Study on Fatigue Damage Characteristics of Sandstone with Different Inclination Angles Under Freeze–Thaw Cycle Conditions

Abstract

1. Introduction

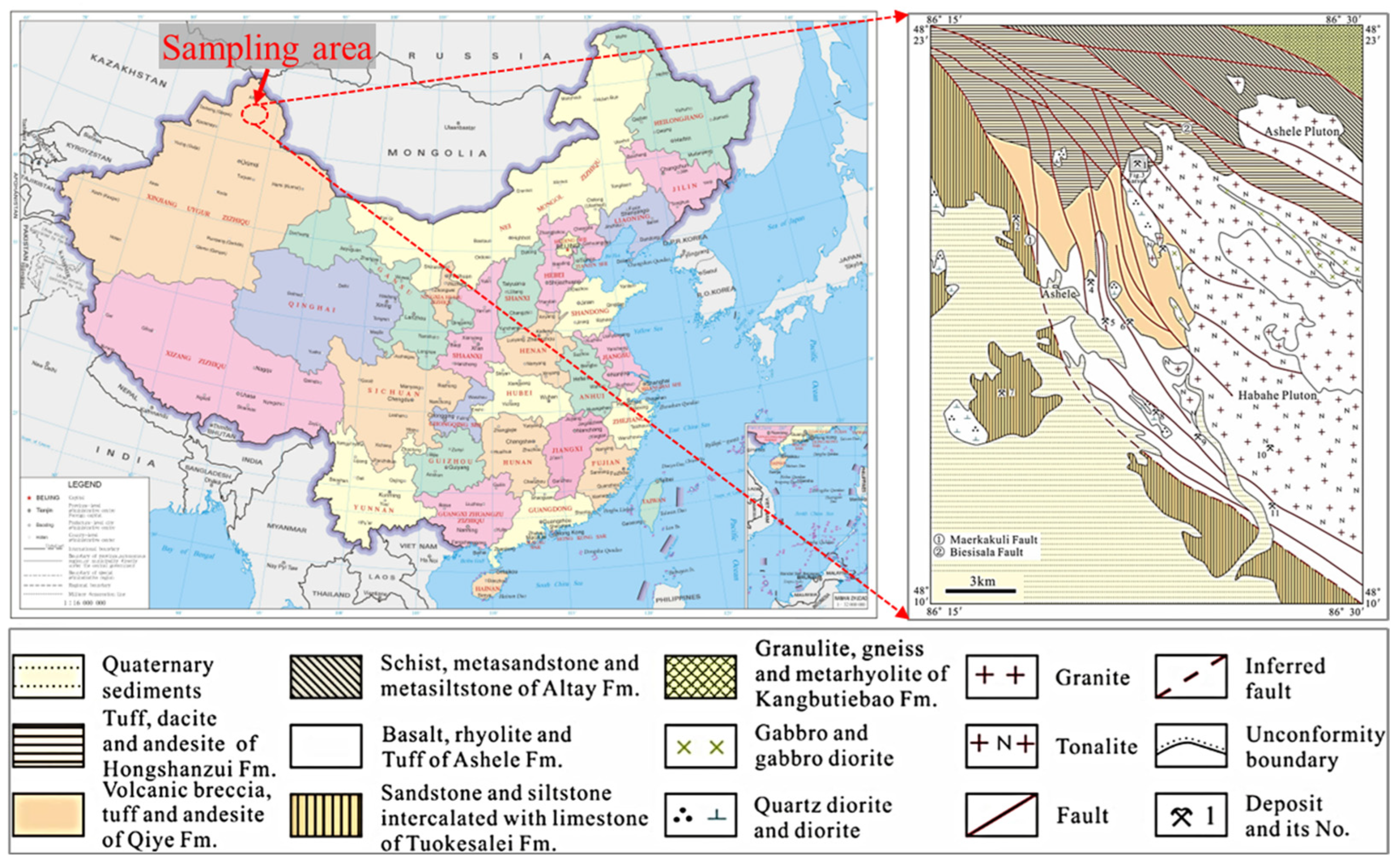

