Comparison Between Active and Hybrid Magnetic Levitation Systems for High-Speed Transportation

Abstract

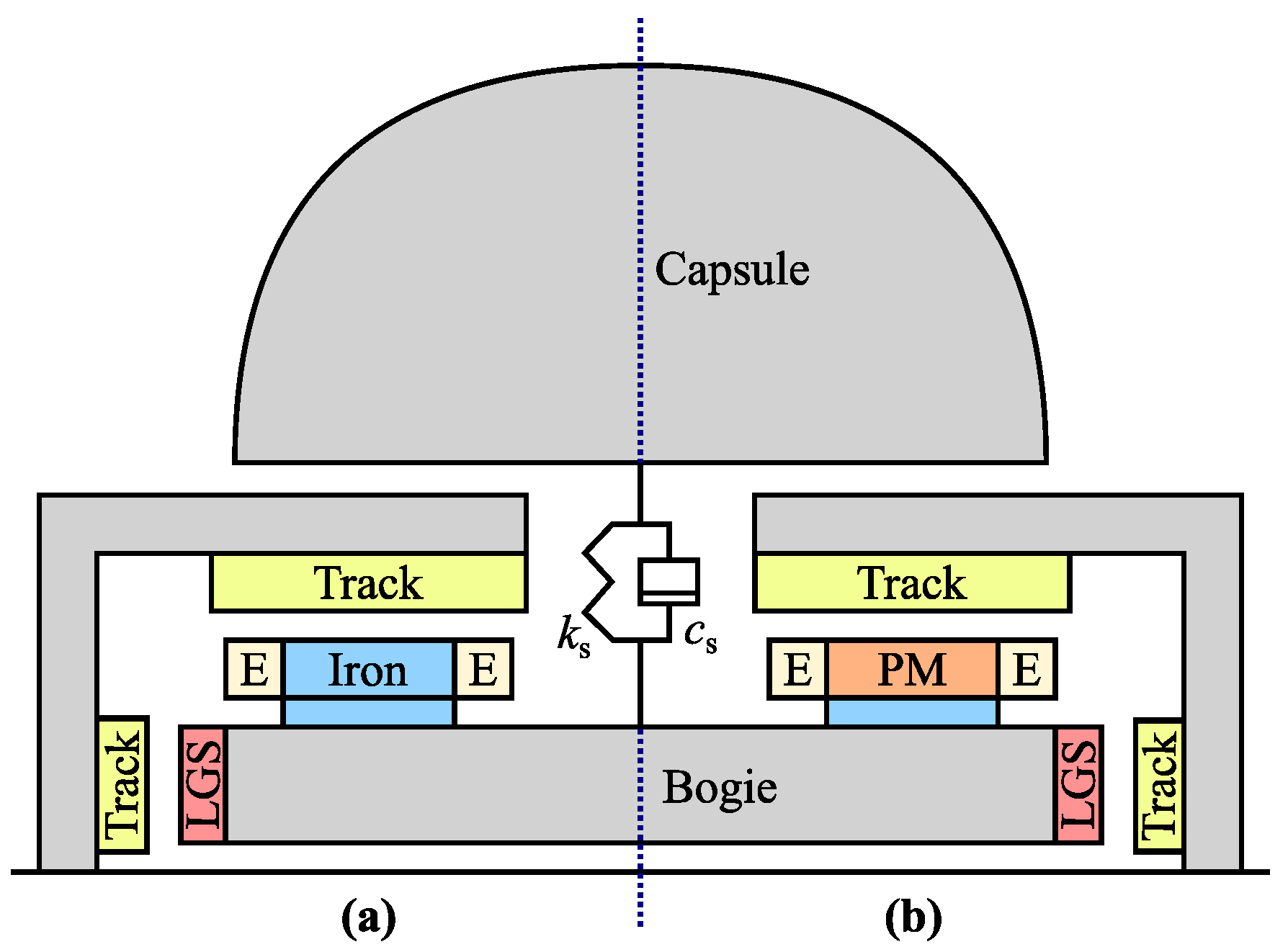

1. Introduction

1.1. Previous Work

1.2. Research Gap

1.3. Objective and Novelty

- A comprehensive approach to component design by means of multi-objective function optimization and subsequent system integration for active and hybrid heteropolar EMS topologies is presented. System integration includes identification of mechanical features such as mass, stiffness, and natural frequency values. Synthesis of levitation gap control policy is also included.

