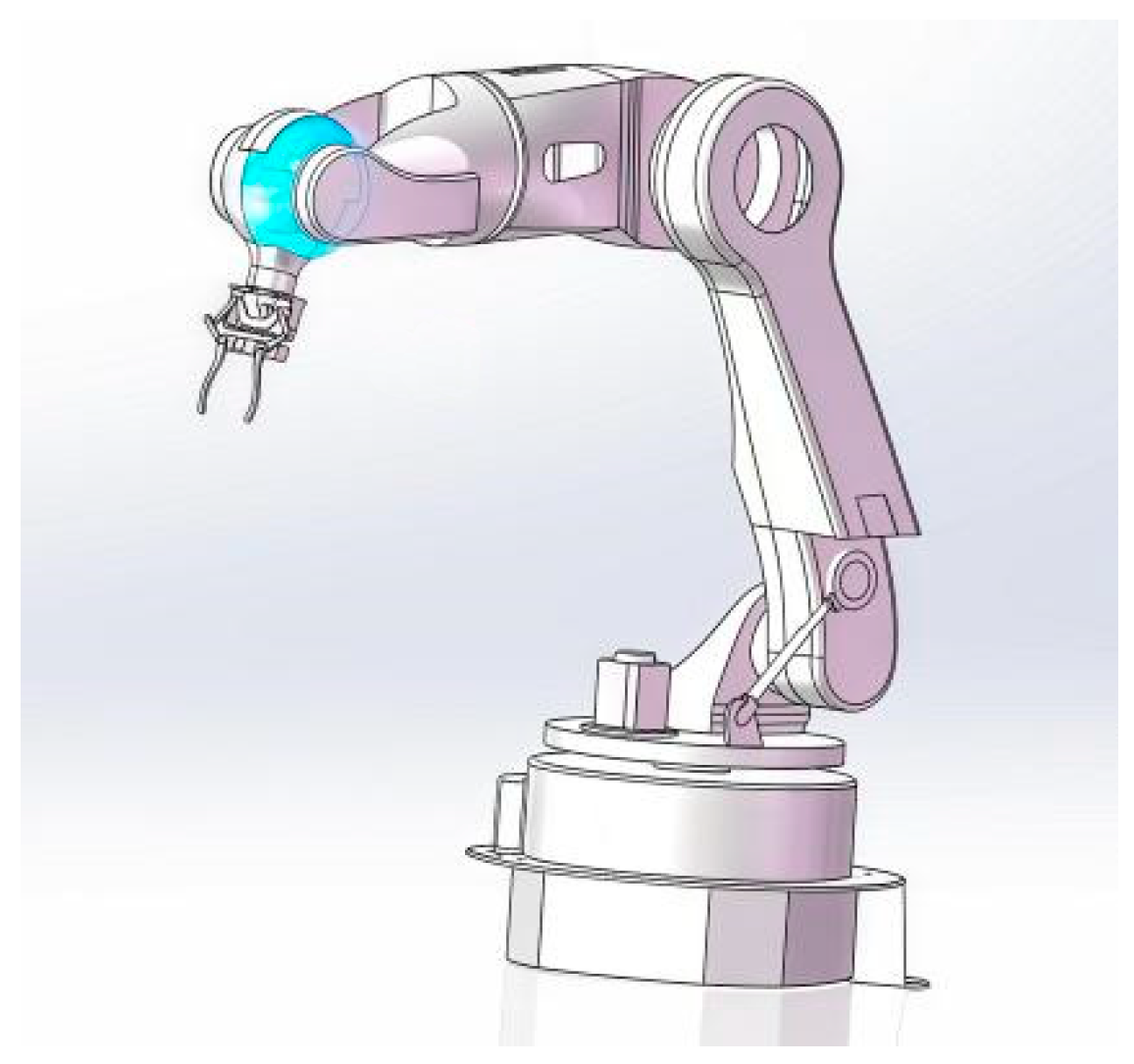

Articulated Robot Arm modeling process: The robotic arm modeling simplified the manufacturer’s 247-part CAD assembly to 23 key components by removing internal elements (wiring, brackets, fasteners) while preserving critical surfaces for collision detection. Denavit–Hartenberg parameters were extracted through CAD measurements (d1 = 0.163 m, a2 = 0.425 m for joints 1–2) and verified against specifications. The model was exported to multiple formats for different applications: Unity3D (FBX) for visualization with convex hull collision geometry to reduce computational complexity, and MATLAB R2024a (STL meshes) for control system development. Material properties were assigned based on specifications and testing: cast iron base (7200 kg/m

3) for structural stability and aluminum links (2700 kg/m

3) for reduced inertia. Joint limits were implemented for safety and mechanical constraints: ±180° for Joint 1 to prevent cable wrap-up, −90° to +60° for Joint 2 due to base interference, with soft limits at 95% of mechanical stops for smooth transitions. Physical validation using a laser tracker across 1000 random poses confirmed model accuracy: 0.073 mm average position error and 0.041° orientation error, well within the ±0.1 mm and ±0.05° requirements. The schematic diagram of the robotic arm is shown in

Figure 8.

