1. Introduction

The study of the mineralogical and petrographic composition and the textural–structural features of magnetite ores in skarns is key to clarifying the conditions of their formation, identifying promising ore-bearing zones, and forecasting the efficiency of iron ore extraction and processing for the group of deposits in the Northwestern Balkhash iron ore region (

Figure 1,

Figure 2,

Figure 3 and

Figure 4).

Iron-bearing skarns are complex metasomatic formations that develop in contact zones between magmatic intrusions and carbonate rocks. They are characterized by a diverse mineralogical composition dominated by magnetite, hematite, pyrites, and a number of other sulfide and silicate minerals. These skarn deposits often represent important sources of iron ore and associated valuable elements.

The mineralogical and textural composition of skarns significantly influences ore quality, which in turn determines the efficiency of its processing. Mineral textures, such as inclusions and mineral zonation, can affect the physico-chemical properties of the ore, its beneficiation potential, and technological suitability. Therefore, detailed study of the mineralogy and textural features of skarn ores is a critical step in selecting optimal enrichment and processing methods.

The natural resources of the Republic of Kazakhstan form the foundation of its economy, with their effective utilization relying on the rational exploitation of identified deposits. The main iron ore deposits are in the north of the country within the Northern Torgai region, and are represented by large magnetite and hematite deposits [

4,

5,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19]. These deposits have been exploited since the middle of the last century.

In the northwestern part of the Balkhash region of Central Kazakhstan, there is a reserve iron ore region, represented by a series of skarn contact-metasomatic deposits and occurrences, such as Bapy, Zhuantobe, Karaulken, Akchagyl, Ushtobe, Kiyik, Taitobe, Tomashev, Kyzyl-Sayak, Abylkhair, Kyzylespe, etc. (

Figure 1,

Figure 2,

Figure 3 and

Figure 4). The history of the study of the region began at the beginning of the 20th century, when a rare network of routes was built in the territory of the region. Later, in connection with the construction of the Karaganda-Balkhash railway, individual areas and ore objects were studied depending on their economic significance [

7,

8,

9,

10,

11,

12].

Iron-bearing skarn processing technologies include magnetic separation, flotation, and hydrometallurgical methods aimed at maximizing the extraction of iron and associated metals. However, the success of these processes largely depends on the mineralogical form of iron and the nature of sulfide inclusions. Thus, comprehensive geological and mineralogical analysis of the ores is a key factor in improving the economic efficiency of mining and processing iron-bearing skarns. The region of the northwestern part of the Balkhash region (Bapy ore field) is a reserve iron ore territory intended for replenishment of mineral resources of the existing mining and metallurgical complexes of Kazakhstan by involving in the development of new medium and small deposits [

20,

21].

2. Geological Background

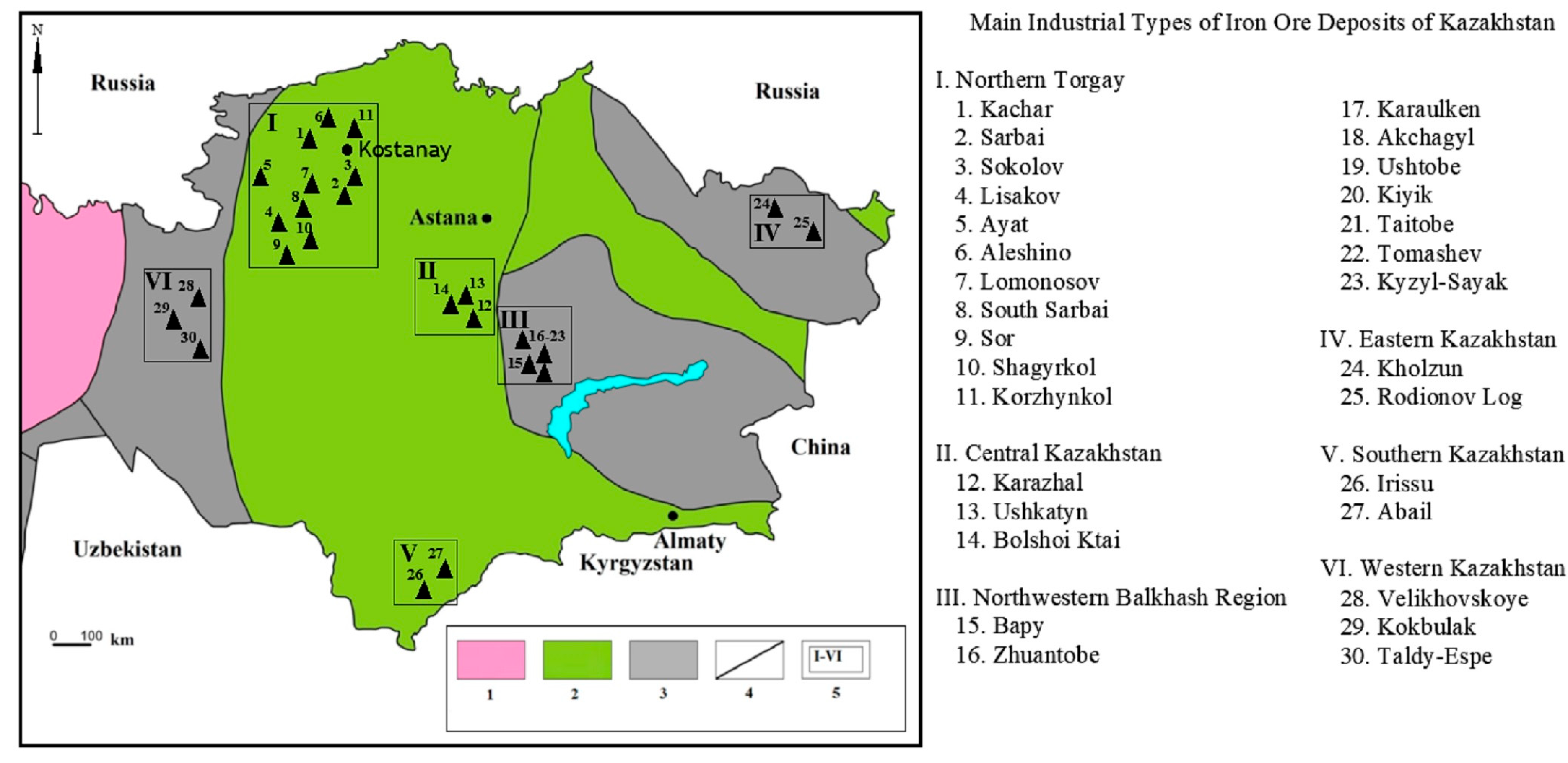

Kazakhstan ranks eighth in the world in terms of explored iron ore reserves [

22,

23,

24]. The country contains the following iron ore regions: I. Northern Torgai; II. Atasu Region; III. Northwestern Balkhash; IV. Eastern Kazakhstan; V. Southern Kazakhstan; VI. Western Kazakhstan [

6,

24]. These regions feature the following main geological-industrial and genetic types of deposits (

Figure 3):

Skarn-type (Northern Torgai and Northwestern Balkhash regions).

Stratiform volcanogenic-sedimentary (Atasu region in Central Kazakhstan).

Sedimentary (Northern Torgai, Northern Aral Sea region).

Magmatic (a number of deposits in Southern Kazakhstan).

The total balance reserves of iron ore (17 deposits), including off-balance reserves (11 deposits), amount to 17 billion tons. Of this, 93% is concentrated in five major deposits: Kachar, Sarybai, Sokolov, Ayat, and Lisakov. All of these are located in the northwestern part of the Torgai region. These deposits have been intensively mined since the 1960s and are now significantly depleted [

3,

6]. Therefore, there is a need to establish a reserve mineral resource base.

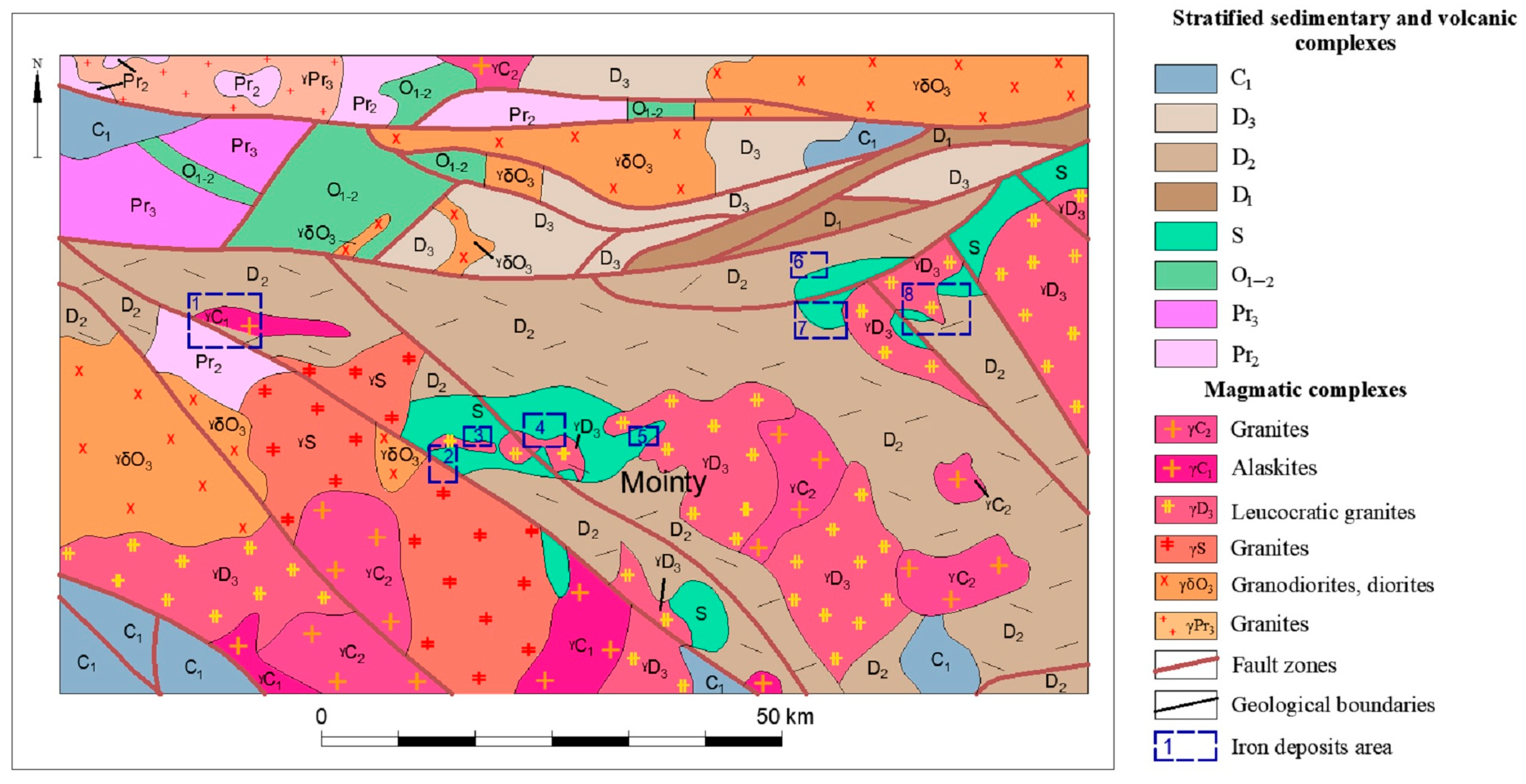

In Central Kazakhstan, the Atasu and Northwestern Balkhash iron ore regions are located (

Figure 3). In the Atasui region, the actively developed deposits are Karazhal, Ushkatyn III, and Kentobe, which contain rich iron-manganese ores. The total explored reserves exceed 300 million tons. The Northwestern Balkhash region is considered a reserve area and includes medium and small-sized deposits (

Figure 3) with commercial-grade iron ore reserves.

In Eastern Kazakhstan, the Kholzun (680.2 million tons) and Rodionov Log (58 million tons) iron ore deposits have been explored. In Southern Kazakhstan, the minor deposits Irisu (327.7 million tons) and Abayl (28.3 million tons) have been explored. In Western Kazakhstan, the largest deposit is Kokbulak (1.9 billion tons) with off-balance oolitic brown iron ores, and the large Velikhovskoye deposit, with estimated reserves of titanomagnetite ores reaching up to 1 billion tons [

6,

24].

The Zhuantobe deposit is in the northwestern part of the Balkhash region (the eastern end of the Betpakdala desert) of Central Kazakhstan (

Figure 3,

Figure 4 and

Figure 5). The geological structure of the deposit has been the subject of extensive study, with numerous publications authored by different institutions and researchers over the years [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

22,

23,

24,

25,

26].

The area and its individual sections were covered by various types of geological and geophysical studies [

7,

8,

9,

10]. The Zhuantobe deposit was discovered in 1964 as a result of a 1:50,000-scale geological survey. Following its discovery, exploration of the mine workings was carried out, and a geological map of the area was compiled [

4,

6,

25].

The factual basis of this work is the materials obtained during the research of the last several decades in the field of formation and distribution patterns of iron ore objects of the northwestern part of the Balkhash region. The results of these studies are reflected in the published works of the geological service of the country. The Zhuantobe deposit was classified as a small industrial deposit, with limited exploration and insufficient investigation of its deeper horizons [

3,

4,

5,

6,

15,

16,

17,

18,

19,

22,

23,

24,

25].

The Zhuantobe skarn-type contact-metasomatic deposit is situated in the central part of the Bapy iron ore field, within the western segment of the marginal continental Devonian volcanoplutonic belt of Central Kazakhstan. In tectonic terms, the Zhuantobe deposit is located in the northwestern part of the Junggar-Balkhash Hercynian folded system [

4,

5,

9,

12,

15,

16,

17,

18], and in the southern part of the Atasu-Mointy Proterozoic massif (

Figure 1,

Figure 2 and

Figure 3) [

17,

18,

19].

3. Materials and Methods

The microscopy method was used in studying the ore-bearing rocks and ores of the Zhuantobe deposit, which allowed us to establish the associations and distribution of ore minerals in them. The electron microscopy method provided information on morphology, allowing us to diagnose ore textures. The description of the thin sections rocks was performed on polarizing microscopes of the LEICA DM 750 (Leica Mikrosysteme Vertrieb GmbH, Wetzlar, Germany) series and POLAM R-312 (LLC “LOMO-Microanalysis”, Saint Petersburg, Russian Federation). The descriptions of polished sections of the rock samples were performed on LEICA DMi8 (Leica Mikrosysteme Vertrieb GmbH, Wetzlar, Germany) inverted microscope.