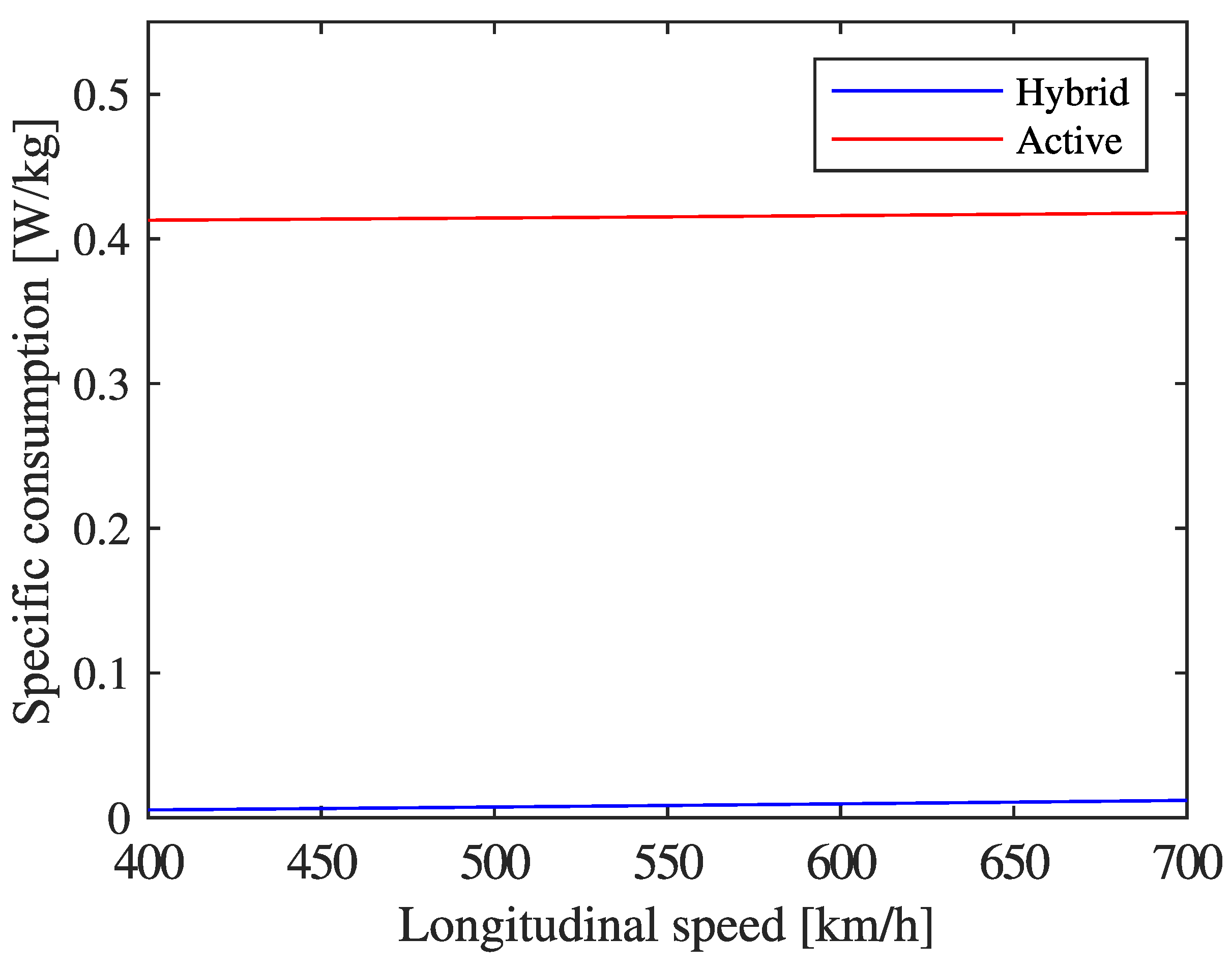

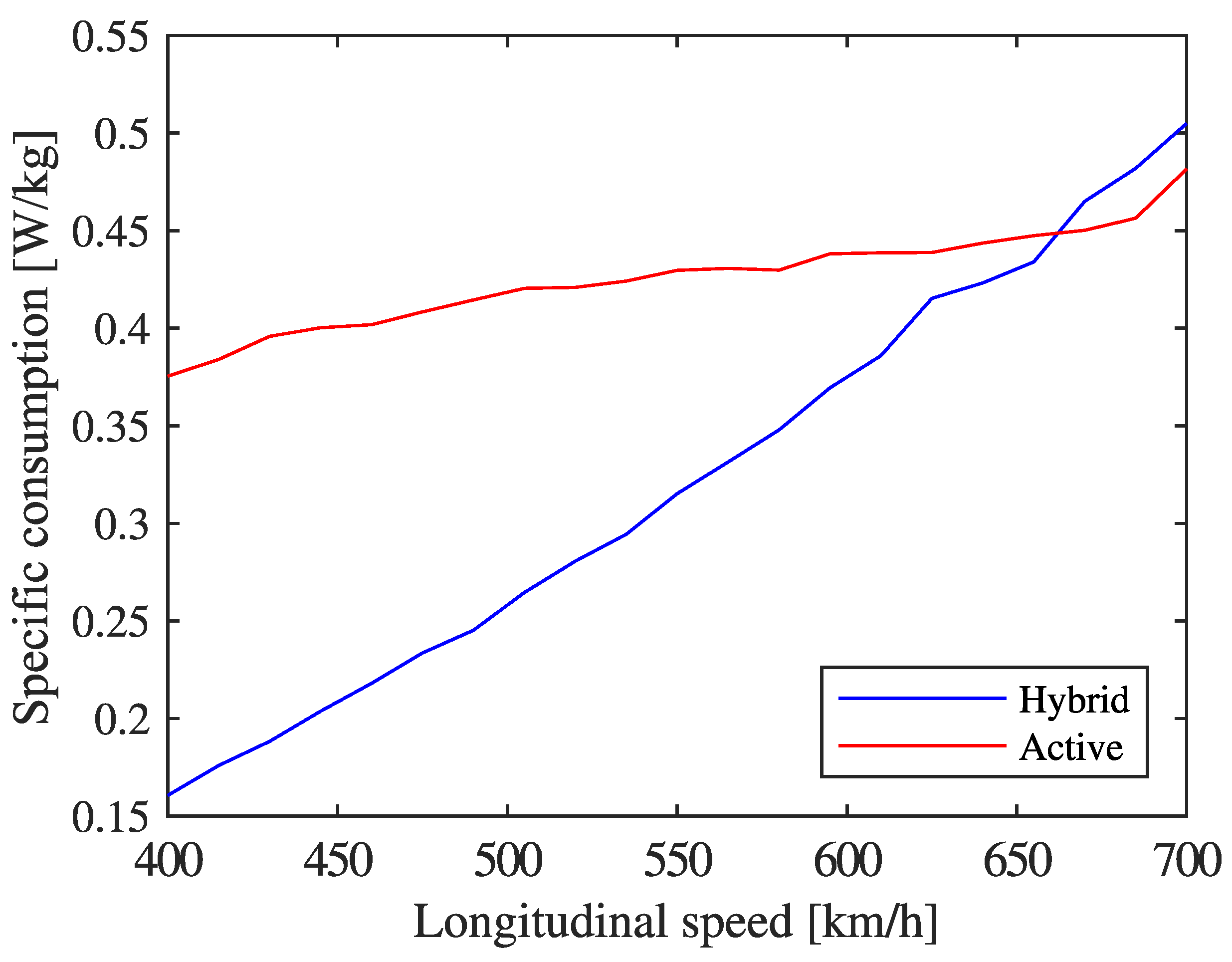

- The benefit of lower overall power consumption associated with the hybrid configuration is quantified at the levitation system level, compared to that of the active configuration.

