1. Introduction

Digital transformation has become a major driver for organizations seeking a competitive edge in the rapidly evolving global market of the day [

1]. For supply chain management, digital transformation translates into adopting technologies at the bleeding edge to achieve efficiency, visibility, resilience, and sustainability [

1,

2,

3]. The shift reimagines supply chains from traditional models to digitally empowered settings [

4]. Digital transformation for supply chain management involves implementing Industry 4.0 technologies to replace traditional practices with new ones that are inspired by digital [

3,

5]. This encompasses varied technologies such as artificial intelligence (AI), machine learning, Internet of Things (IoT), cloud computing, blockchain, robotic process automation, and big data analytics [

3,

4,

6]. The objective is to design a more responsive, flexible, and perceptive supply chain [

2]. This enables better decision making, better use of resources, and increased customer satisfaction [

1].

Managing data in a systematic way allows a firm to respond fast to market demands and enhance customer satisfaction. For instance, the utilization of Six Sigma methods in suppliers’ development has been proven to improve quality and reduce supply chain costs [

7]. This strategy places a strong focus on data for measuring supplier performance and facilitating continuous improvement. Though the benefits are many, the transition to data-driven supply chain management is fraught with challenges. Organizations typically find it difficult to form close relationships with suppliers, which are key to effective supply chain management [

8]. Reliance on data sometimes leads to a schism between organizations and partners because the focus is on technical metrics rather than qualitative relationships.

Trust is a key component in supply chain management, particularly because organizations are sharing sensitive data with partners. Onolaja et al. [

9] propose a dynamic trust management system that employs past and present information to assess the reputation of supply chain partners. The initiative aims at minimizing data sharing risks and maximizing cooperation. The relationship between trust and big data is complex. Sänger et al. [

10] demonstrate how plenty of trust data can be employed to develop future-proofed trust management systems. However, the quality and sources of data are crucial; only when data is trusted will organizations embrace data-driven solutions.

Blockchain technology offers a decentralized, tamper-proof ledger that can potentially enhance trust in supply chain management by presenting transparent and verifiable records of transactions. Blockchain offers the capability of direct transactions between parties without an intermediary, establishing a distributed model of trust based on network participant consensus [

11]. With visibility, fraud risk can be greatly reduced while enhancing accountability in the supply chain. Each transaction placed on a blockchain is time-stamped and linked to previous transactions, creating a complete audit trail. This feature is particularly useful to businesses in sectors where product origin is most important, such as food safety and pharmaceuticals. Blockchain has the potential to provide accurate and trustworthy transaction infrastructure to enable real visibility to supply chain partners [

12].

Blockchain also enables the use of smart contracts, which are self-enforcing contracts where the terms of the deal are embedded directly into code lines. Smart contracts make many of the supply chain processes automated, maintaining manual intervention where there is none and avoiding disputes. Control automation using smart contracts can enhance operational efficiency and further enhance trust between parties [

13]. Several systematic reviews have explored the implications of blockchain technology in supply chain management and logistics (

Table 1).

To complete the existing gaps in literature, future research would have to endeavor to develop overarching frameworks linking transparency, traceability, and trust to operating metrics for logistics. Comparative studies across different sectors can provide interesting observations into the applicability of blockchain solutions and challenges that arise in the implementation process.

While previous studies have highlighted the transformative potential of blockchain across various supply chain functions, they often treat transparency, traceability, and trust either collectively or superficially, without dissecting their individual roles and interdependencies. Despite widespread enthusiasm, empirical clarity regarding the measurable impact of blockchain on these three pillars remains limited and fragmented. This review addresses these gaps by conceptually distinguishing transparency, traceability, and trust as separate yet interlinked outcomes of blockchain-enabled supply chain systems. This article uses a narrative review to synthesize academic ideas. This method integrates conceptual, technological, and regulatory factors into a cohesive synthesis that reflects current trends and gaps. It further synthesizes recent empirical findings with a focus on quantitative metrics, aiming to evaluate how blockchain capabilities contribute to each pillar. The paper also offers a function-oriented analysis of blockchain’s operational mechanisms in data-driven environments and identifies current limitations and future research needs for both scholars and practitioners.

2. Technological and Conceptual Foundations

2.1. Blockchain Capabilities for Supply Chain Data Integrity

Decentralization is a core feature of blockchain technology, and it enables various stakeholders to access and verify information without relying on a central authority. This provision is particularly important in supply chains as numerous stakeholders are involved in the production and distribution of products. Blockchain technologies employ a shared ledger to enhance transparency and trust among supply chain partners, enhancing data management [

22,

23,

24].

Utilization of blockchain in supply chain transactions facilitates the generation of irreversible accounts, shared with all who are involved. Openness encourages accountability, and at the same time reduces fraudulent practices as well as reporting errors of information. For instance, the use of smart contracts, autonomous contracts in which the terms of the agreement are written directly into code, can make various processes automatic, so that transactions are only processed when pre-determined conditions have been met [

25,

26].

One of the most valuable advantages of blockchain technology is its ability to improve data accuracy. As per the traditional supply chain process, data ends up being siloed within various entities. Blockchain addresses this by having a single source of truth that everyone can trust directly. This aspect is particularly critical in the food and pharmaceutical sectors, where traceability and authenticity are very crucial [

23,

27].

For example, in the food industry, blockchain allows the history of foods, from farm to plate, to be traced, with the guarantee that the consumers receive valid information about the origin and quality of food being consumed [

28,

29]. This traceability not only enhances consumer confidence but also allows companies to comply with regulations, thereby enhancing accountability in the supply chain [

30,

31].

The capacity of blockchain technology to automate increases supply chain efficiency. Automating operations and reducing the role of intermediaries, blockchain can reduce transaction time and lower costs. The integration of blockchain with IoT devices, for instance, can track goods in real-time, supporting anticipatory decision making and removing delays [

32,

33].

The use of blockchain within supply chain financing is able to overcome accounting and assurance barriers, facilitating smoother financial flows and overall improved governance [

34]. The ability to automate various elements within supply chain management not only enhances the performance of operations but also allows companies to respond more effectively to shifting markets and consumer demands [

35,

36].

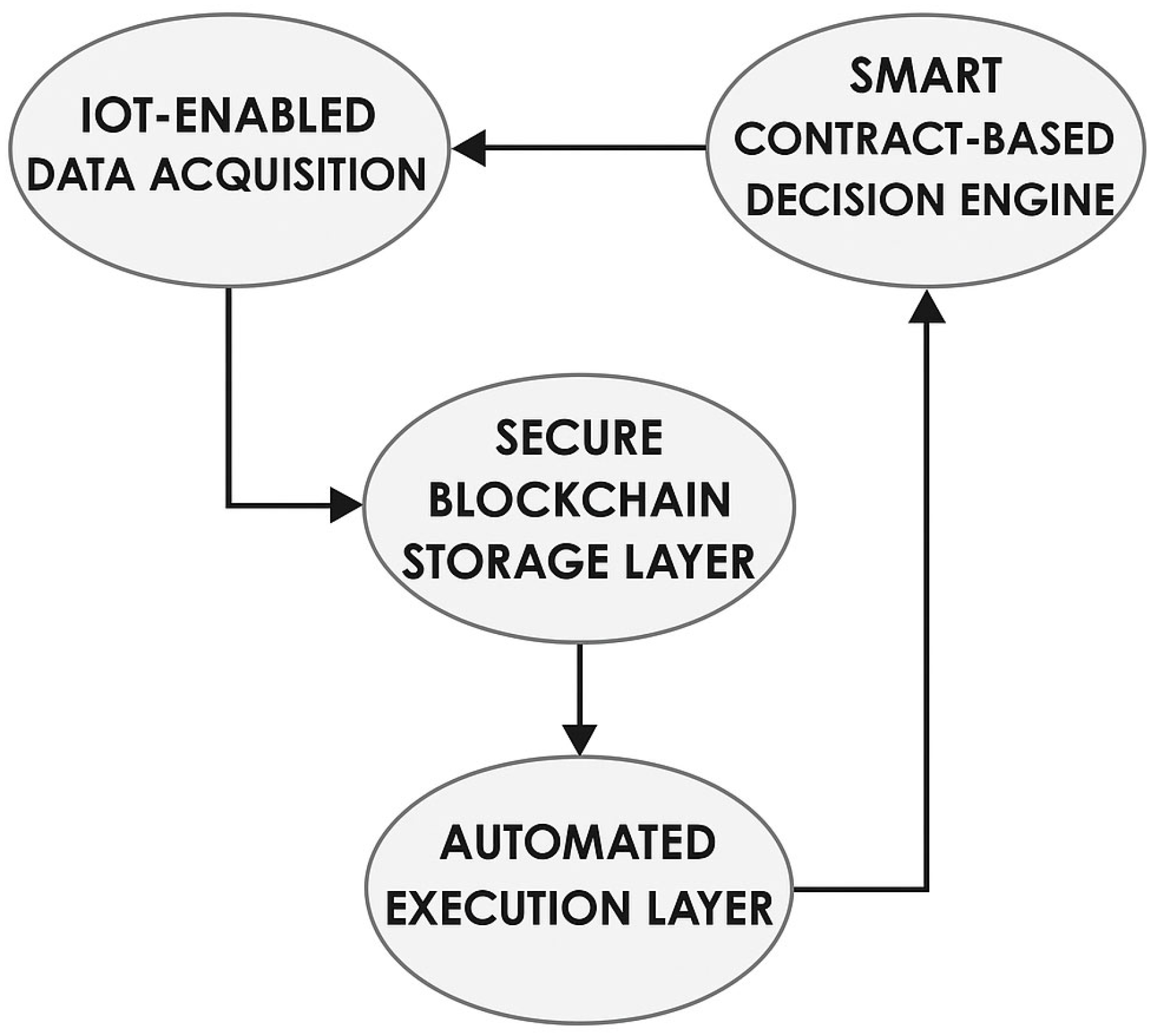

Figure 1 shows how blockchain connects to core components of data-driven supply chain management (data acquisition, storage, decision making, execution).

