Role of Generative AI in AI-Based Digital Twins in Industry 5.0 and Evolution to Industry 6.0

Abstract

Featured Application

Abstract

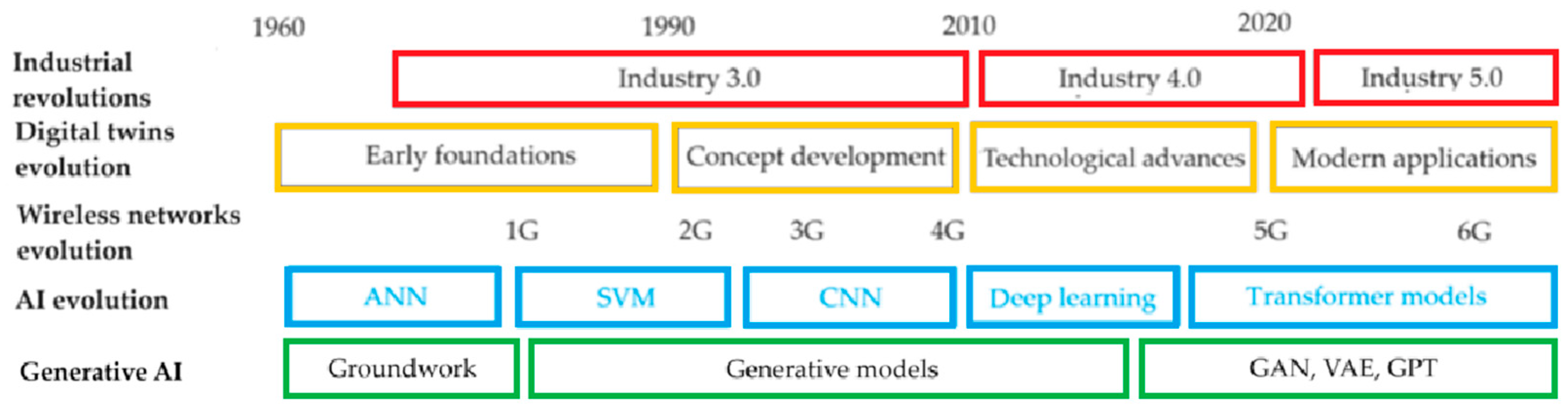

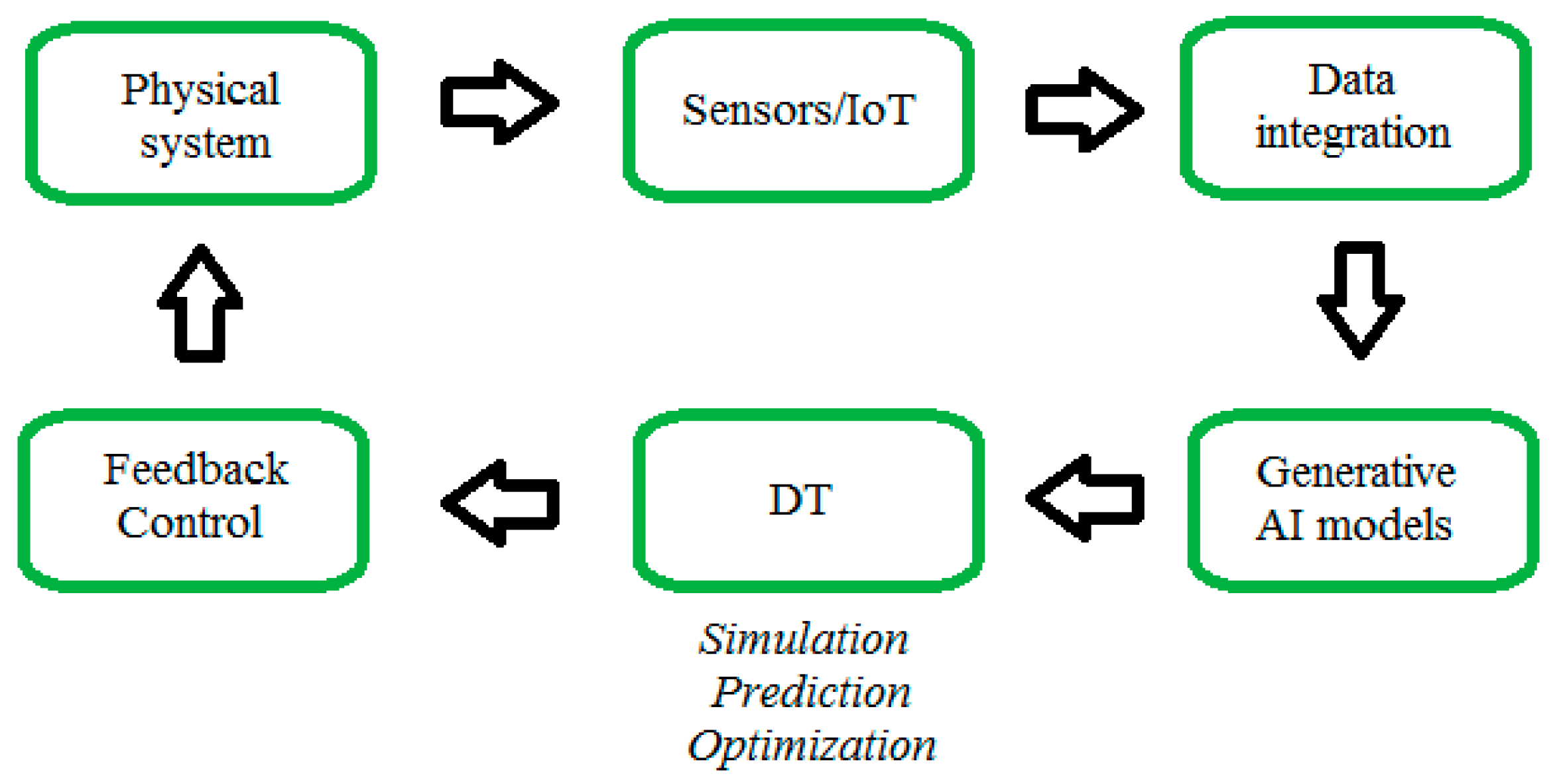

1. Introduction

2. Materials and Methods

2.1. Data Set

2.2. Methods

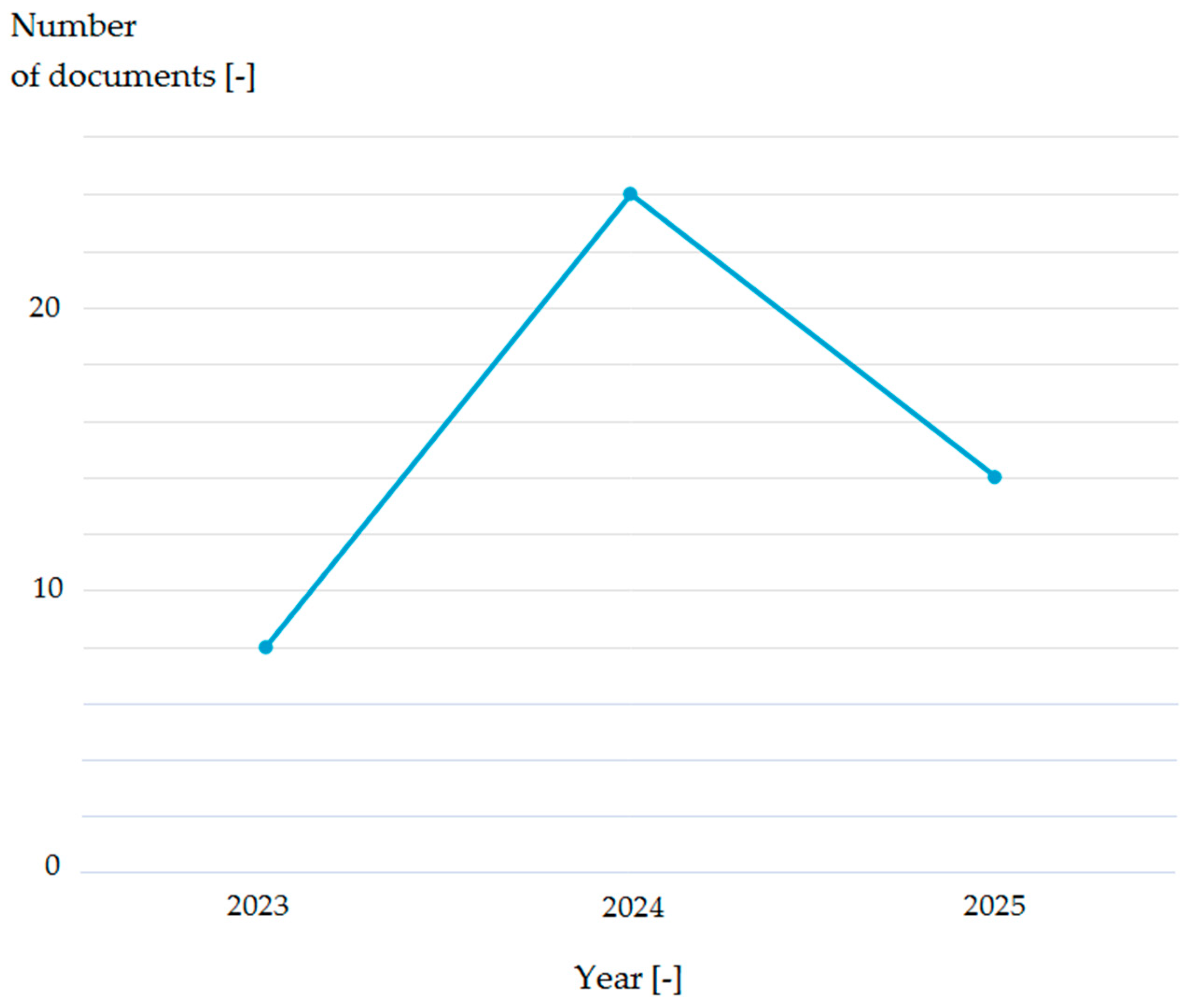

