A Pilot Study of Clarifying (Fining) Agents and Their Effects on Beer Physicochemical Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Viking Malt Pilsner Barley Malt (Viking Malt Oy, Malt House in Strzegom, Poland)

2.1.2. Magnat T-90 Hops (PolishHops, Karczmiska, Poland)

2.1.3. Puławski T-90 Hops (PolishHops, Karczmiska, Poland)

2.1.4. Yeast

2.1.5. Commercial Beer of a Polish Brand

2.1.6. Chitozan 1_(Sweden)

2.1.7. Collagen (Poland)

2.1.8. Chitozan 2 (Poland)

2.2. Physicochemical Analyses and Rheological Measurements

2.2.1. Foam Volume Measurement

2.2.2. pH Measurement

2.2.3. Colour Measurement

2.2.4. Beer Clarity Measurement

2.2.5. Surface Tension Measurement

2.2.6. Rheological Properties Measurement

- Heating Stage: shear stress τ = 0.000 Pa; time t = 600.00 s; set temperature T = 20.00 ± 0.50 °C

- Measurement Stage: shear rate = 1400.0 1/s to 2500.0 1/s in a logarithmic distribution; Time t = 300.00 s; number of measurement points collected = 300; temperature as set in the previous step.

2.3. Determination of Shelf-Life Using the Forced Ageing Method

2.4. Statistical Analysis

2.5. Experimental Characterization

- –

- 46 °C for proteolytic enzymes and β-glucanases.

- –

- 68 °C for β-amylase activity.

- –

- 70–75 °C for optimal α-amylase activity.

- –

- 78 °C for the completion of mashing and filtration of the sweet wort.

