Vibration Tracing Analysis and External Excitation Damping Method of Combine Harvester Based on Short-Time Fourier

Abstract

1. Introduction

2. Materials and Methods

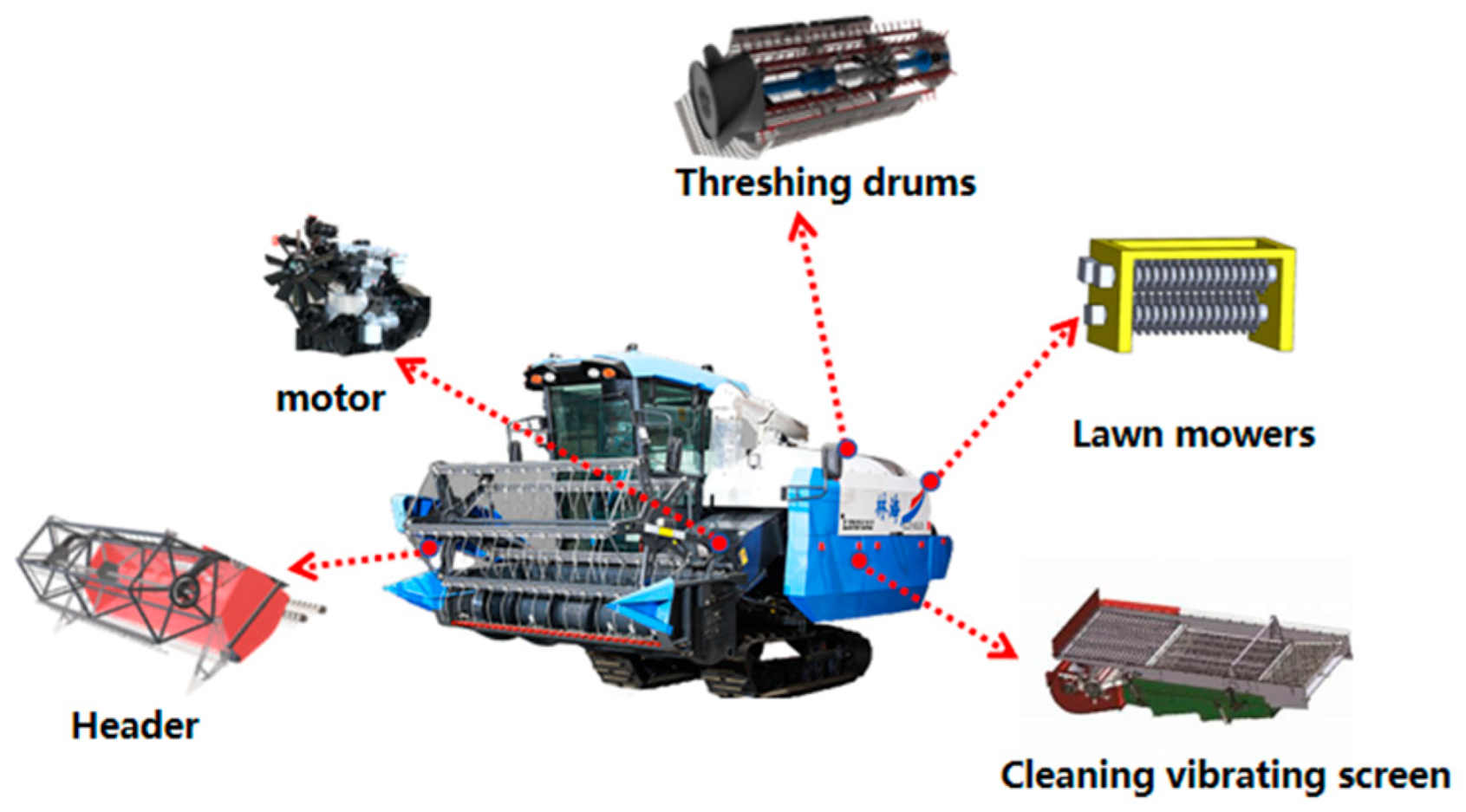

2.1. Combine Overall Structure and Components

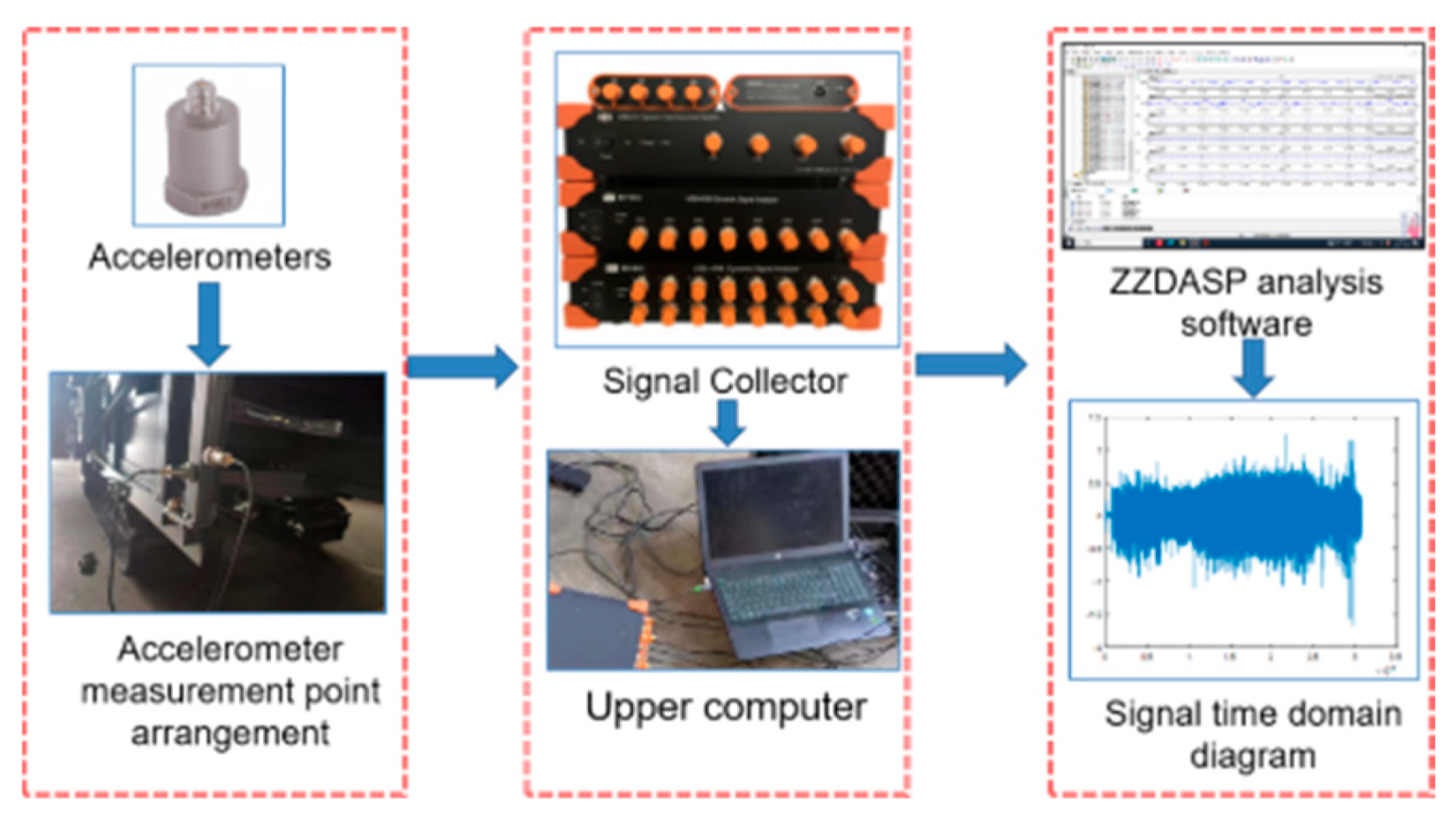