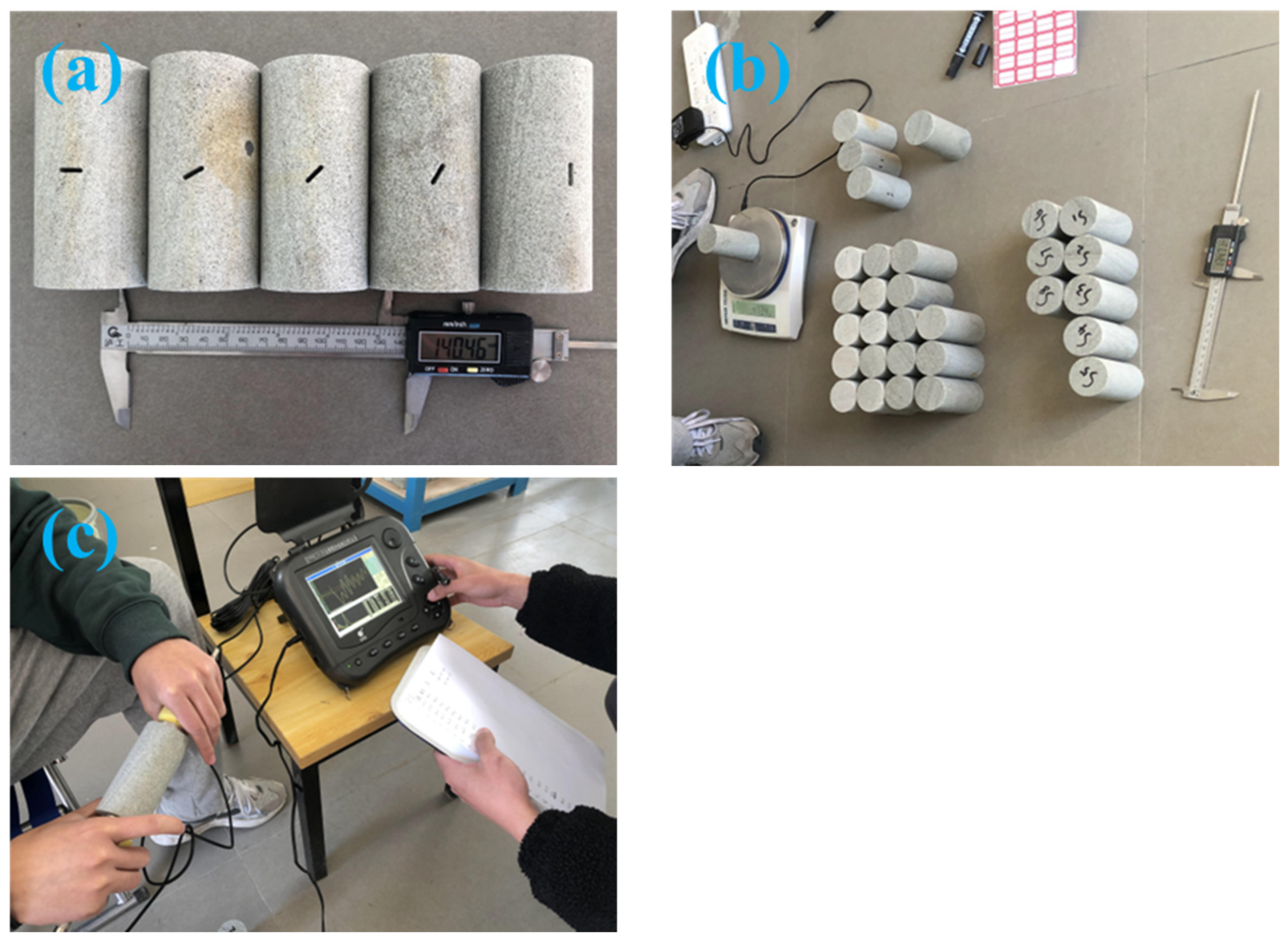

2. Materials and Methods

2.1. Sample Preparation and Processing

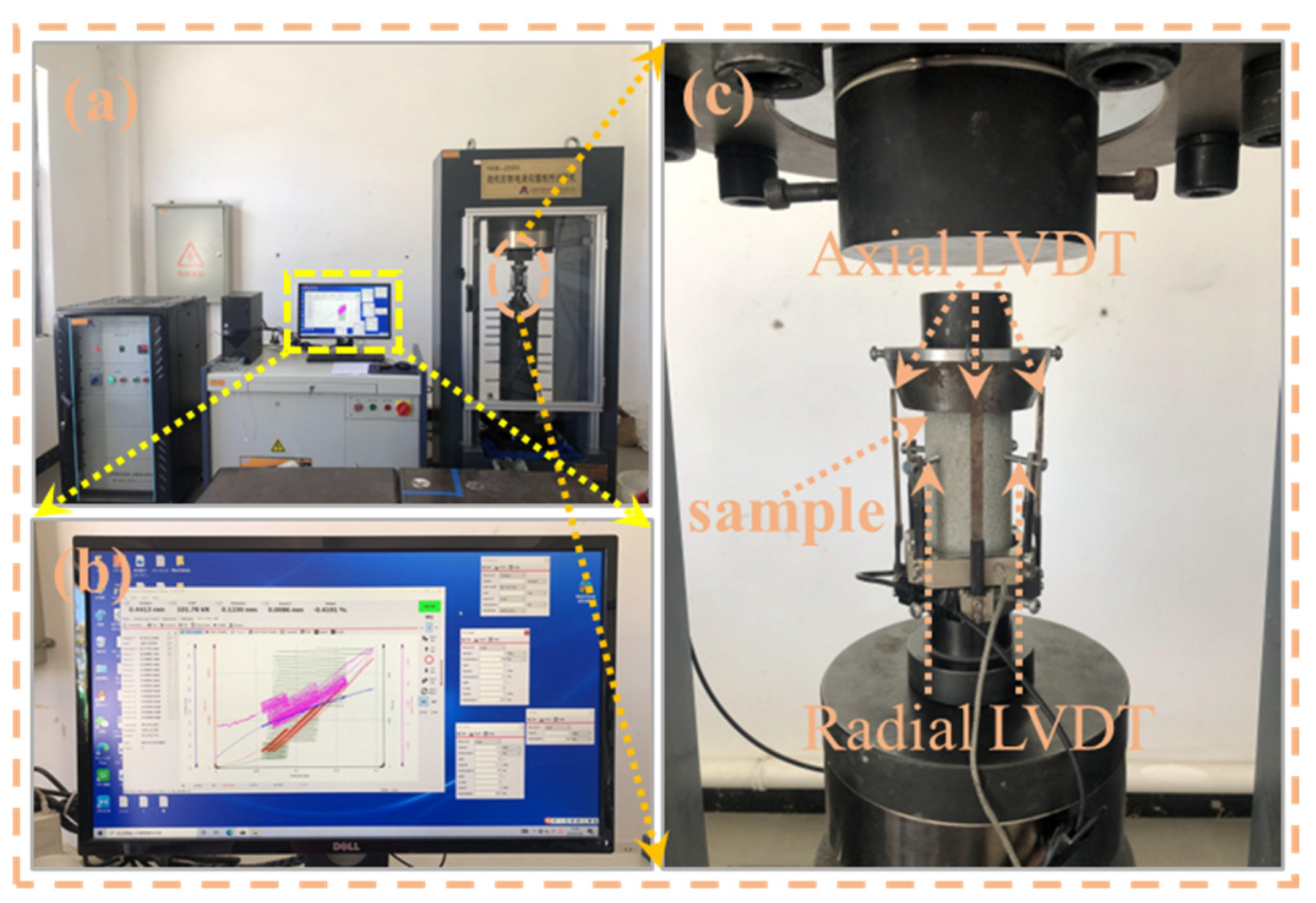

