Study on the Multi-Scale Evolution Mechanism of Shear Bands and Cobweb Effect in Solidified Silt Considering Strain Rate

Abstract

1. Introduction

2. Test Materials and Procedures

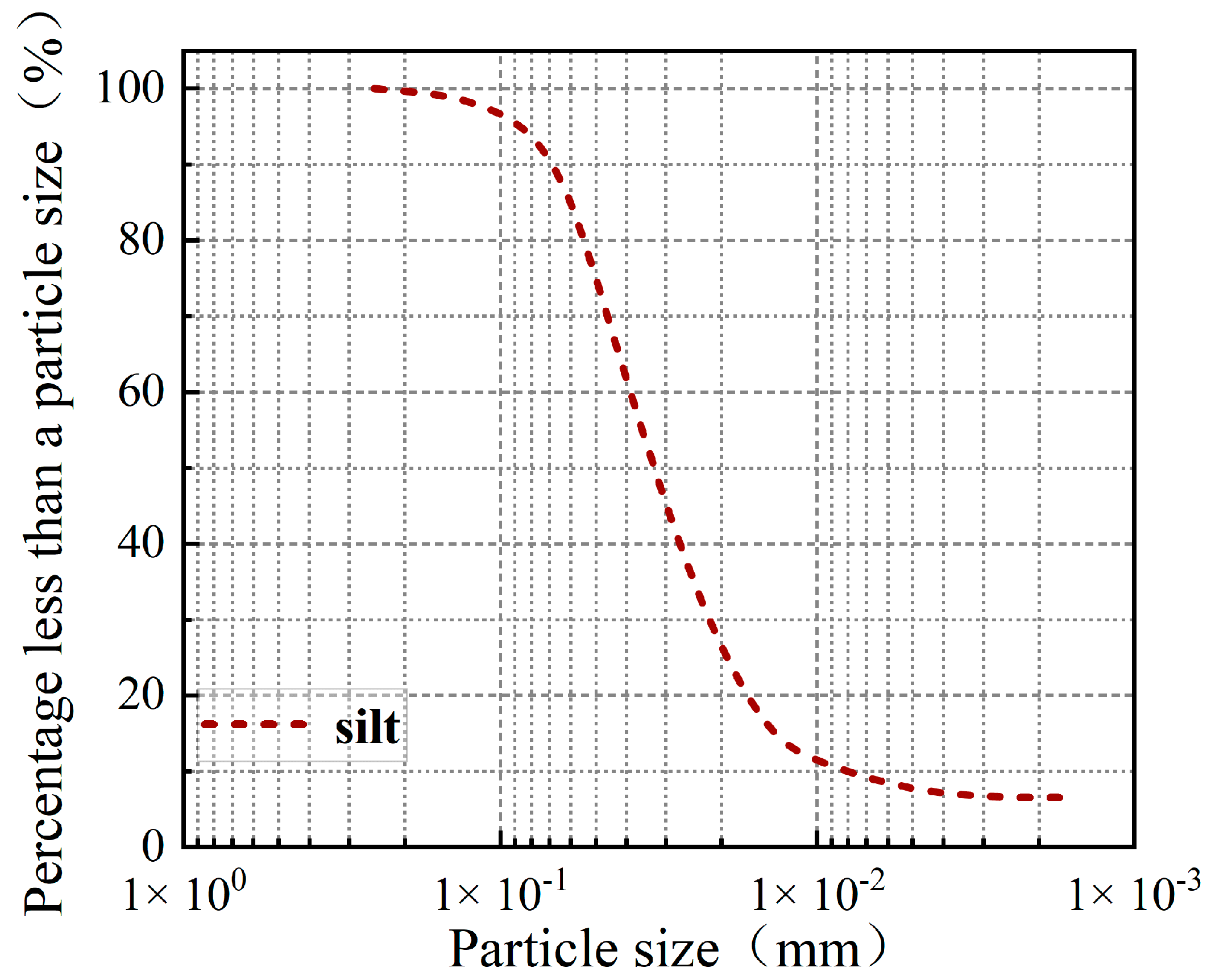

2.1. Materials

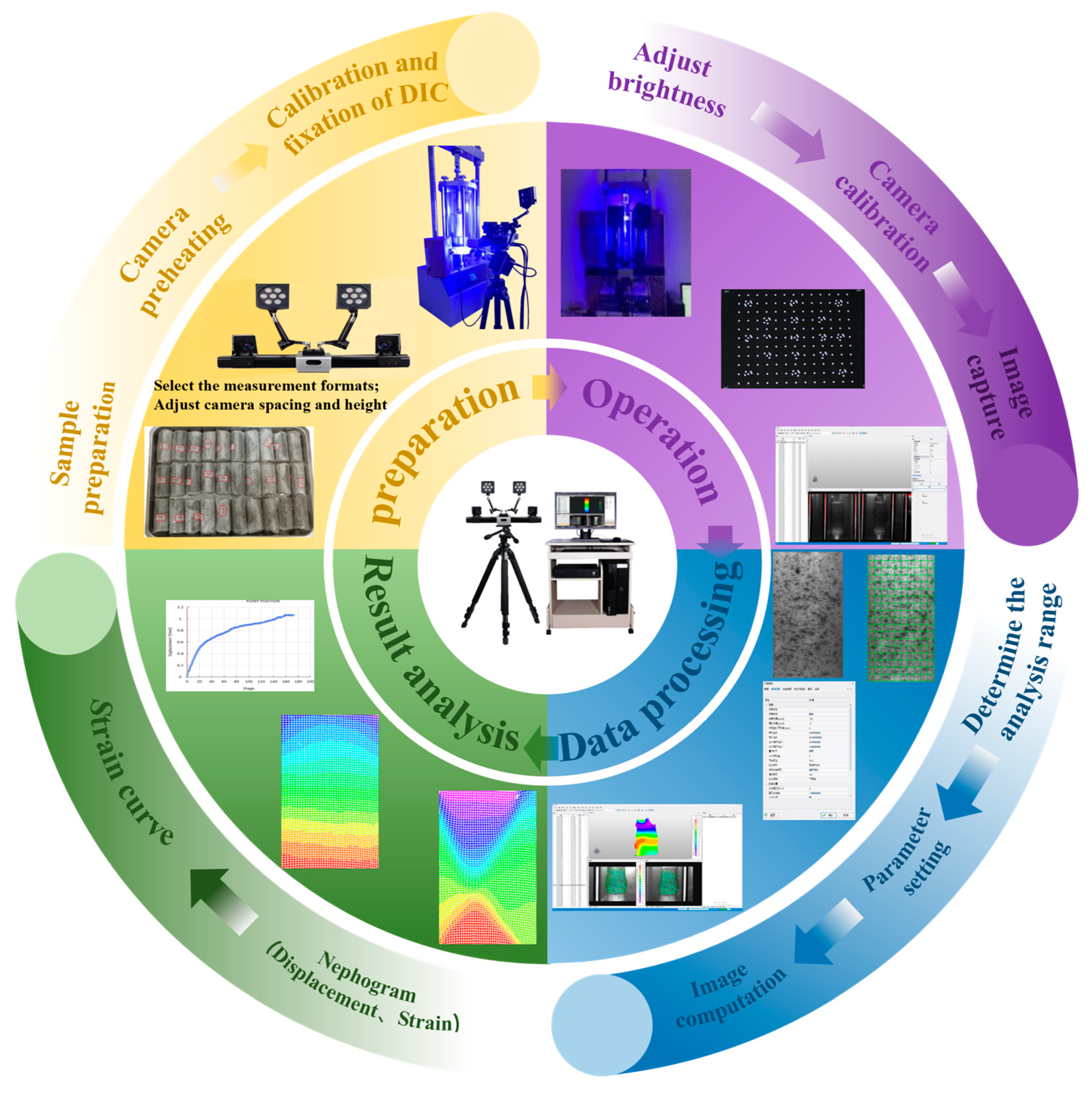

2.2. Test Procedure

3. Results and Discussion