2.2. Functional Linkages to Transparency, Traceability, and Trust

Transparency, in supply chains and other value chains, refers to access by authorized parties to information about processes, transactions, and data [

37,

38]. Blockchain technology facilitates transparency by constituting a distributed ledger system, where all transactions are noted in a block and linked to the prior block, creating a chronological and immutable record [

39]. This shared ledger is accessible to all the sanctioned participants, providing one source of truth and eliminating information asymmetry [

40,

41]. Blockchain has the ability to create end-to-end traceability of product paths, from source to consumer, making it possible for all interested parties to see the same information on product origin, handling, and distribution [

11,

37,

38]. This is especially important in the food sector, as consumers require assurances regarding the safety and authenticity of products [

16,

42,

43].

Traceability is the ability to follow a product or information item in its entire life cycle [

37,

38]. The immutability and time-record keeping of blockchain make it an ideal tool for ensuring traceability in complex systems [

44,

45]. Any transaction or event is logged on the blockchain with a date, which can be traced back to the initial item and present state [

40]. Blockchain allows food products to be traced from production to consumption, which informs consumers about food origin, processing, and handling that they ingest [

16,

37,

40]. Traceability provided by blockchain is an added advantage to the connection between environmental standards and ecological sustainable practices in supply chains. Blockchain integrated with IoT and sensors can further shape supply chain governance mechanisms, standards, and sustainability practices [

46].

Trust is a critical element of any system, particularly for advanced supply chains with various stakeholders [

47,

48]. Blockchain establishes trust by creating a decentralized and open environment where every stakeholder receives access to the same information [

49]. The impossibility of changing the blockchain guarantees that data cannot be tampered with, thus also increasing trust between stakeholders [

44,

50]. Blockchain’s consensus protocols such as Proof-of-Work or Proof-of-Stake ensure that transactions are verified by multiple nodes in the network before they are included on the blockchain [

51]. Decentralized verification makes a central authority redundant, reducing manipulation risk and increasing trust in the system [

11,

52].

Blockchain builds trust among supply chain stakeholders with a secure and transparent platform for information exchange [

51,

53]. It is equally essential in industries where trust is needed as a means to guarantee product quality and safety [

16,

37]. In closed-loop supply chains, blockchain bridges the gap between trust, traceability, and transparency and improves control in waste movement and product returns management processes [

51].

Figure 2 illustrates how key blockchain functions contribute to improving specific supply chain capabilities, such as visibility, accountability, responsiveness, and data resilience.

3. Theoretical Dimensions of Transparency, Traceability, and Trust

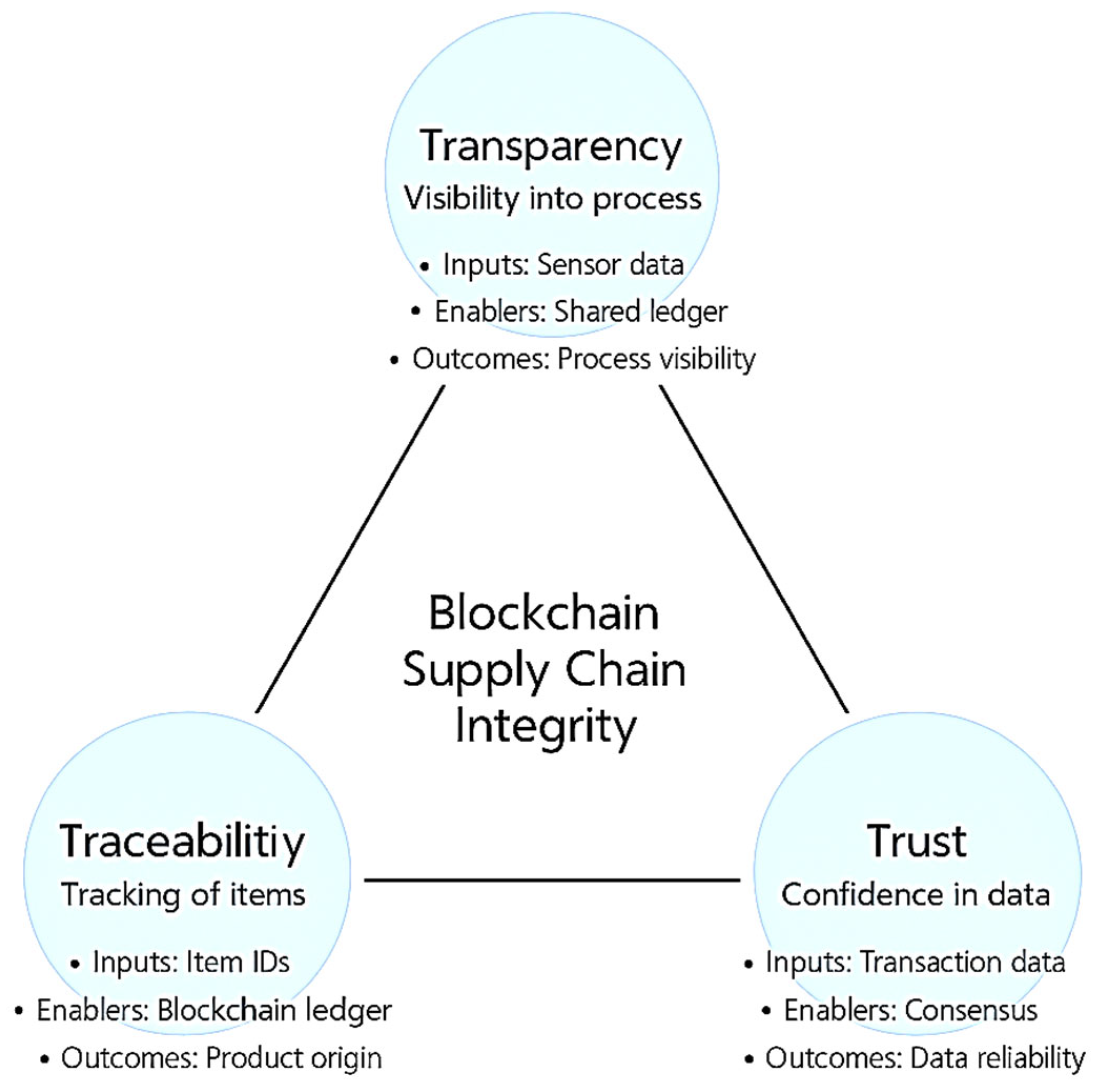

The foundational principles of transparency, traceability, and trust form a triad of critical attributes in the context of modern supply chain systems, particularly those enhanced by blockchain technologies. While often used interchangeably, these concepts possess distinct operational meanings and strategic implications. Understanding the unique inputs, blockchain enablers, and performance indicators associated with each concept is essential for designing robust, ethical, and efficient supply chain systems. The unique and overlapping operational definitions and enablers of transparency, traceability, and trust in supply chain systems are illustrated in

Figure 3.

3.1. Transparency

Visibility of data in real-time is essential for modern supply chains, facilitating stakeholders to track the movement of goods and information in real time. Shared ledgers, particularly through blockchain technology, provide this visibility by establishing an unalterable record of transactions accessible to all authorized parties. Blockchain facilitates transparency through the capability of all stakeholders to view transactions in real time, reducing the reliance on intermediaries and ensuring trust [

54]. The concept of visibility of communication advocates for making invisible interactions in the past visible to enhance metaknowledge among the employees [

55].

One of the primary advantages of blockchain technology is that audits can be conducted without resorting to third parties. Xu et al. [

56] propose a transparency framework that employs blockchain to verify third-party services as reliable. Organizations can automate accountability and ensure users participate in audit procedures with the help of smart contracts and decentralized ledgers. This not only enhances security but also reduces the risk of fraud and error within the supply chain. The LUCE platform, as described by Urovi et al. [

57], is a demonstration of how blockchain technology can make data sharing accountable and compliant. By making data use fully transparent after sharing, LUCE addresses the issues of tracing data once it has been transferred to third parties.

The incentive to be transparent in supply chain management emanates from a plethora of incentives and disincentives. Firms’ attention towards transparency can generate stronger customer and partner trust and stronger regulatory compliance. For instance, the integration of blockchain with SAP systems, researched by Ravi and Jampani [

58], illustrates how transparency can reduce fraud and data inconsistencies costs and enhance efficiency to a maximum.

There also exist, however, disincentives to transparency. Organizations may fear opening up sensitive data or competitive advantages, so there is reluctance to initiate open practices. The installation costs of new processes and technologies deter organizations from initiating transparency efforts.

3.2. Traceability

Provenance tracking is tracing the origin and route of a product along the supply chain. It is of most significance in industries such as food and pharmaceuticals, where product authenticity and safety need to be guaranteed. Recent studies have identified the potential of blockchain technology to scale provenance tracking through an unalterable transaction and event record along the supply chain. For instance, Kim and Laskowski [

59] discuss how blockchain facilitates high-grained provenance analysis, particularly in complex supply chains with numerous organizations and geographies.

Integration of IoT devices with blockchain will be able to further enhance provenance tracking by offering real-time data on the status and whereabouts of products. Powell et al. [

60] emphasize that while blockchain offers a secure means of storing data, the quality of data captured through the use of IoT devices is critical in ensuring the integrity of provenance information.

Physical and virtual supply chain convergence is essential towards achieving end-to-end traceability. Technologies such as radio frequency identification and blockchain can be combined to provide an uninterrupted link between the physical product flow and its virtual equivalent. For example, Frankó et al. [

61] propose a strong identification protocol that uses radio frequency identification technology to track assets in smart manufacturing settings, hence enhancing logistics performance and traceability.

