1. Introduction

Solenoid valves are widely used in automated control systems, with their primary function being to automatically regulate fluid flow, including controlling the opening and closing of fluid flow and switching the direction of fluid flow [

1]. Currently, there is a high demand for solenoid valve products, with primary application areas including nuclear energy, chemical engineering, aerospace, power generation, and professional high-end control systems [

2,

3]. Additionally, solenoid valves are increasingly being recognized in fields requiring ultra-high-pressure fluid control, such as hydrogen fuel cell vehicles and hydrogen refuelling stations [

4]. Generally speaking, solenoid valves with an operating pressure above 21 MPa are considered ultra-high-pressure solenoid valves [

5]. Hard sealing, also known as metal-to-metal sealing technology, involves two metal surfaces coming into direct contact to create a seal. Although they cost more, hard seals have better sealing performance and service life than soft seals. Hard seal valves made of metal with high temperature, high pressure, and strong corrosion resistance are widely used in nuclear power systems in a variety of circuits, pipelines, and thermal equipment to ensure system safety and normal operation [

6]. However, the sealing performance of hard-seal valves depends heavily on the sealing specific pressure. A sealing specific pressure that is too large will damage the sealing surface, and a sealing specific pressure that is too small will cause media leakage [

7]. In valve design, the formula for sealing specific pressure serves as a key reference in determining an appropriate seal pressure; it primarily considers two factors, the fluid pressure and the width of the sealing surface. Although some researchers have explored the relationship between sealing pressure and its influencing factors, most of these studies have focused on analyzing the sealing performance of fixed ball valves [

8,

9], floating ball valves [

10], the structural optimization of fixed ball valves [

11], and valves with non-planar sealing structures, such as butterfly valves [

12].

Solenoid valves are typically required to function in extreme temperature conditions. For example, ultra-high-pressure solenoid valves must operate within a temperature range of −55 °C to 70 °C in nitrogen injection technology [

5]. In the propulsion systems of small and micro satellites and spacecraft, miniature solenoid valves developed by the Beijing Control Engineering Research Institute are designed to perform within temperatures ranging from −20 °C to 60 °C [

13]. Similarly, miniature solenoid valves developed by Moog are engineered to operate in temperature ranges from −60 °C to 50 °C [

14]. In high-end control systems, the sealing performance of solenoid valves is of paramount importance. Given the precision and reliability these systems demand, the effectiveness of the valve sealing directly influences system stability and safety. Temperature fluctuations are a significant factor affecting sealing performance since materials have different coefficients of thermal expansion. When the temperature fluctuates, gaps may form between the seal and the valve body, resulting in leakage.

Venkata Sunil Sai N. et al. investigated the impact of solenoid valve selection on the performance of an orbital experimental module (OEM) cold gas thruster and analyzed whether the design contact seat stress of solenoid valves was adequate to achieve hermetic sealing. This would ensure that soft and hard seals were hermetically sealed at lower temperatures [

15]. Peng Gao et al. investigated the leakage of a tiny seal in a high-pressure hydrogen valve at extreme ambient temperatures and analyzed the distribution of hydrogen leakage in seals with damage gaps of different shapes. The average velocity of the gap inlet and outlet under extreme high-temperature conditions was found to be 21.6% higher than under extreme low-temperature conditions [

16]. Jaeseong Choi et al. proposed a concave contact geometry based on Hertzian contact theory, which enhances the sealing and structural integrity of ultra-high-pressure hydrogen solenoid valves [

17]. Currently, relatively few studies have examined the sealing performance of ultra-high-pressure solenoid valves, particularly in low-temperature environments. Therefore, studying the sealing performance of ultra-high-pressure solenoid valves in such environments is critical. This paper investigates the sealing performance of the hard seal formed between the valve seat and the sealing tube of an ultra-high-pressure solenoid valve. Through theoretical and simulation analysis, it identifies the causes of leakage in ultra-high-pressure solenoid valves at −40 °C. The sealing performance of ultra-high-pressure solenoid valves is improved by appropriately increasing the tightening torque and using sealing adhesive. The remaining part is structured as follows:

Section 2 is based on an ultra-high-pressure solenoid valve sealing model and uses theoretical analysis to reveal the reasons for sealing leakage.

Section 3 uses finite element simulation analysis to explore the dynamic change mechanism of sealing surface contact pressure with temperature decrease.

Section 4 uses a leakage test and optimization of a low-temperature comparison to verify the theoretical analysis and simulation results.

Section 5 builds on the analysis by combining the simulation data with the experimental results, and it draws conclusions.