2.2. Test of Harvester Vibration Signal

2.3. Vibration Signal Test Principle of Harvester Based on Short Time Fourier, VLI Index, and RMS Index

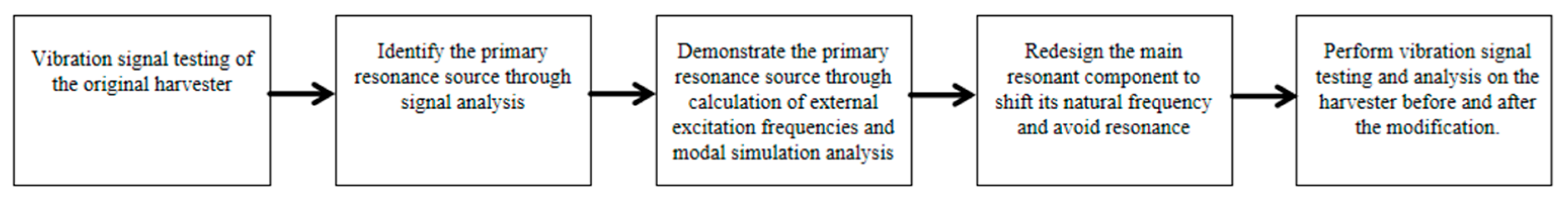

2.4. Overall Process

3. Results

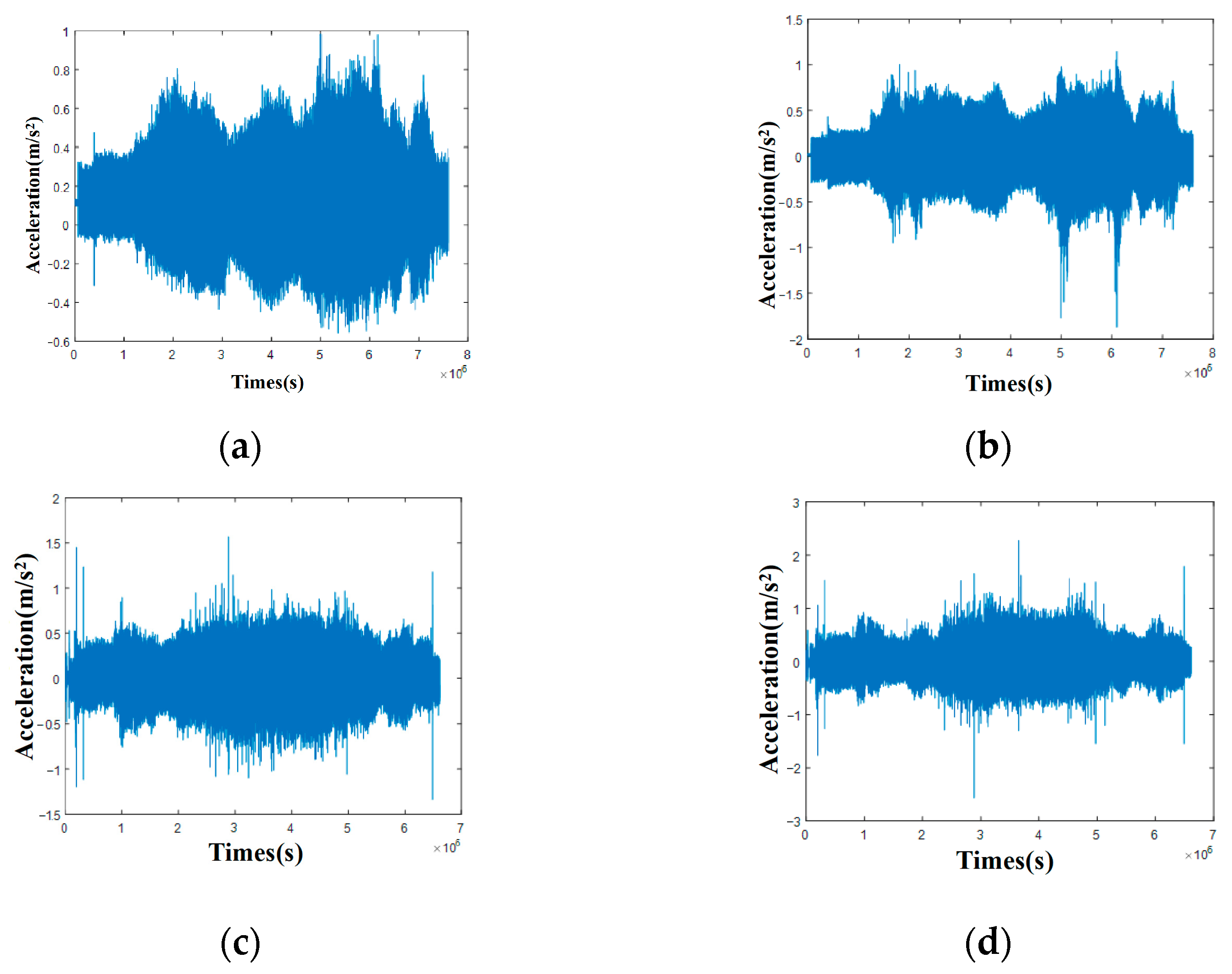