The chemical composition of the samples was analyzed using X-ray fluorescence (XRF) on a SPECTRO XEPOS III (Germany) and energy-dispersive spectroscopy with an INCA 8N8RGY (Oxford Instruments, Abingdon, UK) at 25 kV and 25 mA. Samples were prepared as pressed powder pellets with boric acid or, if needed, as fused glass beads. These methods are effective for mineralogical and geochemical characterization [

27,

28,

29,

30].

The mineral composition of the rocks at the Zhuantobe deposit was determined through the identification of minerals in thin and polished sections, analysis of small-volume samples collected during technological mapping, specialized laboratory and technological investigations, as well as data obtained from spectral and chemical analyses conducted during the exploration phase. The useful components in ore samples were determined only for iron; other associated components were not identified.

During this study, core samples were collected from four boreholes—Z01, Z02, Z03 and Z04, located within the study area (0). The selection of routine core samples was carried out considering the lithological boundaries and wall rock alterations. The length of individual samples varied from 0.15 to 2.7 m, with an average length of 1.7 m. A total of 69 core samples were analyzed. Sample preparation was carried out using both mechanical and manual methods, in accordance with guidelines derived from the Richards–Chechetta formula.

where

Q—reliable mass of the analytical sample (kg);

K = 0.1—coefficient of unevenness;

d—maximum particle size of the crushed material (mm).

The initial mass of each core sample ranged from 9 to 12 kg. Sample preparation included the following step-by-step procedure:

- -

Primary crushing on a BB-100 roller crusher or a RC-10 jaw crusher with screening of fractions < 3 mm.

- -

Obtaining a sample weighing 2.25 kg (not less than 1.8 kg) by reduction on a Johnson divider.

- -

Crushing of the sample to a fraction of 2 mm on the crusher.

- -

Reduction to 1.125 kg (not less than 800 g).

- -

Grinding on the mill RM-170 to a particle size of <0.16 mm.

- -

Reduction to 281 g, of which 3 g were sent for analysis.

To prevent cross-contamination of samples between processing cycles, the crushing equipment was purged with compressed air. Quality control of sample preparation included the following:

- -

Checking the granulometric composition of duplicates (through a 1 mm sieve) and analytical samples (through a 0.07 mm sieve);

- -

Checking the mass of the analytical sample; if it deviated from the standards, the sample was returned for re-crushing;

- -

Random checking of 10 random samples for each batch (5% of the total volume).

Samples were registered and weighed, then dried at 100–105 °C for 2–6 h, depending on the moisture content of the material. Maintenance of sanitary conditions in the sample preparation laboratory included daily wet cleaning, as well as cleaning and blowing out the equipment after each sample. The vibratory grinder cups were thoroughly rinsed with water and dried before reuse.

The chemical composition of the samples was determined by X-ray fluorescence spectrometry (XRF) analysis using a SPECTRO XEPOS III device (SPECTRO Analytical Instruments GmbH, Kleve, Germany). The prepared powder samples were pressed into tablets (pressed powder pellets) using boric acid as a binder. If necessary, fused glass beads were formed to improve the homogeneity of the material.

The measurements were performed automatically using specialized software. Each sample was subjected to duplicate (replicate) analyses, and the arithmetic mean of the two measurements was used to obtain the result. The discrepancy between the results did not exceed the established repeatability limit.

The study included a quantitative determination of total iron content (expressed as Fe2O3), as well as a semi-quantitative multi-element analysis for the content of 46 chemical elements and oxides, including:

Major oxides: Al2O3, SiO2, P2O5, SO3, Cl, K2O, CaO, TiO2, Fe2O3, MnO.

Transition, trace and rare elements: V

2O

5, Cr

2O

3, CoO, NiO, CuO, ZnO, Ga, Ge, As

2O

3, Se, Br, Rb

2O, SrO, Y, ZrO

2, Nb

2O

5, Mo, Ag, Cd, SnO

2, Sb

2O

5, Te, I, Cs, Ba, La, Ce, Hf, Ta

2O

5, WO

3, Hg, Tl, PbO, Bi, Th, U. This work includes detailed results for 69 core samples from boreholes Z01–Z04.

Table S1 shows the average concentrations of chemical components for each borehole; full determinations of each sample for 46 elements are given in the

Supplementary Materials.

4. Results

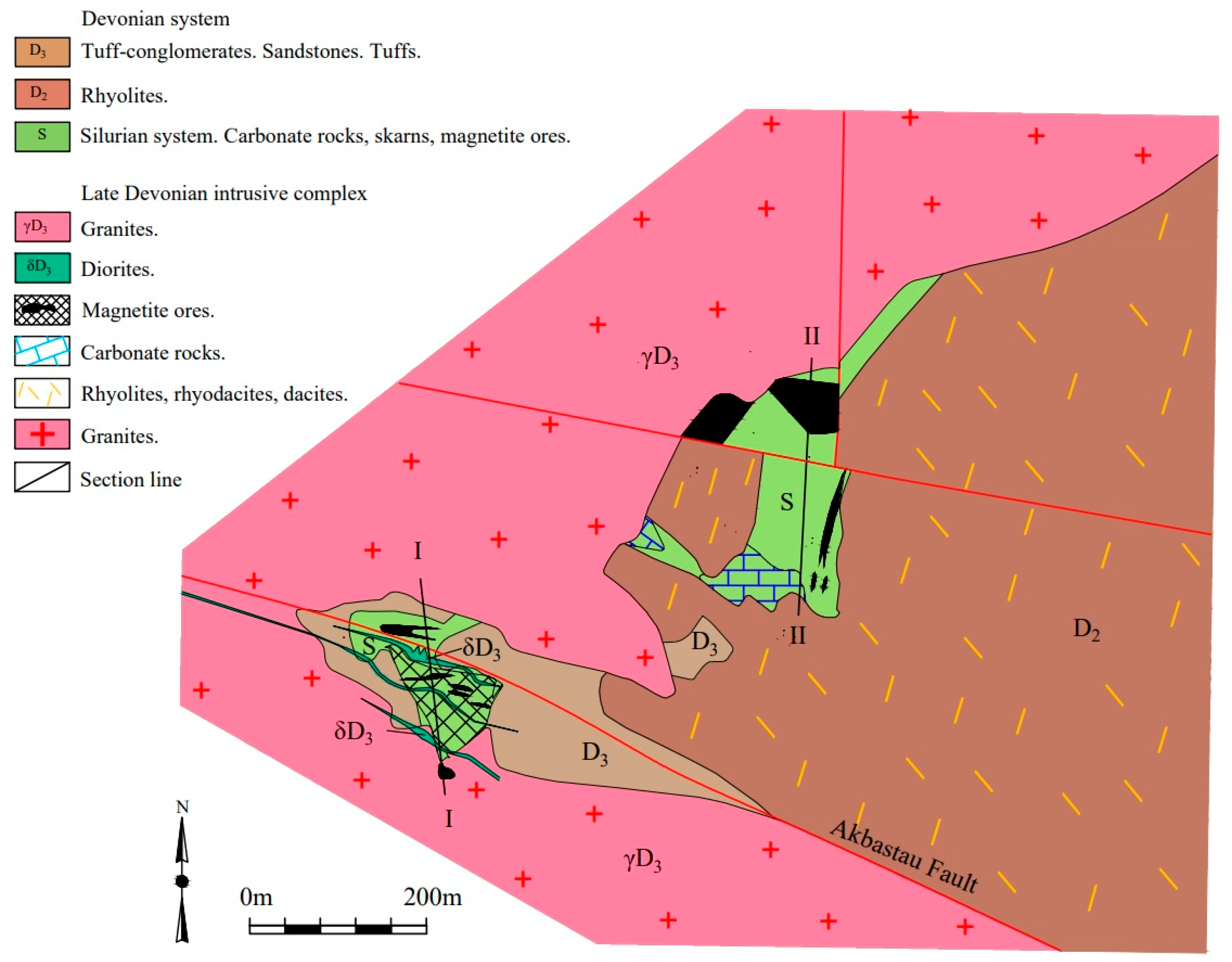

4.1. Geological Characteristics of Deposit

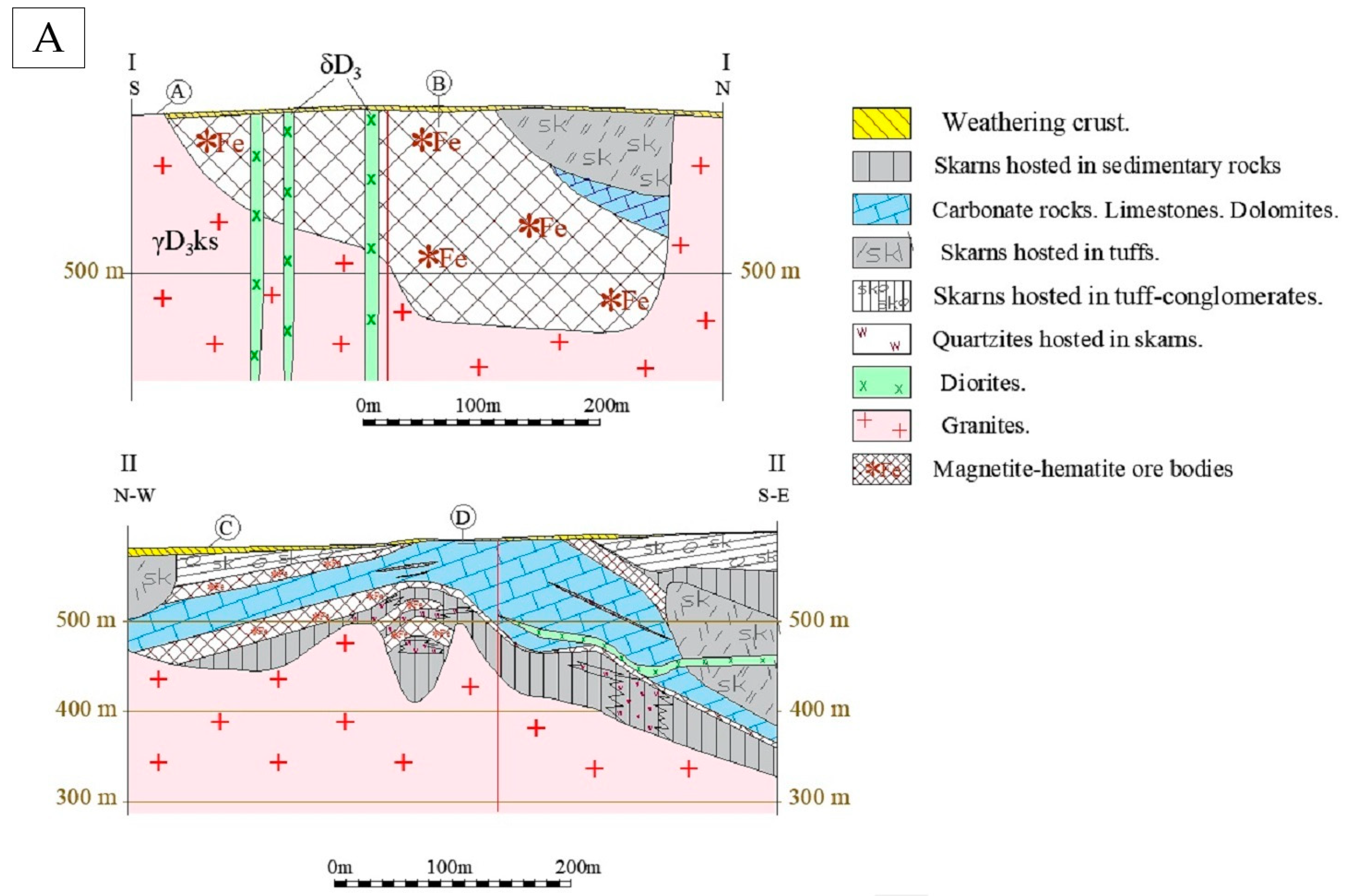

The Zhuantobe deposit area is characterized by a complex geological structure due to the completeness of the stratigraphic section and the diversity of volcanic and intrusive rocks, the presence of many faults, mainly of northwestern strike (

Figure 4 and

Figure 5). Silurian, Devonian and Neogene-Cenozoic age deposits are distinguished. The host-rocks for the magnetite ores are the deposits of the Shumek formation of the Silurian, which are intruded by granitoids of the Kyzylespe massif and transformed into skarned rocks and skarns. The suite is dominated by sedimentary rocks: siltstones, argillites, quartz and polymictic sandstones, siliceous argillites, carbonate rocks, gravelstones and small-pebble conglomerates, less often volcanics of felsic and intermediate composition. The thickness of the suite at the deposit is 300 m.

Magnesian skarns of pyroxene (diopside) composition predominate, containing magnetite inclusions and composed of diopside, olivine, biotite, amphibole, and chlorite aggregates. Skarns in the form of individual lenses up to 25 m long are found, composed of pyroxenes, garnets, and serpentine in the form of elongated prismatic crystals forming tangled-fibrous and, less frequently, radially radiant aggregates containing epidote group minerals, amphibole, chlorite, and rare magnetite inclusions. Carbonate rocks are represented by coarse- and medium-grained marbles composed of calcite grains up to 0.3 mm in size, often impregnated with brown iron hydroxides. Carbonate rocks contain a minor amount of sand impurity consisting of quartz and quartzite fragments. Carbonate rocks form isolated bodies of various shapes and sizes. The thickness of carbonates is from a few meters to 120 m. Almost the entire area of the deposit is covered by Cenozoic deposits.

