Abstract

The enzymatic coagulation of milk, crucial in cheese production, entails the hydrolysis of κ-casein and subsequent micelle aggregation. Conventional assessment standards, such as the Berridge method, depend on visual inspection and are susceptible to operator bias. Recent methods for the identification of milk-clotting time rely on optical, ultrasonic, and image-based technologies. In the present work, the composition of milk was evaluated through standard methods from ISO and AOAC. Milk coagulation time (MCT) was measured through viscosimetry, Berridge’s operator-driven technique, and a machine learning approach employing computer vision. Coagulation was additionally observed using the Optigraph, which measures micellar aggregation through near-infrared light attenuation for immediate analysis. Sheep milk samples were analysed for their composition and coagulation characteristics. Coagulation times, assessed via Berridge (BOB), demonstrated high correlation (R2 = 0.9888) with viscosimetry (Visc) and machine learning (ML). Increased levels of protein and casein were linked to extended MCT, whereas lower pH levels sped up coagulation. The calcium content did not have a notable impact. Optigraph assessments validated variations in firmness and aggregation rate. Principal Component Analysis (PCA) identified significant correlations between total solids, casein, and MCT techniques. Estimates from ML-based MCT closely align with those from operator-based methods, confirming its dependability. This research emphasises ML as a powerful, automated method for evaluating milk coagulation, presenting a compelling substitute for conventional approaches.

1. Introduction

Most varieties of cheese worldwide are produced by enzymatic coagulation [1] in a two stage process: (i) Enzymatic hydrolysis of k-casein at the peptide bond Phe105-Met106, causing the separation of caseinomacropeptides and making the micelles unstable [2]; (ii) Aggregation of casein micelles after hydrolysis of 87% of k-casein [3], forming a three-dimensional network retaining water and fats [2,4]. The assessment of the clotting capacity of rennet enzymes and the impact on the coagulation process has always been of great importance from scientific, technological, and commercial viewpoints [5] as it directly affects the ideal cutting time of the curd [6]. If cutting is made when the curd is still soft, the cheese yield will be lower due to increased loss of fat and curd fines. If made when it is too firm, syneresis will be delayed; thus, cheeses will present a higher moisture content [7].

Since the end of the 19th century, several methodologies have been used to evaluate rennet capacity [5] based initially on visual observation of the curd. In one of the earlier methods, Sommer and Matsen [8] measured the elapsed time between the incorporation of rennet and the visual observation of the first signs of graininess on a film of milk clinging to the inside wall of a revolving bottle [9]. This method would be later developed by Berridge [10,11], defining the moment of clotting based also on observation. The Berridge method remains extensively utilised; however, it is susceptible to human error since it depends on the operator’s expertise to recognise milk flocculation [9]. Nonetheless, multiple continuous and non-destructive techniques that rely on assessing optical properties like reflection, absorbance, scattering, and light refraction have been suggested for observing milk coagulation and identifying gelation/clotting time [12,13,14,15,16,17]. Among the various proposed techniques, the group that stands out is based on optical parameters from light backscatter measurement [18,19,20,21], already applied in the evaluation of the cutting time of cow’s and goat’s curd [22]. The system measures changes in backscatter of infrared light at 880 nm in a specific configuration, yielding a significant signal and correlated with changes occurring in the structure of caseins during coagulation. Light from a light-emitting diode (LED) is transferred to the milk through a fibre, and the light backscattered from the milk is transmitted through an adjacent fibre to an optical detector. Such technology presents certain advantages, such as measurement through small path lengths, reduced size of the equipment, suitability for inline measurement, possibility of continuous results, non-invasiveness, and non-destructiveness. A fibre optic sensor used to measure light backscatter has been demonstrated to be one of the most promising inline technologies for monitoring coagulation and is actually commercially available [23,24,25].

Recent developments in automated optical technologies have significantly enhanced the monitoring and evaluation of milk coagulation. These non-invasive approaches enable a more detailed assessment of gel formation and clotting dynamics, contributing to greater efficiency in dairy processing. The Optigraph, created by the Institut National de la Recherche Agronomique (INRA) in collaboration with Alliance Instruments, represents a modern alternative to the traditional Formagraph, delivering more precise measurements of rennet-induced milk coagulation characteristics [12,26].

The Optigraph is an analytical device designed to monitor milk coagulation by detecting the attenuation of near-infrared light resulting from casein micelle aggregation [27]. This non-invasive method enables real-time quantification of key coagulation parameters, including coagulation onset, curd firmness evolution, optimal curd cutting time, and micellar aggregation rate [28,29]. The real-time data generated allows for a precise and detailed assessment of enzymatic coagulation properties, providing high-resolution insights into the kinetics of curd formation and supporting the optimisation of cheesemaking processes [30].

Taifi et al. [31] demonstrated that a non-invasive ultrasonic monitoring technique is effective for the continuous observation of milk coagulation and syneresis, concluding that the speed of propagation was a reliable parameter of the stability of milk gel and the presence of syneresis. In fact, ultrasonic velocity and attenuation are the parameters most frequently used in ultrasonic measurements [6] and considered in several studies related to coagulation [32,33,34,35].

Recent upgrades of methods based on image analysis have included the acquisition in stand-alone digital camera systems [26,36] or incorporated in an optical microscope [37,38], where image-related parameters correlated with milk-clotting and syneresis. Aldalur et al. [36] observed that the size and shape of curd grains were correlated with cheese yield. Caeiro et al. [26] used a digital camera to monitor the formation of coagulum in the inner wall of a flask in rotation, according to the ISO 23058:2006|IDF 199:2006 standard [39], concluding about the correlation between the standard deviation of digital analysis and coagulation time [26]. Djaowé et al. [37] observed a correlation between image parameters (RGB and luminance) and coagulation.

Artificial Intelligence (AI) includes the creation of algorithms and computational models that allow machines to handle and examine vast quantities of data, recognise patterns and make predictions [40]. The main areas of AI include Computer Vision (CV), Machine Learning (ML), Artificial Neural Networks, Robotics, Natural Language Processing, and Expert Systems, which have been used for decision-making on several processes in the food chain [41]. AI is rapidly changing the agriculture and food sectors by improving productivity, efficiency, and sustainability, a consequence of the growing amount of industrial data available [42]. So far, the applications of AI in the food sector can be found at several levels, including precise farming, crop growth, poultry production, food quality, and food structure, among others [40,41,43]. Reports of implementation of AI in the dairy sector include classification of cheese varieties from Switzerland [44], evaluation of authenticity [45,46,47], and consumer acceptance of Minas Frescal cheese [48].

The objective of this study was to evaluate the application of a novel setup combining machine learning (ML) and computer vision (CV), two main subjects of AI, following the ISO 23058:2006|IDF 199:2006 standard method [39], to determine the milk clotting time in sheep’s milk with different physical–chemical composition.

2. Materials and Methods

2.1. Milk Sampling

Raw sheep milk, from the Lacaune breed, was provided by a dairy farm located in the Baixo Alentejo region of southern Portugal, between February and May 2024, totaling six samples and identified as CH6, CH7, CH9, CH10, CH11, and CH12, collected on different days. The milk samples were transported at 4 °C and, prior to analysis, were thermized to 32 °C ± 1 °C in a water bath (Ref. W720, Memmert, Schwabach, Germany).

2.2. Milk Composition Analysis

Milk acidity was determined according to the AOAC 947.05 standard [49]. The pH was measured using a pH metre (Ref. 713, Metrohm, Herisau, Switzerland). Total solids content was determined following ISO 6731:2010|IDF 21:2010 [50]. Milk fat content was measured according to ISO 19662:2018|IDF 238:2018 [51]. Crude protein content was quantified using ISO 8968-1&2:2014|IDF 20-1&2:2014 [52]. Casein content was determined according to ISO 17997-1:2004|IDF 29-41:2004 [53]. Calcium content was determined by titration, following ISO 12081:2010|IDF 36:2010 (Milk—Determination of calcium content—Titrimetric method. International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2010). Lactose content was quantified using a SugarPak separation column (10 µm, 6.5 mm × 300 mm) with refractive index detection (Waters, Milford, MA, USA) by following the ISO-22662:2024|IDF 198:2024 [54].