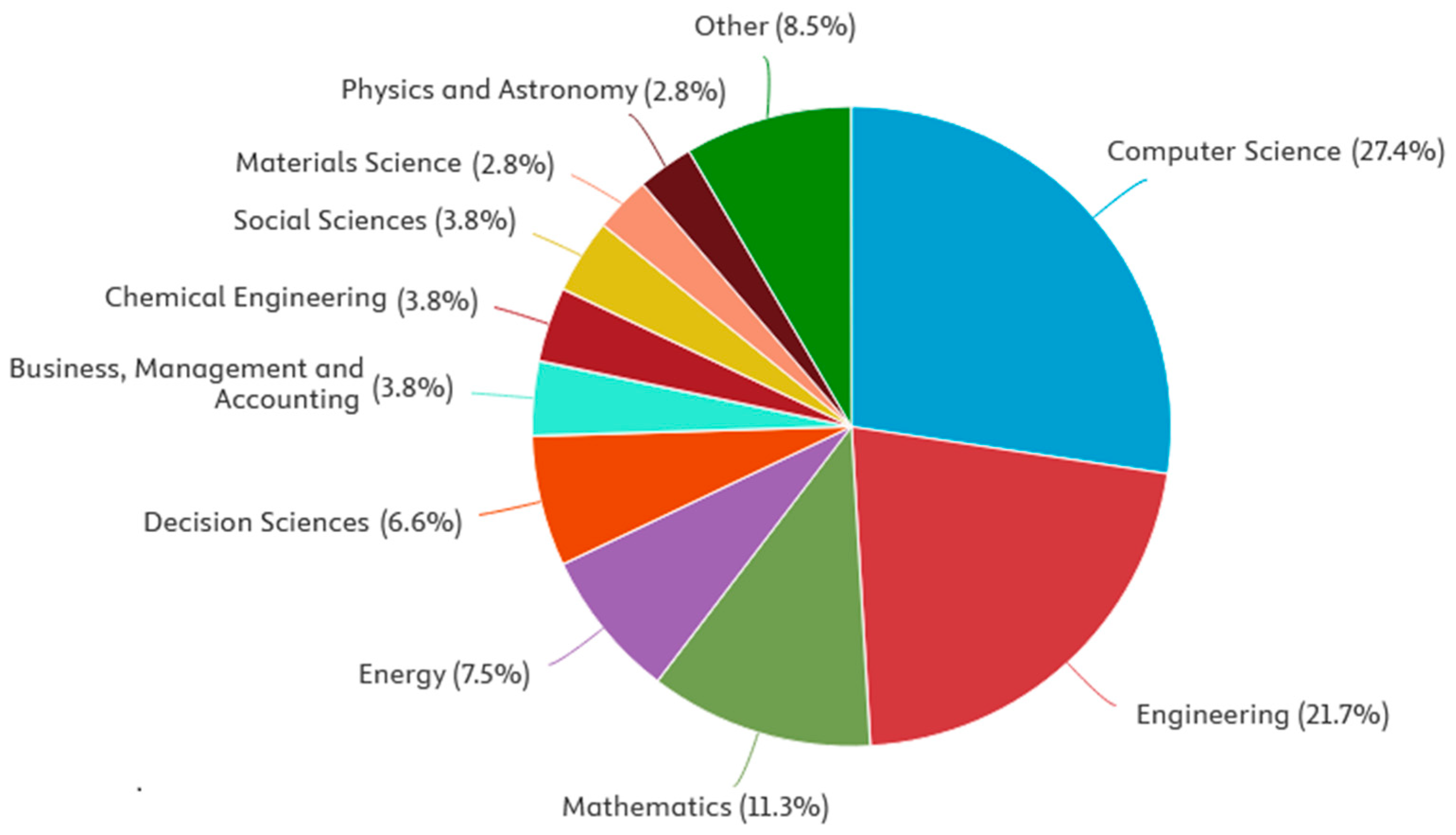

3. Results

- Computer science: 27.4%;

- Engineering: 21.7%;

- Mathematics: 11.3% (Figure 6).

