Study of Microwave Healing Properties of Carbonyl-Iron-Powder-Modified Asphalt Mixture Based on Digital Image Technology

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

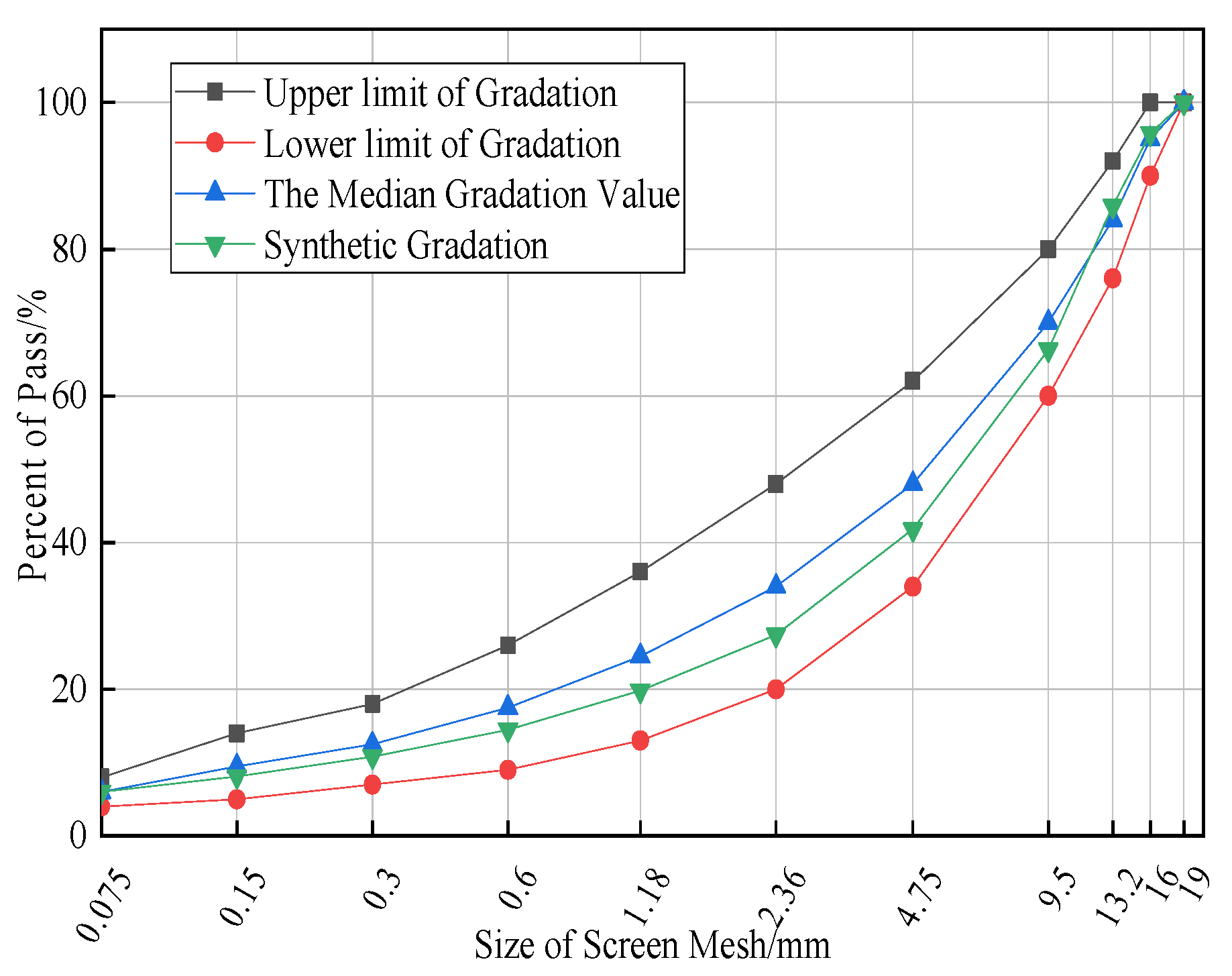

2.2. Asphalt Mixture Gradation Design

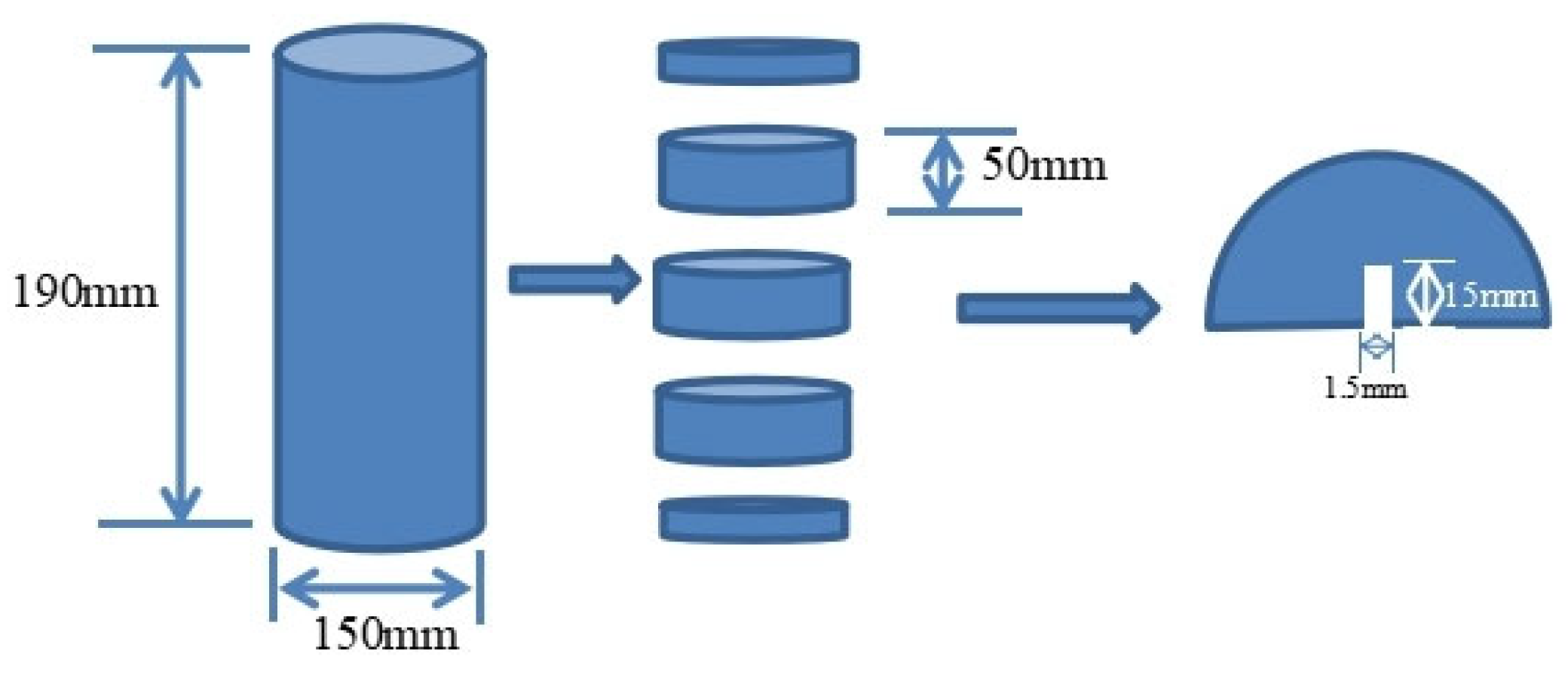

2.3. Preparation of Semi-Circular Samples

2.4. Test Method

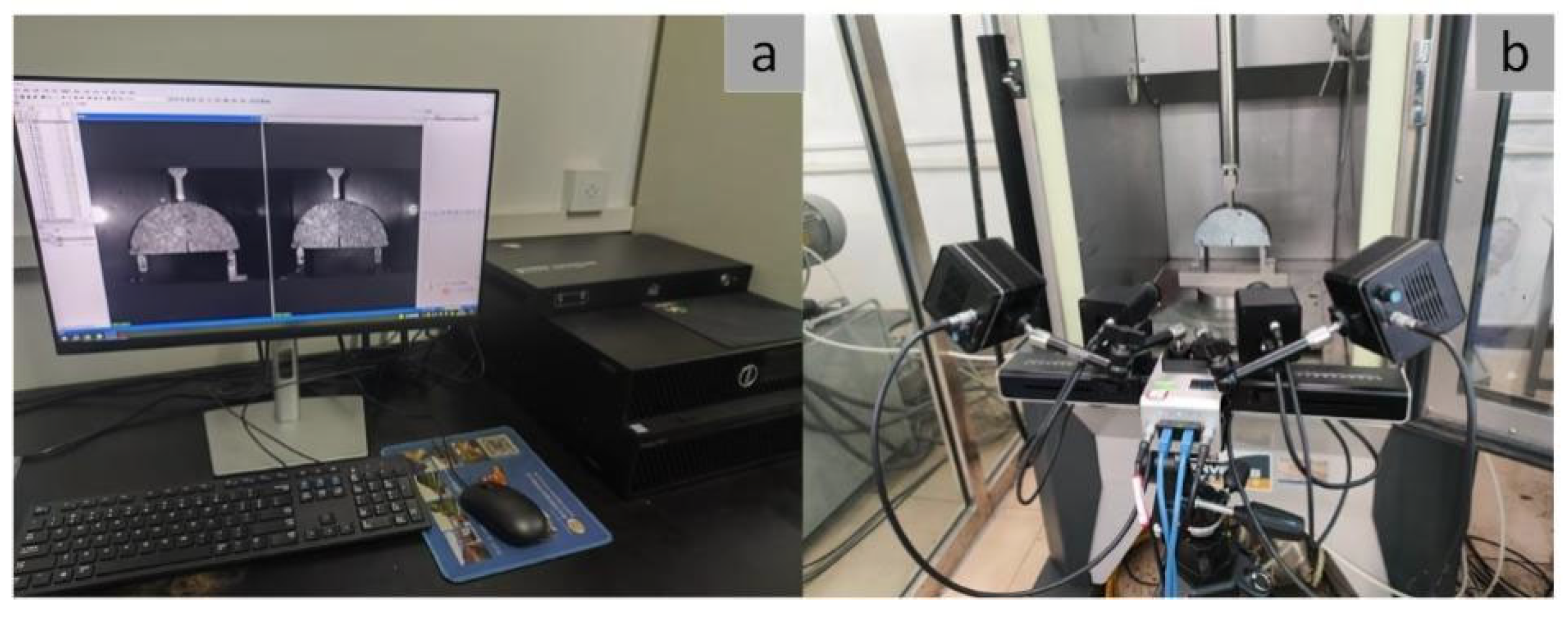

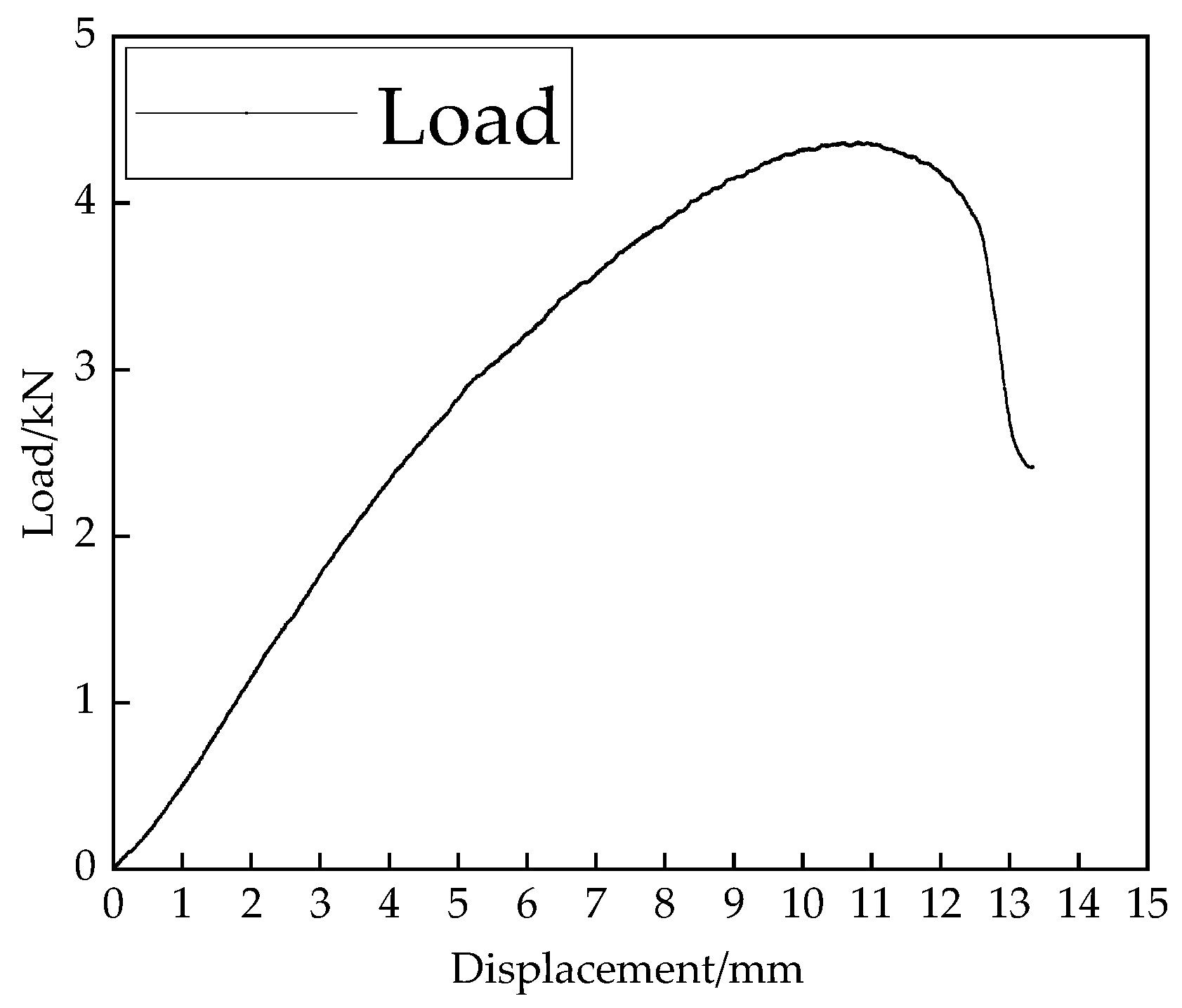

2.4.1. Semi-Circular Bending Healing Test

2.4.2. Microwave-Induced Heating Test

2.5. Metric

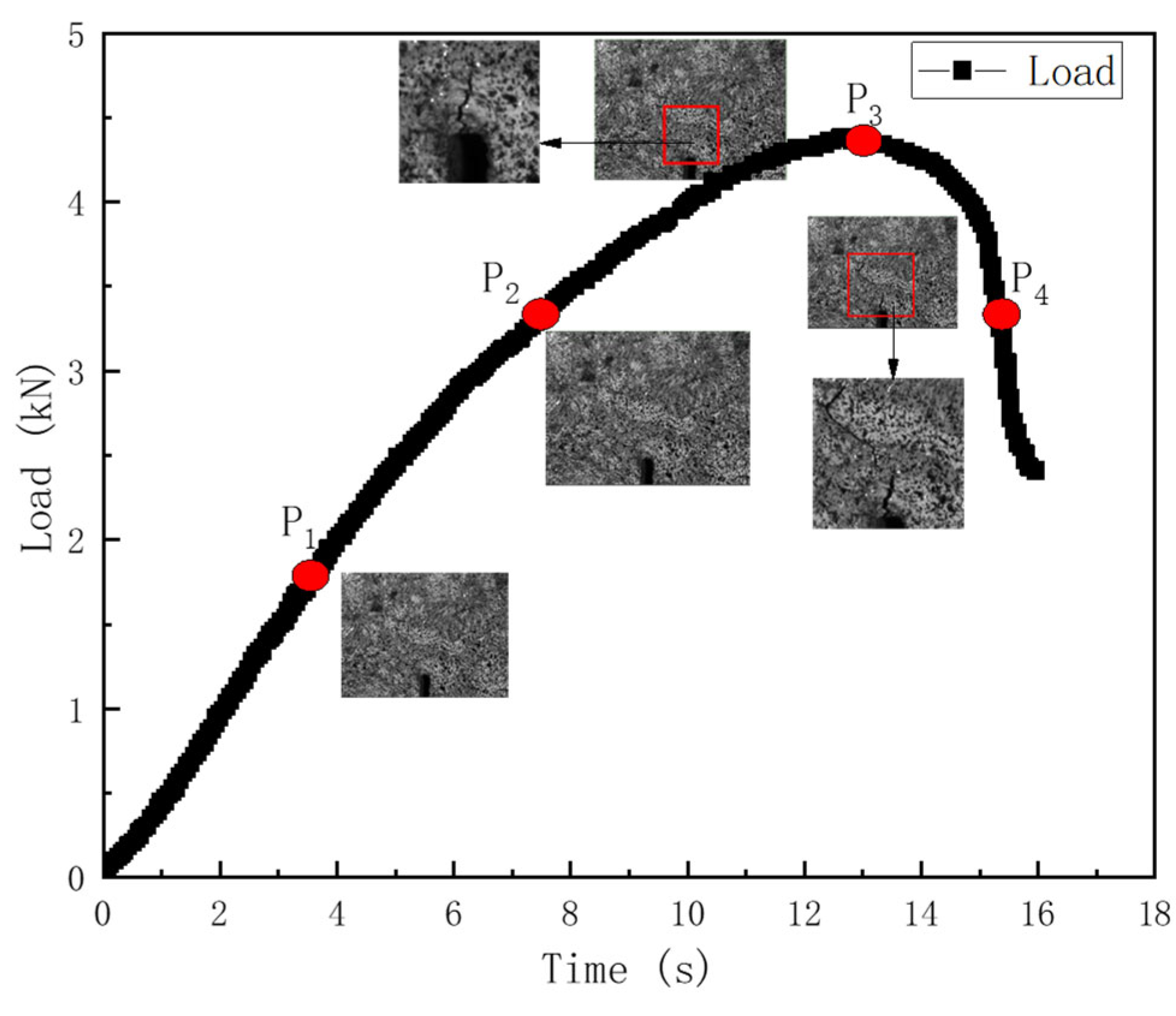

2.5.1. Time of Crack Initiation

2.5.2. Fracture Energy

3. Results and Discussion

3.1. Microwave Heating Characteristics

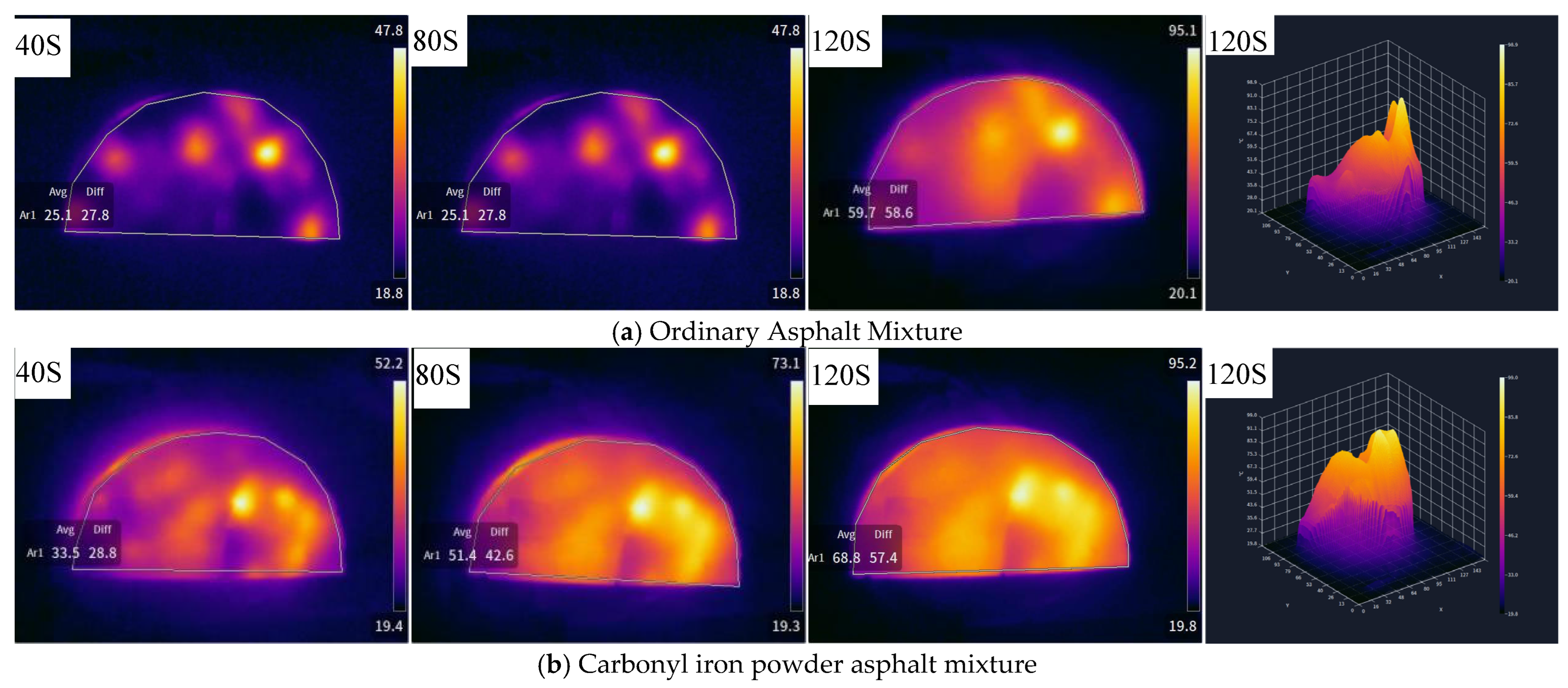

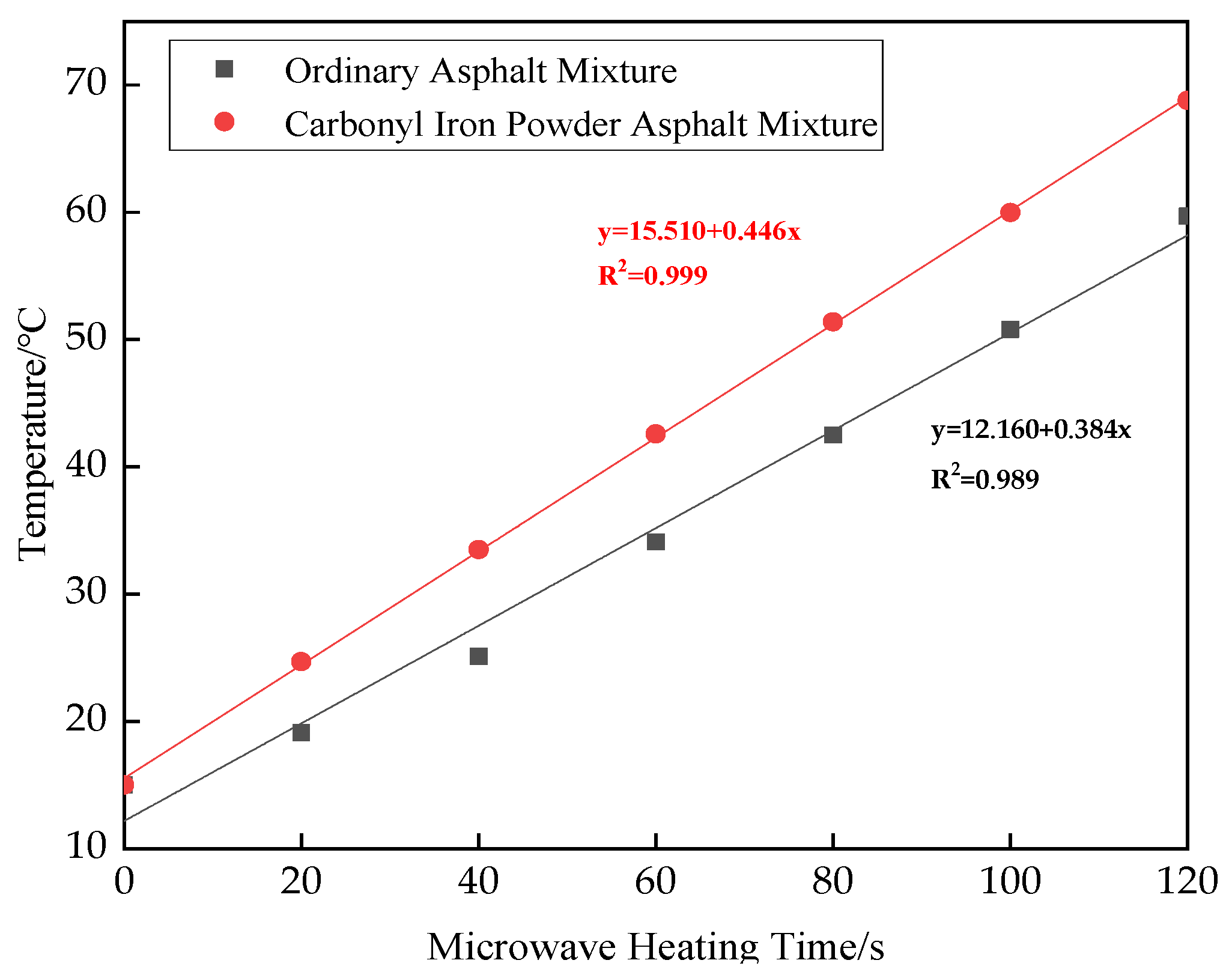

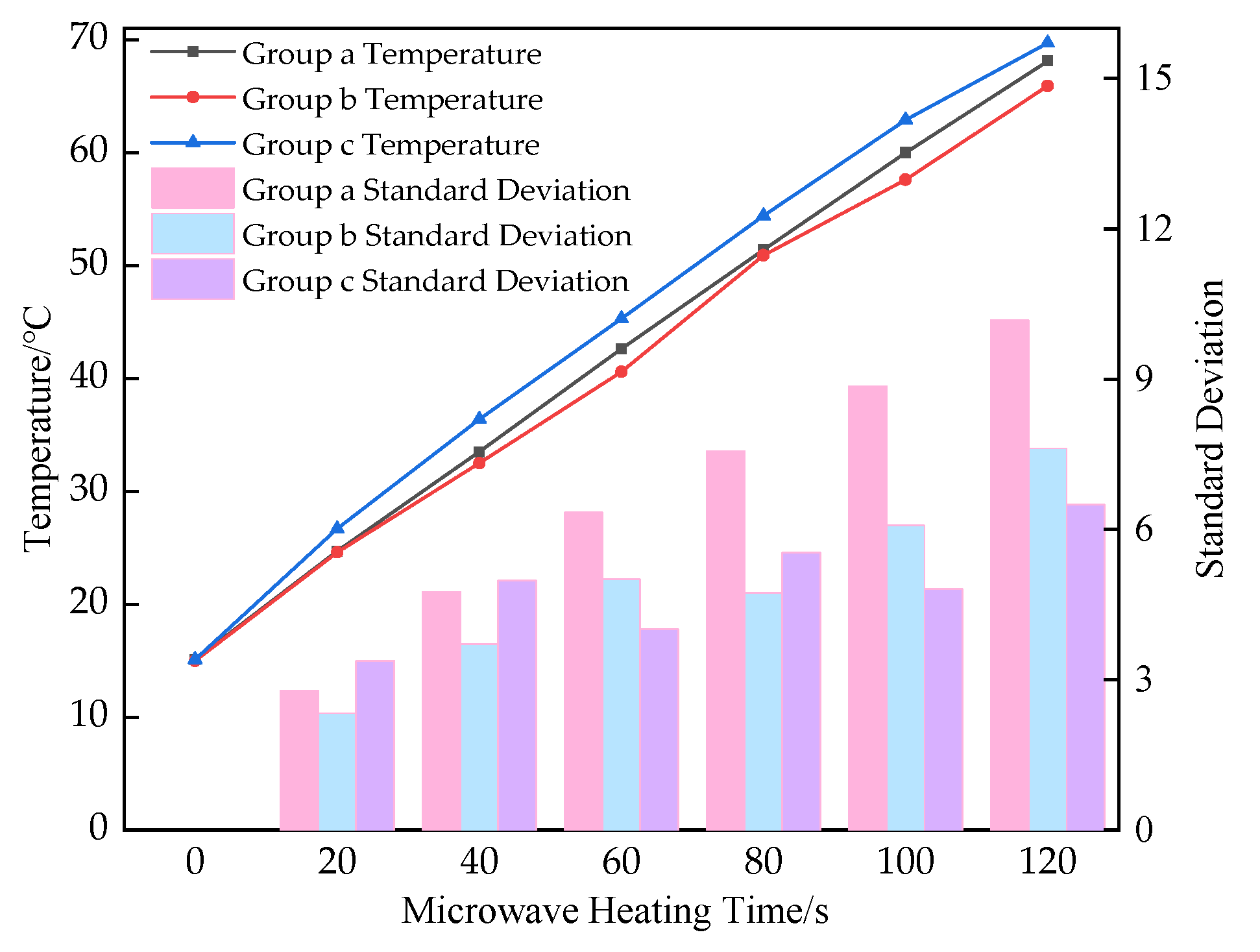

3.1.1. Heating Behavior of Asphalt Mixture Filled with Carbonyl Iron Powder

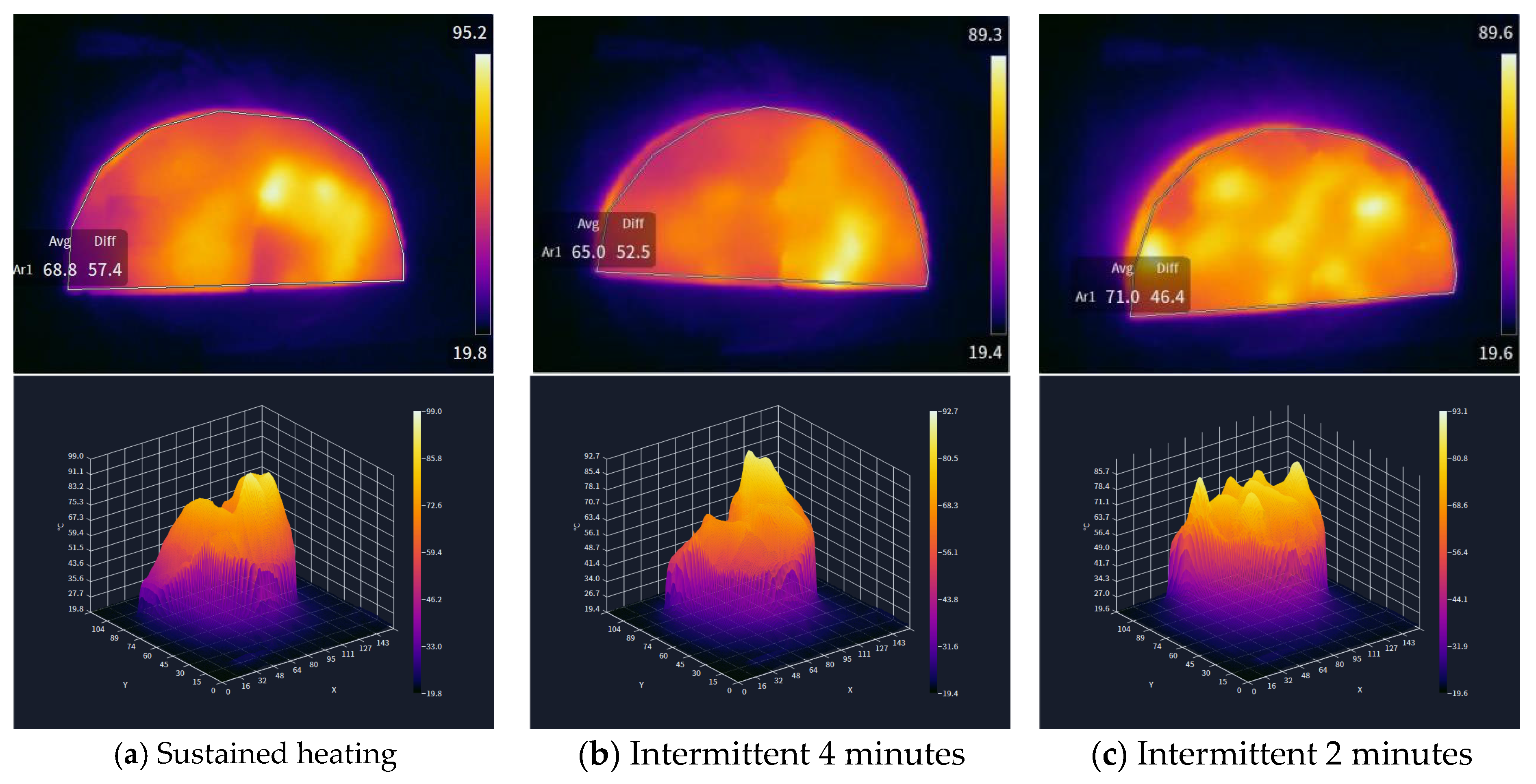

3.1.2. Study on the Heating Characteristics of Carbonyl Iron Powder Asphalt Mixture Under Different Heating Methods

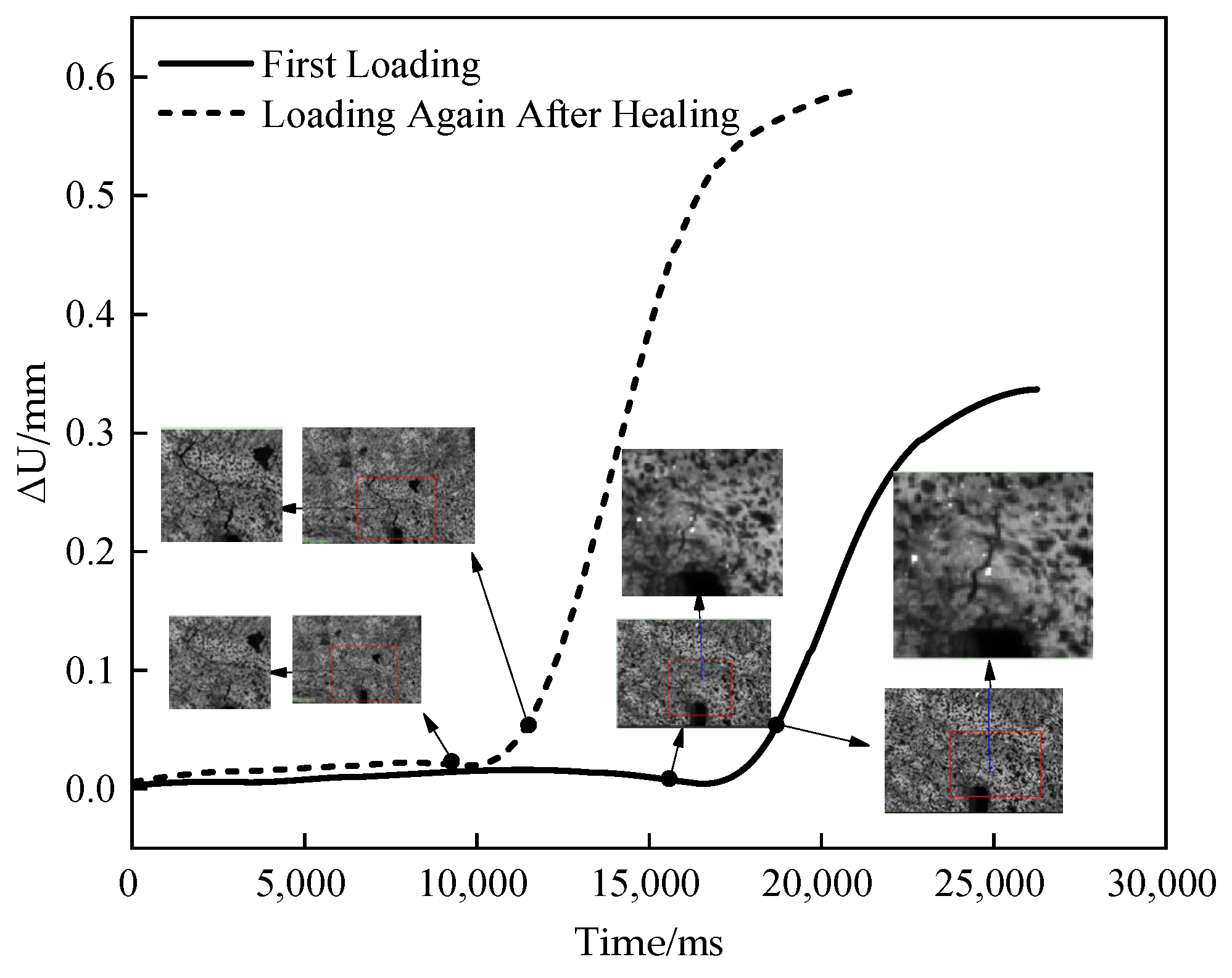

3.2. Horizontal Strain

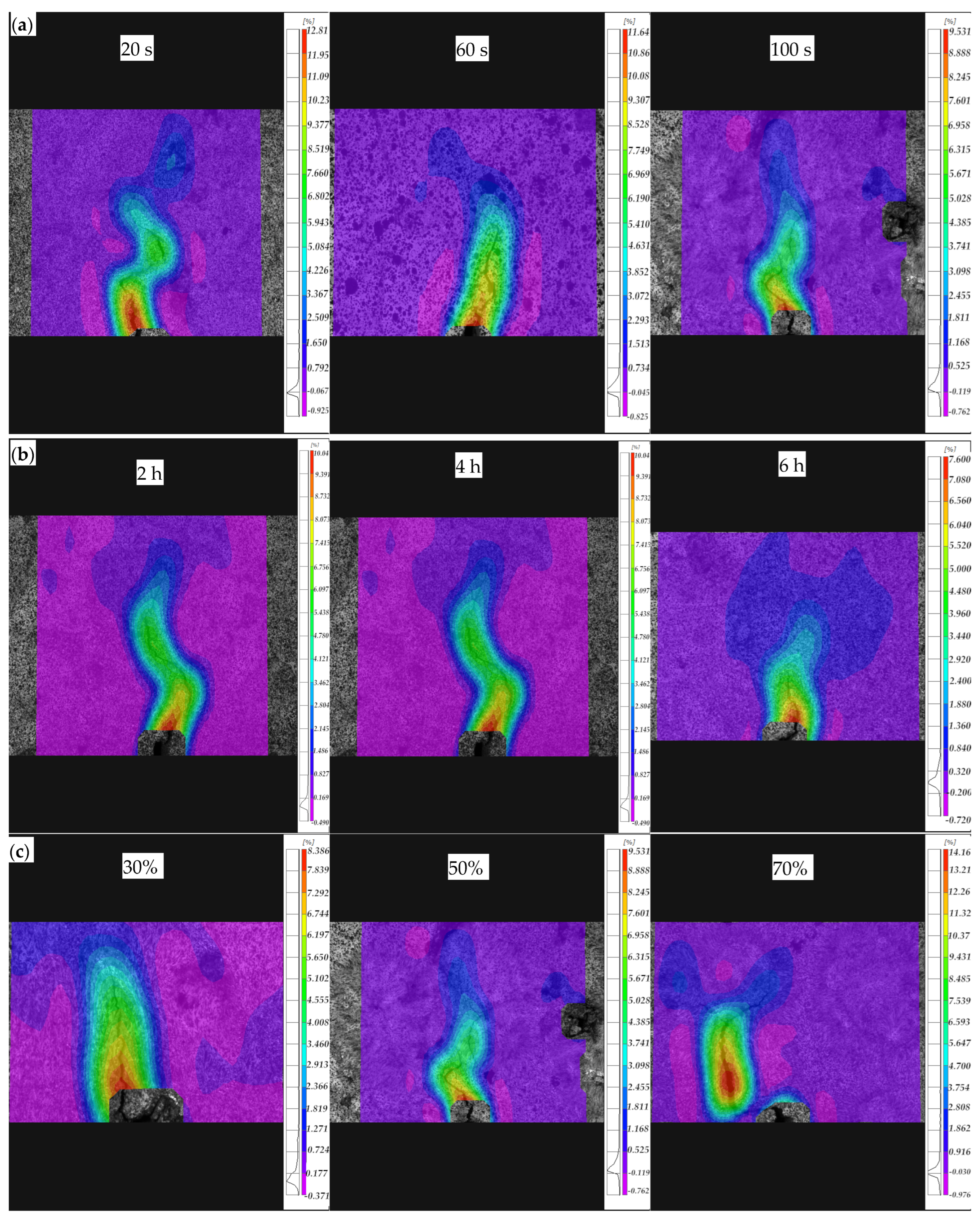

3.2.1. Feature Cloud Map

3.2.2. Analysis of Horizontal Strain Field Variation Before and After Healing