2.3. Preparation of the Commercial Microbial Rennet

A commercial microbial rennet, a fungal protease derived from a pure strain of Rhizomucor miehei, with a milk-clotting activity (MCA) of 250 international milk-clotting units (IMCU/mL), was used as the coagulant (LusoCoalho, Catraia Cimeira, Portugal). To prepare the working solution, 1 mL of the stock rennet was diluted with distilled water to a final volume of 50 mL, resulting in a 1:50 dilution and covered with aluminium foil to protect it from light [26].

2.4. Milk-Clotting Time (MCT) Determination

MCT was determined using three methods: (i) Viscosimetry-based analysis (Visc), which measures changes in viscosity during coagulation; (ii) Berridge’s operator-based method (BOB), a traditional visual technique performed by an experienced observer; and (iii) a machine learning prediction model (ML), developed to estimate MCT based on physical–chemical input variables.

- Viscosimetry-based (Visc)

An aliquot of 60 mL of sheep milk was placed inside the cup with 1200 μL of the 1:50 rennet solution, mixing thoroughly for 5 s, thus initiating renneting. The determination was carried out with a VT 550 rotational viscometer (ThermoHaake, Karlsruhe, Germany) using a concentric cylinder geometry (MV-DIN), shear rate 1 s−1 for 900 s. Water was pumped to the jacketed vessel of the viscometer (Grant LTD6G, Royston, UK) to control the temperature of the samples at 32 ± 1 °C. MCT, in seconds, was defined as the elapsed time from the addition of rennet to attain the shear stress value 1.0 Pa.

- Berridge’s operator-based (BOB)

Berridge’s Operator-Based Method (BOB) was applied to determine the MCT, following the ISO 23058|IDF 199:2006 standard [39], with slight modifications to suit the use of raw sheep milk as the substrate instead of the standard reconstituted skim milk [30]. An aliquot of 25 mL of the sheep milk was pre-heated in a dry conical flask placed in a water bath at 32 °C for 12–20 min. Subsequently, 0.5 mL of the 1:50 rennet solution was added, and the mixture was briefly stirred to ensure homogenization. Simultaneously, a stopwatch was started to measure the MCT, following the IDF protocol [39]. The flask was immediately attached to the rotary device, set to a rotation speed of approximately 0.33–0.67 Hz [30]. The water bath (Heidolph Laborota 4000 Rotary Evaporator & Heizbad Water Bath Lab) was maintained at a constant temperature of 32 ± 1 °C. MCT, in seconds, was defined as the elapsed time from the addition of rennet to the visible appearance of flocculation on the inner wall of the flask.

- Machine-learning prediction model (ML)

In previous studies, Caeiro et al. [26] developed a mathematical model to predict MCT from the variation in the transparency of images collected by a computer vision system based on the Berridge method. However, the results were influenced by noisy data due to the high variability in film transparency resulting from the rotational movement of the flask with milk and rennet. The image artefacts present themselves in terms of periodic changes in the glass reflection and in the surrounding image capture environment, combined with the small variations due to non-uniform viscosity of the milk solution (although attenuated by the flask rotation milk mixing effect), and electronic noise.

In the present work, Berridge’s operator-based method was combined with a machine learning approach for the identification of the local minimum value of transparency, based on the setup prepared according to Caeiro et al. [26]. A randomly chosen set of 50 video sequences (MPEG4, 1920 × 1080, 50 fps) from the operator-based method was recorded and used to train the machine learning system, including the MCT value obtained directly by the operator. Later, the remaining set of 26 video sequences was used to test the developed machine learning model. The machine learning system was built with the scikit-learn 1.7, Python-based toolkit [55]. A supervised training technique was adopted by using a Random Forest classifier, a standard method used in ML that combines a set of decision trees to classify patterns based on a set of features provided as the dataset. For this particular case, the dataset consists of time evolution tables defined in Caeiro et al. [26], namely the video images variance and the MCT point obtained by a skilled operator. When this data is fed to train the classifier, it is able to predict the time bin when the MCT occurs, which is confirmed by testing the classifier with the test dataset. The Random Forest classifier was trained to detect the points in each sample corresponding to the clotting time, and a relative error, < 2.1%, was obtained when the obtained classifier was applied to the whole set of samples.

The MCT, in seconds, was defined as the elapsed time from the addition of rennet to the identification of the following condition (Equation (1)), as stated in Caeiro et al. [26]:

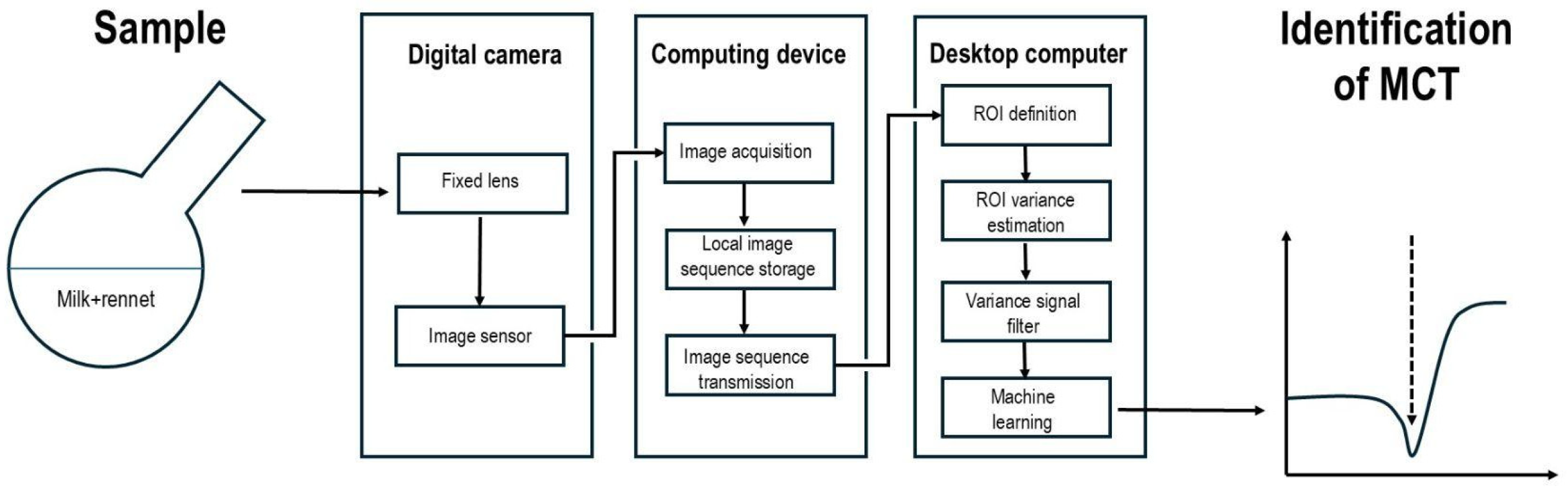

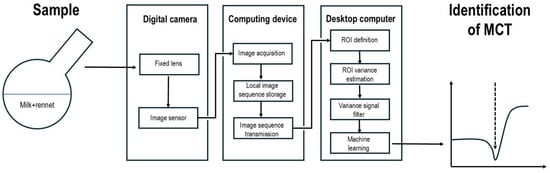

The region of interest (ROI) was defined according to the above-mentioned image acquisition setup. The ML-based system is represented in Figure 1, where the scene composed of sheep milk with rennet solution was captured using a digital image acquisition system, as described in detail in Caeiro et al. [26]. The image dataset was acquired, and the corresponding transparency variance signals were obtained for each image. These signals were processed to reduce noise artefacts, mainly related to the rotation of the flask, a consequence of reflections on its surface. Such processed signals formed the dataset and, due to the nature of sheep milk with rennet solution, presented a challenge concerning the estimation of MCT as more variations were observed in transparency, and the signal-to-noise ratio of the features used for the determination of the clotting-time point. The machine learning sub-system used this dataset for training purposes. Afterwards, the resulting model was used to estimate the MCT.

Figure 1.