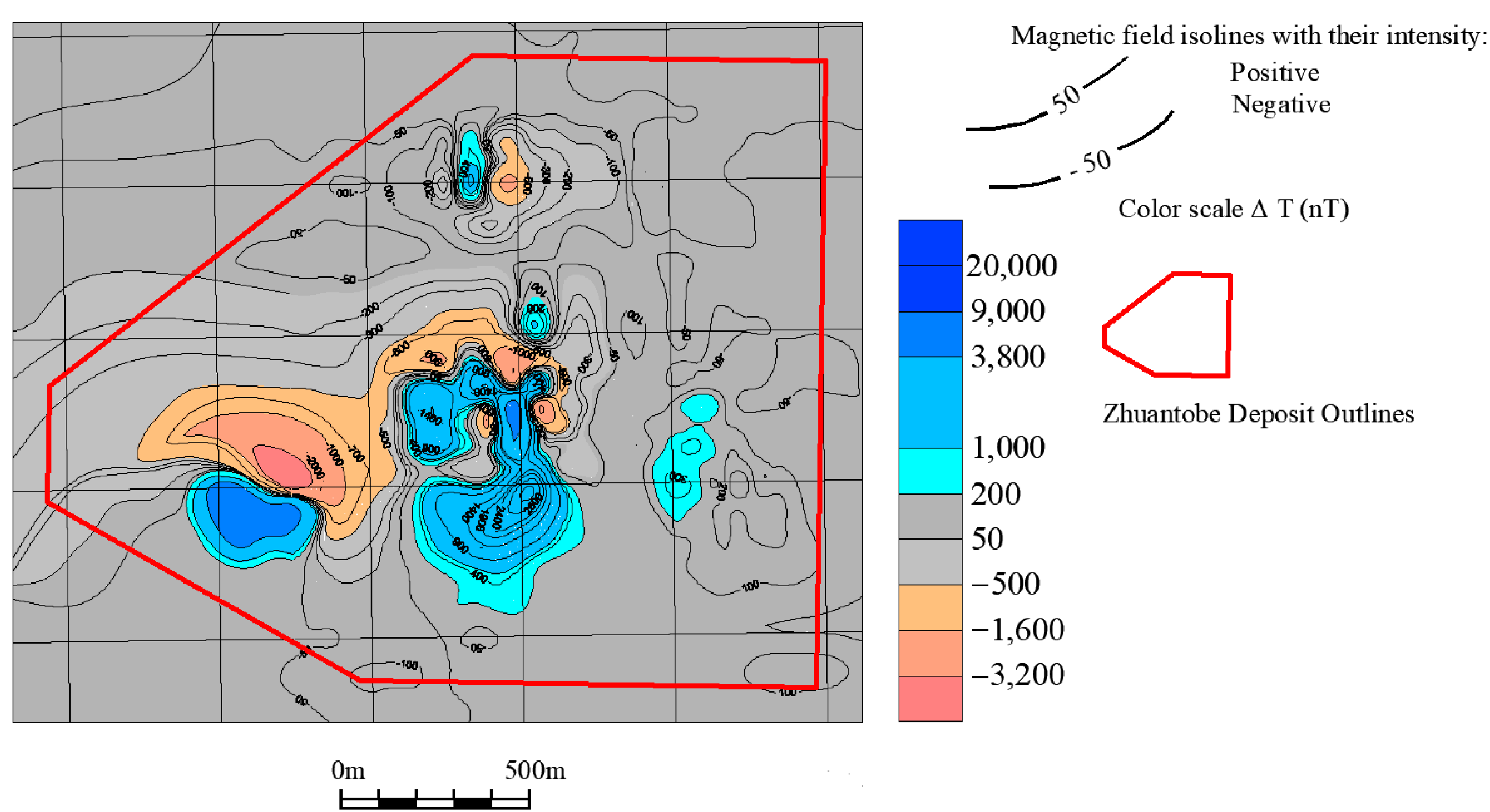

Devonian is represented by volcanogenic rocks, among which the following predominate: tuff conglomerates, crystal clastic tuffs, rhyolites, dacites, ignimbrites, tuffites, sandstones. The thickness of the strata in the area of the deposit is up to 1000 m. The magnetic field varies from positive (+50–70 nT) to negative. Magnetic susceptibility is 0–50 SI units, density is 2.60–2.62 g/cm

3 [

26].

The weathering crusts on the Silurian-Devonian rocks are represented by Neogene clays and Quaternary deposits.

The intrusive formations are composed of the Late Devonian Kyzylespe intrusive complex; the granitoids of this massif are widespread in the deposit area. Among the granitoids of the Kyzylespe complex, the following are distinguished: (1) biotite feldspar granites of the first phase, which make up the main part of the massif; (2) porphyritic biotite feldspar leucogranites of the second phase, which form small bodies often in the marginal parts of the massif; (3) biotite granites, developed mainly in the marginal parts of the massif.

At the Zhuantobe deposit, two types of iron ores are distinguished: (1) skarn magnetite ores of contact-metasomatic genesis, (2) rare hydrothermal quartz-hematite ores that form veins. Skarn magnetite ores are composed of magnetite with a very small admixture of hematite, iron hydroxides, pyrite, chalcopyrite, and pyrrhotite. According to the study of the Zhuantobe deposit, two areas were distinguished: Western and Eastern (

Figure 5 and

Figure 6).

The western section is a small isometric remnant in the roof of the Kyzylespe granitoid massif, measuring 330 by 350 m. The outcrop and decipherability of the rocks are generally poor; almost the entire area is covered by Quaternary deposits. Only individual elements of fault tectonics and individual fragments of rock packs are decipherable. Remnants of Paleozoic rock outcrops and weathering crusts are rarely observed. Individual rock outcrops are composed of skarns on terrigenous and carbonate rocks of the Shumek suite, broken through by bodies of rhyolitic subvolcanites. Magnesian pyroxene (diopside) skarns include rare lenses consisting of epidote group minerals, amphibole, and serpentine aggregates. The outcrop of the ore body on the surface has a strike of 320o, the length of the outcrop is 250 m with a width of 200 m. The ore thickness according to drilling data is up to 150 m. Magnetite forms veins and solid accumulations. In the southern part of the outlet, two lenses of quartz-hematite ore are installed, representing a hydrothermal type of mineralization. The lenses are localized in granites, 12 and 16 m thick, the length along the strike is up to 50 m.

According to magnetic exploration data (

Figure 7), these bodies are marked by a positive magnetic anomaly with an intensity of up to 3000 gammas, which indicates the presence of magnetite. Magnetic exploration work has established a positive magnetic anomaly with an intensity of up to 35,000 gammas [

26]. The anomaly extends 270 m with a maximum width of 170 m. Quantitative interpretation of magnetic exploration data suggests that the ore body extends to a depth of 150 m with a dip to the southwest at angles of 70°.

The eastern section is a remnant of the roof in the marginal part of the Kyzylespe massif, which has poor exposure. Almost the entire area is covered by Quaternary deposits, up to a few meters thick. Skarns are formed on terrigenous rocks (sandstones, siltstones, siliceous rocks) and marbles. Magnetite ore outcrops are observed in the northern half of the site. The sizes of the ore bodies vary up to 100 m in length with a width of 150 m. The thickness of the lens-shaped ore bodies varies from a few meters to 70 m.

The main ore bodies are associated with crushing and mylonitization zones marking the Atasu fault. In the central part of the deposit, local dome-shaped structures are distinguished, in which the greatest thickness of the ore bodies is concentrated.

4.2. Skarn Textures

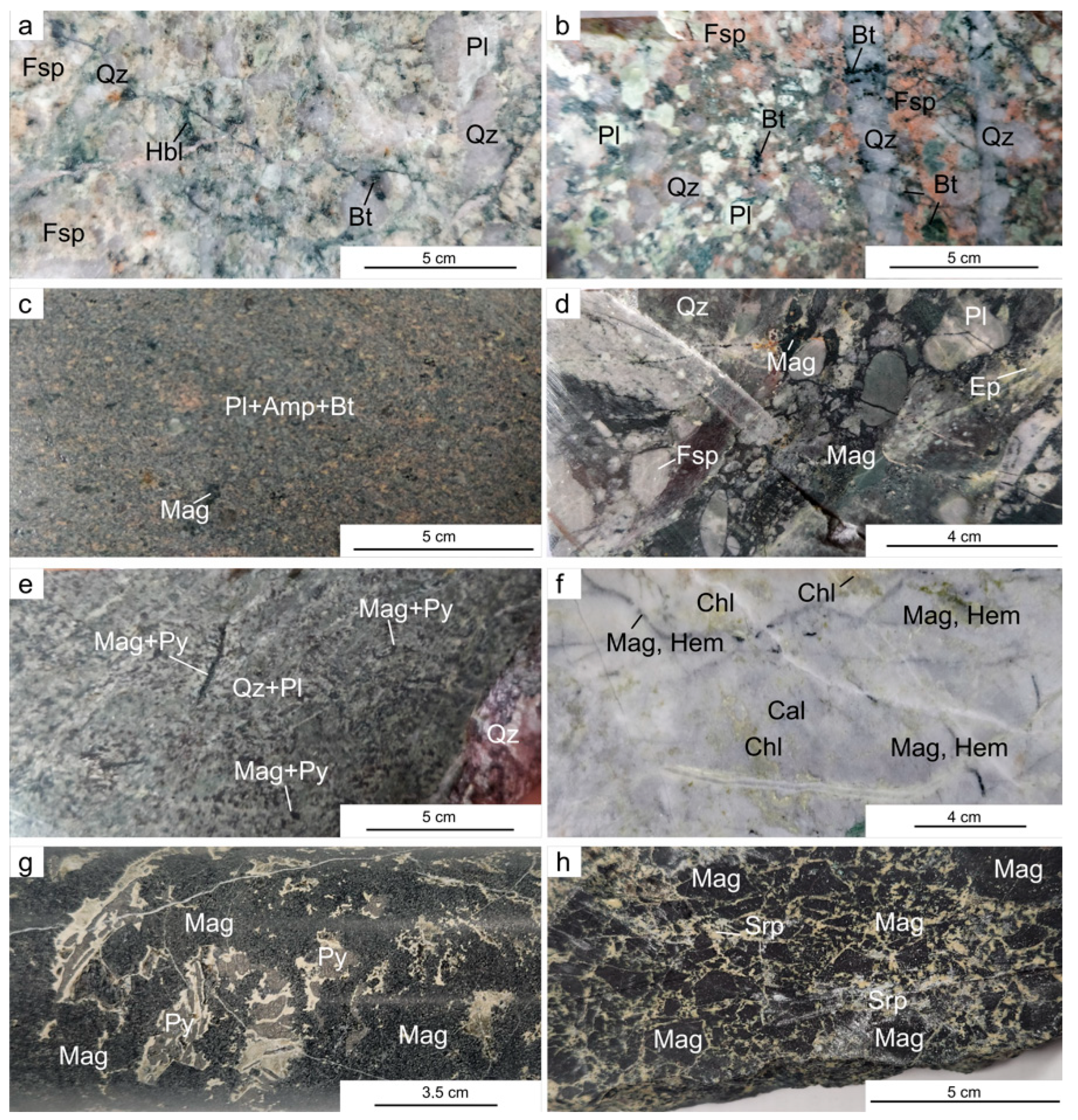

The main rock types of the Zhuantobe deposit in a core samples (

Figure 8):

- (a)

Cataclased coarse-grained granites containing large feldspar (orthoclase and plagioclase) and quartz crystals, giving it a massive texture; dark-colored minerals are represented by tabular forms of biotite and amphibole.

- (b)

Silicified coarse-grained granites, with numerous porphyry-like phenocrysts of plagioclase and orthoclase, with rare inclusions of dark-colored minerals. This rock has a massive texture with a high quartz content. Quartz crystals account for approximately 20–30% of the volume, giving it a characteristic light shade. Feldspars (orthoclase, albite) make up 60% of the rock volume. Dark-colored minerals are represented by biotite and amphibole in an amount of 5% of the rock volume. The rock is unevenly contaminated and contains xenoliths of other rocks and minerals that are not typical of its normal composition.

- (c)

Diorites have a massive texture and medium-grained structure, with porphyry segregations composed of plagioclases (oligoclase, andesine). Biotite and amphibole crystals are also found in the porphyry segregations.

- (d)

Cataclased lithoclastic rhyolite tuffs, the lithoclasts contain fragments of siliceous rocks, volcanics, carbonates and quartz. The rock is subject to contact-metasomatic action in the form of epidotization.

- (e)

Skarns on sandstone—relics of psammitic structure and weakly layered texture are visible. Fragments of plagioclase, quartz and dark-colored minerals are noted. The rocks contain pyrite inclusions embedded in an amorphous matrix.

- (f)

Marbles is a monomineralic rock consisting of crystalline calcite. There are inclusions of magnetite, hematite and other ore minerals. The rocks are characterized by massive areas with indistinctly expressed spotted and lenticular textures.

- (g)

Magnetite ores have a cryptocrystalline texture with a spotted pattern. Pyrite inclusions occur as inclusions in the magnetite matrix.

- (h)

Magnetite ores have a brecciated texture, represented by magnetite cataclasts. The ore matrix is composed of fine-grained accumulations of carbonates, serpentine and magnetite.

The mineral composition of the Zhuantobe ores is represented by magnetite, hematite, iron hydroxides (in the weathering crust), as well as pyrite and chalcopyrite. The ores are characterized by the following structures: disseminated, massive, brecciated and veined. Such structural heterogeneity is due to contact-metasomatic processes and other geochemical changes that occurred at the deposit [

6,

24,

26,

31].

Figure 8.

Samples of the main rock types of the Zhuantobe deposit, details of

Figure 5. (

a) Cataclastic coarse-grained granites, well Z01, from the depth 150.8 m; (

b) silicified coarse-grained granites, well Z02, from the depth 142.0 m; (

c) diorites, well Z01, from the depth 216.2 m; (

d) cataclastic lithoclastic rhyolite tuffs, well Z02, from the depth 47.7; (

e) skarns on sandstone, well Z04, from the depth 48.6 m; (

f) marbles, well Z03, from the depth 121.7 m; (

g) magnetite ores, well Z04, from the depth 40.1 m; (

h) magnetite ores, well Z02, from the depth 150.2 m. Conventional indices of minerals [

32]: feldspar (Fsp); quartz (Qz); hornblende (Hbl); biotite (Bt); plagioclase (Pl); amphibole (Amp); magnetite (Mag); epidote group minerals (Ep); pyrite (Py); chlorite (Chl); calcite (Cal); hematite (Hem); serpentine (Srp).

Figure 8.

Samples of the main rock types of the Zhuantobe deposit, details of

Figure 5. (

a) Cataclastic coarse-grained granites, well Z01, from the depth 150.8 m; (

b) silicified coarse-grained granites, well Z02, from the depth 142.0 m; (

c) diorites, well Z01, from the depth 216.2 m; (

d) cataclastic lithoclastic rhyolite tuffs, well Z02, from the depth 47.7; (

e) skarns on sandstone, well Z04, from the depth 48.6 m; (

f) marbles, well Z03, from the depth 121.7 m; (

g) magnetite ores, well Z04, from the depth 40.1 m; (

h) magnetite ores, well Z02, from the depth 150.2 m. Conventional indices of minerals [

32]: feldspar (Fsp); quartz (Qz); hornblende (Hbl); biotite (Bt); plagioclase (Pl); amphibole (Amp); magnetite (Mag); epidote group minerals (Ep); pyrite (Py); chlorite (Chl); calcite (Cal); hematite (Hem); serpentine (Srp).