3.3. Self-Healing Characteristics

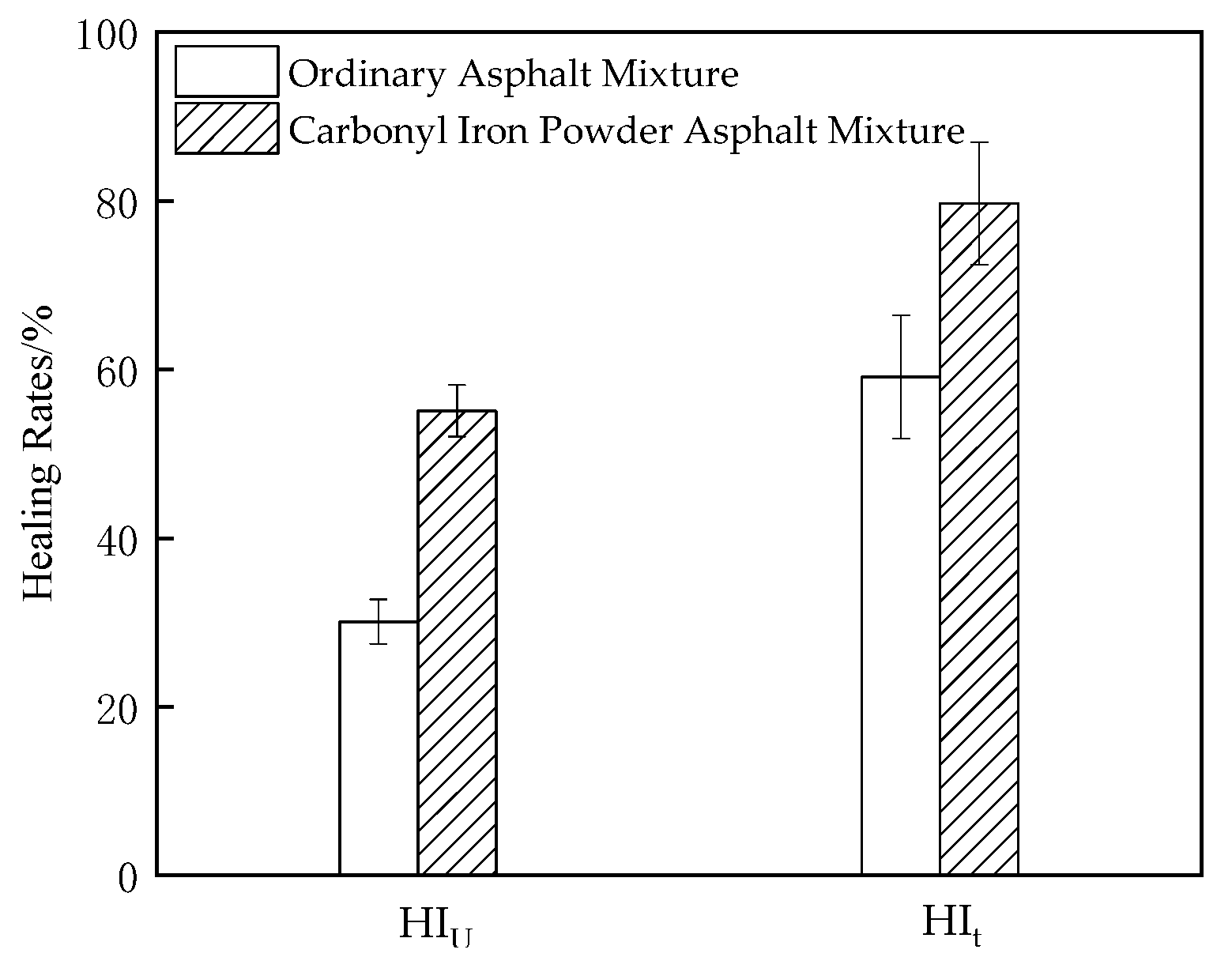

3.3.1. Influence of Carbonyl Iron Powder on Self-Healing Index

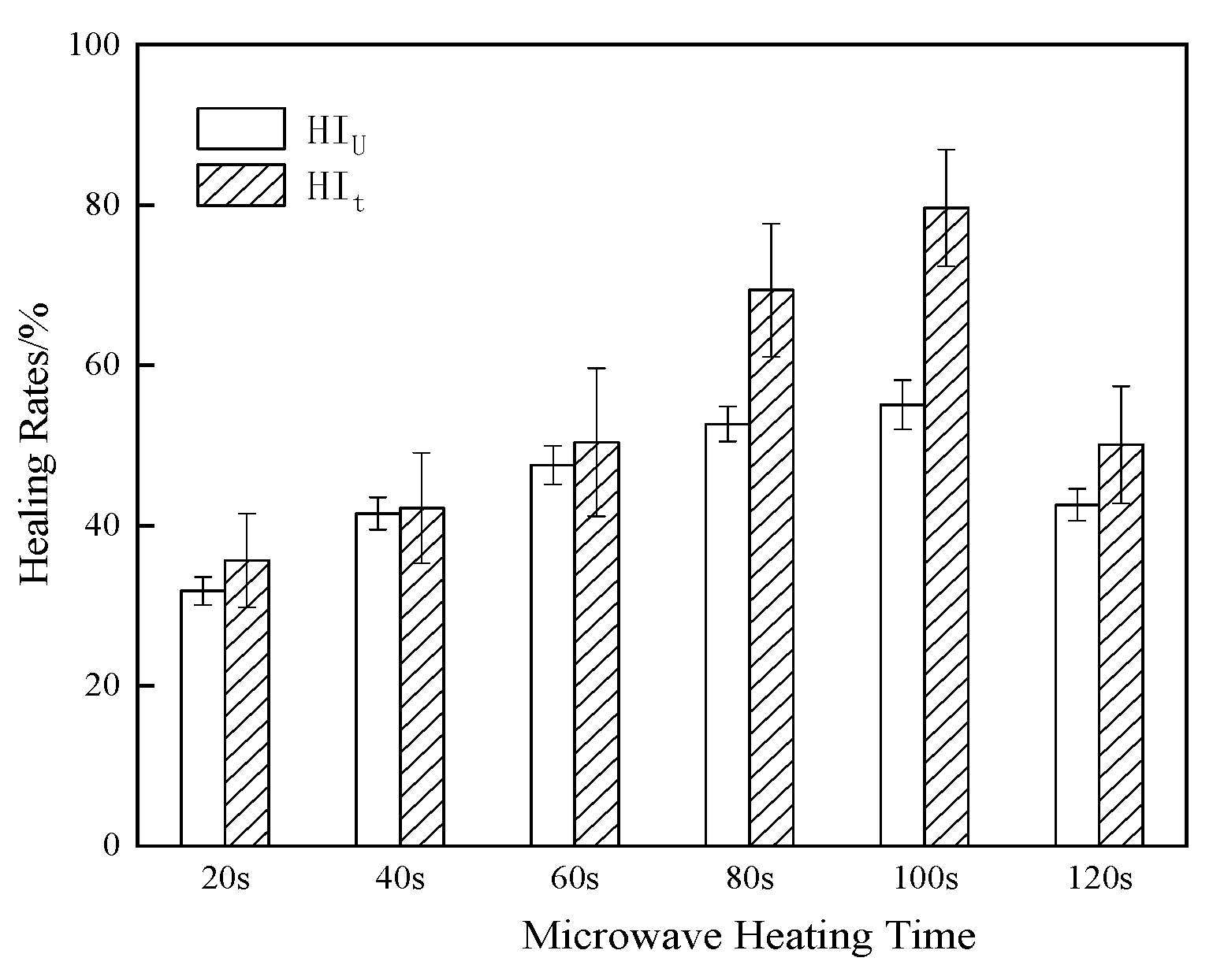

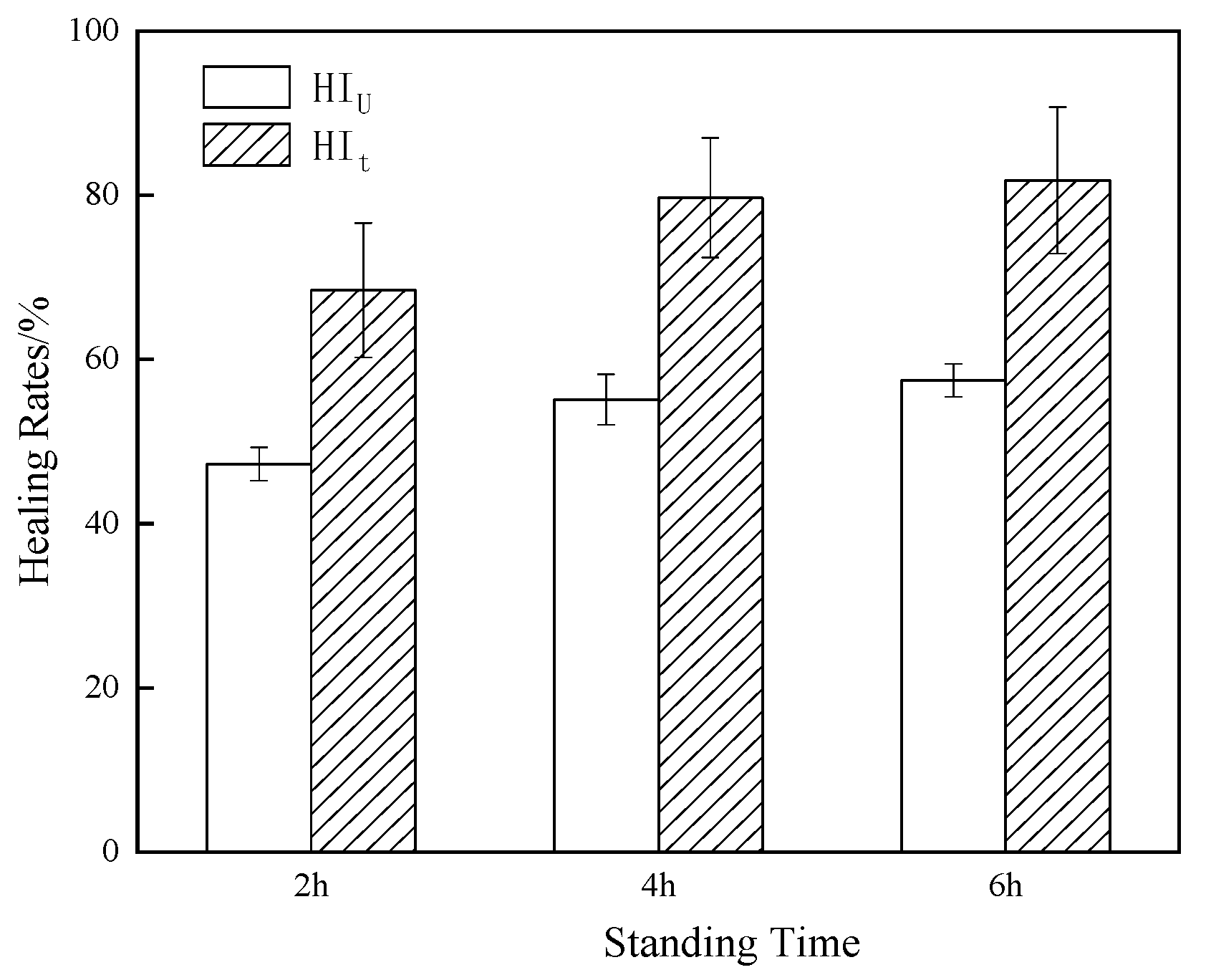

3.3.2. Influence of Healing Factors on Self-Healing Index

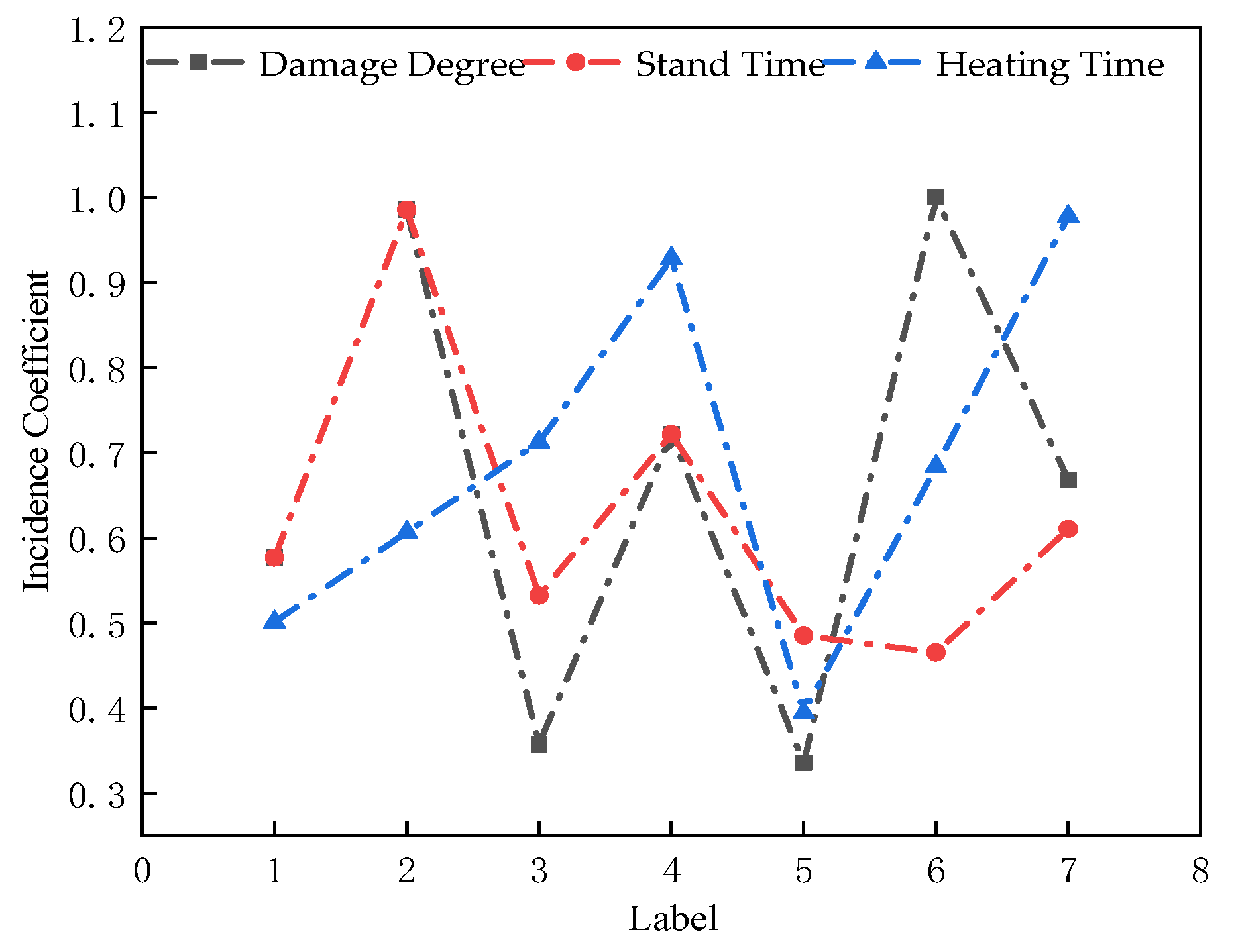

3.3.3. Correlation Analysis of Self-Healing Index

3.3.4. Significance Level Analysis of Healing Influencing Factors

3.4. Theoretical Analysis

4. Conclusions

- (1)

- The carbonyl iron powder asphalt mixture exhibits excellent heat uniformity and linear temperature rise characteristics. Its heating rate is increased by 16.1% with more uniform heating; the average temperature reaches 68.8 °C after 120 s of heating, which can meet the healing temperature requirement of the asphalt mixture.

- (2)

- The heating temperatures of the carbonyl iron powder asphalt mixture under continuous and intermittent heating are basically the same. Intermittent heating has no heat loss and better heating uniformity, and the optimal microwave heating method is a 3-cycle process of “heating for 40 s–resting for 2 min”.

- (3)

- When the wave absorber is mixed into the asphalt mixture as a filler, it can improve the microwave heating efficiency, thereby enhancing the self-healing performance of the mixture.