Architecture of the MCT method based on ML. Arrow indicates the minimum point of transparency variance.

2.5. Monitoring the Enzymatic Coagulation

The coagulation process was monitored using an Optigraph (Alliance, Frépillon, France), a device that, based on the attenuation of the near-infrared signal, can follow the micellar aggregation process in real time and, consequently, the coagulation process [56]. The analysis was performed according to Gomes et al. [30], placing and stabilising the milk at the coagulation temperature of 32 °C in the device’s cuvettes. A total of 1 mL of coagulant working solution previously diluted 1:4 with distilled water was added to each cuvette containing 10 mL of the sheep milk sample. The intensity of the emitted signal was set to 7 V and all tests ran for 90 min for the evaluation of the following: R—clotting time, in seconds (s); 0K20—speed of micellar aggregation measured as time to reach a standard clot firmness, in seconds (s); A20, A40, AR, and A2R—firmness measures, after 20 or 40 min from the beginning of trial or after two or three times R, respectively, in volts (V).

2.6. Statistical Methodology

All experiments were conducted in the laboratory in triplicate. For each parameter, the mean and standard deviation were calculated, followed by a one-way ANOVA with pairwise comparisons of means using Scheffé’s test (n = 3). The relationship between MCT methods and technological parameters (Optigraph data) versus milk composition was performed by Pearson’s correlation analysis. Principal Component Analysis (PCA) was performed to explore patterns of variation among milk samples collected on different dates, aiming to identify potential differences in composition and coagulation performance. Due to the high correlation between ML and BOB, a linear regression Scatterplot between these different methodologies was performed.

3. Results

3.1. Milk Composition

Table 1 presents a summary of the nutrients and physical–chemical characterisation of the sheep milk samples collected from the dairy farm on different dates. The evaluation of these parameters was made for a preliminary characterisation of the milk samples used in the MCT determination, considering the parameters with higher impact on coagulation [1]. The obtained results are consistent with previous reports on the characterisation of sheep milk in Alentejo [30,57] and other regions [58,59,60,61,62,63].

Table 1.

Mean values ± standard deviation of nutrients and physical–chemical characterisation of sheep milk samples.

3.2. Comparative Evaluation of MCT

Table 2 presents a comparative analysis of sheep milk samples based on technological properties measured using the Optigraph equipment and MCT methods. The results align closely with those reported by Gomes et al. [9], who studied the coagulation dynamics of cardoon flower extract versus commercial chymosin, using sheep milk from the Baixo Alentejo region of Portugal. In their study, MCT (BOB method) ranged from 592 to 649 s for commercial chymosin, while R values (coagulation time) varied between 817 and 935 s, comparable to the values observed in the present work.

Table 2.

Mean values ± standard deviation of technological properties (Optigraph parameters) and MCT methods of the sheep milk samples.

Regarding R values, sample CH11 exhibited the longest coagulation time (961 s), indicating slower coagulation, while CH9 showed the shortest coagulation time (733 s). As for curd firmness parameters, sample CH11 demonstrated the highest AR values, 13.69 V, suggesting superior gel strength. In contrast, CH9 recorded the lowest firmness (9.75 V). This pattern is further supported by A2R values, where CH11 showed the highest reading, 21.21 V, reinforcing textural characteristics. The 0K20 parameter, which reflects the time required to reach 20 V of firmness, was shortest in CH6 and CH11 (~117–118 s), indicating faster gel development compared to CH7, CH9, and CH10 (~131–133 s). These findings are consistent with previous observations [56,64], which suggest that faster micellar aggregation (lower K20 values) is associated with firmer curd formation.

A Random Forest-based machine learning model [65] was employed for identifying MCT. The observed results ranged from 349 s (CH7) to 590 s (CH11). This model was selected based on its discriminative ability, previously assessed during the training phase. Later, key factors such as reliability and responsiveness were validated when the forecast of the key variables for differentiating the samples during the test phase, similar to other studies [45]. Machine learning techniques may be favoured over multiple regression and minimum partial squares due to requiring fewer assumptions for the modelling, in addition to the presuppositions of normality and lack of collinearity, typically found in conventional statistical analysis [48]. Additionally, the BOB and ML values obtained in this study are in agreement with those reported by Caeiro et al. [26], who tested a digital method for coagulation assessment, relying on classical statistical tools for the estimation of the local minimum value for transparency, assumed as the MCT. Their results showed that the digital measurements and statistical approach deviated by less than 3% from those obtained by human operators, supporting the reliability of the methodology used in the present study. The results obtained in the present study, considering the same digital setup but replacing conventional statistical tools with ML, presented a 1.12% deviation from a human operator.