2. Ultra-High-Pressure Solenoid Valve Sealing Model and Theoretical Analysis

2.1. Ultra-High-Pressure Solenoid Valve Sealing Model

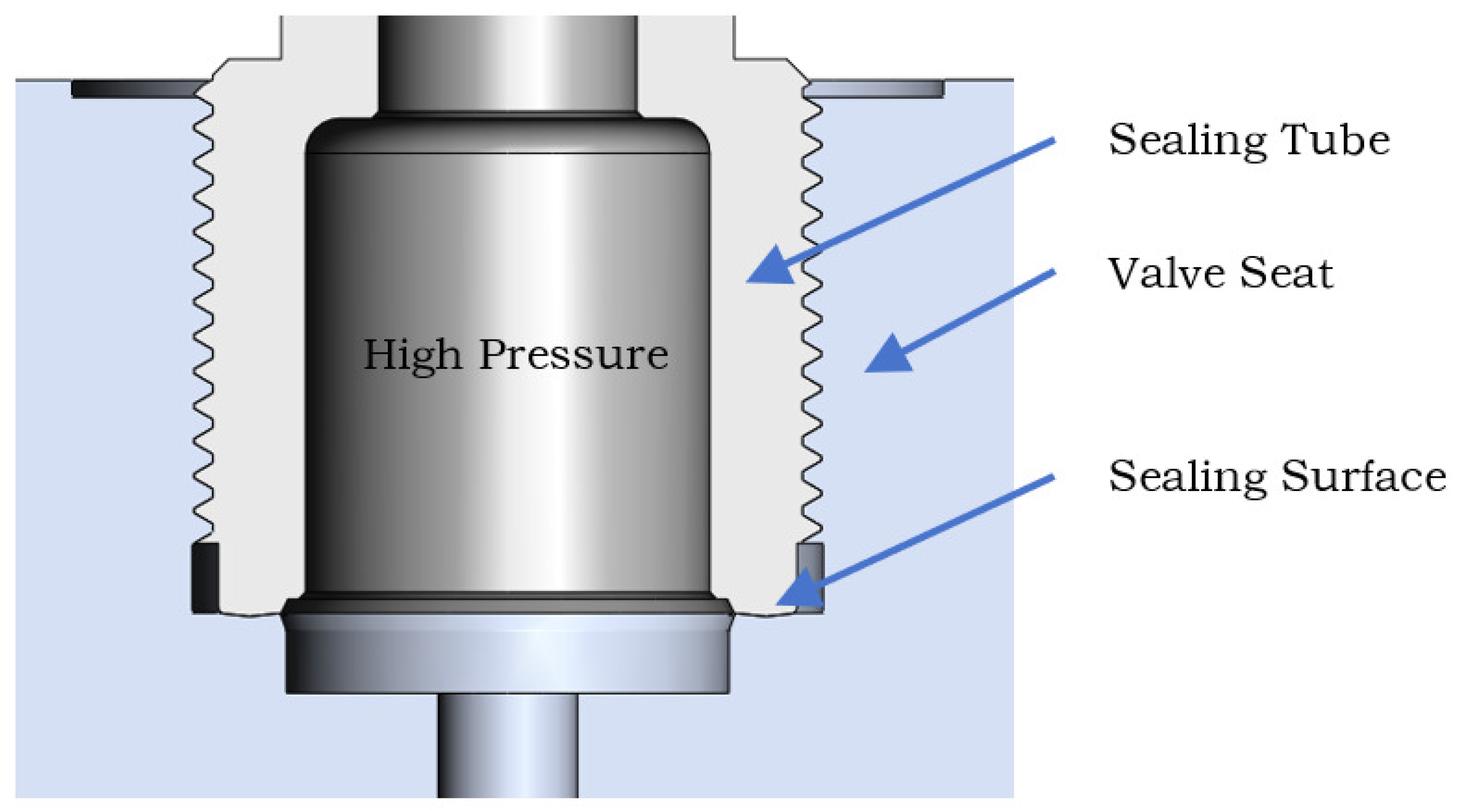

The ultra-high-pressure solenoid valve utilizes a sealing structure design based on a tapered hard seal. Its core sealing components consist of a sealing tube and seat, as depicted in

Figure 1. The end of the sealing tube features a precisely machined tapered sealing surface. Under the combined influence of pre-tensioning force and operating pressure, the sealing surface undergoes elastic deformation, resulting in a uniformly distributed contact stress across the interface. When the contact stress reaches a critical threshold, an effective metal-to-metal hard sealing is achieved under high-pressure differential conditions.

2.2. Theoretical Analysis of Sealing Specific Pressure

As a critical parameter for evaluating hard seal performance, sealing specific pressure represents the compressive stress per unit area of the sealing contact surface [

18]. This crucial index directly influences the reliability of the sealing assembly. When the actual sealing pressure is lower than the required sealing specific pressure, the contact stress is not enough to block the medium penetration path, leading to seal failure and leakage. Conversely, if it exceeds the upper limit of the permissible specific pressure of the material, it causes plastic deformation of the sealing surface or even pressure collapse damage. In engineering practice, the average sealing surface pressure is typically used as a design verification benchmark. This benchmark ensures that the pressure not only exceeds the minimum required sealing specific pressure but also remains below the permissible specific pressure determined by the compressive strength of the material, thereby providing a scientific basis for assessing the rating valve’s sealing performance. The relationship is expressed in Equation (

1).

where

is the sealing surface required specific pressure;

is the average sealing specific pressure;

is the sealing surface permissible specific pressure. The required specific pressure refers to the minimum pressure per unit sealing area needed to ensure leak-tight performance; the calculation of the formula is shown in Equation (

2).

where

C,

K is related to the sealing surface material coefficient;

p is the nominal pressure of the solenoid valve;

b is the sealing surface width.

The higher the sealing specific pressure on the sealing surface, the tighter the fit between the seat and sealing tube, resulting in a more effective sealing performance. Several factors influence the sealing specific pressure, including the width of the sealing surface, the pressure angle, preload, working pressure, and the basic material properties [

19]. Among these factors, the working pressure and material properties are external variables that cannot be altered once the medium’s operating conditions are established. Consequently, the sealing specific pressure must be determined by optimizing the directly influencing parameters. Due to the limitations of material properties, the unit contact pressure on the sealing surface cannot be increased indefinitely; a threshold must be set based on the material’s characteristics.

2.3. Theoretical Analysis of Coefficient of Thermal Expansion

According to the sealing principle, the magnitude of the bolt preload is a crucial factor in ensuring the sealing performance of the ultra-high-pressure solenoid valve. However, the magnitude of the bolt preload is influenced by various factors, and it may fluctuate during both the tightening process and normal operation of the solenoid valve. Therefore, it is essential to analyze the key factors that impact the variation in bolt preload.

The assembly of the sealing tube and valve seat of the ultra-high-pressure solenoid valve is performed at ambient temperature; at the same time, the operating temperature of the solenoid valve is required to reach −40 °C. At this temperature, both the sealing tube and valve seat will undergo deformation, leading to changes in the preload and stress distribution of the threaded connection [

20]. It is assumed that the thermal deformation of both the sealing tube and valve seat, due to temperature fluctuations, remains within the elastic limits of their respective materials, in accordance with Hooke’s law.

Because the coefficients of thermal expansion for the sealing tube and seat materials are different, the thermoelastic deformation of the sealing tube and valve seat is as follows [

21]:

The thermoelastic deformation of the valve seat with respect to the sealing tube is as follows:

while

is the coefficient of linear expansion for the sealing tube material,

is thermoelastic deformation of the sealing tube,

is thermoelastic deformation of the valve seat,

is the coefficient of linear expansion for the valve seat material,

is the effective length of the sealing tube,

is the effective thickness of the valve seat, t is the operating temperature of the ultra-high-pressure solenoid valve,

is ambient temperature at initial preloading of ultra-high-pressure solenoid valves,

is thermoelastic deformation of the valve seat relative to the sealing tube. After measurement, the effective length of the sealing tube is 71.4 mm, and the effective length of the valve seat is 53 mm. The thermal expansion coefficient of the sealing tube material is

, and the thermal expansion coefficient of the valve seat material is

. Therefore, the thermal deformation of the sealing tube and valve seat at a temperature of −40 °C is calculated as follows:

“−” indicates contraction of the sealing tube and valve seat. The thermal deformation of the valve seat relative to the sealing tube is as follows:

The calculation results show that the deformation of the sealing tube and valve seat at −40 °C is at the micrometre level. Therefore, in the subsequent simulation, the contact force and the average sealing specific pressure of the sealing surface increase slightly when the preload is not considered.

