The Affinage of Cheese Using Artisanal Beers from Ricotta Whey: A Sustainable Way to Differentiate Traditional Cheeses

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Cheese Ripening Conditions

2.3. Physicochemical and Microbiological Analyses of Cheeses

2.4. SMart Nose® Analyses

2.5. SPME-GC-MS Analysis

2.5.1. Beer and Cheese Samples

2.5.2. SPME Extraction and GC-MS Conditions

2.5.3. GC/MS Analysis

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results

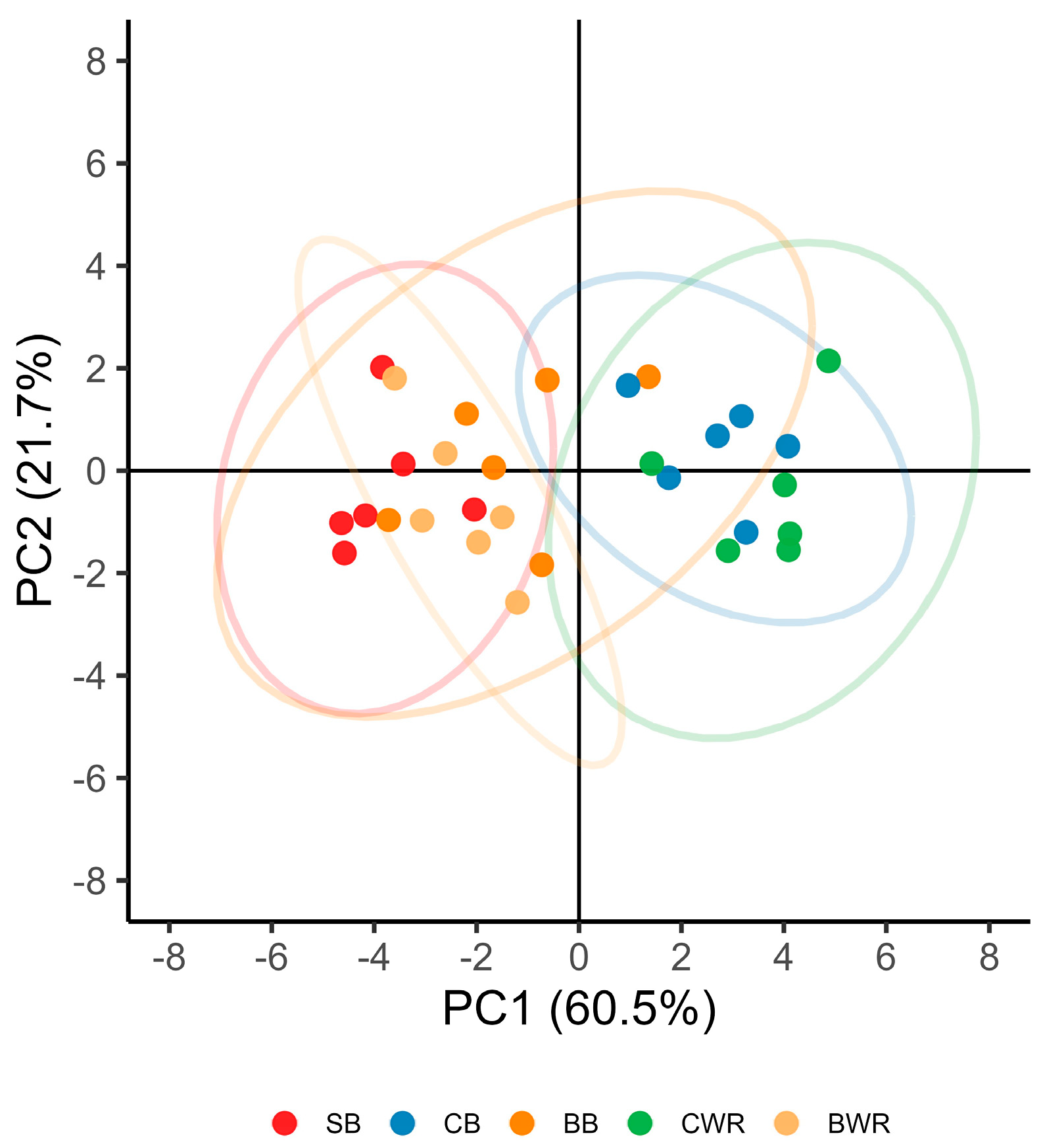

3.1. Smart Nose of Scotta-Based Beer and Cheese

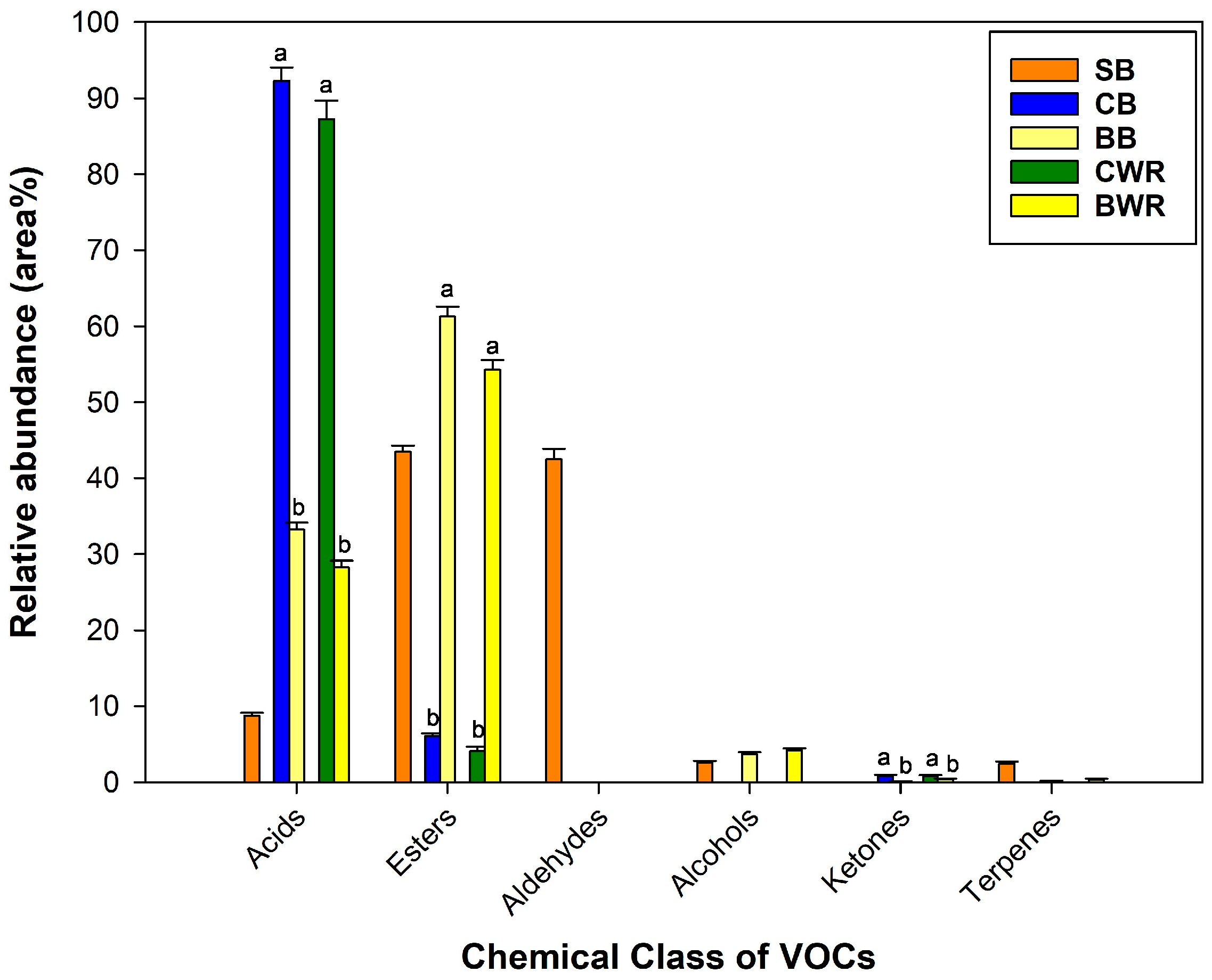

3.2. VOC Profiles of Scotta-Based Beer and Cheeses

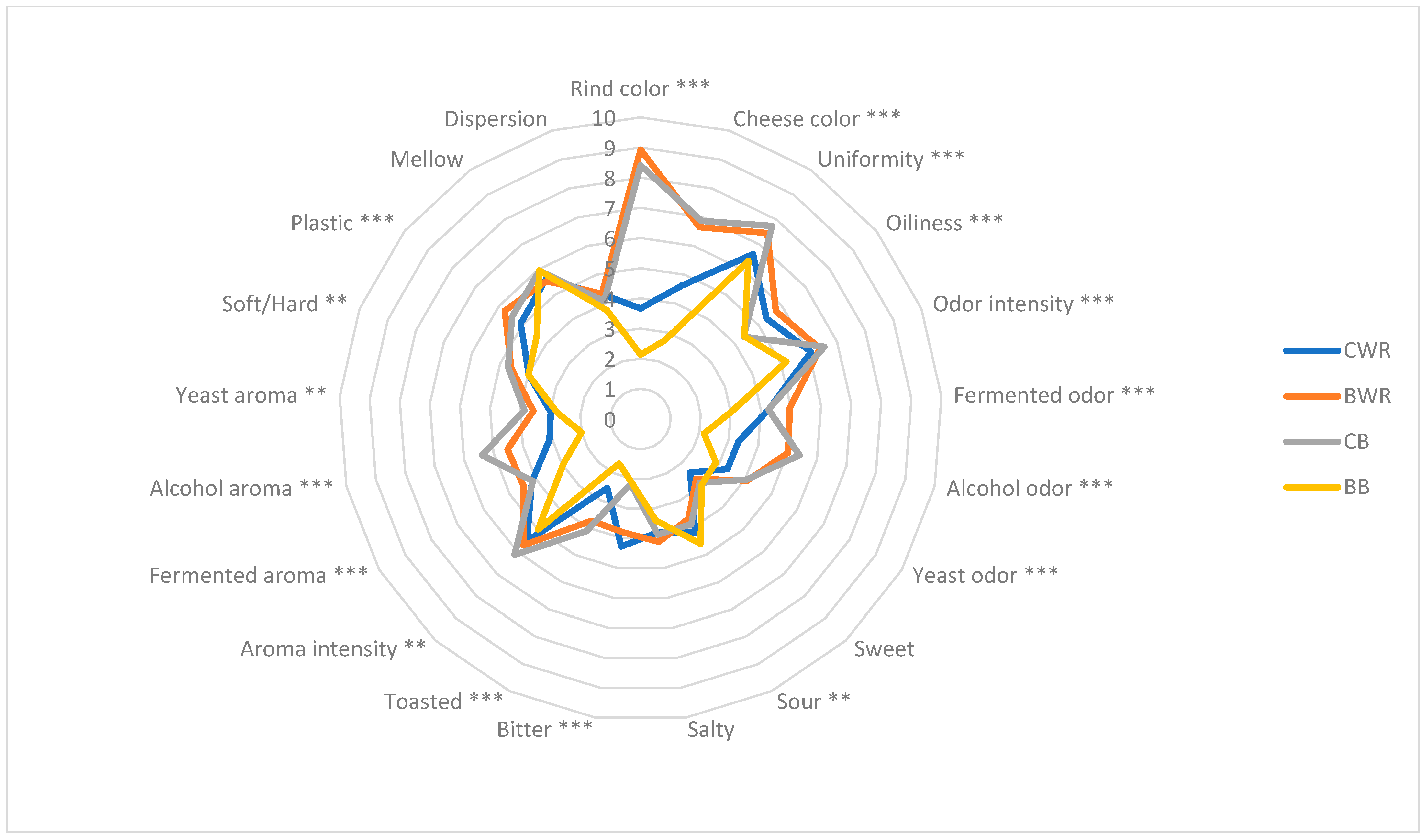

3.3. Cheese Composition and Sensory Profile

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SB | scotta-based beer |

| CWR | control cheeses with a washed rind using saturated water brine |