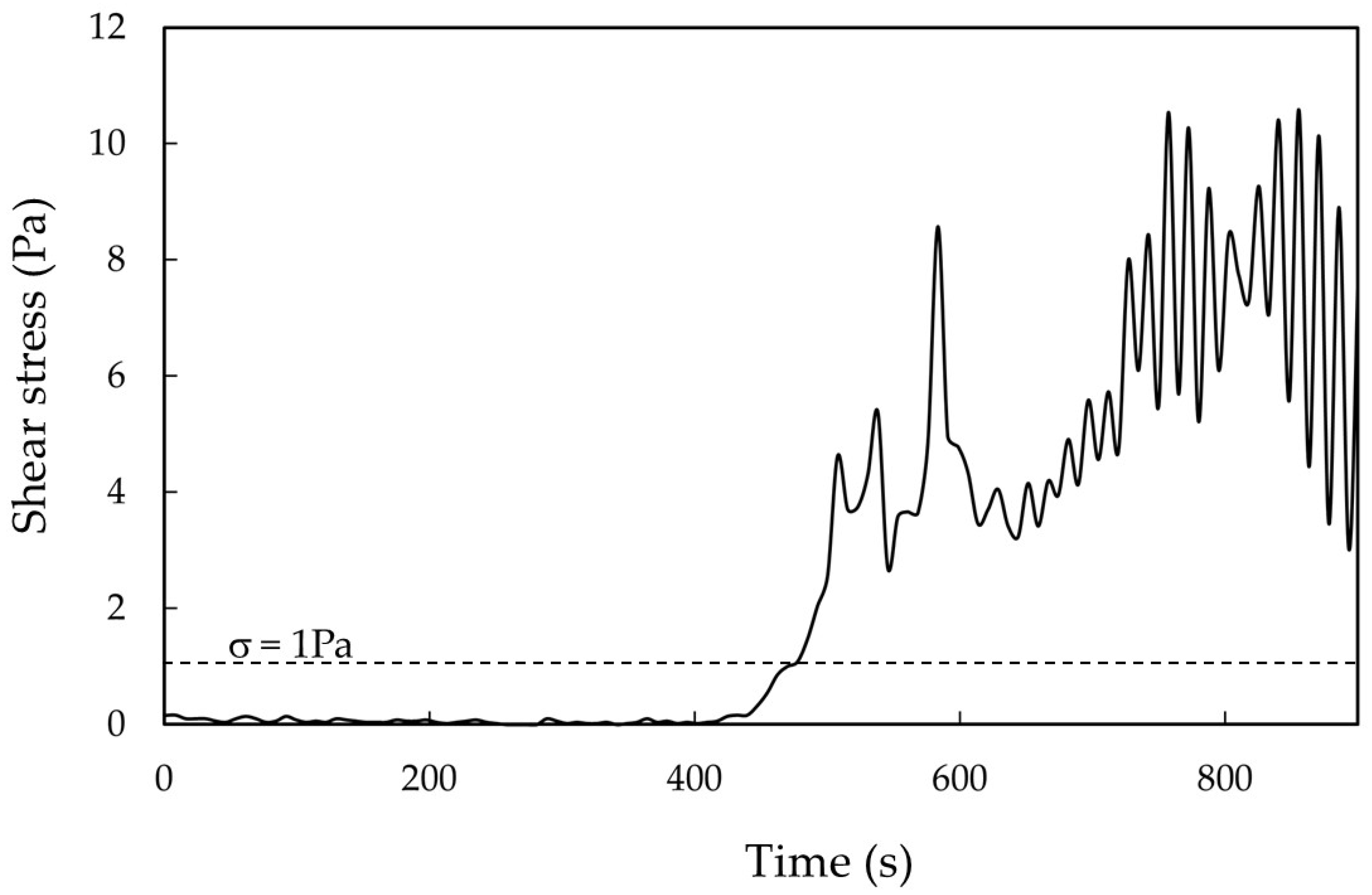

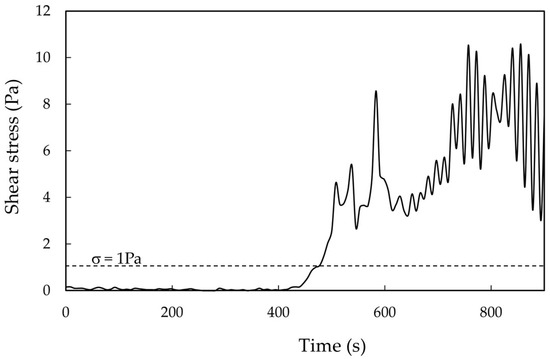

The results of shear stress at the beginning of the runs ranged around 0.1 Pa, decreasing to 0.02–0.03 Pa after 200s, a consequence of the enzymatic cleavage of κ-casein in the primary phase, forming caseinomacropeptide (CMP) and decreasing apparent viscosity during a period equivalent to about 60% of the rennet clotting time [66]. In previous studies, a reduction in about 4–8% of the apparent viscosity has been reported in the primary phase of enzymatic κ-casein degradation [67]. Literature suggests that such an effect is a consequence of a reduction in the volume of the casein micelles after the removal of CMP, which formed a ‘hairy layer’ around 12 nm thick [66,68]. Subsequently, micelles start to aggregate, mostly due to Van der Waals attraction and the concentration of Ca2+ [69], trapping water molecules. This change leads to a dense stable network [70], causing an increase in apparent viscosity [67], as reported previously in works including viscosimetry [71] and rheometry to study the coagulation process [72]. When a value around 8–10 Pa was exceeded (Figure 2), shear stress became more irregular and presented several peaks, a consequence of the contraction with rearrangement of casein micelles followed by gel syneresis [73].

Figure 2.

Example graphic of flow behaviour of sheep milk during coagulation under rotational viscometry (sample CH9).

3.3. Effect of Milk Properties on MCT

As shown in Table 1, all measured parameters exhibited statistically significant differences among the sheep milk samples. However, not all influence the behaviour of milk during coagulation. Regarding fat and total solids content, samples CH9, CH10, and CH12, which presented values closest to the overall mean value (around 6% fat and 17% total solids), exhibited the lowest MCT value (Table 2). In contrast, samples with higher fat and total solid content presented the highest MCT values. Notably, sample CH7 presented the lowest fat and solids content and, however, did not coagulate faster, as might be expected, but it presented the highest MCT values in the three tested methods (Table 2), which may suggest that fat and total solids content do not have a direct or consistent effect on coagulation time. These findings are consistent with the literature [59,61], where no significant influence of fat content on the coagulation time of sheep milk was observed. Sample CH11 exhibited the highest values for the different parameters related to coagulation time (R, ML, Visc, and BOB), as observed in Table 2, and the highest levels of lactose, protein, and casein. On the other hand, samples CH12, CH9, and CH10 presented the lowest coagulation times and also the lowest protein and casein contents (Table 2). This negative correlation aligns with the findings of Martins et al. [57], who observed that samples with lower protein content tended to exhibit shorter coagulation times. Also, Júnior et al. [18] observed that the higher the enzyme concentration and the lower the protein content, the shorter the time for the initial aggregation. In previous studies on the application of ultrasound for monitoring milk curdling, Jiménez et al. [61] stated a correlation between protein content and ultrasound attenuation and, therefore, with the coagulation process.

Calcium content did not appear to influence the coagulation times of the sheep milk samples. The calcium levels showed only slight variation, ranging from 0.15% to 0.19% (Table 1), while the coagulation times varied substantially among samples; for instance, in the ML prediction model, coagulation times ranged from 349 s to 590 s (Table 2). This lack of correlation suggests that, within the natural variation observed, calcium concentration was not a determining factor in clotting behaviour, consistent with Bencini [59], who observed that the addition of calcium to sheep milk did not significantly alter coagulation times. This contrasts with cow milk, where calcium supplementation is known to have a more pronounced effect on clotting kinetics [59,74]. Therefore, in the context of sheep milk, calcium content within the observed range does not appear to be a limiting or enhancing factor for coagulation onset.

Regarding pH values, the results indicate that a decrease in pH accelerates the onset of milk coagulation as observed in previous studies [4]. For instance, sample CH9, which exhibited the lowest pH value (Table 1), also showed the shortest coagulation time according to methods ML and BOB (Table 2). This trend supports the findings of Walstra et al. [75], who reported that the rate of coagulation increases as pH decreases. Similarly, Caballero-Villalobos et al. [76] observed that milk samples with pH values close to 6.5 coagulated more efficiently, where higher pH values were associated with delayed or less effective coagulation.

