Analysis of the Impact of Multi-Angle Polarization Bidirectional Reflectance Distribution Function Angle Errors on Polarimetric Parameter Fusion

Abstract

1. Introduction

- ▪

- Modular and lightweight structural design: The BRDF system features a detachable rail structure that allows flexible indoor and outdoor deployment. The simplified, lightweight design reduces mechanical complexity while maintaining a high-precision measurement capability.

- ▪

- IMU-based closed-loop control: A three-axis inertial measurement unit (IMU) provides real-time feedback on the detector’s azimuth and zenith angles, compensating for errors caused by the simplified mechanical structure and ensuring precise positioning.

- ▪

- Imaging-based geometric correction: A checkerboard calibration method is employed to correct camera pose and image distortions, enhancing imaging consistency and overall measurement accuracy.

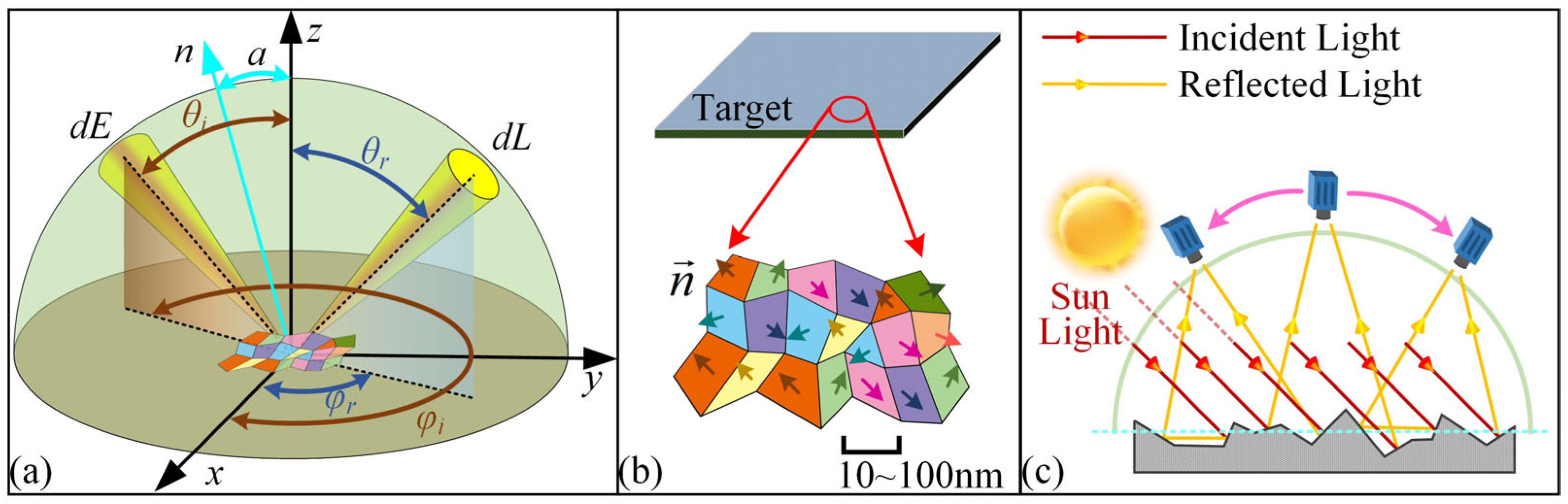

2. BRDF Measurement Principle

2.1. Definition of BRDF

2.2. BRDF Model

3. BRDF Imaging Detection Device Based on IMU Attitude

3.1. Azimuth Module Design

3.2. Zenith Module Design

3.3. Attitude Monitoring and Error Control

3.4. Control System Design and Integration

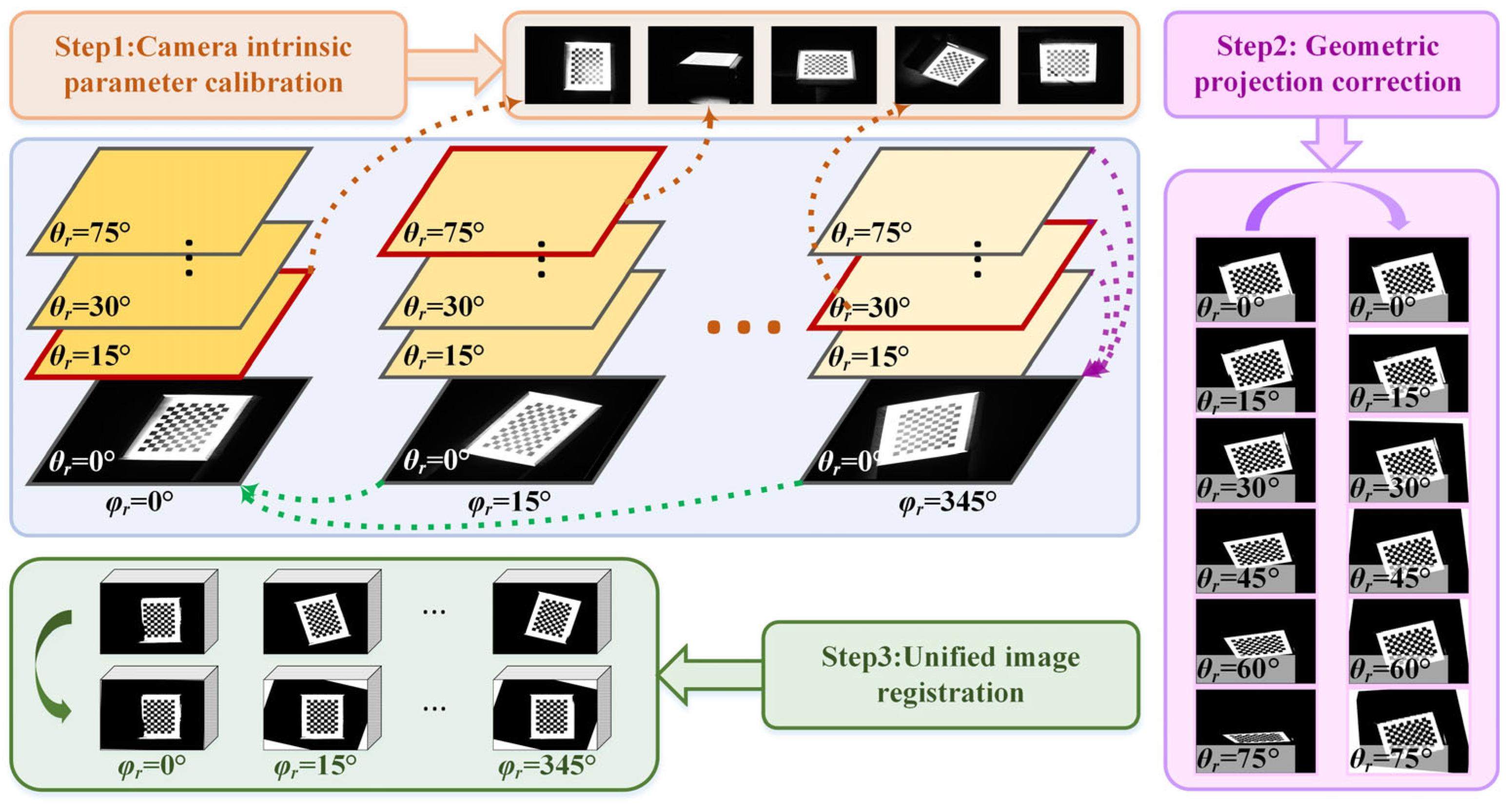

4. Experimental Procedure for Imaging Accuracy Measurement