4.3. In Transmitted Light

The analysis of thin sections of the samples, selected from the core of wells Z01-Z04 (according to

Figure 5,

Figure 6 and

Figure 8) of the Zhuantobe deposit, was carried out at a magnification of 40 × 100 using a polarizing microscope in transmitted and reflected light, using scanning electron microscopy (SEM). The thin sections were examined in parallel and crossed nicols.

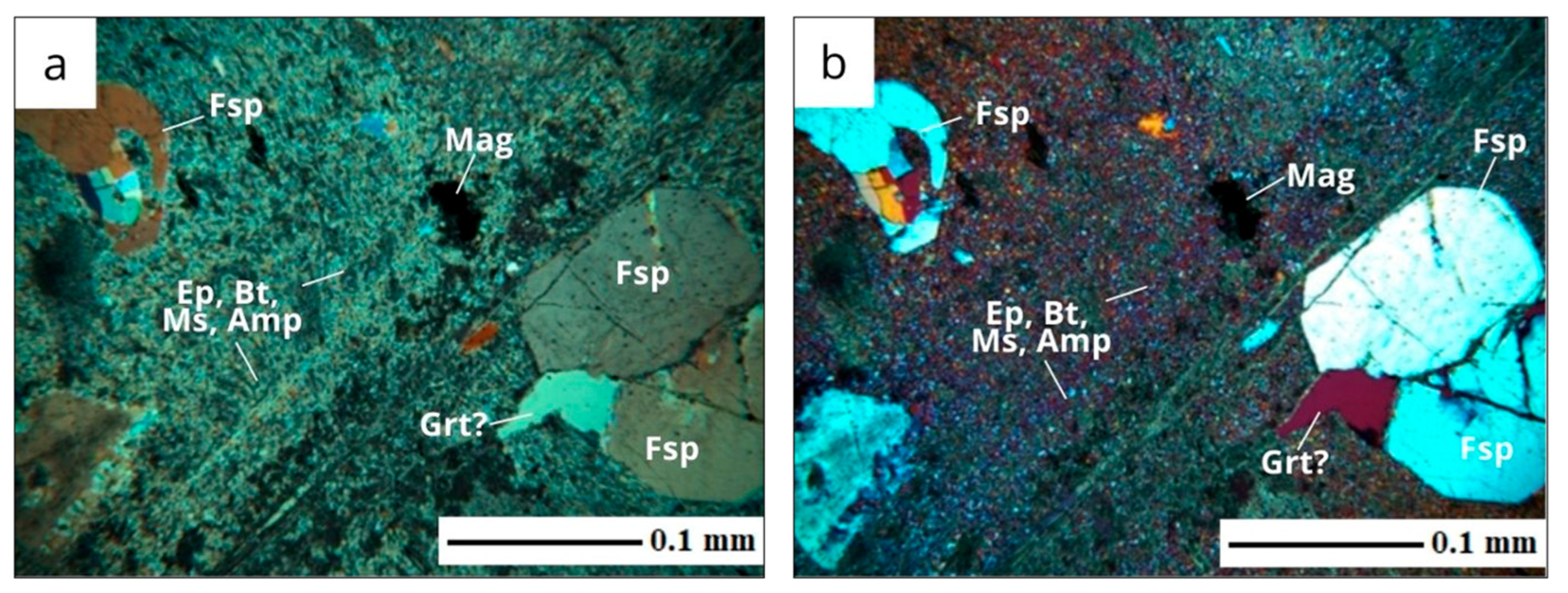

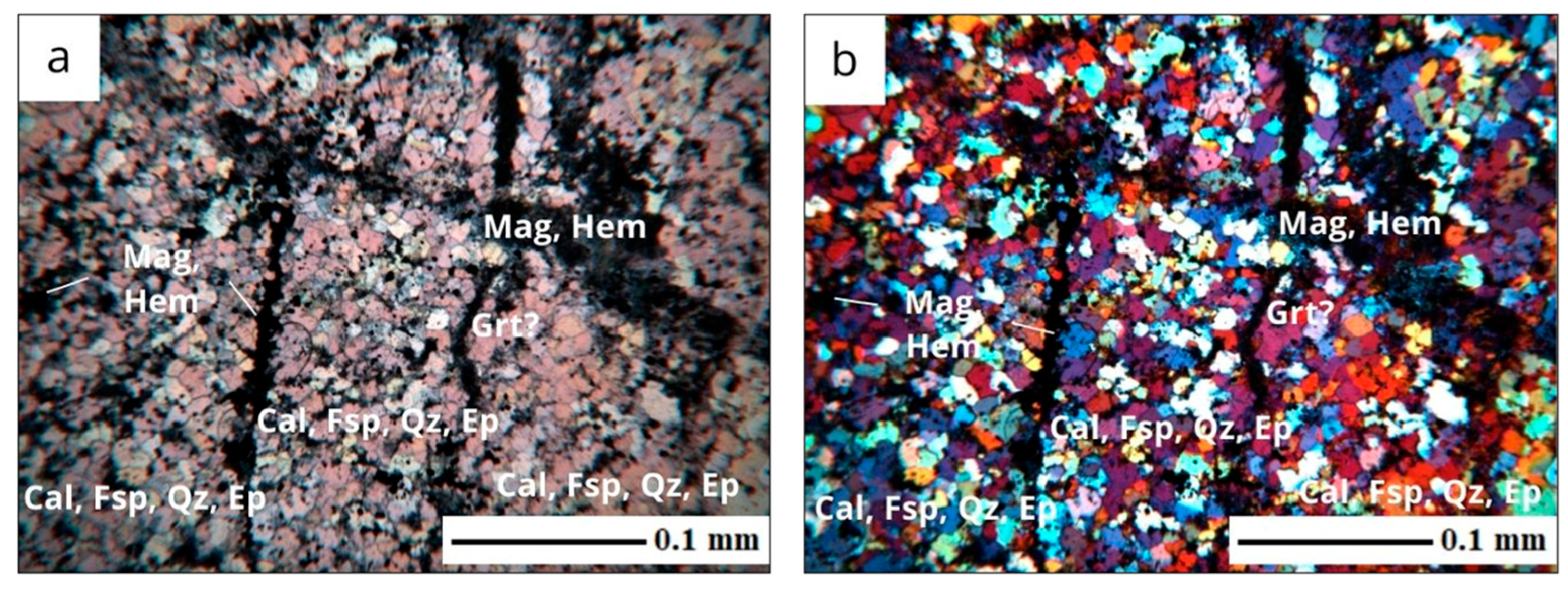

Garnet-epidote skarns with magnetite (

Figure 9) with porphyritic texture expressed in the presence of large phenocrysts of feldspars and magnetite, immersed in a fine-grained groundmass, with inclusions of epidote group minerals, biotite and amphibole. Rare grains of probable garnet and pyrite are present. Magnetite is represented by isotropic grains. Plagioclase is observed in the form of relict grains of light color; the presence of polysynthetic twins is noted. Epidote group minerals fill the intergranular space. The presence of microcracks and microfractures indicates an intense cataclasis of the desired rock. The presence of andradite and magnetite indicate an iron (Fe-rich) skarn type.

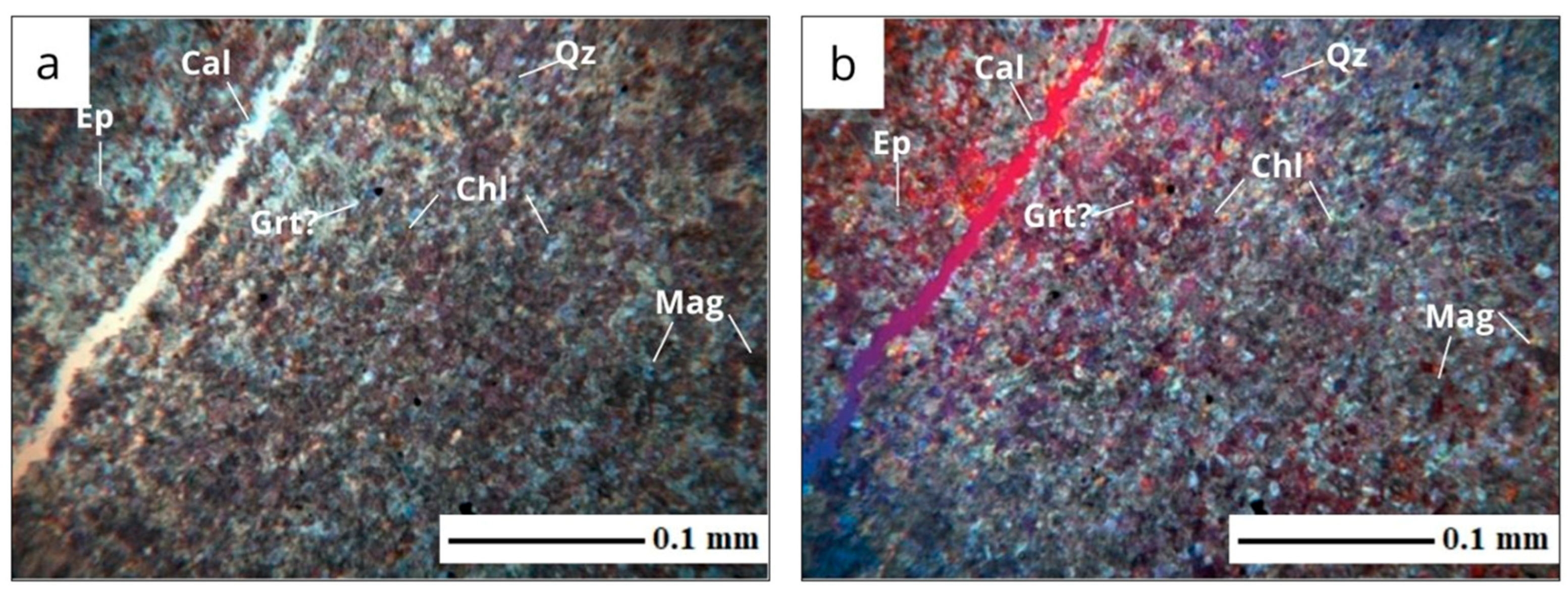

The calc-silicate skarns (

Figure 10) main mass have a fine-grained mosaic structure with a grain size of less than 0.2 mm, and a schistose-banded texture. Aggregates of biotite, muscovite, amphibole, chlorite are present. Numerous accumulations of fine-grained magnetite are observed over the entire area of the thin section. Veins and spots of carbonates are recorded in some areas. Magnetite mineralization is presented uniformly over the entire area of the thin section. Such features are typical of marginal zones of skarns. Calcite is recorded in the form of veins filling cracks. Quartz is present in the form of small anisotropic grains. The episode appears as xenomorphic fine grains. Probable garnet is represented by small isotropic grains in the rock matrix. Chlorite is in the form of greenish-gray areas and is developed in the intergranular space.

The calc-silicate skarns (

Figure 11) have a fine-grained structure and a massive mosaic texture. Elongated and tabular grains of calcite, serpentine, and epidote group minerals are noted, which are oriented along the weakly expressed schistosity. Magnetite inclusions are noted in the central and peripheral parts of the thin section, located both in the form of individual grains and small aggregates.

Silicate-carbonate skarns (

Figure 12) have a granoblastic structure with signs of intense recrystallization. The rock is represented by an aggregate of predominantly small (0.1–0.3 mm) grains of calcite, feldspar, quartz and epidote group minerals. Magnetite is widely developed in the groundmass, forming two generations of occurrence: (1) along microcracks and (2) in the groundmass of the rock. Branched zones of dark minerals extending along fractured areas pass through the central part of the thin section.

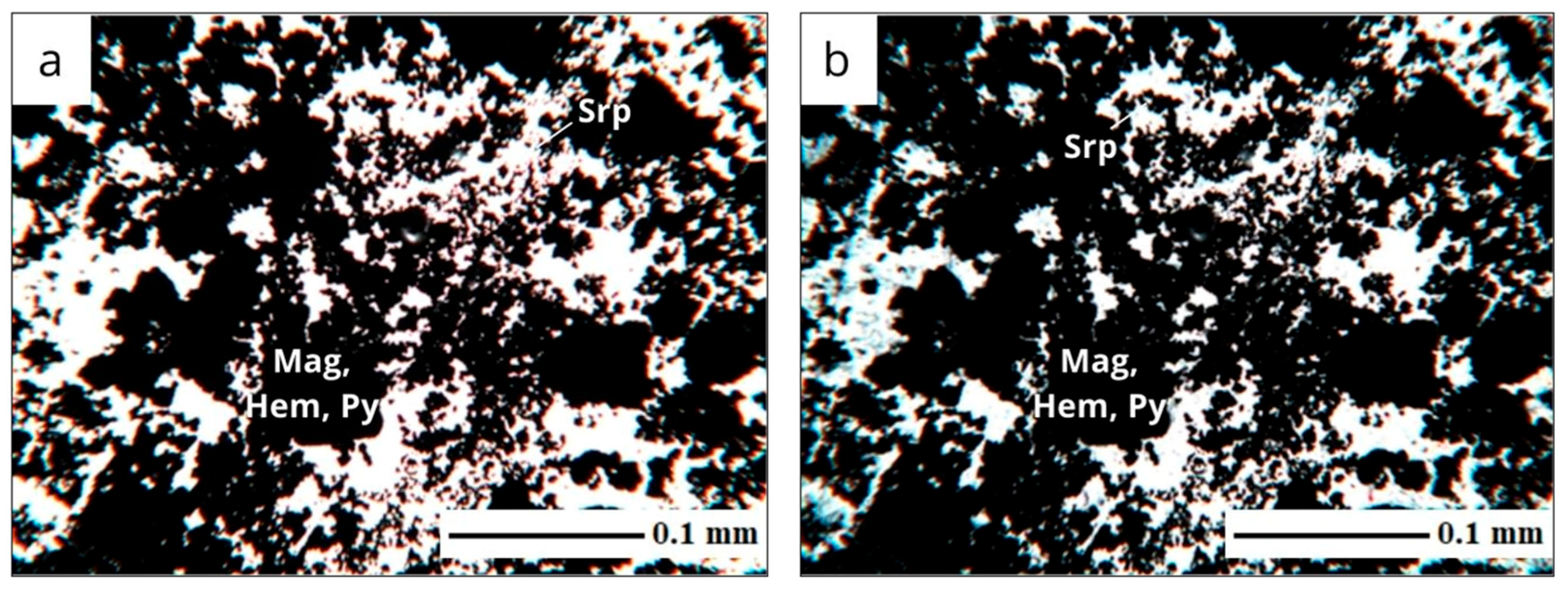

The ore zone of the skarns (

Figure 13) is composed of massive magnetite clusters. The grain shape varies from isometric to elongated. Magnetite forms large and small isotropic grains. Hematite and pyrite are recorded as separate clusters. Serpentine fills the inter-ore space. This sample is defined as magnetite skarn ore formed as a result of intensive iron metasomatism at the contact with carbonate rocks.