1.4. Methodology

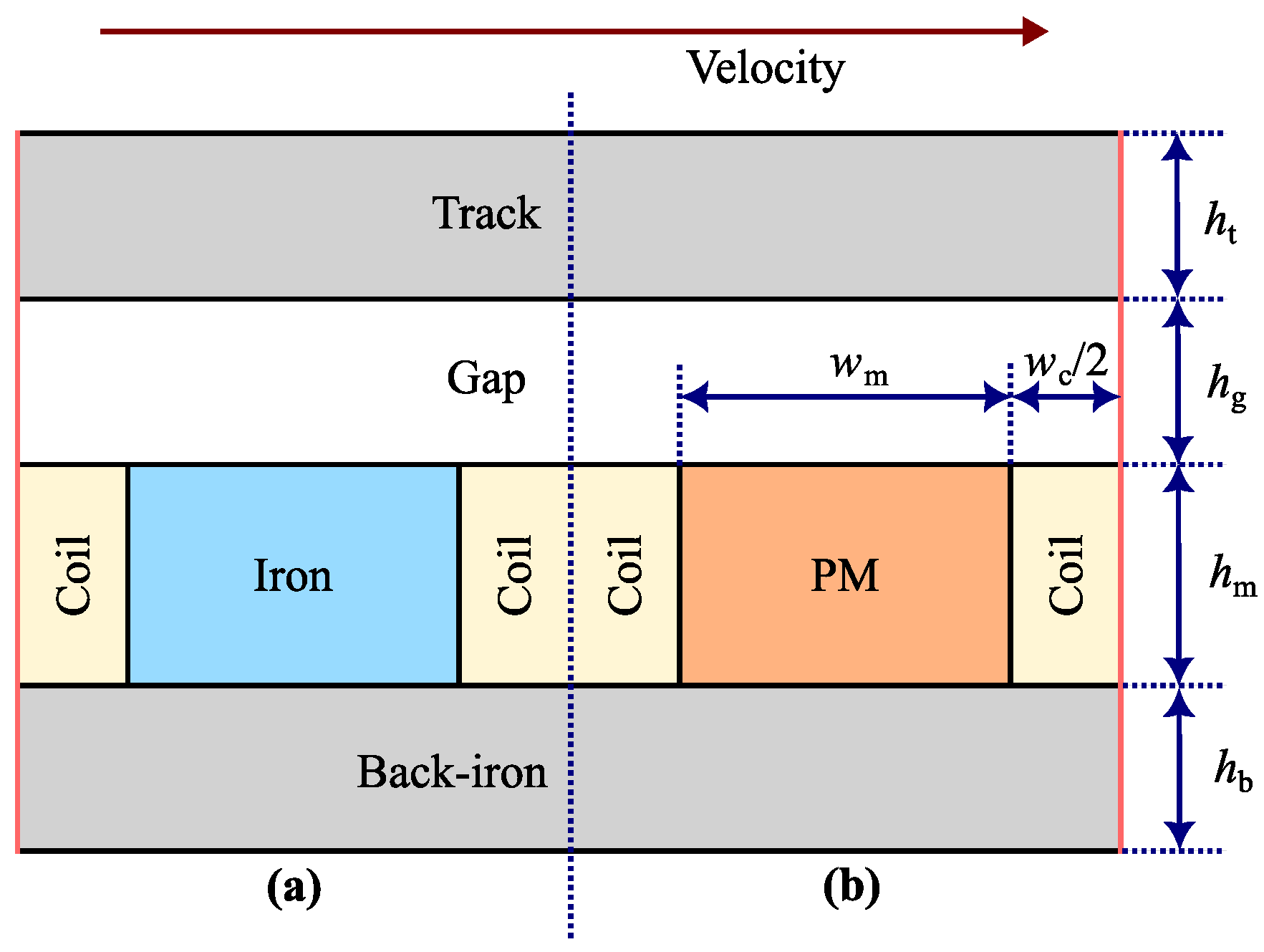

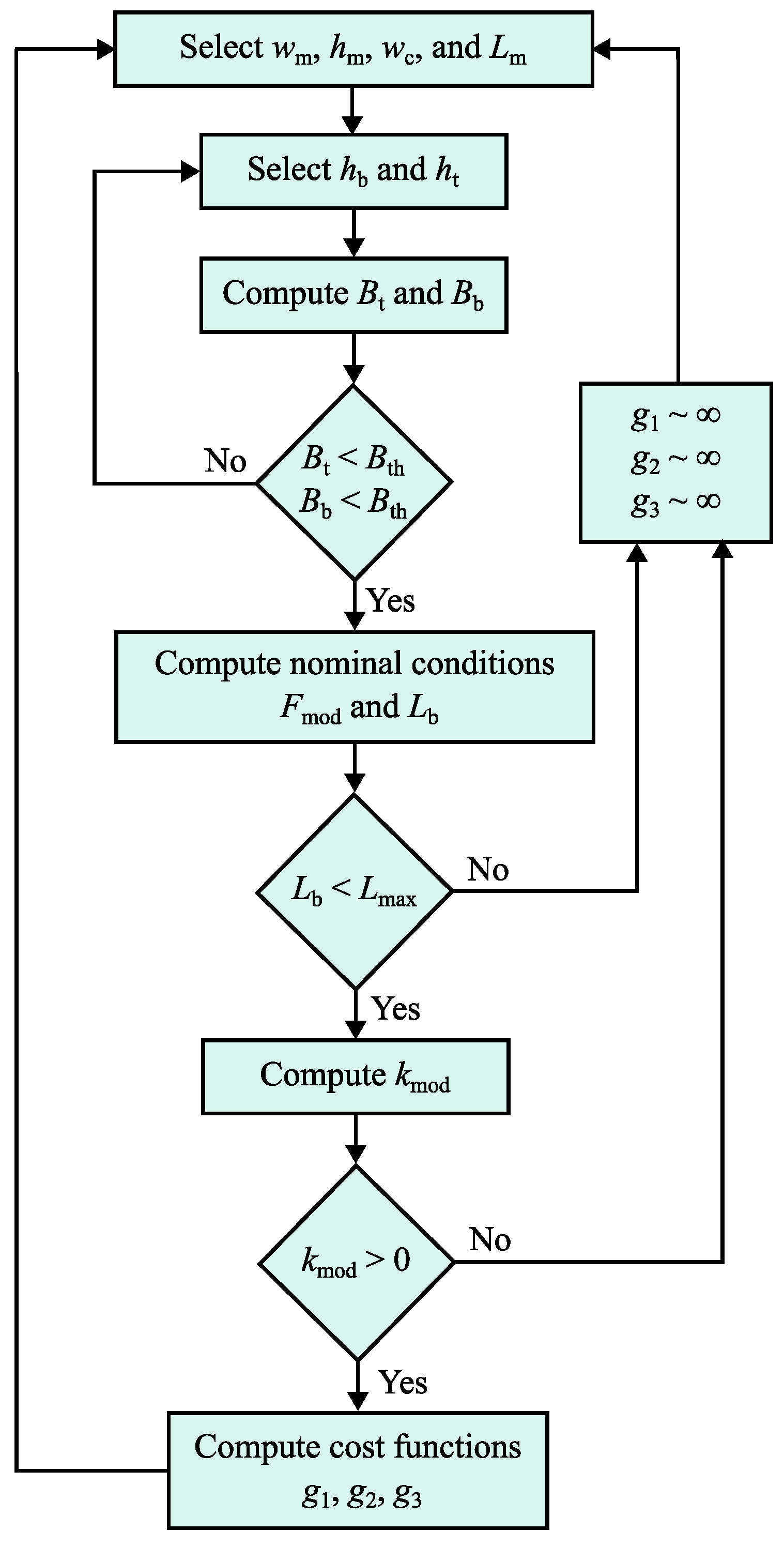

2. Design Methodology

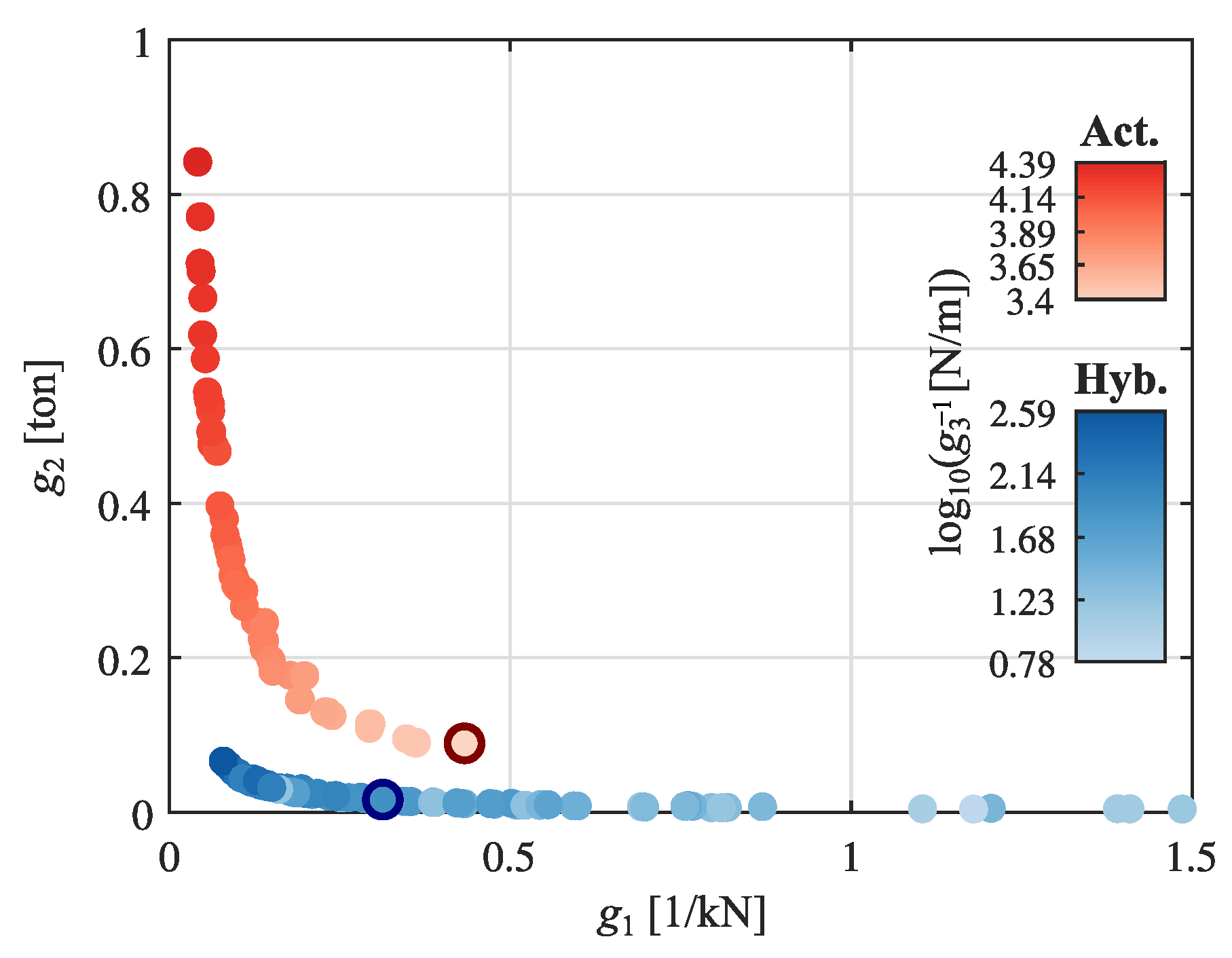

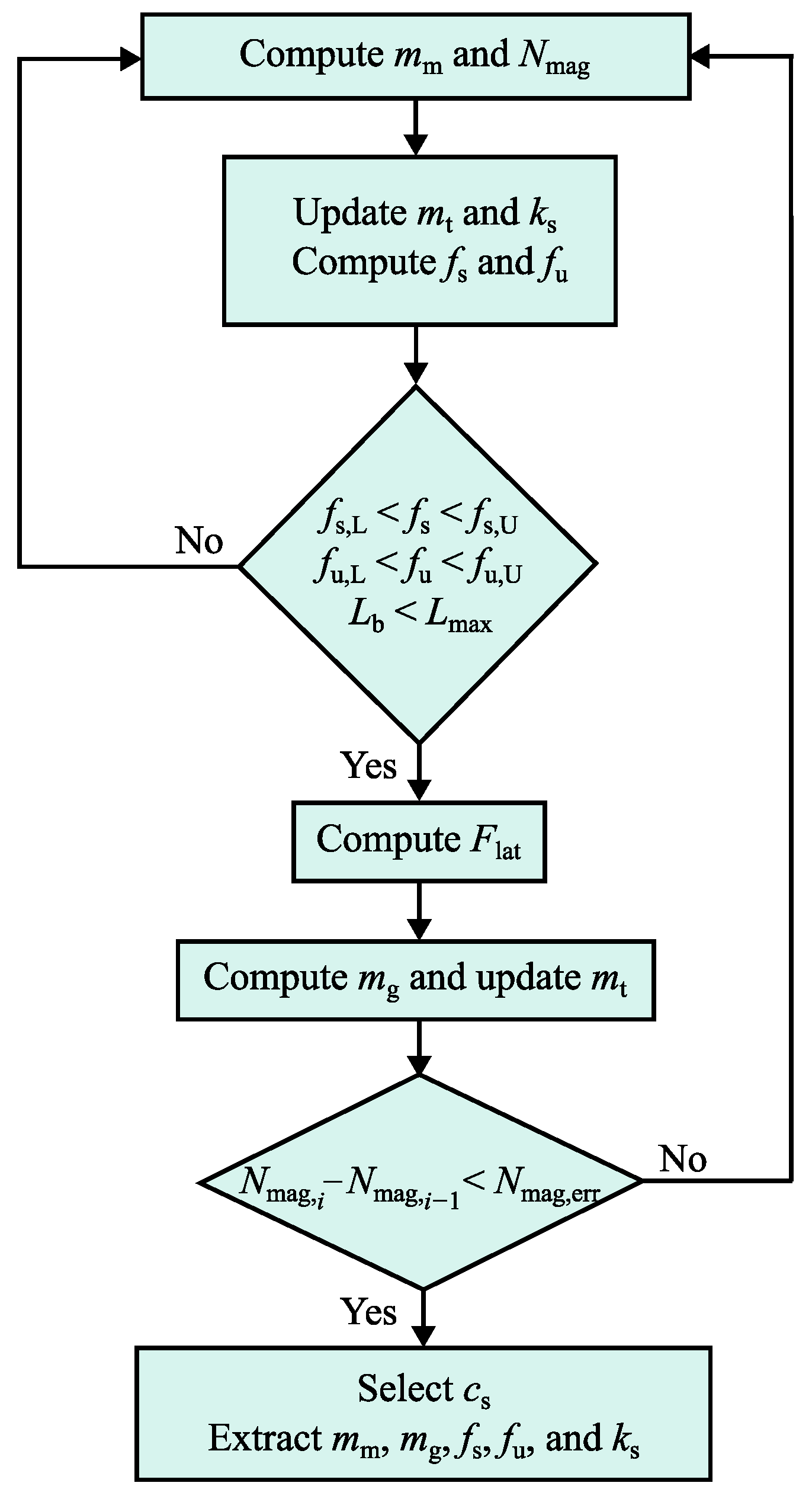

2.1. Multi-Objective Optimization

2.2. Losses and Magnetic Drag

2.3. System-Level Integration

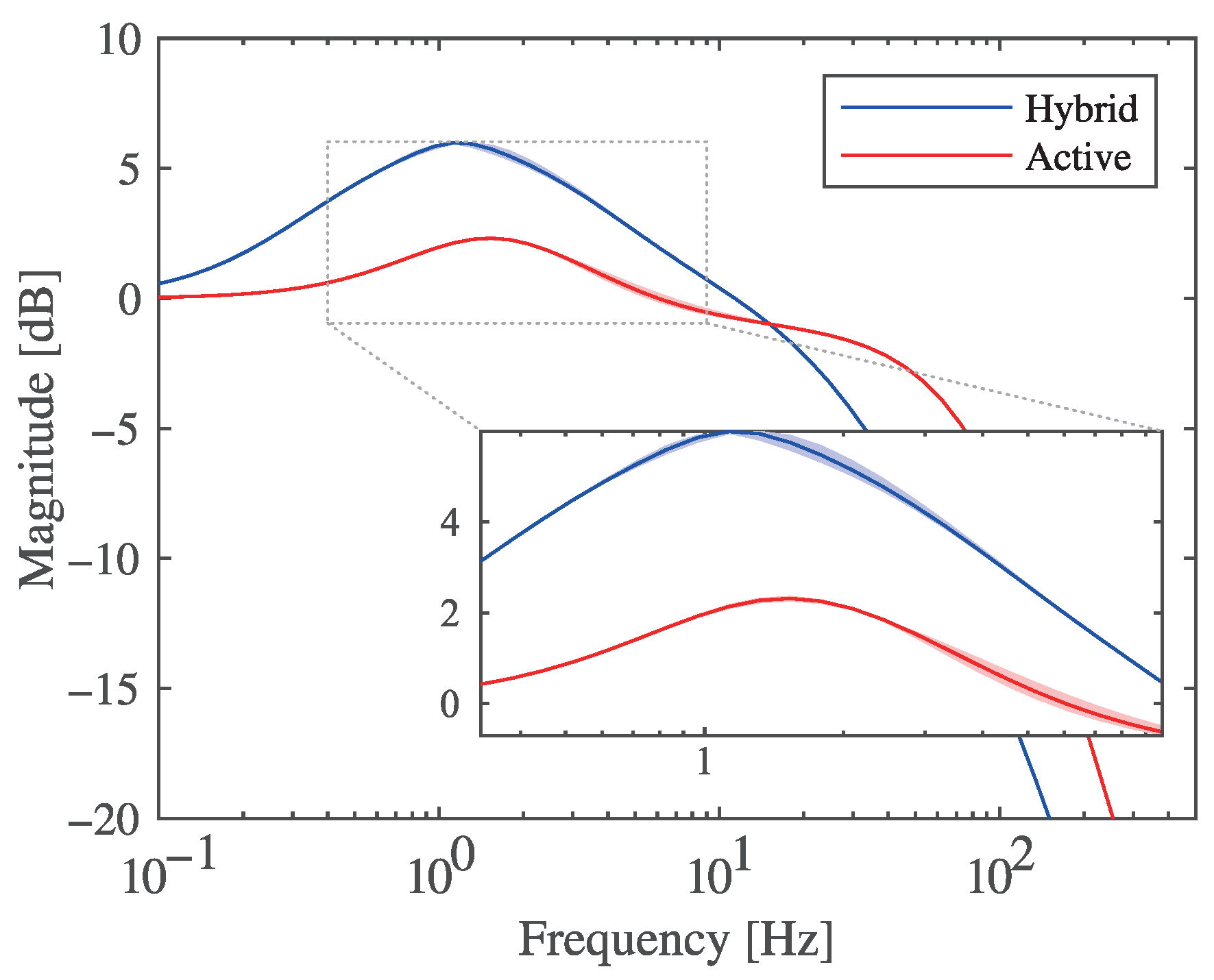

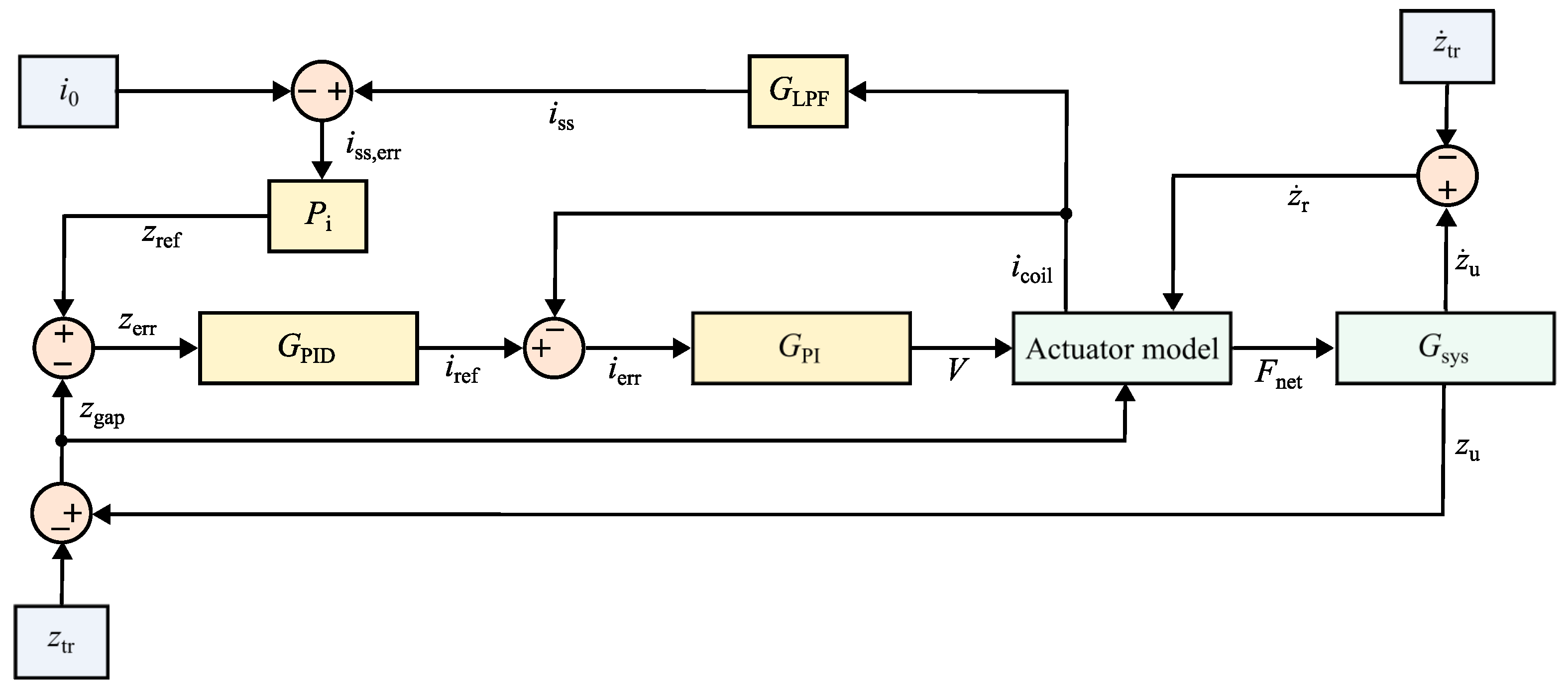

2.4. Control Strategy

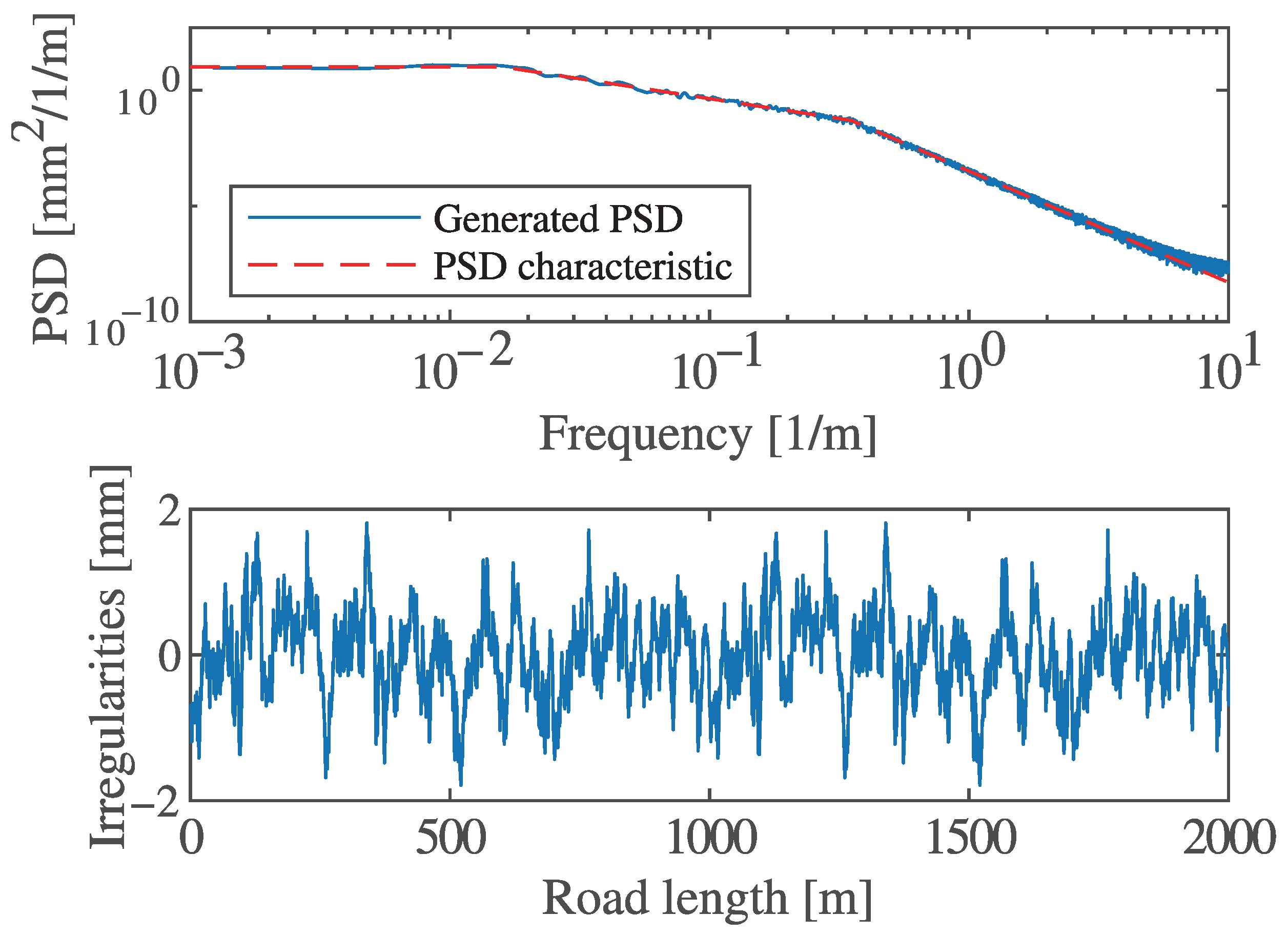

2.5. Track Irregularities

3. Numerical Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| E | End-winding |

| EDS | Electrodynamic suspension |

| EMF | Electromotive force |

| EMS | Electromagnetic suspension |

| FFT | Fast Fourier transform |

| LGE | Lateral guidance electromagnet |

| PM | Permanent magnet |

| PID | Proportional integral derivative |

| PSD | Power spectral density |

| RMS | Root-mean-square |

References