3. Results

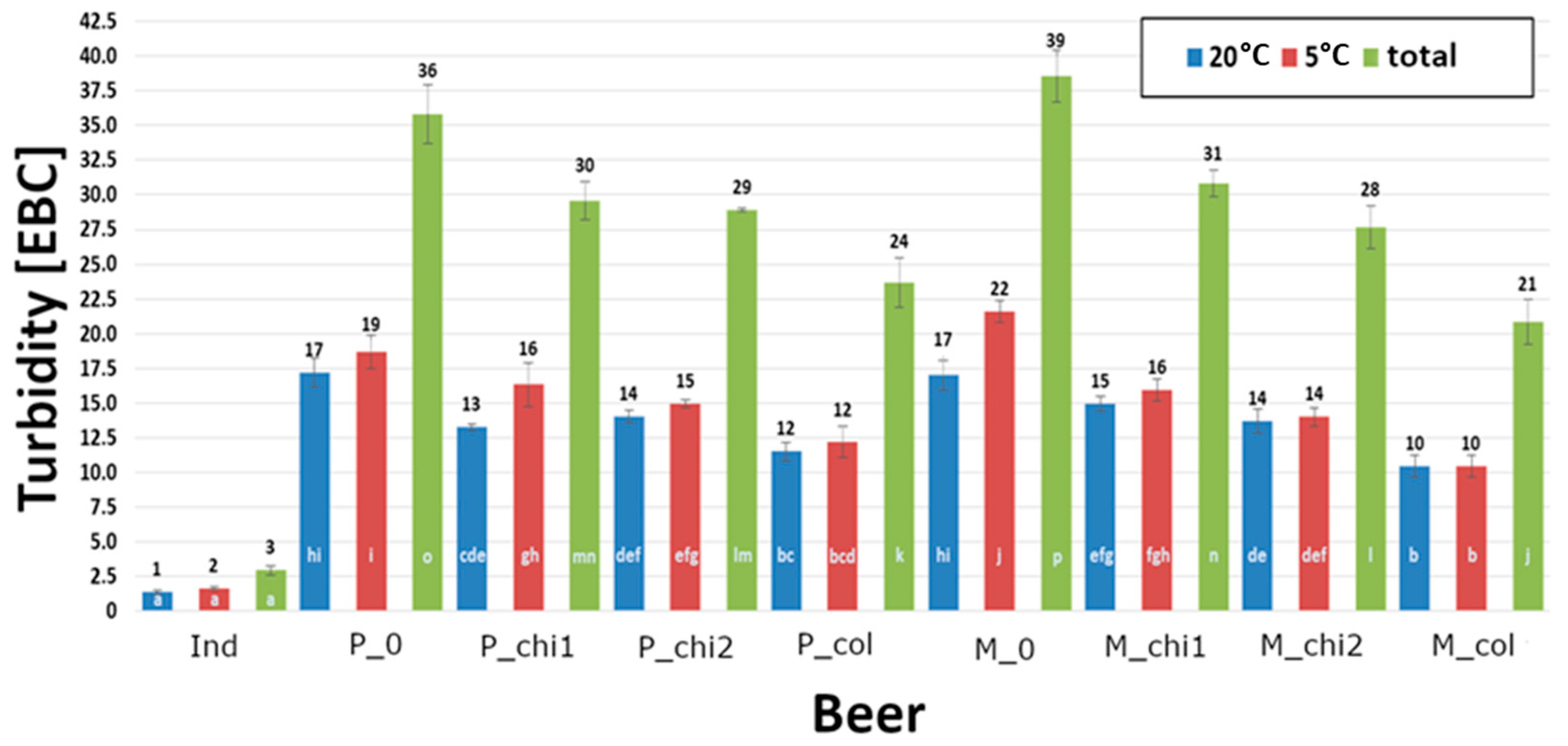

3.1. Turbidity and Clarity of Beers

3.2. Colour

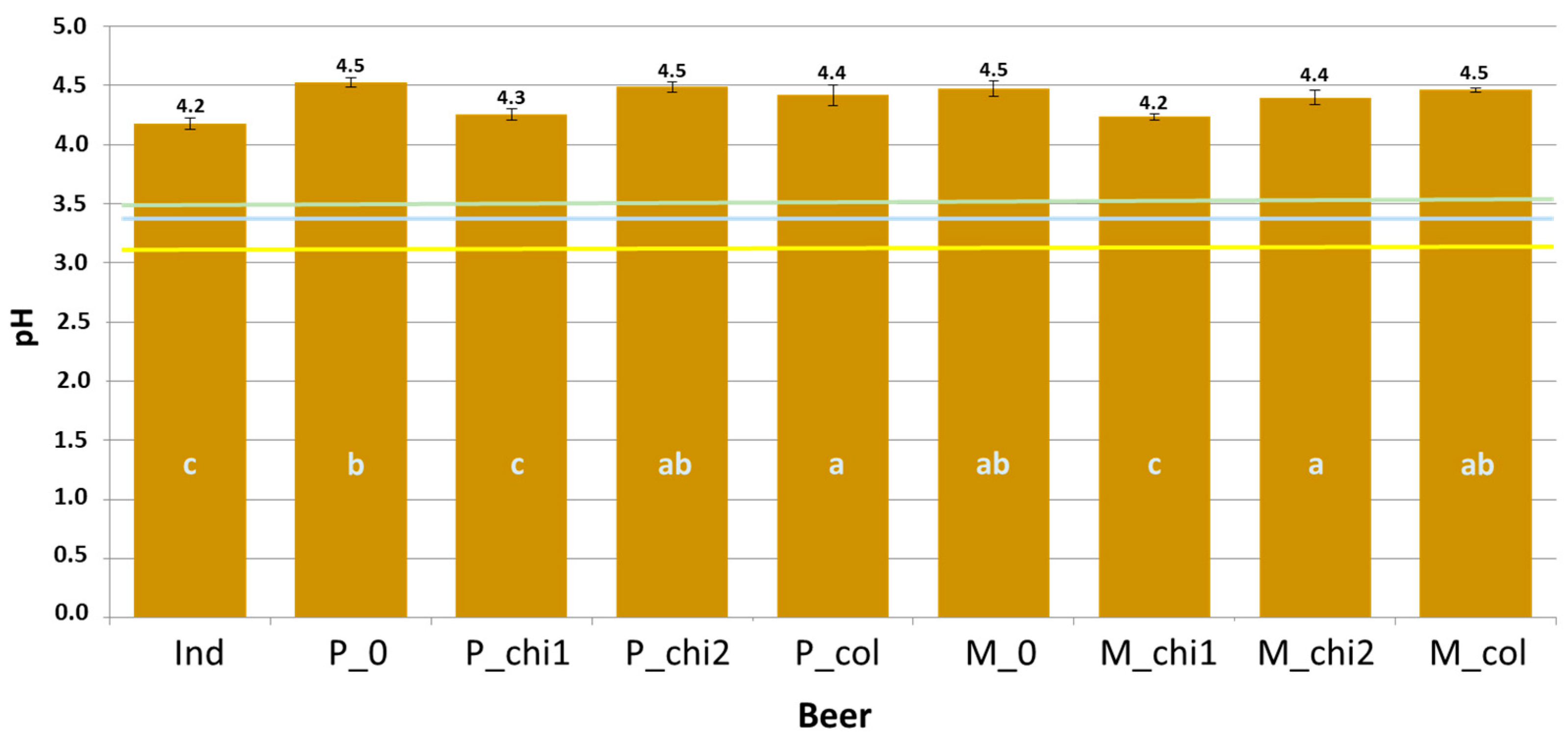

3.3. pH

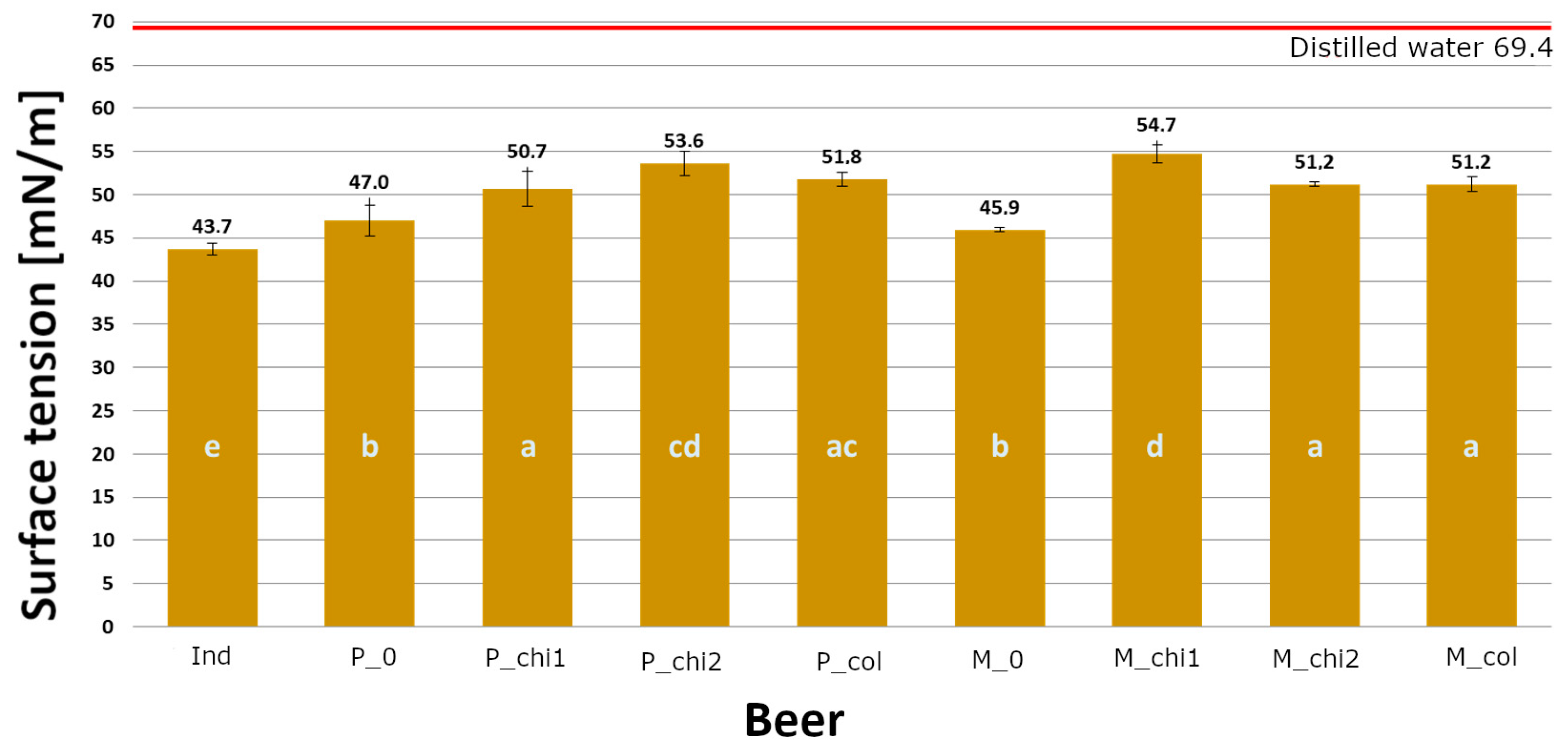

3.4. Surface Tension

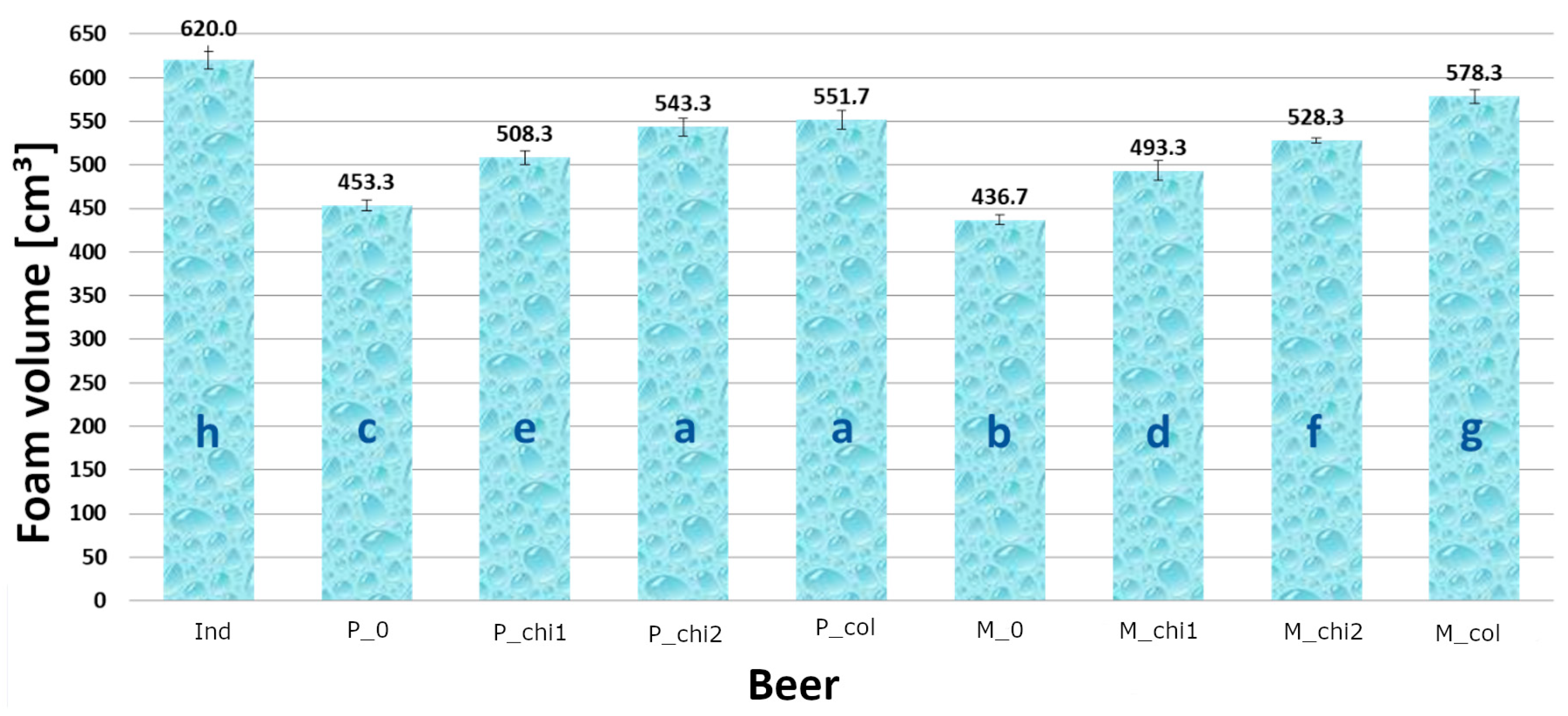

3.5. Foam Volume

3.6. Beer Shelf-Life

3.7. Viscosity

4. Discussion

5. Conclusions

- 1.

- The effectiveness of clarifying agentsIn this pilot dataset, the collagen-based fining agent achieved the lowest turbidity (EBC) across hop variants and temperatures, indicating stronger visual clarity improvements under our conditions.Pilot caveat: The result reflects a small n and laboratory scale; the effect size and rank order require confirmation with more replicates, beer styles, and process settings.

- 2.

- The role of hop varietyAcross the two hop lots (alpha acids 7.5% and 14.5%), we did not detect clear differences in clarification effectiveness or core physicochemical parameters relative to agent choice.Pilot caveat: The absence of detected differences may reflect limited statistical power; broader hop chemistries (oil profiles, polyphenols) and more replicates could reveal effects.