Cataclased carbonate-silicate rocks (skarns) are characterized by the presence of mineral fragments of various compositions, with a pyroxene crystal observed in the central part of the section (

Figure 14).

The ore zone of the skarns (

Figure 15) has a grayish-beige color for the ore-bearing mineral mass. The remaining black part of the section is filled with magnetite, distributed in the form of intergrowths and microinclusions. The grain size varies from 0.05 to 0.2 mm. In the central part of the section there is a microcrack filled with calcite. Along the contacts between magnetite and non-metallic minerals, areas of intergrowth and spotted texture are observed. Together with the presence of microveins and orientation in one direction, this indicates a contact-metasomatic origin of the rock, with subsequent hydrothermal processing and ore mineralization.

4.4. In Reflected Light

The most typical samples (polished sections) are described, covering the transition of contact-metasomatic alterations from endoskarns to exoskarns.

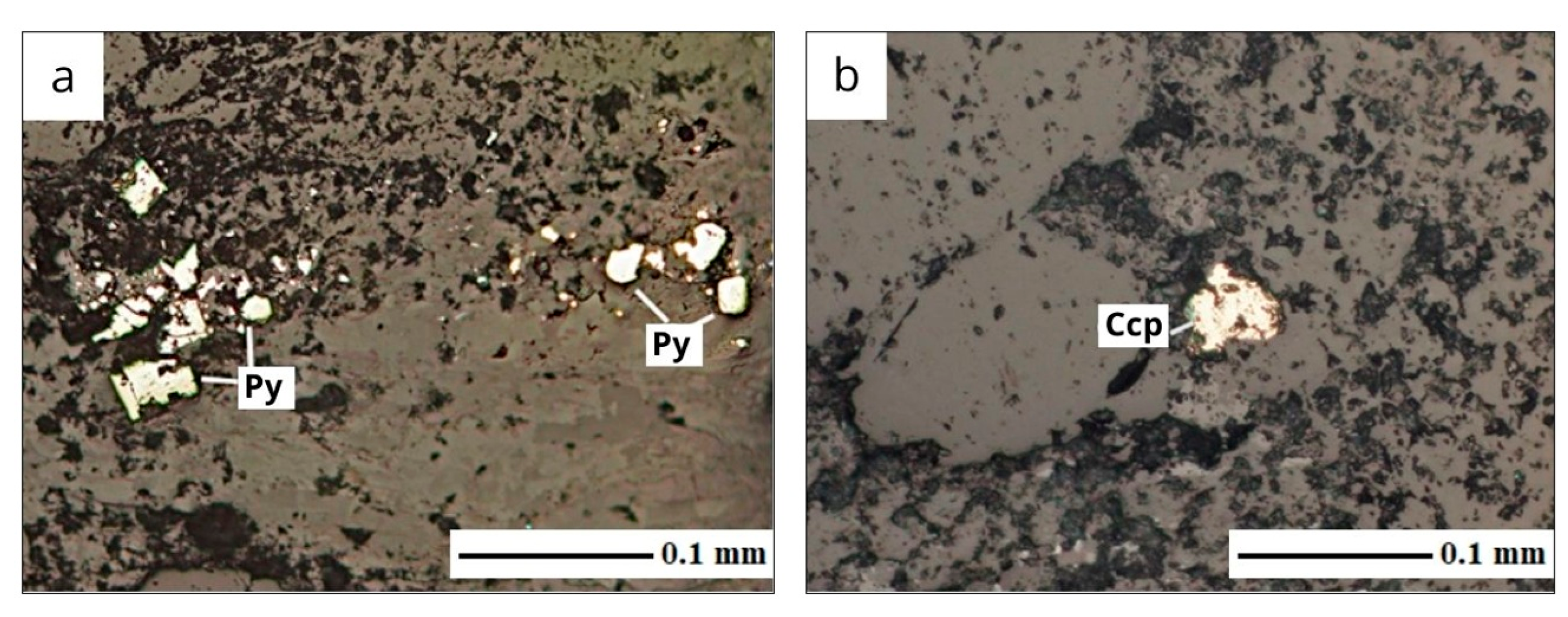

Skarns (

Figure 16,

Table 1) with ore mineralization, consists of porphyroblasts, feldspars up to 3.5 mm in cross-section. Ore mineralization has a hypidiomorphic structure, with a vein-disseminated texture, composed of pyrite and chalcopyrite. Pyrite is noted in euhedral grains, only in a linear vein crossing the entire polished section (0.5 mm thick), it is cataclased and corroded (the only accumulation of 0.8 mm). Chalcopyrite is noted in single isometric grains (0.03–0.06 mm) with weak anisotropy. One grain of zircon (0.14 mm) was encountered.

Magnesian skarns (

Figure 17,

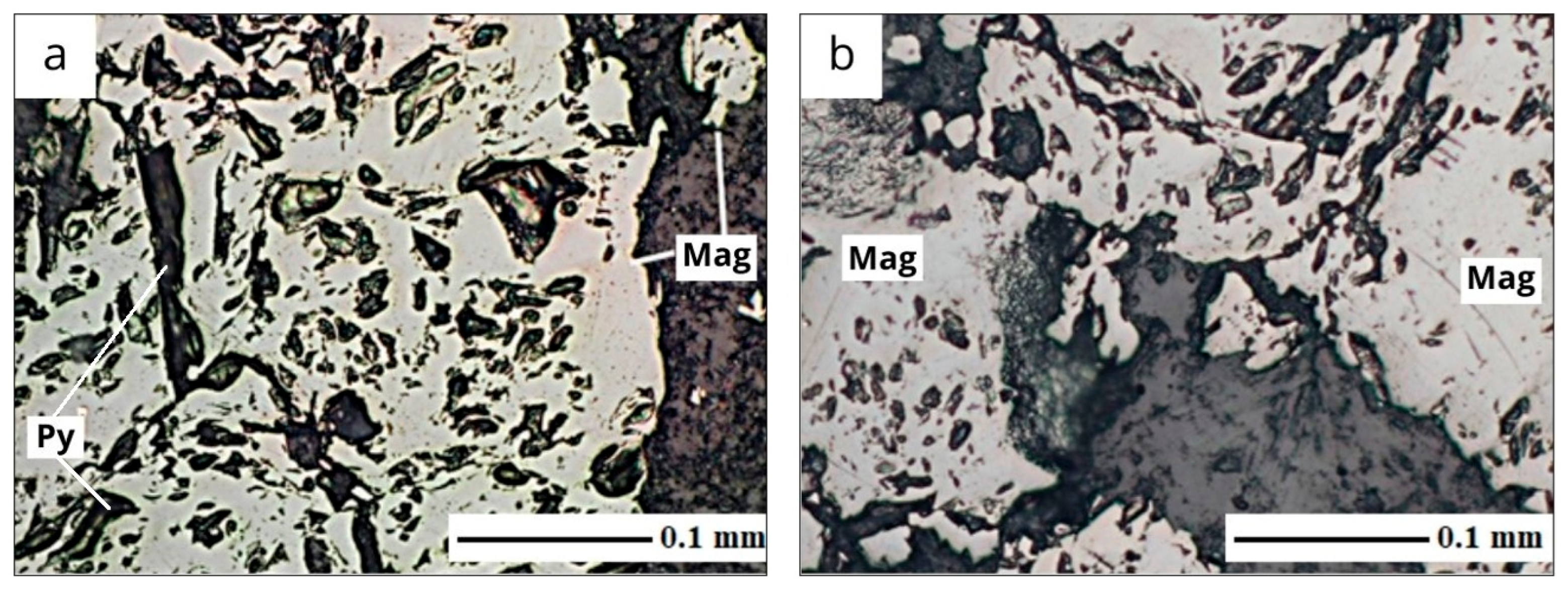

Table 2) with ore mineralization, have a hypidiomorphic-granular structure and vein-disseminated texture. Pyrite is recorded as fine-grained disseminated grains (<0.01 mm), individual crystals (up to 0.22 mm). Pyrite also forms crystal intergrowths (up to 0.4 mm), uniformly distributed over the polished section area (about 1%). Magnetite in the form of isometric grains (0.07 mm) to fine disseminated grains (micron disseminated grains) is unevenly disseminated and controlled by veins and cracks between rock-forming minerals.

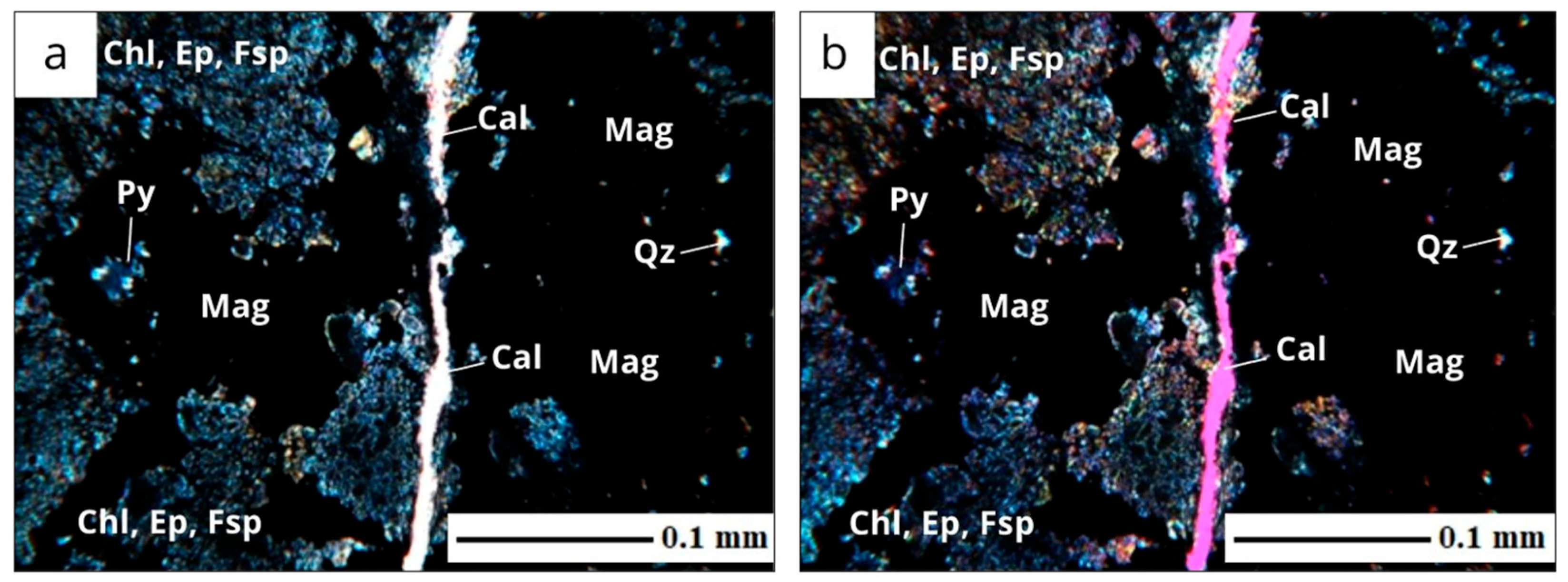

Calcareous skarn (

Figure 18) with ore mineralization has a granular structure and veinlet-disseminated texture. Ore minerals are represented by magnetite of varying degrees of martitization (pseudomorphosis of hematite after magnetite), both dispersed in the host-rock and in larger grains concentrated in linear veinlets and crushing zones. Magnetite inclusions in micron-sized fragments are single, inclusions in the cementing mass are larger (0.04–0.06 mm) and more numerous, up to 1% in the cement material. In the crushing zones around the veinlets, the grain size is maximum up to 0.12 mm.

Skarns of the near-ore (peripheral) zone (

Figure 19,

Table 3)—the ore minerals of which are represented by magnetite and pyrite, which have a granular structure and disseminated texture. Magnetite is characterized by an abnormal bluish-gray anisotropy changing to brown, gray, there are a large number of inclusions and small voids with crystallographic faceting. Pyrite is present in the form of single plate grains in magnetite.

Magnesian skarns (

Figure 20) with a granular structure and vein-disseminated texture. Ore minerals are represented by magnetite (up to 5% of the section area) in the form of small inclusions (from microns to the first fractions of a mm) in the host-rock and in veins.

The largest veins are up to 1.5 mm thick and have an injection-metasomatic character. These veins consist of magnetite and amorphous iron oxides, forming a crustified structure of individual aggregates. Another type of veins is represented by rectilinear and parallel series, within which intergrowths of magnetite with dolomite and serpentine are fixed.

5. Determination of Sample Chemical Composition Using X-Ray Fluorescence (XRF) Spectrometry

The results of sample analyses (

Table 4 and

Table S1) indicate that the ores are predominantly composed of iron, with no significant concentrations of associated valuable components detected. Phase-specific chemical analysis of iron reveals that the majority of iron is bound in magnetite, with lesser amounts occurring in hematite and iron hydroxides; the distribution of these phases varies within the first few percent. Minor iron content is also present in sulfide minerals, such as pyrite, chalcopyrite, and pyrrhotite.

These analytical results provide a basis for assessing the potential beneficiation characteristics of the studied ore. A notable feature of the primary ore is that approximately 40–50% of the magnetite occurs in a liberated state, while more than 50% is finely intergrown with gangue minerals in the form of grains, aggregates, and microveinlets ranging from a few microns to 1.0 mm in size. This texture suggests that finer crushing or grinding is required to achieve sufficient liberation. For beneficiation, both dry and wet magnetic separation techniques may be considered depending on the degree of magnetite exposure and particle size.

The formation of the Zhuantobe skarn deposit is associated with magmatic activity during the Hercynian stage of the formation of the consolidated continental crust of the Junggar-Balkhash fold belt [

1,

5,

12,

17]. Numerous models have been proposed in studies focused on the ore-forming processes of skarn iron deposits to illustrate the staged development of such deposits [

10,

13,

18,

19,

27,

33,

34,

35,

36,

37,

38].

As a result of the conducted studies, the main types of ore minerals have been identified (

Table 5):

Magnetite forms an unevenly disseminated texture composed of both fine and coarse grains ranging from 0.01 to 0.05 mm to 0.3–0.5 mm, often grouped into clusters up to 3.0 mm or more. Massive aggregates with grain sizes of 0.20–1.0 mm are also present. Magnetite grains exhibit varying degrees of leaching and replacement by non-metallic minerals, which leads to the formation of cavities filled with secondary minerals; in some cases, only skeletal remnants remain. Corrosion textures are observed, indicating the replacement of magnetite by hematite.