- Galluzzi, R.; Circosta, S.; Amati, N.; Tonoli, A.; Bonfitto, A.; Lembke, T.A.; Kertész, M. A Multi-domain Approach to the Stabilization of Electrodynamic Levitation Systems. J. Vib. Acoust. 2020, 142, 061004. [Google Scholar] [CrossRef]

- Tramacere, E.; Pakštys, M.; Galluzzi, R.; Amati, N.; Tonoli, A.; Lembke, T.A. Modeling and experimental validation of electrodynamic maglev systems. J. Sound Vib. 2024, 568, 117950. [Google Scholar] [CrossRef]

- Pakštys, M.; Delfarah, K.; Galluzzi, R.; Tramacere, E.; Amati, N.; Tonoli, A. Damping allocation and comfort-oriented suspension control for electrodynamic maglev systems. J. Sound Vib. 2025, 618, 119311. [Google Scholar] [CrossRef]

- Zhang, Z.; Shang, C.; She, L.; Chang, W.; Zhang, L. Structural optimal design of a permanent-electro magnetic suspension magnet for middle-low-speed maglev trains. IET Electr. Syst. Transp. 2011, 1, 61–68. [Google Scholar] [CrossRef]

- Zhao, C.; Oka, K.; Sun, F.; Harada, A.; Jin, J.; Zhang, M. Design of Zero-Power Control Strategy with Resisting Tilt of Hybrid Magnetic Levitation System. IEEE Trans. Ind. Electron. 2022, 69, 11394–11402. [Google Scholar] [CrossRef]