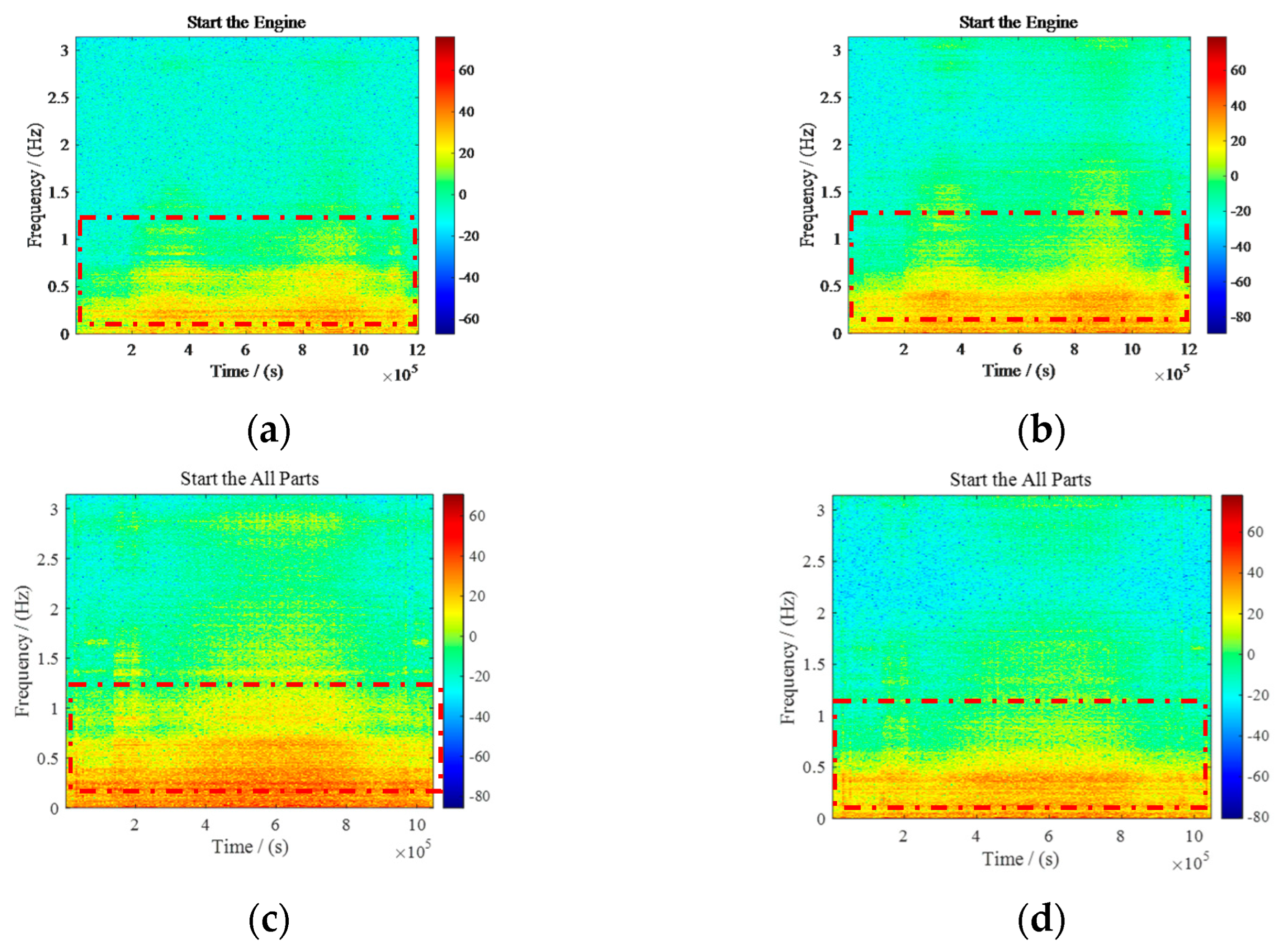

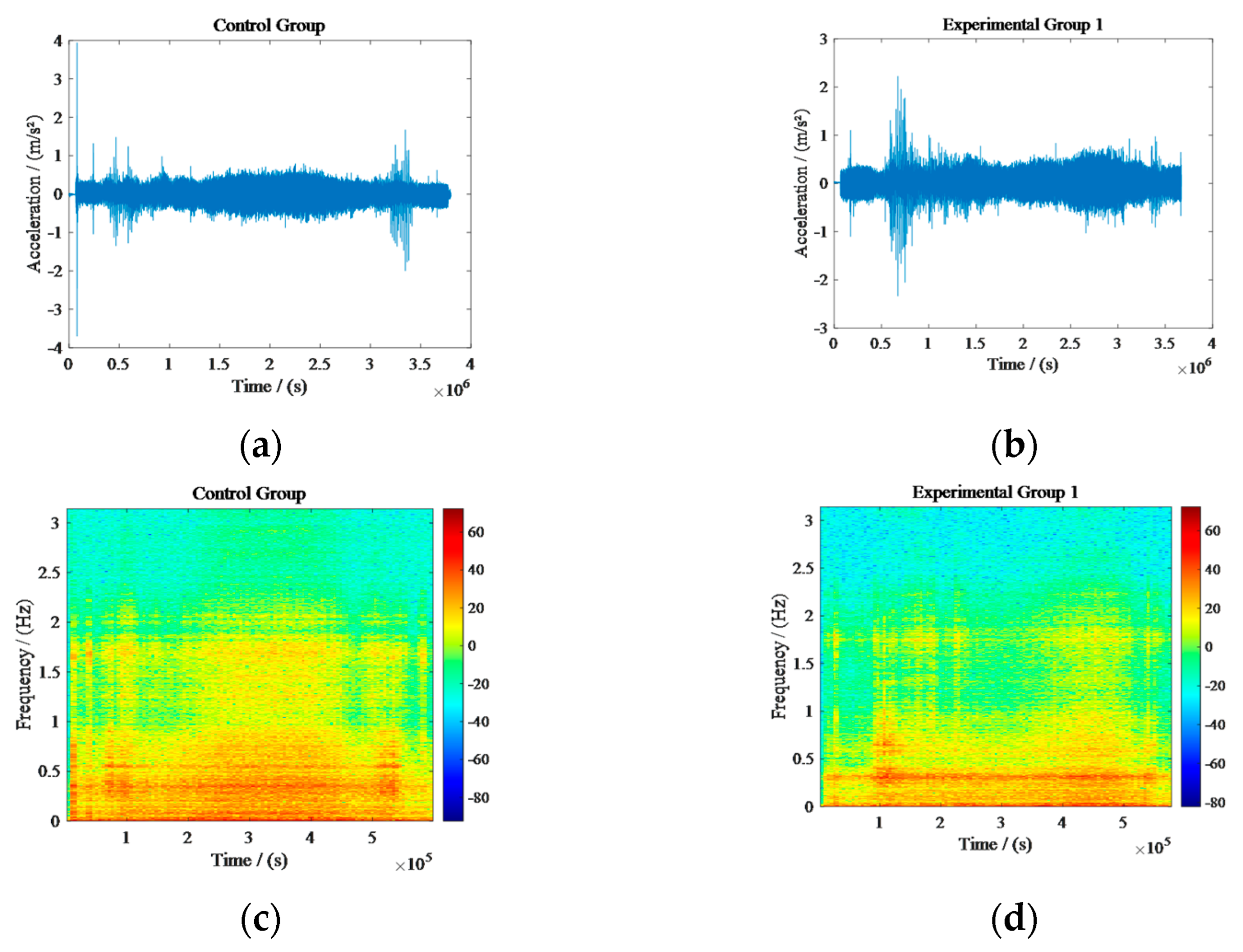

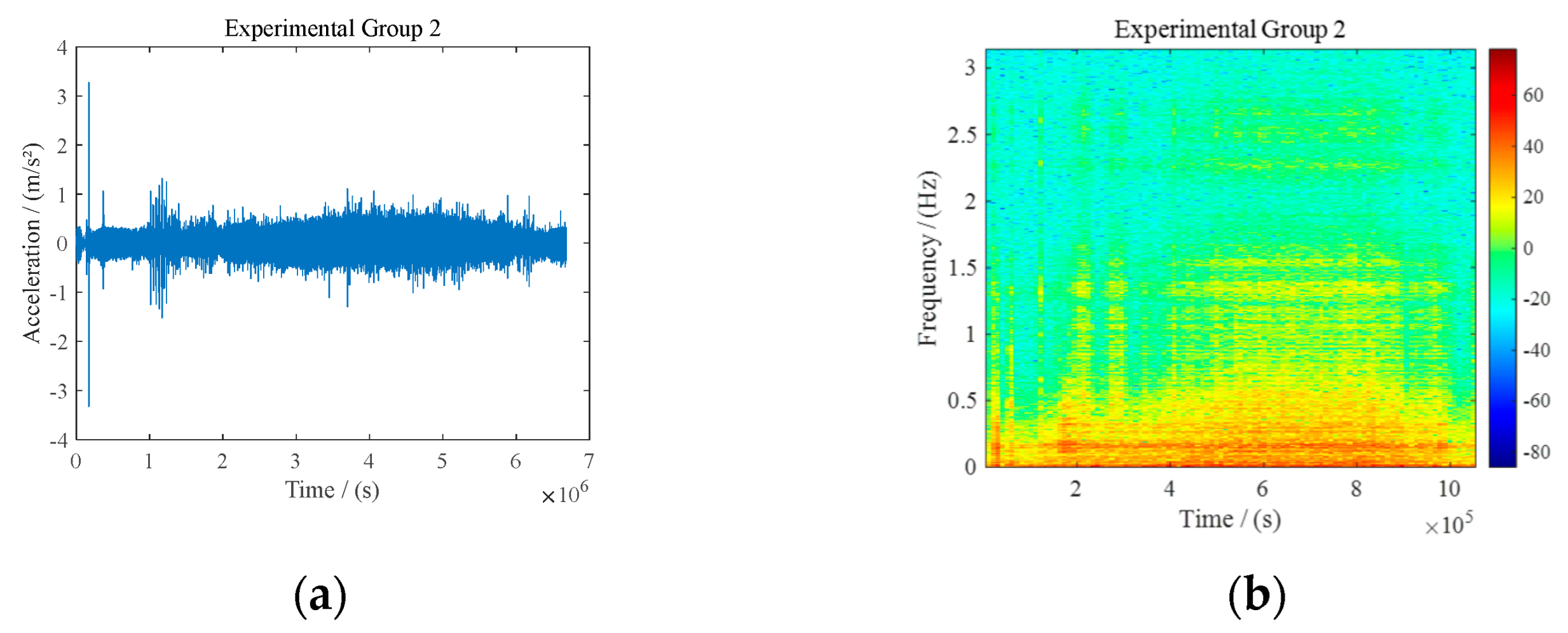

3.1. Analysis of Harvester Vibration Signal Based on Time-Frequency Processing Method

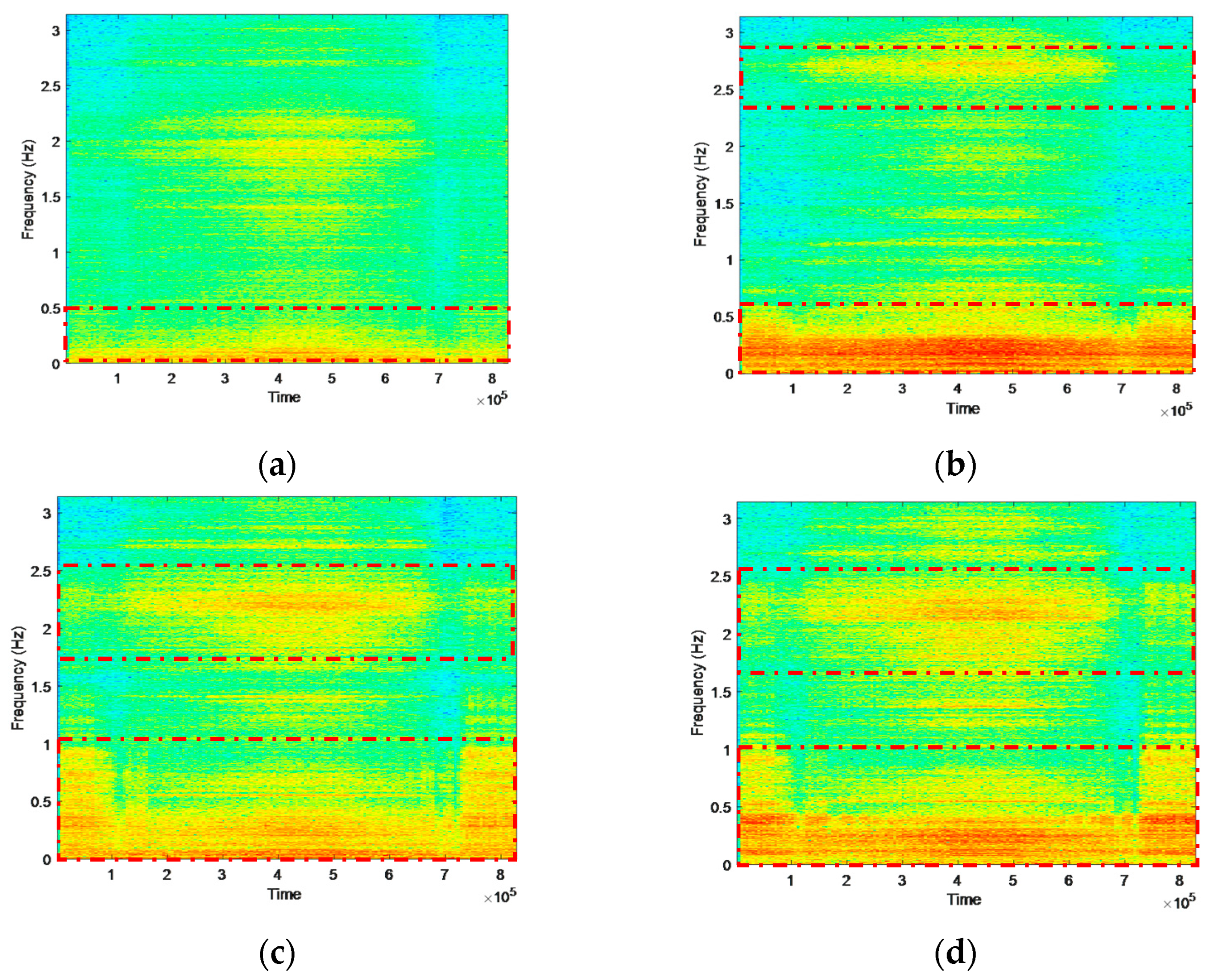