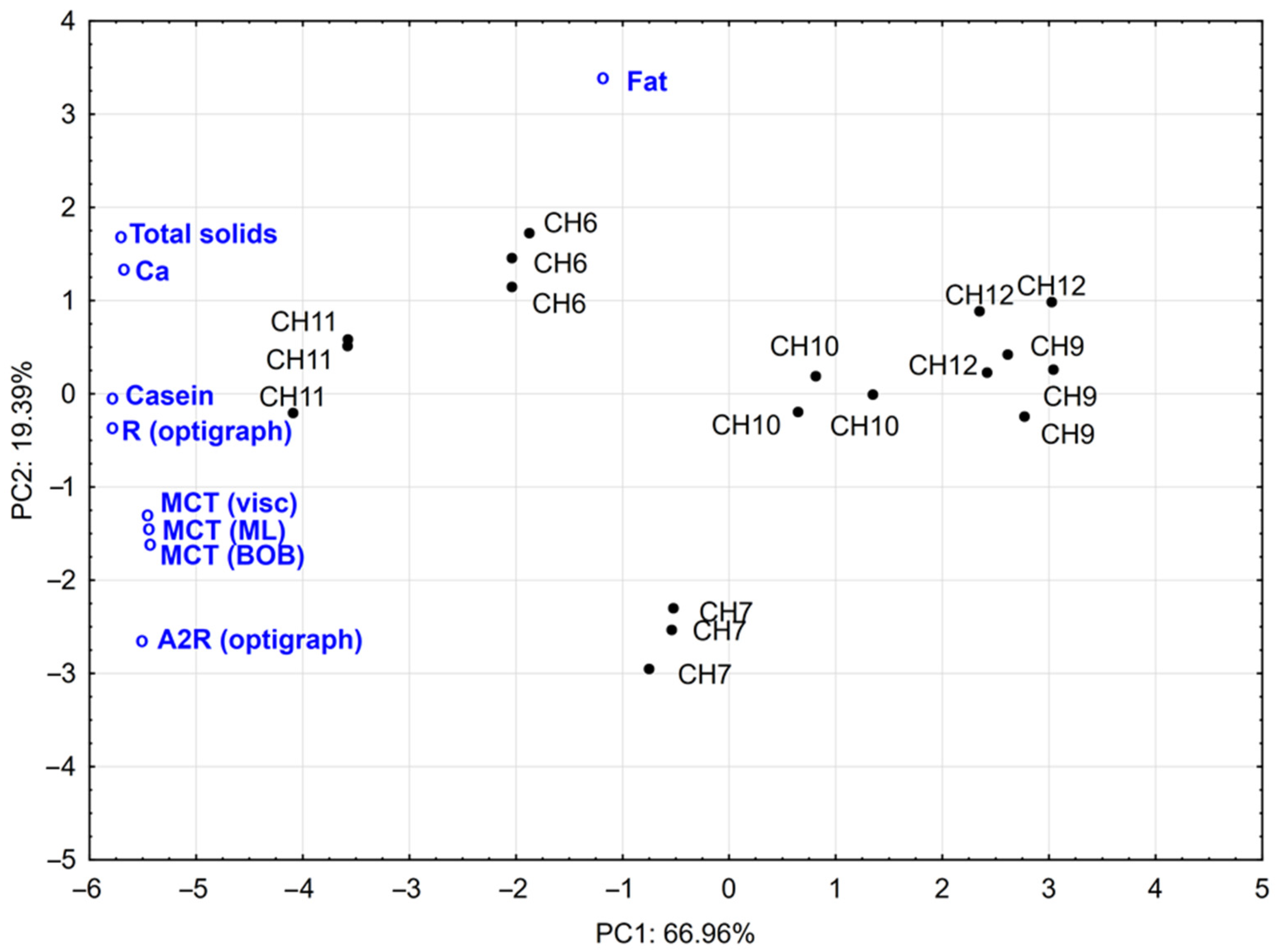

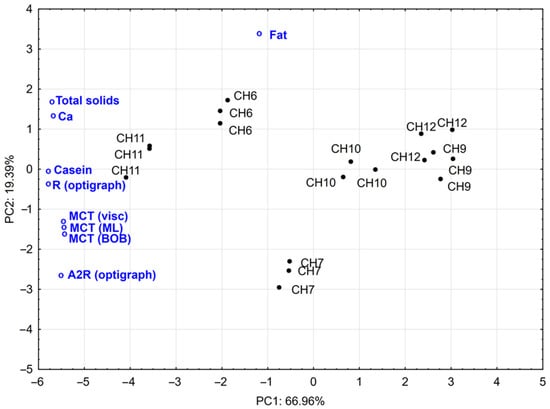

Principal Component Analysis (PCA) was performed (Table 3) to evaluate the relationships among different methodologies for relating MCT to the properties of milk samples. MCT was assessed using a novel machine learning and computer vision approach (ML), alongside established techniques including visual observation based on Berridge’s operator-based approach (BOB), a viscosimetry-based method (Visc), and Optigraph measurements such as R and A2R. These data were integrated with the physical–chemical composition of the milk samples, particularly focusing on casein, calcium, fat, and total solids, to explore their influence on coagulation parameters.

Table 3.

Principal Component Analysis.

The PC1 was heavily correlated with total solids, calcium, casein, Optigraph parameters (R and A2R), and all MCT methods (BOB, Visc, and ML). The PC2 is only explained by fat content. Figure 3 shows the projection of the samples onto the PC1/PC2 plane.

Figure 3.

Principal Component Analysis: PC1 vs. PC2 projection of samples (n = 3). The key variables contributing to the definition of each principal component are represented along the axis, illustrating the direction of increasing values for each variable.

The PCA reveals differences in sample composition and coagulation performance, as suggested by the separation of samples along the principal components. In the analysis of the plot, three distinct groups of closely related attributes can be observed: (1) total solids and calcium content are closely positioned on the factor plane, reflecting their strong association; (2) casein concentration is located near the variable representing the beginning of coagulation (R parameter from Optigraph), suggesting a potential link between casein levels and the initiation of the coagulation process; thus, higher casein content may delay the onset of coagulation due to a lower enzyme-to-substrate ratio [9,63]; (3) furthermore, a key finding of this study is that all used methods for MCT estimation are positioned very closely in the PCA plot, indicating a high level of agreement among them.

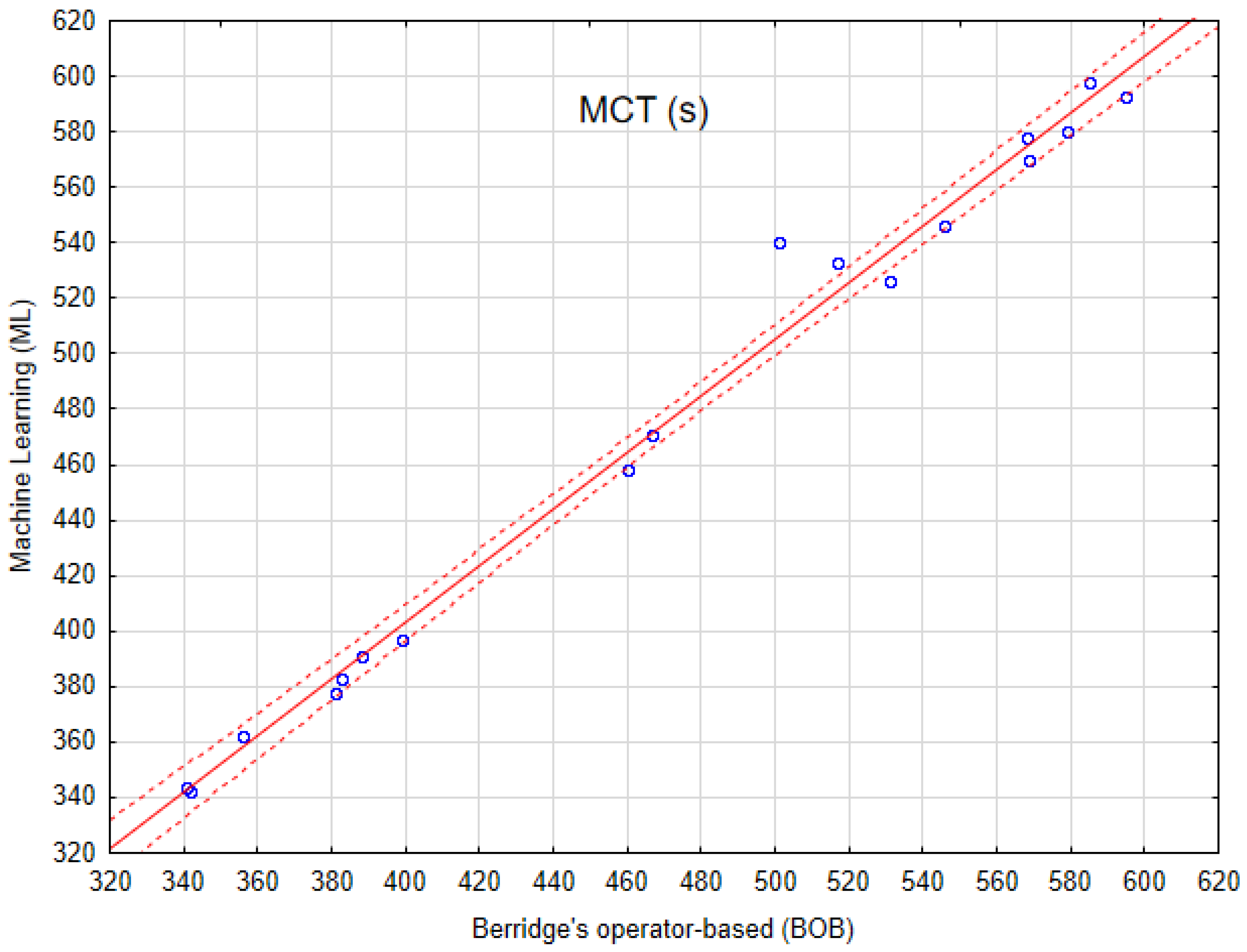

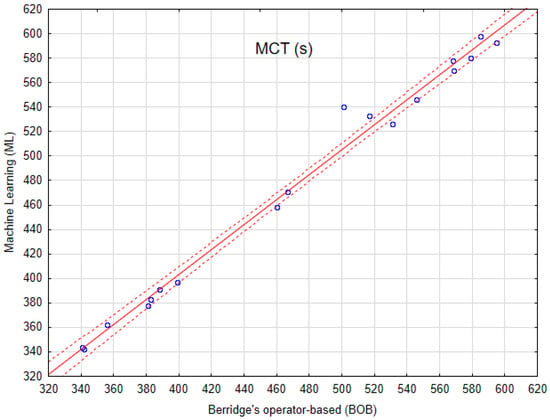

The results consistently demonstrated a strong correlation (R2 = 0.9888, p < 0.05) between BOB and ML results. Therefore, a linear regression scatterplot (Figure 4) was performed, supporting the conclusion that, due to the similarity in results, the ML method developed in this study can serve as a reliable substitute for the traditional Berridge’s method in determining MCT.