Converging physical tracking technologies with blockchain can improve raw material supply chain transparency. Bacchetta et al. [

62] demonstrate how the convergence of the two technologies can enable improved tracking of raw materials, which in turn can improve supply chain transparency as well as stakeholder trust.

Serialization and batch tracking are of paramount importance in achieving effective traceability, especially in industries with large-scale production. Serialization entails assigning distinct identifiers to a single product, while batch tracking recognizes batches of products produced in tandem. Westerkamp et al. [

63] put forth a blockchain-based traceability system for a supply chain founded on smart contracts in order to create immutable recipes, being a representation of product compositions, so the ingredients and their transformations through manufacturing processes could be traced effectively.

Data anchoring is also a prime component of traceability, ensuring that data in electronic systems correctly aligns with real products. For food supply chains, this is particularly critical because traceability back to ingredients can help avoid issues related to food fraud as well as food safety. Qian et al. [

64] review many approaches to implementing traceability in food processing, emphasizing the combination of different approaches to enhance granularity and reliability.

3.3. Trust

Trust is classified into three broad dimensions, which are trust in data, trust in actors, and trust in processes. Trust in data refers to the reliability and honesty of data being applied in decision making. Trust has been found to be one of the vital factors contributing to regional development and technology transfer in economic geography, connecting the spatial challenges with social and economic conceptualizations of trust [

65]. Trust in processes refers to systems and processes that manage interactions, for instance, procurement processes in construction projects. From studies, it is clear that overemphasis on price and control in procurement disempowers trust, which suggests that there has to be a balance between trust and control to ensure proper governance [

66].

Blockchain technology and smart contracts have ushered in a paradigm change in the establishment and maintenance of trust. Smart contracts aim to replace conventional centralized powers with code-based, decentralized agreements that, in return, construct trust into their design. Blockchain systems are referred to as “trustless”, where they do not require putting any central authority into trust, since the technology itself ensures transparency and accountability [

67].

However, practical implementation of blockchain shows complexity. One instance of this is the manner in which blockchain can be implemented to facilitate trust in transactions, but social problems remain, as in the case of cryptocurrency where trust relationships between users and developers are influenced by a set of factors [

68]. Trust is not merely technical; it is also a social phenomenon, albeit influenced by cultural context and interpersonal relations. Wright et al. argue that by constructing trust as a social entity, it can be recognized as having fluidity and narrative nature [

69]. The technical and social trust dynamics are observed in sociotechnical systems where trust is architecturally and cognitively perceived. This dual strategy allows for a richer appreciation of how trust operates in complex systems, within which interdependencies between actors are made possible through trust relations [

70,

71].

4. Blockchain Capabilities in Supply Chain Data Operations

By leveraging distributed ledgers, consensus protocols, and smart contracts, blockchain systems provide an auditable and tamper-proof environment for recording transactions and verifying asset flows. This technological foundation directly supports the operationalization of the core principles introduced earlier, ensuring data integrity, enhancing inter-organizational collaboration, and mitigating risks related to fraud, counterfeiting, and opacity.

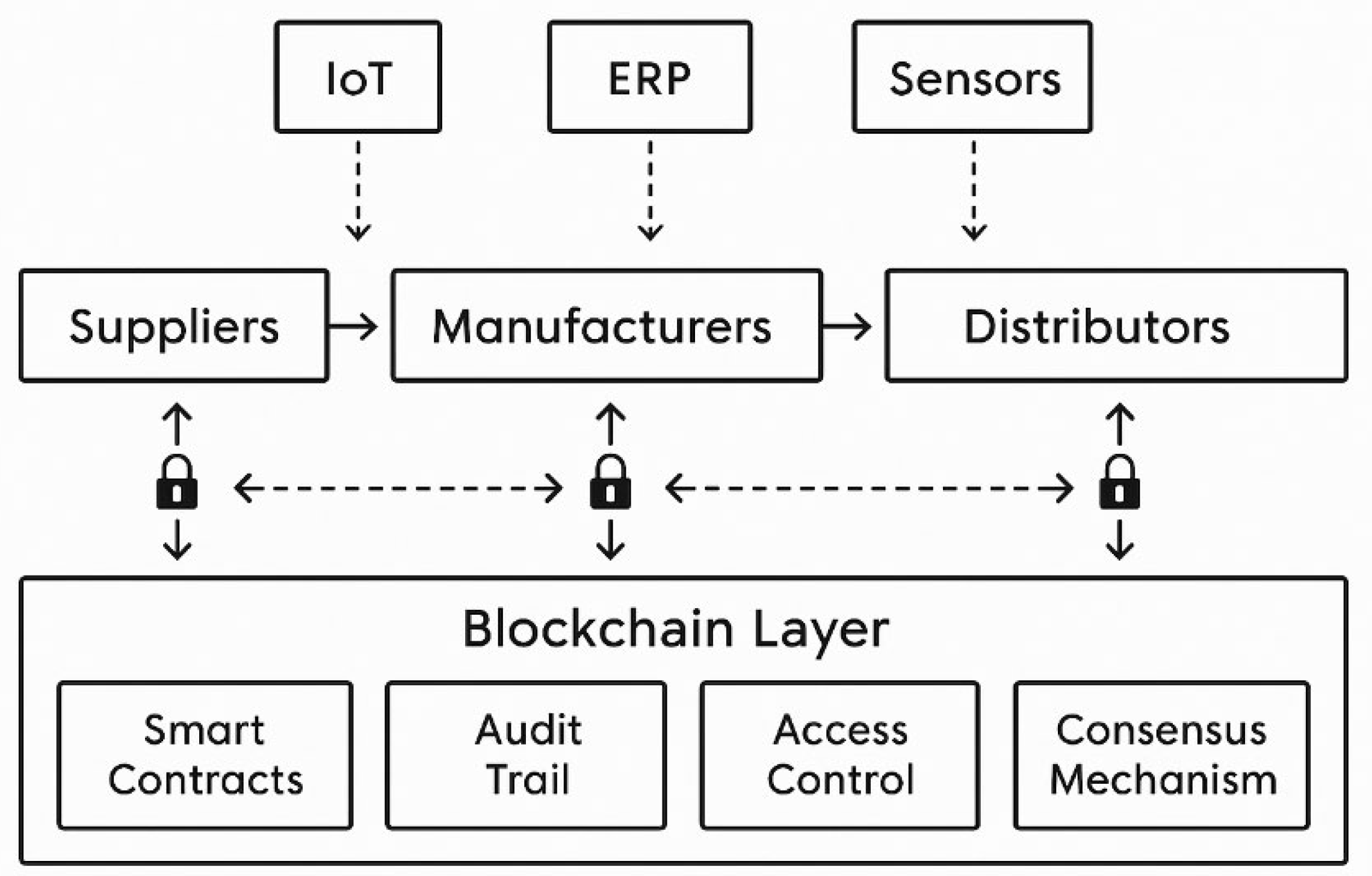

Figure 4 shows how blockchain interacts with various data sources and supply chain entities to support secure information flow. This section explores how blockchain architecture enables these outcomes, with a focus on practical implementations, key performance metrics, and strategic value creation across diverse supply chain sectors.

4.1. Data Integrity and Validation

Traditional supply chain networks are usually marred by data manipulation, fraud, and lack of transparency, which equate to significant operating inefficiencies and loss of trust between partners [

72,

73]. Blockchain technology addresses these issues by providing a decentralized record book that saves transactions securely and in a tamper-proof manner. Each transaction is connected to the prior transaction with the help of cryptography, and the set of blocks creates an immutable chain that can be confirmed by all players in the network. Through this method, information inscribed on the blockchain cannot be erased or changed without the consensus of the network, thereby preserving its integrity [

74,

75].

Several studies have proposed the practical application of blockchain technology in enhancing data integrity in supply chains. For instance, Kerschbaum [

72] shares the usage of public-key-encrypted Bloom filters to verify supply chain data while maintaining privacy. The presence of the data can be verified by authorized individuals without revealing sensitive information, thereby providing integrity and confidentiality.

The application of smart contracts on blockchain technology has been proven to secure and automate transactions and enhance data integrity. Koirala et al. [

76] outline a model that employs smart contracts to provide ownership and traceability within supply chains and illustrate how blockchain technology can make administrative processes easier and reduce fraud risks. Shetty et al. [

77] illustrate how a blockchain system can ensure the integrity of personal health data through record anchoring on an unhackable ledger. Not only does this protect sensitive information, but it also ensures a permanent record of data integrity accessible to authorized parties.

4.2. Decentralized Identity and Access Control

The use of decentralized identifiers enables users to authenticate and manage their access to various resources throughout the supply chain. In addition to enhancing security, this approach ensures legitimate parties have access to sensitive information only, thereby solving privacy problems typical in standard centralized systems [

78,

79].

Access control is extremely critical in supply chains, where sensitivity of the data requires them to be protected from unapproved access. Traditional access control models suffer from scaling and security problems, particularly in large environments with a large number of stakeholders. Blockchain technology introduces novel paradigms of access control that utilize smart contracts and attribute-based access control (ABAC) models. One such implementation is the Access Chain framework, which deploys a dual-ledger approach to dynamically manage access privileges. Fine-grained access control is offered by this framework to ensure access to only authorized data by authenticated users while ensuring network scalability [

79]. Multiauthority attribute-based access control schemes have also been proposed for enhanced security and privacy in multi-authority blockchain-based information sharing, with multiple authorities governing user attributes and access permissions effectively [

80].

The decentralized nature of blockchain naturally improves security by eliminating points of failure. All transactions are recorded on a network of ledgers, hence making it virtually impossible for hackers to alter data without the agreement of the network. Transparency is crucial in supply chains, where the trust of participants takes precedence over everything. Blockchain can integrate advanced cryptographic techniques to ensure sensitive information remains secure. For example, the use of zero-knowledge proofs allows for the verification of transactions without compromising on underlying information, thus enhancing privacy while maintaining integrity in shared information [

81,

82]. This is particularly useful in sectors like healthcare, where patient data should not be disclosed but access should be provided to stakeholders who need it [

83,

84].