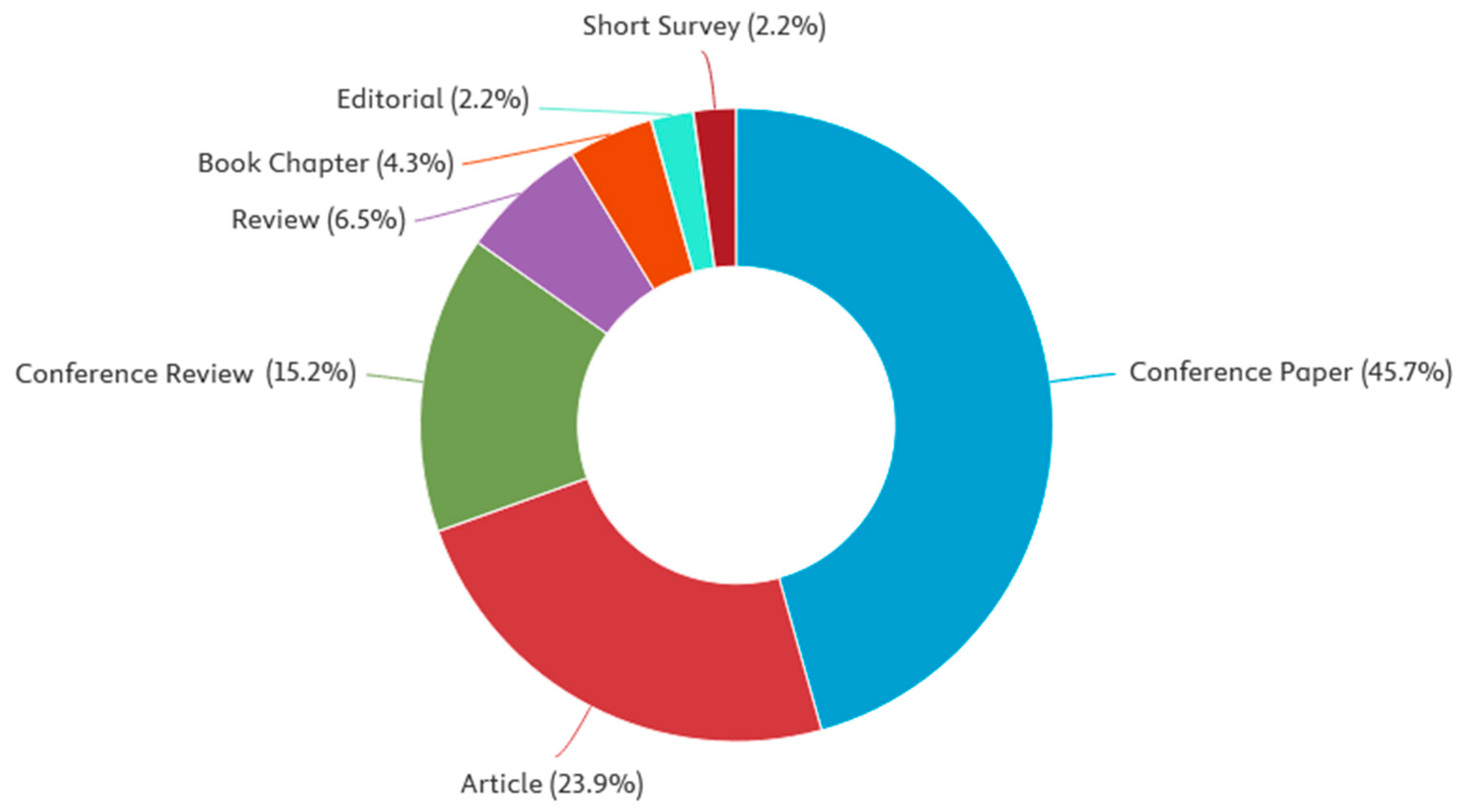

- Conference paper: 45.7%;

- Article: 23.9%;

- Conference review: 15.2% (Figure 7).

- USA: 9;

- India: 6;

- China: 5 (Figure 8).

- “Innovation and industry infrastructure”;

- “Responsible production and consumption”;

- “Good health and well-being”.

3.1. Quantitative Analysis

3.2. Specific/Case Analysis

4. Discussion

4.1. Limitations of Current Studies

4.2. Directions of Further Research

4.3. Economic Implications

4.4. Societal Implications

4.5. Ethical, Legal and Environmental Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| DT | Digital twin |

| GAN | Generative Adversarial Networks |

| genAI | Generative AI |

| GPT | Generative Pre-trained Transformer |

| HMM | Hidden Markov model |

| IoT | Internet of Things |

| VAE | Variational autoencoders |

| NLP | Natural language processing |

References

- Lee, C.I.; Chen, J.H.; Kohli, M.D.; Smith, A.D.; Liao, J.M. Generative Artificial Intelligence. J. Am. Coll. Radiol. 2024, 21, 1318–1320. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital Twins in Product Lifecycle for Sustainability in Manufacturing and Maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Menaguale, O. Digital twin and cultural heritage—The future of society built on history and art. In The Digital Twin; Springer International Publishing: Cham, Switzerland, 2023; pp. 1081–1111. [Google Scholar]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Kopowski, J. Specificity of 3D Printing and AI-Based Optimization of Medical Devices Using the Example of a Group of Exoskeletons. Appl. Sci. 2023, 13, 1060. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Mikołajewski, D.; Pawłowski, L.; Wegrzyn-Wolska, K. Modern approach to sustainable production in the context of Industry 4.0. Bull. Pol. Acad. Sci. Tech. Sci. 2022, 70, e143828. [Google Scholar] [CrossRef]

- Hawkinson, E. Automationin Education with Digital Twins: Trends and Issues. Int. J. Open Distance E-Learn. 2022, 8. [Google Scholar] [CrossRef]

- Dihan, M.S.; Akash, A.I.; Tasneem, Z.; Das, P.; Das, S.K.; Islam, M.R.; Islam, M.M.; Badal, F.R.; Ali, M.F.; Ahamed, M.H.; et al. Digital twin: Data exploration, architecture, implementation and future. Heliyon 2024, 10, e26503. [Google Scholar] [CrossRef]

- Meijer, C.; Uh, H.W.; El Bouhaddani, S. Digital Twins in Healthcare: Methodological Challenges and Opportunities. J. Pers. Med. 2023, 13, 1522. [Google Scholar] [CrossRef] [PubMed]

- Gkontzis, A.F.; Kotsiantis, S.; Feretzakis, G.; Verykios, V.S. Enhancing Urban Resilience: Smart City Data Analyses, Forecasts, and Digital Twin Techniques at the Neighborhood Level. Future Internet 2024, 16, 47. [Google Scholar] [CrossRef]

- Avanzato, R.; Beritelli, F.; Lombardo, A.; Ricci, C. Heart DT: Monitoring and Preventing Cardiac Pathologies Using AI and IoT Sensors. Future Internet 2023, 15, 223. [Google Scholar] [CrossRef]

- Orlova, E.V. Design Technology and AI-Based Decision Making Model for Digital Twin Engineering. Future Internet 2022, 14, 248. [Google Scholar] [CrossRef]

- Singh, Y.; Hathaway, Q.A.; Erickson, B.J. Generative AI in oncological imaging: Revolutionizing cancer detection and diagnosis. Oncotarget 2024, 15, 607–608. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Prakash, P.K.S.; Samanta, S.; Chilukuri, S. ClinicalGAN: Powering patient monitoring in clinical trials with patient digital twins. Sci. Rep. 2024, 14, 12236. [Google Scholar] [CrossRef]