Figure 4.

Linear regression scatterplot between ML and BOB: ML = −5.1 + 1.0X × BOB (r2 = 0.9888, --- 0.95 confidence interval).

4. Conclusions

The present study aimed to assess the performance of a novel machine learning model (ML) integrated with computer vision for predicting milk-clotting time, comparing it to the Berridge operator-based method, a viscosimetry-based method, and the Optigraph. The ML system was designed to identify the local minimum in transparency variance derived from image sequences during milk coagulation, following the IDF 199 ISO standard. The values of coagulation time using the ML approach varied notably among samples, from 349 s to 590 s, corresponding to differences in protein and casein content. Higher casein levels were associated with firmer curd (higher A2R and AR values), while faster gel formation (lower K20) was observed in CH6 and CH11. The ML model, supported by computer vision, showed strong agreement with the IDF standard (BOB method), with a deviation of only 1.12%. Shear stress measurements aligned with known coagulation phases: an initial viscosity drop due to κ-casein cleavage, followed by an increase during micelle aggregation and gel formation. Despite significant differences in composition, not all physical–chemical parameters of milk influenced coagulation. Fat and total solids showed no consistent effect on milk-clotting time, while protein and casein were inversely correlated with coagulation time. Calcium content, within the range of 0.15–0.19%, had a negligible influence. Lower pH values were associated with shorter coagulation times, confirming previous findings on acid-induced acceleration of coagulation. Principal Component Analysis highlighted the association between total solids, calcium, and casein with all coagulation parameters; casein levels were linked to delayed coagulation onset, likely due to enzyme-substrate ratio effects; and the strong proximity of BOB, Visc, and ML results in the PCA plot supports the interchangeability of these methods. A linear regression (R2 = 0.9888, p < 0.05) further confirmed the equivalence between ML and BOB, establishing the ML method as a reliable alternative for MCT determination in sheep milk. This model proved more flexible than classical approaches, requiring fewer assumptions, and reliably predicted MCT across samples; however, a more solid and broader effort must be taken to validate the use of ML in milk clotting. Immediate steps should include the application of this new method in other species to evaluate the performance in other matrices with different ranges of solids, fat, protein, casein, and mineral content.

Author Contributions

Methodology, writing, and formal analysis, J.D., S.G., K.S.S., D.F., M.L., J.F., J.M., J.J.C. and N.A.; review and editing, J.D., S.G., K.S.S., D.F., J.F., M.L., J.M., J.J.C. and N.A.; project administration and funding, J.D. and N.A. All authors have read and agreed to the published version of the manuscript.

Funding

The present work was co-financed by the EU Recovery and Resilience Plan (PRR), under the project “CASEUS Combined use of renewable energy sources to improve energy efficiency in cheese in-dustry” (RRP-C05-i03-I-000249), by FCT—Fundação para a Ciência e a Tecnologia, I.P., under the “R & D Unit GEOBIOTEC-UID/04035: GeoBioCiências, GeoTecnologias e GeoEngenharias: https://doi.org/10.54499/UIDB/04035/2020”, under the “Project UIDB/05183 (Mediterranean Institute for Agriculture, Environment and Development. https://doi.org/10.54499/UIDB/05183/2020)”, and under CREATE (UIDB/06107/2023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are included in the manuscript.

Acknowledgments

The authors would like to acknowledge the companies Queijaria Charrua (Portugal), Queijaria Pacheco (Portugal), and Queijaria Guilherme (Portugal) for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fox, P.F.; McSweeney, P.L.H. Cheese Chemistry, Physics & Microbiology, 4th ed.; Academic Press: London, UK, 2017; pp. 5–21. [Google Scholar]

- Kübarsepp, I.; Henno, M.; Kärt, O.; Tupasela, T. A comparison of the methods for determination of the rennet coagulation properties of milk. Acta Agric. Scand. A Anim. Sci. 2005, 55, 145–148. [Google Scholar] [CrossRef]

- Lucey, J.A. Encyclopedia of Dairy Sciences, 1st ed.; Academic Press: London, UK, 2002; pp. 286–293. [Google Scholar]

- Zhang, W.; Zheng, S.; Gao, P.; Ren, Q.; Zhang, Y.; Chen, B.; Hettinga, K.; Pang, X.; Lv, J.; Zhang, S. Identification of the coagulation properties of Chinese Holstein bovine milk: Effects of milk compositions, milk protein polymorphism, and phosphorylation levels on milk coagulation ability. Food Hydrocoll. 2023, 145, 109112. [Google Scholar] [CrossRef]

- Silva, S.V.; Allmere, T.; Malcata, F.X.; Andrén, A. Comparative studies on the gelling properties of cardosins extracted from Cynara cardunculus and chymosin on cow’s skim milk. Int. Dairy J. 2003, 13, 559–564. [Google Scholar] [CrossRef]

- Budelli, E.; Pérez, N.; Negreira, C.; Lema, P. Evaluation of Ultrasonic Techniques for On-Line Coagulation Monitoring in Cheesemaking. J. Food Eng. 2017, 209, 83–88. [Google Scholar] [CrossRef]

- McMahon, D.J.; Brown, R.J.; Ernstrom, C.A. Enzymic coagulation of milk casein micelles. J. Dairy Sci. 1984, 67, 745–748. [Google Scholar] [CrossRef]

- Sommer, H.; Matsen, H. The relation of mastitis to rennet coagulability and curd strength of milk. J. Dairy Sci. 1935, 18, 741–749. [Google Scholar] [CrossRef]

- Gomes, S.; Pina, I.; Fernandes, J.; Dias, J.; Reboredo, F.; Martins, A.P.L.; Alvarenga, N. Comparative Study of Coagulation Dynamics: Cardoon Flower Extract vs. Chymosin. Dairy 2024, 5, 817–827. [Google Scholar] [CrossRef]

- Berridge, N.J. Some observations on the determination of the activity of rennet. Analyst 1952, 77, 57b–62. [Google Scholar] [CrossRef]

- Berridge, N.J. An improved method of observing the clotting of milk containing rennin. J. Dairy Res. 1952, 19, 328–329. [Google Scholar] [CrossRef]

- Tabayehnejad, N.; Castillo, M.; Payne, F.A. Comparison of total milk-clotting activity measurement precision using the Berridge clotting time method and a proposed optical method. J. Food Eng. 2012, 108, 549–556. [Google Scholar] [CrossRef]

- Arango, O.; Castillo, M. A method for the inline measurement of milk gel firmness using an optical sensor. J. Dairy Sci. 2018, 101, 3910–3917. [Google Scholar] [CrossRef]

- Abdelgawad, A.R.; Guamis, B.; Castillo, M. Using a fiber optic sensor for cutting time prediction in cheese manufacture from a mixture of cow, sheep and goat milk. J. Food Eng. 2014, 125, 157–168. [Google Scholar] [CrossRef]

- Castillo, M.; Payne, F.A.; Hicks, C.L.; Lopez, M.B. Predicting cutting and clotting time of coagulating goat’s milk using diffuse reflectance: Effect of pH, temperature and enzyme concentration. Int. Dairy J. 2000, 10, 551–562. [Google Scholar] [CrossRef]

- Fagan, C.C.; Castillo, M.; Payne, F.A.; O’Donnell, C.P.; Leedy, M.; O’Callaghan, D.J. Novel online sensor technology for continuous monitoring of milk coagulation and whey separation in cheesemaking. J. Agric. Food Chem. 2007, 55, 8836–8844. [Google Scholar] [CrossRef] [PubMed]

- Mateo, M.J.; O’Callaghan, D.J.; Everard, C.D.; Fagan, C.C.; Castillo, M.; Payne, F.A.; O’Donnell, C.P. Influence of curd cutting programme and stirring speed on the prediction of syneresis indices in cheese-making using NIR light backscatter. LWT 2009, 42, 950–955. [Google Scholar] [CrossRef]

- Leite Júnior, B.R.C.; Tribst, A.A.L.; Cristianini, M. Comparative study among rheological, near-infrared light backscattering and confocal microscopy methodologies in enzymatic milk coagulation: Impact of different enzyme and protein concentrations. Food Hydrocoll. 2017, 62, 73–82. [Google Scholar] [CrossRef]