Certain case studies illustrate the practical applications of blockchain in decentralized identity and access control in supply chains. For instance, utilization of a blockchain-based identity management system for disaster relief has identified how decentralized identity can make relief and resources easily accessible to refugees so that only legitimate individuals receive help [

85]. Within the agricultural sector, blockchain has been utilized to roll out a data system to enhance traceability and security along the supply chain. It facilitates secure sharing of information between consumers, distributors, and farmers, where all the stakeholders obtain access to information they need without exposing sensitive information [

82,

86].

4.3. Automated Transactions and Smart Contracts

The application of smart contracts to supply chains has been proven to drastically improve operating efficiency. For instance, in vendor-managed inventory, smart contracts enable real-time data sharing and automatic processing of replenishment, which can lead to cost reduction and an improved service level [

87]. In the pharmaceutical sector, smart contracts can support complex interactions among multiple stakeholders, with guaranteed compliance and long traceability of drug products [

88].

Use of smart contracts in agricultural supply chains has also demonstrated the ability to enhance traceability and responsibility. Through the maintenance of every transaction related to agricultural products on a blockchain, parties can easily trace the origin and history of products, thus guaranteeing quality and safety [

89]. This is particularly critical where consumer trust is the largest consideration, such as in the case of food and medicine.

There have been several reports of the practical uses of smart contracts in supply chain management. For example, it was proposed that a traceability platform for goods on a blockchain system would address transparency and accountability challenges in food safety [

90]. Smart contracts are employed by such a system to mark each transaction on a distributed ledger so that tracking goods from farm to plate is easy.

The COVID-19 pandemic highlighted that having robust supply chain solutions is important. A blockchain solution through smart contracts was intended to run the supply chain of personal protective equipment such that transactions would be traceable and secure [

84]. The solution improved visibility but also facilitated faster response times during times of acute shortage.

4.4. Interoperability and System Integration

The fact that data management systems cannot interoperate is a major discourager of traceability operations in supply chain management [

91]. This can be best observed within multimodal transportation activities, where heterogeneous systems must communicate to track products effectively. Karan and Irizarry [

92] emphasize the need for a spatial data platform that unifies various data sources, like building information modeling and geographic information systems. This infrastructure not only enhances data exchange but also supports spatial analysis, which is critical in logistics and supply chain management. The integration of these technologies supports a more integrated operational environment, allowing stakeholders to make informed decisions through real-time information.

Blockchain technology offers a robust solution for interoperability problems in supply chains. By offering a decentralized, immutable ledger, blockchain enables secure and transparent data sharing among all stakeholders in the supply chain. Transparency builds trust and collaboration, which are crucial in enabling supply chains to function correctly. For instance, Montes et al. [

93] refer to the way IBM utilized blockchain to mechanize supply chain functions, reducing transaction times significantly and making operations more efficient. Utilizing blockchain in supply chain management can strengthen coordination and information-sharing capabilities. Interoperating blockchain technology without interruptions in supply chain systems improves operational-level capabilities, leading to improvements in performance metrics such as process efficiency and quality compliance [

94].

4.5. Governance and Stakeholder Collaboration

Blockchain technology enhances governance by having a tamper-proof and decentralized ledger that records all transactions in an open format. Transparency using the technology fosters stakeholder trust as all the stakeholders can authenticate and validate data integrity without relying on a central entity. The ability to track and trace the product throughout the supply chain also helps to fulfill environmental, social, and governance (ESG) criteria, which are gaining more prominence in the eyes of stakeholders [

95].

Collaboration among stakeholders is important towards creating operational efficiencies and supply chain sustainability. Blockchain enables such collaboration through the facilitation of real-time data sharing and communication among all stakeholders involved. This aspect proves beneficial in complex supply chains, where multiple stakeholders must cooperate in their behavior to enable smooth operations. Research has determined that blockchain can significantly increase stakeholder interaction and collaboration by reducing information asymmetry and enhancing trust [

73,

96]. For instance, in the renewable energy sector, blockchain ensures stakeholders can validate the origin of materials and certify compliance with sustainability standards, thereby encouraging collaboration among manufacturers, suppliers, and buyers [

95].

Incorporating cultural intelligence into blockchain governance also improves cooperation. Awan et al. [

97] explain that cultural intelligence in intercultural relations in supply chains is essential, and businesses with higher cultural intelligence are more likely to employ blockchain for cooperative activities.

5. Synthesis of Quantitative Findings

Empirical research over the past decade has developed various metrics to quantify transparency, traceability, and trust outcomes in organizations and supply chains. Studies often construct composite indices/scores (e.g., transparency score, trust index, traceability score) or measure concrete outcomes (e.g., time-to-trace, audit counts, defect rates) using survey data, experiments, or system logs. For example, Crepaz & Arikan [

98] used a controlled experiment to show that higher policy “transparency” (through information disclosure) raised an aggregate political trust score among participants (mean trust rose from ~0.532 to 0.557 in the high-transparency group). Similarly, blockchain-based traceability interventions in supply chains have been found to sharply improve trust metrics and trace metrics. One study of blockchain in food and auto supply chains reported that a consumer trust index climbed from ~0.50 to ~0.85 after implementing traceability technology [

99], while traceability time was cut by two-thirds (e.g., from 72 h to 24 h) and counterfeiting rates halved [

100]. Surveys of consumers and managers repeatedly find positive correlations between information transparency (or traceability) and trust: for instance, supply-chain transparency (via accurate, timely data) was shown to significantly boost consumer trust and purchase intent [

101]. In finance and governance, “transparency scores” of reports or disclosure practices correlate with stakeholder confidence: effective audits and open reporting reduce information asymmetry and increase investor confidence [

102]. In short, quantitative metrics—transparency indices, trust indices, trace delays, audit frequency, etc.—consistently show that higher transparency/traceability associates with higher trust and performance (

Table 2).

Transparency metrics. Many studies define a composite transparency score or index (often on a 0–1 or 0–100 scale) based on reported information. For example, country or organizational transparency indices (analogous to the Open Budget or Corruption Perception indices) are used in policy studies [

98,

102]. Higher scores indicate more open reporting. In audit-focused work, “transparency” is often operationalized by the degree of disclosure in financial statements; firms with higher audited-report transparency tend to earn higher stakeholder trust [

102,

103]. In practice, transparency metrics might count disclosed items or use survey scales (e.g., Likert ratings of perceived disclosure).

Traceability metrics. Traceability is frequently measured by trace delays, traceability time, or a traceability index. For instance, researchers may record the elapsed time to trace a product from shelf to source, or use checklists to rate the percentage of supply-chain stages that are trackable. In a case study of blockchain deployment, the average traceability time dropped from 72 h to 24 h (a 66.7% reduction) [

100]. Other work uses an abstract traceability score (e.g., 1–10) to reflect how fully products can be tracked; one multi-industry survey reported a pre- vs. post-blockchain traceability score change from 5.4 to 8.6 [

104]. Supply-chain reviews also track related metrics like reductions in counterfeit incidence or product recall frequency under improved traceability regimes [

100,

104].

Trust metrics. Trust outcomes are often quantified via trust indices or scales. Studies commonly survey participants or consumers and compute an aggregate trust score (e.g., 0–10 or 0–100) representing confidence in an organization, brand, or supply chain. For example, Crepaz and Arikan combined multiple trust-related questions into a political trust index [

98]. In supply-chain contexts, scholars have defined a Consumer Trust Index (CTI) to gauge trust in product provenance. Nalini et al. (2024) measured the CTI before and after blockchain-based milk traceability for two dairy brands: the CTI rose from ~0.50 to ~0.85 (on a 0–1 scale) with the new system [

99]. Another study reported a trust index rising from 4.8 to 7.9 (on a 0–10 scale) following blockchain adoption, alongside fraud rates dropping from 10% to 2% [

104]. In field surveys, consumers generally indicate significantly higher trust in products or companies that offer greater visibility. Nguyen and Nguyen (2025) found that transparency and traceability in Vietnamese food supply chains had strong positive effects on consumer trust [

101].

Table 2.

Selected empirical studies and their quantitative transparency/traceability/trust metrics and outcomes. (Metrics shown illustrate measurement scales or baseline→post-treatment changes).

Table 2.

Selected empirical studies and their quantitative transparency/traceability/trust metrics and outcomes. (Metrics shown illustrate measurement scales or baseline→post-treatment changes).

| Study | Metric(s) | Data/Method | Outcome (Change/Correlation) | Year | Sector |

|---|

| Crepaz & Arikan (2023) [98] | Political Trust Index (0–1 scale) | Lab experiment/survey | Mean trust ↑ from 0.532 (control) to 0.557 (high info) | 2023 | Public (govt. policy) |

| Nguyen & Nguyen (2025) [101] | Consumer trust (survey scale); transparency/traceability factors | Online survey + PLS-SEM | Greater transparency/traceability → higher consumer trust and buying intent | 2025 | Food supply chain |

| Nalini et al. (2024) [99] | Consumer Trust Index (CTI, 0–1 scale) | Field pilot (IoT and blockchain in dairy) | CTI ↑ from ~0.50 to ~0.85 after blockchain traceability | 2024 | Dairy supply chain |

| Kumar (2024) [100] | Traceability time (h); Consumer Trust Index (0–10); counterfeit incidence (%) | Mixed: surveys (120 SC managers), case studies | Traceability time ↓ 72 h→24 h; Trust index ↑6.5→8.2 (±0.3); counterfeits ↓15%→5% | 2024 | Automotive supply chain |

| Radhika et al. (2025) [105] | Customer Trust Index (0–100); blockchain adoption score (0–1) | Case comparisons (blockchain vs. control) | Trust Index avg. ≈68.4; correlated positively with blockchain use; higher trust → higher recycling rates | 2024 | Circular economy/manufacturing |

| Kannaa and Akram (2025) [104] | Traceability score (1–10); Trust Index (0–10); fraud incidence (%) | Cross-industry survey (50 firms) | Traceability score ↑5.4→8.6; Trust Index ↑4.8→7.9; fraud ↓10%→2% post-blockchain | 2025 | Mixed (manuf., agri., med.) |

| Allee et al. (2019) [103] | Disclosure transparency (binary/score) | Archival (govt. financials) | “High-trust” agencies more likely to report errors transparently, showing trust fosters disclosure | 2019 | Public finance |

| Anjani (2023) [102] | Audit effectiveness (qualitative) | Lit. review/case examples | Effective audits reduce asymmetry, and boost stakeholder confidence and credibility | 2023 | Financial auditing |

Most studies combine quantitative surveys or experiments with metric construction. Strengths include the use of controlled experiments (e.g., Crepaz and Arikan’s randomized transparency treatments [

98]) and objective pre/post measures (e.g., trace time logs [

100]). Mixed-method designs (surveys plus case studies) add depth, as in the automotive blockchain study [

100]. Many employ structural equation modeling or regression to validate links between transparency/traceability and trust.