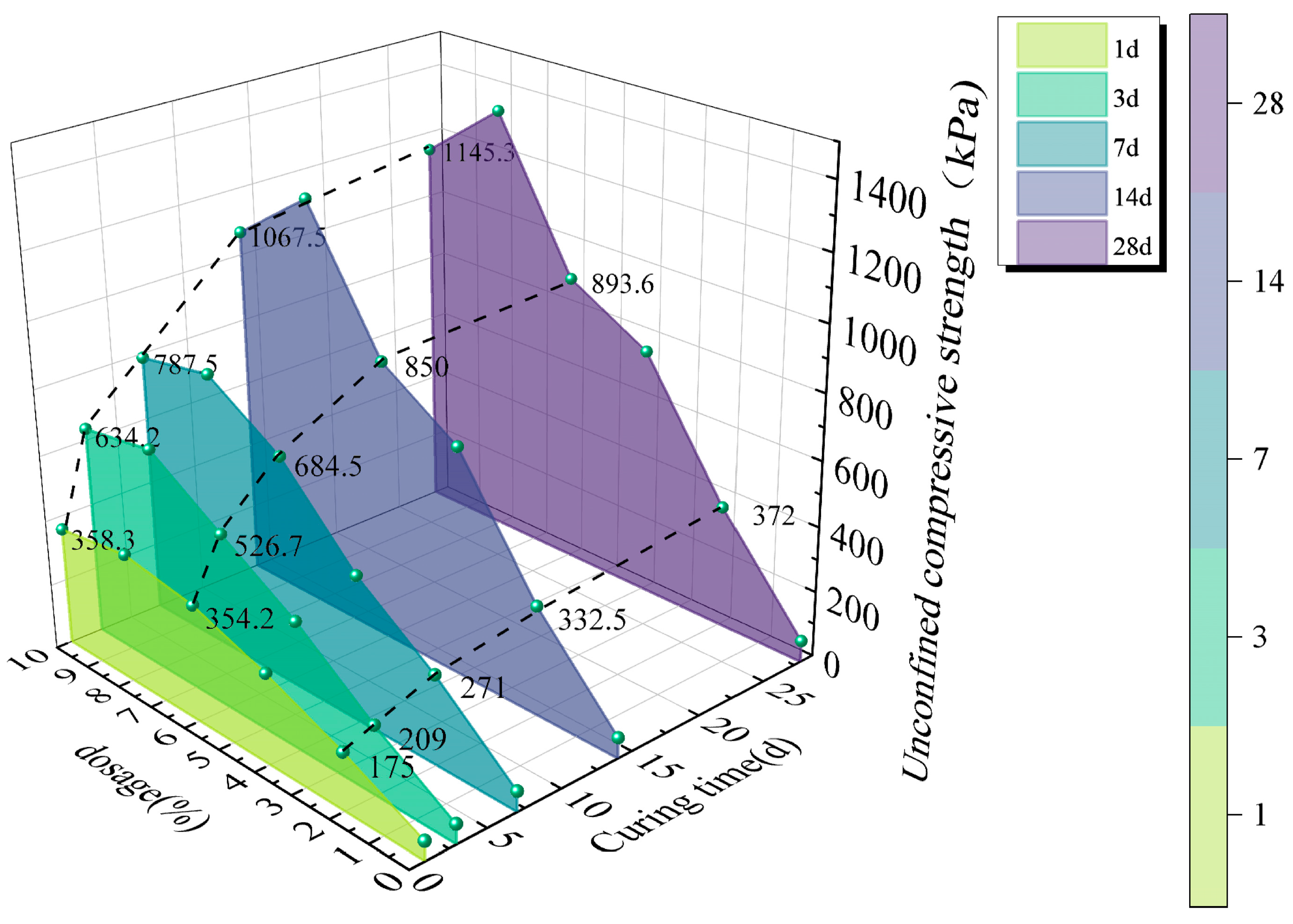

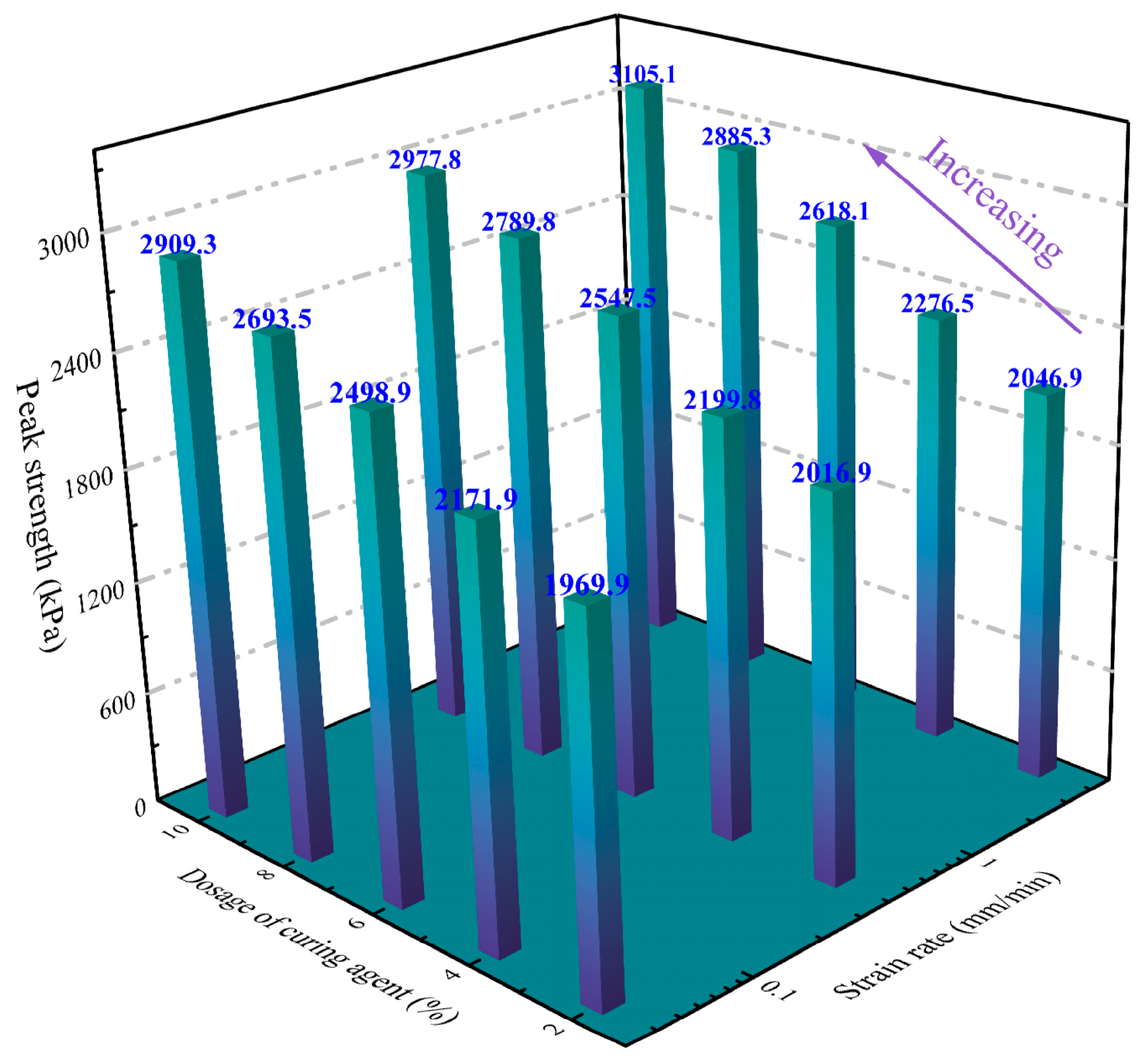

3.1. UCS of Stabilized Silt

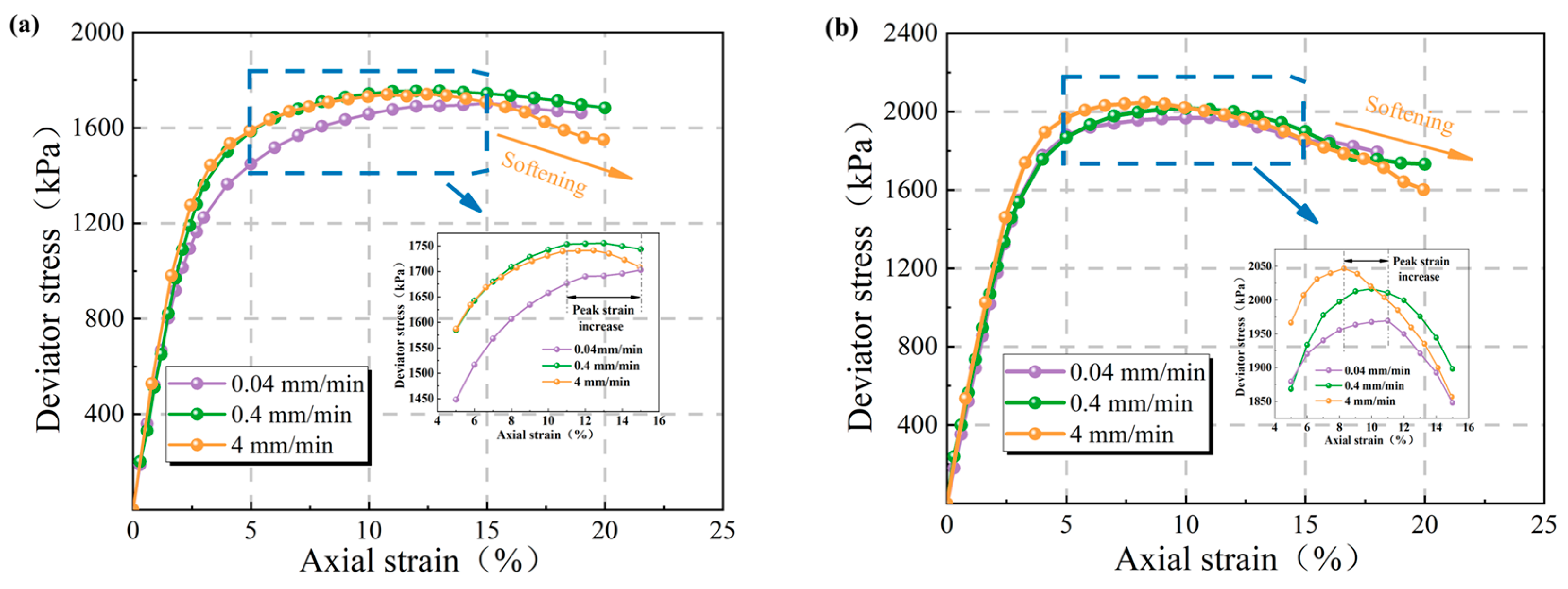

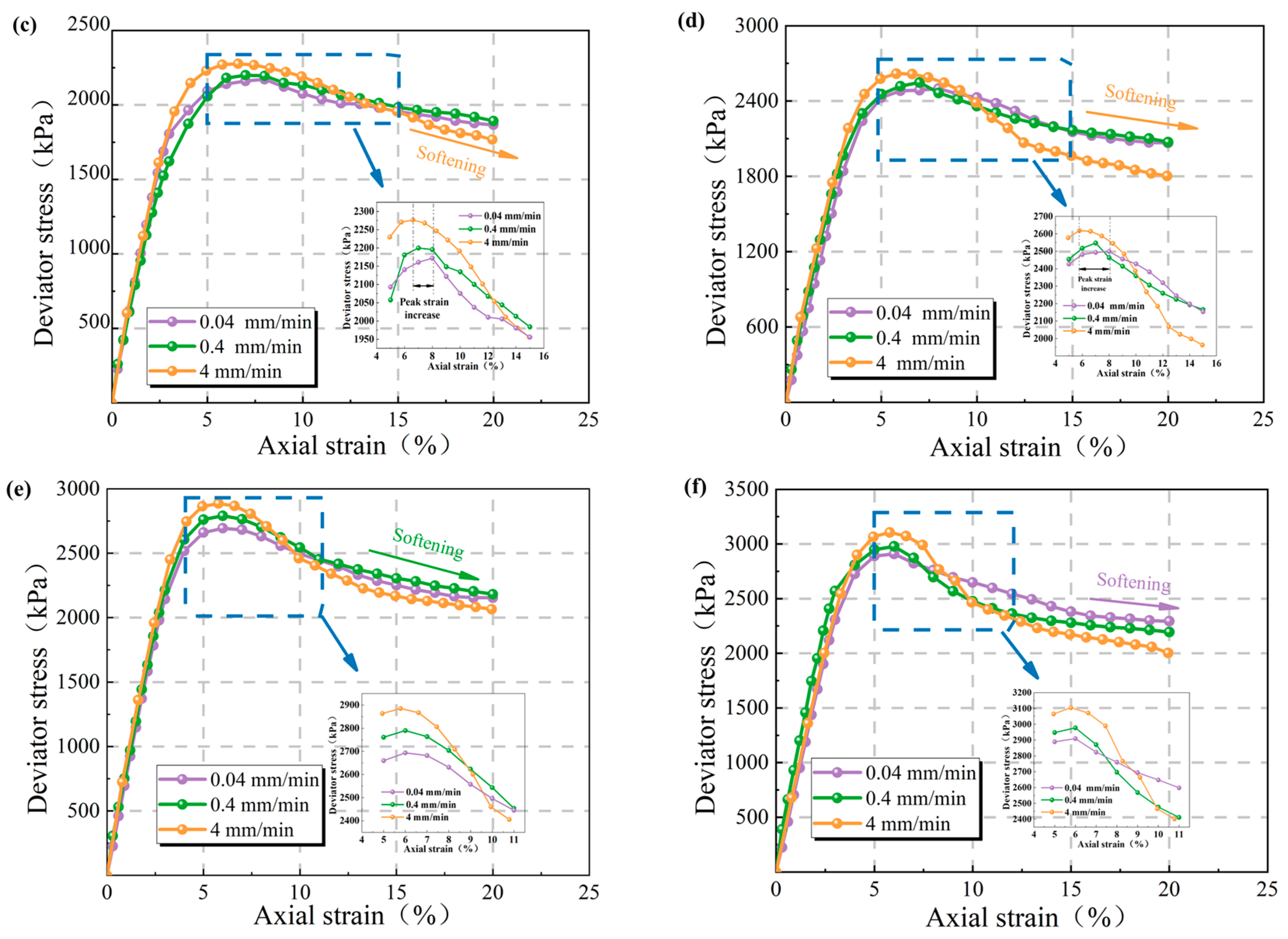

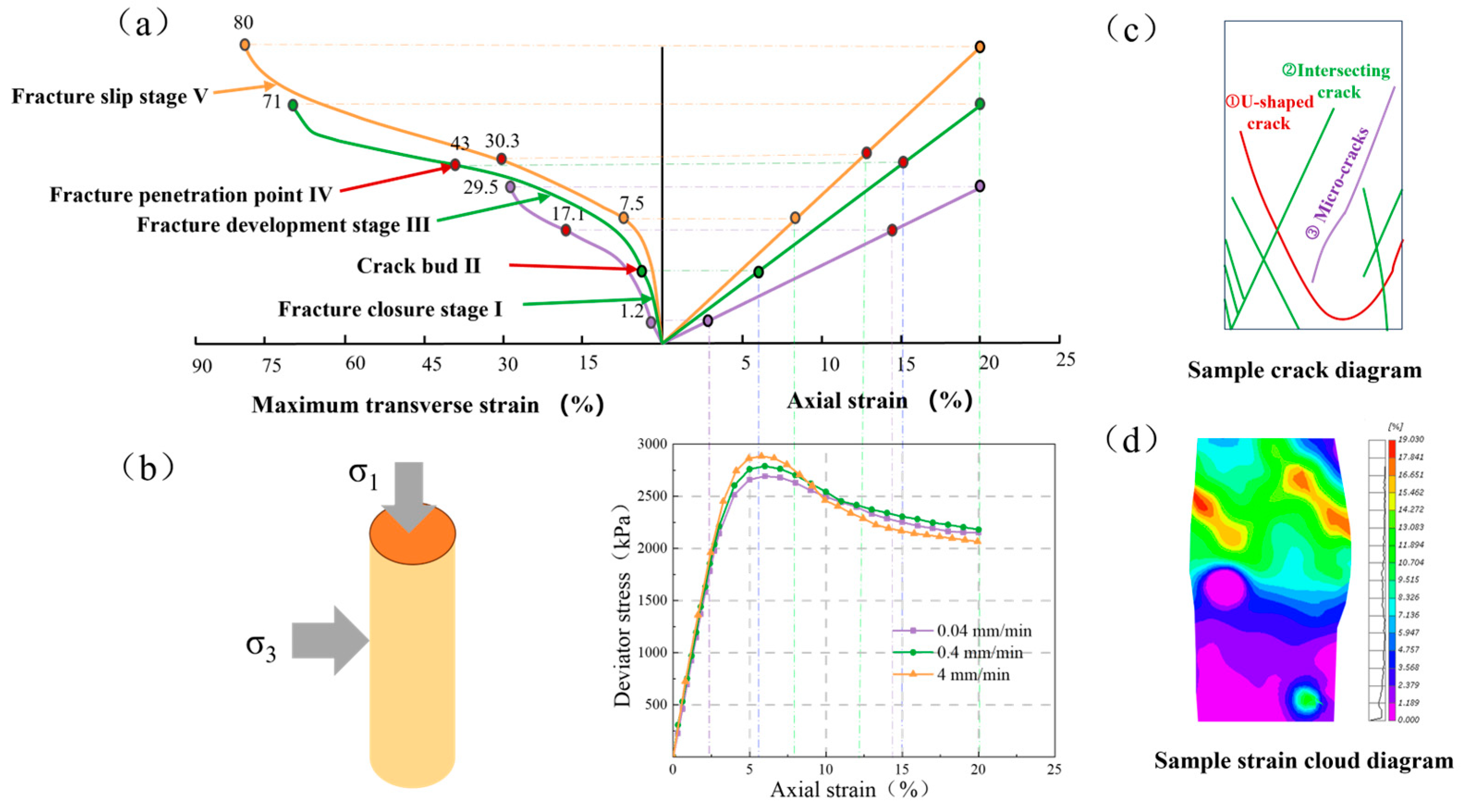

3.2. Stress–Strain Relationship of Stabilized Silt