- (4)

- The macroscopic fracture energy healing index, HIU, is highly correlated with the mesoscopic crack initiation time healing index, HIt, and multi-scale evaluation can improve the reliability of conclusions. Carbonyl iron powder significantly improves the healing effect of the mixture, and the optimal healing effect is achieved under the best condition of microwave heating for 100 s (at a temperature of 60 °C).

- (5)

- External factors have a significant impact on the healing effect of the carbonyl iron powder asphalt mixture, with the order of influence being microwave heating time > damage degree > standing time. The optimal healing scheme is as follows: heating for 100 s, standing for 4 h, and performing healing at the initial stage of damage (before crack initiation).

- (6)

- The dosage of carbonyl iron powder needs to balance high-temperature performance, low-temperature performance, microwave heating temperature sensitivity, and healing performance. Relevant studies have been conducted in previous research on the self-healing behavior and rheological properties of carbonyl-iron-powder-modified asphalt mortar based on microwave induction. However, no corresponding research has been carried out on asphalt mixtures. The current research has certain limitations, which can serve as a direction for future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, S.; García, A.; Su, J.; Liu, Q.; Tabaković, A.; Schlangen, E. Self-healing asphalt review: From idea to practice. Adv. Mater. Interfaces 2018, 5, 1800536. [Google Scholar] [CrossRef]

- Liu, Q.; García, Á.; Schlangen, E.; van de Ven, M. Induction healing of asphalt mastic and porous asphalt concrete. Constr. Build. Mater. 2011, 25, 3746–3752. [Google Scholar] [CrossRef]

- Gulisano, F.; Gallego, J. Microwave heating of asphalt paving materials: Principles, current status and next steps. Constr. Build. Mater. 2021, 278, 121993. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Ajam, H.; Lastra-González, P.; Garcia, A. Effect of air voids content on asphalt self-healing via induction and infrared heating. Constr. Build. Mater. 2016, 126, 957–966. [Google Scholar] [CrossRef]

- Câmara, G.; Micaelo, R.; Monteiro Azevedo, N. 3D DEM model simulation of asphalt mastics with sunflower oil. Comput. Part. Mech. 2023, 10, 1569–1586. [Google Scholar] [CrossRef]

- Câmara, G.; Azevedo, N.M.; Micaelo, R. Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength. Sustainability 2025, 17, 7502. [Google Scholar] [CrossRef]

