Mechanical Characterization and Azithromycin Coating of Melt Electrowritten Polycaprolactone Mesh Implants for Prolapse Repair

Abstract

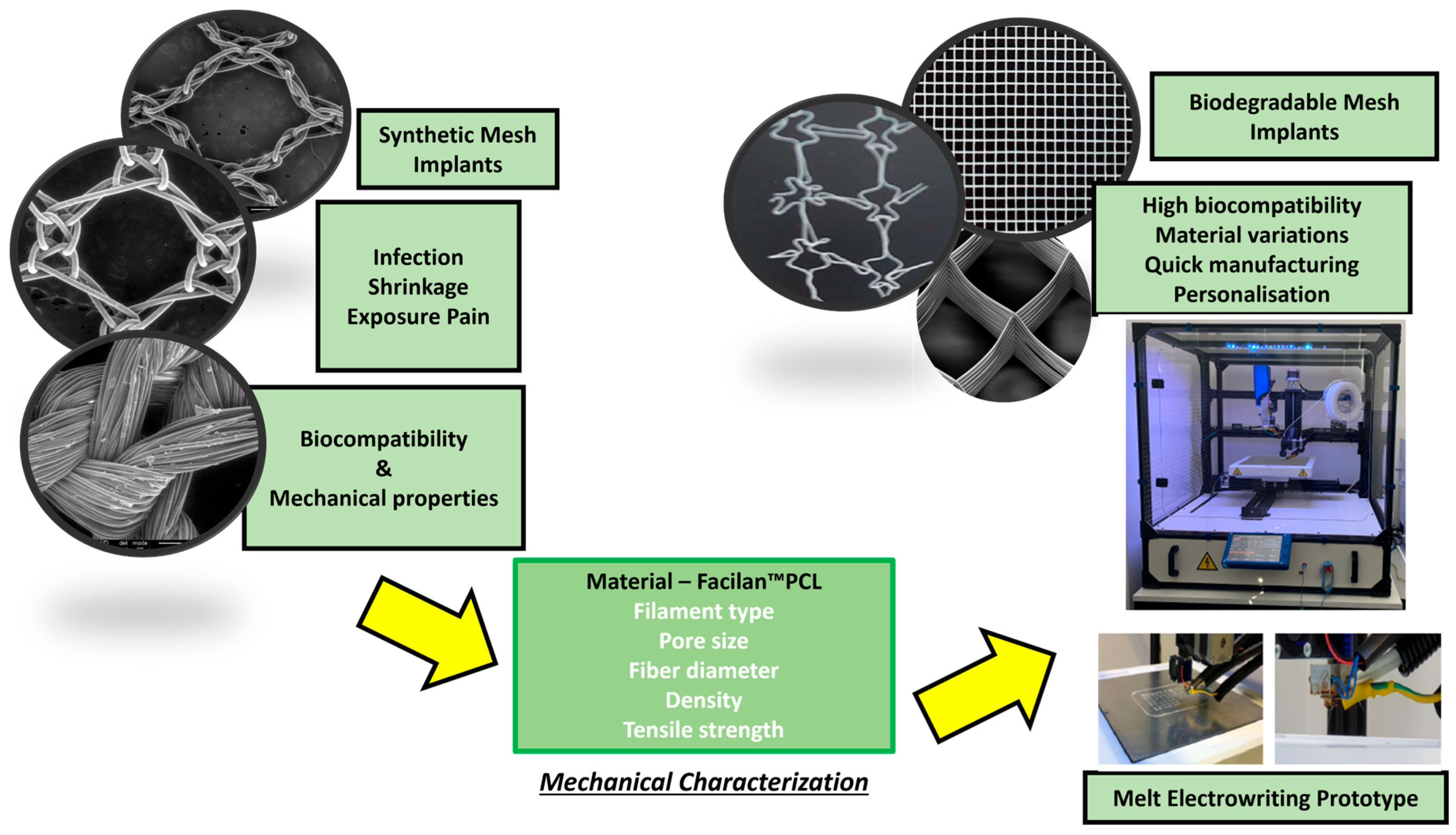

1. Introduction

2. Materials and Methods

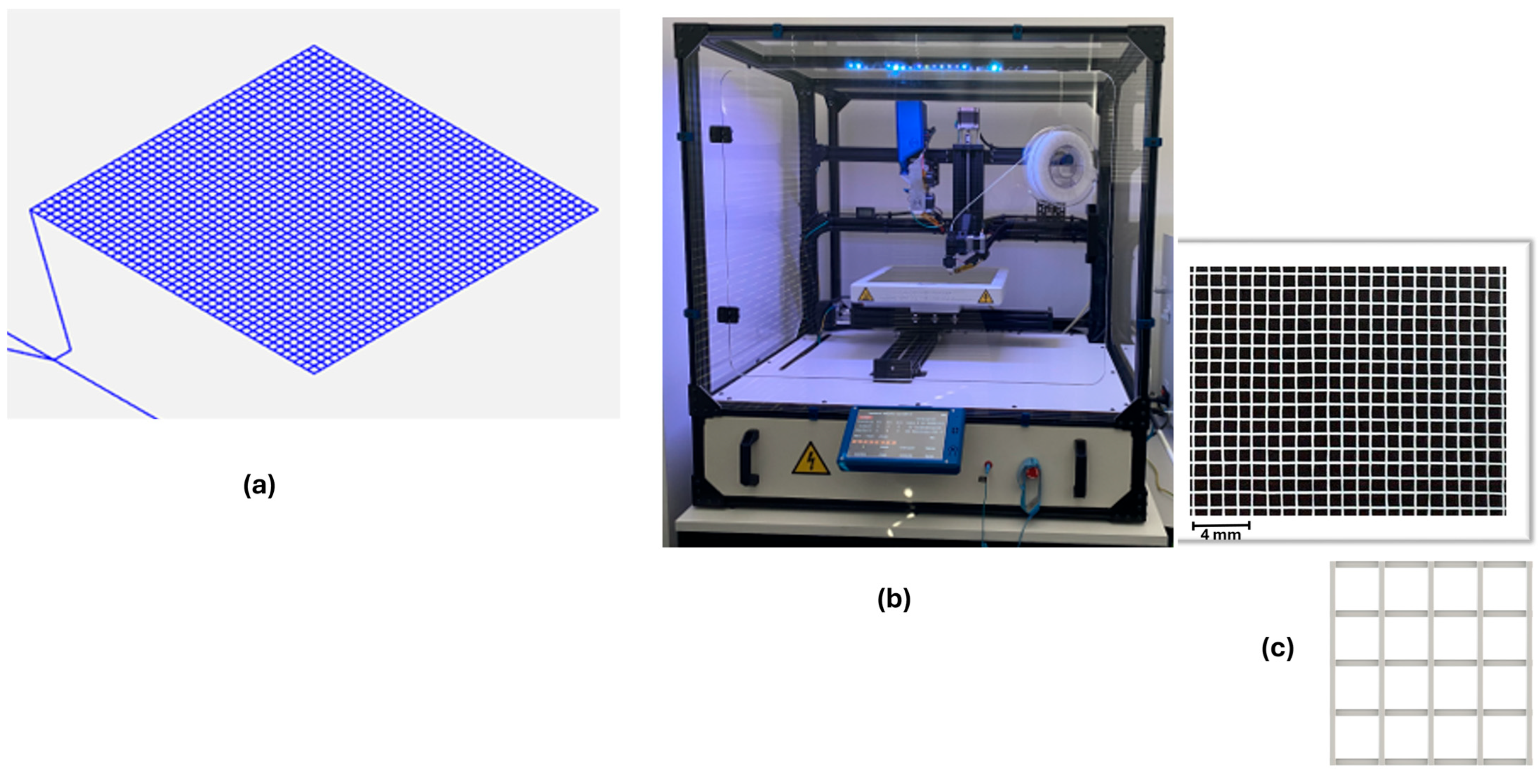

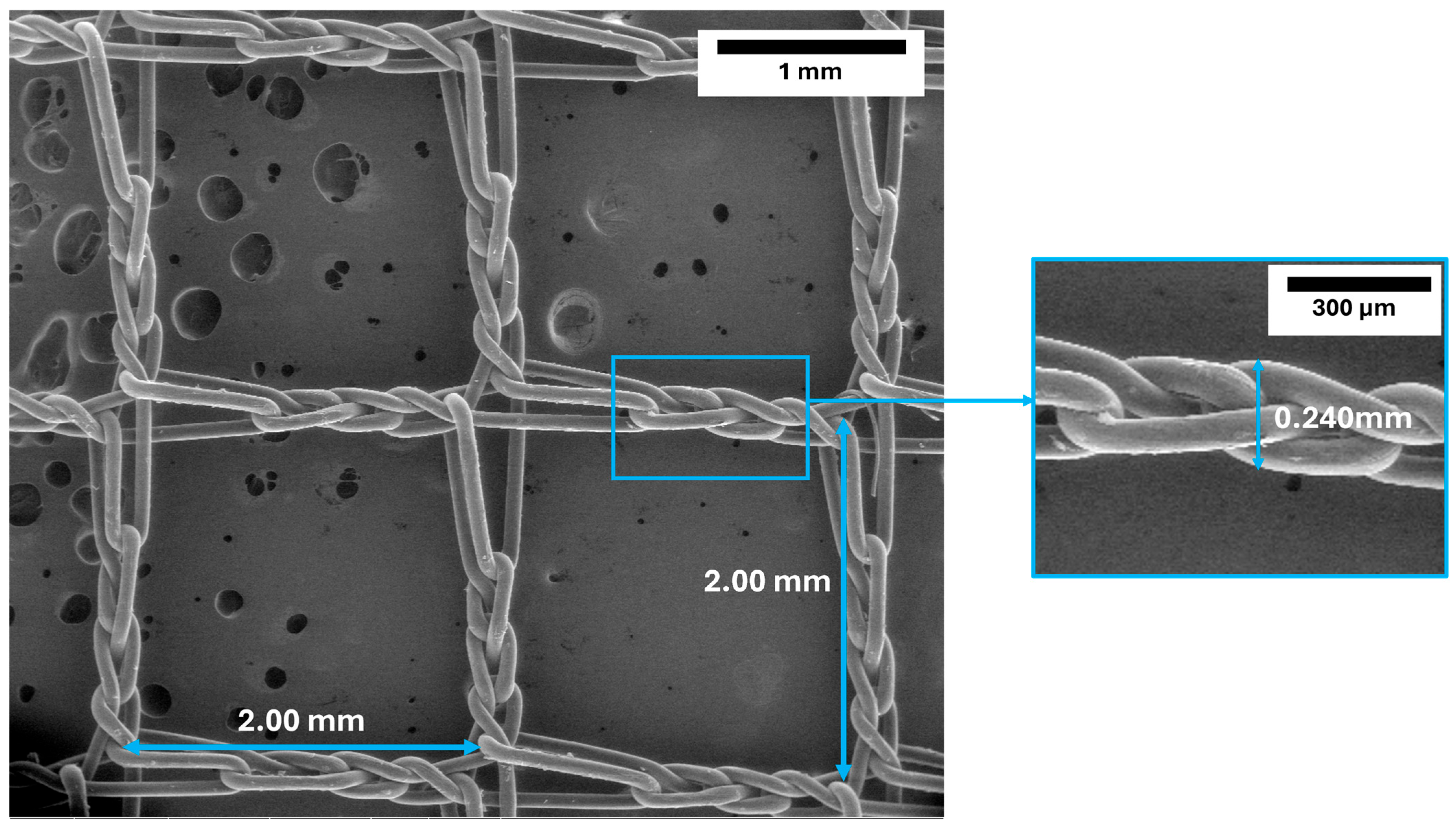

2.1. Biodegradable PCL Mesh Implants Production

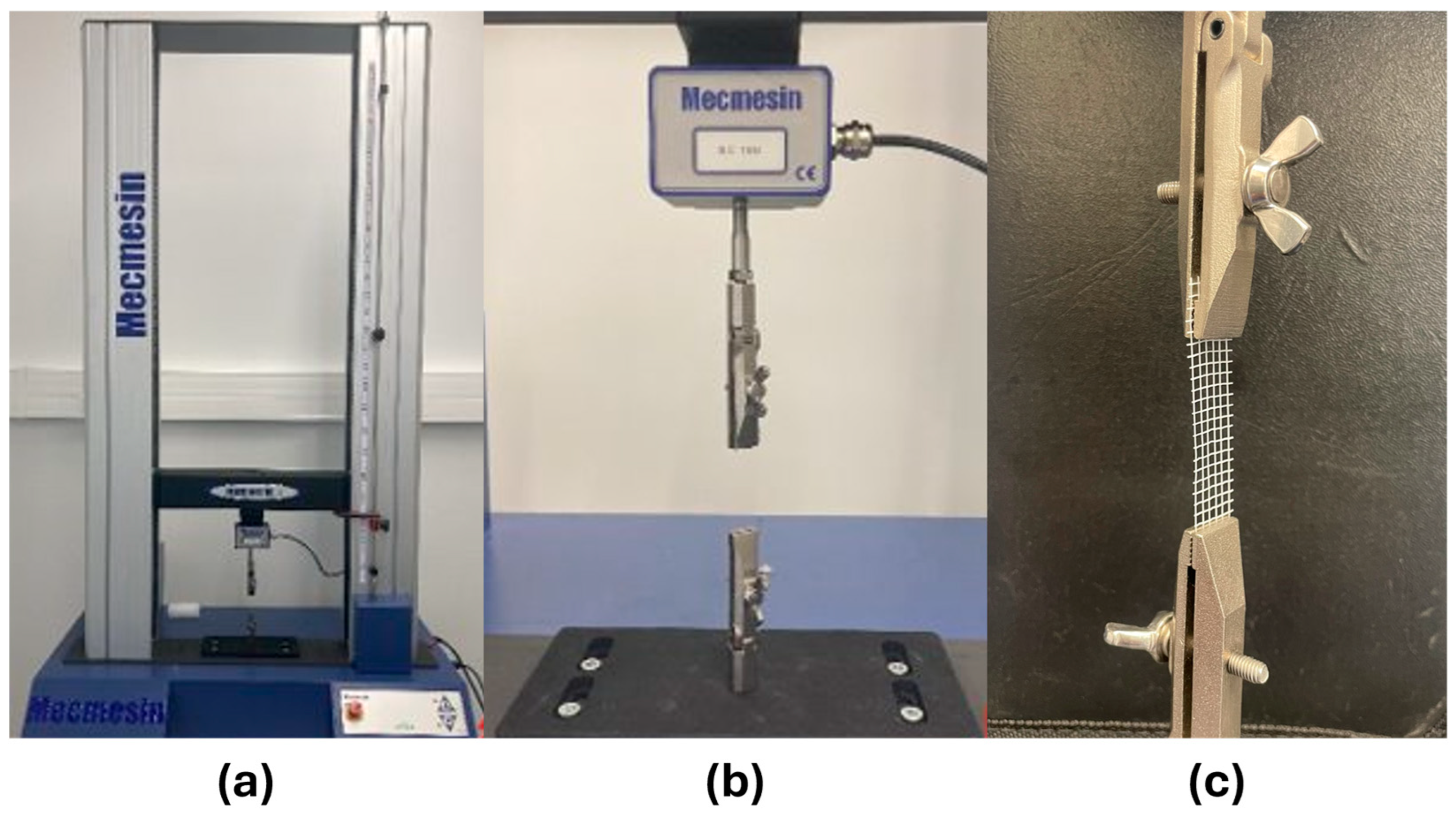

2.2. Mechanical Tests

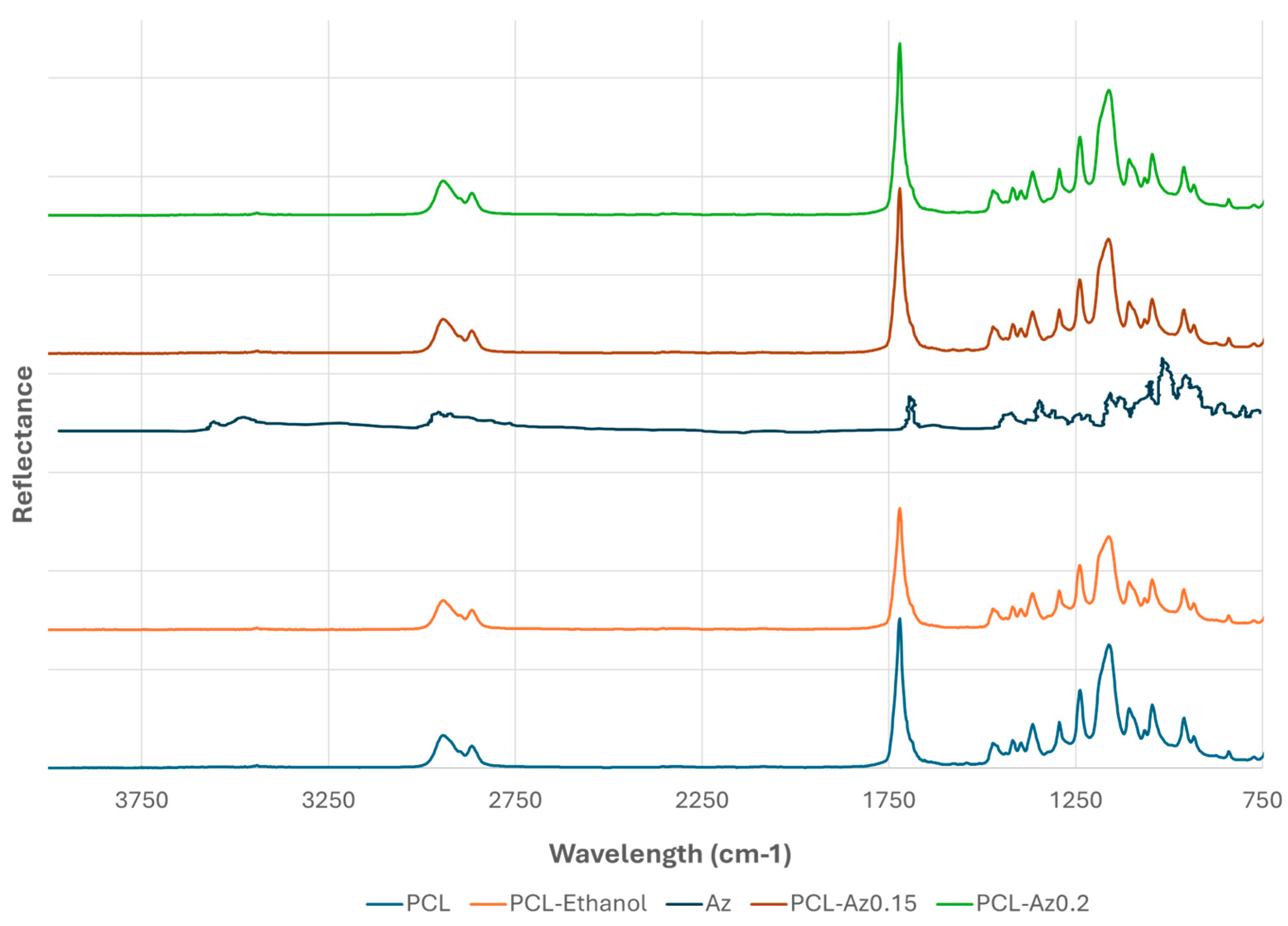