2.4. Characterization of High-Pressure Seals in Low-Temperature Environments

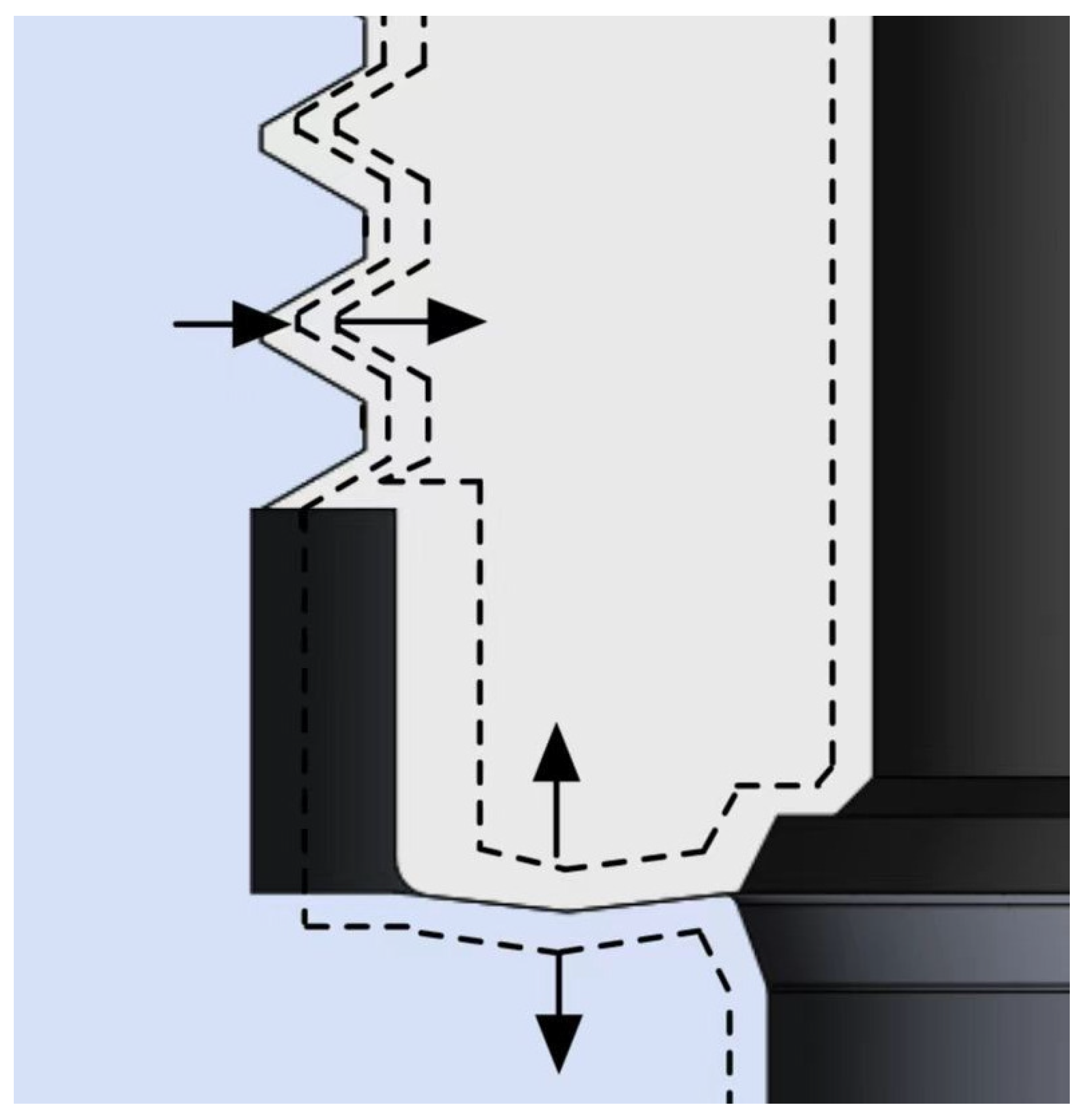

When the solenoid valve operates at an ambient temperature of −40 °C, both the sealing tube and valve seat undergo contraction, as illustrated in

Figure 2. As the temperature decreases, the elastic deformation of the sealing tube and valve seat diminishes. In low-temperature environments, the materials of the sealing tube and valve seat become more brittle and lose their original elasticity. This effect is particularly pronounced in the threaded connection, where reduced elasticity leads to a decrease in preload force. At low temperatures, the contraction of the sealing tube and threaded part tends to be inward and upward, while the valve seat’s threaded part contracts outward. However, the overall contraction of the valve seat tends toward the center, causing the threaded part to contract inward and downward, with the sealing surface also contracting downward, as depicted in

Figure 2. Due to the lower coefficient of thermal expansion of the sealing tube material compared to that of the valve seat, the sealing tube experiences less shrinkage than the valve seat. In the longitudinal direction, this results in the sealing tube exerting downward pressure on the valve seat, thereby increasing the contact force on the sealing surface. Although the differing coefficients of thermal expansion lead to variations in the contact force on the sealing surface, the decrease in preload due to reduced elasticity in the threaded connection has a greater impact than the changes in contact force caused by thermal expansion. Simultaneously, the ultra-high-pressure medium passing through the solenoid valve further reduces preload. Additionally, as the temperature decreases, the material’s toughness diminishes, causing small defects or cracks to expand rapidly. This increases the leakage channels in the sealing surface. As the elastic modulus of the material decreases with temperature, the distribution of contact stress on the sealing surface also changes, ultimately leading to a reduction in the average sealing specific pressure, which may fall below the required sealing specific pressure, resulting in leakage.

3. Finite Element Simulation Analysis

The sealing tube material of the ultra-high-pressure solenoid valve is TC4 titanium alloy and the valve seat material is aluminium alloy 6061-T6 [

22]. The physical properties of these two materials are shown in

Table 1 below.