3.2. The Shaker and the Grass Crusher Are Stimulated Externally During Normal Operation

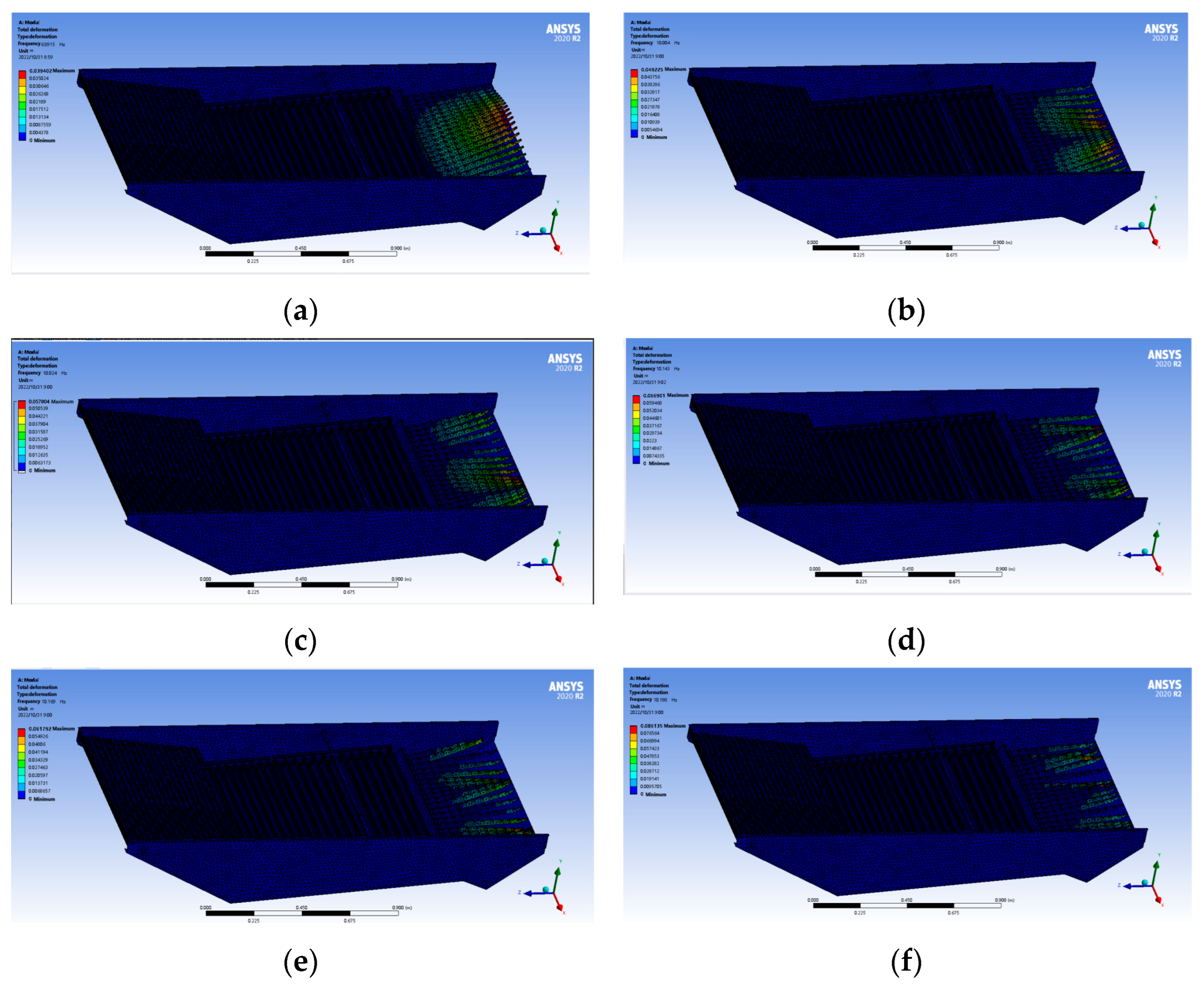

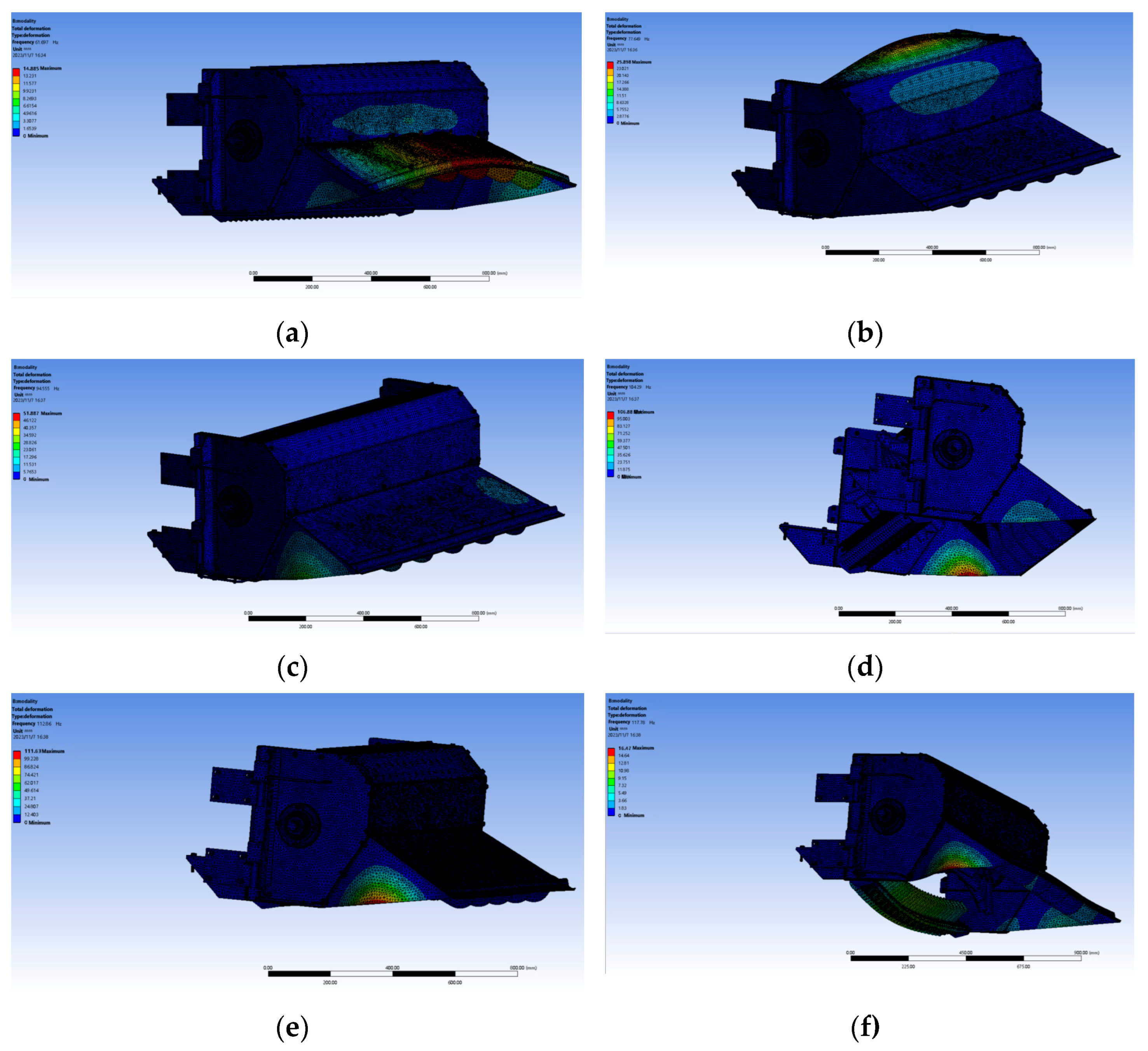

3.3. Modal Simulation Analysis of Vibration Screen and Grass Chopper

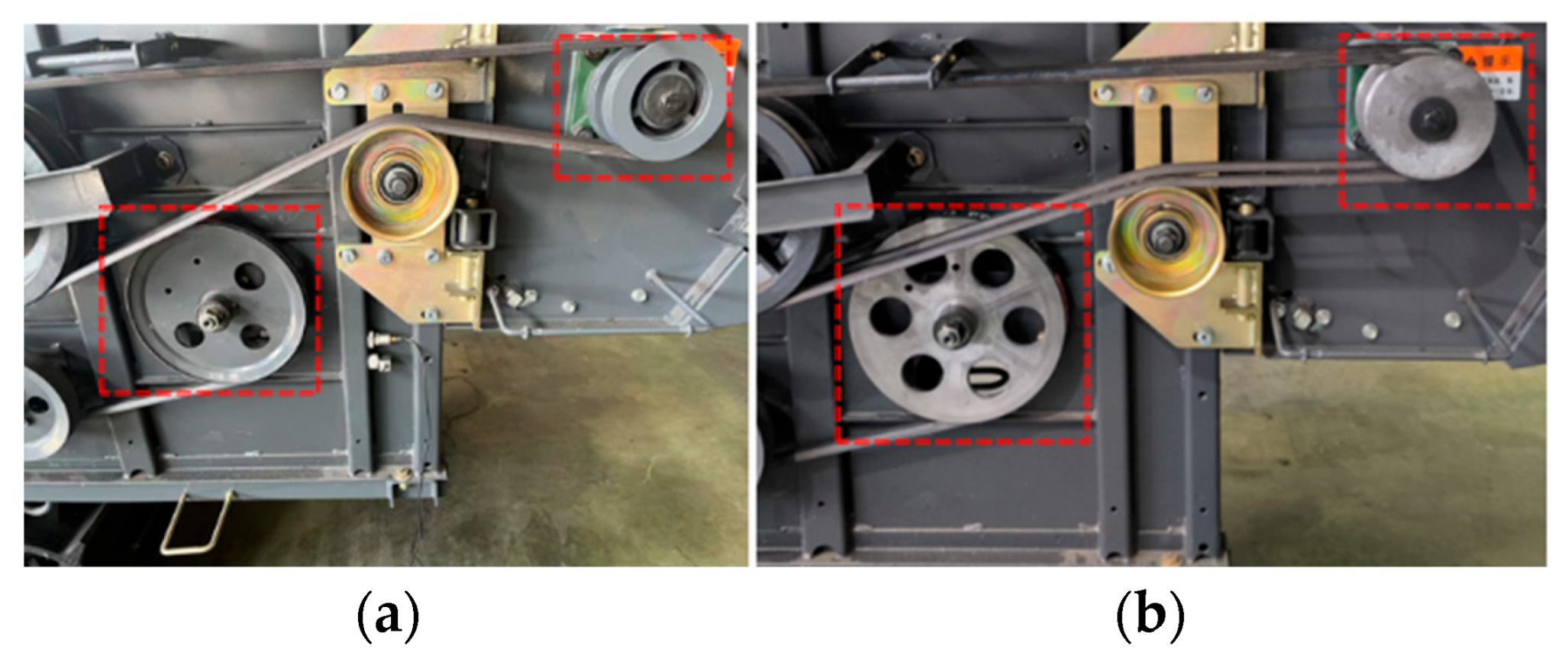

3.4. Improvement of the Drive Pulley for the Vibrating Screen and Grass Shredder to Avoid Resonance

3.5. Comparative Analysis of Vibration Signals Before and After Improvement

4. Conclusions

- By collecting and analyzing the time-domain vibration signals of the combine harvester cab under two working conditions, it was found that after the working components of the harvester were in operation, resonance occurred and was transmitted to the cab, causing an increase in the VLI of the cab. The vibration amplitude in the X direction of the cab door pillar was particularly significant.