2.3. Preparation of Azithromycin-Loaded PCL Meshes

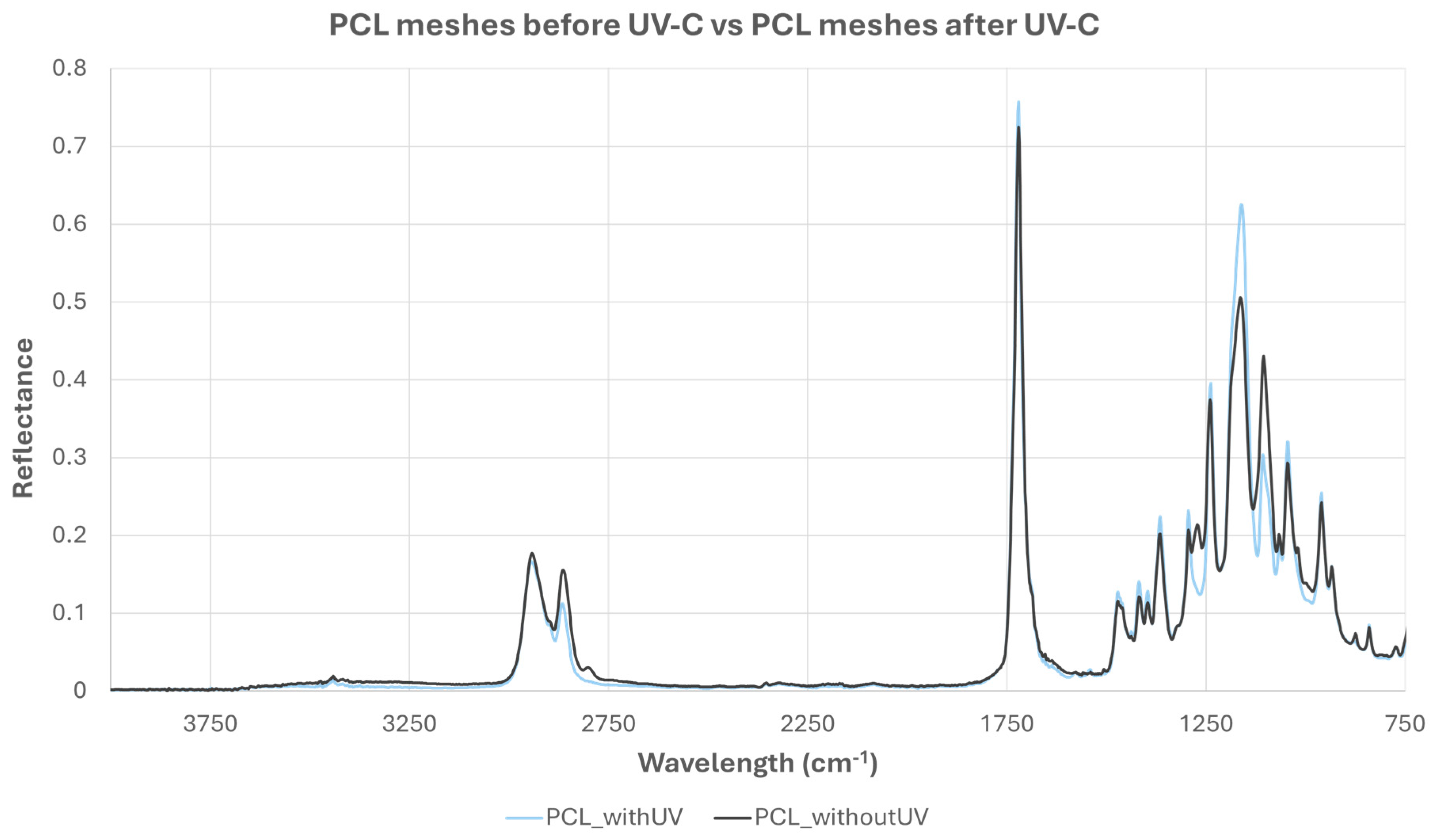

2.4. FTIR Spectral Analysis of PCL Meshes Before and After UV-C Sterilization

2.5. In Vitro Assessment of Microbial Growth

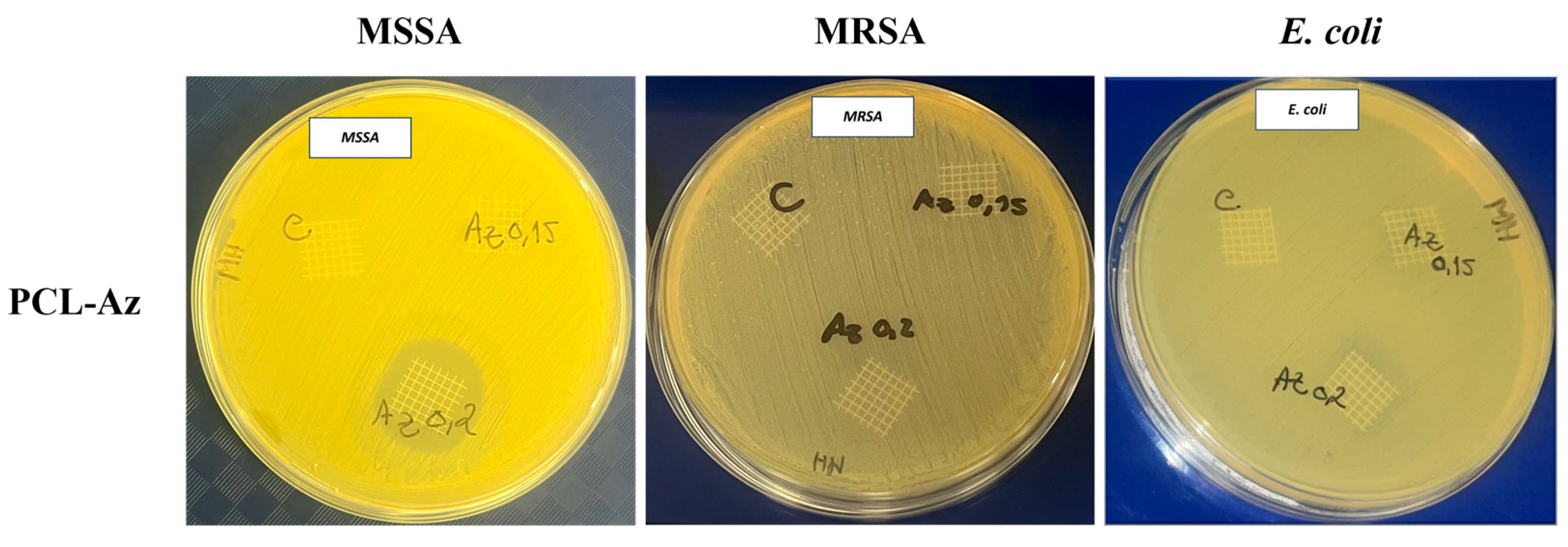

2.5.1. Agar Diffusion Assay for Antibacterial Activity

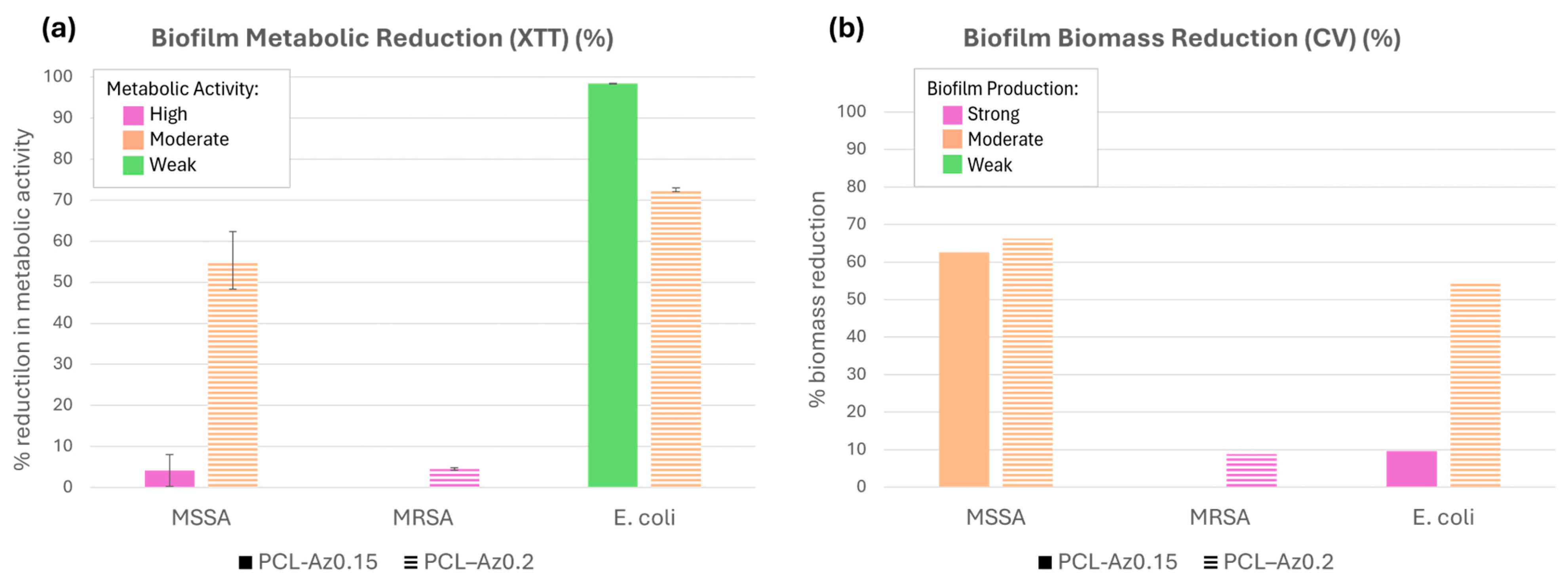

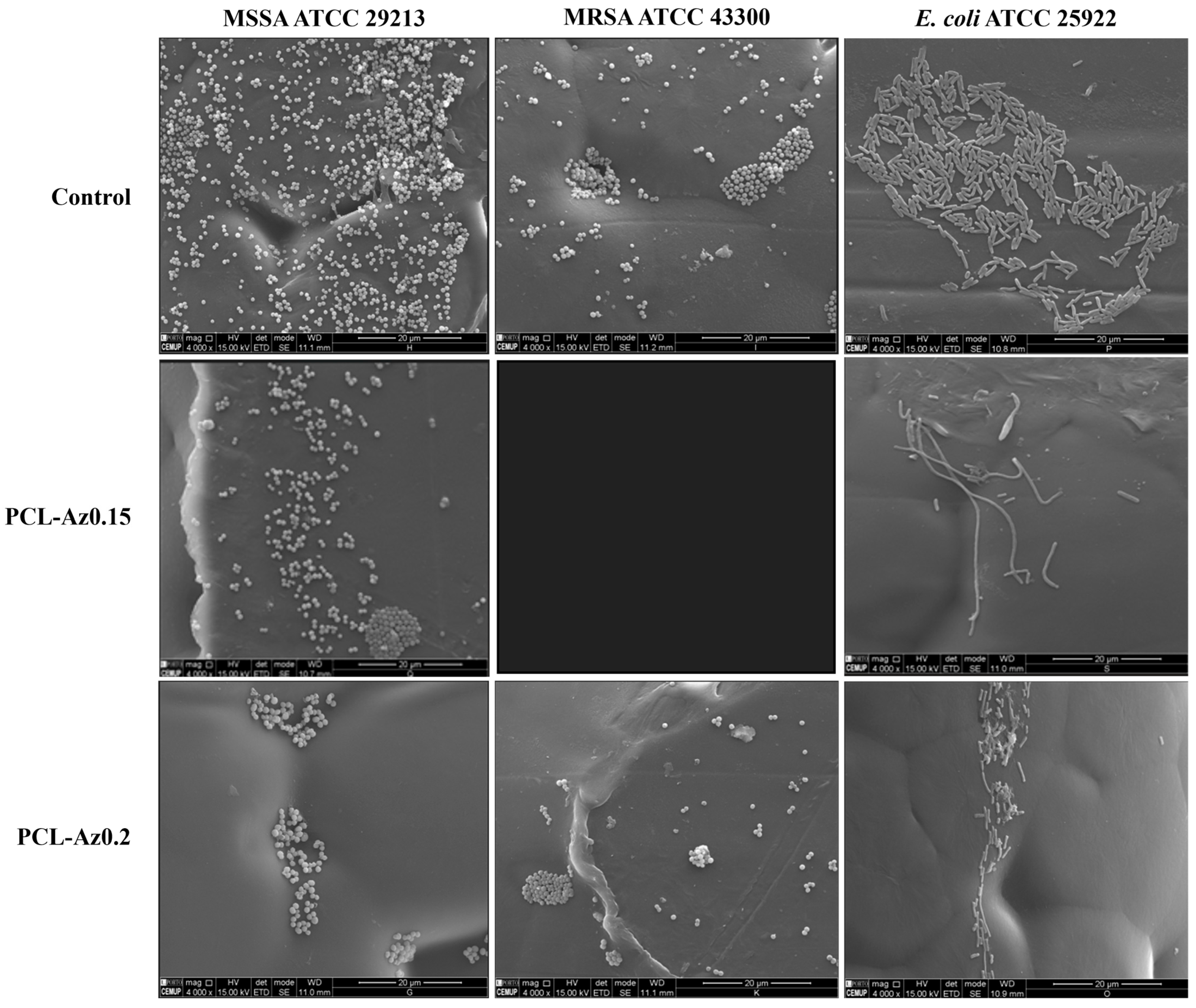

2.5.2. Assessment of Biofilm Formation on Coated Meshes

2.6. SEM Analysis of Mesh Morphology and Bacterial Colonization