Hematite occurs in minor amounts (up to 1.4%) and formed during late fluid-hydrothermal processes.

Pyrite and chalcopyrite (with minor amounts of sphalerite and galena) are present as fine inclusions and scattered grains (<0.02 mm) within magnetite and the surrounding host rocks. Their textural features indicate that they crystallized later than magnetite.

Iron hydroxides (limonite) occur in subordinate amounts, mainly as fine-grained aggregates in near-surface zones, formed as a result of supergene oxidation.

Analysis of the spatial distribution of ore bodies at the Zhuantobe deposit shows that the highest concentrations of iron are controlled by: (1) contact zones between granitoids and carbonate rocks, associated with skarn formation and albite-silicate metasomatism; (2) secondary tectonic faults; and (3) local structural traps that control ore accumulation. These patterns can be used to predict new ore-bearing zones and guide further exploration efforts.

6. Discussion

This study examines the textures and compositions of mineral associations in the Zhuantobe skarn deposit. It presents a combination of the material characteristics of the iron skarns and compares them with the results of studies on several iron deposits worldwide [

33,

34,

35,

36,

37,

38,

39,

40,

41]. Such a comparison allows for outlining a schematic picture of the evolution of the contact metasomatic fluids in the Zhuantobe deposit, which also broadens our understanding of the ore-forming processes responsible for other similar iron deposits located in the North Balkhash mining region.

Comparative characteristics of the study of the mineral composition, textural–structural features, and geological environment of skarn formation at the Zhuantobe iron ore deposit in the northwestern Balkhash region (Central Kazakhstan) allow us to find common correlations with global skarn-iron deposits in Eurasia.

A classic example is the model of the formation of the Campiglia iron ore deposit, located in the Tuscany region (Italy), which was periodically developed from the Copper Age to the end of the twentieth century [

39]. At the same time, the developed model of skarn formation at the Campiglia deposit cannot fully explain the textural and geochemical features of the skarns. The study conducted by VonRath [

40] and comparison with the chemical model of D.S. Korzhinsky [

33] in the 20th century made Campiglia a “classic” example of a skarn ore deposit, starting with the causal intrusion of granitoids into the host marbles. In recent years, detailed field studies integrated with petrographic, geochemical, and isotopic analyses have revealed a more complex skarn formation history similar to the Zhuantobe deposit.

The Kaladawan iron ore deposit is located in the Northern Altyn Tagh of China and is characterized by the presence of iron ore bodies in the contact zone of Ordovician igneous rocks (basalts, rhyolites, and granodiorites) with marble. However, uncertainties remain with the genetic classification and metallogenic mechanism of this deposit. The results of field studies, in situ geochemical analysis of individual minerals, whole-rock geochemical analysis, and iron isotope determination indicate that magnetite from all studied rocks underwent hydrothermal metasomatism, while the diagrams indicate a skarn origin of these magnetites, which is largely comparable with the data obtained from studying similar processes occurring at Zhuantobe. Therefore, it can be concluded that the Kaladawan and Zhuantobe iron ore deposits belong to the skarn type, which indicates that the ore-forming materials of the iron ore mainly come from granitoid and volcanic rocks [

41].

The Makeng iron deposit in southwest Fujian Province, China, is a large iron ore deposit containing various types of iron ore including garnet magnetite, diopside magnetite, and quartz magnetite [

34]. The metallogenic type of the deposit is a matter of debate, especially with respect to the genesis of the magnetite and the source of the iron. In situ trace element microanalysis of Makeng magnetite from various ores shows relatively low levels of V, Ti, Cu, and Zn, with higher concentrations of Ca and Si, indicating the characteristics of a skarn-type deposit; a similar pattern is observed at the Zhuantobe deposit. Studies of skarns indicate that the Makeng iron ore deposit is a skarn-type magnetite deposit associated with the Yanshan granite intrusions. Therefore, it is suggested that the original ore-forming fluid is a high-temperature magmatic hydrothermal fluid with high oxygen fugacity. This fluid penetrates into the spaces such as the interlayer fracture zones between the carbonate rocks of the Upper Carboniferous Jingshe Formation—Middle Permian Qixia Formation and the Lower Carboniferous Lindi Formation sandstones, resulting in the formation of various magnetite ores through metasomatism, similar to the processes that occurred in the Zhuantobe deposit located in central Kazakhstan. The mineralization process of the Makeng iron deposit is basically similar because it is composed of typical skarn deposits. Magnetite was mainly formed during the formation stage of calcium skarns, and this process continued until the initial phase of retrograde alteration of skarns. In contrast, sulfide minerals including molybdenite, sphalerite, and galena precipitated during the quartz-sulfide stage [

34].

The Guodian iron ore deposit is a representative of the recently discovered rich Qihe-Yucheng iron skarn ore cluster in the Luxi Block in the eastern North China Craton [

35]. The obtained results, combined with the existing isotopic age data, indicate that the Guodian skarn iron ore deposit was formed simultaneously with the large-scale skarn iron mineralization in the Luxi Block in the late Mesozoic, similar to the events that occurred in central Kazakhstan in the Devonian-Early Carboniferous [

35].

The Beizhang iron deposit (468 Mt with an average grade of 41% Fe) is the largest iron deposit in the Avulale iron metallogenic belt in the Western Tien Shan, northwest China [

36]. High-grade magnetite ores are hosted by Carboniferous volcanic rocks with extensive development of skarn metasomatic complexes. Similar geological settings are observed at the Zhuantobe deposit in central Kazakhstan. However, despite significant progress in understanding the characteristics of Beizhang and Zhuantobe and their genetic relationship with volcanic rocks, genetic models of ore formation are not well substantiated and remain controversial. Trace element concentrations in magnetite reveal the complex origin of different ore types, suggesting precipitation of magnetite from both magmatic and hydrothermal fluids. The use of a magnesite thermometer at Beizhang revealed a marked temperature discrepancy among the different varieties of magnetite, ranging from relatively higher temperatures in the magmatic brecciated magnetite (average ~641 and 6120C) to relatively lower temperatures in the hydrothermal magnetite (average ~5520C). The iron isotopic composition of the massive and brecciated magnetite grains indicates a magmatic or high-temperature hydrothermal origin. In contrast, the higher iron values observed in magnetite are attributed to the influence of pyrrhotite, indicating late precipitation from low-temperature hydrothermal fluids [

36]. These results support the conclusion that the Beizhang and Zhuantobe iron deposits have undergone plutonic hydrothermal mineralization.

A comprehensive analysis of the material composition and textural and structural features of the iron ores of the Zhuantobe deposit made it possible to establish the significant influence of these parameters on the technological properties of the ores on their enrichment [

42,

43,

44].

It has been established that ores with massive, banded, and vein-disseminated textures in combination with a granoblastic structure demonstrate a higher degree of liberation of iron-containing minerals, such as magnetite and hematite, during crushing and grinding [

20,

21]. This, in turn, contributes to the high efficiency of gravity and magnetic enrichment. For example, when processing magnetite ores with a granoblastic structure, iron extraction of up to 75–80% is achieved at the stage of wet magnetic separation, which is comparable with the results obtained during the enrichment of ores in the Lake Superior region (USA), where two-stage magnetic separation with iron extraction of up to 78–82% is used in similar geological conditions [

45].

In contrast, ores with a brecciated or cataclastic structure are usually characterized by an uneven distribution of iron-containing phases and a high content of secondary silicates and clay components, which lead to a lower level of extraction in standard enrichment schemes. In such cases, the efficiency of the process can only be increased by additional grinding and the use of flotation or hydrocyclone classification, which requires additional costs [

42,

43].

The identified dependencies allow for more accurate prediction of the technological behavior of ores during processing and the identification of zones with promising characteristics [

46,

47,

48,

49,

50]. Such an approach meets modern requirements for resource efficiency and sustainable development of the mineral resource base.

7. Conclusions

A comprehensive study of the Zhuantobe iron ore deposit was conducted, including fieldwork, sampling, laboratory investigations, and analysis of geological and geophysical data. This allowed for a detailed characterization of the mineralogical, petrographic, and textural–structural composition of skarn magnetite ores. Two types of ores were distinguished: (a) primary skarn magnetite ores of contact-metasomatic origin, and (b) secondary hydrothermal quartz-hematite ores. Their mineralogical composition is predominantly magnetite with minor admixtures of hematite, iron hydroxides (limonite), and sulfide minerals (pyrite, chalcopyrite, and pyrrhotite).

Magnetite is characterized by a heterogeneous texture with grain sizes ranging from submicron- to millimeter-scale, often grouped into nests and aggregates. These magnetite occurrences undergo varying degrees of leaching and metasomatic replacement and sometimes contain late-stage inclusions of pyrite and chalcopyrite. The spatial distribution of iron concentration is closely related to the contact zones between granitoids and carbonate rocks, as well as second-order tectonic disturbances, which are important criteria for predicting new ore zones and guiding further exploration.

Geochemical analyses show elevated Fe2O3 content, low levels of harmful impurities (S, P, Pb, etc.), and varying amounts of SiO2 depending on texture. Massive magnetite ores with high iron content and low impurity levels are particularly promising for industrial beneficiation.

Mining conditions at Zhuantobe are favorable and suitable for designing open-pit operations with low groundwater levels, especially in the western part of the deposit where ore bodies are almost homogeneous and overburden thickness is minimal. The analysis results indicate that the ore has good potential for beneficiation. A distinctive feature of the ore is the presence of a significant portion of magnetite in a free state, while the rest is closely associated with rock-forming minerals in the form of grains, aggregates, and fine veins. For efficient iron extraction, finer crushing or grinding is recommended, along with the use of magnetic separation methods—both dry and wet—depending on technological conditions.

This study contributes to a deeper understanding of the genesis of skarn iron ores and provides a solid foundation for the effective development and processing of the Zhuantobe deposit. It also holds significant importance for the exploration and development of similar skarn iron ore systems in Central Kazakhstan.

Supplementary Materials

The following supporting information can be downloaded at:

https://www.mdpi.com/article/10.3390/app15179816/s1, Table S1: The concentrations of iron and associated elements at the Zhuantobe deposit were determined through the analysis of core samples from wells Z01–Z04, utilizing data obtained via X-ray fluorescence (XRF) spectrometry.

Author Contributions

Conceptualization, V.K. and A.N.; methodology, V.K. and A.N.; software, A.N. and A.C.; validation, V.K., A.N., A.C., and Z.T.; formal analysis, V.K. and A.N.; investigation, V.K. and A.N.; resources, V.K., A.N., A.C., and Z.T.; data curation, V.K. and A.N.; writing—original draft preparation, V.K. and A.N.; writing—review and editing, V.K., A.N., A.C., and Z.T.; visualization, V.K., A.N., and A.C.; supervision, V.K.; project administration, V.K.; funding acquisition, V.K., A.N., A.C., and Z.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education of the Republic of Kazakhstan (Program IRN BR21882301).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This research was supported by the leadership of the Kazakh-British Technical University (Almaty, Kazakhstan).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Korobkin, V.V.; Buslov, M.M. Tectonics and geodynamics of the western Central Asian Fold Belt (Kazakhstan Paleozoides). Rus. Geol. Geoph. 2011, 52, 1600–1618. [Google Scholar] [CrossRef]

- Korobkin, V.V.; Chaklikov, A.Y.; Tulemissova, Z.S. Tectonic zoning of paleozoids of Kazakhstan and its oil and gas-bearing regions. Kaz. J. Oil Gas Ind. 2022, 4, 39–49. [Google Scholar] [CrossRef]

- Nikitchenko, I.I. Minerals of Kazakhstan: Explanatory Note to the Map of Minerals of Kazakhstan at a Scale of 1:1,000,000; Ministry of Energy and Mineral Resources of the Republic of Kazakhstan: Kokshetau, Kazakhstan, 2002; p. 188. (In Russian)

- Abdulin, A.A.; Shlygin, A.E. Metallogeny and Mineral Resources of Kazakhstan; Nauka: Alma-Ata, Kazakhstan, 1983; p. 310. (In Russian) [Google Scholar]

- Bekzhanov, G.R.; Koshkin, V.Y.; Nikitchenko, I.I. Geological Structure of Kazakhstan; AMR of the Republic of Kazakhstan: Almaty, Kazakhstan, 2000; p. 396. (In Russian) [Google Scholar]

- Daukeev, S.Z.; Uzhkenov, B.S.; Abdulin, A.A.; Miroshnichenko, L.A.; Zhukov, H.M.; Mazurov, A.K.; Bespaev, K.A.; Dolgopolov, B.M.; Akylbekov, S.A.; Zhautikov, T.M.; et al. Metallogeny. In Deep Structure and Mineral Resources of Kazakhstan; National Academy of Sciences of the Republic of Kazakhstan: Almaty, Kazakhstan, 2002; Volume 2, p. 265. (In Russian) [Google Scholar]

- Satpayev, K.I. Main patterns of spatial distribution of endogenous mineralization zones in Central Kazakhstan. Sov. Geol. 1957, 58, 93–109. (In Russian) [Google Scholar]

- Novokhatsky, I.P. Genetic types of iron ore deposits in Central Kazakhstan. In Iron Ore Deposits of Central Kazakhstan and Ways of Their Use; USSR Academy of Sciences: Moscow, Russia, 1960. (In Russian) [Google Scholar]

- Satpayev, K.I. Selected Works. Problems of Metallogeny and Mineral Resources of Kazakhstan; Nauka: Alma-Ata, Kazakhstan, 1968; Volume 3, p. 312. (In Russian) [Google Scholar]

- Shcherba, G.N. Atasu type deposits in Kazakhstan. End. Ore Dep. 1967, 5, 185–196. (In Russian) [Google Scholar]

- Bogdanov, A.A. Tectonic zoning of the Paleozoides of Central Kazakhstan and Tien Shan. Bul. M. Soc. Nat. 1965, 40, 8–42. (In Russian) [Google Scholar]

- Bespalov, V.F. Tectonic Map of the Kazakh SSR and Adjacent Territories of the Union Republics at 8 Scale of 1:1,500,000. Explanatory Note; Academy of Sciences of the Kazakh SSR: Alma-Ata, Kazakhstan, 1975; p. 160. (In Russian) [Google Scholar]