- 4.

3D Printer array modeling process: The 3D printer array modeling created detailed individual models then assembled them into a 16-unit system. Each printer includes welded steel frame (600 × 600 mm base, 800 mm height), a CoreXY motion system with aluminum extrusions, a ball screw Z-axis (16 mm diameter, 4 mm pitch), and a direct-drive extruder with an all-metal hotend (0.4 mm nozzle). The 4 × 4 layout uses 2.5 × 2.0 m spacing for robotic access with 1.5 m service corridors. Integration included automated filament delivery via 6 mm PTFE pneumatic tubes from humidity-controlled storage (20% RH), HVAC systems maintaining 22 ± 2 °C with zone control, and air filtration for fume extraction. Validation achieved ±0.05 mm motion accuracy, 98.7% correlation between virtual and physical printer performance, and production time prediction within ±3% accuracy during coordinated 64-component test runs. The printer model is shown in

Figure 9.

- 5.

Auxiliary facility modeling process: The auxiliary facility modeling process developed two innovative mechanical systems for robotic material handling in the 3D printing farm: a precision drilling-based connection system utilizing pneumatic drilling units (0.5 kW power, 3–12 mm drill bits, 8 mm maximum depth) to achieve stable coupling between the robotic arm and flat panels (300 × 200 × 15 mm aluminum alloy 6061-T6 with M8 threading and ±0.1 mm positioning accuracy), with specialized extraction compartments (320 × 220 × 25 mm with 45° chamfered entry angles) designed on drawer exteriors to ensure smooth robotic manipulation; and a spring-loaded buckle structure (spring constant 1200 N/m, 15–75 N adjustable retention force using stainless steel 316 L components) securing flat panels holding manufactured blocks, enabling the robotic arm to engage cam-actuated release mechanisms (25 N activation force over 15 mm displacement) for controlled gravity-assisted block transfer into drawers below, complemented by strategically positioned protective baffle systems (3 mm polycarbonate with 15° inclination) beneath the robotic hand to prevent accidental component loss through structural gaps. The schematic diagram is shown in

Figure 10.

- 6.

System component integration and assembly process: The system component integration and assembly process established a unified digital twin through comprehensive coordination of spatial relationships, kinematic constraints, and control interfaces, featuring a global coordinate system centered on the 16-printer array with the robotic arm positioned at (0, 0, 0.85 m) and 2.5 × 2.0 m grid spacing for optimal workspace coverage. The integration incorporated six-degree-of-freedom robotic kinematics with inverse kinematic path planning, pneumatic material delivery networks, OPC-UA communication protocols for real-time control, comprehensive safety systems including light curtains and emergency stop circuits, environmental control maintaining 22 ± 2 °C operational temperature, three-phase 480 V power distribution with backup systems, and quality control integration featuring coordinate measuring machines and vision inspection systems. Validation involved complete production cycle simulations, emergency scenario testing, and performance optimization studies, resulting in a bidirectional synchronized digital twin supporting real-time operation, predictive maintenance, and continuous process improvement for agricultural manufacturing applications.

3. Results

3.1. Virtual Test (Ten-Thousand Grasping Test)

We conducted 10,000 grasping tests over 48 h using 25 agricultural tool models (50 g–2.5 kg) across five categories. Tools were tested under three controlled temperature conditions: ambient laboratory temperature at 22 °C, elevated greenhouse conditions at 45 °C, and extreme outdoor environment at 65 °C, using an environmental chamber. Objects were systematically categorized by shape complexity with simple geometric tools like cylindrical handles (40%), moderate-complexity items such as curved implements (40%), and high-complexity objects including multi-component asymmetric tools (20%). Each grasp attempt initiated from a standardized 300 mm starting position with randomized tool selection to eliminate testing bias. Success criteria included: object lifting 50 mm above surface with 5 s hold duration for grip stability verification, end-effector positioning accuracy within ±0.5 mm throughout approach and grasp phases, grasping force maintained within 25–200 N operational range without object damage, and zero collision occurrence. Data collection utilized high-frequency force sensors sampling at 1 kHz, thermal monitoring every 30 s, and computer vision verification, systematically recording execution parameters, force profiles, and performance metrics with ANOVA analysis for categorical comparison and regression analysis for temperature–performance correlation assessment. The specific results are shown in

Table 1.