2.2. Testing Equipment

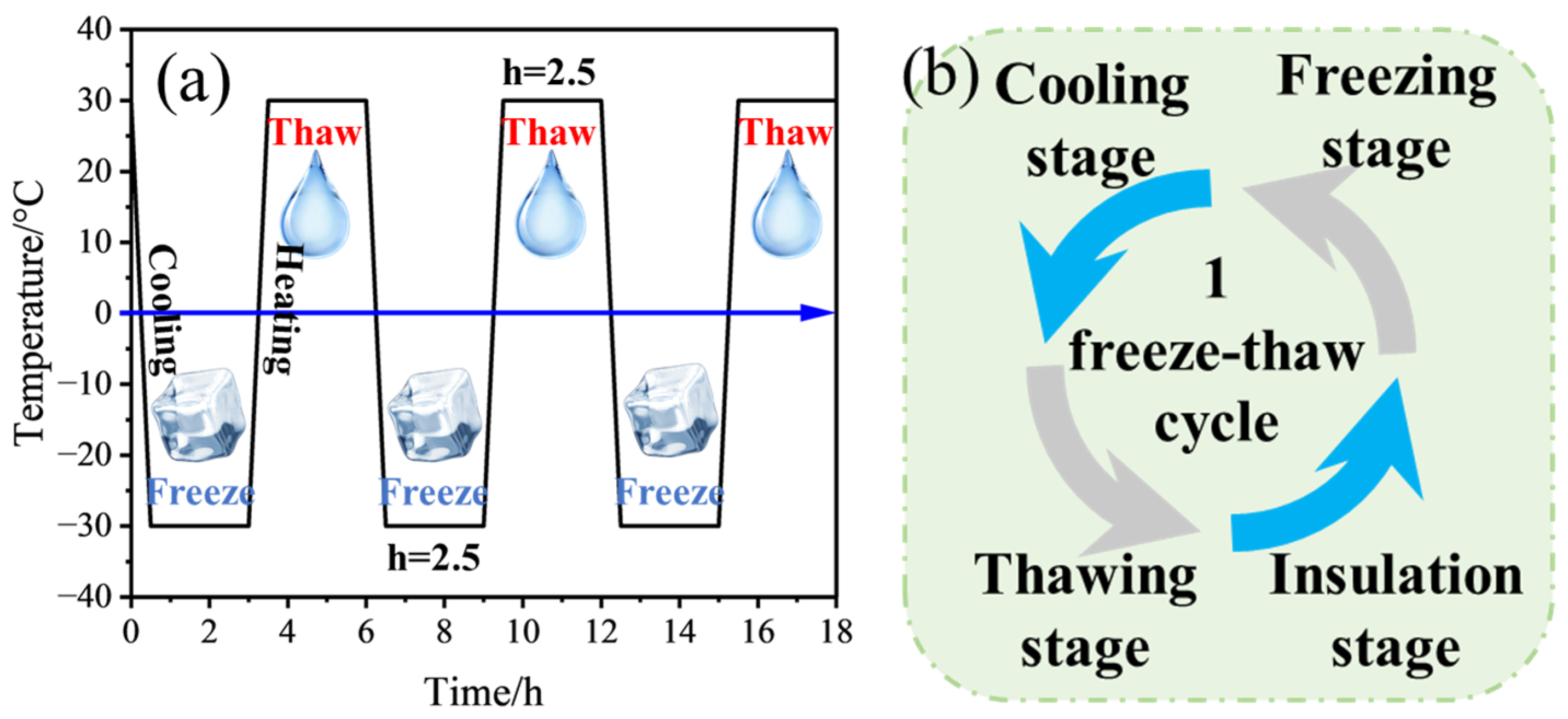

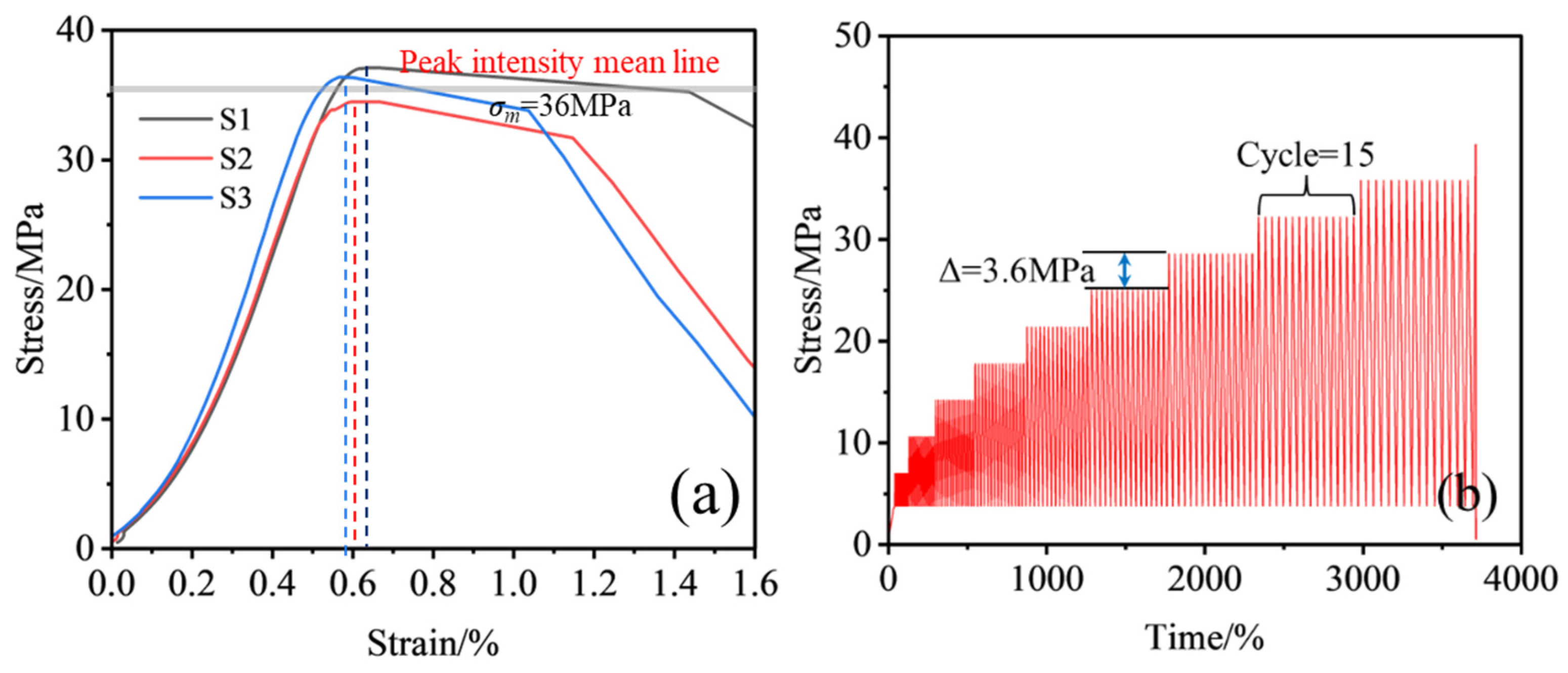

2.3. Testing Procedure

- (1)

- Freeze–Thaw Cycling Test

- (2)