- Strani, L.; Grassi, S.; Alamprese, C.; Casiraghi, E.; Ghiglietti, R.; Locci, F.; Pricca, N.; De Juan, A. Effect of physicochemical factors and use of milk powder on milk rennet-coagulation: Process understanding by near infrared spectroscopy and chemometrics. Food Control 2021, 119, 107494. [Google Scholar] [CrossRef]

- Andrewes, P.; Bullock, S.; Turnbull, R.; Coolbear, T. Chemical instrumental analysis versus human evaluation to measure sensory properties of dairy products: What is fit for purpose? Int. Dairy J. 2021, 121, 105098. [Google Scholar] [CrossRef]

- Arango, O.; Trujillo, A.J.; Castillo, M. Influence of fat replacement by inulin on rheological properties, kinetics of rennet milk coagulation, and syneresis of milk gels. J. Dairy Sci. 2013, 96, 1984–1996. [Google Scholar] [CrossRef]

- Arango, O.; Trujillo, A.J.; Castillo, M. Predicting coagulation and syneresis parameters of milk gels when inulin is added as fat substitute using infrared light backscatter. J. Food Eng. 2015, 157, 63–10605569. [Google Scholar] [CrossRef]

- Fagan, C.C.; Leedy, M.; Castillo, M.; Payne, F.A.; O’Donnell, C.P.; O’Callaghan, D.J. Development of a light scatter sensor technology for on-line monitoring of milk coagulation and whey separation. J. Food Eng. 2007, 83, 61–67. [Google Scholar] [CrossRef]

- Payne, F.A.; Castillo, M. Light Backscatter Sensor Applications in Milk Coagulation. In Encyclopedia of Agricultural, Food, and Biological Engineering; Heldman, D.R., Ed.; Taylor & Francis: Boca Raton, FL, USA, 2007; Available online: https://www.researchgate.net/publication/257366181_Light_Backscatter_Sensor_Applications_in_Milk_Coagulation (accessed on 2 May 2025).

- Reflectronics Inc. Available online: https://reflectronics.com/ (accessed on 2 May 2025).

- Caeiro, J.J.; Martins, J.C.; Alvarenga, N.; Gomes, S.; Martins, A.P.L.; Reboredo, F.; Dias, J. Comparison of milk-clotting activity measurement using the Berridge’s operator-based approach and a proposed digital method. Int. Dairy J. 2024, 159, 106055. [Google Scholar] [CrossRef]

- Queiroz Macedo, I.; Faro, C.J.; Pires, E.M. Caseinolytic specificity of cardosin, an aspartic protease from the cardoon Cynara cardunculus L.: Action on bovine αs- and β-casein and comparison with chymosin. J. Agric. Food Chem. 1996, 44, 42–47. [Google Scholar] [CrossRef]

- Pino, A.; Prados, F.; Galán, E.; McSweeney, P.L.H.; Fernández-, J. Proteolysis during the ripening of goats’ milk cheese made with plant coagulant or calf rennet. Food Res. Int. 2009, 42, 324–330. [Google Scholar] [CrossRef]

- Juan, B.; Trujillo, A.-J. Acid and Rennet Coagulation Properties of A2 Milk. Foods 2022, 11, 3648. [Google Scholar] [CrossRef]

- Salguero Conceição, C.; Martins, P.; Alvarenga, N.; Dias, J.; Lamy, E.; Garrido, L.; Gomes, S.; Freitas, S.; Belo, A.; Brás, T.; et al. Cynara cardunculus: Use in Cheesemaking and Pharmaceutical Applications; Technological Approaches for Novel Applications in Dairy Processing; InTech: Tokyo, Japan, 2018; pp. 73–107. [Google Scholar] [CrossRef]

- Taifi, N.; Bakkali, F.; Faiz, B.; Moudden, A.; Maze, G.; Décultot, D. Characterization of the syneresis and the firmness of the milk gel using an ultrasonic technique. Meas. Sci. Technol. 2005, 17, 281–287. [Google Scholar] [CrossRef]

- Ay, C.; Gunasekaran, S. Ultrasonic attenuation measurements for estimating milk coagulation time. Am. Soc. Agric. Eng. 1994, 37, 857–862. [Google Scholar] [CrossRef]

- Koc, A.B.; Ozer, B. Nondestructive monitoring of renetted whole milk during cheese manufacturing. Food Res. Int. 2008, 41, 745–750. [Google Scholar] [CrossRef]

- Bakkali, F.; Moudden, A.; Faiz, B.; Amghar, A.; Maze, G.; Espinosa, F.M.; Akhnak, M. Ultrasonic measurement of milk coagulation time. Meas. Sci. Technol. 2001, 12, 2154–2159. [Google Scholar] [CrossRef]

- Wang, Q.; Bulca, S.; Kulozik, U. A Comparison of Low-Intensity Ultrasound and Oscillating Rheology to Assess the Renneting Properties of Casein Solutions after UHT Heat Pre-Treatment. Int. Dairy J. 2007, 17, 50–58. [Google Scholar] [CrossRef]

- Aldalur, A.; Bustamante, M.Á.; Barron, L.J.R. Characterization of curd grain size and shape by 2-dimensional image analysis during the cheesemaking process in artisanal sheep dairies. J. Dairy Sci. 2019, 102, 1083–1095. [Google Scholar] [CrossRef]

- Djaowé, G.; Bitjoka, L.; Boukar, O.; Libouga, D.G.; Waldogo, B. Measurement of the rennet clotting time of milk by digital image sequences (2D + t) processing. J. Food Eng. 2013, 114, 235–241. [Google Scholar] [CrossRef]

- Lagaude, A.; Fernandez, L.; Cuq, J.-L.; Marchesseau, S. Characterization of curd formation during the rennet coagulation of milk by an optical microscopic method. Int. Dairy J. 2004, 14, 1033–1039. [Google Scholar] [CrossRef]

- ISO 23058:2006|IDF 199:2006; Milk and Milk Products—Ovine and Caprine Rennets—Determination of Total Milk-Clotting Activity. International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2006.

- Taneja, A.; Nair, G.; Joshi, M.; Sharma, S.; Sharma, S.; Jambrak, A.R.; Roselló-Soto, E.; Barba, F.J.; Castagnini, J.M.; Leksawasdi, N.; et al. Artificial Intelligence: Implications for the Agri-Food Sector. Agronomy 2023, 13, 1397. [Google Scholar] [CrossRef]

- Kutyauripo, I.; Rushambwa, M.; Chiwazi, L. Artificial intelligence applications in the agrifood sectors. J. Agric. Food Res. 2023, 11, 100502. [Google Scholar] [CrossRef]

- Esmaeily, R.; Razavi, M.A.; Razavi, S.H. A step forward in food science, technology and industry using artificial intelligence. Trends Food Sci. Technol. 2024, 143, 104286. [Google Scholar] [CrossRef]

- Mengucci, C.; Ferranti, P.; Romano, A.; Masi, P.; Picone, G.; Capozzi, F. Food structure, function and artificial intelligence. Trends Food Sci. Technol. 2022, 123, 251–263. [Google Scholar] [CrossRef]

- Fröhlich-Wyder, M.-T.; Bachmann, H.-P.; Schmidt, R.S. Classification of cheese varieties from Switzerland using machine learning methods: Free volatile carboxylic acids. LWT 2023, 184, 115095. [Google Scholar] [CrossRef]

- Farah, J.S.; Cavalcanti, R.N.; Guimarães, J.T.; Balthazar, C.F.; Coimbra, P.T.; Pimentel, T.C.; Esmerino, E.A.; Duarte, M.C.K.H.; Freitas, M.Q.; Granato, D.; et al. Differential scanning calorimetry coupled with machine learning technique: An effective approach to determine the milk authenticity. Food Control 2021, 121, 107585. [Google Scholar] [CrossRef]

- Iymen, G.; Tanriver, G.; Hayirlioglu, Y.Z.; Ergen, O. Artificial intelligence-based identification of butter variations as a model study for detecting food adulteration. Innov. Food Sci. Emerg. Technol. 2020, 66, 102527. [Google Scholar] [CrossRef]

- Lima, J.S.; Ribeiro, D.C.S.Z.; Asseiss Neto, H.; Campos, S.V.A.; Leite, M.O.; Fortini, M.E.R.; Carvalho, B.P.M.; Almeida, M.V.O.; Fonseca, L.M. A machine learning proposal method to detect milk tainted with cheese whey. J. Dairy Sci. 2022, 105, 9496–9508. [Google Scholar] [CrossRef]

- Rocha, R.S.; Calvalcanti, R.N.; Silva, R.; Guimarães, J.T.; Balthazar, C.F.; Pimentel, T.C.; Esmerino, E.A.; Freitas, M.Q.; Granato, D.; Costa, R.G.B.; et al. Consumer acceptance and sensory drivers of liking of Minas Frescal Minas cheese manufactured using milk subjected to ohmic heating: Performance of machine learning methods. LWT 2020, 126, 109342. [Google Scholar] [CrossRef]

- AOAC 947.05; Acidity of Milk-Titrimetric Method. Association of Official Analytical Collaboration: Rockville, MD, USA, 1997.