- Ding, L.; Wang, X.; Zhang, W.; Wang, S.; Zhao, J.; Li, Y. Microwave deicing efficiency: Study on the difference between microwave frequencies and road structure materials. Appl. Sci. 2018, 8, 2360. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, S.; Liu, Q.; Hu, J.; Yuan, Y.; Ye, Q. Snow and ice melting properties of self-healing asphalt mixtures with induction heating and microwave heating. Appl. Therm. Eng. 2018, 129, 871–883. [Google Scholar] [CrossRef]

- Liu, C.; Leng, L. Application of microwave heating technology in pothole repair. Munic. Technol. 2023, 41, 42–46. [Google Scholar] [CrossRef]

- Hua, Z. Microwave Absorbing Properties and Road Performance of Asphalt Mixture Doped with Natural Magnetite. Doctor’s Thesis, Chang’an University, Xi’an, China, 2016. [Google Scholar]

- Yang, H.; Ouyang, J.; Jiang, Z.; Ou, J. Effect of fiber reinforcement on self-healing ability of asphalt mixture induced by microwave heating. Constr. Build. Mater. 2023, 362, 129701. [Google Scholar] [CrossRef]

- Zhenhui, L. Research on the Self-Healing Performance of Steel Slag Porous Asphalt Mixtures Through Microwave Heating. Master’s Thesis, Nanjing University of Science & Technology, Nanjing, China, 2023. [Google Scholar]