- Padoan, A.; Plebani, M. Dynamic mirroring: Unveiling the role of digital twins, artificial intelligence and synthetic data for personalized medicine in laboratory medicine. Clin. Chem. Lab. Med. 2024, 62, 2156–2161. [Google Scholar] [CrossRef]

- Bordukova, M.; Makarov, N.; Rodriguez-Esteban, R.; Schmich, F.; Menden, M.P. Generative artificial intelligence empowers digital twins in drug discovery and clinical trials. Expert Opin. Drug Discov. 2024, 19, 33–42. [Google Scholar] [CrossRef]

- Nyholm, S. Is Academic Enhancement Possible by Means of Generative AI-Based Digital Twins? Am. J. Bioeth. 2023, 23, 44–47. [Google Scholar] [CrossRef]

- Hueso, M.; Álvarez, R.; Marí, D.; Ribas-Ripoll, V.; Lekadir, K.; Vellido, A. Is generative artificial intelligence the next step toward a personalized hemodialysis? Rev. Investig. Clin. Organo Hosp. Enfermedades Nutr. 2023, 75, 309–317. [Google Scholar] [CrossRef]

- Du, B.; Du, H.; Liu, H.; Niyato, D.; Xin, P.; Yu, J.; Qi, M.; Tang, Y. YOLO-Based Semantic Communication With Generative AI-Aided Resource Allocation for Digital Twins Construction. IEEE Internet Things J. 2023, 11, 7664–7678. [Google Scholar] [CrossRef]

- Wen, J.; Kang, J.; Niyato, D.; Zhang, Y.; Mao, S. Sustainable Diffusion-based Incentive Mechanism for Generative AI-driven Digital Twins in Industrial Cyber-Physical Systems. IEEE Trans. Ind. Cyber-Phys. Syst. 2024, 3, 139–149. [Google Scholar] [CrossRef]

- Paul, G.; Abele, N.D.; Kluth, K. A Review and Qualitative Meta-Analyss of Digital Human Modeling and Cyber-Physical-Systems in Ergonomics 4.0. IISE Trans. Occup. Ergon. Hum. Factors 2021, 9, 111–123. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Qiu, C.; Zhou, S.; Liu, Z.; Gao, Q.; Tan, J. Digital assembly technology based on augmented reality and digital twins: A review. Virtual Real. Intell. Hardw. 2019, 1, 597–610. [Google Scholar] [CrossRef]

- Murgod, T.R.; Sundaram, S.M.; Mahanthesha, U.; Murugesan, P. A Survey of Digital Twin for Industry 4.0: Benefits, Challenges and Opportunities. SN Comput. Sci. 2024, 5, 76. [Google Scholar] [CrossRef]

- Upadhyay, D.; Sharma, T.; Fatima, A. Impact of AI-Driven Digital Twins in Industry 4.0: An Exploratory Analysis. Int. Res. J. Adv. Eng. Manag. 2024, 2, 1548–1557. [Google Scholar]

- Espina-Romero, L.; Gutiérrez Hurtado, H.; Ríos Parra, D.; Vilchez Pirela, R.A.; Talavera-Aguirre, R.; Ochoa-Díaz, A. Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis. Sci 2024, 6, 60. [Google Scholar] [CrossRef]

- Arruda, H.M.; Bavaresco, R.S.; Kunst, R.; Bugs, E.F.; Pesenti, G.C.; Barbosa, J.L.V. Data Science Methods and Tools for Industry 4.0: A Systematic Literature Review and Taxonomy. Sensors 2023, 23, 5010. [Google Scholar] [CrossRef] [PubMed]

- Gürses, A.; Reddy, G.; Masrur, S.; Özdemir, Ö.; Güvenç, I.; Sichitiu, M.L.; Sahin, A.; Alkhateeb, A.; Dutta, R. Digital Twins for Supporting AI Research with Autonomous Vehicle Networks. arXiv 2024, arXiv:2404.00954. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the digital twin data in manufacturing by using augmented reality. Procedia CIRP 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Afzal, M.; Li, R.Y.M.; Shoaib, M.; Ayyub, M.F.; Tagliabue, L.C.; Bilal, M.; Ghafoor, H.; Manta, O. Delving into the Digital Twin Developments and Applications in the Construction Industry: A PRISMA Approach. Sustainability 2023, 15, 16436. [Google Scholar] [CrossRef]

- Li, S.; Lin, X.; Li, G.; Chen, L.; Liao, S.; Wang, J.; Li, J. DPG-DT: Differentially Private Generative Digital Twin for Imbalanced Learning in Industrial IoT. In Proceedings of the 2023 19th International Conference on Mobility, Sensing and Networking (MSN), Nanjing, China, 14–16 December 2023; pp. 270–276. [Google Scholar] [CrossRef]

- Rojek, I.; Macko, M.; Mikołajewski, D.; Saga, M.; Burczynski, T. Modern methods in the field of machine modeling and simulation as a research and practical issue related to Industry 4.0. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e136719. [Google Scholar] [CrossRef]

- Yang, X.; Liu, X.; Zhang, H.; Fu, L.; Yu, Y. An ontology-based shop-floor digital twin configuration approach. Procedia CIRP 2023, 120, 326–331. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, S.; Xiong, N.N.; Guo, W. A survey on knowledge graph embedding: Approaches, applications and benchmarks. Electronics 2020, 9, 750. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Jazdi, N.; Weyrich, M. Generation of Asset Administration Shell with Large Language Model Agents: Towards Semantic Interoperability in Digital Twins in the Context of Industry 4.0. IEEE Access 2024, 12, 84863–84877. [Google Scholar] [CrossRef]