- Frequency-domain analysis of the vibration signals from all sensors revealed that the energy of the frequency-domain information near the vibrating screen increased and resonance occurred. By comparing the external excitation frequencies with the modal simulation results, it was determined that the vibration sources of the harvester were the vibrating screen and the chopper. The external excitation frequencies of these two components during normal operation were 8 Hz and 59.7 Hz, respectively, while their modal frequencies were 6.89 Hz and 61.6 Hz. To avoid resonance in the simplest and most cost-effective manner, the drive pulleys of the vibrating screen and chopper were redesigned to change the external excitation frequencies to 8 Hz and 49 Hz, respectively. This effectively avoided resonance in the harvester. Additionally, the rotational speed of the vibrating screen increased from 409 r/min to 480 r/min, thereby enhancing the vibration cleaning efficiency of the harvester.

- After replacing the drive pulleys of the vibrating screen and chopper, the VLI of the vibration signal in the X direction of the cab door pillar decreased from 1215 in the original model to 112, a reduction of over 90%. The RMS value also decreased by 26% after modification. This aligns with human perception, as the author noticed a significant reduction in vibration and improved comfort when operating the harvester with the new pulleys installed.

- Unlike previous studies, which have sought to reduce harvester vibration by modifying cab panels or the overall chassis or by adding damping to specific sub-assemblies, this work begins with an analysis of the vibration signals at their source to identify the component most responsible for excessive cab vibration. By redesigning this single component and shifting its excitation frequency, resonance is avoided. The approach delivers an efficient reduction in vibration at minimal cost for agricultural-machinery manufacturers. Although further refinements are needed, future research will continue to explore how the dominant vibration source can be optimized even further.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pang, J. Vibration Source-Response Analysis and Transmission Main Path Identification of Crawler Grain Combine. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2018. [Google Scholar] [CrossRef]

- Yao, Y.C.; Du, Y.F.; Zhu, Z.X.; Mao, E.R.; Song, Z.H. Modal based analysis and optimization of vibration characteristics of corn harvesting locomotive frame. Trans. Agric. Eng. 2015, 31, 46–53. [Google Scholar] [CrossRef]

- Wang, Y.D. Vibration Analysis and Structure Optimization of Crawler Combined Harvester Driver. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Chen, S.R.; Zhou, Z.P.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Mo, H.N.; Li, S.P.; Qiu, C.; Ma, S.C.; Huang, Z.M.; Zhou, J.H. Effects of knife disc axial vibration and cutting parameters on the cutting quality of sugarcane harvester. J. Agric. Eng. 2020, 38, 62–71. [Google Scholar] [CrossRef]

- Yang, F.; Du, Y.F.; Li, X.Y.; Zhang, Y.A.; Mao, E.R.; Li, Z. Control and test of large spray machine combined with pavement characteristics. J. Agric. Mach. 2023, 54, 110–120. [Google Scholar] [CrossRef]

- Liu, C.; Chen, Z.L.; Yan, R.L. Study on vibration reduction and noise reduction of a certain construction machinery. Mech. Des. Res. 2023, 39, 102–107+123. [Google Scholar] [CrossRef]

- Jain, P. Design and analysis of a tractor-trailer cabin suspension. SAE Tech. Pap. 2007, 26, 47. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Esfahanian, M.; Ziaei-Rad, S. Vibration modeling and modification of cutting platform in a harvest combine by means of operational modal analysis (OMA). Measurement 2013, 46, 3959–3967. [Google Scholar] [CrossRef]

- Bulgakov, V.; Adamchuk, V.; Ihnatiev, Y. Theory of Vibrations of Sugar Beet Leaf Harvester Front-Mounted on Universal Tractor. Acta Technol. Agric. 2017, 20, 96–103. [Google Scholar] [CrossRef][Green Version]

- Aldair, A.A.; Alsaedee, E.B.; Abdalla, T.K. Design of ABCF control scheme for full vehicle nonlinear active suspension system with passenger seat. Iran. J. Sci. Technol. Trans. Electr. Eng. 2019, 43, 289–302. [Google Scholar] [CrossRef]

- Ma, Z.; Jiang, S.; Xu, L.Z.; Li, Y.M. Recognition methods of threshing load conditions based on machine learning algorithms. Comput. Electron. Agric. 2022, 200, 107250. [Google Scholar] [CrossRef]

- Pang, J.; Li, Y.M.; Ji, J.T.; Xu, L.Z. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Yang, X.Z.; Zhou, J.J. Vibration Analysis and Optimization Design of Blade Discs in Compact Sugarcane Harvesters. Hubei Agric. Sci. 2022, 61, 162–165. [Google Scholar] [CrossRef]

- Hao, S.; Tang, Z.; Guo, S.; Ding, Z.; Su, Z. Model and Method of Fault Signal Diagnosis for Blockage and Slippage of Rice Threshing Drum. Agriculture 2022, 12, 1968. [Google Scholar] [CrossRef]

- Li, Y.; Tang, Z.; Wang, X.Z.; Zhang, H.; Li, Y.M. Bearing Seat Vibration Modes Undergoing Unbalanced Excitation of Multirotating Drums. Shock. Vib. 2021, 2021, 5655150. [Google Scholar] [CrossRef]

- Jing, J.; Sun, H.; Liang, R.; Chen, S.; Tang, Z.; He, X.; Chen, Y. Noise Testing of the Conveyor Trough Sprocket and Surface Noise Reduction Performance Evaluation of the Cavity Structure in a Combine Harvester. Agriculture 2025, 15, 1299. [Google Scholar] [CrossRef]

- Yuan, L.; Sun, M.; Yan, G.; Que, K.; Wang, B.; Xu, S.; Lian, Y.; Tang, Z. Experimental Study on Loosening and Vibration Characteristics of Vibrating Screen Bolts of Combine Harvester. Agriculture 2025, 15, 749. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, H.; Kwon, J. Transformer-based GAN with multi-STFT for rotating machinery vibration data analysis. Electronics 2024, 13, 4253. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Fu, S.; Feng, K.; Han, X.; Hu, Y.; Zhu, Q.; Wei, X. Analysis of Vibration Characteristics of Tractor–Rotary Cultivator Combination Based on Time Domain and Frequency Domain. Agriculture 2024, 14, 1139. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Hu, Y.; Han, X.; Feng, K.; Li, P.; Wei, X.; Zhai, C. Study on Operating Vibration Characteristics of Different No-Tillage Planter Row Units in Wheat Stubble Fields. Agriculture 2024, 14, 1878. [Google Scholar] [CrossRef]