3. Results

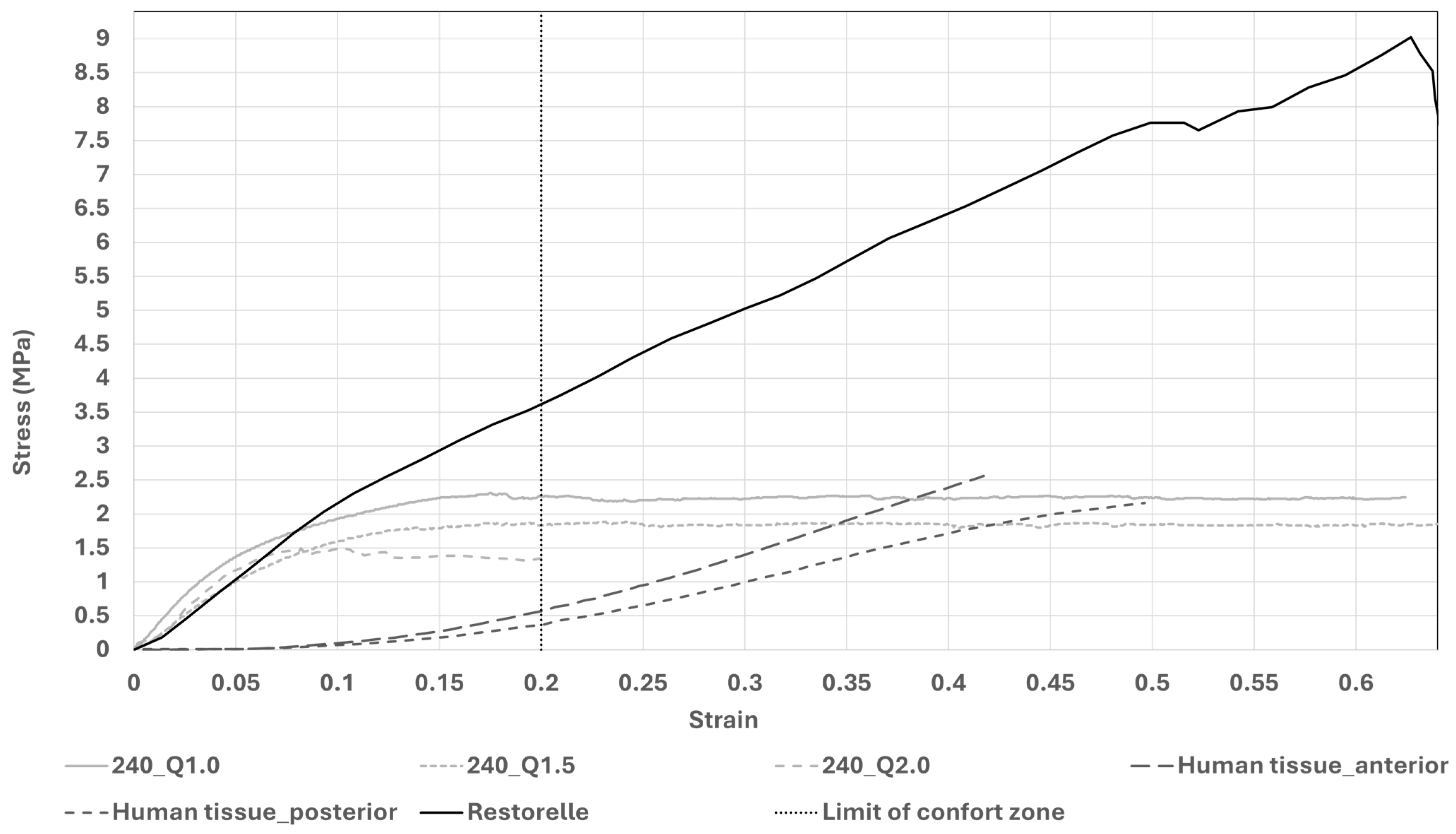

3.1. Uniaxial Tensile Tests

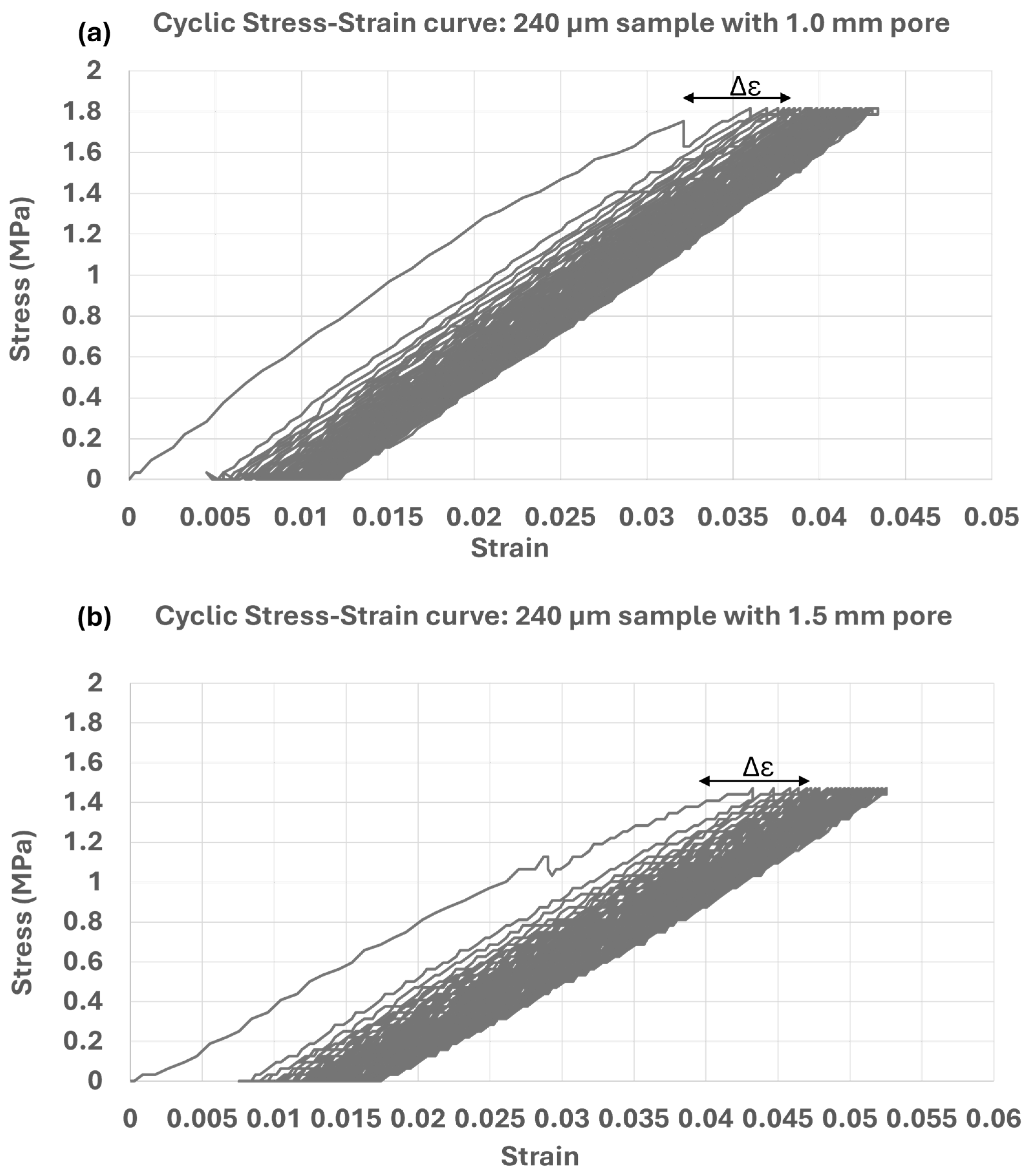

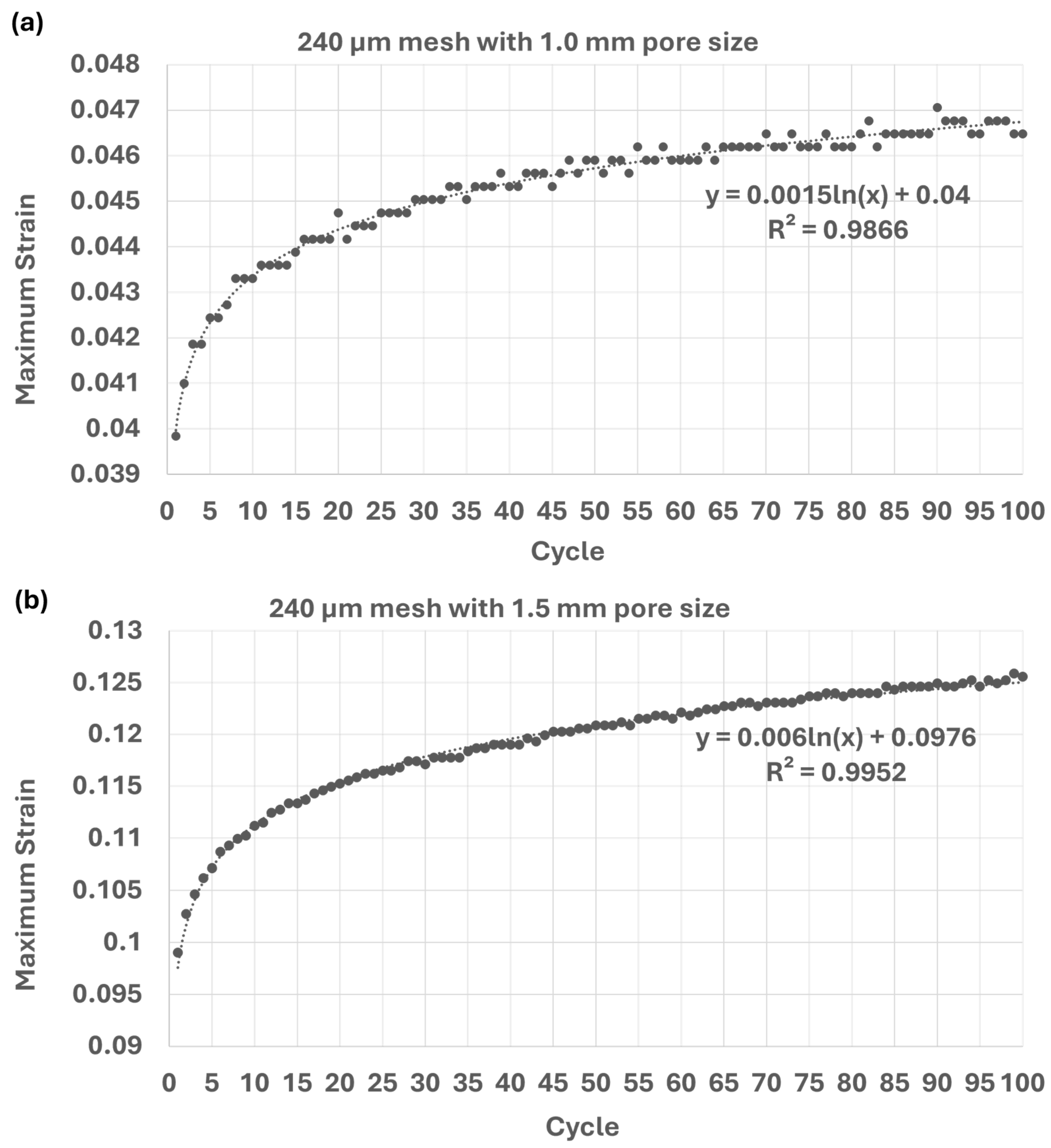

3.2. Cyclic Tests

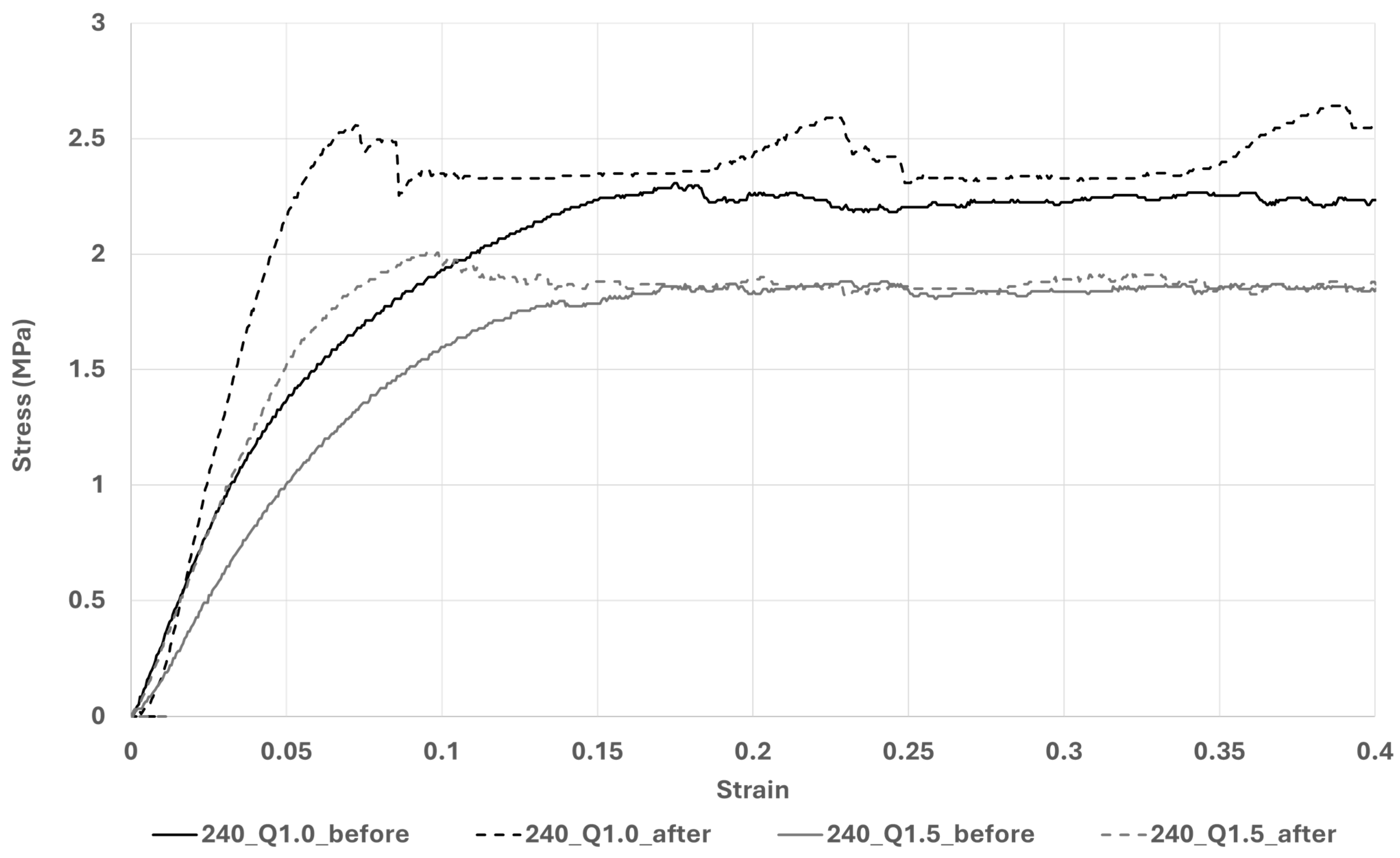

3.3. Tensile Tests After Cyclic Loading Conditions

3.4. Preparation of PCL Meshes Loaded with Az

3.5. Assessment of the Antimicrobial Effect Through the Zone of Inhibition

3.6. Evaluation of Biofilm Metabolic Activity and Biomass Reduction