- Mechanical Testing

3. Results and Analysis

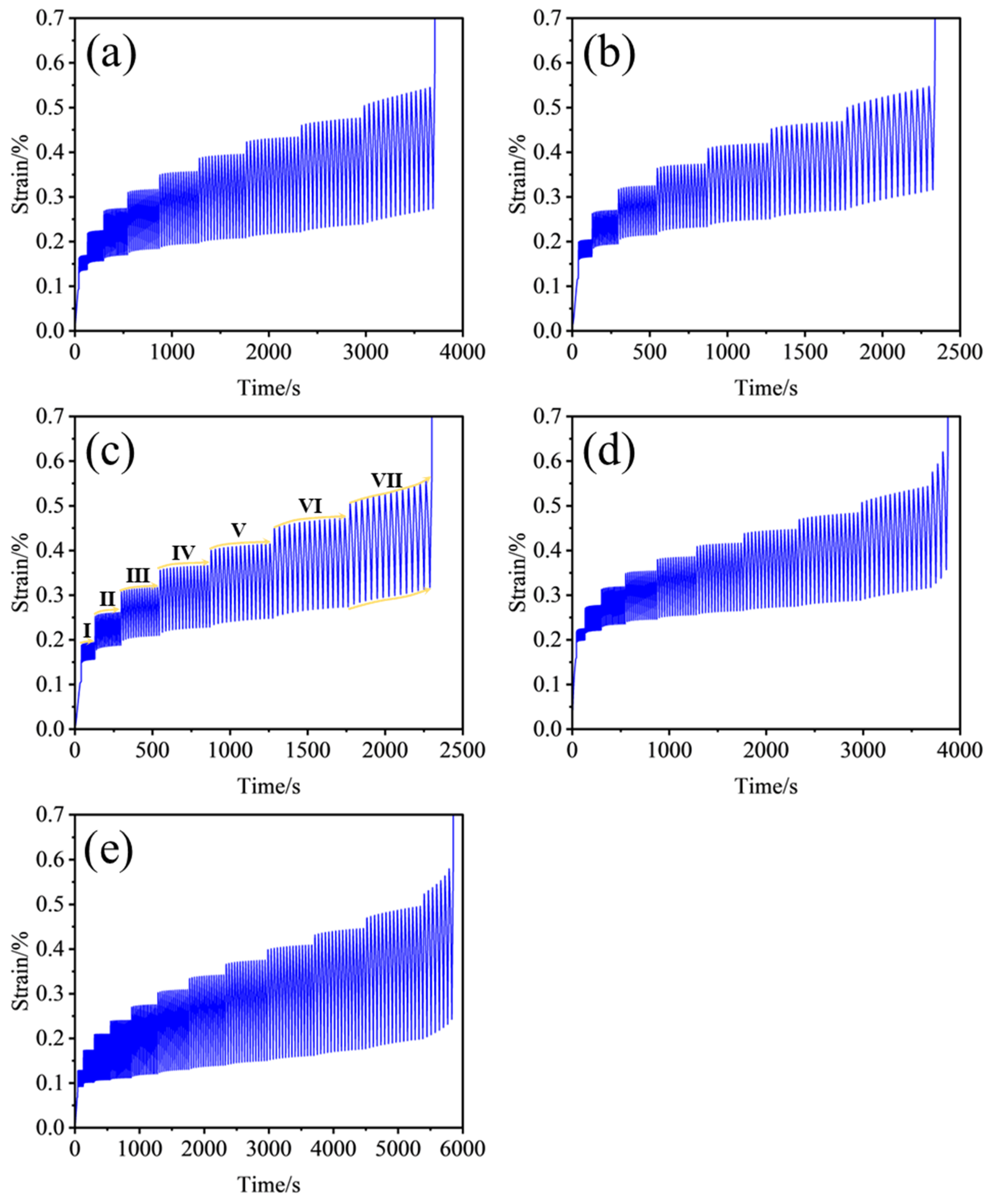

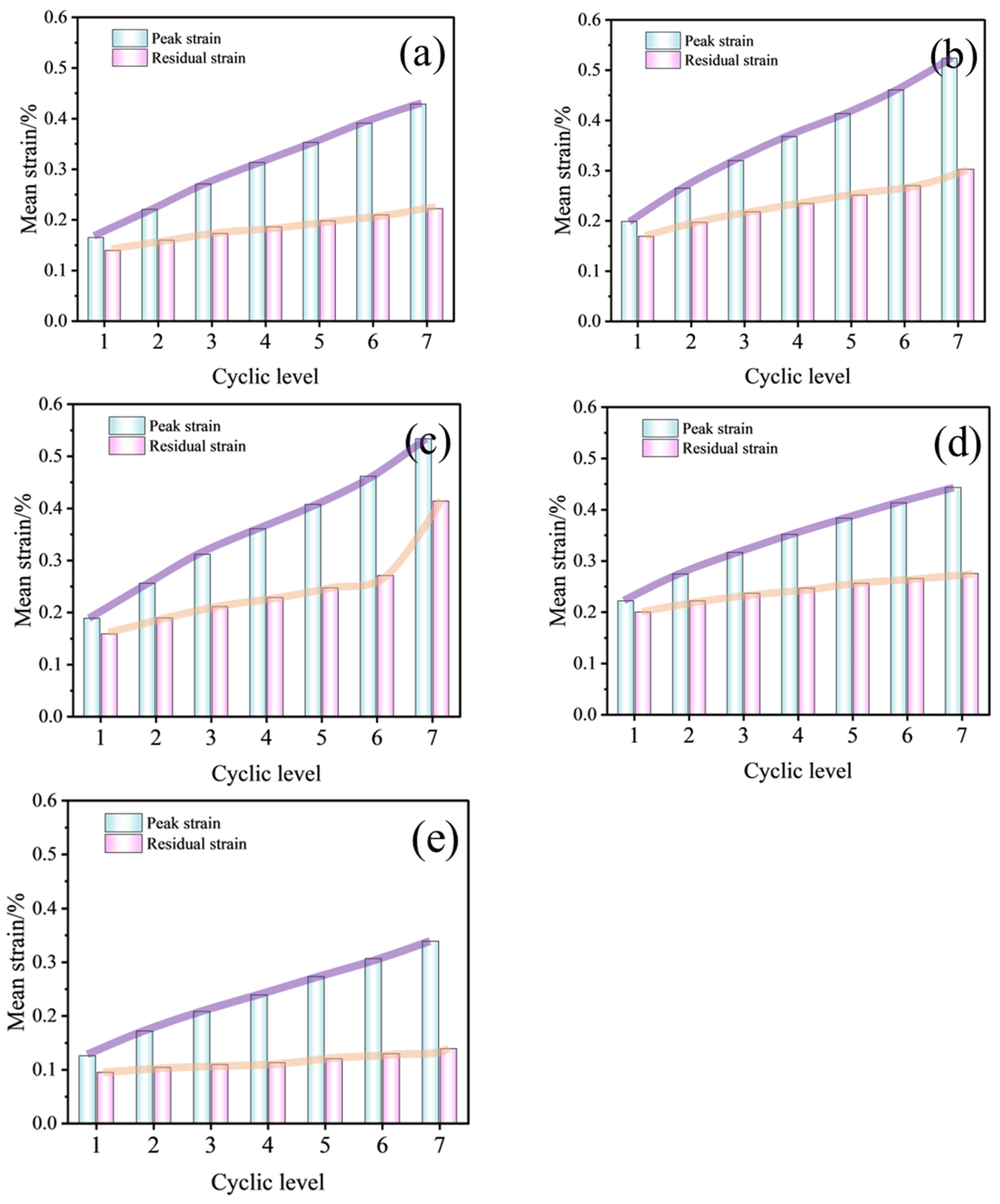

3.1. Deformation Characteristics

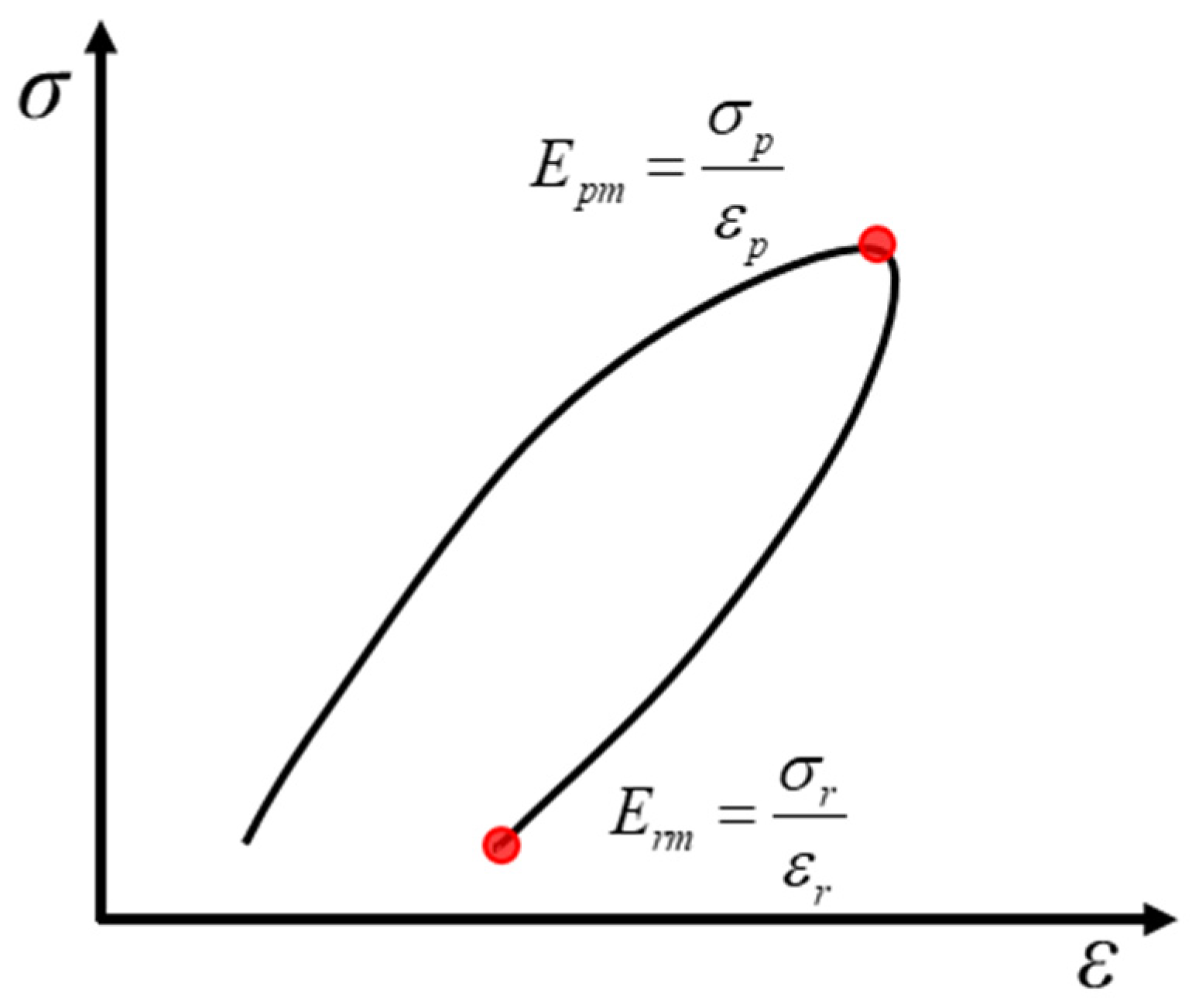

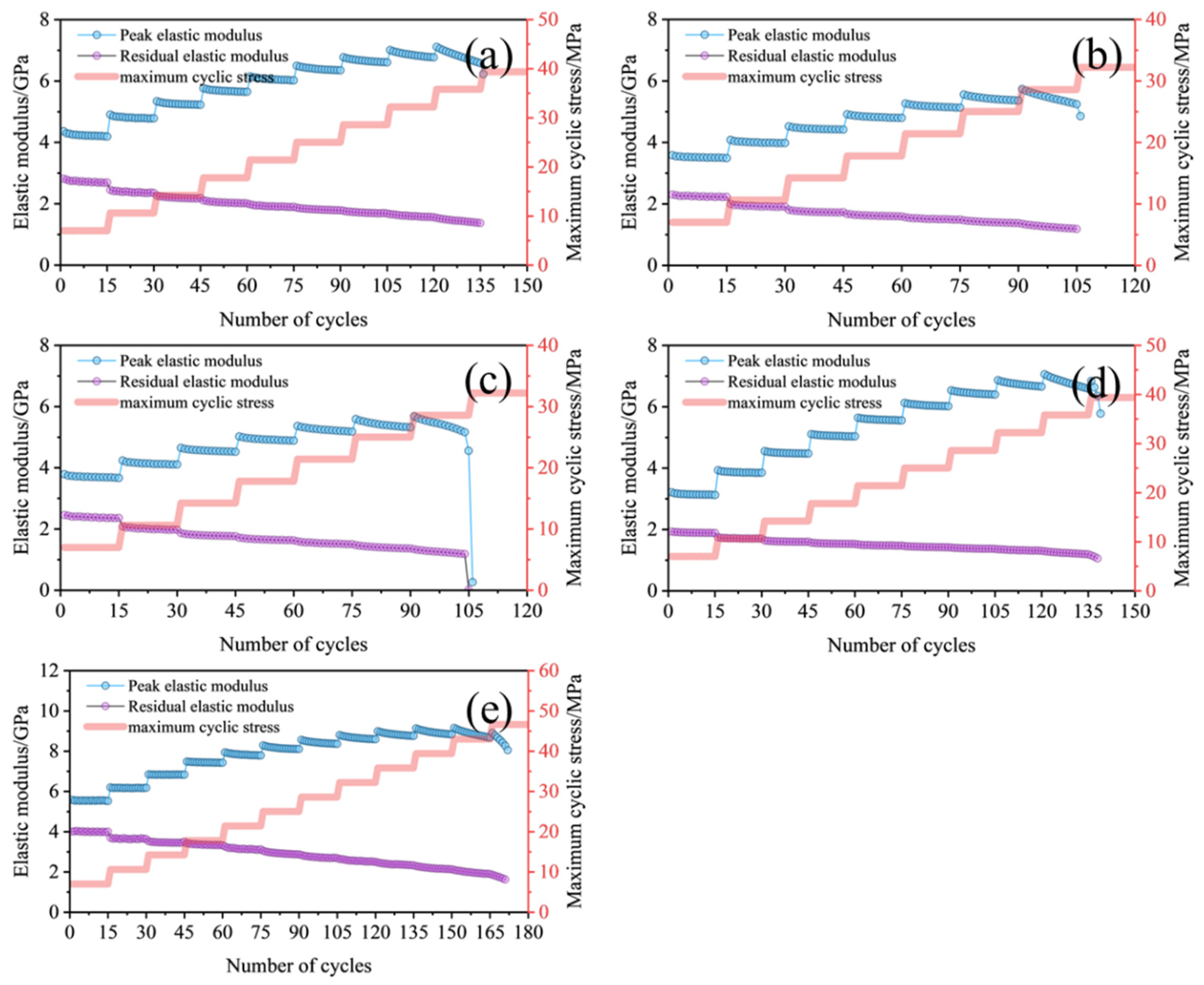

3.2. Stiffness Evolution

3.3. Poisson’s Ratio Evolution

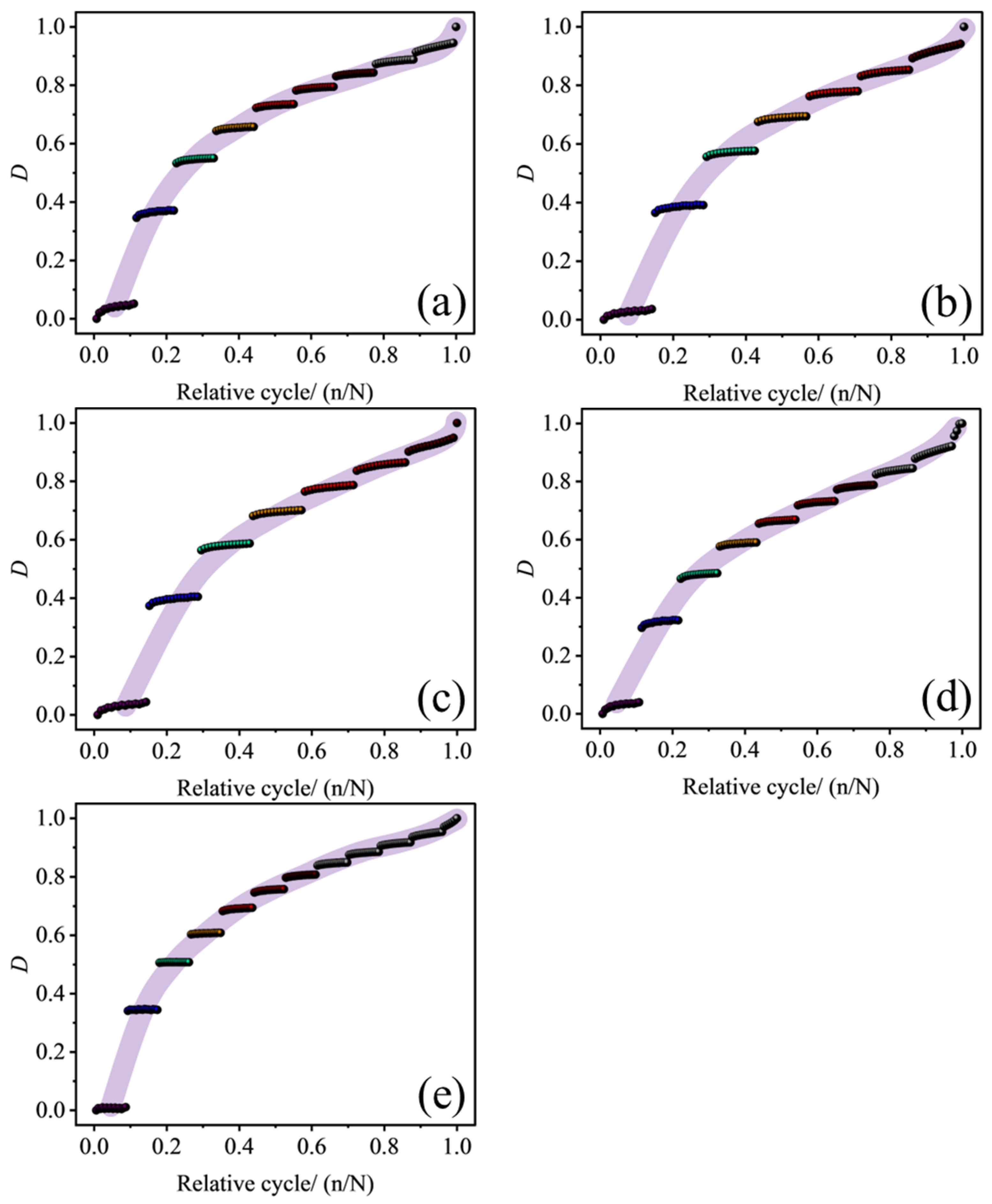

3.4. Damage Characteristics Analysis

4. Conclusions

- Under cyclic loading, sandstone strain exhibits a “staircase accumulation” pattern, with peak and residual strains increasing with cycle progression, the former showing larger increments. Samples with a 45° fracture inclination exhibit the fastest strain growth before failure, while those with a 90° inclination show the highest peak strength, indicating a significant influence of fracture inclination on deformation accumulation and load-bearing capacity.

- The peak elastic modulus shows “continuous intra-level decrease and inter-level initial increase followed by decrease” (initial increase due to compaction and later decrease due to damage dominance), while residual elastic modulus decreases throughout, with both showing a sharp drop near failure, reflecting rapid load-bearing capacity deterioration.