However, limitations abound. Self-reported trust/transparency indices can suffer subjective bias and vary by context. Survey samples are often small or localized (e.g., 430 Vietnamese consumers [

101], 120 supply-chain professionals [

100]), limiting generalizability. Most work is cross-sectional or single-intervention, making causal claims difficult (except where experiments are used [

98]). Definitions and scales also vary widely—what one study calls the “traceability score” might be another’s “trace delay”—hindering comparison. Many studies focus on promising technologies (blockchain/IoT) or specific sectors (food/dairy, manufacturing), raising concerns of publication bias. Quantitative results often omit long-term dynamics: e.g., an initial rise in trust post-intervention may not persist.

6. Discussion

The prospects for blockchain adoption vary significantly across different industries. For instance, in the management of food supply chains, blockchain promises improvements in traceability and compliance with safety standards [

106,

107]. Nevertheless, industries like construction may face more significant barriers due to the complexity of stakeholder communication along with the traditional nature of the business [

12]. Chang et al. [

22] propose a blockchain-based supply chain process framework emphasizing the need for transparency and collaboration among the stakeholders. The framework illustrates how blockchain can facilitate a shared information ledger, promoting multilateral collaboration and accountability.

Blockchain has been hailed as a game-changing innovation in supply chain management, but its use is not universally applicable across all industries. The feasibility of blockchain adoption and value proposition depend on the character of the supply chain, regulatory imperatives, and the kind of products or services being handled.

Table 3 outlines sector-specific blockchain applications, benefits, and limitations.

6.1. Barriers and Implementation Challenges

Despite the potential applications of blockchain in supply chain management, there are several challenges to its widespread adoption. The challenges vary from inter-organizational and intra-organizational barriers to technical limitations and exogenous factors such as regulatory compliance [

114]. Cultural fit of blockchain solutions is one of the important determinants of their success in different industries [

115]. Also, there is a lack of sector-specific adoption frameworks that align blockchain design with the unique operational, regulatory, and cultural contexts of different industries. Much of the literature discusses blockchain in broad terms, without adequately considering industry-specific constraints such as perishable product lifecycles, data privacy laws, or proprietary data sensitivity.

6.1.1. Technical Problems

Technical problems related to the application of blockchain technology in supply chains are significant. The most alarming of these problems is that system integration and design may be extremely complicated. Most companies find it difficult to adapt existing infrastructure to accommodate blockchain solutions, potentially resulting in interoperability issues and increasing cost [

116,

117]. The scalability of blockchain networks is an issue as most current solutions are not capable of managing the amount of transactions in a large supply chain [

118].

The integration of blockchain with other emerging technologies, such as the IoT and AI, is necessary to tap into its full potential. Such adoption, however, has the tendency to require heavy monetary investments in emerging technologies as well as staff training, which could be a hindrance to most organizations [

29,

119]. High degrees of cybersecurity are also necessary, as the decentralized nature of blockchain can render organizations susceptible to new types of risks unless properly managed [

120].

6.1.2. Organizational Issues

Organizational issues also play a significant role in applying blockchain technology to supply chains. Resistance to change is a daily problem because stakeholders may oppose the application of new technologies that disrupt existing procedures [

119]. It is caused by ignorance of the possible benefits of blockchain, as well as the fear of investment costs [

121].

The successful implementation of blockchain requires collaboration among various stakeholders including suppliers, manufacturers, and retailers. The variations in goals and priorities among these stakeholders might discourage mutual creation of the strategy for adopting blockchain [

122,

123]. Employee and management unacquaintance with blockchain technology is also a hindrance to advancement since companies might not possess the necessary expertise required to execute and oversee blockchain applications [

122,

124].

6.1.3. Legal and Ethical Challenges

The legal and ethical implications of the use of blockchain technology in supply chain management are multifaceted. One of the key issues is the lack of a clear regulatory framework for using blockchain technology. This creates uncertainty, which may dissuade organizations to invest in blockchain technology solutions as they may fear probable legal suits or breaches [

118,

125]. The decentralized nature of blockchain raises concerns about ownership of data and privacy. Companies must find their way through complex regulatory climates to ensure data protection laws, such as the European Union’s General Data Protection Regulation (GDPR) [

117]. The ethical implications of using blockchain technology, particularly transparency and accountability, also need utmost consideration. Companies should balance the benefits of openness with the potential risks of exposing sensitive information [

126].

6.2. Limitations of the Review

This study is a narrative review, not a systematic review. Consequently, no attempt is made to claim exhaustive coverage of all literature, and no inclusion and exclusion criteria, whether formal or not, are invoked. Sources were selected on the basis of thematic relevance, range of opinion, and balance of geographies and sectors. While this approach enables broad conceptual synthesis, certain relevant studies may be omitted. The findings are thus to be considered a conceptual mapping and gap identification exercise, rather than a statistically generalizable study.

6.3. Research Gaps and Future Directions

While many studies establish their own indices, for example, “trust score” or “traceability level”, insufficient consensus has emerged about definitions, scales, or validation procedures. Such variability hinders cross-study comparison as well as the conduct of a meta-analysis or policy benchmarking. Future research should be directed toward developing uniform frameworks and scalable metrics deployable across industries, possibly in terms of available standards in financial auditing, quality control, or cybersecurity.

Most of the current work is based on consumer, manager, or expert surveys in which transparency, traceability, and trust improvements are rated subsequent to blockchain implementation. While useful for exploratory research, self-reported measures suffer from social desirability bias and contextual limitedness. Stronger work involving objective performance measures such as audit logs, product tracking timestamps, defect frequencies, or recall frequencies is needed. The connection of real supply chain data, particularly in blockchain pilots, would make it possible to verify more strongly blockchain’s measurable impact on transparency, traceability, and trust outcomes.

There is a paucity of longitudinal and multi-step research comparing blockchain’s impact over the long-term. Most existing research measures transparency, traceability, and trust results soon after deployment or with cross-sectional designs, failing to capture supply chain relationship dynamics and trust changes. Trust, in particular, is not a time-invariant variable, it grows and erodes over time. Long-term-effect studies of how mechanisms of traceability and transparency affect the resilience of trust against disruptions, regulatory changes, or reputation crises should be included in future research.

Whereas blockchain provides structural data integrity and auditability of the transactions, IoT, AI, and digital twin technologies offer real-time sensing, forecasting, and simulation. There is limited research that investigates how these technologies interact synergistically to enhance transparency, traceability, and trust in supply chain systems. Hybrid digital infrastructure models may be researched further for how sensor data or AI processing can be anchored or certified on the blockchain for improving traceability and facilitating trust-based automated decision making.

There is a need for broader, cross-industry empirical studies with consideration of various regulatory environments, culture contexts, and firm sizes. There are few studies, restricted to food, pharma, or manufacturing supply chains, normally confined to one country or region. Such narrow constraints limit the generalizability of findings. Future studies ought to use comparative or international designs, including small and medium-sized enterprises (SMEs), public–private partnerships, and developing economy supply chains. Such studies may provide information on the scalability and adaptability of blockchain solutions to transparency, traceability, and trust over a variety of operating environments.

7. Conclusions

Across sectors such as food, pharmaceuticals, and manufacturing, blockchain’s core capabilities, immutability, distributed consensus, smart contracts, and decentralized identity, offer significant potential to enhance the quality, security, and transparency of supply chain data. Its integration with other digital technologies like IoT and AI has further expanded its applicability in real-time tracking, event validation, and automation. However, the review also underscores important limitations, particularly concerning scalability, interoperability, legal ambiguity, and the cost and complexity of implementation. Blockchain’s potential remains compelling, but its practical realization demands tailored strategies aligned with organizational maturity and ecosystem readiness.

This paper reasserts the critical importance of treating transparency, traceability, and trust as distinct yet interconnected pillars within blockchain-enabled data-driven supply chain management. Transparency enables visibility into transactions and operations, traceability ensures the end-to-end trackability of goods and data, and trust serves as both an outcome and a prerequisite for multi-stakeholder collaboration. By disaggregating these concepts, this review has demonstrated how specific blockchain functions, such as data anchoring, access control, and smart contract enforcement, map uniquely to each of these pillars. The conceptual clarity gained through this dissection not only helps overcome the ambiguity in the existing literature but also strengthens the theoretical foundation for future empirical assessments and system design.