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| POP | Pelvic Organ Prolapse |

| PFD | Pelvic Floor Dysfunction |

| PP | Polypropylene |

| PET | Polyethylene Terephthalate |

| PCL | Polycaprolactone |

| PLA | Polylactic Acid |

| PU | Polyurethane |

| ES | Electrospinning |

| MEW | Melt Electrospinning Writing |

| SEM | Scanning Electron Microscopy |

| AZ | Azithromycin |

| FTIR | Fourier Transform Infrared Spectroscopy |

| ATR | Attenuated Total Reflectance |

| MSSA | Methicillin Susceptible Staphylococcus Aureus |

| MRSA | Methicillin Resistant Staphylococcus Aureus |

| BH | Brain Heart |

| XTT | Tetrazolium Salt |

| CV | Crystal Violet |

| PBS | Phosphate-Buffered Saline |

| OP | Optical Density |

References

- Weintraub, A.Y.; Glinter, H.; Marcus-Braun, N. Narrative review of the epidemiology, diagnosis and pathophysiology of pelvic organ prolapse. Int. Braz. J. Urol. 2020, 46, 5–14. [Google Scholar] [CrossRef]

- Deng, Z.; Zhu, L.; Hu, X.; Fu, C.-W.; Xu, X.; Zhang, Q.; Qin, J.; Heng, P.-A. An international urogynecological association (IUGA)/international continence society (ICS) joint report on the terminology for female pelvic floor dysfunction. Neurourol. Urodyn. 2010, 29, 4–20. [Google Scholar] [CrossRef]

- Clinic, M. Pelvic Organ Prolapse. Available online: https://www.mayoclinic.org/diseases-conditions/pelvic-organ-prolapse/symptoms-causes/syc-20360557 (accessed on 4 June 2024).