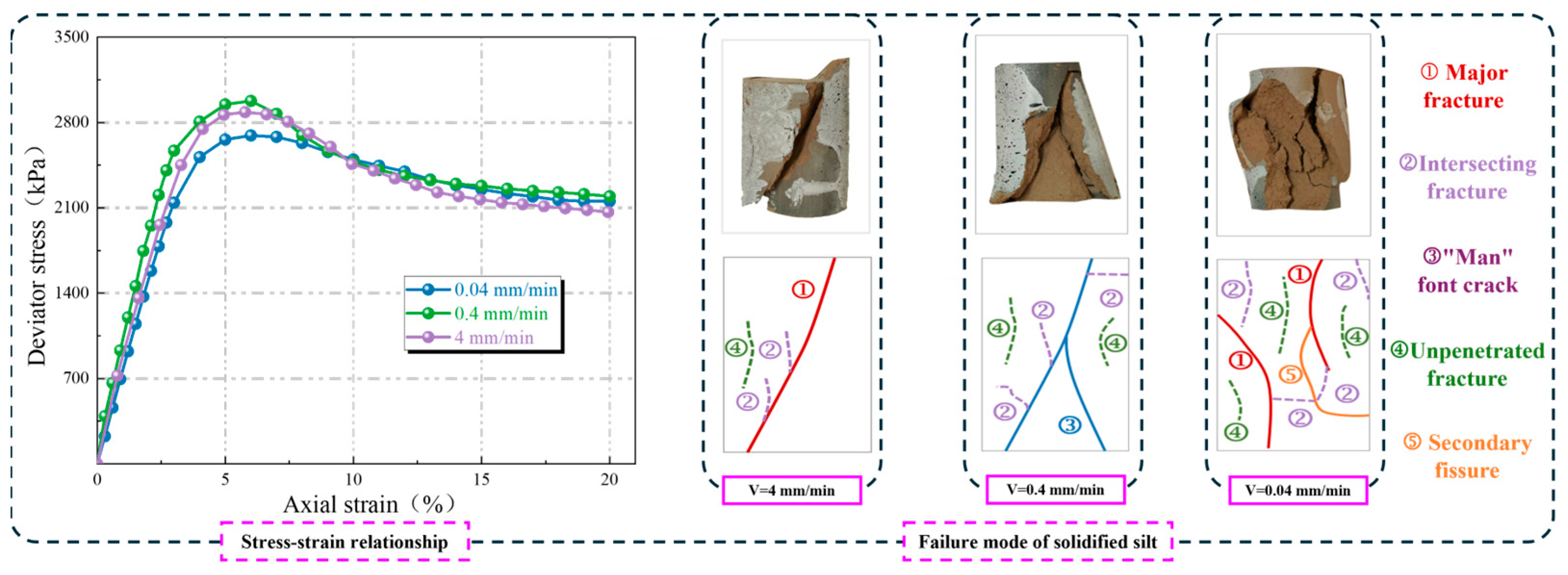

3.3. Failure Modes and Shear Band Evolution Characteristics of Stabilized Silt

3.3.1. Failure Mode and Crack Characteristics of Stabilized Silt

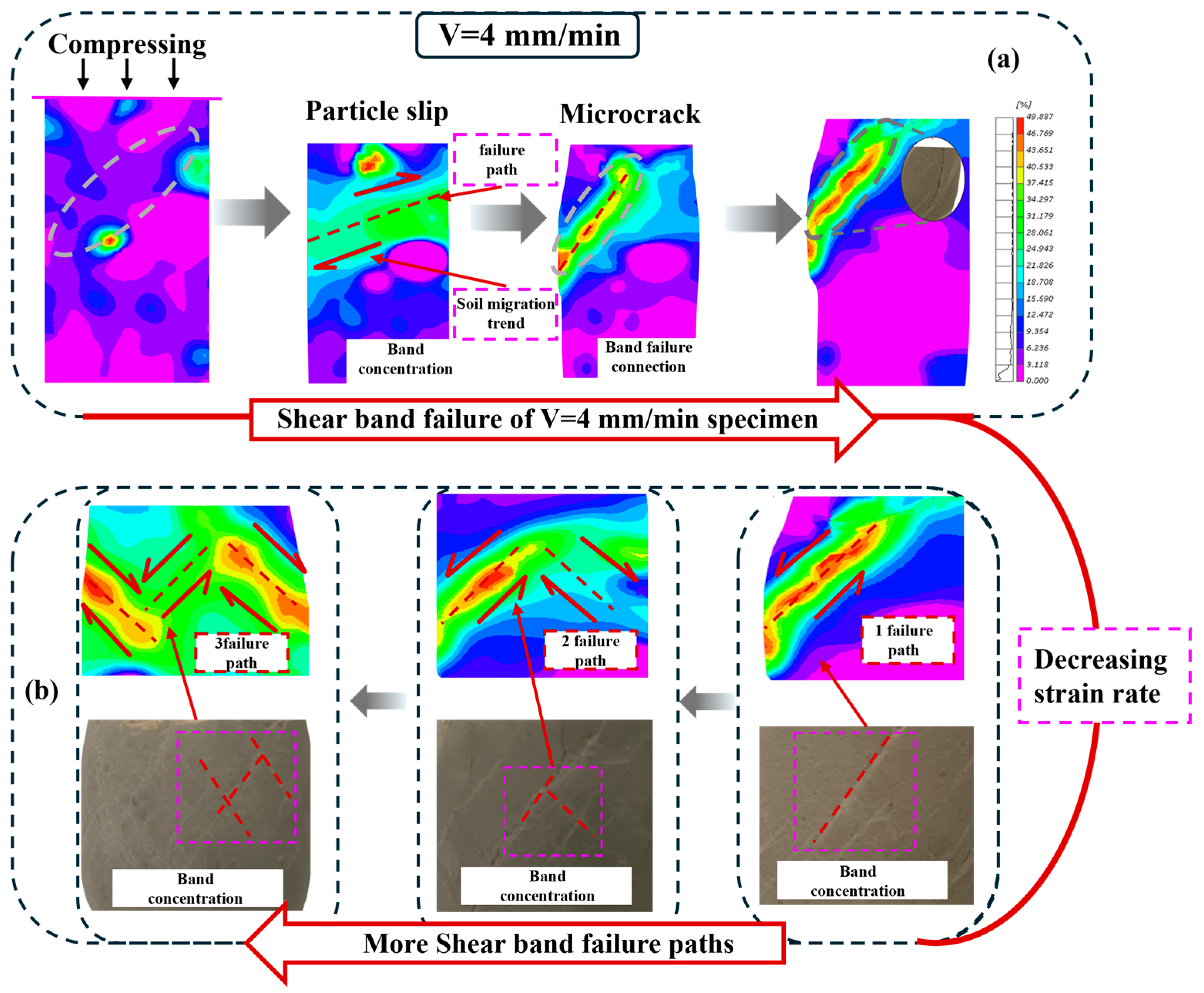

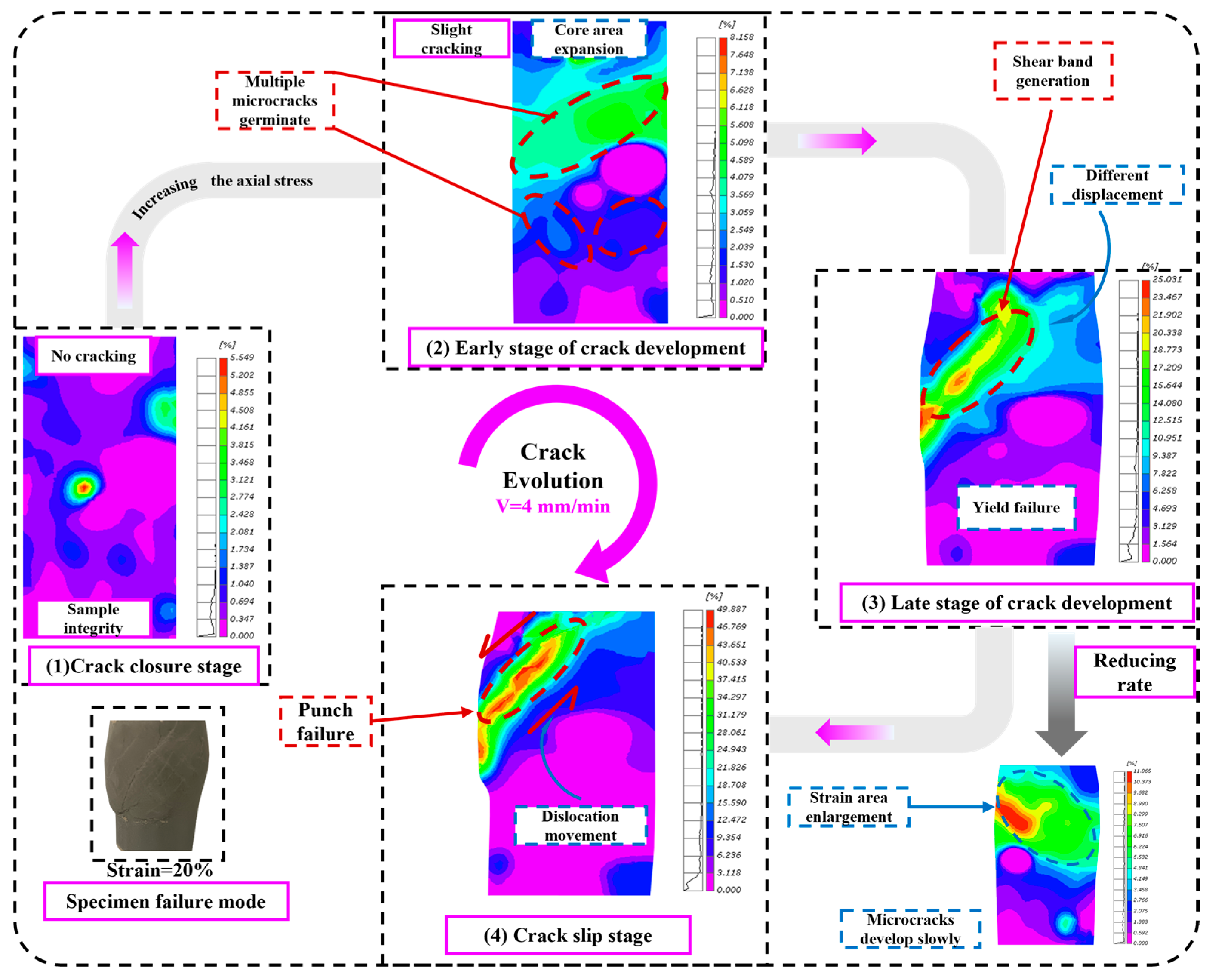

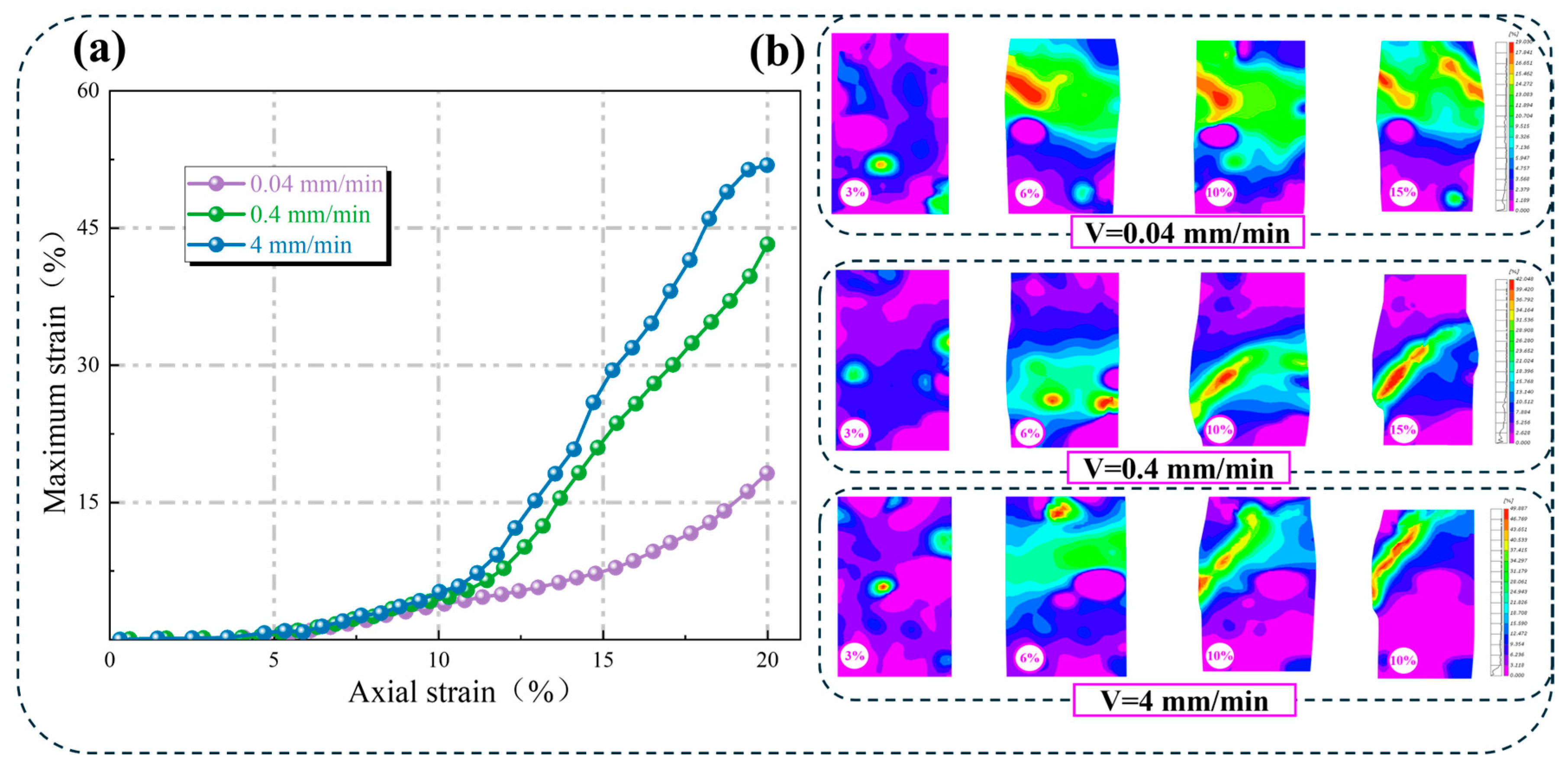