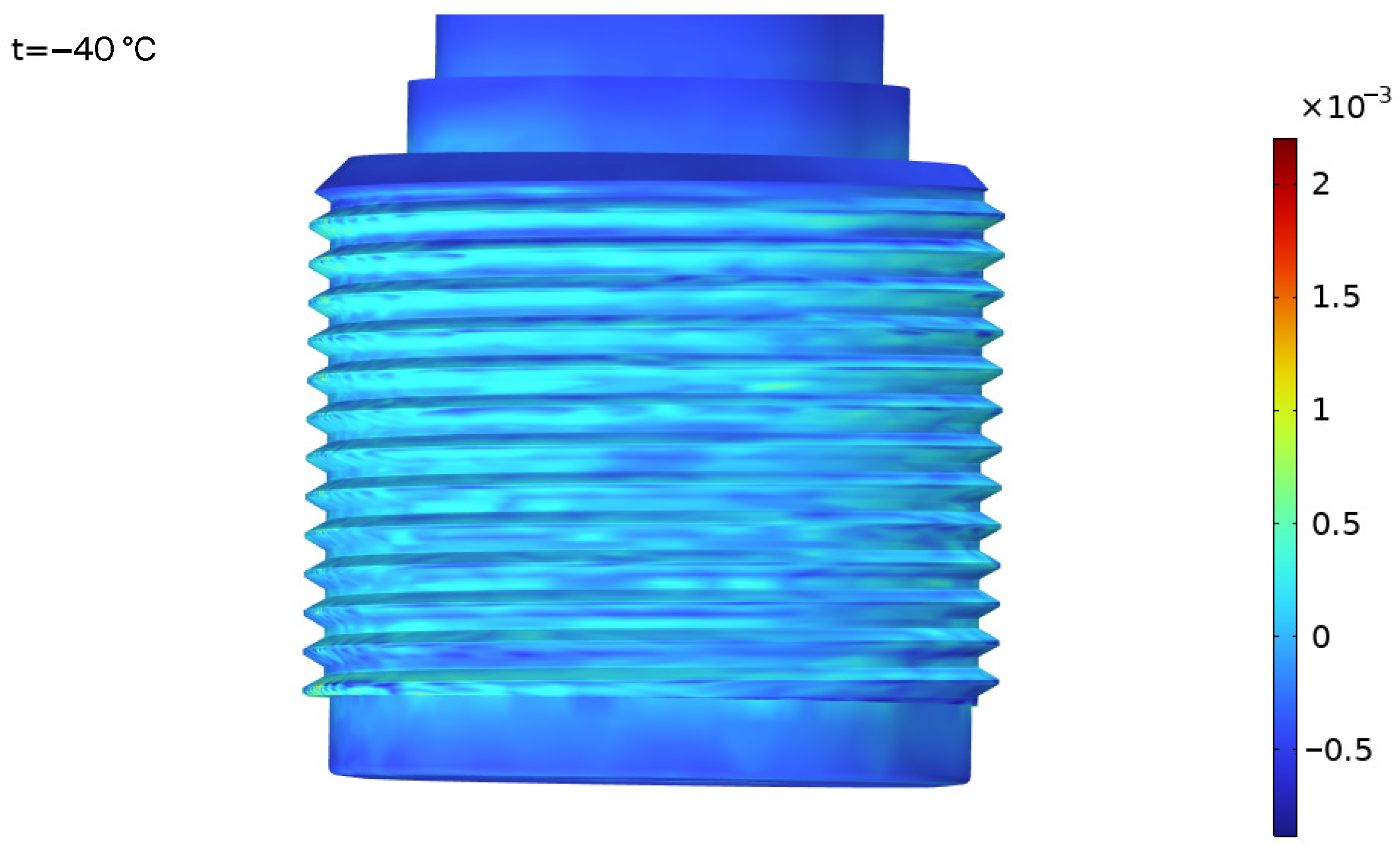

In this study, COMSOL6.2 is utilized to analyze the model. To enhance the accuracy of the simulation and optimize computational workload, the mesh was locally refined at the solenoid valve’s threaded connection region. Simultaneously, to ensure mesh independence, the mesh refinement was adjusted iteratively until convergence was achieved. When the number of cells is 43,093 and 72,325, the corresponding preload forces at a temperature of −40 °C are 23,886 N and 23,674 N, respectively. Ultimately, the mesh model with 72,325 cells is selected. Some details about the grid model are as follows: The grid type used in the model is a free tetrahedral grid; Number of vertex elements: 231; Number of edge elements: 8307; Number of boundary elements: 22,374; Total number of elements: 72,325; Minimum element mass: 0.01073; Maximum element size: 0.00873 m; Minimum element size: 0.00109 m; Maximum element growth rate: 1.45; Curvature factor: 0.5; Narrow region resolution: 0.6. The convergence criteria are as follows: Nonlinear method: bilinear; Initial damping coefficient: 1; Residual scaling: per-field; Number of iterations before restart: 7; Termination technique: tolerance; Maximum number of iterations: 25; Tolerance factor: 1; Relative tolerance: 0.001. The mesh is shown in

Figure 3 below.