- Jie, T.; Hua, Z.; Hongcheng, G. Microwave Self-healing Properties and Reasonable Content of Silicon CarbidePowder kiled Asphalt Mixtures. Mater. Rep. 2024, 38, 101–110. [Google Scholar]

- Wenliang, W.; Junlin, P.; Zhi, L. Numerical study on the internal heating mechanism of asphalt mixtures undermicrowave thermal induction. J. Henan Polytech. Univ. Nat. Sci. 2025, 44, 164–171. [Google Scholar] [CrossRef]

- Zheng, J.; Lü, S.; Liu, C. Technical system, key scientific problems and technical frontier of long-life pavement. Sci. Bull. 2020, 65, 3219–3227. [Google Scholar] [CrossRef]

- Ren, X.; Sha, A.; Jiang, W.; Jiao, W.; Li, J.; Wu, W.; Ling, X.; Li, J. Carbon Fiber Powder as a Microwave-Sensitive Filler in Asphalt Mastic: Improving High-Temperature and Fatigue Resistance Properties. J. Mater. Civ. Eng. 2025, 37, 04025111. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Jia, H.; Jing, H.; Chen, H.; Zhou, L.; Yuan, L.; Hoff, I. Characteristics and properties of asphalt mortar containing FO filler. Constr. Build. Mater. 2023, 392, 132039. [Google Scholar] [CrossRef]

- Yi, Z.; Bin, K.; Tianbao, W.; Yu, Z. Preparation of Microwave absorbing Asphalt Mixture andMicrowave Self-healing Properties. J. Mater. Sci. Eng. 2024, 42, 129–136. [Google Scholar] [CrossRef]