| CB | control cheeses immersed in unsaturated water brine |

| BWR | experimental cheeses with a washed rind using beer brine |

| BB | experimental cheeses immersed in unsaturated beer brine |

| VOC | volatile organic compound |

| PCA | principal component analysis |

References

- Bosco, F.; Carletto, R.A.; Marmo, L. An integrated cheese whey valorization process. Chem. Eng. Trans. 2018, 64, 379–384. [Google Scholar] [CrossRef]

- Zotta, T.; Solieri, L.; Iacumin, L.; Picozzi, C.; Gullo, M. Valorization of cheese whey using microbial fermentations. Appl. Microbiol. Biotechnol. 2020, 104, 2749–2764. [Google Scholar] [CrossRef] [PubMed]

- Pasta, C.; Caccamo, M.; Petriglieri, R.; Difalco, A.; Farina, G.; Marino, G.; Marino, V.M.; Garavaldi, A.; Musi, V.; Alcaine, S.D. Sicilian whey: Utilization of Ricotta whey in the production of value-added artisanal beers. Fermentation 2024, 10, 19. [Google Scholar] [CrossRef]

- Soumati, B.; Atmani, M.; Benabderrahmane, A.; Benjelloun, M. Whey Valorization–Innovative strategies for sustainable development and value-added product creation. J. Ecol. Eng. 2023, 24, 86–104. [Google Scholar] [CrossRef]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science, 2nd ed.; Springer: New York, NY, USA, 2017. [Google Scholar]

- Licitra, G.; Carpino, S. The microfloras and sensory profiles of selected Protected Designation of Origin Italian cheeses. Microbiol. Spectr. 2014, 2, 151–165. [Google Scholar] [CrossRef]

- Massart, D.L.; Vandeginste, B.G.M.; Deming, S.N.; Michotte, Y.; Kaufman, L. Chemometrics: A Textbook; Elsevier: Amsterdam, The Netherlands, 1988; Volume 2. [Google Scholar]

- Zeppa, G.; Tallone, G.; Bertolino, M. Utilizzo di birra e i suoi derivati nella produzione di formaggi innovativi. Sci. Tec. Latt.-Casearia 2013, 64, 195–200. [Google Scholar]

- ISTAT. Available online: http://dati.istat.it/Index.aspx?QueryId=16775 (accessed on 23 May 2023).

- Assobirra. Available online: https://www.assobirra.it/altri-stili/ (accessed on 23 May 2023).

- Sunesen, L.O.; Lund, P.; Sørensen, J.; Hølmer, G. Development of volatile compounds in processed cheese during storage. LWT-Food Sci. Technol. 2002, 35, 128–134. [Google Scholar] [CrossRef]

- da Silva, G.C.; da Silva, A.A.; da Silva, L.S.; Godoy, R.L.D.O.; Nogueira, L.C.; Quitério, S.L.; Raices, R.S. Method development by GC–ECD and HS-SPME–GC–MS for beer volatile analysis. Food Chem. 2015, 167, 71–77. [Google Scholar] [CrossRef]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 6579-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Sal-monella—Part 1: Detection of Salmonella spp. 1st ed. International Organization for Standardization: Geneva, Switzerland, 2017.