- Peter, B.; Federico, B.; Elena, C. Comparisons between Fourier and STFT multipliers: The smoothing effect of the short-time Fourier transform. J. Math. Anal. Appl. 2022, 529, 15–31. [Google Scholar] [CrossRef]

- Chai, X.Y.; Ma, T.L.; Liu, P.; Shi, M.L.; Zhu, L.J.; Zhang, M.; Xu, L.Z. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude-Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar]

- Wang, B.Z.; Chen, S.R.; Wang, G.Q.; Tang, Z.; Ding, H.T. Damping Optimization Method of Combine Harvester Frame Undergoing Multi-Source Excitation. Agriculture 2024, 14, e815. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Li, X.Y.; Xu, T.B. Rice threshing state prediction of threshing cylinder undergoing unbalanced harmonic response. Comput. Electron. Agric. 2019, 186, 323–336. [Google Scholar] [CrossRef]

- Wang, X.Z.; Hong, T.Y.; Fang, W.Q.; Chen, X.Y. Optimized Design for Vibration Reduction in a Residual Film Recovery Machine Frame Based on Modal Analysis. Agriculture 2024, 14, 543. [Google Scholar] [CrossRef]

- Wang, L.J.; Wang, W.; Du, Y.X.; Xu, L.; Huang, W.C.; Liu, J.W. Modal analysis and topology optimization of hydraulic machine rack based on ANSYS-workbench. Coal Mine Mach. 2019, 40, 79–83. [Google Scholar] [CrossRef]

- Tang, D.; Zhang, Z.; Hua, L.; Pan, J.C.; Xiao, Y. Prediction of cold start emissions for hybrid electric vehicles based on genetic algorithms and neural networks. J. Clean. Prod. 2023, 420, e138403. [Google Scholar] [CrossRef]

- Gao, J.J.; Liu, Z.Y.; Gu, W.; Zhang, F.F.; Zhu, L.P. Modal analysis and optimization of grain combine harvester undercarriage frame. Mach. Des. Res. 2023, 39, 199–205. [Google Scholar] [CrossRef]

- Meng, Z.; Kong, L.; Yi, J.X.; Peng, H. Optimum-pursuing method for constrained optimization and reliability-based design optimization problems using Kriging model. Comput. Methods Appl. Mech. Eng. 2024, 420, 116704. [Google Scholar] [CrossRef]

- Ding, Z.X.; Tang, Z.; Zhang, B.; Ding, Z. Vibration Response of Metal Plate and Shell Structure under Multi-Source Excitation with Welding and Bolt Connection. Agriculture 2024, 14, 816. [Google Scholar] [CrossRef]

- Zheng, G.Q.; Li, Y.M.; Ji, K.Z.; Liang, Z.W.; Ma, X. Vibration Analysis and Structural Optimization of the Cutting Platform Frame for Grain Combine Harvesters. Agric. Mech. Res. 2024, 46, 41–45. [Google Scholar] [CrossRef]

| Working Condition | Cab Door Post X-Axle | Cab Door Post Y-Axle |

|---|---|---|

| Working Condition a | 29.9 | 9.5 |

| Working Condition b | 1.255 × 103 | 1.195 × 103 |

| Material | Modulus of Elasticity (GPa) | Poisson Ratio | Density ((kgm3)−1) |

|---|---|---|---|

| Steel (Q235) | 210 | 0.3 | 7800 |

| Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Frequency (Hz) | 6.89 | 10.00 | 10.02 | 10.13 | 10.17 | 10.19 |

| Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Frequency (Hz) | 61.6 | 77.6 | 94.5 | 104.2 | 112.8 | 117.7 |

| The Drive Wheel of the Vibrating Screen | Diameter (mm) | Transmission Ratio | Speed (rpm) | External Excitation Frequency (Hz) |

| 232 | 5.868 | 409 | 6.82 | |

| The Drive Wheel of the Chopper | Diameter (mm) | Transmission Ratio | Speed (rpm) | External Excitation Frequency (Hz) |

| 123 | 0.67 | 3582 | 59.7 |

| The Drive Wheel of the Vibrating Screen | Diameter (mm) | Transmission Ratio | Speed (rpm) | External Excitation Frequency (Hz) |

| 197 | 5 | 480 | 8 | |

| The Drive Wheel of the Chopper | Diameter (mm) | Transmission Ratio | Speed (rpm) | External Excitation Frequency (Hz) |

| 132 | 0.82 | 2927 | 49 |

| Indicators | Type | Cab Door Post X-Axle |

|---|---|---|

| VLI | Original harvest machine | 1.215 × 103 |

| VLI | Change into the harvester behind two new belt wheels | 4.67 × 102 |

| RMS | Original harvest machine | 0.1744 |

| RMS | Replace only harvesters driven by grass crusher wheels | 0.1296 |

| Indicators | Type | Cab Door Post X-Axle |

|---|---|---|

| VLI | Original harvest machine | 1.215 × 103 |

| VLI | Change into the harvester behind two new belt wheels | 4.67 × 102 |

| RMS | Original harvest machine | 0.1744 |

| RMS | Replace only harvesters driven by grass crusher wheels | 0.1576 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, K.; Liu, Y. Vibration Tracing Analysis and External Excitation Damping Method of Combine Harvester Based on Short-Time Fourier. Appl. Sci. 2025, 15, 10134. https://doi.org/10.3390/app151810134

Ji K, Liu Y. Vibration Tracing Analysis and External Excitation Damping Method of Combine Harvester Based on Short-Time Fourier. Applied Sciences. 2025; 15(18):10134. https://doi.org/10.3390/app151810134

Chicago/Turabian StyleJi, Kuizhou, and Yanbin Liu. 2025. "Vibration Tracing Analysis and External Excitation Damping Method of Combine Harvester Based on Short-Time Fourier" Applied Sciences 15, no. 18: 10134. https://doi.org/10.3390/app151810134

APA StyleJi, K., & Liu, Y. (2025). Vibration Tracing Analysis and External Excitation Damping Method of Combine Harvester Based on Short-Time Fourier. Applied Sciences, 15(18), 10134. https://doi.org/10.3390/app151810134