- ISO 6731|IDF 21: 2010; Milk, Cream and Evaporated Milk—Determination of Total Solids Content (Reference Method). International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2010.

- ISO 19662|IDF 238: 2018; Milk—Determination of Fat Content—Acido-butyrometric (Gerber Method). International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2018.

- ISO 8968-1&2:2014|IDF 20-1&2:2014; Milk and Milk Products—Determination of Nitrogen Content. International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2014.

- ISO 17997-1|IDF 29-1: 2004; Milk—Determination of the Casein-Nitrogen Content—Part 1: Indirect Method (Reference Method). International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2004.

- ISO-22662:2024|IDF 198:024; Milk and Milk Products—Determination of Lactose Content by High-Performance Liquid Chromatography (Reference Method). International Organisation for Standardisation: Geneva, Switzerland; International Dairy Federation: Brussels, Belgium, 2024.

- SciKit Learn. Available online: https://scikit-learn.org/stable/ (accessed on 2 May 2025).

- Gomes, S.; Belo, A.T.; Alvarenga, N.; Dias, J.; Lage, P.; Pinheiro, C.; Pinto-Cruz, C.; Brás, T.; Duarte, M.F.; Martins, A.P.L. Characterization of Cynara cardunculus L. flower from Alentejo as a coagulant agent for cheesemaking. Int. Dairy J. 2019, 91, 178–184. [Google Scholar] [CrossRef]

- Martins, A.P.L.; Belo, A.T.; Vasconcelos, M.M.; Fontes, A.L.; Pereira, E.A.; Belo, C.C. Characterisation of production system of Niza cheese (PDO): Effect of sheep breed on milk composition and coagulation properties. In Changes in Sheep and Goat Farming Systems at the Beginning of 21st Century; Morand-Fehr, P., Ed.; CIHEAM/DRAP-Norte/FAO: Zaragoza, Spain, 2009; pp. 221–225. [Google Scholar]

- Balthazar, C.F.; Pimentel, T.C.; Ferrão, L.L.; Almada, C.N.; Santillo, A.; Albenzio, M.; Mollakhalili, N.; Mortazavian, A.M.; Nascimento, J.S.; Silva, M.C.; et al. Sheep Milk: Physicochemical Characteristics and Relevance for Functional Food Development. Compr. Rev. Food Sci. Food Saf. 2017, 16, 247–262. [Google Scholar] [CrossRef] [PubMed]

- Bencini, R. Factors affecting the clotting properties of sheep milk. J. Sci. Food Agric. 2002, 82, 705–719. [Google Scholar] [CrossRef]

- Park, Y.W.; Juárez, M.; Ramos, M.; Haenlein, G.F.W. Physico-chemical characteristics of goat and sheep milk. Small Rumin. Res. 2007, 68, 88–113. [Google Scholar] [CrossRef]

- Jiménez, A.; Rufo, M.; Paniagua, J.M.; Crespo, A.T.; Guerrero, M.P.; Riballo, M.J. Contributions to ultrasound monitoring of the process of milk curdling. Ultrasonics 2017, 76, 192–199. [Google Scholar] [CrossRef]

- Figueroa Sánchez, A.; Perea Muñoz, J.; Caballero-Villalobos, J.; Arias Sánchez, R.; Garzón, A.; Angón Sánchez de Pedro, E. Coagulation process in Manchega sheep milk from Spain: A path analysis approach. J. Dairy Sci. 2021, 104, 7544–7554. [Google Scholar] [CrossRef]

- Pazzola, M. Coagulation Traits of Sheep and Goat Milk. Animals 2019, 9, 540. [Google Scholar] [CrossRef]

- Zikiou, A.; Esteves, A.C.; Esteves, E.; Rosa, N.; Gomes, S.; Martins, A.P.L.; Zidoune, M.N.; Barros, M. Algerian cardoon flowers express a large spectrum of coagulant enzymes with potential applications in cheesemaking. Int. Dairy J. 2020, 105, 104689. [Google Scholar] [CrossRef]

- Géron, A. Hands-On Machine Learning with Scikit-Learn, Keras, and TensorFlow, 3rd ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2022. [Google Scholar]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science, 2nd ed.; Springer: New York, NY, USA, 2017; pp. 185–229. [Google Scholar]

- Jacob, M.; Schmidt, M.; Jaros, D.; Rohm, H. Measurement of milk clotting activity by rotational viscometry. J. Dairy Res. 2011, 78, 191–195. [Google Scholar] [CrossRef]

- López, M.B.; Jordán, M.J.; Granados, M.V.; Fernández, J.C.; Castillo, M.; Laencina, J. Viscosity changes during rennet coagulation of Murciano-Granadina goat milk. Int. J. Dairy Technol. 1999, 52, 102–106. [Google Scholar] [CrossRef]

- Salvador, D.; Acosta, Y.; Zamora, A.; Castillo, M. Rennet-Induced Casein Micelle Aggregation Models: A Review. Foods 2022, 11, 1243. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Zhang, X.; Wei, G.; Tao, G.; Shi, Y.; Huang, A. Novel insights into the coagulation mechanism induced by Dregea sinensis protease: Rheological properties, molecular and microstructural changes. LWT 2025, 224, 117816. [Google Scholar] [CrossRef]

- Lomholt, S.B.; Qvist, K.B. Relationship between rheological properties and degree of k-casein proteolysis during renneting of milk. J. Dairy Res. 1997, 64, 541–549. [Google Scholar] [CrossRef]

- Lucey, J.A. Formation and physical properties of milk protein gels. J. Dairy Sci. 2002, 85, 281–294. [Google Scholar] [CrossRef]

- Shaker, R.R.; Jumah, R.Y.; Abu-Jdayil, B. Rheological properties of plain yogurt during coagulation process: Impact of fat content and preheat treatment of milk. J. Food Eng. 2000, 44, 175–180. [Google Scholar] [CrossRef]

- Arango, O.; Trujillo, A.J.; Castillo, M. Monitoring the effect of inulin, protein, and calcium on milk coagulation phases using a fibre optic sensor. Int. Dairy J. 2018, 81, 80–86. [Google Scholar] [CrossRef]

- Walstra, P.; Woulters, J.T.M.; Geurts, T.M. Dairy Science and Technology, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Caballero-Villalobos, J.; Perea, J.M.; Angón, E.; Arias, R.; Garzón, A. Coagulation efficiency and its determinant factors: A case study for Manchega ewe milk in the region of Castilla-La Mancha, Spain. J. Dairy Sci. 2018, 101, 3878–3886. [Google Scholar] [CrossRef]

- Alvarenga, N.; Martins, J.; Caeiro, J.; Garcia, J.; Pássaro, J.; Coelho, L.; Santos, M.T.; Lampreia, C.; Martins, A.; Dias, J. Applying Computational Fluid Dynamics in the Development of Smart Ripening Rooms for Traditional Cheeses. Foods 2021, 10, 1716. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).