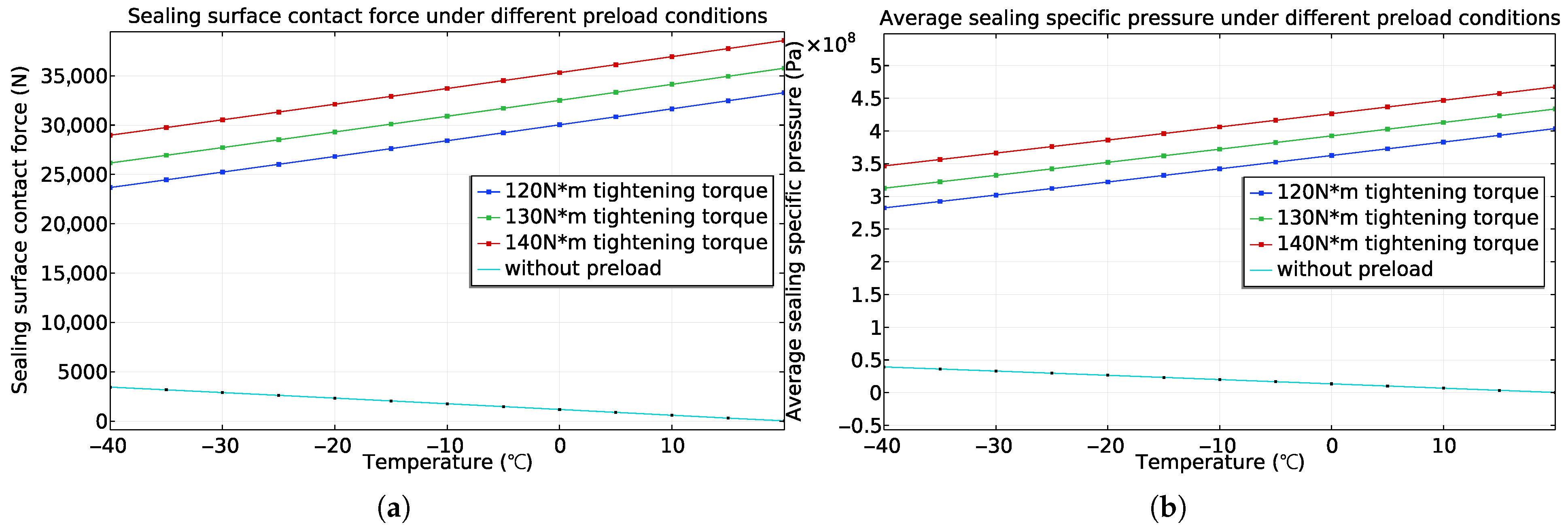

The contact forces at the sealing surfaces are analyzed using COMSOL for two scenarios: with and without preload. Initially, in the no-preload case, a fixed constraint is applied to the bottom of the valve seat, and thermal expansion boundary conditions are incorporated into the linear elastic material to simulate thermal deformation due to temperature variations. Next, for the preload analysis, a torque of 120 N·m is applied to the sealing tube using a torque wrench, corresponding to a preload of approximately 33 kN. In the simulation, a boundary condition of a fixed displacement of 0.2 mm is applied to the upper surface of the seat to achieve the desired preload of 33 kN. The upper surface of the inner thread of the seat is then pressed downward onto the upper surface of the outer thread of the sealing tube through face displacement, and the contact force at the sealing surface is monitored using a boundary probe to generate the preload. Since the focus is on analyzing the pressure at the sealing surface and changes in the average sealing specific pressure, this simulation method accurately reflects the real-world situation. The temperature is varied from 20 °C to −40 °C to observe the contact force at the sealing surface and the changes in the average sealing specific pressure. In order to better select the tightening torque for subsequent experiments, we also simulate the cases of 130 N·m and 140 N·m. The simulation results are shown in

Figure 4 below:

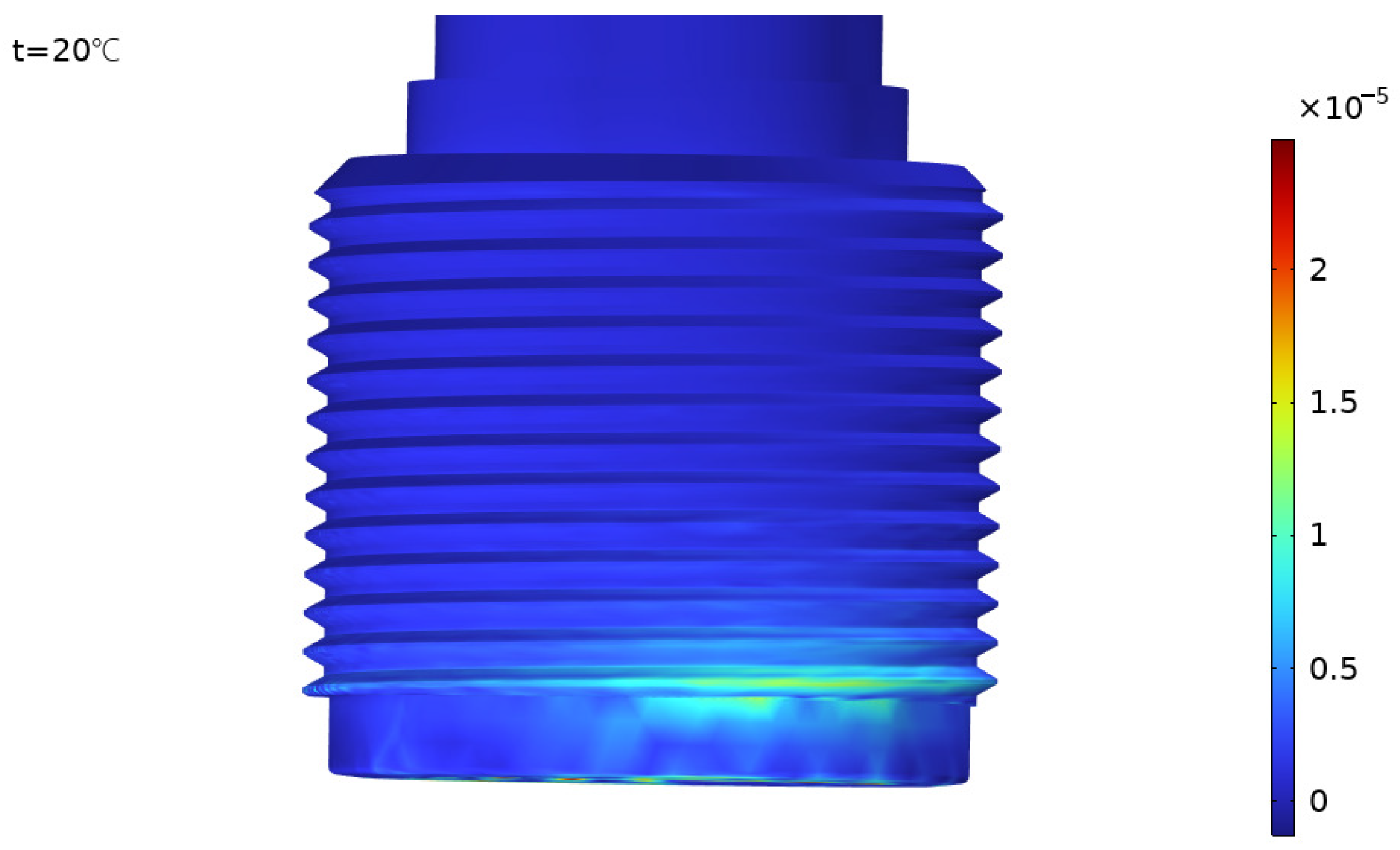

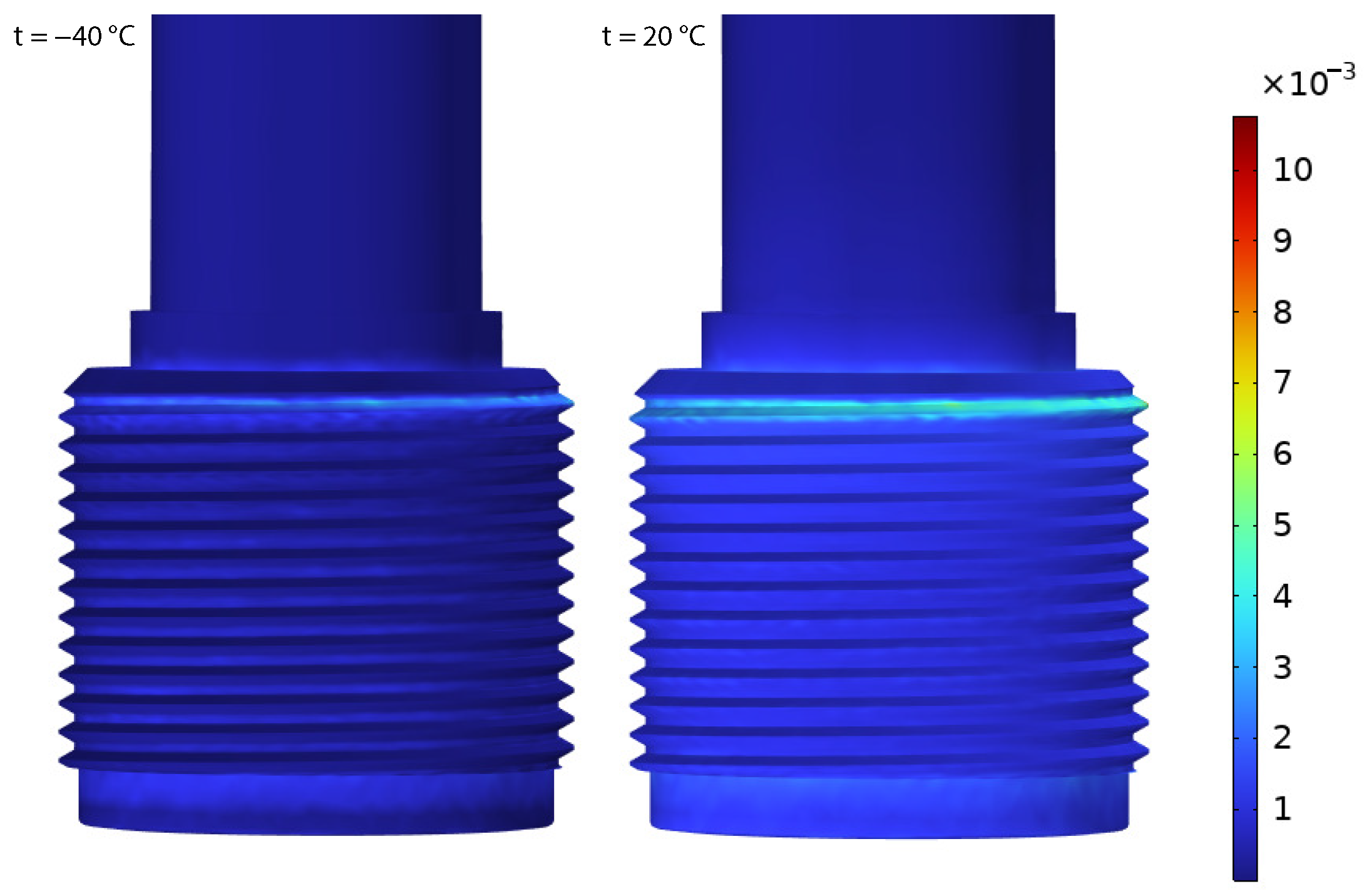

The simulation results demonstrate that as the ambient temperature decreases, both the contact force at the sealing surface and the average sealing specific pressure exhibit an upward trend when preload is not considered, and only the differing coefficients of thermal expansion of the materials are accounted for. From the strain diagram of the sealing tube, it is evident that the strain at −40 °C exceeds that at 20 °C when preload is disregarded, as shown in

Figure 5 and

Figure 6.

This confirms that the contact force at the sealing surface increases as the temperature decreases. This is because the coefficient of thermal expansion of the valve seat material is greater than that of the sealing tube material. Without considering preload, this implies that the contraction of the valve seat is greater than that of the sealing tube at low temperatures. This results in an increase in the contact force at the sealing surface and a corresponding rise in the average sealing specific pressure. However, after applying preload, the results show that as the temperature decreases from 20 °C to −40 °C, the sealing contact force reduces by approximately 10 kN, and the average sealing specific pressure decreases by nearly 120 MPa. Furthermore, from the strain diagram of the sealing tube at −40 °C, it is evident that the strain value is smaller than that at 20 °C, as depicted in

Figure 7. The left side of the figure shows the strain of the sealing tube at −40 °C, while the right side shows the strain at 20 °C. This demonstrates that, in the absence of preload, the thermal expansion and contraction of materials cause an increase in sealing surface contact force. However, the application of preload reduces the elastic deformation of the solenoid valve’s threaded part as the temperature drops. The reduction in preload is greater than the increase in sealing surface contact force caused by the materials’ differing thermal expansion coefficients alone, resulting in a downward trend in both the sealing surface contact force and the average sealing specific pressure.

Insufficient contact force will prevent the average sealing specific pressure from reaching the required sealing specific pressure. When the average sealing specific pressure falls below the necessary threshold, leakage in the solenoid valve occurs. Additionally, under actual operating conditions, solenoid valves typically endure high-pressure mediums, which exert force on the valve structure. This resulting separation force partially counters the contact force on the sealing surface, meaning that, under identical low-temperature conditions, the effective contact force in practice will be less than the value predicted in simulations. This highlights that in real-world low-temperature environments, the risk of seal failure is greater than simulation results suggest, since these only account for temperature fluctuations. Therefore, in the design of low-temperature ultra-high-pressure solenoid valve sealing systems, it is crucial to thoroughly evaluate the low-temperature properties of the material and the pressure of the operating medium. This ensures that the sealing surface can provide sufficient contact force to maintain reliable sealing performance and surpass the required sealing specific pressure, even under extreme low-temperature conditions.