- Bin, K. Study on Self-Healing Performance of Microwave-Absorbing Asphalt Mixture by Microwave Heating. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2023. [Google Scholar]

- Yi, Z.; Bin, K.; Wan-jun, J.; Yu, Z. Study on the self-healing properties of carbonyl-iron powderfilled with asphalt mixture under microwave action. Appl. Chem. Ind. 2023, 52, 1078–1082. [Google Scholar] [CrossRef]

- Ziqiang, Z. Study on Self-Healing Characteristics and Enhancement Technology of Asphalt Mixture. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2024. [Google Scholar]

- Junying, R. Effect on Self-Healing of Conductive Asphalt Mixtures by Conductive Heat Generation. Master’s Thesis, Guilin University of Technology, Guilin, China, 2024. [Google Scholar]

- Jiang, L.; Shi-qi, L.; Sheng-jun, Y.; Chuang-min, L. Optimization of Influencing Factors of Self-healing Ability of SBS Modified Asphalt Mixture. J. Highw. Transp. Res. Dev. 2019, 36, 17–22. [Google Scholar]

- Weiyue, L. Research on Anti-Cracking Open-Graded Macroporous Asphalt Mixture. Master’s Thesis, South China University of Technology, Guangzhou, China, 2023. [Google Scholar]

- Chen, Y.; Simms, R.; Koh, C.; Lopp, G.; Roque, R. Development of a test method for evaluation and quantification of healing in asphalt mixture. Road Mater. Pavement Des. 2013, 14, 901–920. [Google Scholar] [CrossRef]