- Qian, M.; Reineccius, G. Identification of aroma compounds in Parmigiano-Reggiano cheese by gas chromatography/olfactometry. J. Dairy Sci. 2002, 85, 1362–1369. [Google Scholar] [CrossRef]

- Pinho, O.; Ferreira, I.M.; Santos, L.H. Method optimization by solid-phase microextraction in combination with gas chromatography with mass spectrometry for analysis of beer volatile fraction. J. Chromatogr. A 2006, 1121, 145–153. [Google Scholar] [CrossRef]

- ISO 13299:2016; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization: Geneva, Switzerland, 2017.

- Drake, M.A. Invited Review: Sensory Analysis of Dairy Foods. J. Dairy Sci. 2007, 90, 4925–4937. [Google Scholar] [CrossRef]

- Senoussi, A.; Rapisarda, T.; Schadt, I.; Chenchouni, H.; Saoudi, Z.; Senoussi, S.; Aissaoui Zitoun, Q.; Zidoune, M.N.; Carpino, S. Formation and dynamics of aroma compounds during manufacturing-ripening of Bouhezza goat cheese. Int. Dairy J. 2022, 129, 105349. [Google Scholar] [CrossRef]

- Luo, S.; DeMarsh, T.A.; deRiancho, D.; Stelick, A.; Alcaine, S.D. Characterization of the fermentation and sensory profiles of novel yeast-fermented acid whey beverages. Foods 2021, 10, 1204. [Google Scholar] [CrossRef] [PubMed]

- Curioni, P.M.G.; Bosset, J.O. Key odorants in various cheese types as determined by gas chromatography-olfactometry. Int. Dairy J. 2002, 12, 959–984. [Google Scholar] [CrossRef]

- Johnson, J. Washed-rind Cheeses Ripened with Beer. All About Beer Magazine. 2015. Available online: https://allaboutbeer.com/article/washed-rind-cheeses-ripened-with-beer/ (accessed on 10 July 2025).

- Ferraz, A.R.; Pintado, C.S.; Maria Luísa Serralheiro, M.L. A global review of cheese colour: Microbial discolouration and innovation opportunities. Dairy 2024, 5, 768–785. [Google Scholar] [CrossRef]

- Duensing, P.W.; Hinrichs, J.; Schieberle, P. Formation of key aroma compounds during 30 weeks of ripening in Gouda-type cheese produced from pasteurized and raw milk. J. Agric. Food Chem. 2024, 72, 11072–11079. [Google Scholar] [CrossRef]

- McSweeney, P.L.H. Biochemistry of cheese ripening: Introduction and overview. Int. J. Dairy Technol. 2004, 57, 127–144. [Google Scholar]

- Andriot, I.; Septier, S.; Peltier, C.; Noirot, E.; Barbet, P.; Palme, R.; Arnould, C.; Buchin, S.; Salles, C. Influence of cheese composition on aroma content, release, and perception. Molecules 2024, 29, 3412. [Google Scholar] [CrossRef]

- Bertuzzi, A.S.; McSweeney, P.L.; Rea, M.C.; Kilcawley, K.N. Detection of volatile compounds of cheese and their contribution to the flavor profile of surface-ripened cheese. Compr. Rev. Food Sci. Food Saf. 2018, 17, 371–390. [Google Scholar] [CrossRef]

- Dragone, G.; Mussatto, S.I.; Oliveira, J.M.; Teixeira, J.A. Characterisation of volatile compounds in an alcoholic beverage produced by whey fermentation. Food Chem. 2009, 112, 929–935. [Google Scholar] [CrossRef]