3.3.2. Development Characteristics of Shear Bands in Stabilized Silt

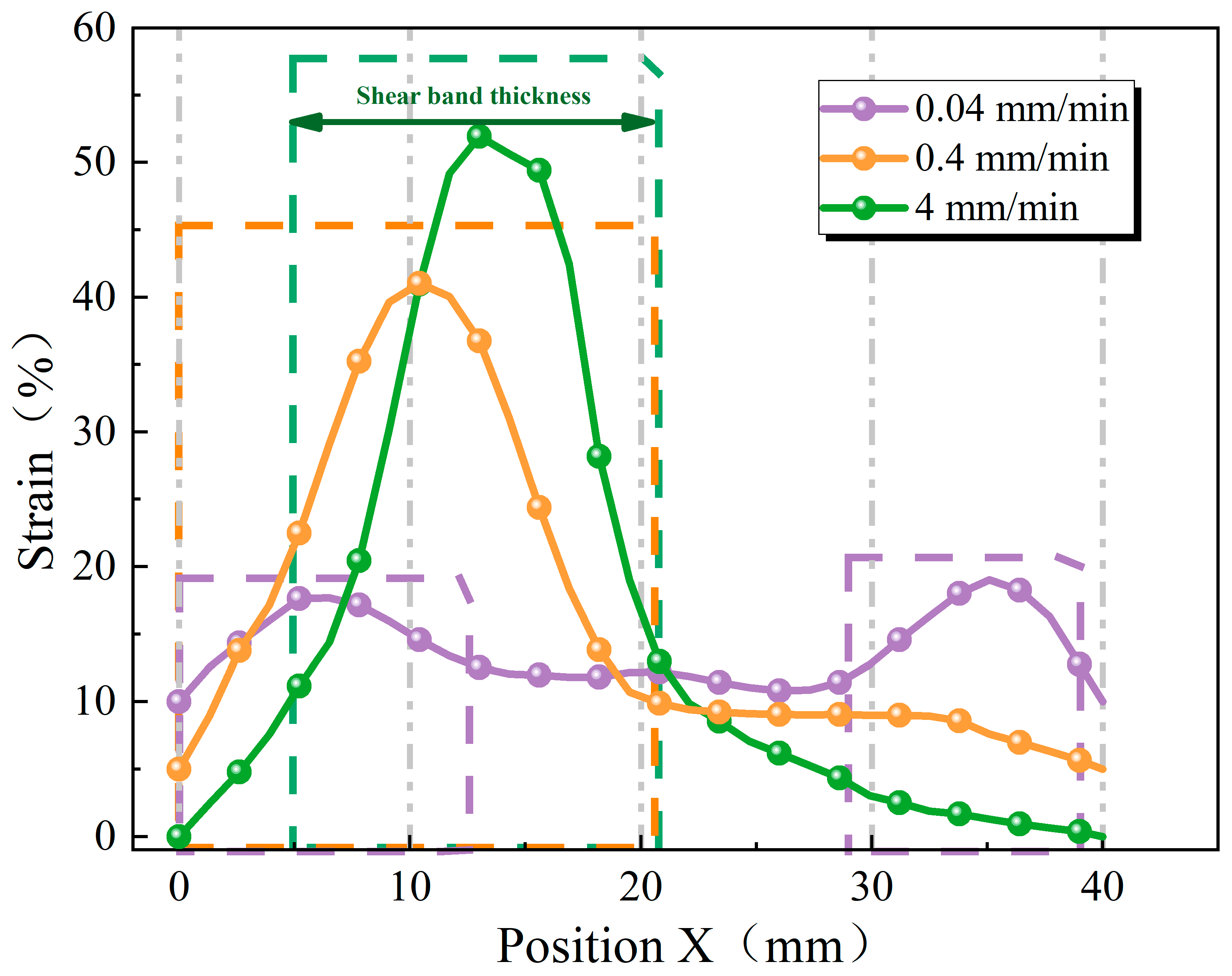

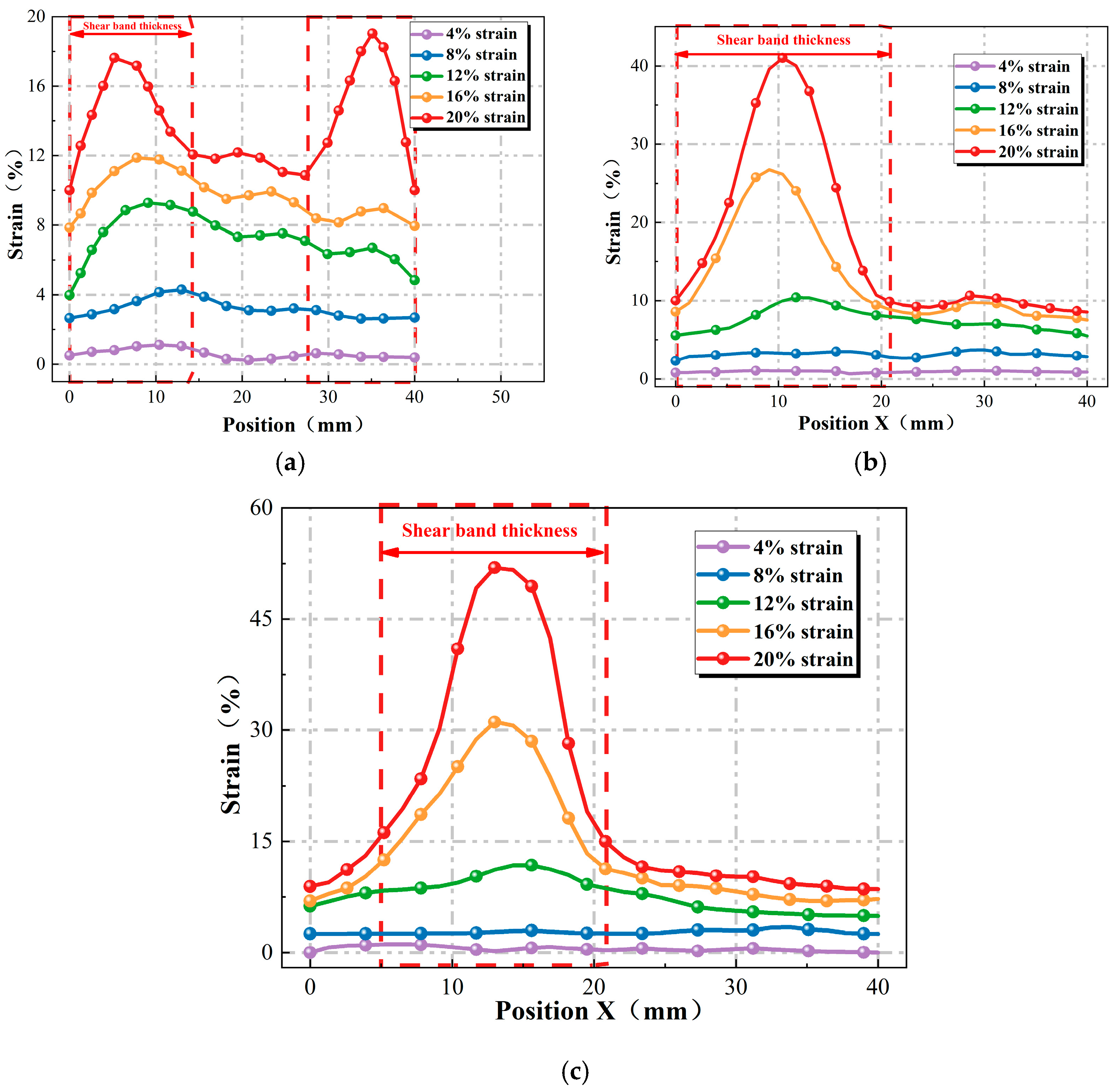

3.3.3. Thickness of Stabilized Silt Shear Band

4. Conclusions

- (1)

- A strength prediction model incorporating curing agent dosage and curing age was developed, effectively characterizing the strength development law of stabilized silt. The optimal content was determined to be 8%. As the curing agent dosage increases, the sensitivity of strain rate to the peak strength change rate of stabilized silt is enhanced, and a distinct lag effect of peak strain is observed under high strain rates.