4.1. Rail Deformation Error Analysis and IMU Comparison

4.2. Experimental Conditions and Image Acquisition Protocol

4.3. Image Distortion Correction Based on IMU Attitude

5. Polarization Imaging Experiments and Impact Analysis of Angular Errors on Polarized Information

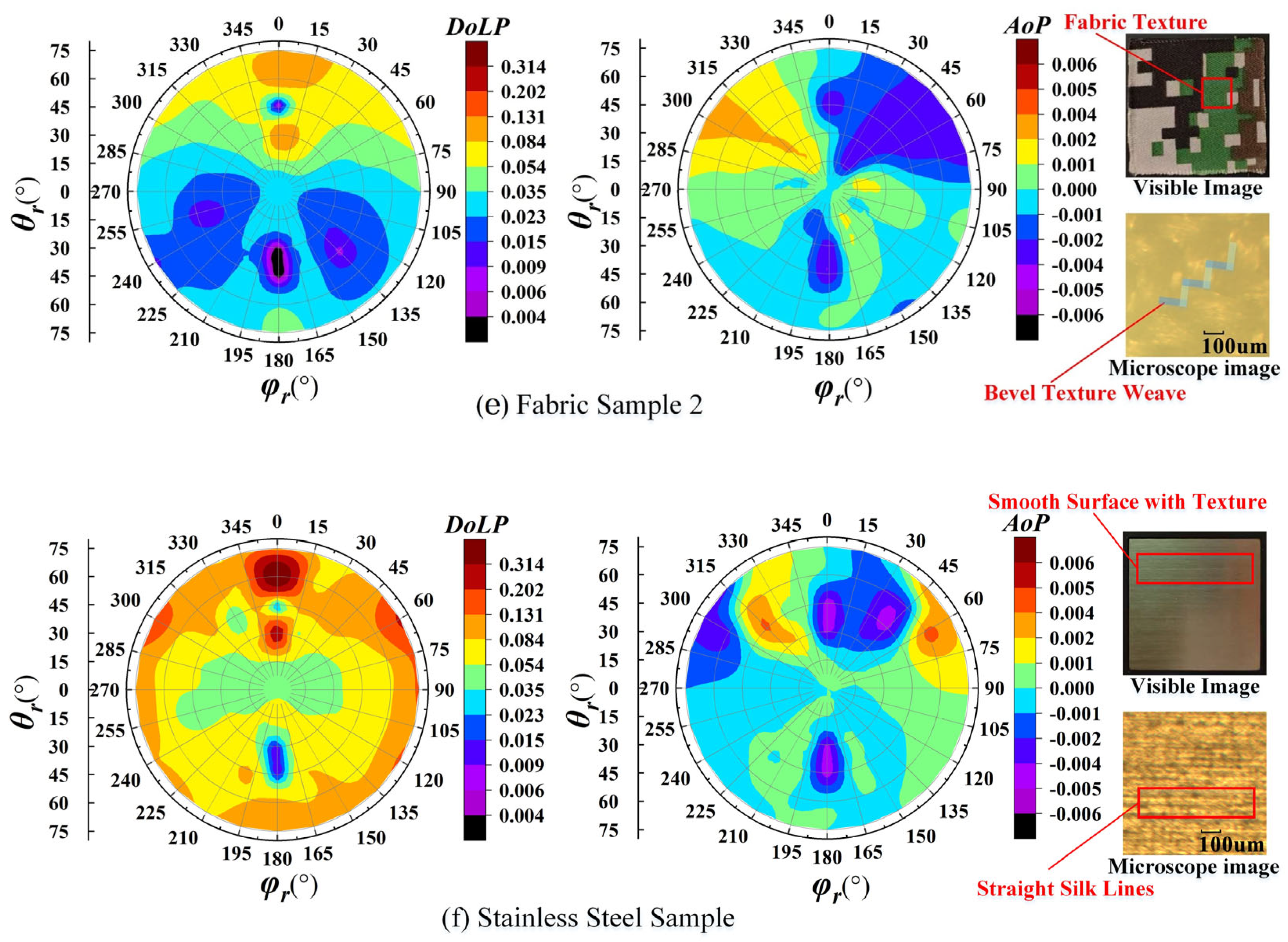

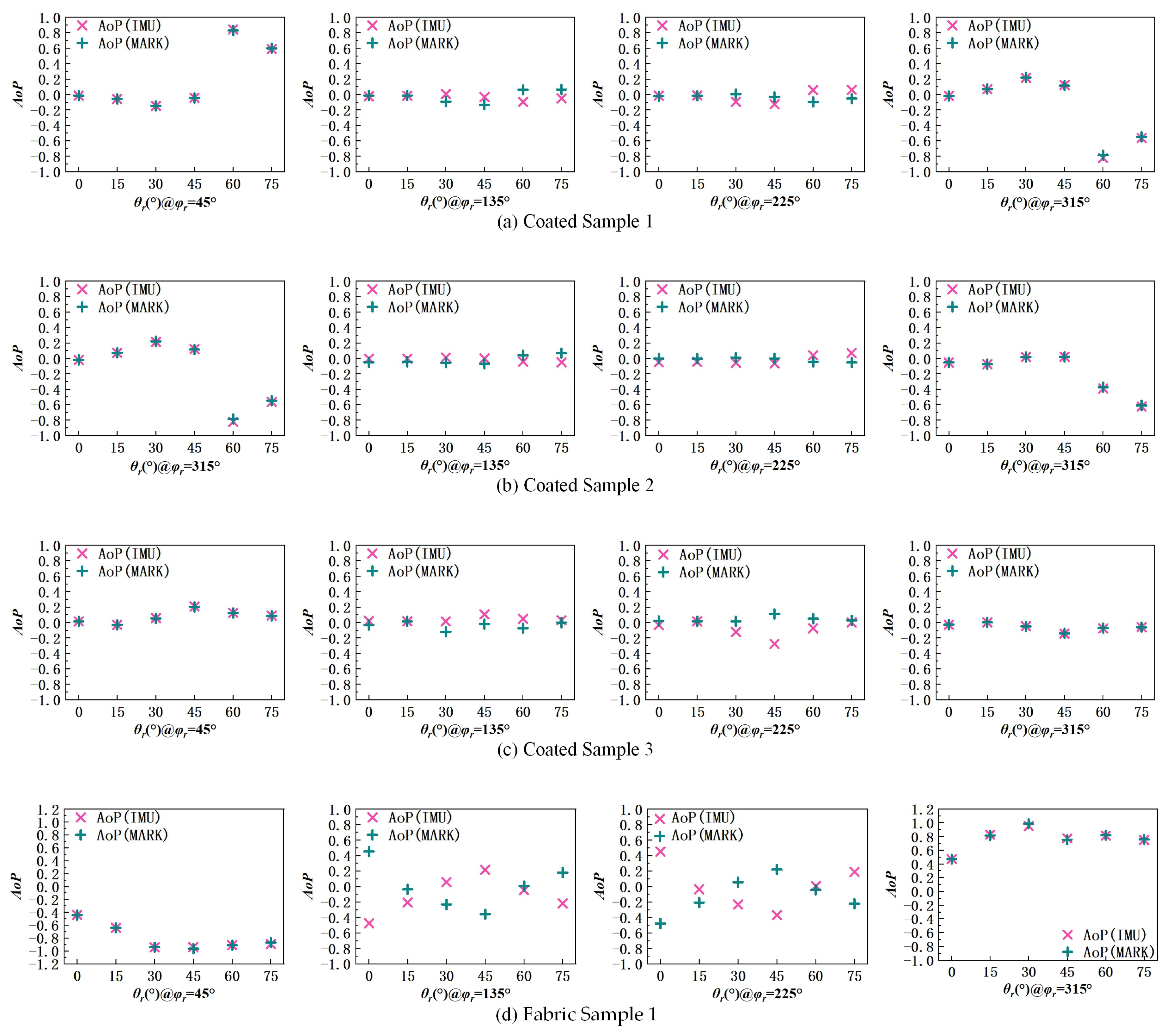

5.1. Polarization Imaging Experiments

- (a)