- Hetherington, J.; Loch, A.J.; Juliano, P. Food waste: Cheese whey: A hidden opportunity to tackle Australia’s food loss and waste problem. Food Aust. 2025, 77, 46–47. [Google Scholar]

| Compound (Area%) | CB | BB | Aroma Description | p-Value | Significance |

|---|---|---|---|---|---|

| Acids | |||||

| Butanoic acid | 31.17 ± 1.10 | 26.85 ± 0.80 | Rancid, cheesy, pungent | 1.5 × 10−5 | *** |

| Pentanoic acid | 0.92 ± 0.09 | n.d | Sweaty, cheesy, rancid | n.d | |

| Hexanoic acid | 45.85 ± 1.32 | n.d | Goaty, cheesy, rancid | n.d | |

| Octanoic acid | 9.61 ± 0.32 | n.d | Fatty, soapy, cheesy | n.d | |

| Nonanoic acid | 0.31 ± 0.03 | n.d | Fatty, waxy, cheesy | n.d | |

| n-Decanoic acid | 4.43 ± 0.22 | 3.48 ± 0.19 | Fatty, soapy, waxy | 1.2 × 10−5 | *** |

| Heptanoic acid | n.d | 0.34 ± 0.05 | Fatty, cheesy | ||

| Dodecanoic acid | n.d | 2.36 ± 0.21 | Soapy, fatty | ||

| Tetradecanoic acid | n.d | 0.26 ± 0.03 | Waxy, fatty | ||

| Esters | |||||

| Hexanoic acid, ethyl ester | 6.17 ± 0.27 | 37.47 ± 1.05 | Fruity, sweet | 7.5 × 10−15 | *** |

| Heptanoic acid, ethyl ester | n.d | 2.22 ± 0.20 | Fruity, floral | ||

| Octanoic acid, ethyl ester | n.d | 21.64 ± 0.58 | Pineapple, creamy, fruity | ||

| Alcohols | |||||

| Phenylethyl Alcohol | n.d | 3.78 ± 0.19 | Floral, honey-like | ||

| Ketones | |||||

| 2-Heptanone | 0.43 ± 0.05 | n.d | Fruity, buttery | ||

| 2-Nonanone | 0.51 ± 0.05 | 0.12 ± 0.03 | Fatty, fruity, buttery | 2.7 × 10−8 | *** |

| Terpenes | |||||

| Limonene | n.d | 0.18 ± 0.04 | Citrus, fresh | ||

| Total Compounds | 9 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caccamo, M.; Pasta, C.; Petriglieri, R.; Difalco, A.; Calandra Checco, G.A.; Farina, G.; Belvedere, G.; Marino, G.; Alcaine, S.D.; Caggia, C. The Affinage of Cheese Using Artisanal Beers from Ricotta Whey: A Sustainable Way to Differentiate Traditional Cheeses. Appl. Sci. 2025, 15, 10057. https://doi.org/10.3390/app151810057

Caccamo M, Pasta C, Petriglieri R, Difalco A, Calandra Checco GA, Farina G, Belvedere G, Marino G, Alcaine SD, Caggia C. The Affinage of Cheese Using Artisanal Beers from Ricotta Whey: A Sustainable Way to Differentiate Traditional Cheeses. Applied Sciences. 2025; 15(18):10057. https://doi.org/10.3390/app151810057

Chicago/Turabian StyleCaccamo, Margherita, Catia Pasta, Rosario Petriglieri, Antonio Difalco, Giacomo Antonio Calandra Checco, Giovanni Farina, Giovanni Belvedere, Giovanni Marino, Samuel David Alcaine, and Cinzia Caggia. 2025. "The Affinage of Cheese Using Artisanal Beers from Ricotta Whey: A Sustainable Way to Differentiate Traditional Cheeses" Applied Sciences 15, no. 18: 10057. https://doi.org/10.3390/app151810057

APA StyleCaccamo, M., Pasta, C., Petriglieri, R., Difalco, A., Calandra Checco, G. A., Farina, G., Belvedere, G., Marino, G., Alcaine, S. D., & Caggia, C. (2025). The Affinage of Cheese Using Artisanal Beers from Ricotta Whey: A Sustainable Way to Differentiate Traditional Cheeses. Applied Sciences, 15(18), 10057. https://doi.org/10.3390/app151810057