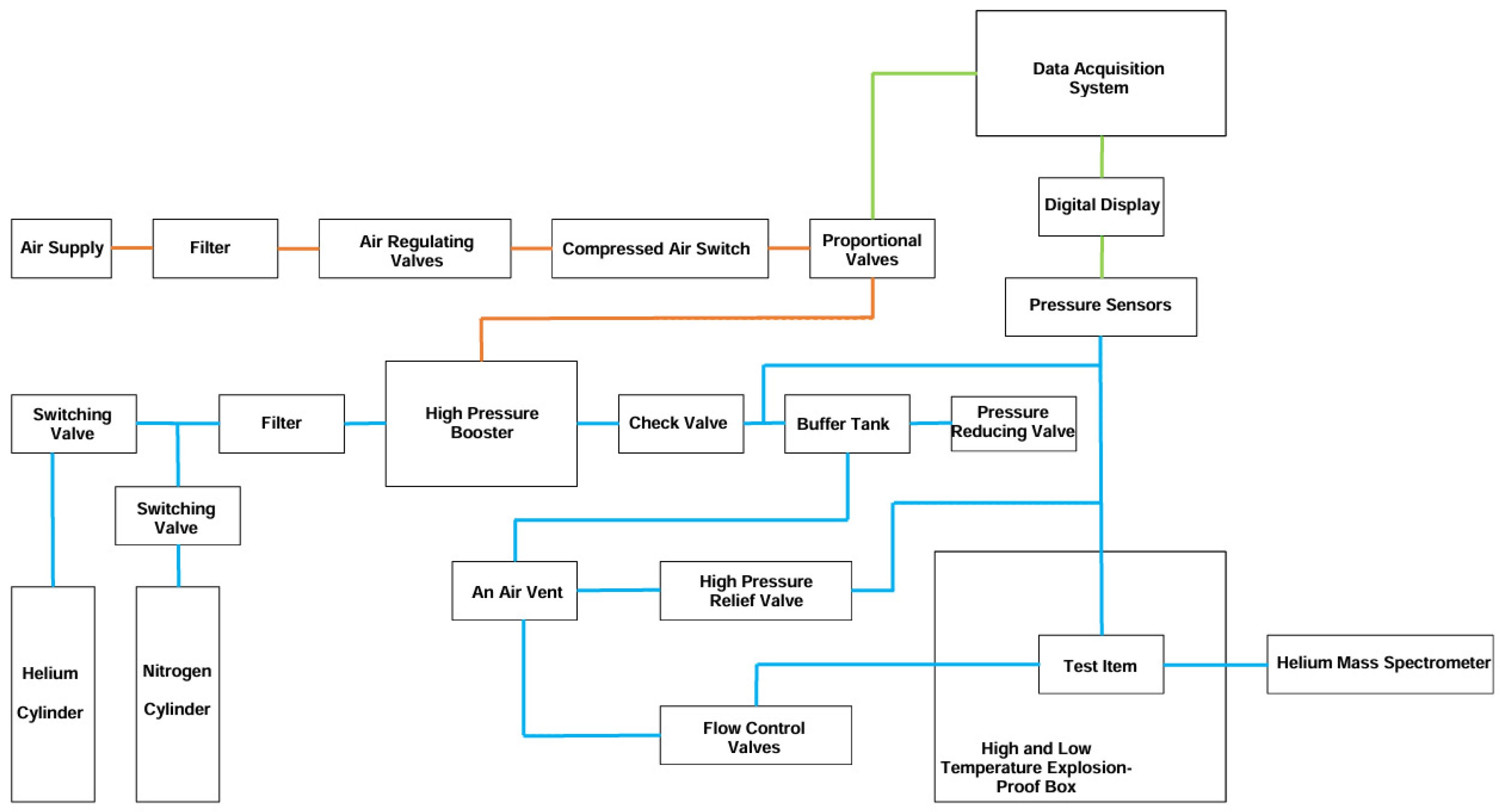

4. Low Temperature Leakage Test

In this study, a comprehensive low-temperature sealing performance test is conducted on the structure of the ultra-high-pressure solenoid valve. The leakage test and leakage rate are evaluated at various test pressures and temperatures, with the testing principle illustrated in

Figure 8.

The helium mass spectrometer leak detector in the core equipment has a minimum detectable leak rate of

mbar·L/s. Temperature control relies on high and low-temperature humidity test chambers and high-precision temperature sensors attached to the surface of the test piece, while the data logger simultaneously collects data from all sensors. During cooling or heating processes, a stepwise regulation strategy is employed: after the target temperature is reached, the chamber is maintained at that temperature for ≥1 h, and testing is initiated once the temperature fluctuation within the chamber is ≤±0.5 °C. Pressure monitoring utilizes multiple multi-range, high-precision pressure transmitters, which transmit data in real-time via high-frequency sampling. The test setup is shown in

Figure 9 and the test results are presented in

Table 2:

At a test pressure of 1.4 MPa, the sealing structure demonstrates remarkable temperature adaptability. The helium test leakage rate remains stable at mbar·L/s under both 25 °C ambient and 85 °C high-temperature conditions. However, the leakage rate slightly increases to mbar·L/s in the −40 °C low-temperature environment. When the test pressure is raised to 10 MPa, the sealing performance remains reliable, with leakage rates of mbar·L/s and mbar·L/s for high, ambient, and low-temperature conditions, respectively. This indicates that the sealing surface maintains effective contact even under high-pressure and low-temperature operating conditions. Notably, during the 87.5 MPa ultra-high-pressure solenoid valve external leakage test, the helium detection external leakage rates at 25 °C and 85 °C ambient temperatures are mbar·L/s and mbar·L/s, respectively. These values represent nearly an order of magnitude increase compared to the leakage rate under 10 MPa. Even in the −40 °C low-temperature environment, the leakage rate reaches mbar·L/s. This highlights the reduced sealing performance of the ultra-high-pressure solenoid valve under the 87.5 MPa test pressure, with the leakage rate increasing substantially—particularly at −40 °C, where it nearly doubled. Moreover, the test data reveal a clear trend: as temperature decreases, the helium leakage rate gradually increases when the test pressure is constant. Similarly, at constant temperature, increasing the test pressure also leads to a gradual increase in the leakage rate. This phenomenon corroborates the previous analysis, where the elastic deformation of the sealing tube and valve seat diminishes with decreasing temperature, resulting in a reduction in preload force. Although the valve seat contracts more than the sealing tube in the low-temperature environment, the sealing surface contact force increases with the temperature drop. However, the decline in preload is more pronounced than the increase in sealing surface contact force. Additionally, the high-pressure medium internally reduces the contact force, ultimately leading to leakage in the ultra-high-pressure solenoid valve at 87.5 MPa and −40 °C.

The following measures are implemented and subsequently tested: (1) the tightening torque is increased from the original 120 N·m to 130 N·m; (2) a thread adhesive is applied to the threaded connection. The solenoid valve is then placed in a −40 °C low-temperature environment to replicate the low-temperature operating conditions it will encounter during use. Three sets of repetitive tests are conducted on the solenoid valve using a helium mass spectrometer to record the helium leakage rate at various pressures. The detailed test results are presented in

Table 3 below:

The test results clearly demonstrate a significant reduction in the helium leakage rate of the solenoid valve during the second test at −40 °C. Notably, the leakage rate at a test pressure of 87.5 MPa decreased from mbar·L/s to mbar·L/s. Similarly, the leakage rates at test pressures of 1.4 MPa and 10 MPa stabilized around mbar·L/s. These findings indicate that increasing the tightening torque and applying thread adhesive can significantly enhance sealing performance in low-temperature environments.

5. Conclusions

Through theoretical analysis, simulation, and experimental verification, the factors contributing to the increased leakage rate and seal failure of ultra-high-pressure solenoid valves in low-temperature environments are identified in this study. The key conclusions are as follows:

(1) Through simulation analysis, the effect of thread preload decay in low-temperature environments exceeds the increase in contact force caused by differences in thermal expansion coefficients. Therefore, the overall result is a decrease in contact force and average sealing specific pressure on the sealing surface.

(2) In low-temperature environments, and under the combined influence of preload, thermal expansion coefficients, and high-pressure media, the average sealing specific pressure on the sealing surface of ultra-high-pressure solenoid valves decreases to below the required sealing specific pressure, resulting in leakage.

(3) A moderate increase in bolt preload and the application of sealant at the threaded connection can effectively improve the sealing performance of ultra-high-pressure solenoid valves under low-temperature conditions.