- Amangeldy, B.; Tasmurzayev, N.; Imankulov, T.; Baigarayeva, Z.; Izmailov, N.; Riza, T.; Abdukarimov, A.; Mukazhan, M.; Zhumagulov, B. AI-Powered Building Ecosystems: A Narrative Mapping Review on the Integration of Digital Twins and LLMs for Proactive Comfort, IEQ, andEnergy Management. Sensors 2025, 25, 5265. [Google Scholar] [CrossRef]

- Zamini, M.; Reza, H.; Rabiei, M. A review of knowledge graph completion. Information 2022, 13, 396. [Google Scholar] [CrossRef]

- Cao, Y.; Li, S.; Liu, Y.; Yan, Z.; Dai, Y.; Yu, P.; Sun, L. A survey of ai-generated content (aigc). ACM Comput. Surv. 2025, 57, 1–38. [Google Scholar] [CrossRef]

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.-C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Mroziński, A.; Macko, M. Machine Learning- and Artificial Intelligence-Derived Prediction for Home Smart Energy Systems with PV Installation and Battery Energy Storage. Energies 2023, 16, 6613. [Google Scholar] [CrossRef]

- Rojek, I.; Mroziński, A.; Kotlarz, P.; Macko, M.; Mikołajewski, D. AI-Based Computational Model in Sustainable Transformation of Energy Markets. Energies 2023, 16, 8059. [Google Scholar] [CrossRef]

- Xu, M.; Niyato, D.; Chen, J.; Zhang, H.; Kang, J.; Xiong, Z.; Mao, S.; Han, Z. Generative AI-empowered Simulation for Autonomous Driving in Vehicular Mixed Reality Metaverses. arXiv 2023, arXiv:2302.08418. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Du, H.Y.; Niyato, D.; Kang, J.; Xiong, Z.; Kim, D.I.; Jamalipour, A. Deep Generative Model and Its Applications for Effective Wireless Network Management: Tutorial and Case Study. IEEE Wirel. Commun. 2024, 31, 199–207. [Google Scholar] [CrossRef]

- Martini, B.; Bellisario, D.; Coletti, P. Human-Centered and Sustainable Artificial Intelligence in Industry 5.0: Challenges and Perspectives. Sustainability 2024, 16, 5448. [Google Scholar] [CrossRef]

- Hang, C.-N.; Yu, P.-D.; Morabito, R.; Tan, C.-W. Large Language Models Meet Next-Generation Networking Technologies: A Review. Future Internet 2024, 16, 365. [Google Scholar] [CrossRef]

- Scalise, P.; Boeding, M.; Hempel, M.; Sharif, H.; Delloiacovo, J.; Reed, J. A Systematic Survey on 5G and 6G Security Considerations, Challenges, Trends, and Research Areas. Future Internet 2024, 16, 67. [Google Scholar] [CrossRef]

- Musa, A.A.; Hussaini, A.; Qian, C.; Guo, Y.; Yu, W. Open Radio Access Networks for Smart IoT Systems: State of Art and Future Directions. Future Internet 2023, 15, 380. [Google Scholar] [CrossRef]

- Hu, F.; Wang, C.; Wu, X. Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm. Appl. Sci. 2025, 15, 5697. [Google Scholar] [CrossRef]

- Hosseini-Nasab, H.; Fereidouni, S.; Fatemi Ghomi, S.M.T.; Fakhrzad, M.B. Classification of facility layout problems: A review study. Int. J. Adv. Manuf. Technol. 2018, 94, 957–977. [Google Scholar] [CrossRef]

- Heinbach, B.; Burggräf, P.; Wagner, J. Gym-flp: A Python Package for Training Reinforcement Learning Algorithms on Facility Layout Problems. Oper. Res. Forum 2024, 5, 20. [Google Scholar] [CrossRef]

- Sulaiman, S.S.; Jancy, P.L.; Muthiah, A.; Janakiraman, V.; Gnanaraj, S.J.P. An evolutionary optimal green layout design for a production facility by simulated annealing algorithm. Mater. Today Proc. 2021, 47, 4423–4430. [Google Scholar] [CrossRef]

- Klar, M.; Langlotz, P.; Aurich, J.C. A framework for automated multiobjective factory layout planning using reinforcement learning. Procedia CIRP 2022, 112, 555–560. [Google Scholar] [CrossRef]

- Pérez-Gosende, P.; Mula, J.; Díaz-Madroñero, M. A bottom-up multi-objective optimisation approach to dynamic facility layout planning. Int. J. Prod. Res. 2024, 62, 626–643. [Google Scholar] [CrossRef]

- Caneparo, L. Semantic knowledge in generation of 3D layouts for decision-making. Autom. Constr. 2022, 134, 104012. [Google Scholar] [CrossRef]

- Yao, Z.; Chen, Y.; Cui, J.; Zhang, S.; Li, S.; Hao, A. Conditional room layout generation based on graph neural networks. Comput. Graph. 2024, 122, 103971. [Google Scholar] [CrossRef]

- Shi, Y.; Shang, M.; Qi, Z. Intelligent layout generation based on deep generative models: A comprehensive survey. Inf. Fusion 2023, 100, 101940. [Google Scholar] [CrossRef]