- Dymkin, A.M. Contact-Metasomatic Iron Deposits of the Southern Part of the Main Ore Belt of Turgay; Publishing house of the Siberian Branch of the USSR Academy of Sciences: Novosibirsk, Russia, 1962; p. 239. (In Russian) [Google Scholar]

- Dymkin, A.M. Petrology and Genesis of Magnetite Deposits of Turgay; Nauka: Novosibirsk, Russia, 1966; p. 169. (In Russian) [Google Scholar]

- Esenov, S.H.E.; Lyapichev, G.F.; Sidorenko, A.V.; Shlygin, E.D. Geology of the USSR. Volume XX. Central Kazakhstan. Geological Description Book 1; Nedra: Moscow, Russia, 1972; p. 532. (In Russian) [Google Scholar]

- Zaicev, Y.U.A. Geology of the USSR. Volume XX. Central Kazakhstan. Minerals; Nedra: Moscow, Russia, 1979; p. 541. (In Russian) [Google Scholar]

- Abdulin, A.A. Geology and Mineral Resources of Kazakhstan; Gylym: Almaty, Kazakhstan, 1994; p. 394. (In Russian) [Google Scholar]

- Zholtayev, G.Z.H.; Zhukov, N.M.; Antonenko, A.A. Atlas of Solid Mineral Deposits of the Republic of Kazakhstan; Institute of Geological Sciences named after K.I. Satpayev: Almaty, Kazakhstan, 2024; p. 263. (In Russian) [Google Scholar]

- Bekmukhametov, A.E. Magmatogenic Iron Ore Formations; Nedra: Moscow, Russia, 1987; p. 212. (In Russian) [Google Scholar]

- Kubeeva, L.V.; Zyabkin, V.F.; Yugay, V.D.; Baimuldina, N.N.; Muzgina, V.S. Geoecological studies during the development of the Bapy iron ore deposit in the Republic of Kazakhstan. Subs. Use 21st Cent. 2010, 1, 81–83. (In Russian) [Google Scholar]

- Edilbaev, A.I. Development of technologies for enrichment of poor iron ore raw materials. Min. Inf. An. Bul. 2011, 10, 247–251. (In Russian) [Google Scholar]

- Bekmukhametov, A.E.; Pankratova, N.L.; Kryukov, A.S. Iron Ore Formations. In Chu Ili Ore Belt; Shcherba, G.N., Ed.; Nauka: Alma-Ata, Kazakhstan, 1980. (In Russian) [Google Scholar]

- Bekmukhametov, A.E.; Bekmukhametova, Z.A. Classification of skarn-magnetite deposits of Kazakhstan, features of formation, metamorphism, dynamometamorphism and their further regeneration to oolitic iron ores. Litol. Miner. Resour. 2007, 2, 80–105. (In Russian) [Google Scholar]

- Zhukov, N.M.; Akylbekov, S.A.; Antonenko, A.A.; Amanbayev, R. Iron Deposits of Kazakhstan: A Handbook; Institute of Geological Sciences named after K.I. Satpayev: Almaty, Kazakhstan, 2016; p. 258. (In Russian) [Google Scholar]

- Daukeev, S.Z.; Uzhkenov, B.S.; Abdulin, A.A.; Bespaev, K.A.; Votsalevsky, E.S.; Lyubetsky, V.N.; Mazurov, A.K.; Miroshnichenko, L.A. Deep structure and geodynamics. In Deep Structure and Mineral Resources of Kazakhstan; National Academy of Sciences of the Republic of Kazakhstan: Almaty, Kazakhstan, 2002; Volume 1, p. 224. (In Russian) [Google Scholar]

- Boyko, O.N.; Filatova, G.V.; Zyabkin, V.F.; Lim, D.K. Report on the Results of Exploration of Iron-Containing Ores in the Bapy Area in the Karaganda Region for 2015–2018; Ministry of Ecology, Geology and Natural Resources of the Republic of Kazakhstan: Karaganda, Karaganda, 2019.

- Zhao, W.W.; Zhou, M.F. In-situ LA-ICP-MS trace elemental analyzes of magnetite: The Mesozoic Tengtie skarn Fe deposit in the Nanling Range, South China. Ore Geol. Rev. 2015, 65, 872–883. [Google Scholar] [CrossRef]

- Korobkin, V.; Chaklikov, A.; Tulemissova, Z.; Samatov, I.; Dobrovolskaya, Y. Results of the Study of Epigenetic Changes of Famennian–Tournaisian Carbonate Rocks of the Northern Marginal Shear Zone of the Caspian Syneclise (Kazakhstan). Minerals 2023, 13, 249. [Google Scholar] [CrossRef]

- Korobkin, V.; Samatov, I.; Chaklikov, A.; Tulemissova, Z. Peculiarities of Dynamics of Hypergenic Mineral Transformation of Nickel Weathering Crusts of Ultramafic Rocks of the Kempirsay Group of Deposits in Western Kazakhstan. Minerals 2022, 12, 650. [Google Scholar] [CrossRef]

- Korobkin, V.V.; Tulemissova, Z.S.; Samatov, I.B.; Chaklikov, A.Y. Secondary calcite in carbonate reservoirs of oil fields: A method for its quantitative determination. Kaz. J. Oil Gas Ind. 2025, 7, 84–95. (In Russian) [Google Scholar] [CrossRef]

- Askarova, N.S.; Roman, A.T.; Portnov, V.S.; Kopobayeva, A.N. Feature space of the Atasu type deposits (Central Kazakhstan). Nauk. Vis. Nats. Hirn. Un. 2021, 5, 5–10. [Google Scholar] [CrossRef]

- Whitney, D.L.; Evans, B.W. Abbreviations for Names of Rock-Forming Minerals. Amer. Mineral. 2010, 95, 185–187. [Google Scholar] [CrossRef]

- Reverdatto, V.V. Facies of Contact Metamorphism; Nedra: Moscow, Russia, 1970; p. 272. (In Russian) [Google Scholar]

- Yi, J.; Shi, X.; Ji, G.; Zhang, L.; Wang, S.; Deng, H. The Geochemical Characteristics of Trace Elements in the Magnetite and Fe Isotope Geochemistry of the Makeng Iron Deposit in Southwest Fujian and Their Significance in Ore Genesis. Minerals 2024, 14, 217. [Google Scholar] [CrossRef]

- Feng, Q.; Gao, M.; Fu, C.; Li, S.; Li, Y.; Gao, J.; Ma, M.; Wang, Z.; Zhu, Y.; Wu, B.; et al. Phlogopite 40Ar/39Ar Geochronology for Guodian Skarn Fe Deposit in Qihe–Yucheng District, Luxi Block, North China Craton: A Link between Craton Destruction and Fe Mineralization. Minerals 2024, 14, 690. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Wang, D.; Zhang, Z.; Duan, S. Genesis of the Beizhan Iron Deposit in Western Tianshan, China: Insights from Trace Element and Fe-O Isotope Compositions of Magnetite. Minerals 2024, 14, 304. [Google Scholar] [CrossRef]

- Meng, L.; Huang, F.; Gao, W.; Wang, D.; Zhu, J.; Xing, C.; Tan, W.; Tang, X. Multi-stage hydrothermal processes at the Laozuoshan gold deposit in NE China: Insights from textures and compositions of sulfide assemblages. Ore Geol. Rev. 2020, 117, 103275. [Google Scholar] [CrossRef]

- Wang, R.; Chen, F.; Wang, J.; Hao, X.; Chen, H.; Liu, H. Prospecting criteria for skarn-type iron deposits in the thick overburden area of Qihe-Yucheng mineral-rich area using geological and geophysical modelling. J. Appl. Geophys. 2024, 228, 105442. [Google Scholar] [CrossRef]

- Vezzoni, S.; Rocchi, S.; Dini, A. Campiglia Marittima Skarn (Tuscany): A Challenging Example for the Evolution of Skarn-Forming Models. Minerals 2023, 13, 482. [Google Scholar] [CrossRef]

- Vom Rath, G. Die Berge von Campiglia in Der Toskanischen Maremme. Z. Dtsch. Geol. Ges. 1868, 20, 307–364. [Google Scholar]

- Chen, Y.; Cao, Y.; Liu, L.; Wang, C.; Yang, W.; Gai, Y.; Xie, T.; Song, L.; Xie, F. Elucidating the Genetic Mechanism and the Ore-Forming Materials of the Kaladawan Iron Deposit in the North Altyn Tagn, Western China. Minerals 2024, 14, 589. [Google Scholar] [CrossRef]

- Matiolo, E.; Couto, H.J.B.; Lima, N.; Silva, K.; de Freitas, A.S. Improving recovery of iron using column flotation of iron ore slimes. Min. Eng. 2020, 158, 106608. [Google Scholar] [CrossRef]

- Nakhaei, F.; Irannajad, M. Reagents types in flotation of iron oxide minerals: A review. Miner. Process. Extr. Metall. Rev. 2018, 39, 89–124. [Google Scholar] [CrossRef]

- Silva, R.C.F.; Ardisson, J.D.; Cotta, A.A.C.; Araujo, M.H.; de Carvalho Teixeira, A.P. Use of iron mining tailings from dams for carbon nanotubes synthesis in fluidized bed for 17α-ethinylestradiol removal. Environ. Pollut. 2020, 260, 114099. [Google Scholar] [CrossRef] [PubMed]

- Kolm, H.; Oberteuffer, J.; Kelland, D. HIGH-GRADIENT MAGNETIC SEPARATION. Sci. Am. 1975, 233, 46–55. Available online: http://www.jstor.org/stable/24949937 (accessed on 5 May 2025). [CrossRef]

- Araujo, A.C.; Amarante, S.C.; Souza, C.C.; Silva, R.R.R. Ore mineralogy and its relevance for selection of concentration methods in processing of Brazilian iron ores. Miner. Process. Extr. Metall. 2003, 112, 54–64. [Google Scholar] [CrossRef]

- Lima, R.M.F.; Abreu, F.P.V.F. Characterization and concentration by selective flocculation/magnetic separation of iron ore slimes from a dam of Quadrilátero Ferrífero—Brazil. J. Mater. Res. Technol. 2020, 9, 12356–12362. [Google Scholar] [CrossRef]

- Muwanguzi, A.J.B.; Karasev, A.V.; Byaruhanga, J.K.; Jönsson, P.G. Characterization of the Physical and Metallurgical Properties of Natural Iron Ore for Iron Production. ISRN Mater. Sci. 2012, 2012, 147420. [Google Scholar] [CrossRef]

- Yellishetty, M.; Ranjith, P.G.; Tharumarajah, A. Iron ore and steel production trends and material flows in the world: Is this really sustainable? Resour. Conserv. Recycl. 2010, 54, 1084–1094. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Han, Y.; Parra-Álvarez, N.; Claremboux, V.; Kawatra, S.K. Flotation of Iron Ores: A Review. Miner. Process. Extr. Metall. Rev. 2021, 42, 184–212. [Google Scholar] [CrossRef]

Figure 1.

Overview of the western segment of the Central Asian folded belt (

A) and the administrative scheme of the Republic of Kazakhstan (

B). The blue circle indicates the area of the iron ore region of the northwestern Balkhash region. The main faults are as follows: MKF—Main Karatau and TFF—Talas-Fergana, ZhNF—Zhalair-Naiman, MJF—Main Junggar, MChF—Main Chingiz, IRF—Irtysh [

1,

2].

Figure 1.

Overview of the western segment of the Central Asian folded belt (

A) and the administrative scheme of the Republic of Kazakhstan (

B). The blue circle indicates the area of the iron ore region of the northwestern Balkhash region. The main faults are as follows: MKF—Main Karatau and TFF—Talas-Fergana, ZhNF—Zhalair-Naiman, MJF—Main Junggar, MChF—Main Chingiz, IRF—Irtysh [

1,

2].

Figure 2.

Scheme of tectonic zoning of the Palaeozoic regions of Kazakhstan [

1,

2] (the iron ore region of the northwestern Balkhash region is highlighted by a white rectangle).

Figure 2.

Scheme of tectonic zoning of the Palaeozoic regions of Kazakhstan [

1,

2] (the iron ore region of the northwestern Balkhash region is highlighted by a white rectangle).

Figure 3.

Scheme of major tectonic units and locations of main industrial types of iron ore deposits in Kazakhstan [

2,

3]: (1) East European Craton, (2, 3) Kazakhstanian segment of the Central Asian Fold Belt (2—Caledonian, 3—Hercynian fold systems), (4) geological boundaries, (5) outlines of iron ore regions.

Figure 3.

Scheme of major tectonic units and locations of main industrial types of iron ore deposits in Kazakhstan [

2,

3]: (1) East European Craton, (2, 3) Kazakhstanian segment of the Central Asian Fold Belt (2—Caledonian, 3—Hercynian fold systems), (4) geological boundaries, (5) outlines of iron ore regions.

Figure 4.

The scheme of the geological structure of the iron ore region of the North-West Balkhash, compiled according to data [

4,

5,

6]. The deposits are marked with blue contours: (1) Kiyik, (2) Western Bapy, (3) Bapy, (4) Eastern Bapy, (5) Bale, (6) Ushtobe, (7) Akchagyl, (8) Zhuantobe.

Figure 4.

The scheme of the geological structure of the iron ore region of the North-West Balkhash, compiled according to data [

4,

5,

6]. The deposits are marked with blue contours: (1) Kiyik, (2) Western Bapy, (3) Bapy, (4) Eastern Bapy, (5) Bale, (6) Ushtobe, (7) Akchagyl, (8) Zhuantobe.

Figure 5.

Geological map of the Zhuantobe deposit, constructed by the authors using data obtained from fieldwork.

Figure 5.

Geological map of the Zhuantobe deposit, constructed by the authors using data obtained from fieldwork.

Figure 6.

(A) Detailed geological cross-section of the Zhuantobe deposit: Western section, profile I–I; Eastern section, profile II–II. Compiled by the authors using data obtained from field investigations and documentation of mine workings. (B) Photographs of the outcrops. Letters in circles correspond to photographs of geological outcrops.

Figure 6.

(A) Detailed geological cross-section of the Zhuantobe deposit: Western section, profile I–I; Eastern section, profile II–II. Compiled by the authors using data obtained from field investigations and documentation of mine workings. (B) Photographs of the outcrops. Letters in circles correspond to photographs of geological outcrops.

Figure 7.

Map of the magnetic field of the Zhuantobe deposit. Positive anomalies correspond to ore-bearing skarn zones. The map was compiled using field investigation results and supplemented with data from geophysical surveys [

26].

Figure 7.

Map of the magnetic field of the Zhuantobe deposit. Positive anomalies correspond to ore-bearing skarn zones. The map was compiled using field investigation results and supplemented with data from geophysical surveys [

26].