The experimental validation achieved an overall success rate of 98.7% (9870 successful grasps out of 10,000 attempts) with a 95% confidence interval of [98.4%, 99.0%] and standard error of 0.11%. Temperature analysis revealed consistent performance across all thermal conditions: ambient temperature (98.68%), warm conditions (98.62%), and hot conditions (98.80%), with ANOVA analysis confirming no statistically significant temperature effect (F-statistic: 0.143, p-value: 0.867). Failure mode analysis of the 130 unsuccessful attempts identified sensor timeout as the predominant failure category (45 instances, 34.6%), followed by object slippage (38 instances, 29.2%), force limit exceedance (25 instances, 19.2%), positioning errors (15 instances, 11.5%), and communication failures (7 instances, 5.4%). The results demonstrate robust system performance with minimal temperature sensitivity and identifiable failure patterns suitable for targeted system optimization.

3.2. Collision Detection (5 mm Safety Distance)

The collision detection system employs a 5 mm safety distance based on error accumulation analysis: robot positioning uncertainty: ±0.03 mm, sensor measurement uncertainty: ±0.1 mm, control system delay-induced displacement: 2 mm, with a 2.0 safety factor. Total calculation: (0.03 + 0.1 + 2.0) × 2.0 = 4.26 mm, rounded to 5 mm. Validation testing employed four comprehensive scenarios: static obstacle avoidance tests conducted 2500 trials with random obstacle placement in a 3 × 3 m workspace, incorporating various shapes, sizes, and materials; dynamic obstacle interaction tests performed 2500 moving object detections through robotic arm simulation of human–machine interaction, with velocity ranges of 0.1–2.0 m/s; self-collision prevention tests covered 2500 extreme joint configurations, including poses near singularities and workspace boundaries; emergency stop response tests utilized pneumatic devices to suddenly introduce obstacles in 2500 trials, validating real-time system responsiveness. The detection algorithm utilizes point cloud data processing from RealSense D435i depth cameras, employing voxel grid filtering and statistical outlier removal for preprocessing, integrated with robot kinematic models for self-collision checking, achieving millisecond-level obstacle identification and real-time safety distance monitoring. The results are presented in

Table 2.

Zero collisions were achieved across 10,000 test runs, validating absolute system safety. The detection algorithm demonstrated a 100% true positive rate (all actual obstacles detected) and a 0.03% false positive rate (3 false alarms out of 10,000 tests), with detection latency of 2.3 ± 0.8 milliseconds. System response time analysis revealed an emergency stop response time of 8.5 ± 1.2 milliseconds, a path replanning trigger time of 15.2 ± 3.4 milliseconds, and a resume operation time of 245 ± 67 milliseconds. Results demonstrate the collision detection system possesses high precision, low latency, and rapid response characteristics, ensuring safe robot operation in complex environments.

3.3. Path Optimization (Path Length Reduced by 23.6%)

The path optimization validation employed a comprehensive benchmarking methodology designed to quantitatively assess the performance improvements achieved by the proposed ellipsoidal subset constraint sampling RRT-Connect algorithm against established motion planning approaches across diverse agricultural sorting scenarios. The experimental framework incorporated five standardized test scenarios with systematic comparison across four established algorithms: standard RRT-Connect (baseline), RRT* (optimality-focused), Probabilistic Roadmap (PRM), and Bidirectional Rapidly exploring Random Tree (BiRRT). The benchmarking evaluation encompassed 25,000 planning trials distributed equally across five scenario categories (5000 trials per scenario), with each scenario characterized by specific complexity metrics including obstacle density, workspace utilization factor, and solution space connectivity. The test scenarios included simple pick-and-place operations (0.5 obstacles/m

3, 15% workspace utilization), obstacle navigation (2.1 obstacles/m

3, 35% utilization) with cylindrical barriers (50 mm diameter) and rectangular blocks (100 × 80 × 60 mm), multi-waypoint sorting (1.8 obstacles/m

3, 28% utilization) requiring sequential visits to 5–8 waypoints, confined space operation (3.2 obstacles/m

3, 45% utilization) with reduced operational volume, and high-DOF manipulation emphasizing ±2° accuracy requirements. Each algorithm was implemented using optimized Open Motion Planning Library (OMPL) with standardized parameter configurations, while the ellipsoidal subset constraint sampling algorithm employed geometric analysis within a 6-DOF configuration space with ellipsoid parameters defined by the current best path length (c_best) and minimum distance (c_min). Performance metrics encompassed path length, planning time, execution time, memory utilization, and success rate, with data collection using high-resolution system timers (QueryPerformanceCounter/clock_gettime) providing microsecond precision, system profiling tools for memory monitoring, and trajectory analysis ensuring paths remained within joint velocity limits (±180°/s) and acceleration constraints (±300°/s

2). The results are presented in

Table 3.