- Cohen, Y.; Aperstein, Y. Generative Shop floor Layout Design: Challenges and Proposed Modelling Approach. IFAC-Papers OnLine 2024, 58, 748–753. [Google Scholar] [CrossRef]

- Tian, L.; Zhou, X.; Wu, Y.-P.; Zhou, W.-T.; Zhang, J.-H.; Zhang, T.-S. Knowledge graph and knowledge reasoning: A systematic review. J. Electron. Sci. Technol. 2022, 20, 100159. [Google Scholar] [CrossRef]

- Różanowski, K.; Piotrowski, Z.; Ciolek, M. Mobile Application for Driver’s Health Status Remote Monitoring. In Proceedings of the 9th International Wireless Communications and Mobile Computing Conference (IWCMC), Sardinia, Italy, 1–5 July 2013; pp. 1738–1743. [Google Scholar]

- Sondej, T.; Zawadzka, S. Influence of cuff pressures of automatic sphygmomanometers on pulse oximetry measurements. Measurement 2022, 187, 110329. [Google Scholar] [CrossRef]

- Akter, N.; Molnar, A.; Georgakopoulos, D. Toward Improving Human Training by Combining Wearable Full-Body IoT Sensors and Machine Learning. Sensors 2024, 24, 7351. [Google Scholar] [CrossRef]

- Chen, X.; Eder, M.A.; Shihavuddin, A.; Zheng, D. A Human-Cyber-Physical System toward Intelligent Wind Turbine Operation and Maintenance. Sustainability 2021, 13, 561. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Kłodowski, A.; Mikołajewska, E.; Walkowiak, P.; Berjano, P.; Villafañe, J.H.; Aggogeri, F.; Borboni, A.; Fausti, D.; Petrogalli, G. Design and control of system for elbow rehabilitation: Preliminary findings. Adv. Clin. Exp. Med. 2018, 27, 1661–1669. [Google Scholar] [CrossRef]

- Kawala-Janik, A.; Podpora, M.; Baranowski, J.; Bauer, W.; Pelc, M. Innovative Approach in Analysis of EEG and EMG Signals—Comparision of the Two Novel Methods. In Proceedings of the 19th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 2–5 September 2014; pp. 804–807. [Google Scholar]

- Bickel, S.; Goetz, S.; Wartzack, S. Symbol Detection in Mechanical Engineering Sketches: Experimental Study on Principle Sketches with Synthetic Data Generation and Deep Learning. Appl. Sci. 2024, 14, 6106. [Google Scholar] [CrossRef]

- Miny, T.; Thies, M.; Lukic, L.; Käbisch, S.; Oladipupo, K.; Diedrich, C.; Kleinert, T. Overview and Comparison of Asset Information Model Standards. IEEE Access 2023, 11, 99189–99221. [Google Scholar] [CrossRef]

- Salins, S.S.; Zaidi, S.A.R.; Deepak, D.; Sachidananda, H.K. Design of an improved layout for a steel processing facility using SLP and lean Manufacturing techniques. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 3827–3848. [Google Scholar] [CrossRef]

- Burggräf, P.; Adlon, T.; Lehde, N.; Lindholm, N. Uncovering the behaviour of facility layout problem solutions in relation to factory design applications. Procedia CIRP 2024, 126, 93–98. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Kotlarz, P.; Tyburek, K.; Kopowski, J.; Dostatni, E. Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials 2021, 14, 7625. [Google Scholar] [CrossRef]

- Wang, W.Y.; Zhang, S.; Li, G.; Lu, J.; Ren, Y.; Wang, X.; Gao, X.; Su, Y.; Song, H.; Li, J. Artificial intelligence enabled smart design and manufacturing of advanced materials: The endless Frontier in AI+era. Mater. Genome Eng. Adv. 2024, 2, e56. [Google Scholar] [CrossRef]

- Rao, S.; Neethirajan, S. Computational Architectures for Precision Dairy Nutrition Digital Twins: A Technical Review and Implementation Framework. Sensors 2025, 25, 4899. [Google Scholar] [CrossRef]

- Rojek, I.; Kotlarz, P.; Dorożyński, J.; Mikołajewski, D. Sixth-Generation (6G) Networks for Improved Machine-to-Machine (M2M) Communication in Industry 4.0. Electronics 2024, 13, 1832. [Google Scholar] [CrossRef]

- Zachariades, C.; Xavier, V. A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines. Sensors 2025, 25, 5128. [Google Scholar] [CrossRef] [PubMed]

- Coelho, P.; Bessa, C.; Landeck, J.; Silva, C. Industry 5.0: The arising of a concept. Procedia Comput. Sci. 2023, 217, 1137–1144. [Google Scholar] [CrossRef]

- Jin, J.; Xu, H.; Leng, B. Adaptive Points Sampling for Implicit Field Reconstruction of Industrial Digital Twin. Sensors 2022, 22, 6630. [Google Scholar] [CrossRef]

- Akar, N.; Turgay, S. Optimizing Cellular Manufacturing Facility Layout Design through Digital Twin Simulation: A Case Study. Ind. Eng. Innov. Manag. 2023, 6, 1–12. [Google Scholar] [CrossRef]

- Martinez, E.M.; Ponce, P.; Macias, I.; Molina, A. Automation Pyramidas Constructor for a Complete Digital Twin, Case Study: A Didactic Manufacturing System. Sensors 2021, 21, 4656. [Google Scholar] [CrossRef]