Despite numerous pilot projects demonstrating blockchain’s value in enhancing transparency, traceability, and trust, widespread adoption at scale remains elusive. Many current implementations are limited to controlled environments or single-use cases, constrained by technical challenges, lack of standardization, and stakeholder resistance. Moving from pilot to scaled deployment requires a concerted effort to overcome both technical and organizational barriers. This includes creating interoperable platforms, refining legal and governance frameworks, ensuring data quality at the point of entry, and aligning incentives among diverse stakeholders. Moreover, clearer performance benchmarks and return-on-investment indicators are needed to justify long-term investment and integration.

The path forward involves both research innovation and strategic implementation. Researchers must pursue more robust, cross-industry studies that measure the long-term, quantifiable effects of blockchain on transparency, traceability, and trust in diverse supply chain environments. Practitioners, meanwhile, must shift from proof-of-concept to operational readiness by embedding blockchain within broader digital transformation agendas. When paired with supportive policies, standards, and digital ecosystems, blockchain can transition from a promising pilot technology to a scalable, trust-enhancing engine at the core of data-driven supply chain management.

Author Contributions

Conceptualization, M.M.; methodology, H.T.; validation, M.M. and H.T.; formal analysis, H.T. and M.M.; resources, H.T.; data curation, M.M.; writing—original draft preparation, M.M.; writing, review and editing, M.M. and H.T.; visualization, M.M.; supervision, H.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| IoT | Internet of Things |

| AI | Artificial intelligence |

References

- Özkanlısoy, Ö.; Akkartal, E. Digital transformation in supply chains: Current applications, contributions and challenges. Bus. Manag. Stud. Int. J. 2021, 9, 32–55. [Google Scholar] [CrossRef]

- Li, P.; Chen, Y.; Guo, X. Digital transformation and supply chain resilience. Int. Rev. Econ. Financ. 2025, 99, 104033. [Google Scholar] [CrossRef]

- Buntak, K.; Kovačić, M.; Mutavdžija, M. Measuring digital transformation maturity of supply chain. Teh. Glas. 2021, 15, 199–204. [Google Scholar] [CrossRef]

- Adama, H.E.; Popoola, O.A.; Okeke, C.D.; Akinoso, A.E. Economic theory and practical impacts of digital transformation in supply chain optimization. Int. J. Adv. Econ. 2024, 6, 95–107. [Google Scholar] [CrossRef]

- Taherdoost, H.; Drazenovic, G.; Madanchian, M.; Khan, I.U.; Arshi, O. Business Transformation in the Era of Digital Disruption; IGI Global: New York, NY, USA, 2024. [Google Scholar]

- Hartley, J.L.; Sawaya, W.J. Tortoise, not the hare: Digital transformation of supply chain business processes. Bus. Horiz. 2019, 62, 707–715. [Google Scholar] [CrossRef]

- Wang, F.-K.; Du, T.; Li, E. Applying six-sigma to supplier development. Total Qual. Manag. Bus. Excell. 2004, 15, 1217–1229. [Google Scholar] [CrossRef]

- Singh, A.; Narain, R.; Yadav, R. A survey on relationships and cultural issues in supply chain management practices in Indian organisations. Int. J. Serv. Oper. Manag. 2006, 2, 256–278. [Google Scholar] [CrossRef]

- Onolaja, O.; Bahsoon, R.; Theodoropoulos, G. Trust dynamics: A data-driven simulation approach. In Proceedings of the IFIP International Conference on Trust Management, Copenhagen, Denmark, 29 June–1 July 2021; pp. 323–334. [Google Scholar]

- Sänger, J.; Richthammer, C.; Hassan, S.; Pernul, G. Trust and big data: A roadmap for research. In Proceedings of the 2014 25th International Workshop on Database and Expert Systems Applications, Munich, Germany, 1–5 September 2014; pp. 278–282. [Google Scholar]

- Francisco, K.; Swanson, D. The supply chain has no clothes: Technology adoption of blockchain for supply chain transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Akyuz, G.A.; Gursoy, G. Transformation of supply chain activities in blockchain environment. In Digital Business Strategies in Blockchain Ecosystems: Transformational Design and Future of Global Business; Springer: Berlin/Heidelberg, Germany, 2019; pp. 153–175. [Google Scholar]

- Gencer, A.E.; van Renesse, R.; Sirer, E.G. Service-oriented sharding with aspen. arXiv 2016, arXiv:1611.06816. [Google Scholar] [CrossRef]

- Grover, P.; Kar, A.K.; Vigneswara Ilavarasan, P. Blockchain for businesses: A systematic literature review. In Proceedings of the Challenges and Opportunities in the Digital Era: 17th IFIP WG 6.11 Conference on e-Business, e-Services, and e-Society, I3E 2018, Kuwait City, Kuwait, 30 October–1 November 2018; Proceedings 17. pp. 325–336. [Google Scholar]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Chavez, N.; Kendzierskyj, S.; Jahankhani, H.; Hosseinian, A. Securing transparency and governance of organ supply chain through blockchain. In Policing in the Era of AI and Smart Societies; Springer: Berlin/Heidelberg, Germany, 2020; pp. 97–118. [Google Scholar]

- Shahaab, A.; Maude, R.; Hewage, C.; Khan, I. Blockchain—A panacea for trust challenges in public services? A socio-technical perspective. J. Br. Blockchain Assoc. 2020, 3, 1–11. [Google Scholar] [CrossRef]

- Bustamante, P.; Cai, M.; Gomez, M.; Harris, C.; Krishnamurthy, P.; Law, W.; Madison, M.J.; Murtazashvili, I.; Murtazashvili, J.B.; Mylovanov, T. Government by code? Blockchain applications to public sector governance. Front. Blockchain 2022, 5, 869665. [Google Scholar] [CrossRef]

- Li, Z.-P.; Ceong, H.-T.; Lee, S.-J. The effect of blockchain operation capabilities on competitive performance in supply chain management. Sustainability 2021, 13, 12078. [Google Scholar] [CrossRef]

- Mvubu, M.; Naude, M.J. Blockchain in the logistics sector: A systematic literature review of benefits and constraints. J. Transp. Supply Chain Manag. 2024, 18, a1068. [Google Scholar] [CrossRef]

- Chang, S.E.; Chen, Y.-C.; Lu, M.-F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technol. Forecast. Soc. Change 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Fortuna, F.; Risso, M. Blockchain technology in the food industry. Symphonya. Emerg. Issues Manag. 2019, 2, 151–158. [Google Scholar] [CrossRef]

- Taherdoost, H. Application of Blockchain in the Manufacturing Sector. In Blockchain Technology for the Engineering and Service Sectors; Vaishnavi, V., Rajasekar, R., Moganapriya, C., Kumar, P.S., Eds.; Wiley: Hoboken, NJ, USA, 2025; pp. 345–375. [Google Scholar] [CrossRef]

- Wei, J.; Yi, X.; Yang, X.; Liu, Y. Blockchain-based design of a government incentive mechanism for manufacturing supply chain data governance. Sustainability 2023, 15, 6968. [Google Scholar] [CrossRef]

- Eletter, S.F.; Elrefae, G.A.; Yasmin, T.; Qasem, A.; Alshehadeh, A.R.; Belarbi, A. Leveraging Blockchain-Based Smart Contracts in the Management of Supply Chain: Evidence from Carrefour UAE. In Proceedings of the 2022 International Arab Conference on Information Technology (ACIT), Abu Dhabi, United Arab Emirates, 22–24 November 2022; pp. 1–5. [Google Scholar]

- Gomasta, S.S.; Dhali, A.; Tahlil, T.; Anwar, M.M.; Ali, A.M.S. PharmaChain: Blockchain-based drug supply chain provenance verification system. Heliyon 2023, 9, e17957. [Google Scholar] [CrossRef]

- Ellahi, R.M.; Wood, L.C.; Bekhit, A.E.-D.A. Blockchain-based frameworks for food traceability: A systematic review. Foods 2023, 12, 3026. [Google Scholar] [CrossRef]

- Adewusi, A.O.; Chikezie, N.; Eyo-Udo, N.L. Blockchain technology in agriculture: Enhancing supply chain transparency and traceability. Financ. Account. Res. J. 2023, 5, 479–501. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.; Keogh, J.G. Exploring blockchain research in supply chain management: A latent Dirichlet allocation-driven systematic review. Information 2023, 14, 557. [Google Scholar] [CrossRef]

- Kleinknecht, L. Can blockchain capabilities contribute to sustainable supply-chain governance? IEEE Eng. Manag. Rev. 2021, 49, 150–154. [Google Scholar] [CrossRef]

- Wang, M.; Wang, B.; Abareshi, A. Blockchain technology and its role in enhancing supply chain integration capability and reducing carbon emission: A conceptual framework. Sustainability 2020, 12, 10550. [Google Scholar] [CrossRef]

- Mohammed, C.P.; Chopra, S.R. Blockchain security implementation using Python with NB-IoT deployment in food supply chain. In Proceedings of the 2023 International Conference on Emerging Smart Computing and Informatics (ESCI), Pune, India, 1–3 March 2023; pp. 1–5. [Google Scholar]

- Rijanto, A. Blockchain technology roles to overcome accounting, accountability and assurance barriers in supply chain finance. Asian Rev. Account. 2024, 32, 728–758. [Google Scholar] [CrossRef]

- Ahmad, N.R. Exploring the Role of Digital Technologies in Enhancing Supply Chain Efficiency: A Case Study of E-Commerce Companies. Indus J. Soc. Sci. 2025, 3, 226–237. [Google Scholar] [CrossRef]

- Alotaibi, E.M.; Khallaf, A.; Abdallah, A.A.-N.; Zoubi, T.; Alnesafi, A. Blockchain-Driven Carbon Accountability in Supply Chains. Sustainability 2024, 16, 10872. [Google Scholar] [CrossRef]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Menon, S.; Jain, K. Blockchain technology for transparency in agri-food supply chain: Use cases, limitations, and future directions. IEEE Trans. Eng. Manag. 2021, 71, 106–120. [Google Scholar] [CrossRef]