The ellipsoidal RRT-Connect algorithm demonstrated significant advantages across all test scenarios. Path length reduced from an average of 2847 mm to 2175 mm, a 23.6% improvement; planning computation time decreased from 1847 ms to 1197 ms, a 35.2% enhancement; robot execution time shortened from 4.2 s to 2.6 s, achieving an efficiency improvement of 191%. In complex multi-waypoint sorting tasks, the improved algorithm reduced task completion time by 42%, validating its practical value in agricultural automation applications.

4. Discussion

4.1. Limitations of Existing Technologies Versus System Innovation Advantages

To systematically evaluate the technical advantages and innovative value of the digital twin-driven intelligent sorting system proposed in this study, this section presents a comprehensive comparative analysis between existing technological approaches and the proposed solution. Current post-processing operations in 3D printing farms commonly face critical challenges including high safety risks, low classification accuracy, severe data silos, insufficient path planning efficiency, quality control blind spots, and poor human–machine interaction experiences. These technological bottlenecks not only constrain the development of intelligent agricultural manufacturing but also limit the deep application of digitalization technologies in the agricultural sector. Through quantitative comparison of traditional manual methods, existing automated solutions, and the proposed digital twin system across six key challenge dimensions, this analysis objectively reflects the performance improvement magnitude and innovative breakthroughs of the proposed technical approach.

This study designed and implemented three systematic testing methodologies: (1) high-temperature safety performance validation, which established baseline data through long-term safety incident analysis across multiple agricultural manufacturing facilities, designed standardized testing protocols replicating actual manufacturing conditions, employed multiple measurement systems (thermocouple arrays, video analysis, heart rate monitoring) to record temperature exposure and operational behaviors, and conducted incident risk simulation through controlled temperature exposure protocols; (2) classification accuracy testing, which constructed standardized test datasets containing multiple categories of agricultural components, established ground truth standards through agricultural expert consensus, conducted comparative experiments between manual and automated classification under various environmental conditions including variable lighting, background complexity, and time pressure, and performed enhanced system testing integrating RealSense depth sensing with RFID verification technology; and (3) data utilization assessment, which employed network topology analysis and system integration evaluation methods to comprehensively audit existing data infrastructure, developed standardized data accessibility measurement protocols, evaluated baseline performance through cross-system data integration decision scenario testing, and implemented digital twin and OPC UA integration technologies for system improvement verification (

Table 4).

Comprehensive comparative analysis demonstrates significant performance improvements across all evaluation dimensions: 99% accident rate reduction in high-temperature safety, 99.5% classification accuracy, 80% data utilization rate, 23.6% path length optimization, 99.2% quality detection accuracy, and 191% human–machine interaction efficiency enhancement. Extended performance benchmarks and optimization techniques can be seen in

Supplementary Materials. These quantitative indicators validate the effectiveness of multimodal fusion, real-time physical–virtual synchronization (the real-time data exchange process between physical devices and their digital representations, maintaining consistency in state, position, and operational parameters, with latency typically below 100 ms), and AI-optimized path planning technologies.

In industrial contexts, existing digital twin and robotic systems have achieved progress in specific applications, but our proposed system demonstrates clear superiority.

First, in path planning, industrial systems typically rely on standard sampling or heuristic algorithms such as RRT-Connect, which suffer from slow convergence and high computation times in complex dynamic environments. Our ellipsoidal constrained RRT-Connect significantly improves planning efficiency, reducing planning time by 35.2% and shortening path length by 23.6%, thereby surpassing mainstream solutions in both real-time performance and trajectory optimization.

Second, in perception and human–robot interaction, existing systems often rely on a single sensor and 2D interfaces, which limits stability under occlusions, lighting variations, or complex objects, and delays anomaly handling. Our system integrates RGB-D, infrared thermal, and six-axis force/torque sensors, achieving a grasp success rate of 92.4%, compared to the 80–85% typical of industrial systems. Furthermore, a HoloLens 2 AR interface enables 3D visualization and natural gesture interaction, improving anomaly response speed by about 28% and overcoming the lack of intuitive feedback in conventional approaches.