- Franesqui, M.A.; Yepes, J.; García-González, C. Top-down cracking self-healing of asphalt pavements with steel filler from industrial waste applying microwaves. Constr. Build. Mater. 2017, 149, 612–620. [Google Scholar] [CrossRef]

- Safavizadeh, S.A.; Kim, Y.R. DIC technique to investigate crack propagation in grid-reinforced asphalt specimens. J. Mater. Civ. Eng. 2017, 29, 04017011. [Google Scholar] [CrossRef]

- Zhu, X.; Ye, F.; Cai, Y.; Birgisson, B.; Yu, Y. Digital image correlation-based investigation of self-healing properties of ferrite-filled open-graded friction course asphalt mixture. Constr. Build. Mater. 2020, 234, 117378. [Google Scholar] [CrossRef]

- Zhao, L.; Yan, X.; Mi, S.; Gao, J.; Li, Y. Study on the self-healing behavior and rheological properties of carbonyl iron powder-modified asphalt mastic induced by microwave heating. Front. Built Environ. 2025, 11, 1629147. [Google Scholar] [CrossRef]

- Fei, C.; Linyan, Z.; Jiliang, F.; Yong, M.; Yanbin, Z. Research Progress on Test Methods of Asphalt Mixture’s Low-temperatureAnti-cracking Performance. Mater. Rep. 2021, 35, 127–137. [Google Scholar]

- Karimi, M.M.; Jahanbakhsh, H.; Jahangiri, B.; Nejad, F.M. Induced heating-healing characterization of activated carbon modified asphalt concrete under microwave radiation. Constr. Build. Mater. 2018, 178, 254–271. [Google Scholar] [CrossRef]

- Liu, H.; Yang, X.; Xia, C.; Zheng, J.; Huang, T.; Lv, S. Nonlinear fatigue damage model of asphalt mixture based on dynamic modulus and residual strength decay. Materials 2019, 12, 2236. [Google Scholar] [CrossRef]

- Weimin, S.; Zihao, X.; Hao, W.; Fei, X.; Yiqun, Z. A unified evaluation method for intermediate and lowtemperature fracture performance of asphalt concrete. J. Cent. South Univ. Sci. Technol. 2021, 52, 2386–2393. [Google Scholar]

- Haopeng, W.; Jun, Y.; Zheng, W.; Minghui, G.; Xiao, W. Investigation of Fatigue and Self-healing Characteristics of Asphalt Mixtures. Mod. Transp. Technol. 2014, 11, 1–5. [Google Scholar]

- Jun, Y.; Minghui, G.; ZHENG, W. Multiscale research progress of fatigue and self-healing properties of asphalt mixtures. China Sci. 2013, 8, 435–440. [Google Scholar]

- Haopeng, W.; Jun, Y.; Zheng, W.; Minghui, G.; Xiao, W. Study on Influence Factors of Self-healingCharacteristics of Asphalt. Pet. Asph. 2013, 27, 11–15. [Google Scholar]

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2012.

- Zhou, Z.F.; Tang, H.C.; Ou, X.W. Simulation analysis on SCB test of asphalt concrete using cohesive zone model. J. Jilin Univ. Eng. Technol. Ed. 2024, 1–9. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, H.; Shu, B.; Li, Y.; Gu, D.; Gao, Y.; Chen, A.; Feng, J.; Wu, S.; Liu, Q. Microwave heating mechanism and self-healing performance of asphalt mixture with basalt and limestone aggregates. Constr. Build. Mater. 2022, 342, 127973. [Google Scholar] [CrossRef]

- Qingyu, Z.; Jing, L.; Yi, Z.; Ying, L.; Xinyong, Z. Heat Transfer Characteristics and Its Influencing Factors of Aggregate Heated by Microwave. Mater. Rep. 2023, 37, 62–69. [Google Scholar]

- Sun, T.; Chen, L. Temperature field of asphalt mixture based on microwave heating. J. Microw. Power Electromagn. Energy 2017, 51, 59–70. [Google Scholar] [CrossRef]

- Zhou, Z. Research on Cracking Behavior and Fracture Mechanism of Plant Produced Reclaimed Asphalt Pavement Mixtures. Doctor’s Thesis, School of Transportation Southeast University, Nanjing, China, 2020. [Google Scholar]

- Tang, J.; Liu, Q.; Wu, S.; Ye, Q.; Sun, Y.; Schlangen, E. Investigation of the optimal self-healing temperatures and healing time of asphalt binders. Constr. Build. Mater. 2016, 113, 1029–1033. [Google Scholar] [CrossRef]

- Zhixiong, Z. Research on Relationship of Filler and the High-and-Low Temperatureperformance of Asphalt Mortar and Performance Prediction of Asphalt Mortar. Master’s Thesis, Hunan University, Changsha, China, 2013. [Google Scholar]

| Technical Specifications | Penetration (25 °C, 5 s, 100 g)/0.1 mm | Ductility (10 °C)/cm | Softening Point /°C | Dynamic Viscosity (60 °C)/Pa. s | Density/g/cm3 | Mass Loss (After TFOT)/% |

|---|---|---|---|---|---|---|

| Measured Value | 90 | 55 | 46 | 190 | 1.02 | 0.5 |

| Grain Size/mm | Apparent Relative Density | Relative Bulk Density | Water Absorption/% |

|---|---|---|---|

| 10–20 | 3.198 | 3.121 | 1.18 |

| 5–10 | 3.042 | 2.929 | 1.26 |

| 0–5 | 2.734 | 2.558 | — |

| Technical Specifications | Mineral Constituent/% | Rate of Water Content/% | Apparent Density/g/cm3 | Through Sieve Percentage/% | |||

|---|---|---|---|---|---|---|---|

| 0.6 mm | 0.15 mm | 0.075 mm | |||||

| Mineral Powder | CaCO3 | 96.5 | 0.2 | 2.745 | 100 | 97.1 | 83.8 |

| CaMg(CO3)2 | 3 | ||||||

| Others | 0.5 | ||||||

| Carbonyl Iron Powder | α-iron (body-centered cubic iron) | 99.6 | 0.1 | 7.812 | 100 | 100 | 100 |

| Others | 0.4 | ||||||

| Carbonyl Iron Powder Replacement Ratio/% | Optimal Asphalt-Aggregate Ratio/% | Bulk Specific Gravity/g/cm3 | VV/% | VMA/% | VFA/% | Stability/kN | Flow Value /mm |

|---|---|---|---|---|---|---|---|

| 0 | 4.62 | 2.760 | 4.0 | 14.2 | 69.1 | 17.52 | 3.01 |

| 20 | 4.58 | 2.755 | 3.9 | 13.8 | 70.2 | 16.28 | 3.23 |

| Influencing Factor | Variate Value | Micro-Index: HIt/% | Macro-Index: HIU/% | Healing Indicators: Pearson Correlation |

|---|---|---|---|---|

| Heating Time/s | 20 | 35.7 | 31.9 | 0.932 |

| 40 | 42.2 | 41.5 | ||

| 60 | 50.4 | 47.5 | ||

| 80 | 69.4 | 52.7 | ||

| 100 | 79.7 | 55.1 | ||

| 120 | 50.1 | 42.6 | ||

| Standing Time/h | 2 | 68.4 | 47.2 | 0.998 |

| 4 | 79.7 | 55.1 | ||

| 6 | 81.8 | 57.4 | ||

| Damage Degree/% | 30 | 83.7 | 65.2 | 0.991 |

| 50 | 79.7 | 55.1 | ||

| 70 | 51.2 | 25.2 |

| Grade | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Heating Time/s | 20 | 60 | 100 | 100 | 100 | 100 | 100 |

| Standing Time/h | 4 | 4 | 4 | 4 | 4 | 2 | 6 |

| Damage Degree/% | 50 | 50 | 30 | 50 | 70 | 50 | 50 |

| HIU/% | 31.9 | 47.5 | 65.2 | 55.1 | 25.2 | 47.2 | 57.4 |

| Evaluation Items | Correlation | Ranking |

|---|---|---|

| Heating Time/s | 0.686 | 1 |

| Damage Degree/% | 0.663 | 2 |

| Standing Time/h | 0.625 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Li, Y.; Zhao, L.; Gao, M. Study of Microwave Healing Properties of Carbonyl-Iron-Powder-Modified Asphalt Mixture Based on Digital Image Technology. Appl. Sci. 2025, 15, 10185. https://doi.org/10.3390/app151810185

Jia Y, Li Y, Zhao L, Gao M. Study of Microwave Healing Properties of Carbonyl-Iron-Powder-Modified Asphalt Mixture Based on Digital Image Technology. Applied Sciences. 2025; 15(18):10185. https://doi.org/10.3390/app151810185

Chicago/Turabian StyleJia, Yongjie, Yongxiang Li, Longwei Zhao, and Mingxing Gao. 2025. "Study of Microwave Healing Properties of Carbonyl-Iron-Powder-Modified Asphalt Mixture Based on Digital Image Technology" Applied Sciences 15, no. 18: 10185. https://doi.org/10.3390/app151810185

APA StyleJia, Y., Li, Y., Zhao, L., & Gao, M. (2025). Study of Microwave Healing Properties of Carbonyl-Iron-Powder-Modified Asphalt Mixture Based on Digital Image Technology. Applied Sciences, 15(18), 10185. https://doi.org/10.3390/app151810185