- Peak Poisson’s ratio decreases initially, transitions to logarithmic growth, and surges near failure. Residual Poisson’s ratio follows a similar trend, surpassing peak values in the final cycle level, reflecting dominant irreversible deformation, with fracture inclination showing minimal impact on evolution pace.

- Damage variable evolution follows an S-shaped three-stage pattern: rapid initial growth due to irreversible compaction deformation, stable middle-stage growth due to microcrack propagation, and approaching 1 in the final stage. Steep inclination samples initiate damage earlier and grow faster, while gentle inclinations show slower initial growth, indicating fracture inclination modulates evolution pace through compaction and shear damage proportions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Meng, X.; Yang, G. A study on mechanical properties and damage model of rock subjected to freeze-thaw cycles and confining pressure. Cold Reg. Sci. Technol. 2020, 174, 103056. [Google Scholar] [CrossRef]

- Ali, M.; Zubair, A.; Farooq, Z.; Farooq, K.; Masoud, Z. Prediction of small-strain elastic stiffness of natural and artificial soft rocks subjected to freeze-thaw cycles. J. Rock Mech. Geotech. Eng. 2025, 17, 3546–3562. [Google Scholar] [CrossRef]

- Yahaghi, J.; Liu, H.; Chan, A.; Fukuda, D. Experimental and numerical studies on failure behaviours of sandstones subject to freeze-thaw cycles. Transp. Geotech. 2021, 31, 100655. [Google Scholar] [CrossRef]

- Wang, X.; Mu, W.; Li, L.; Yang, T.; Bai, M.; Du, S. Study on freeze-thaw damage and mechanical properties of fractured rock mass grouting reinforcement in alpine region open-pit mines. Int. J. Rock Mech. Min. Sci. 2025, 192, 106143. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, H.; Gu, C.; Shao, C.; Jiang, Z.; Wang, Y.; Chen, X. Analysis of concrete damage evolution in cold regions under combined freeze-thaw cycle-crack effect. Constr. Build. Mater. 2024, 456, 139296. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Zhou, K.; Jiang, C.; Shen, Y.; Jia, H. Fracture mechanical properties of sandstone with pre-fabricated cracks under freeze–thaw cycles. Theor. Appl. Fract. Mech. 2024, 131, 104444. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y.; Du, R.; Zhao, X.; Wu, J. Macroscopic and microscopic mechanical characteristics and crack propagation behavior of sandstone-like samples with single cracks under freeze–thaw cycles: Experimental and numerical simulation. Theor. Appl. Fract. Mech. 2024, 129, 104201. [Google Scholar] [CrossRef]