- (2)

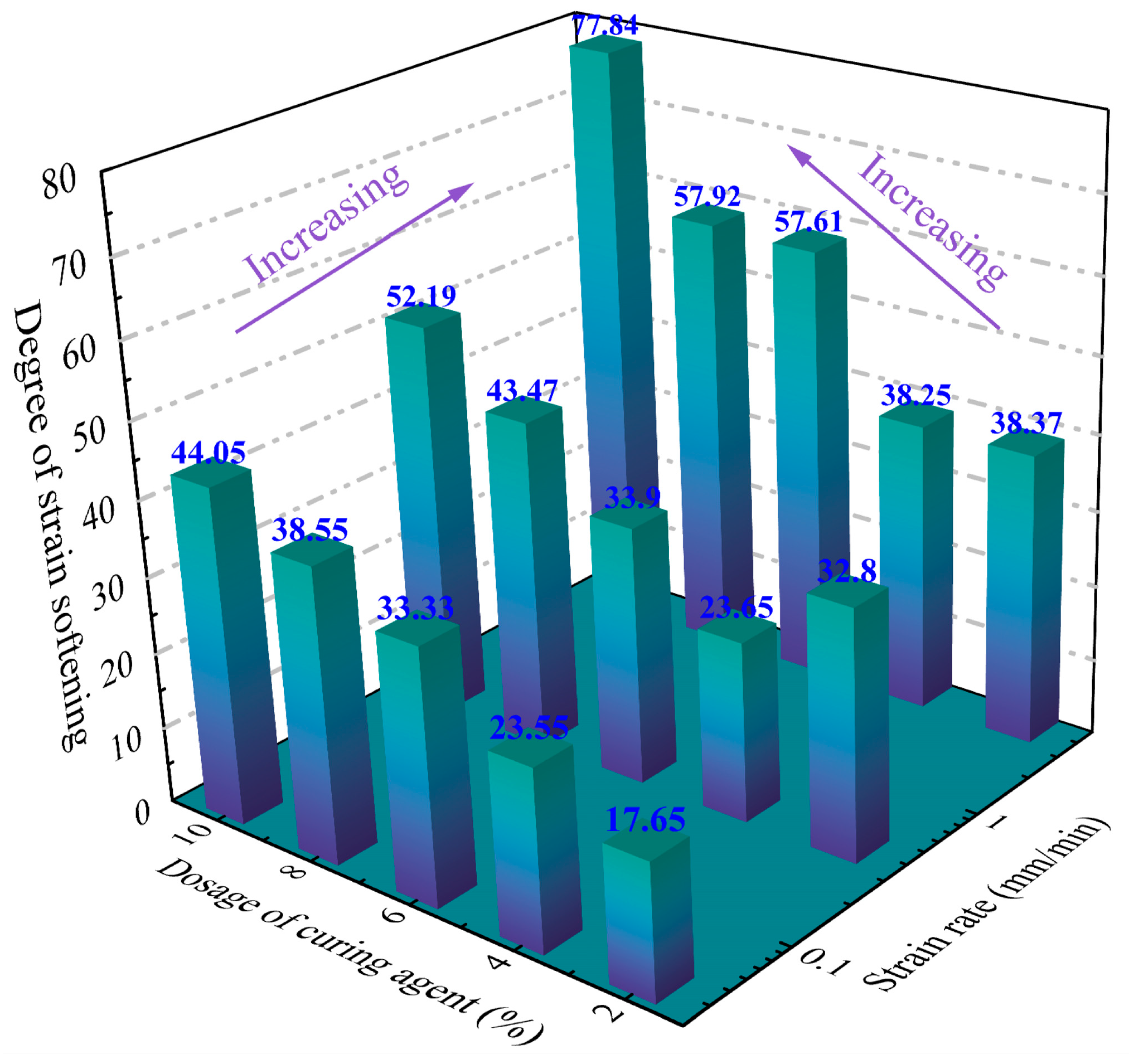

- The strain softening degree is sensitive to variations in strain rate and curing agent dosage, exhibiting a positive correlation with both factors. Specifically, at a curing agent dosage of 10%, an increase in strain rate from 0.04 mm/min to 4 mm/min results in a 33.79 kPa rise in strain softening degree. In contrast, the influence on pure silt is relatively minor.

- (3)

- Shear bands are a gradual process of development, and the development of shear bands in specimens can be obtained in three stages: crack closure stage, crack development stage, and crack slip stage; Under varying strain rates, changes occur in the internal energy dissipation and pore water pressure within the specimen, which in turn alter the development pattern of the shear band. Specifically, as the strain rate decreases, the development pattern of the shear band transitions from a single failure band to multiple diffuse bands.

- (4)

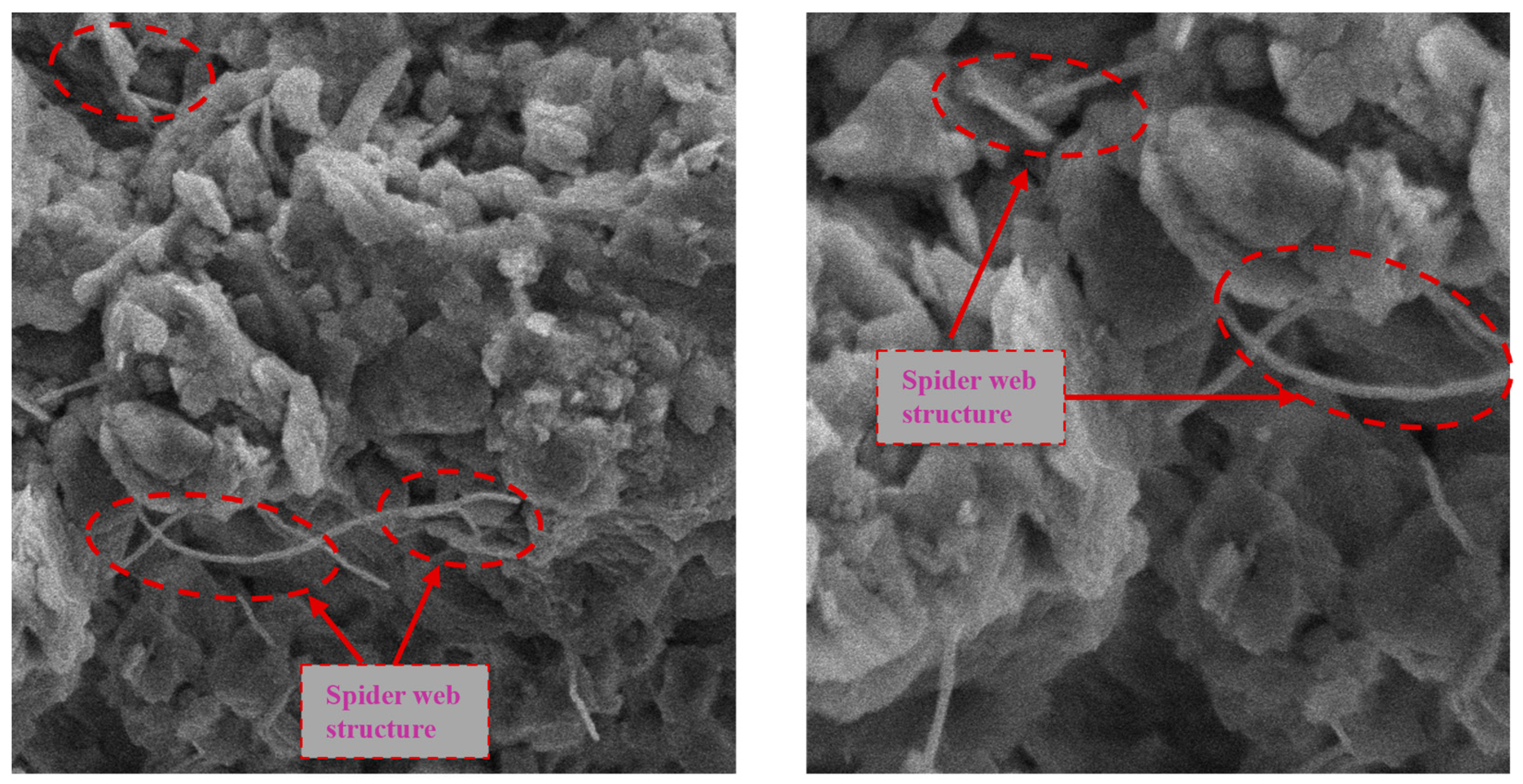

- The “spiderweb diffusion effect” of the shear band in stabilized silt under low strain rates is proposed. Compared with pure silt, the hydration products of stabilized silt form permanent chemical anchoring at interparticle contact points. Each cementation node within the spiderweb-like structure is capable of undergoing independent micro-damage, which mitigates stress mutations in the specimen.

- (5)

- Based on DIC, the shear band thickness and shear band characteristics of stabilized silt under varying strain rates were investigated. As the strain rate decreases, the cemented structure of the stabilized silt undergoes “adaptive adjustment,” which redistributes localized stress concentrations, retards the propagation of microcracks, and leads to a gradual increase in the thickness of the shear band. Compared with the maximum strain at a strain rate of 0.04 mm/min, the maximum strain along the shear band at strain rates of 0.4 mm/min and 4 mm/min decreased by 16.1% and 61.8%, respectively.