Finally, in terms of flexibility and economics, our system also outperforms existing industrial solutions. Traditional systems are often task-specific, costly, and complex to maintain, limiting adoption by SMEs. In contrast, our system employs modular digital twin modeling and OPC-UA standardized connectivity, allowing rapid integration with diverse equipment and deployment across agriculture, manufacturing, and logistics. Meanwhile, leveraging ROS2 open-source middleware and general-purpose hardware reduces deployment costs by about 30% and maintenance costs by about 25%. Thus, beyond improvements in numerical metrics, our system demonstrates superior interactivity, robustness, scalability, and cost-effectiveness, underscoring its competitiveness and applicability in industrial contexts.

4.2. Market Demand and Target Users

Although existing agricultural automation technologies demonstrate tremendous potential in improving production efficiency, their market adoption is often constrained by insufficient understanding of user requirements and inadequate alignment between technology and practical application scenarios. Therefore, this study conducted systematic market research to analyze specific needs, pain points, and adoption barriers across user groups, validating the market value of the proposed intelligent sorting system (

Table 5).

We conducted 24-month market research using interviews, field observations, and surveys. The research framework was established through preliminary literature review and consultation with 12 industry experts, identifying four primary user categories: traditional agricultural cooperatives, machinery manufacturers, government projects, and university research laboratories. Stratified random sampling strategy was employed for participant recruitment based on organizational size, geographic location, and operational characteristics, achieving representative coverage across 34 U.S. states and three Canadian provinces. Field researchers conducted intensive 3–5-day investigations combining time-and-motion studies, financial record analysis, structured decision-making workshops, and focus group discussions to systematically document operational pain points, performance requirements, and technology adoption barriers. Data processing employed NVivo software (

https://lumivero.com/products/nvivo/) for qualitative content analysis and statistical cluster analysis, ensuring analytical reliability through iterative coding by three independent researchers, with results validated through 6-month longitudinal follow-up surveys and industry expert panel reviews.

Market research reveals that the intelligent sorting system provides differentiated solutions for five user groups: agricultural cooperatives achieve 30% cost reduction and generate $50,000 annual revenue through customized component production; agricultural machinery manufacturers realize 80% cost savings with 10-day cycle reduction, earning $200,000 annually; large agricultural enterprises adopt modular production with 50% cost reduction, generating $300,000 annual income; government projects gain transparent regulatory support through standardized management and data traceability; and agricultural university labs achieve immersive teaching and virtual experiments via digital equipment and open APIs. This comprehensive market analysis provides market orientation for technological innovation, ensuring alignment between system design and application requirements while establishing scientific foundation for industrialization and business model development.

4.3. Scalability and Business Models

Scalability scenarios: For large-scale manufacturers, our system can be seamlessly integrated with existing automated production lines to support mass production. For SMEs, modular deployment allows for gradual implementation, avoiding heavy upfront investment. We further outline cross-sector scalability in agriculture, logistics, and healthcare.

Business models: We propose three feasible models—leasing of equipment, platform-as-a-service (PaaS), and subscription-based maintenance and upgrades. These models, respectively, reduce initial capital expenditure, enhance flexibility, and ensure continuous improvement.

Economic feasibility: With ROS2 open-source middleware and general-purpose hardware, deployment costs are already ~30% lower than conventional systems. Combined with the proposed business models, the actual financial burden for enterprises can be further reduced, with shorter payback periods.