- 3.

- Shelf-life and physical stabilityClarification was associated with improved short-term stability (e.g., lower turbidity, altered surface tension). We did not observe a consistent advantage of one agent over another for longer term stability in this study.Pilot caveat: The stability findings are time- and condition-limited and based on a small sample; longer, replicated storage trials are needed.

- 4.

- The effect on viscosityChitosan-treated beers tended toward a lower viscosity than collagen-treated beers and the industrial reference, which could aid operations (pumping/filtration), while a higher viscosity can benefit sediment compaction.Pilot caveat: The viscosity trends are preliminary and method-specific; confirmation with more batches and process scales is required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Atkinson, S. Beer Clarification. Membr. Technol. 2005, 7, 8–9. [Google Scholar] [CrossRef]

- Bailey, B.A. The Influence of Hop Harvest Date on Hop Aroma in Dry-Hopped Beers. MBAA Tech. Q. 2009, 46, 109–115. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, L. Haze in Beer: Its Formation and Alleviating Strategies, from a Protein-Polyphenol Complex Angle. Foods 2021, 10, 3114. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Gresser, A. Stability of Beer. In Handbook of Brewing: Processes, Technology, Markets; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 399–435. ISBN 9783527316748. [Google Scholar]

- Walker, S.L.; Camarena, M.C.D.; Freeman, G. Alternatives to Isinglass for Beer Clarification. J. Inst. Brew. 2007, 113, 347–354. [Google Scholar] [CrossRef]

- Deville, S. Freezing Colloids: Observations, Principles, Control, and Use. In Engineering Materials and Processes; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Bamforth, C.W. 125th Anniversary Review: The Non-Biological Instability of Beer. J. Inst. Brew. 2011, 117, 488–497. [Google Scholar] [CrossRef]

- Siebert, K.J. Haze formation in beverages. LWT—Food Sci. Technol. 2006, 39, 987–994. [Google Scholar] [CrossRef]

- Stewart, G.G. Beer Shelf Life and Stability. In The Stability and Shelf Life of Food; Elsevier: Amsterdam, The Netherlands, 2016; pp. 293–309. [Google Scholar] [CrossRef]

- Cimini, A.; Moresi, M. Innovative Rough Beer Conditioning Process Free from Diatomaceous Earth and Polyvinylpolypyrrolidone. Foods 2020, 9, 1228. [Google Scholar] [CrossRef]

- Mastanjević, K.; Krstanović, V.; Lukinac, J.; Jukić, M.; Vulin, Z.; Mastanjević, K. Beer—The Importance of Colloidal Stability (Non-Biological Haze). Fermentation 2018, 4, 91. [Google Scholar] [CrossRef]

- Gassara, F.; Antzak, C.; Ajila, C.M.; Sarma, S.J.; Brar, S.K.; Verma, M. Chitin and Chitosan as Natural Flocculants for Beer Clarification. J. Food Eng. 2015, 166, 80–85. [Google Scholar] [CrossRef]

- Wang, L.; Xu, X.; Guo, S.; Peng, Z.; Tang, T. Novel Water Soluble Phosphonium Chitosan Derivatives: Synthesis, Characterization and Cytotoxicity Studies. Int. J. Biol. Macromol. 2011, 48, 375–380. [Google Scholar] [CrossRef]

- Cosme, F.; Vilela, A. Chitin and Chitosan in the Alcoholic and Non-Alcoholic Beverage Industry: An Overview. Appl. Sci. 2021, 11, 11427. [Google Scholar] [CrossRef]

- Nielsen, E.B. Beer from 100% Barley. In Proceedings of the EBC Congress, Estoril, Portugal, 1971; pp. 149–170. Available online: https://www.bricksite.com/uf/20000_29999/22215/355c442783ee060fd383a6ac152705cc.pdf (accessed on 15 March 2017).

- Bamforth, C.W. Beer Is Proof God Loves Us: Reaching for the Soul of Beer and Brewing; FT Press: London, UK, 2010. [Google Scholar]

- Šulc, R.; Bojas, J. Beer foam decay: Effect of glass surface quality and CO2 content. EPJ Web Conf. 2018, 180, 02101. [Google Scholar] [CrossRef]

- Available online: https://dev.brewup.brewersofeurope.eu/ebc-analytica/beer/ph-of-beer-formerly-published-as-iob-method-9-42/9.35 (accessed on 2 March 2017).