- Cromwell, J.; Turkson, C.; Dora, M.; Yamoah, F.A. Digital technologies for traceability and transparency in the global fish supply chains: A systematic review and future directions. Mar. Policy 2025, 178, 106700. [Google Scholar] [CrossRef]

- Keogh, J.G.; Rejeb, A.; Khan, N.; Dean, K.; Hand, K.J. Optimizing global food supply chains: The case for blockchain and GSI standards. Build. Future Food Saf. Technol. 2020, 171–204. [Google Scholar] [CrossRef]

- Dave, M.; Patil, K.; Jaiswal, R.; Pawar, R. Monitoring supply chain of pharmaceutical drugs using blockchain. In Proceedings of the 2022 IEEE Delhi Section Conference (DELCON), New Delhi, India, 13 February 2022; pp. 1–5. [Google Scholar]

- Friedman, N.; Ormiston, J. Blockchain as a sustainability-oriented innovation?: Opportunities for and resistance to Blockchain technology as a driver of sustainability in global food supply chains. Technol. Forecast. Soc. Change 2022, 175, 121403. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, S.K. Application of blockchain technology in shaping the future of food industry based on transparency and consumer trust. J. Food Sci. Technol. 2023, 60, 1237–1254. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Influence of blockchain technology in manufacturing supply chain and logistics. Logistics 2022, 6, 15. [Google Scholar] [CrossRef]

- Prashanth, M.S.; Aluvalu, R.; Kantipudi, M. Enhancing Health Product Traceability on the Blockchain: A Novel Approach for Supply Chain Management inspection to AI. EAI Endorsed Transactions on Pervasive Health and Technology. 2024. Volume 10. Available online: https://publications.eai.eu/index.php/phat/article/view/5544 (accessed on 1 July 2025).

- Jimenez-Castillo, L.; Sarkis, J.; Saberi, S.; Yao, T. Blockchain-based governance implications for ecologically sustainable supply chain management. J. Enterp. Inf. Manag. 2024, 37, 76–99. [Google Scholar] [CrossRef]

- Jain, G.; Shrivastava, A.; Paul, J.; Batra, R. Blockchain for SME Clusters: An ideation using the framework of Ostrom Commons Governance. Inf. Syst. Front. 2022, 24, 1125–1143. [Google Scholar] [CrossRef]

- Mostafa, Q.; Houssaini, A. Blockchain: An ambitious technology for managing SCM. In Proceedings of the 2022 14th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), El Jadida, Morocco, 25–27 May 2022; pp. 1–6. [Google Scholar]

- Grover, P.; Kar, A.K.; Janssen, M.; Ilavarasan, P.V. Perceived usefulness, ease of use and user acceptance of blockchain technology for digital transactions–insights from user-generated content on Twitter. Enterp. Inf. Syst. 2019, 13, 771–800. [Google Scholar] [CrossRef]

- Ali, S.; Abdullah; Armand, T.P.T.; Athar, A.; Hussain, A.; Ali, M.; Yaseen, M.; Joo, M.-I.; Kim, H.-C. Metaverse in healthcare integrated with explainable AI and blockchain: Enabling immersiveness, ensuring trust, and providing patient data security. Sensors 2023, 23, 565. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Del Vecchio, P.; Oropallo, E.; Secundo, G. Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Inf. Manag. 2022, 59, 103508. [Google Scholar] [CrossRef]

- Bellini, E.; Iraqi, Y.; Damiani, E. Blockchain-based distributed trust and reputation management systems: A survey. IEEE Access 2020, 8, 21127–21151. [Google Scholar] [CrossRef]

- Mahyuni, L.P.; Adrian, R.; Darma, G.S.; Krisnawijaya, N.N.K.; Dewi, I.G.A.A.P.; Permana, G.P.L. Mapping the potentials of blockchain in improving supply chain performance. Cogent Bus. Manag. 2020, 7, 1788329. [Google Scholar] [CrossRef]

- Borole, M.; Nilange, A.; Velhal, K.; Joshi, T. A survey on blockchain for enabling transparency in transactions of government direct benefit transfers (DBT). Int. J. Comput. Appl. 2019, 181, 27–31. [Google Scholar] [CrossRef]

- Leonardi, P.M. Social media, knowledge sharing, and innovation: Toward a theory of communication visibility. Inf. Syst. Res. 2014, 25, 796–816. [Google Scholar] [CrossRef]

- Xu, R.; Li, C.; Joshi, J. Blockchain-based transparency framework for privacy preserving third-party services. IEEE Trans. Dependable Secur. Comput. 2022, 20, 2302–2313. [Google Scholar] [CrossRef]

- Urovi, V.; Jaiman, V.; Angerer, A.; Dumontier, M. Luce: A blockchain-based data sharing platform for monitoring data license accountability and compliance. Blockchain Res. Appl. 2022, 3, 100102. [Google Scholar] [CrossRef]

- Ravi, V.K.; Jampani, S. Blockchain integration in SAP for supply chain transparency. Integr. J. Res. Arts Humanit. 2024, 4, 10.55544. [Google Scholar] [CrossRef]

- Kim, H.M.; Laskowski, M. Toward an ontology-driven blockchain design for supply-chain provenance. Intell. Syst. Account. Financ. Manag. 2018, 25, 18–27. [Google Scholar] [CrossRef]

- Powell, W.; Foth, M.; Cao, S.; Natanelov, V. Garbage in garbage out: The precarious link between IoT and blockchain in food supply chains. J. Ind. Inf. Integr. 2022, 25, 100261. [Google Scholar] [CrossRef]

- Frankó, A.; Vida, G.; Varga, P. Reliable identification schemes for asset and production tracking in industry 4.0. Sensors 2020, 20, 3709. [Google Scholar] [CrossRef] [PubMed]

- Bacchetta, A.v.B.; Krümpel, V.; Cullen, E. Transparency with blockchain and physical tracking technologies: Enabling traceability in raw material supply chains. Mater. Proc. 2021, 5, 1. [Google Scholar]

- Westerkamp, M.; Victor, F.; Küpper, A. Blockchain-based supply chain traceability: Token recipes model manufacturing processes. In Proceedings of the 2018 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Halifax, NS, Canada, 30 July–3 August 2018; pp. 1595–1602. [Google Scholar]

- Qian, J.; Dai, B.; Wang, B.; Zha, Y.; Song, Q. Traceability in food processing: Problems, methods, and performance evaluations—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 679–692. [Google Scholar] [CrossRef]

- Murphy, J.T. Building trust in economic space. Prog. Hum. Geogr. 2006, 30, 427–450. [Google Scholar] [CrossRef]

- Erik Eriksson, P.; Laan, A. Procurement effects on trust and control in client-contractor relationships. Eng. Constr. Archit. Manag. 2007, 14, 387–399. [Google Scholar] [CrossRef]

- De Filippi, P.; Mannan, M.; Reijers, W. Blockchain as a confidence machine: The problem of trust & challenges of governance. Technol. Soc. 2020, 62, 101284. [Google Scholar] [CrossRef]

- Lee, M.; Frank, L.; IJsselsteijn, W. Brokerbot: A cryptocurrency chatbot in the social-technical gap of trust. Comput. Support. Coop. Work (CSCW) 2021, 30, 79–117. [Google Scholar] [CrossRef]

- Wright, A.; Ehnert, I. Making sense of trust across cultural contexts. In Organizational Trust: A Cultural Perspective; Cambridge University Press: Cambridge, UK, 2010; pp. 107–126. [Google Scholar]

- Chopra, A.K.; Paja, E.; Giorgini, P. Sociotechnical trust: An architectural approach. In Proceedings of the International Conference on Conceptual Modeling, Brussels, Belgium, 31 October 31–3 November 2011; pp. 104–117. [Google Scholar]

- Paja, E.; Chopra, A.K.; Giorgini, P. Trust-based specification of sociotechnical systems. Data Knowl. Eng. 2013, 87, 339–353. [Google Scholar] [CrossRef]

- Kerschbaum, F. Public-key encrypted Bloom filters with applications to supply chain integrity. In Proceedings of the IFIP Annual Conference on Data and Applications Security and Privacy, Richmond, VA, USA, 11–13 July 2011; pp. 60–75. [Google Scholar]

- Longo, F.; Nicoletti, L.; Padovano, A.; d’Atri, G.; Forte, M. Blockchain-enabled supply chain: An experimental study. Comput. Ind. Eng. 2019, 136, 57–69. [Google Scholar] [CrossRef]

- Ngamsuriyaroj, S.; Likittheerameth, T.; Kahutson, A.; Pathummasut, T. Package delivery system based on blockchain infrastructure. In Proceedings of the 2018 Seventh ICT International Student Project Conference (ICT-ISPC), Nakhon Pathom, Thailand, 11–3 July 2018; pp. 1–6. [Google Scholar]

- Dwivedi, S.K.; Amin, R.; Vollala, S. Blockchain based secured information sharing protocol in supply chain management system with key distribution mechanism. J. Inf. Secur. Appl. 2020, 54, 102554. [Google Scholar] [CrossRef]

- Koirala, R.C.; Dahal, K.; Matalonga, S. Supply chain using smart contract: A blockchain enabled model with traceability and ownership management. In Proceedings of the 2019 9th International Conference on Cloud Computing, Data Science & Engineering (Confluence), Noida, India, 10–11 January 2019; pp. 538–544. [Google Scholar]

- Shetty, S.; Liang, X.; Bowden, D.; Zhao, J.; Zhang, L. Blockchain-based decentralized accountability and self-sovereignty in healthcare systems. In Business Transformation Through Blockchain: Volume II; Springer: Berlin/Heidelberg, Germany, 2018; pp. 119–149. [Google Scholar]

- Figueroa, S.; Añorga, J.; Arrizabalaga, S. An attribute-based access control model in RFID systems based on blockchain decentralized applications for healthcare environments. Computers 2019, 8, 57. [Google Scholar] [CrossRef]