Figure 9.

Garnet–epidote skarns with magnetite: (

a) parallel nicols; (

b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals [

32]: feldspar (Fsp); magnetite (Mag); epidote group minerals (Ep); biotite (Bt); muscovite (Ms); amphibole (Amp); probable garnet (Grt?).

Figure 9.

Garnet–epidote skarns with magnetite: (

a) parallel nicols; (

b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals [

32]: feldspar (Fsp); magnetite (Mag); epidote group minerals (Ep); biotite (Bt); muscovite (Ms); amphibole (Amp); probable garnet (Grt?).

Figure 10.

Calc–silicate rocks: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); magnetite (Mag); chlorite (Chl); epidote group minerals (Ep); quartz (Qz); probable garnet (Grt?).

Figure 10.

Calc–silicate rocks: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); magnetite (Mag); chlorite (Chl); epidote group minerals (Ep); quartz (Qz); probable garnet (Grt?).

Figure 11.

Calc–silicate rocks: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); chlorite (Chl); epidote group minerals (Ep); calcite (Cal); serpentine (Srp).

Figure 11.

Calc–silicate rocks: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); chlorite (Chl); epidote group minerals (Ep); calcite (Cal); serpentine (Srp).

Figure 12.

Silicate–carbonate rocks (skarns): (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); calcite (Cal); feldspars (Fsp); quartz (Qz); epidote group minerals (Ep); probable garnet (Grt?).

Figure 12.

Silicate–carbonate rocks (skarns): (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); calcite (Cal); feldspars (Fsp); quartz (Qz); epidote group minerals (Ep); probable garnet (Grt?).

Figure 13.

Ore zone of skarns: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); pyrite (Py); serpentine (Srp).

Figure 13.

Ore zone of skarns: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: magnetite (Mag); hematite (Hem); pyrite (Py); serpentine (Srp).

Figure 14.

Cataclased carbonate–silicate rocks (magnetite skarns): (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); feldspar (Fsp); quartz (Qz); epidote group minerals (Ep); chlorite (Chl); pyroxene (Px); magnetite (Mag); hematite (Hem).

Figure 14.

Cataclased carbonate–silicate rocks (magnetite skarns): (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); feldspar (Fsp); quartz (Qz); epidote group minerals (Ep); chlorite (Chl); pyroxene (Px); magnetite (Mag); hematite (Hem).

Figure 15.

Ore zone of skarns: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); feldspar (Fsp); quartz (Qz); epidote group minerals (Ep); chlorite (Chl); magnetite (Mag); pyrite (Py).

Figure 15.

Ore zone of skarns: (a) parallel nicols, (b) crossed nicols with compensator; magnification ×40. Conventional indices of minerals: calcite (Cal); feldspar (Fsp); quartz (Qz); epidote group minerals (Ep); chlorite (Chl); magnetite (Mag); pyrite (Py).

Figure 16.

Sulfide inclusions in skarns. Microphotographs of polished sections (a,b) with the analyzer switched on, direct reflected light, in parallel nicols. Conventional indices of ore minerals: pyrite (Py); chalcopyrite (Ccp).

Figure 16.

Sulfide inclusions in skarns. Microphotographs of polished sections (a,b) with the analyzer switched on, direct reflected light, in parallel nicols. Conventional indices of ore minerals: pyrite (Py); chalcopyrite (Ccp).

Figure 17.

Inclusions of ore minerals in magnesian skarn, microphotographs of polished sections (a–c) with the analyzer switched on, direct light reflected in parallel nicols. Conventional indices of ore minerals: magnetite (Mag); pyrite (Py).

Figure 17.

Inclusions of ore minerals in magnesian skarn, microphotographs of polished sections (a–c) with the analyzer switched on, direct light reflected in parallel nicols. Conventional indices of ore minerals: magnetite (Mag); pyrite (Py).

Figure 18.

Magnetite inclusions in skarns, microphotographs of polished sections (a,c) with the analyzer on, direct light reflected in parallel nicols; (b) with the analyzer on, direct light reflected in crossed nicols. Conventional indices of ore mineral: magnetite (Mag).

Figure 18.

Magnetite inclusions in skarns, microphotographs of polished sections (a,c) with the analyzer on, direct light reflected in parallel nicols; (b) with the analyzer on, direct light reflected in crossed nicols. Conventional indices of ore mineral: magnetite (Mag).

Figure 19.

Magnetite inclusions in skarns of the outer zone, microphotographs of polished sections (a,b) with the analyzer turned on, direct light reflected in parallel nicols. Conventional indices of the ore mineral: magnetite (Mag); pyrite (Py).

Figure 19.

Magnetite inclusions in skarns of the outer zone, microphotographs of polished sections (a,b) with the analyzer turned on, direct light reflected in parallel nicols. Conventional indices of the ore mineral: magnetite (Mag); pyrite (Py).

Figure 20.

Magnetite and hematite inclusions in magnesian skarns, micrographs of polished sections (a,c,e) with the analyzer on, direct reflected light, in parallel nicols; (b,d,f) with the analyzer on, direct reflected light, in crossed nicols. Conventional indices of the ore minerals: magnetite (Mag), hematite (Hem).

Figure 20.

Magnetite and hematite inclusions in magnesian skarns, micrographs of polished sections (a,c,e) with the analyzer on, direct reflected light, in parallel nicols; (b,d,f) with the analyzer on, direct reflected light, in crossed nicols. Conventional indices of the ore minerals: magnetite (Mag), hematite (Hem).

Table 1.

Morphology of ore minerals and their dimensions of polished section A (

Figure 16).

Table 1.

Morphology of ore minerals and their dimensions of polished section A (

Figure 16).

| Mineral | Sizes | Shape of the Grains | % of the Polished Section Area |

|---|

| pyrite | from microns to 0.03 mm, in splash (segregation) up to 0.8 mm | isometric, idiomorphic | about 1% |

| chalcopyrite | up to 0.05 mm | isometric | about 1% |

Table 2.

Morphology of ore minerals and their dimensions of polished section A (

Figure 17).

Table 2.

Morphology of ore minerals and their dimensions of polished section A (

Figure 17).

| Mineral | Sizes | Shape of the Grains | % of the Polished Section Area |

|---|

| pyrite | up to 0.01 mm, rarely 0.22 mm | idiomorphic in intergrowths | about 1% |

| magnetite | from microns to 0.07 mm | isometric, rarely hypidiomorphic | up to 1% |

Table 3.

Morphology of ore minerals and their dimensions of polished section 1 (

Figure 19).

Table 3.

Morphology of ore minerals and their dimensions of polished section 1 (

Figure 19).

| Mineral | Sizes | Shape of the Grains | % of the Polished Section Area |

|---|

| magnetite | from microns to 1.3 mm | isometric | 30–40% |

| pyrite | 0.005–0.02 mm | lamellae | about 1% |

Table 4.

The average concentrations of iron and associated elements at the Zhuantobe deposit were determined through the analysis of core samples from wells Z01–Z04, utilizing data obtained via X-ray fluorescence (XRF) spectrometry.

Table 4.

The average concentrations of iron and associated elements at the Zhuantobe deposit were determined through the analysis of core samples from wells Z01–Z04, utilizing data obtained via X-ray fluorescence (XRF) spectrometry.

| Well No— Z01. Well Depth—220 m. Fe total—24.04%. Sample initial weight—4.992kg. Sample final weight—0.250 kg. |

| Al2O3, % | SiO2, % | P2O5, % | SO3, % | CI, % | K2O, % | CaO, % | TiO2, % | V2O5, % | Cr2O3, % | MnO, % | Fe2O3, % | CoO, % | NiO, % | CuO, % | ZnO, % | Ga, % | Ge, % | As2O3, % | Se, % | Br, % | Rb2O, % | SrO, % |

| 7.6144 | 33.0600 | 0.3978 | 0.1931 | 0.0082 | 0.1078 | 20.8579 | 0.5316 | 0.0261 | 0.0149 | 0.8110 | 39.8021 | 0.0035 | 0.0053 | 0.0161 | 0.0185 | 0.0018 | 0.0004 | 0.0047 | 0.0001 | 0.0001 | 0.0022 | 0.0399 |

| Y, % | ZrO2, % | Nb2O5, % | Mo, % | Ag, % | Cd, % | SnO2, % | Sb2O5, % | Te, % | I, % | Cs, % | Ba, % | La, % | Ce, % | Hf, % | Ta2O5, % | WO3, % | Hg, % | Ti, % | PbO, % | Bi, % | Th, % | U, % |

| 0.0016 | 0.0107 | 0.0002 | 0.0001 | 0.0003 | 0.0002 | 0.0005 | 0.0026 | 0.0016 | 0.0008 | 0.0011 | 0.0012 | 0.0030 | 0.0053 | 0.0005 | 0.0045 | 0.0010 | 0.0002 | 0.0003 | 0.0054 | 0.0011 | 0.0024 | 0.0003 |

| Well No—Z02. Well Depth—152 m. Fe total—28.26%. Sample initial weight—5.844kg. Sample final weight—0.250 kg. |

| Al2O3, % | SiO2, % | P2O5, % | SO3, % | CI, % | K2O, % | CaO, % | TiO2, % | V2O5, % | Cr2O3, % | MnO, % | Fe2O3, % | CoO, % | NiO, % | CuO, % | ZnO, % | Ga, % | Ge, % | As2O3, % | Se, % | Br, % | Rb2O, % | SrO, % |

| 6.6778 | 28.0693 | 0.3903 | 0.5584 | 0.0088 | 0.1802 | 17.4014 | 0.5118 | 0.0238 | 0.0156 | 0.6913 | 43.7339 | 0.0035 | 0.0065 | 0.0209 | 0.0211 | 0.0017 | 0.0002 | 0.0070 | 0.0001 | 0.0000 | 0.0030 | 0.0370 |

| Y, % | ZrO2, % | Nb2O5, % | Mo, % | Ag, % | Cd, % | SnO2, % | Sb2O5, % | Te, % | I, % | Cs, % | Ba, % | La, % | Ce, % | Hf, % | Ta2O5, % | WO3, % | Hg, % | Ti, % | PbO, % | Bi, % | Th, % | U, % |

| 0.0014 | 0.0112 | 0.0002 | 0.0001 | 0.0004 | 0.0003 | 0.0004 | 0.0043 | 0.0018 | 0.0007 | 0.0012 | 0.0027 | 0.0020 | 0.0051 | 0.0004 | 0.0036 | 0.0005 | 0.0002 | 0.0002 | 0.0067 | 0.0013 | 0.0027 | 0.0004 |

| Well No—Z03. Well Depth—140 m. Fe total—26.52%. Sample initial weight—5.549 kg. Sample final weight—0.250 kg. |

| Al2O3, % | SiO2, % | P2O5, % | SO3, % | CI, % | K2O, % | CaO, % | TiO2, % | V2O5, % | Cr2O3, % | MnO, % | Fe2O3, % | CoO, % | NiO, % | CuO, % | ZnO, % | Ga, % | Ge, % | As2O3, % | Se, % | Br, % | Rb2O, % | SrO, % |

| 6.8064 | 28.1794 | 0.4006 | 1.9164 | 0.0050 | 0.0790 | 21.6641 | 0.5066 | 0.0246 | 0.0160 | 0.7589 | 44.2771 | 0.0040 | 0.0057 | 0.0086 | 0.0165 | 0.0020 | 0.0003 | 0.0103 | 0.0001 | 0.0001 | 0.0024 | 0.0332 |

| Y, % | ZrO2, % | Nb2O5, % | Mo, % | Ag, % | Cd, % | SnO2, % | Sb2O5, % | Te, % | I, % | Cs, % | Ba, % | La, % | Ce, % | Hf, % | Ta2O5, % | WO3, % | Hg, % | Ti, % | PbO, % | Bi, % | Th, % | U, % |

| 0.0015 | 0.0102 | 0.0002 | 0.0001 | 0.0005 | 0.0003 | 0.0005 | 0.0036 | 0.0020 | 0.0009 | 0.0017 | 0.0027 | 0.0024 | 0.0082 | 0.0005 | 0.0042 | 0.0007 | 0.0002 | 0.0002 | 0.0040 | 0.0013 | 0.0029 | 0.0003 |

| Well No—Z04. Well Depth—53 m. Fe total—25.70%. Sample initial weight 5.289 kg. Sample final weight—0.250 kg. |

| Al2O3, % | SiO2, % | P2O5, % | SO3, % | CI, % | K2O, % | CaO, % | TiO2, % | V2O5, % | Cr2O3, % | MnO, % | Fe2O3, % | CoO, % | NiO, % | CuO, % | ZnO, % | Ga, % | Ge, % | As2O3, % | Se, % | Br, % | Rb2O, % | SrO, % |

| 6.4795 | 28.6370 | 0.3568 | 1.4463 | 0.0073 | 0.4152 | 14.8074 | 0.4563 | 0.0131 | 0.0138 | 0.6358 | 36.8670 | 0.0038 | 0.0066 | 0.0122 | 0.0116 | 0.0017 | 0.0001 | 0.0073 | 0.0001 | 0.0001 | 0.0034 | 0.0303 |

| Y, % | ZrO2, % | Nb2O5, % | Mo, % | Ag, % | Cd, % | SnO2, % | Sb2O5, % | Te, % | I, % | Cs, % | Ba, % | La, % | Ce, % | Hf, % | Ta2O5, % | WO3, % | Hg, % | Ti, % | PbO, % | Bi, % | Th, % | U, % |

| 0.0015 | 0.0092 | 0.0002 | 0.0001 | 0.0006 | 0.0003 | 0.0004 | 0.0036 | 0.0018 | 0.0011 | 0.0017 | 0.0108 | 0.0024 | 0.0125 | 0.0003 | 0.0039 | 0.0015 | 0.0001 | 0.0003 | 0.0046 | 0.0018 | 0.0022 | 0.0004 |

Table 5.

Skarn process model at the Zhuantobe Deposit.

Table 5.

Skarn process model at the Zhuantobe Deposit.

| Stage | Skarn Process Model |

|---|

| 1. Contact Metamorphism | Formation of iron-poor, barren diopside hornfels and marbles |

| 2. Early Skarn | Development of anhydrous, dark-colored endo- and exoskarns: pyroxene, magnetite |

| 3. Late Fluid-Hydrothermal | Amphibole, epidote, dolomite, calcite, hematite, sulfides (pyrite, chalcopyrite, sphalerite, galena) |

| 4. Oxidation | Supergene stage in near-surface conditions (limonite, iron hydroxides) |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).