- (6)

- Actual slope failure processes often exhibit non-uniform velocity deformation. This study focuses on elucidating the evolution mechanism of shear bands under constant strain rates. Future work will extend this research to examine the development behavior of shear bands under variable strain rates and multiple influencing factors, thereby providing a theoretical foundation for predicting and addressing slope instability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.J.; Li, F.Y.; Guo, C.C. Mechanical properties and consolidation mechanism of polymer-solidified silt. J. Build. Mars. 2022, 25, 598–606. [Google Scholar] [CrossRef]

- Zhou, Q.Y.; Xiong, B.L.; Yang, G.Q.; Liu, W.C. Microstructure of Low Liquid Limit Silt. J. Geotech. Eng. 2013, 35, 439–444. [Google Scholar]

- Bai, J.H.; Yu, L.; Ye, X.F.; Yu, Z.B.; Wang, D.W.; Guan, Y.N.; Cui, B.S.; Liu, X.H. Dynamics of phosphorus fractions in surface soils of different flooding wetlands before and after flow-sediment regulation in the Yellow River Estuary. China J. Hydrol. 2020, 580, 124256. [Google Scholar] [CrossRef]

- Park, S.S.; Sung, S.W.; Nguyen, T.; Tran, D. Effect of silt uniformity on the liquefaction resistance of sand–silt mixtures. Soils Found. 2024, 64, 101507. [Google Scholar] [CrossRef]

- Li, J.D.; Zhang, Y.J.; Wang, X.; Jiang, D.J.; Wang, X.W. Research Status and Prospect of New Curing Agent Reinforcement of Expansive Soil. Mater. Rev. 2023, 37, 86–96. [Google Scholar] [CrossRef]

- Xu, F.; Cai, Y.B.; Qian, W.X.; Wei, H.; Zuang, H.X.; He, Y. Characterization and mechanism analysis of polynaphthalene sulfonate modified cemented soil. Constr. Build. Mater. 2020, 240, 117936. [Google Scholar] [CrossRef]

- Ding, L.Q.; Vanapalli, S.; Zou, W.L.; Han, Z.; Wang, X.Q. Freeze-thaw and wetting-drying effects on the hydromechanical behavior of a stabilized expansive soil. Constr. Build. Mater. 2021, 275, 122162. [Google Scholar] [CrossRef]

- Prakash, K.G.; Krishnamoorthy, A. Stability of embankment constructed on soft soil treated with soil cement columns. Transp. Infrastruct. Geotechnol. 2023, 10, 595–615. [Google Scholar] [CrossRef]

- Bian, X.; Wang, Z.F.; Ding, G.Q.; Cao, Y.P. Compressibility of cemented dredged clay at high water content with super-absorbent polymer. Eng. Geol. 2016, 208, 198–205. [Google Scholar] [CrossRef]

- Pu, S.Y.; Zhu, Z.D.; Wang, H.R.; Song, W.L.; Wei, R.J. Mechanical characteristics and water stability of silt solidified by incorporating lime, lime and cement mixture, and SEU-2 binder. Constr. Build. Mater. 2019, 214, 111–120. [Google Scholar] [CrossRef]

- Saidate, I.; Berga, A.; Rikioui, T. Stabilization of gypsum clay soil by adding lime. Civ. Eng. J. 2022, 8, 2511–2520. [Google Scholar] [CrossRef]

- Li, Y.; Su, L.; Ling, X.Z.; Wang, J.H.; Yang, Y.Z. Model studies on load-settlement characteristics of coarse-grained soil treated with geofiber and cement. Polymers 2018, 10, 621. [Google Scholar] [CrossRef]

- Zhu, J.F.; Tao, Y.L.; Xu, R.Q.; Yang, H.; Pan, B.J. Investigation on the optimal formulation and mechanism of marine organic silt improved with magnesium-cement- based stabilizer. Constr. Build. Mater. 2022, 341, 127233. [Google Scholar] [CrossRef]

- Sadek, Y.; Rikioui, T.; Abdoun, T.; Dadi, A. Influence of compaction energy on cement stabilized soil for road construction. Civ. Eng. J. 2022, 8, 580–594. [Google Scholar] [CrossRef]

- Wang, S.N.; Xue, Q.P.; Zhu, Y.; Li, G.Y.; Wu, Z.J.; Zhao, K. Experimental study on material ratio and strength performance of geopolymer-improved soil. Constr. Build. Mater. 2021, 267, 120469. [Google Scholar] [CrossRef]

- Mareya, M.; Tchadjie, L.; Sithole, T. Turning fly ash and waste gypsum into a resource for backfilling applications. Case Stud. Constr. Mater. 2024, 20, e02703. [Google Scholar] [CrossRef]

- Sukprasert, S.; Hoy, M.; Horpibulsuk, S.; Arulrajah, A.; Rashid, A.S.; Nazir, R. Fly ash based geopolymer stabilisation of silty clay/blast furnace slag for subgrade applications. Road Mater. Pavement Des. 2021, 22, 357–371. [Google Scholar] [CrossRef]

- Chen, R.M.; Jian, W.B.; Zhang, X.F.; Fang, Z.H. Experimental study on performance of sludge stabilized by CSFG-FR synergy. Rock Soil Mech. 2022, 43, 1020–1030. [Google Scholar]

- Huang, S.B.; He, Y.B.; Liu, X.W.; Xin, Z.K. Experimental investigation of the influence of dry-wet, freeze-thaw and water immersion treatments on the mechanical strength of the clay-bearing green sandstone. Int. J. Rock Mech. Min. Sci. 2021, 138, 104613. [Google Scholar] [CrossRef]

- Shen, K.Y. Experimental study on pressure sensitive properties of copper contaminated soil solidified by modified red mud. J. Environ. Eng. 2019, 27, 93–100. [Google Scholar] [CrossRef]

- Mozejko, C.A.; Francisca, F.M. Enhanced mechanical behavior of compacted clayey silts stabilized by reusing steel slag. Constr. Build. Mater. 2020, 239, 117901. [Google Scholar] [CrossRef]

- Sun, R.J.; Fang, C.; Gao, F.L.; Ge, Z.; Zhang, H.Z.; Lu, Q. Study on pavement performance and solidified mechanism of solidified soil based on solid waste. China J. Highw. Transp. 2021, 34, 216. [Google Scholar] [CrossRef]

- Kang, X.R.; Li, H.B.; Zhang, G.; Li, S.; Shan, L.; Zhao, J.; Zhang, Z. A Binary Medium Constitutive Model for Frozen Solidified Saline Soil in Cold Regions and Its Fractal Characteristics Analysis. Fractal Fract. 2024, 8, 33. [Google Scholar] [CrossRef]

- Shang, Y.Z.; Cui, Z.L.; Li, Y.J.; Zhang, Y.N.; Cheng, Y.H. Strength and Microscopic Mechanism of Cement–Fly Ash–Slag–Desulfurization Gypsum Solidified Mica Schist Weathered Soil. Materials 2023, 16, 6957. [Google Scholar] [CrossRef]

- Shu, H.; Yu, Q.B.; Niu, C.C.; Sun, D.; Wang, Q. The coupling effects of wet-dry and freeze–thaw cycles on the mechanical properties of saline soil synergistically solidified with sulfur-free lignin, basalt fiber and hydrophobic polymer. Catena 2024, 238, 107832. [Google Scholar] [CrossRef]

- Wang, X.B.; Zhang, N.; Pan, Y.S.; Du, Y.Z. Experimental study on Shear Zone Interaction and Damage of Uniaxial compressed cohesive Soil. Rock Soil Mech. 2018, 39, 1168–1175. [Google Scholar] [CrossRef]

- Thomas, T.Y. Plastic Flow and Fracture in Solids by Tracy Y Thomas; Elsevier: Amsterdam, The Netherlands, 1961. [Google Scholar]

- Chen, C.B.; Ye, G.L. Development of small-strain triaxial apparatus using LVDT sensors and its application to soft clay test. Rock Soil Mech. 2018, 39, 2304–2310. [Google Scholar] [CrossRef]

- Belmokhtar, M.; Delage, P.; Ghabezloo, S.; Conil, N. Drained triaxial tests in low-permeability shales: Application to the Callovo-Oxfordian claystone. Rock Mech. Rock Eng. 2018, 51, 1979–1993. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, J.F.; Coop, M.R.; Ye, G.L. A miniature triaxial apparatus for investigating the micromechanics of granular soils with in situ X-ray micro-tomography scanning. Front. Struct. Civ. Eng. 2020, 14, 357–373. [Google Scholar] [CrossRef]

- Salazar, S.E.; Barnes, A.; Coffman, R.A. Development of an internal camera–based volume determination system for triaxial testing. Geotech. Test. J. 2015, 38, 549–555. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.P.; Chen, H.; Shao, L.T.; Zhou, X.G.; Wang, S.H. Triaxial shear behavior of basalt fiber-reinforced loess based on digital image technology. KSCE J. Civ. Eng. 2021, 25, 3714–3726. [Google Scholar] [CrossRef]

- Wang, P.P.; Guo, X.X.; Sang, Y.; Shao, L.T.; Yin, Z.N.; Wang, Y.D. Measurement of local and volumetric deformation in geotechnical triaxial testing using 3D-digital image correlation and a subpixel edge detection algorithm. Acta Geotech. 2020, 15, 2891–2904. [Google Scholar] [CrossRef]

- Batiste, S.; Alshibli, K.A.; David Suits, L.; Sheahan, T. Shear Band Characterization of Triaxial Sand Specimens Using Computed Tomography. Geotech. Test. J. 2004, 27, 568–579. [Google Scholar] [CrossRef]