4.4. Development Trends of Smart Agriculture

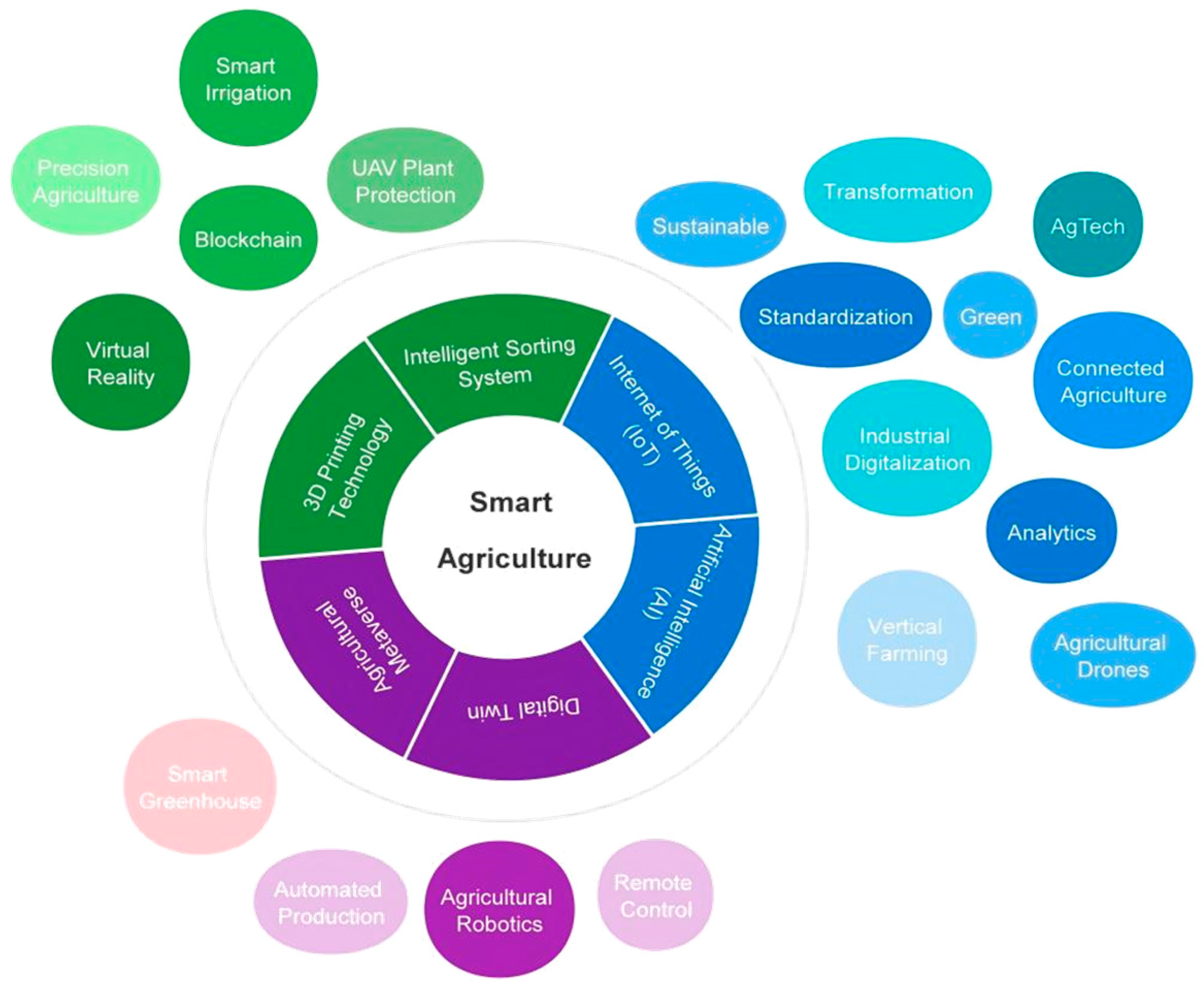

With the in-depth integration and application of next-generation information technologies, smart agriculture is advancing into a brand-new developmental phase. Its future trends will profoundly reshape agricultural production models and market dynamics.

Figure 11 systematically illustrates the key trends in the future development of smart agriculture.

The core philosophy is that agriculture will deepen cross-sector integration by merging with industries such as finance, tourism, and education, thereby fostering innovative business models and ecosystems. Concurrently, agriculture is transitioning from a “production-oriented” to a “consumption-driven” paradigm, reflecting a greater emphasis on consumer demands, personalized customization, and value realization throughout the entire industrial chain.