- Rojek, I.; Kowal, M.; Stoic, A. Predictive compensation of thermal deformations of ball screws in cnc machines using neural networks. Teh. Vjesn. Tech. Gaz. 2017, 24, 1697–1703. [Google Scholar]

- Gao, T.; Wang, L.; Song, W.; Cheng, Y.; Zuo, Y.; Xiang, F.; Zhang, H.; Tao, F. Ten industrial software towards smart manufacturing. J. Manuf. Syst. 2025, 79, 255–285. [Google Scholar] [CrossRef]

- Singh, R.; Akram, S.V.; Gehlot, A.; Buddhi, D.; Priyadarshi, N.; Twala, B. Energy System 4.0: Digitalization of the Energy Sector with Inclination towards Sustainability. Sensors 2022, 22, 6619. [Google Scholar] [CrossRef] [PubMed]

- Damisa, U.; Nwulu, N.I.; Siano, P. Towards Blockchain-Based Energy Trading: A Smart Contract Implementation of Energy Double Auction and Spinning Reserve Trading. Energies 2022, 15, 4084. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Liu, X.; Qiu, C.; Shi, J.; Huang, J.; Zhu, C.; Ni, Z.; Zhu, M.; Liu, T. A digital twin modeling method for production resources of shop floor. Int. J. Adv. Manuf. Technol. 2023, 128, 743–761. [Google Scholar] [CrossRef]

- Rojek, I. Hybrid Neural Networks as Prediction Models. In Artificial Intelligence and Soft Computing, Lecture Notes in Artificial Intelligence; Rutkowski, L., Scherer, R., Tadeusiewicz, R., Zadeh, L.A., Zurada, J.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 88–95. [Google Scholar]

- Han, X.; Lin, Z.; Clark, C.; Vucetic, B.; Lomax, S. AI Based Digital Twin Model for Cattle Caring. Sensors 2022, 22, 7118. [Google Scholar] [CrossRef]

- Shaposhnyk, O.; Lai, K.; Wolbring, G.; Shmerko, V.; Yanushkevich, S. Next Generation Computing and Communication Hub for First Responders in Smart Cities. Sensors 2024, 24, 2366. [Google Scholar] [CrossRef] [PubMed]

- Rojek, I. Models for Better Environmental Intelligent Management within Water Supply Systems. Water Resour. Manag. 2014, 28, 3875–3890. [Google Scholar] [CrossRef]

- Choi, H.; Yu, S.; Lee, D.; Noh, S.D.; Ji, S.; Kim, H.; Yoon, H.; Kwon, M.; Han, J. Optimization of the Factory Layout and Production Flow Using Production-Simulation-Based Reinforcement Learning. Machines 2024, 12, 390. [Google Scholar] [CrossRef]

- Tasmurzayev, N.; Amangeldy, B.; Imanbek, B.; Baigarayeva, Z.; Imankulov, T.; Dikhanbayeva, G.; Amangeldi, I.; Sharipova, S. Digital Cardiovascular Twins, AI Agents, and Sensor Data: A Narrative Review from System Architecture to Proactive Heart Health. Sensors 2025, 25, 5272. [Google Scholar] [CrossRef]

- Xie, R.; Chen, M.; Liu, W.; Jian, H.; Shi, Y. Digital Twin Technologies for Turbo machinery in a Life Cycle Perspective: A Review. Sustainability 2021, 13, 2495. [Google Scholar] [CrossRef]

- Negri, V.; Zanella, S.; Mingotti, A.; Tinarelli, R.; Peretto, L.; Barchi, F.; Acquaviva, A. Towars the DT of educational building: An AI-based distributed measurement system for the power forecasting. In Proceedings of the 2024 IEEE 14th International Workshop on Applied Measurements for Power Systems (AMPS), Caserta, Italy, 18–20 September 2024; pp. 1–6. [Google Scholar]

- Hevesli, M.; Mohammed Seid, A.; Erbad, A.; Abdallah, M.M. Energy efficient delay-aware design for MEC-enabled DT-assisted air-ground network. In Proceedings of the 2024 IEEE 35th International Symposium on Personal, Indoor and Mobile Radio Communications (PIMRC), Valencia, Spain, 2–5 September 2024; p. 106. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Mikołajewski, D.; Piszcz, A.; Małolepsza, O.; Kozielski, M. Role of Generative AI in AI-Based Digital Twins in Industry 5.0 and Evolution to Industry 6.0. Appl. Sci. 2025, 15, 10102. https://doi.org/10.3390/app151810102

Rojek I, Mikołajewski D, Piszcz A, Małolepsza O, Kozielski M. Role of Generative AI in AI-Based Digital Twins in Industry 5.0 and Evolution to Industry 6.0. Applied Sciences. 2025; 15(18):10102. https://doi.org/10.3390/app151810102

Chicago/Turabian StyleRojek, Izabela, Dariusz Mikołajewski, Adrianna Piszcz, Olga Małolepsza, and Mirosław Kozielski. 2025. "Role of Generative AI in AI-Based Digital Twins in Industry 5.0 and Evolution to Industry 6.0" Applied Sciences 15, no. 18: 10102. https://doi.org/10.3390/app151810102

APA StyleRojek, I., Mikołajewski, D., Piszcz, A., Małolepsza, O., & Kozielski, M. (2025). Role of Generative AI in AI-Based Digital Twins in Industry 5.0 and Evolution to Industry 6.0. Applied Sciences, 15(18), 10102. https://doi.org/10.3390/app151810102