- Li, Y.; Dai, C.; Hu, R.; Li, X. Levitation control technology for high-speed maglev trains of PEM hybrid levitation. In Proceedings of the 2024 36th Chinese Control and Decision Conference (CCDC), Xi’an, China, 25–27 May 2024; pp. 5384–5389. [Google Scholar] [CrossRef]

- Afshar, K.K.; Javadi, A. Mass estimation and adaptive output feedback control of nonlinear electromagnetic levitation system. J. Sound Vib. 2021, 495, 115923. [Google Scholar] [CrossRef]

- Wang, M.; Hao, Z.; He, Y.; Zeng, S.; Qi, Z.; Liu, P. Active Disturbance Rejection Backstepping Cross-Coupling Controller Design for a Magnetic Levitation Vehicle Suspension Frame. IEEE Trans. Transp. Electrif. 2024, 11, 4634–4644. [Google Scholar] [CrossRef]

- Najafi, A.; Mobayen, S.; Rouhani, S.H.; Mokhtare, Z.; Jalilvand, A.; Fridman, L.; Su, C.L. Robust Adaptive Fault-Tolerant Control for MAGLEV Train Systems: A Non-Singular Finite-Time Approach. IEEE Trans. Transp. Electrif. 2024, 11, 3680–3690. [Google Scholar] [CrossRef]