- Li, C.S.; Kong, L.W.; Shu, R.J.; An, R.; Jia, H.B. Dynamic three-dimensional imaging and digital volume correlation analysis to quantify shear bands in grus. Mech. Mater. 2020, 151, 103646. [Google Scholar] [CrossRef]

- Li, C.S.; Kong, L.W.; Zhang, B.X.; Liu, Z.J.; Shu, R.J.; Li, T.G. Determination of damage evolution characteristics in granite residual soil shear bands by micro-CT-based advanced digital volume correlation. Eng. Geol. 2024, 333, 107505. [Google Scholar] [CrossRef]

- Liu, B.H.; Kong, L.W.; Li, C.S.; Wang, J.T. Evolution of shear band in plane strain compression of naturally structured clay with a high sensitivity. Appl. Sci. 2022, 12, 1180. [Google Scholar] [CrossRef]

- Su, D.; Wu, D.Z.; Fan, M.; Zhang, R.Q.; Chen, J.H.; Xiong, H.; Chen, X.S. DEM investigation into the coupling effects of particle asphericity and interface roughness on shear behaviour of soil-structure interface. Particuology 2025, 97, 39–57. [Google Scholar] [CrossRef]

- Ye, Z.T.; Gao, Y.F.; Shu, S.; He, X.C.; Sun, Y.F. Effects of Surface Roughness, Gradation, Relative Density, and Normal Stiffness on Global and Local Behaviors of the Sand–Steel Interface. J. Geotech. Geoenviron. Eng. 2025, 151, 04025078. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for geotechnical testing method. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2024.

- Zhang, T. Research on the Solidification and Improvement Technology and Engineering Application of Silt Based on Industrial By-Product Lignin; Southeast University: Nanjing, China, 2017. [Google Scholar]

- Yang, H.; Zhu, J.F.; Tao, Y.L.; Wang, Z.Q.; Zheng, Q.Q. Effect of the dry-wet cycle on the performance of marine waste silt solidified by calcium carbide residue and plant ash. J. Mar. Sci. Eng. 2022, 10, 1442. [Google Scholar] [CrossRef]

- Shang, Y.Z.; Cui, Z.L.; Zhang, Y.N. Experimental Study on the Synergistic Solidification of Soft Soil with Ceramic Powder–Slag–Phosphorus Slag. Sustainability. 2023, 15, 15474. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, H.C.; Cheng, M.Y.; Lu, H.W.; Wang, Z.J.; Feng, P.Y. Dynamic triaxial test and microscopic study of solidified muddy soil with different mixing ratios and curing ages. Front. Mater. 2021, 8, 731449. [Google Scholar] [CrossRef]

- Chen, M.L.; Wu, D.Z.; Chen, K.Y.; Cheng, P.R.; Tang, Y.H. The influence of fly ash-based geopolymer on the mechanical properties of OPC-solidified soil. Constr. Build. Mater. 2024, 432, 136591. [Google Scholar] [CrossRef]

- Wang, H.B.; Ren, H.; Zhang, X.J.; Sun, W.C.; Xu, F.; Luo, A.J.; Xu, W.J. The influence of fine-grained soil and loading rate on the mechanical behavior of soil-rock mixtures. Hydrogeol. Eng. Geol. 2024, 51, 86–92. [Google Scholar] [CrossRef]

- Su, C.D.; Li, H.Z.; Zhang, S.; Gou, P.F. Experimental investigation on the effect of Strain Rate on the Mechanical Properties of Marble. J. Rock Mech. Eng. 2013, 32, 943–950. Available online: https://rockmech.whrsm.ac.cn/CN/abstract/abstract28122.shtml (accessed on 19 November 2012).

- Zhou, R.X. Research on the Influence of Strain Rate on the Localization of Planar Strain in Frozen Sand. Master’s Thesis, Xi'an University of Technology, Xi'an, China, 2024. [Google Scholar] [CrossRef]

- Cai, Y.; Kong, L.W.; Guo, A.G.; Tuo, Y.F. The influence of shear strain rate on the mechanical properties of strong structural clay in Zhanjiang. Geotech. Mech. 2006, 8, 1235–1240. [Google Scholar]

- Xu, X.T.; Wang, Y.B.; Yin, Z.H.; Zhang, H.W. Effect of temperature and strain rate on mechanical characteristics and constitutive model of frozen Helin loess. Cold Reg. Sci. Technol. 2017, 136, 44–51. [Google Scholar] [CrossRef]

- Gylland, A.S.; Jostad, H.P.; Nordal, S. Experimental study of strain localization in sensitive clays. Acta Geotech. 2014, 9, 227–240. [Google Scholar] [CrossRef]

- Yao, X.L.; Wang, W.L.; Zhang, M.Y.; Wang, S.H.; Wang, L.P. Strain localization of a frozen sand under different test conditions. Cold Reg. Sci. Technol. 2021, 183, 103226. [Google Scholar] [CrossRef]

- Gong, L.X.; Nie, L.; Xu, Y. Discrete Element Analysis of the Strength Anisotropy of Fiber-Reinforced Sands Subjected to Direct Shear Load. Appl. Sci. 2020, 10, 3693. [Google Scholar] [CrossRef]

- Shi, C.; Yang, J.X.; Chu, W.J.; Tang, H.; Zhang, Y.P. Macro-and micromechanical behaviors and energy variation of sandstone under different unloading stress paths with DEM. Int. J. Geomech. 2021, 21, 04021127. [Google Scholar] [CrossRef]

- Lu, X.B.; Wang, S.Y.; Peng, C. On the evolution of simple shear in saturated soils. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 269–278. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.H.; Ma, C.H.; Mok, C.M.B. Experimental characterization and 3D DEM simulation of bond breakages in artificially cemented sands with different bond strengths when subjected to triaxial shearing. Acta Geotech. 2017, 12, 987–1002. [Google Scholar] [CrossRef]

- Vardoulakis, I. Deformation of water-saturated sand: II. Effect of pore water flow and shear banding. Géotechnique 1996, 46, 457–472. [Google Scholar] [CrossRef]

- Sulem, J.; Vardoulakis, I. Bifurcation Analysis in Geomechanics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar] [CrossRef]

- Jostad, H.; Andresen, L.; Thakur, V. Calculation of shear band thickness in sensitive clays. Numer. Methods Geotech. Eng. 2006, 1, 27–32. [Google Scholar] [CrossRef]

- Thakur, V. Numerically observed shear bands in soft sensitive clays. Geomech. Geoengin. 2011, 6, 131–146. [Google Scholar] [CrossRef]

- Thakur, V. Strain Localization in Sensitive Soft Clays. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2007. [Google Scholar]

- Soltanbeigi, B.; Adlen, A.; Cinicioglu, O. Influence of dilatancy on shear band characteristics of granular backfills. Eur. J. Environ. Civ. Eng. 2021, 25, 1201–1218. [Google Scholar] [CrossRef]

- Menon, S.; Song, X. Shear banding in unsaturated geomaterials through a strong nonlocal hydromechanical model. Eur. J. Environ. Civ. Eng. 2022, 26, 3357–3371. [Google Scholar] [CrossRef]

- Lu, N.; Likos, W.J. Unsaturated Soil Mechanics; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2004. [Google Scholar] [CrossRef]

| Optimal Moisture Content/% | Maximum Dry Density g/cm3 | Liquid Limit/% | Plastic Limit/% | Specific Gravity | Plasticity Index |

|---|---|---|---|---|---|

| 17.70 | 1.62 | 29.64 | 20.36 | 2.70 | 9.28 |

| Sample Number | Curing Agent Content (%) | Strain Rate (mm/min) | Sample Number | Curing Agent Content (%) | Strain Rate (mm/min) |

|---|---|---|---|---|---|

| M1 | 0 | 0.04 | M10 | 6 | 0.04 |

| M2 | 0.4 | M11 | 0.4 | ||

| M3 | 4 | M12 | 4 | ||

| M4 | 2 | 0.04 | M13 | 8 | 0.04 |

| M5 | 0.4 | M14 | 0.4 | ||

| M6 | 4 | M15 | 4 | ||

| M7 | 4 | 0.04 | M16 | 10 | 0.04 |

| M8 | 0.4 | M17 | 0.4 | ||

| M9 | 4 | M18 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wu, X.; Cui, Y.; Zhang, Y.; Duan, H.; Ling, X. Study on the Multi-Scale Evolution Mechanism of Shear Bands and Cobweb Effect in Solidified Silt Considering Strain Rate. Appl. Sci. 2025, 15, 10128. https://doi.org/10.3390/app151810128

Yang Z, Wu X, Cui Y, Zhang Y, Duan H, Ling X. Study on the Multi-Scale Evolution Mechanism of Shear Bands and Cobweb Effect in Solidified Silt Considering Strain Rate. Applied Sciences. 2025; 15(18):10128. https://doi.org/10.3390/app151810128

Chicago/Turabian StyleYang, Zhongnian, Xiaoyang Wu, Yuxue Cui, Yingying Zhang, Hongfei Duan, and Xianzhang Ling. 2025. "Study on the Multi-Scale Evolution Mechanism of Shear Bands and Cobweb Effect in Solidified Silt Considering Strain Rate" Applied Sciences 15, no. 18: 10128. https://doi.org/10.3390/app151810128

APA StyleYang, Z., Wu, X., Cui, Y., Zhang, Y., Duan, H., & Ling, X. (2025). Study on the Multi-Scale Evolution Mechanism of Shear Bands and Cobweb Effect in Solidified Silt Considering Strain Rate. Applied Sciences, 15(18), 10128. https://doi.org/10.3390/app151810128