- Available online: https://dev.brewup.brewersofeurope.eu/ebc-analytica/beer/colour-of-beer-spectrophotometric-method-im/9.6 (accessed on 2 March 2017).

- Available online: https://brewup.eu/ebc-analytica/malt/method-to-measure-congress-mash-wort-turbidity/4.23 (accessed on 2 March 2017).

- Ebnesajjad, S. Surface tension and its measurement. In Elsevier eBooks; Elsevier B.V.: Amsterdam, The Netherlands, 2013; pp. 7–24. [Google Scholar] [CrossRef]

- Blšáková, L.; Gregor, T.; Mešťánek, M.; Hřivna, L.; Kumbár, V. The Use of Unconventional Malts in Beer Production and Their Effect on the Wort Viscosity. Foods 2021, 11, 31. [Google Scholar] [CrossRef]

- Available online: https://dev.brewup.brewersofeurope.eu/ebc-analytica/beer/prediction-of-shelf-life-of-beer/9.30 (accessed on 2 March 2017).

- Van Doorn, G.; Timora, J.; Watson, S.; Moore, C.; Spence, C. The Visual Appearance of Beer: A Review Concerning Visually-Determined Expectations and Their Consequences for Perception. Food Res. Int. 2019, 126, 108661. [Google Scholar] [CrossRef]

- Piqueras-Fiszman, B.; Spence, C. Sensory Expectations Based on Product-Extrinsic Food Cues: An Interdisciplinary Review of the Empirical Evidence and Theoretical Accounts. Food Qual. Prefer. 2015, 40, 165–179. [Google Scholar] [CrossRef]

- Reinoso-Carvalho, F.; Dakduk, S.; Wagemans, J.; Spence, C. Dark vs. Light Drinks: The Influence of Visual Appearance on the Consumer’s Experience of Beer. Food Qual. Prefer. 2019, 74, 21–29. [Google Scholar] [CrossRef]

- Michiels, P.; Debyser, W.; De Sutter, W.; Langenaeken, N.; De Rouck, G.; Courtin, C. Enhancing the mouthfeel of non-alcoholic beers: The influence of dextrin and arabinoxylan on perceived viscosity and body. Food Hydrocoll. 2024, 159, 110642. [Google Scholar] [CrossRef]

- Gasiński, A.; Kawa-Rygielska, J.; Spychaj, R.; Opiela, E.; Sowiński, J. Production of gluten-free beer brewing from sorghum malts mashed without external enzyme preparations. J. Cereal Sci. 2023, 112, 103693. [Google Scholar] [CrossRef]

- Cimini, A.; De Francesco, G.; Perretti, G. Effect of Crossflow Microfiltration on the Clarification and Stability of Beer from 100% Low-β-Glucan Barley or Malt. LWT 2017, 86, 55–61. [Google Scholar] [CrossRef]

- Kløverpris, J.; Wenzel, H.; Nielsen, P.H. Life Cycle Inventory Modelling of Land Use Induced by Crop Consumption: Part 1: Conceptual Analysis and Methodological Proposal. Int. J. Life Cycle Assess. 2008, 13, 13–21. [Google Scholar] [CrossRef]

- Gobbi, L.; Stanković, M.; Ruggeri, M.; Savastano, M. Craft Beer in Food Science: A Review and Conceptual Framework. Beverages 2024, 10, 91. [Google Scholar] [CrossRef]

- Craft Brewing Business. 3 Important Clarification Strategies for Beer. 2025. Available online: https://www.craftbrewingbusiness.com/featured/2025-on-premise-outlook-fresh-data-points-for-craft-beer-growth-opportunities/ (accessed on 17 July 2025).