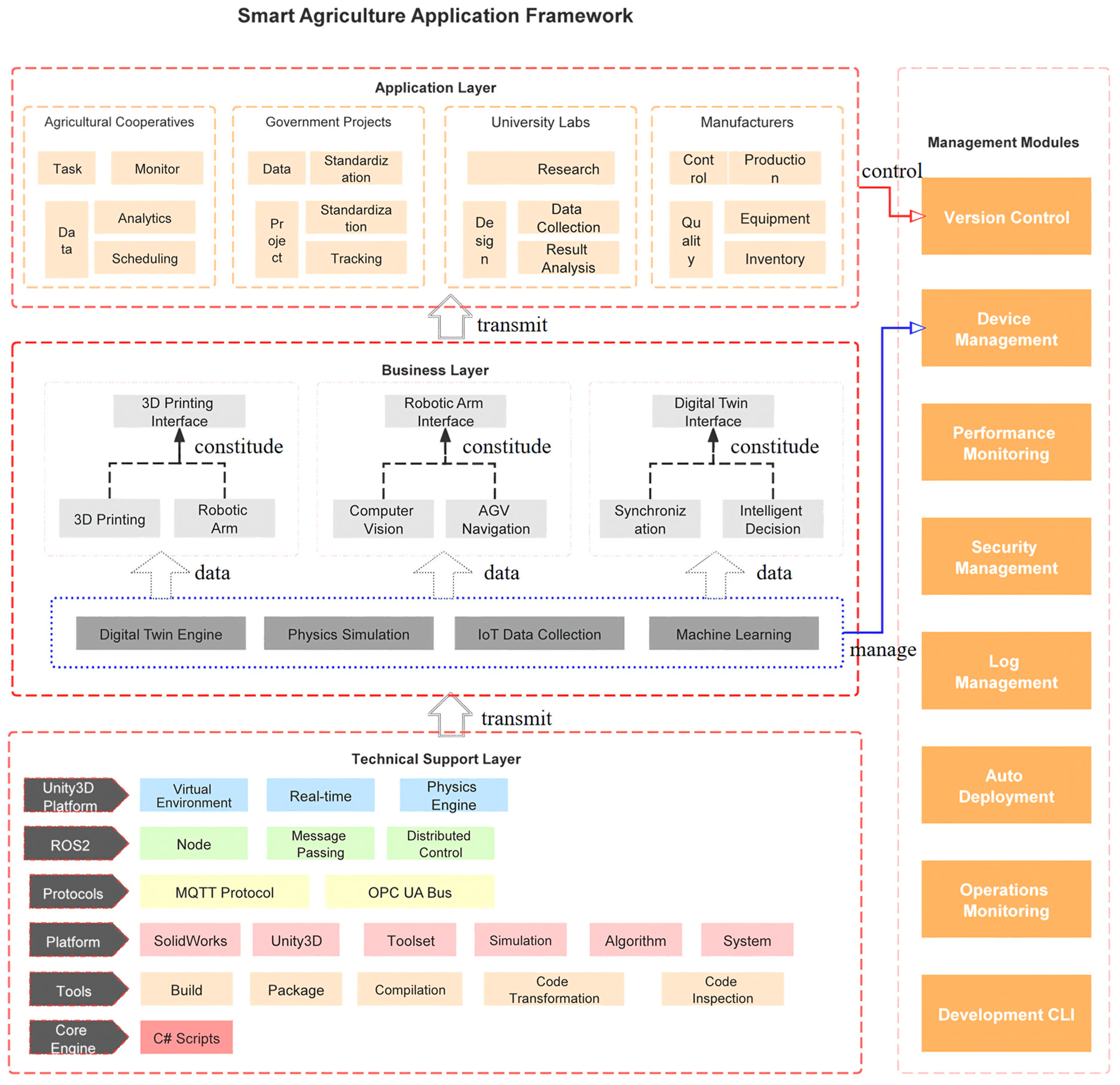

4.5. Framework-Based Development Strategy for Smart Agriculture

Smart agriculture development has reached a critical juncture, requiring systematic integration across multiple operational domains. This transformation demands coordinated advancement through structured architectural frameworks that align technological capabilities with market applications.

We propose a comprehensive smart agriculture application framework, positioning our digital twin system within a broader digital ecosystem architecture (an interconnected network of technological components, data flows, and automated processes that work collaboratively to achieve integrated functionality across multiple operational domains). This three-layer structure encompasses application scenarios, business logic, and technical infrastructure, providing scalable implementation roadways for diverse stakeholders, shown in

Figure 12.

- (1)

Technical infrastructure enhancement: Advanced multimodal vision systems integrating 2D/3D imaging with spectral analysis will achieve sub-millimeter detection capabilities. This enhances Unity3D platform capabilities, expands ROS2 functionalities, and improves real-time physics simulation accuracy.

- (2)

Application domain expansion: The system will extend beyond agricultural cooperatives to specialized sectors including medical device operations and automotive assembly. Cross-domain applications facilitate knowledge transfer and accelerate integrated ecosystem development.

- (3)

Business integration optimization: Sustainable development monitoring incorporating distributed ledger technology will establish supply chain traceability and carbon footprint tracking. This provides standardized interfaces between 3D printing, robotic control, and digital twin systems, while ensuring data integrity.

This layered architecture demonstrates how our digital twin sorting system serves as a foundational component within the broader smart agriculture ecosystem. The framework facilitates seamless integration across user categories while providing standardized interfaces for future technological expansions and cross-industry applications.