- Tan, L.; Shi, N.; Yu, K.; Aloqaily, M.; Jararweh, Y. A blockchain-empowered access control framework for smart devices in green internet of things. ACM Trans. Internet Technol. (TOIT) 2021, 21, 3433542. [Google Scholar] [CrossRef]

- Liu, C.; Xiang, F.; Sun, Z. Multiauthority Attribute-Based Access Control for Supply Chain Information Sharing in Blockchain. Secur. Commun. Netw. 2022, 2022, 8497628. [Google Scholar] [CrossRef]

- Thantharate, P.; Thantharate, A. ZeroTrustBlock: Enhancing security, privacy, and interoperability of sensitive data through ZeroTrust permissioned blockchain. Big Data Cogn. Comput. 2023, 7, 165. [Google Scholar] [CrossRef]

- Yakubu, B.M.; Alabdulatif, A.A.; Bhattarakosol, P. RiceChain-Plus: An enhanced framework for blockchain-based rice supply chain systems-ensuring security, privacy, and efficiency. PeerJ Comput. Sci. 2025, 11, e2926. [Google Scholar] [CrossRef]

- Egala, B.S.; Pradhan, A.K.; Badarla, V.; Mohanty, S.P. Fortified-chain: A blockchain-based framework for security and privacy-assured internet of medical things with effective access control. IEEE Internet Things J. 2021, 8, 11717–11731. [Google Scholar] [CrossRef]

- Omar, I.A.; Debe, M.; Jayaraman, R.; Salah, K.; Omar, M.; Arshad, J. Blockchain-based supply chain traceability for COVID-19 personal protective equipment. Comput. Ind. Eng. 2022, 167, 107995. [Google Scholar] [CrossRef]

- McIsaac, J.; Brulle, J.; Burg, J.; Tarnacki, G.; Sullivan, C.; Wassel, R. Blockchain technology for disaster and refugee relief operations. Prehospital Disaster Med. 2019, 34, s106. [Google Scholar] [CrossRef][Green Version]

- Yang, C.; Sun, Z. Data management system based on blockchain technology for agricultural supply chain. In Proceedings of the 2020 International Conference on Data Mining Workshops (ICDMW), Sorrento, Italy, 20 November 2020; pp. 907–911. [Google Scholar]

- Omar, I.A.; Jayaraman, R.; Salah, K.; Debe, M.; Omar, M. Enhancing vendor managed inventory supply chain operations using blockchain smart contracts. IEEE Access 2020, 8, 182704–182719. [Google Scholar] [CrossRef]

- Liu, X.; Barenji, A.V.; Li, Z.; Montreuil, B.; Huang, G.Q. Blockchain-based smart tracking and tracing platform for drug supply chain. Comput. Ind. Eng. 2021, 161, 107669. [Google Scholar] [CrossRef]

- Wang, L.; Xu, L.; Zheng, Z.; Liu, S.; Li, X.; Cao, L.; Li, J.; Sun, C. Smart contract-based agricultural food supply chain traceability. IEEE Access 2021, 9, 9296–9307. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Zhang, Y.; Chen, J. Smart contract-based product traceability system in the supply chain scenario. IEEE Access 2019, 7, 115122–115133. [Google Scholar] [CrossRef]

- Abed, M.; Charfeddine, I.; Benaissa, M.; Starostka-Patyk, M. Intelligent traceability system of containerized goods. Appl. Mech. Mater. 2013, 309, 241–251. [Google Scholar]

- Karan, E.P.; Irizarry, J. Developing a spatial data framework for facility management supply chains. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, Georgia, 19–21 May 2014; pp. 2355–2364. [Google Scholar]

- Montes, J.M.; Larios-Rosillo, V.M.; Avalos, M.; Ramírez, C.E. Applying Blockchain to Supply Chain Operations at IBM Implementing Agile Practices in a Smart City Environment. Res. Comput. Sci. 2018, 147, 65–75. [Google Scholar] [CrossRef]

- Nandi, M.L.; Nandi, S.; Moya, H.; Kaynak, H. Blockchain technology-enabled supply chain systems and supply chain performance: A resource-based view. Supply Chain Manag. Int. J. 2020, 25, 841–862. [Google Scholar] [CrossRef]

- Onukwulu, E.; Dienagha, I.; Digitemie, W.; Egbumokei, P. Blockchain for transparent and secure supply chain management in renewable energy. Int. J. Sci. Technol. Res. Arch. 2022, 3, 251–272. [Google Scholar] [CrossRef]

- Duan, K.; Pang, G.; Lin, Y. Exploring the current status and future opportunities of blockchain technology adoption and application in supply chain management. J. Digit. Econ. 2023, 2, 244–288. [Google Scholar] [CrossRef]

- Awan, U.; Kraslawski, A.; Huiskonen, J. Governing interfirm relationships for social sustainability: The relationship between governance mechanisms, sustainable collaboration, and cultural intelligence. Sustainability 2018, 10, 4473. [Google Scholar] [CrossRef]

- Kannaa, M.; Arikan, G. The effects of transparency regulation on political trust and perceived corruption: Evidence from a survey experiment. Regul. Gov. 2024, 18, 896–913. [Google Scholar]

- Nalini, P.; Balusamy, R.; Sivakumar, C. Smart Contracts and IoT Based Blockchain Framework for Decentralized Monitoring of Dairy Supply Chain Operations. J. Comput. Anal. Appl. (JoCAAA) 2024, 33, 561–579. [Google Scholar]

- Kumar, S. Enhancing transparency and traceability in supply chain management through blockchain integration. Int. J. Automob. Eng. 2024, 5, 01–07. [Google Scholar]

- Nguyen, M.H.; Nguyen, D.H. How do transparency and traceability enhance purchasing behaviors via consumer trust? Insights for food supply chains. J. Consum. Mark. 2025. [Google Scholar] [CrossRef]

- Anjani, P. Enhancing transparency and trust through effective financial statement audits. Adv. Manag. Audit. Res. 2023, 1, 103–113. [Google Scholar] [CrossRef]

- Allee, K.D.; Baik, B.; Han, S.Y.; Kim, B.H. Trust and Disclosure Transparency in Financial Reporting of Government Agencies (28 August 2019). Available online: https://ssrn.com/abstract=3444477 (accessed on 1 July 2025).

- K V Dinesh Kannaa, V.A.J. Impact of Blockchain Technology on Supply Chain Transparency and Efficiency. Int. J. Progress. Res. Eng. Manag. Sci. 2025, 5, 149–153. [Google Scholar]

- Radhika, K.; Uthaman, V.S.; Murgai, A.; Dnyaneshwar, V.D.; Singh, A.K.; Borah, S. Driving Circular Economy Strategies Through Digital Transformation and Emerging Technologies. J. Inf. Syst. Eng. Manag. 2025, 10, 30. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Yan, J.; Hu, G.; Shi, Y. Processes, benefits, and challenges for adoption of blockchain technologies in food supply chains: A thematic analysis. Inf. Syst. E-Bus. Manag. 2021, 19, 909–935. [Google Scholar] [CrossRef]

- Casino, F.; Kanakaris, V.; Dasaklis, T.K.; Moschuris, S.; Stachtiaris, S.; Pagoni, M.; Rachaniotis, N.P. Blockchain-based food supply chain traceability: A case study in the dairy sector. Int. J. Prod. Res. 2021, 59, 5758–5770. [Google Scholar] [CrossRef]

- Clauson, K.A.; Breeden, E.A.; Davidson, C.; Mackey, T.K. Leveraging Blockchain Technology to Enhance Supply Chain Management in Healthcare: An exploration of challenges and opportunities in the health supply chain. Blockchain Healthc. Today 2018, 1, 1–12. [Google Scholar] [CrossRef]

- Archa; Alangot, B.; Achuthan, K. Trace and track: Enhanced pharma supply chain infrastructure to prevent fraud. In Proceedings of the International Conference on Ubiquitous Communications and Network Computing, Bangalore, India, 3–5 August 2017; pp. 189–195. [Google Scholar]

- Harini, M.; Dhinakaran, D.; Prabhu, D.; Sankar, S.U.; Pooja, V.; Sruthi, P.K. Levarging blockchain for transparency in agriculture supply chain management using iot and machine learning. In Proceedings of the 2023 World Conference on Communication & Computing (WCONF), Raipur, India, 14–16 July 2023; pp. 1–6. [Google Scholar]

- Sajja, G.S.; Rane, K.P.; Phasinam, K.; Kassanuk, T.; Okoronkwo, E.; Prabhu, P. Towards applicability of blockchain in agriculture sector. Mater. Today Proc. 2023, 80, 3705–3708. [Google Scholar] [CrossRef]

- Bakhtiarizadeh, E.; Shahzad, W.M.; Poshdar, M.; Rotimi, J.O.B. Blockchain technology applicability in New Zealand’s prefabricated construction industry. Eng. Manag. Prod. Serv. 2022, 14, 103–112. [Google Scholar] [CrossRef]

- Toromade, A.S.; Soyombo, D.A.; Kupa, E.; Ijomah, T.I. Technological innovations in accounting for food supply chain management. Financ. Account. Res. J. 2024, 6, 1248–1258. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- AlKubaisy, Z.M.; Al-Somali, S.A. Factors influencing blockchain technologies adoption in supply chain management and logistic sectors: Cultural compatibility of blockchain solutions as moderator. Systems 2023, 11, 574. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Sharabati, A.-A.A.; Jreisat, E.R. Blockchain technology implementation in supply chain management: A literature review. Sustainability 2024, 16, 2823. [Google Scholar] [CrossRef]

- Weller, F. Blockchain Technology for Secure and Transparent Supply Chain Management. Int. J. Comput. Eng. 2024, 6, 15–28. [Google Scholar] [CrossRef]