- Ko, K.J.; Lee, K.-S. Current surgical management of pelvic organ prolapse: Strategies for the improvement of surgical outcomes. Investig. Clin. Urol. 2019, 60, 413–424. [Google Scholar] [CrossRef]

- Pelvic Organ Prolapse: Learn More—Surgery for Pelvic Organ Prolapse. In InformedHealth.org, Institute for Quality and Efficiency in Health Care (IQWiG): Cologne, Germany. 2006. Available online: https://www.ncbi.nlm.nih.gov/books/NBK525780/ (accessed on 22 August 2025).

- Dessie, S.G.; Shapiro, A.; Haviland, M.J.; Hacker, M.R.; Elkadry, E.A. Obliterative Versus Reconstructive Prolapse Repair for Women Older than 70: Is There an Optimal Approach? Female Pelvic Med. Reconstr. Surg. 2017, 23, 23–26. [Google Scholar] [CrossRef]

- Houman, J.; Weinberger, J.M.; Eilber, K.S. Native Tissue Repairs for Pelvic Organ Prolapse. Curr. Urol. Rep. 2017, 18, 6. [Google Scholar] [CrossRef] [PubMed]

- Yuan, M.; Hu, M.; Dai, F.; Fan, Y.; Deng, Z.; Deng, H.; Cheng, Y. Application of synthetic and natural polymers in surgical mesh for pelvic floor reconstruction. Mater. Des. 2021, 209, 109984. [Google Scholar] [CrossRef]

- Mancuso, E.; Downey, C.; Doxford-Hook, E.; Bryant, M.G.; Culmer, P. The use of polymeric meshes for pelvic organ prolapse: Current concepts, challenges, and future perspectives. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 108, 771–789. [Google Scholar] [CrossRef] [PubMed]

- Baylón, K.; Rodríguez-Camarillo, P.; Elías-Zúñiga, A.; Díaz-Elizondo, J.A.; Gilkerson, R.; Lozano, K. Past, Present and Future of Surgical Meshes: A Review. Membranes 2017, 7, 47. [Google Scholar] [CrossRef]

- Food and Drug Administration. Urogynecologic Surgical Mesh Implants. Available online: https://www.fda.gov/medical-devices/implants-and-prosthetics/urogynecologic-surgical-mesh-implants (accessed on 10 May 2025).

- Rynkevic, R.; Silva, M.; Martins, P.; Mascarenhas, T.; Alves, J.; Fernandes, A. Characterisation of polycaprolactone scaffolds made by melt electrospinning writing for pelvic organ prolapse correction—A pilot study. Mater. Today Commun. 2022, 32, 104101. [Google Scholar] [CrossRef]

- Seifalian, A.; Basma, Z.; Digesu, A.; Khullar, V. Polypropylene Pelvic Mesh: What Went Wrong and What Will Be of the Future? Biomedicines 2023, 11, 741. [Google Scholar] [CrossRef]

- Mangir, N.; Roman, S.; Chapple, C.R.; MacNeil, S. Complications related to use of mesh implants in surgical treatment of stress urinary incontinence and pelvic organ prolapse: Infection or inflammation? World J. Urol. 2019, 38, 73–80. [Google Scholar] [CrossRef]

- Mellano, E.M.; Nakamura, L.Y.; Choi, J.M.; Kang, D.C.; Grisales, T.; Raz, S.; Rodriguez, L.V. The Role of Chronic Mesh Infection in Delayed-Onset Vaginal Mesh Complications or Recurrent Urinary Tract Infections. Female Pelvic Med. Reconstr. Surg. 2016, 22, 166–171. [Google Scholar] [CrossRef]

- Pfizer Labs. Zithromax® (Azithromycin) for Injection, for Intravenoususe. U.S. Food and Drug Administration. 2022. Available online: https://www.accessdata.fda.gov/drugsatfda_docs/label/2022/050733Orig1s049lbl.pdf (accessed on 17 May 2024).

- Ren, J.; Murray, R.; Wong, C.S.; Qin, J.; Chen, M.; Totsika, M.; Riddell, A.D.; Warwick, A.; Rukin, N.; Woodruff, M.A. Development of 3D Printed Biodegradable Mesh with Antimicrobial Properties for Pelvic Organ Prolapse. Polymers 2022, 14, 763. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef] [PubMed]

- Vaz, M.F.R.; Martins, J.A.P.; Pinheiro, F.; Ferreira, N.M.; Brandão, S.; Alves, J.L.; Fernandes, A.A.; Parente, M.P.L.; Silva, M.E.T. Medical- and Non-Medical-Grade Polycaprolactone Mesh Printing for Prolapse Repair: Establishment of Melt Electrowriting Prototype Parameters. Appl. Sci. 2024, 14, 9670. [Google Scholar] [CrossRef]

- Vaz, M.F.; Martins, J.A.P.; Pinheiro, F.; Ferreira, N.M.; Brandão, S.; Alves, J.L.; Fernandes, A.A.; Parente, M.P.L.; Silva, M.E. Optimizing melt electrowriting prototypes for printing non-medical and medical grade polycaprolactone meshes in prolapse repair. J. Appl. Polym. Sci. 2024. [Google Scholar] [CrossRef]

- Sterk, S.; Silva, M.E.T.; Fernandes, A.A.; Huß, A.; Wittek, A. Development of new surgical mesh geometries with different mechanical properties using the design freedom of 3D printing. J. Appl. Polym. Sci. 2024, 142, e56408. [Google Scholar] [CrossRef]

- da Cunha, M.N.B.; Rynkevic, R.; da Silva, M.E.T.; Brandão, A.F.M.d.S.; Alves, J.L.; Fernandes, A.A. Melt Electrospinning Writing of Mesh Implants for Pelvic Organ Prolapse Repair. 3D Print. Addit. Manuf. 2022, 9, 389–398. [Google Scholar] [CrossRef]

- Martins, J.P.; da Silva, E.T.; Fernandes, A.A.; de Oliveira, S.C. Three-Dimensional Melted Electrowriting Drug Coating Fibers for the Prevention of Device-Associated Infections: A Pilot Study. Bioengineering 2024, 11, 636. [Google Scholar] [CrossRef]

- ISO 1183-1:2025; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. International Organization for Standardization: Geneva, Switzerland, 2025.