- Zaimoğlu, A.Ş.; Kılıç, E.A.; Artuk, F. Analysis of the effect of rock salt on grout’s freeze-thaw strength with the Taguchi Method. Polar Sci. 2022, 34, 100899. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Sun, Y.; Jiang, J.; He, Z. A study of the frost heave damage mechanism and numerical simulation of earth-rock dam slope protection in cold regions under the combined effects of moisture migration and ice loads. Cold Reg. Sci. Technol. 2025, 104584. [Google Scholar] [CrossRef]

- Fu, X.; Zhao, G.; Wang, M.; Wang, J.; Xu, Y.; Gu, C. Comprehensive evaluation method for structural behavior of concrete dams in cold regions. Eng. Struct. 2023, 278, 115435. [Google Scholar] [CrossRef]

- Yu, Y.; Tang, L.; Ling, X.; Geng, L.; Wei, S.; Zhou, G. Investigation of the soil-lining interaction at a tunnel entrance during freeze-thaw cycling: Model testing and semi-empirical modeling. Tunn. Undergr. Space Technol. 2021, 115, 104028. [Google Scholar] [CrossRef]

- Jaiswal, A.; Sabri, M.S.; Verma, A.K.; Sardana, S.; Singh, T.N. Prediction of UCS and BTS under freeze-thaw conditions in the NW himalayan rock mass using petrographic analysis and laboratory testing. Quat. Sci. Adv. 2024, 15, 100225. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Cheng, Y.; Zhou, L. Experimental investigation on non-linear flow and convective heat transfer of damaged multi-fractured rock. Appl. Therm. Eng. 2025, 264, 125466. [Google Scholar] [CrossRef]

- Li, J.; Shi, Z.; Yuan, F.; Guo, B.; Wang, M.; Lin, H.; Han, D.; Li, K. Mechanical properties and fracture damage behavior of thermal storage rocks under constant amplitude low cycle fatigue loading. Eng. Fract. Mech. 2025, 321, 111069. [Google Scholar] [CrossRef]

- Yang, D.; Gao, S.; Feng, W.; Ding, S.; Li, J.; Jiao, H. Effect of prefabricated fractured rock dip angles on mechanical properties and failure modes under dynamic and static loads. Green Smart Min. Eng. 2025, 2, 184–195. [Google Scholar] [CrossRef]

- Yu, M.; Wang, Z.; Xu, Y.; Chang, Y.; Wang, L.; Zhu, Y. The failure behavior of prefabricated fractured sandstone with different rock bridge inclination angles under freeze-thaw cycles. Unconv. Resour. 2025, 6, 100152. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, S.; Wei, J.; Jiang, Z.; Hu, Q. Deformation characteristics and fracture damage model of freezing weakly cemented jointed rock masses. Comput. Geotech. 2025, 187, 107463. [Google Scholar] [CrossRef]

- Guler, S.; Akbulut, Z.F. A comprehensive review of concrete durability in freeze-thaw conditions: Mechanisms, prevention, and mitigation strategies. Structures 2025, 75, 108804. [Google Scholar] [CrossRef]

- Deng, Z.; Min, J.; Jin, J.; Liu, S.; Wei, J. The macro-meso damage model for jointed rock mass under the sequential effects of freeze–thaw cycles and compressive shear load. Comput. Geotech. 2024, 174, 106644. [Google Scholar] [CrossRef]

- Che, Y.; Song, Y.; Yang, H.; Guo, X. Creep properties and model of fractured sandstone under freezing environment. Geomech. Energy Environ. 2024, 38, 100554. [Google Scholar] [CrossRef]

- He, J.; Niu, F.; Luo, F.; Jiang, H.; He, P.; Ju, X. Mechanical properties and modified binary–medium constitutive model for red–bed soft rock subjected to freeze–thaw cycles. Cold Reg. Sci. Technol. 2023, 209, 103803. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, L.; Song, Y.; Tan, Y. Experimental study on the mechanical properties of grouted rock bolts subjected to sulfate attack and freeze-thaw cycling. Constr. Build. Mater. 2021, 291, 123391. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Q.; Yang, T.; Chen, Y.; Zhang, P.; Liu, H. Investigation of crack propagation and acoustic emission characteristics in jointed rock under freeze–thaw cycles based on DEM. Int. J. Min. Sci. Technol. 2025, 35, 1171–1195. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Mu, W.; Yang, T.; Du, Y.; Lu, J. Damage characteristics and mechanisms of shear strength at the interface between fiber-reinforced concrete and rock under freeze-thaw cycles. J. Build. Eng. 2024, 98, 111191. [Google Scholar] [CrossRef]

- He, K.; Wang, Q.; Liu, J.; Zhang, D.; Huang, Z.; Fang, J.; Luo, D. Study on the Deterioration Mechanisms of Basalt with Fractures Under Freeze-Thaw Cycling. Res. Cold Arid. Reg. 2025, 84, 222. [Google Scholar] [CrossRef]

- Lei, B.; Yu, L.; Chen, T.; Lv, Z.; Zaland, S.; Tang, Z. Experimental study on the initial damage and mechanical property evolution of recycled coarse aggregates under freeze–thaw cycles and repeated loads. Constr. Build. Mater. 2023, 375, 130972. [Google Scholar] [CrossRef]

- Zhang, F.; Yin, W.; Zhang, K.; Jiang, H. Study on shear creep test and nonlinear model of granite structural plane under coupled freeze-thaw cycle and chemical corrosion. Int. J. Non-Linear Mech. 2025, 170, 105012. [Google Scholar] [CrossRef]

- Xu, Y.; Yue, T.; Wu, B.; Wang, Q.; Cheng, C.; Xu, Z. Dynamic tensile properties of sandstone under coupling effects of water chemical corrosion and freeze-thaw cycles at sub-zero temperatures. Constr. Build. Mater. 2025, 458, 139734. [Google Scholar] [CrossRef]

- Xuan, Z.; Sun, Z.; Wang, J.; Sun, W.; Liang, B.; Ma, Z. Pore structure evolution and damage creep model of shale subjected to freeze-thaw treatment. J. Mater. Res. Technol. 2022, 19, 821–836. [Google Scholar] [CrossRef]

- Mitchell, A.; Sass, O. Rock weathering: The effects of varying rock moisture on controlled weathering cycles in low porosity limestone. Geomorphology 2024, 457, 109149. [Google Scholar] [CrossRef]

- Kongandembou, M.L.; Yu, Q. Blockiness and hydraulic conductivity of rocks with different fracture geometries. J. Hydrol. 2025, 661, 133700. [Google Scholar] [CrossRef]