- Ni, F.; Mu, S.; Kang, J.; Xu, J. Robust Controller Design for Maglev Suspension Systems Based on Improved Suspension Force Model. IEEE Trans. Transp. Electrif. 2021, 7, 1765–1779. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, H.; Zhang, T.; Yao, X.; Long, Z. Lazy Prescribed-Time Synchronization Control of Half Bogie for High-Speed Maglev Train Considering Track Irregularities and Input Constraints. IEEE Trans. Veh. Technol. 2022, 71, 6924–6937. [Google Scholar] [CrossRef]

- Lv, G.; Cui, L.; Zhi, R.; Zhang, Z. Characteristic Analysis of Improved Transverse Flux Linear Synchronous Motor Integrated Propulsion, Levitation and Guidance for Maglev Train. IEEE Trans. Veh. Technol. 2023, 72, 11428–11436. [Google Scholar] [CrossRef]

- Schiefer, P.; Kleikemper, O.; Holzapfel, F. Modeling of Coupled Electric and Magnetic Circuits in Electromagnetic Suspension Vehicles. IEEE Trans. Transp. Electrif. 2025, 11, 648–655. [Google Scholar] [CrossRef]

- Tudor, D.; Paolone, M. Optimal Design of the Propulsion System of a Hyperloop Capsule. IEEE Trans. Transp. Electrif. 2019, 5, 1406–1418. [Google Scholar] [CrossRef]

- Tudor, D.; Paolone, M. Operational-driven optimal-design of a hyperloop system. Transp. Eng. 2021, 5, 100079. [Google Scholar] [CrossRef]

- Lai, Q.; Liu, J.; Haghani, A.; Meng, L.; Wang, Y. Energy-efficient speed profile optimization for medium-speed maglev trains. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102007. [Google Scholar] [CrossRef]

- Zhai, D.; Lai, X.; Meng, J.; Liu, G.; Wu, J.; Xiao, S. The Hybrid Suspension System for Middle-to-Low-Speed Maglev Trains Considering the Prevention of Firm Absorption. IEEE Trans. Transp. Electrif. 2022, 8, 1482–1492. [Google Scholar] [CrossRef]

- Gao, T.; Yang, J.; Jia, L.; Deng, Y.; Zhang, W.; Zhang, Z. Design of New Energy-Efficient Permanent Magnetic Maglev Vehicle Suspension System. IEEE Access 2019, 7, 135917–135932. [Google Scholar] [CrossRef]