- Steiner, E.; Auer, A.; Becker, T.; Gastl, M. Comparison of Beer Quality Attributes between Beers Brewed with 100% Barley Malt and 100% Barley Raw Material. J. Sci. Food Agric. 2012, 92, 803–813. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Viejo, C.; Hernandez-Brenes, C.; Villarreal-Lara, R.; De Anda-Lobo, I.C.; Ramos-Parra, P.A.; Perez-Carrillo, E.; Clorio-Carrillo, J.A.; Tongson, E.; Fuentes, S. Effects of Different Beer Compounds on Biometrically Assessed Emotional Responses in Consumers. Fermentation 2023, 9, 269. [Google Scholar] [CrossRef]

- Rizzo, L.; Di Gennaro, A.; Gallo, M.; Belgiorno, V. Coagulation/Chlorination of Surface Water: A Comparison between Chitosan and Metal Salts. Sep. Purif. Technol. 2008, 62, 79–85. [Google Scholar] [CrossRef]

- Sadosky, P.; Schwarz, P.B.; Horsley, R.D. Effect of Arabinoxylans, β-Glucans, and Dextrins on the Viscosity and Membrane Filterability of a Beer Model Solution. J. Am. Soc. Brew. Chem. 2002, 60, 153–162. [Google Scholar] [CrossRef]

- Bertuzzi, T.; Mulazzi, A.; Rastelli, S.; Donadini, G.; Rossi, F.; Spigno, G. Targeted Healthy Compounds in Small and Large-Scale Brewed Beers. Food Chem. 2020, 310, 125935. [Google Scholar] [CrossRef]

- Ghosh, M.; Ghosh, M.; Chakraborty, R. Clarification of Fruit Juices and Beverages Using Membrane Technology. J. Food Eng. 2015, 160, 8–15. [Google Scholar] [CrossRef]

- Czekaj, P.; López, F.; Güell, C. Membrane Fouling by Turbidity Constituents of Beer and Wine: Characterization and Prevention by Means of Infrasonic Pulsing. J. Food Eng. 2001, 49, 25–36. [Google Scholar] [CrossRef]

- Domingues, R.C.C.; Faria Junior, S.B.; Silva, R.B.; Cardoso, V.L.; Reis, M.H.M. Clarification of Passion Fruit Juice with Chitosan: Effects of Coagulation Process Variables and Comparison with Centrifugation and Enzymatic Treatments. Process Biochem. 2012, 47, 467–471. [Google Scholar] [CrossRef]

- Rao, L.; Hayat, K.; Lv, Y.; Karangwa, E.; Xia, S.; Jia, C.; Zhong, F.; Zhang, X. Effect of Ultrafiltration and Fining Adsorbents on the Clarification of Green Tea. J. Food Eng. 2011, 102, 321–326. [Google Scholar] [CrossRef]

- Taştan, Ö.; Baysal, T. Chitosan as a Novel Clarifying Agent on Clear Apple Juice Production: Optimization of Process Conditions and Changes on Quality Characteristics. Food Chem. 2017, 237, 818–824. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Chatterjee, S.; Chatterjee, B.P.; Guha, A.K. Clarification of Fruit Juice with Chitosan. Process Biochem. 2004, 39, 2229–2232. [Google Scholar] [CrossRef]

| Variant Symbol | Description |

|---|---|

| Ind | Industrial beer: water, barley malt, hops |

| P_0 (without clarifying agent) | Laboratory beer with water (32 dm3 including sparging), 5 kg barley malt, 60 g Puławski hops |

| P_chi2 (with chitosan) | |

| P_chi1 (with chitosan) | |

| P_col (with collagen) | |

| M_0 (without clarifying agent) | Laboratory beer with water (32 dm3 including sparging), 5 kg barley malt, 60 g Magnat hops |

| M_chi2 (with chitosan) | |

| M_chi1 (with chitosan) | |

| M_col (with collagen) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sterczyńska, M.; Zdaniewicz, M.; Stachnik, M. A Pilot Study of Clarifying (Fining) Agents and Their Effects on Beer Physicochemical Parameters. Appl. Sci. 2025, 15, 9330. https://doi.org/10.3390/app15179330

Sterczyńska M, Zdaniewicz M, Stachnik M. A Pilot Study of Clarifying (Fining) Agents and Their Effects on Beer Physicochemical Parameters. Applied Sciences. 2025; 15(17):9330. https://doi.org/10.3390/app15179330

Chicago/Turabian StyleSterczyńska, Monika, Marek Zdaniewicz, and Marta Stachnik. 2025. "A Pilot Study of Clarifying (Fining) Agents and Their Effects on Beer Physicochemical Parameters" Applied Sciences 15, no. 17: 9330. https://doi.org/10.3390/app15179330

APA StyleSterczyńska, M., Zdaniewicz, M., & Stachnik, M. (2025). A Pilot Study of Clarifying (Fining) Agents and Their Effects on Beer Physicochemical Parameters. Applied Sciences, 15(17), 9330. https://doi.org/10.3390/app15179330