- Ajami, M.; Asgari, K.; Kadkhodaie, A. Analysis of the correlation between fracture topology and mechanical properties of rocks in fractured carbonate reservoirs: In Dehram group, Fars arc Zone (Southwest Iran). Mar. Pet. Geol. 2025, 177, 107368. [Google Scholar] [CrossRef]

- Su, Q.; Qian, H. Dynamic mechanical properties and failure mechanisms of rock-like materials containing main and auxiliary holes with various arrangement inclinations and spacing ratios. Theor. Appl. Fract. Mech. 2024, 131, 104456. [Google Scholar] [CrossRef]

- Hu, C.; Li, X.; Wu, Y.; Meng, B.; Jia, B. Experimental and numerical investigation on mechanical and fracture characteristics of jointed rock with varying roughness. J. Saf. Sustain. 2025, 2, 59–71. [Google Scholar] [CrossRef]

- Xue, F.; Zhou, X.; Wang, X.; Wu, J.; Lin, Z.; Zhou, S. Experimental investigation of lithology-dependent response to loading rate in rock fracture: From microcracking mechanisms to macroscopic fracture characteristics. Theor. Appl. Fract. Mech. 2025, 139, 105088. [Google Scholar] [CrossRef]

- Guo, T.; Liu, K.; Wang, H.; Si, X.; Rui, Y.; Pu, C.; Zhang, Y.; Yuan, C. Mechanical characteristics and fracturing behavior of rock-concrete composite specimens with two pre-existing parallel flaws under uniaxial compression based on AE and DIC systems. Theor. Appl. Fract. Mech. 2025, 136, 104866. [Google Scholar] [CrossRef]

- Li, Z.; Hu, F.; Qi, S.; Hu, R. Strain-softening failure mode after the post-peak as a unique mechanism of ruptures in a frozen soil-rock mixture. Eng. Geol. 2020, 274, 105725. [Google Scholar] [CrossRef]

- Liu, M.; Ma, W.; Niu, F.; Luo, J.; Yin, G. Thermal performance of a novel crushed-rock embankment structure for expressway in permafrost regions. Int. J. Heat Mass Transf. 2018, 127, 1178–1188. [Google Scholar] [CrossRef]

- Yu, M.; Wang, Z.; Xu, Y.; Wang, Y.; Wang, L.; Wen, J. Study on mechanical properties and energy evolution characteristics of excavation unloading rock under freeze–thaw temperature range. Eng. Fract. Mech. 2025, 325, 111293. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Shi, X.; Liu, Q.; Xiong, T. Microstructure, seepage regimes and stress-strain analysis of bedded rock salt interface. J. Energy Storage 2025, 120, 116521. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, W.; Tang, X.; Xing, M.; Zhang, Y.; Zhu, Y. Test study on failure and energy supply characteristics of rock under different loading stiffness. Eng. Fail. Anal. 2022, 142, 106796. [Google Scholar] [CrossRef]

- Li, K.; Li, Y.; Yin, F.; Dai, F.; Wang, C.; Zhang, S.; Wang, K. Mechanical properties and failure mechanism of rock-like specimens with arc-shaped flaws under freeze–thaw cycles. Theor. Appl. Fract. Mech. 2024, 130, 104275. [Google Scholar] [CrossRef]

- Chang, K.W.; Ross, T.S.A. Cyclic loading–unloading impacts on geomechanical stability of multiple salt caverns for underground hydrogen storage. Int. J. Hydrogen Energy 2025, 102, 767–777. [Google Scholar] [CrossRef]

- Yu, X.; Tan, Y.; Song, W.; Kemeny, J.; Qi, S.; Zheng, B.; Guo, S. Damage evolution of rock-encased-backfill structure under stepwise cyclic triaxial loading. J. Rock Mech. Geotech. Eng. 2024, 16, 597–615. [Google Scholar] [CrossRef]

- Kallimogiannis, V.; Saroglou, C. Mechanical properties of carbonate fault rocks. Int. J. Rock Mech. Min. Sci. 2024, 176, 105681. [Google Scholar] [CrossRef]

- Liu, X.; Li, P.; Guo, X.; Luo, X.; Zhou, X.; Miao, L.; Zhou, F.; Wang, H. A statistical damage-based constitutive model for shearing of rock joints in brittle drop mode. Int. J. Min. Sci. Technol. 2024, 34, 1041–1058. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Xia, Y.; Li, P.; Cai, M. The Effect of Cyclic Disturbed Frequency on Mechanical, Acoustic Emission and Crack Pattern for Rock–Backfill Composites Exposed to Fatigue Loading Condition. Rock Mech. Rock Eng. 2025, 58, 7041–7066. [Google Scholar] [CrossRef]

| No. | Mass [g] | High [mm] | Diameter [mm] | Density [g/m3] | Axial Longitudinal Wave Velocity [m/s] | Radial Longitudinal Wave Velocity [m/s] |

|---|---|---|---|---|---|---|

| S1 | 475.2 | 100.42 | 49.53 | 2.46 | 2632 | 2155 |

| S2 | 474.4 | 100.25 | 49.63 | 2.45 | 2737 | 2232 |

| S3 | 474.4 | 100.41 | 49.61 | 2.44 | 2670 | 2232 |

| S4 | 475.6 | 99.74 | 50.76 | 2.36 | 2078 | 1786 |

| S5 | 480.8 | 100.26 | 50.59 | 2.39 | 2150 | 1866 |

| S6 | 475.4 | 99.61 | 50.66 | 2.37 | 2260 | 2049 |

| S7 | 483.6 | 100.18 | 50.57 | 2.40 | 2282 | 1894 |

| S8 | 479.8 | 50.66 | 100.13 | 2.38 | 2315 | 2083 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Bi, J.; Wu, Y.; Wu, Y.; Wang, M. Study on Fatigue Damage Characteristics of Sandstone with Different Inclination Angles Under Freeze–Thaw Cycle Conditions. Appl. Sci. 2025, 15, 9757. https://doi.org/10.3390/app15179757

Zhou X, Bi J, Wu Y, Wu Y, Wang M. Study on Fatigue Damage Characteristics of Sandstone with Different Inclination Angles Under Freeze–Thaw Cycle Conditions. Applied Sciences. 2025; 15(17):9757. https://doi.org/10.3390/app15179757

Chicago/Turabian StyleZhou, Xiaolong, Jiancheng Bi, Yaning Wu, Yunfeng Wu, and Meinan Wang. 2025. "Study on Fatigue Damage Characteristics of Sandstone with Different Inclination Angles Under Freeze–Thaw Cycle Conditions" Applied Sciences 15, no. 17: 9757. https://doi.org/10.3390/app15179757

APA StyleZhou, X., Bi, J., Wu, Y., Wu, Y., & Wang, M. (2025). Study on Fatigue Damage Characteristics of Sandstone with Different Inclination Angles Under Freeze–Thaw Cycle Conditions. Applied Sciences, 15(17), 9757. https://doi.org/10.3390/app15179757