- Kade, J.C.; Dalton, P.D. Polymers for Melt Electrowriting. Adv. Healthc. Mater. 2020, 10, e2001232. [Google Scholar] [CrossRef]

- Qin, J.; Chen, Y.; Guo, X.; Huang, Y.; Chen, G.; Zhang, Q.; He, G.; Zhu, S.; Ruan, X.; Zhu, H. Regulation of Hard Segment Cluster Structures for High-performance Poly(urethane-urea) Elastomers. Adv. Sci. 2024, 11, e2400255. [Google Scholar] [CrossRef]

- Roman, S.; Mangir, N.; Hympanova, L.; Chapple, C.R.; Deprest, J.; MacNeil, S. Use of a simple in vitro fatigue test to assess materials used in the surgical treatment of stress urinary incontinence and pelvic organ prolapse. Neurourol. Urodyn. 2018, 38, 107–115. [Google Scholar] [CrossRef]

- de Sousa Martins, P.A.L. Experimental and Numerical Studies of Soft Biological Tissues. Ph.D. Thesis, Faculty of Engineering of the University of Porto, Porto, Portugal, 2010. [Google Scholar]

- Klinge, U.; Otto, J.; Mühl, T. High Structural Stability of Textile Implants Prevents Pore Collapse and Preserves Effective Porosity at Strain. BioMed Res. Int. 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Elzein, T.; Nasser-Eddine, M.; Delaite, C.; Bistac, S.; Dumas, P. FTIR study of polycaprolactone chain organization at interfaces. J. Colloid Interface Sci. 2004, 273, 381–387. [Google Scholar] [CrossRef]

- Robaina, N.F.; de Paula, C.E.R.; Brum, D.M.; de la Guardia, M.; Garrigues, S.; Cassella, R.J. Novel approach for the determination of azithromycin in pharmaceutical formulations by Fourier transform infrared spectroscopy in film-through transmission mode. Microchem. J. 2013, 110, 301–307. [Google Scholar] [CrossRef]

- Bhadra, S. Formulation & process development of azithromycin ophthalmic nanosuspension. Int. J. Pharm. Pharm. Sci. 2013, 5, 490–497. [Google Scholar]

- Lade, H.; Park, J.H.; Chung, S.H.; Kim, I.H.; Kim, J.-M.; Joo, H.-S.; Kim, J.-S. Biofilm Formation by Staphylococcus aureus Clinical Isolates is Differentially Affected by Glucose and Sodium Chloride Supplemented Culture Media. J. Clin. Med. 2019, 8, 1853. [Google Scholar] [CrossRef] [PubMed]

- Głuchowski, A.; Sas, W. Long-Term Cyclic Loading Impact on the Creep Deformation Mechanism in Cohesive Materials. Materials 2020, 13, 3907. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 10th ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Vinogradov, A.M.; Schumacher, S. Cyclic Creep of Polymers and Polymer-Matrix Composites. Mech. Compos. Mater. 2001, 37, 29–34. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Lu, K.; Gao, B. Study of Cyclic Plasticity and Creep Ratchet Behavior of PTFE. Appl. Sci. 2023, 13, 10039. [Google Scholar] [CrossRef]

- Barriere, T.; Gabrion, X.; Holopainen, S.; Jokinen, J. Testing and analysis of solid polymers under large monotonic and long-term cyclic deformation. Int. J. Plast. 2020, 135, 102781. [Google Scholar] [CrossRef]

- Bradley, M.; Izzia, F.; Nunn, S. Analysis of Mixtures by FT-IR: Spatial and Spectral Separation of Complex Samples. Available online: https://www.spectroscopyonline.com/view/analysis-mixtures-ft-ir-spatial-and-spectral-separation-complex-samples (accessed on 22 August 2025).

- Xu, Z.; Liang, Y.; Lin, S.; Chen, D.; Li, B.; Li, L.; Deng, Y. Crystal Violet and XTT Assays on Staphylococcus aureus Biofilm Quantification. Curr. Microbiol. 2016, 73, 474–482. [Google Scholar] [CrossRef] [PubMed]

- Høiby, N.; Henneberg, K.; Wang, H.; Stavnsbjerg, C.; Bjarnsholt, T.; Ciofu, O.; Johansen, U.R.; Sams, T. Formation of Pseudomonas aeruginosa inhibition zone during tobramycin disk diffusion is due to transition from planktonic to biofilm mode of growth. Int. J. Antimicrob. Agents 2019, 53, 564–573. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, S.; Bir, R.; Majumdar, T. Evaluation of Multidrug Resistant Staphylococcus aureus and their Association with Biofilm Production in a Tertiary Care Hospital, Tripura, Northeast India. J. Clin. Diagn. Res. 2015, 9, DC01-4. [Google Scholar] [CrossRef]

- Cayron, J.; Dedieu-Berne, A.; Lesterlin, C. Bacterial filaments recover by successive and accelerated asymmetric divisions that allow rapid post-stress cell proliferation. Mol. Microbiol. 2023, 119, 237–251. [Google Scholar] [CrossRef]

- Bizot, E.; Cointe, A.; Bidet, P.; Mariani-Kurkdjian, P.; Hobson, C.A.; Courroux, C.; Liguori, S.; Bridier-Nahmias, A.; Magnan, M.; Merimèche, M.; et al. Azithromycin Resistance in Shiga Toxin-Producing Escherichia coli in France between 2004 and 2020 and Detection of mef (C)- mph (G) Genes. Antimicrob. Agents Chemother. 2022, 66, e0194921. [Google Scholar] [CrossRef]

- Yassin, A.E.; Albekairy, A.M.; Omer, M.; Almutairi, A.; Alotaibi, Y.; Althuwaini, S.; Alaql, O.A.; Almozaai, S.S.; Almutiri, N.M.; Alluhaim, W.; et al. Chitosan-Coated Azithromycin/Ciprofloxacin-Loaded Polycaprolactone Nanoparticles: A Characterization and Potency Study. Nanotechnol. Sci. Appl. 2023, 16, 59–72. [Google Scholar] [CrossRef]

- Hamzehloo, M.; Karimi, J.; Eghbali, N.; Mirzakhani, M.; Aghapoor, K.; Darabi, H.R. A new blend of polymeric encapsulation of azithromycin by spray-drying with a pH responsive in drug release. Dry. Technol. 2017, 35, 1688–1695. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Temperature | 195 °C |

| Voltage | 3.23 kV |

| Speed | 825 mm/min |

| Height | 3 mm |

| Variables | Pore Size (mm) | σmax (MPa) | σmax comfort zone (MPa) |

|---|---|---|---|

| 240 µm diameter meshes | 1.0 | 2.31 | 2.26 |

| 1.5 | 1.88 | 1.84 | |

| Restorelle® | 2.0 | 9.02 | 3.62 |

| Anterior Human Tissue | _________ | 5.30 | 0.56 |

| Posterior Human Tissue | _________ | 3.20 | 0.36 |

| Filament Diameter (µm) | Pore Size (mm) | ∆ε (%) |

|---|---|---|

| 240 | 1.0 | 0.73 |

| 1.5 | 1.79 |

| Pore Size (mm) | σmax (MPa) | E (MPa) | |

|---|---|---|---|

| Before Cyclic Loading | 1.0 | 2.31 | 32.47 |

| 1.5 | 1.88 | 23.43 | |

| After Cyclic Loading | 1.0 | 2.65 | 40.19 |

| 1.5 | 2.01 | 33.16 | |

| ∆ (%) | 1.0 | 12.8 | 19.2 |

| 1.5 | 6.5 | 29.3 |

| MSSA 29213 | MRSA 43300 | E. coli 25922 | |

|---|---|---|---|

| Control group | 0 mm | 0 mm | 0 mm |

| PCL-Az0.15 | 11 mm | 0 mm | 0 mm |

| PCL-Az0.2 | 35 mm | 0 mm | 22 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, J.P.; Sousa, A.S.; Costa de Oliveira, S.; Fernandes, A.A.; Silva, E. Mechanical Characterization and Azithromycin Coating of Melt Electrowritten Polycaprolactone Mesh Implants for Prolapse Repair. Appl. Sci. 2025, 15, 9436. https://doi.org/10.3390/app15179436

Martins JP, Sousa AS, Costa de Oliveira S, Fernandes AA, Silva E. Mechanical Characterization and Azithromycin Coating of Melt Electrowritten Polycaprolactone Mesh Implants for Prolapse Repair. Applied Sciences. 2025; 15(17):9436. https://doi.org/10.3390/app15179436

Chicago/Turabian StyleMartins, Joana Pinheiro, Ana Sofia Sousa, Sofia Costa de Oliveira, António Augusto Fernandes, and Elisabete Silva. 2025. "Mechanical Characterization and Azithromycin Coating of Melt Electrowritten Polycaprolactone Mesh Implants for Prolapse Repair" Applied Sciences 15, no. 17: 9436. https://doi.org/10.3390/app15179436

APA StyleMartins, J. P., Sousa, A. S., Costa de Oliveira, S., Fernandes, A. A., & Silva, E. (2025). Mechanical Characterization and Azithromycin Coating of Melt Electrowritten Polycaprolactone Mesh Implants for Prolapse Repair. Applied Sciences, 15(17), 9436. https://doi.org/10.3390/app15179436