- Demicoli, J.; Kleikemper, O.; Steinhorst, S. Systematic Optimization of Electromagnet Hardware for Electromagnetic Suspension: A Fusion of Simulation and Multi-objective Optimization Techniques. IEEE Trans. Magn. 2024, 60, 1–5. [Google Scholar] [CrossRef]

- Tomczuk, B.; Wajnert, D. Field–circuit model of the radial active magnetic bearing system. Electr. Eng. 2018, 100, 2319–2328. [Google Scholar] [CrossRef]

- Wajnert, D.; Tomczuk, B. Two Models for Time-Domain Simulation of Hybrid Magnetic Bearing’s Characteristics. Sensors 2022, 22, 1567. [Google Scholar] [CrossRef]

- Li, X.; Palazzolo, A.; Wang, Z. A Combination 5-DOF Active Magnetic Bearing for Energy Storage Flywheels. IEEE Trans. Transp. Electrif. 2021, 7, 2344–2355. [Google Scholar] [CrossRef]

- Xu, S.; Sun, J.; Ren, H. An Active Magnetic Bearing With Controllable Permanent-Magnet Bias Field. IEEE/ASME Trans. Mechatronics 2022, 27, 3474–3481. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Li, A.; Xiang, Q. Multiphysics Fields Analysis and Optimization Design of a Novel Saucer-Shaped Magnetic Suspension Flywheel Battery. IEEE Trans. Transp. Electrif. 2024, 10, 5473–5483. [Google Scholar] [CrossRef]

- Chiba, A.; Fukao, T.; Ichikawa, O.; Oshima, M.; Takemoto, M.; Dorrell, D.G. Magnetic Bearings and Bearingless Drives; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Bertotti, G. Hysteresis in Magnetism; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Wang, J.; Jin, X.; Cao, Y.; Du, X. Numerical Simulation of High-Speed Maglev Vehicle-Guideway-Tunnel-Soil System. Int. J. Comput. Methods Eng. Sci. Mech. 2012, 13, 93–107. [Google Scholar] [CrossRef]

- Yang, P.; Sun, Y.; Luo, Y.; Ou, H. Stability Simulation and Analysis of Maglev Vehicle at Different Speed Based on UM. Mechatronics Intell. Transp. Syst. 2023, 2, 42–52. [Google Scholar] [CrossRef]

- Zhao, C.; Zhai, W. Maglev Vehicle/Guideway Vertical Random Response and Ride Quality. Veh. Syst. Dyn. 2002, 38, 185–210. [Google Scholar] [CrossRef]

- Rill, G. Road Vehicle Dynamics, 1st ed.; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar] [CrossRef]

- Aguilar-Zamorate, I.S.; Pakštys, M.; Galluzzi, R.; Ibarra, L.; Amati, N. Comparison of four liquid-cooling strategies for in-wheel motors. In Proceedings of the 2024 International Symposium on Electromobility (ISEM), Guadalajara, Mexico, 18–20 September 2024; pp. 1–7. [Google Scholar] [CrossRef]

| Operating Point | Gap [mm] | Current Density | |

|---|---|---|---|

| Hybrid | Active * | ||

| (extremum point 1) | 23 | 9 | 8 |

| (extremum point 2) | 17 | ||

| Dimension * | Symbol | Hybrid | Active | ||||

|---|---|---|---|---|---|---|---|

| Lower | Upper | Optimal | Lower | Upper | Optimal | ||

| Magnet height | 20 | 100 | 20 | 400 | |||

| Magnet/tooth width | 20 | 100 | 20 | 100 | |||

| Total coil width | 10 | 50 | 46 | 10 | 200 | ||

| Out-of-plane thickness | 10 | 300 | 10 | 300 | 147 | ||

| Back-iron height | 5 | 65 | 23 | 7 | 420 | ||

| Track height | 5 | 65 | 23 | 7 | 420 | ||

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Hysteresis loss coefficient | |||

| Eddy current loss coefficient | 2 | ||

| Anomalous loss coefficient | |||

| Hysteresis loss exponent | − | ||

| Number of harmonics | N | 10 | − |

| Number of strips | 100 | − |

| Parameter | Symbol | Value | Unit | |

|---|---|---|---|---|

| Hybrid | Active | |||

| Total number of magnets | 216 | 200 | − | |

| Levitation system mass | 1272 | 5578 | ||

| Guidance system mass | 1711 | 2631 | ||

| Capsule mass | 20 | 20 | ||

| Bogie mass | 5 | 5 | ||

| Capsule nat. freq. | 1 | |||

| Bogie nat. freq. | ||||

| Capsule nat. freq. lower bound | ||||

| Capsule nat. freq. upper bound | 2 | 2 | ||

| Bogie nat. freq. lower bound | 4 | 4 | ||

| Bogie nat. freq. upper bound | 15 | |||

| Secondary susp. stiffness | ||||

| Secondary susp. damping | 150 | 600 | ||

| Parameter | Symbol | Value | Unit | |

|---|---|---|---|---|

| Hybrid | Active | |||

| Proportional gain | P | |||

| Integral gain | I | 50 | 20 | |

| Derivative gain | D | 900 | 300 | |

| Closure pole factor | N | − | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tonoli, A.; Pakštys, M.; Galluzzi, R.; Amati, N.; Ouagued, S. Comparison Between Active and Hybrid Magnetic Levitation Systems for High-Speed Transportation. Appl. Sci. 2025, 15, 9793. https://doi.org/10.3390/app15179793

Tonoli A, Pakštys M, Galluzzi R, Amati N, Ouagued S. Comparison Between Active and Hybrid Magnetic Levitation Systems for High-Speed Transportation. Applied Sciences. 2025; 15(17):9793. https://doi.org/10.3390/app15179793

Chicago/Turabian StyleTonoli, Andrea, Marius Pakštys, Renato Galluzzi, Nicola Amati, and Sofiane Ouagued. 2025. "Comparison Between Active and Hybrid Magnetic Levitation Systems for High-Speed Transportation" Applied Sciences 15, no. 17: 9793. https://doi.org/10.3390/app15179793

APA StyleTonoli, A., Pakštys, M., Galluzzi, R., Amati, N., & Ouagued, S. (2025). Comparison Between Active and Hybrid Magnetic Levitation Systems for High-Speed Transportation. Applied Sciences, 15(17), 9793. https://doi.org/10.3390/app15179793