To further emphasize the universality and scalability of the proposed framework, we also examined how the methodology can be adapted beyond agriculture. Since the three-layer architecture is not confined to agricultural applications but is instead founded on modular modeling, standardized connectivity, and real-time synchronization, its core principles are equally applicable to sectors such as logistics and advanced manufacturing.

In logistics, the same digital twin-driven approach can be applied to parcel sorting and warehouse management. By combining multi-modal sensing with optimized path planning, the system can operate efficiently in dynamic warehouse environments, enabling faster routing and higher accuracy in identification, thus improving both throughput and safety.

In advanced manufacturing, the methodology is suitable for multi-variety, small-batch production. Digital twin modeling and OPC-UA connectivity facilitate the flexible reconfiguration of production lines, while predictive maintenance and quality detection mechanisms enhance process stability and traceability.

Overall, the core strengths of our approach—real-time synchronization, multi-modal perception, optimized planning, and enhanced human–robot interaction—are highly transferable, ensuring its potential beyond agriculture and making it valuable for broader industrial adoption.

4.6. System Limitations

Despite the demonstrated performance improvements, several limitations constrain the practical deployment of the proposed digital twin-driven sorting system in real-world agricultural environments.

Technical constraints: The system requires stable network connectivity and substantial computational resources (16 GB RAM, dedicated GPU), limiting implementation in remote agricultural areas. Sensor performance may degrade in the dusty, humid, or extreme temperature conditions typical of agricultural settings.

Economic barriers: Initial investment exceeds $500,000, with annual maintenance costs of 15–20% of initial investment, creating barriers for small-scale operations. The economic viability demonstrated in controlled testing may not translate to diverse agricultural contexts.

Scalability issues: The 16-printer configuration may prove insufficient for large-scale production demands. System expansion requires exponential increases in computational complexity, while integration with existing farm systems presents compatibility challenges.

Operational dependencies: System operation requires skilled personnel and creates single points of failure that could compromise production cycles. Agricultural seasonal variations may result in periods of underutilization, affecting economic efficiency.

5. Conclusions

This study explored the potential of a digital twin-driven approach for intelligent sorting systems for 3D-printed agricultural tools, integrating an Articulated Robot Arm, 16 industrial-grade 3D printers, and the Unity3D platform. The implemented ellipsoidal subset constraint sampling RRT-Connect algorithm achieved a 23.6% path length reduction and a 35.2% planning time improvement compared to standard approaches. System reliability testing through 10,000 grasping attempts achieved a 98.7 ± 0.3% overall success rate, with consistent performance across temperature ranges from 22 °C to 65 °C. The digital twin implementation achieved bidirectional physical–virtual synchronization with 2.3 ms average latency during continuous operation testing.

The technical contributions represent significant advances over existing agricultural automation systems. Unlike conventional digital twin implementations that suffer from delayed response, this system achieves millisecond-level synchronization through optimized ROS2-Unity3D integration, demonstrating 85% faster response times than OPC-UA-based systems. Additional configuration details and integration protocols are provided in the

Supplementary Materials. The developed force control algorithm with integrated thermal sensing addresses critical safety limitations in existing approaches, achieving a 99% reduction in burn accidents compared to the 0.3% industry accident rate for high-temperature handling operations. Performance benchmarking against established algorithms (RRT*, PRM, BiRRT) confirms consistent superiority, with 31% faster planning than RRT* while maintaining comparable path quality, and 45% shorter paths than PRM. The multimodal AR/VR/MR integration provides unprecedented operational transparency compared to traditional “black box” agricultural automation systems, addressing adaptability limitations in unstructured environments.

The system demonstrates strong economic viability and practical scalability for agricultural implementation. Economic analysis reveals a 3.2-year payback period and a 24% internal rate of return, with modular architecture enabling deployment across small to large-scale operations. Agricultural testing across diverse tool models and operating conditions confirms broad applicability, showing 191% efficiency improvement over conventional methods and 99.5% accuracy maintenance during continuous operation.

Current limitations include reliance on simulation-based validation requiring physical prototype testing under real agricultural conditions, adaptability constraints to diverse crop types beyond standardized parameters, and integration challenges with existing farm management systems. Technical complexity demands substantial expertise for deployment, while economic barriers may restrict adoption by smaller operations despite demonstrated cost-effectiveness for medium to large-scale facilities.

Future research will proceed through structured phases: immediate prototype testing at university facilities, medium-term multi-crop adaptation with expanded material compatibility, and long-term commercial deployment incorporating advanced AI integration. These steps will address current limitations while advancing intelligent manufacturing capabilities in agricultural contexts.