Experimental results demonstrate that increasing torque and applying thread adhesive significantly reduced leakage by an order of magnitude at −40 °C, confirming improved low-temperature sealing reliability.

Author Contributions

Conceptualization and project administration, T.H.; writing—original draft preparation, Y.W.; investigation, C.S.; visualization, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the 8th China innovation challenge (Ningbo) and Yuyao Sanlixin Solenoid Valve Co., Ltd.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to relevant data protection.

Acknowledgments

The authors gratefully acknowledge Shanhai Mao and Guoyun Gu. They not only provide study materials and study instrumentation, but also validate both theoretical calculations and experimental results. Furthermore, we explore research approaches and resolve various difficulties encountered during the experiments. With the help of them, our experiments are able to proceed and be completed more effectively.

Conflicts of Interest

The authors declare that this study received funding from Yuyao Sanlixin Solenoid Valve Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Ma, D.; Liu, Z.H.; Gao, Q.H.; Huang, T. Fault Diagnosis of a Solenoid Valve Based on Multi-Feature Fusion. Appl.Sci. 2022, 12, 5904. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Mu, L.; Tang, H. Research on electromagnetic characteristics of high-pressure air solenoid valve. Mod. Mach. 2024, 5, 41–47. [Google Scholar]

- Chakrabarti, S.; Sidhartha, P.A.V.; Sai, N.V.S.; Verma, A.; Venkittaraman, D.; Kodeeswaran, M.; Kumar, A.; Sahoo, B. Effect of annealing of the core material on magnetic and mechanical performance of a plunger type solenoid valve during its start transient. J. Magn. Magn. Mater. 2025, 628, 173158. [Google Scholar] [CrossRef]

- Choi, J.; Ahn, J.H.; Kim, H.Y. Modeling the Dynamic Behavior of a Pilot-Operated Solenoid Valve for an Ultra-High Pressure Vessel. Appl. Sci. 2021, 11, 2329. [Google Scholar] [CrossRef]

- Zhang, S.P. Research on reliability of superhigh pressure-solenoid valve for launch equipment with nitrogen resource. J. Ordnance Equip. Eng. 2013, 34, 24–27. [Google Scholar]

- Wang, J.H.; Zhang, T.; Zhou, D.; Zhang, W.X.; Wang, T.; Xu, G.L. Experimental study of the factors influencing the sealing performance of metal-to-metal sealing cut-off valves. Lubr. Eng. 2025, 50, 23–29, 40. [Google Scholar]

- Yu, L.J.; Qian, J.Y.; Jin, Z.J. Research progress on sealing performance of valve. Lubr. Eng. 2021, 46, 134–142, 153. [Google Scholar]

- Geng, P.C.; Hu, G.L.; Sun, B.B. Analysis of sealing characteristics of seated ball valves with hard seal. Chem. Eng. Mach. 2024, 51, 84–89. [Google Scholar]

- Feng, Z.R.; Wei, J.; Guo, Z.H.; Yao, K.P. Sealing performance analysis and optimization of high-pressure hard sealing fixed ball valve. J. Nanchang Hangkong Univ. (Nat. Sci.) 2017, 31, 61–67. [Google Scholar]

- Peng, K.; Chen, Q.; Yu, J.Y.; Yu, J.Y.; Wang, J.X.; Xia, Y.Z.; Wang, Z.H.; Zhang, H. Sealing performance analysis of glass fiber reinforced plastic floating ball valve. Lubr. Eng. 2023, 48, 116–122. [Google Scholar]

- Zhang, J.B.; Hu, J.T.; Yang, L.L.; Li, W.; Ye, K.Q.; Ye, X.B. Design and research of a new type of double elastic self tightening hard seal structure. Hydraul. Pneum. Seals 2022, 42, 83–86. [Google Scholar]

- Chu, J.W.; Liu, Y.; Liu, J.T.; Shao, J.N.; Liu, J.H. Full nominal diameter two-way hard seal butterfly valve design and calculation. Chin. J. Valve 2023, 5, 540–542. [Google Scholar]

- Lin, T.; Wu, C.L.; Sun, S.H. Design and application of micro high pressure solenoid valve. Aerosp. Control 2004, 5, 93–96. [Google Scholar]

- Bzibziak, R. Update of cold gas propulsion at Moog. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 17–19 July 2000. [Google Scholar]

- Sai, N.V.S.; Verma, A.; Sanoj, A.; Ram, G.Y.; Muthuselvi, K.; Venkittaraman, D.; Krishna Mohan Shanbhogue, K.; Chakrabarti, S. Importance of solenoid valve selection for performance of a cold gas thruster for an orbital experimental module. Adv. Space Res. 2025, 76, 1626–1645. [Google Scholar]

- Gao, P.; Hu, D.H.; Lu, D.G.; Wang, J.; Cheng, Z.X.; Yi, F.Y.; Zhou, J.M. Modeling and analysis of minor seal leakages in high-pressure hydrogen valves under extreme environmental temperatures. Int. J. Hydrogen Energy 2024, 64, 26–38. [Google Scholar] [CrossRef]

- Choi, J.; Kim, H. Concave Contact Geometry for Enhanced Sealing and Structural Integrity in Ultra-High Pressure Hydrogen Solenoid Valves. Appl. Sci. 2025, 15, 6184. [Google Scholar] [CrossRef]

- Wang, C.L.; Xu, D.T.; Liu, Y.N.; Huang, K.X.; Meng, X.R. Response surface optimization of hard sealing structure for a tri-eccentric butterfly valve. Chin. Hydraul. Pneum. 2024, 48, 120–128. [Google Scholar]

- Li, S.L.; Jing, H.; Li, H.W.; Wang, W.B.; Shang, H.Z.; Jiang, Y.B. Design and analysis of sealing pressure ratio of hard sealed ball valve. Chin. J. Valve 2024, 5, 519–526. [Google Scholar]

- Yan, Y.; Wen, M.G.; Li, Y. FEM analysis and preload evaluation of bolted joints subject to low temperature. In Proceedings of the ASME 2015 Pressure Vessels and Piping Conference PVP2015, Boston, MA, USA, 19–23 July 2015. [Google Scholar]

- Li, S.X.; Yi, H.Q.; Zhao, M.J.; Yang, L.X.; Liu, T.Y. Analysis of bolt preload for LNG ultra-low temperature ball valves. J. South China Univ. Technol. (Nat. Sci. Ed.) 2021, 7, 49. [Google Scholar]

- ASM International. Metals Handbook, 9th ed.; Vol.2: Performance and Selection: Non-ferrous Alloys and Pure Metals; China Machine Press: Beijing, China, 1994; pp. 216–255. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).