- Coated Sample 1

- (b)

- Coated Sample 2

- (c)

- Coated Sample 3

- (d)

- Fabric Sample 1

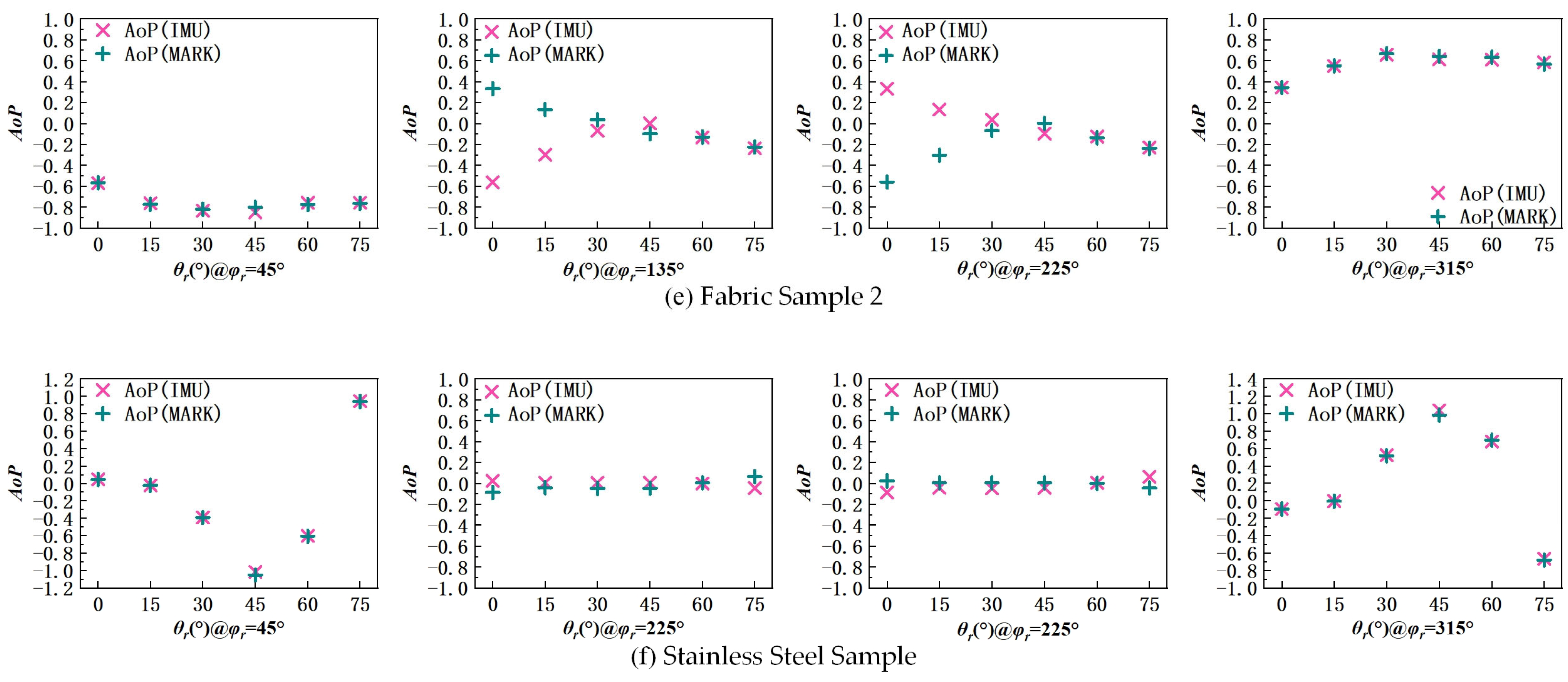

- (e)

- Fabric Sample 2

- (f)

- Stainless Steel Sample

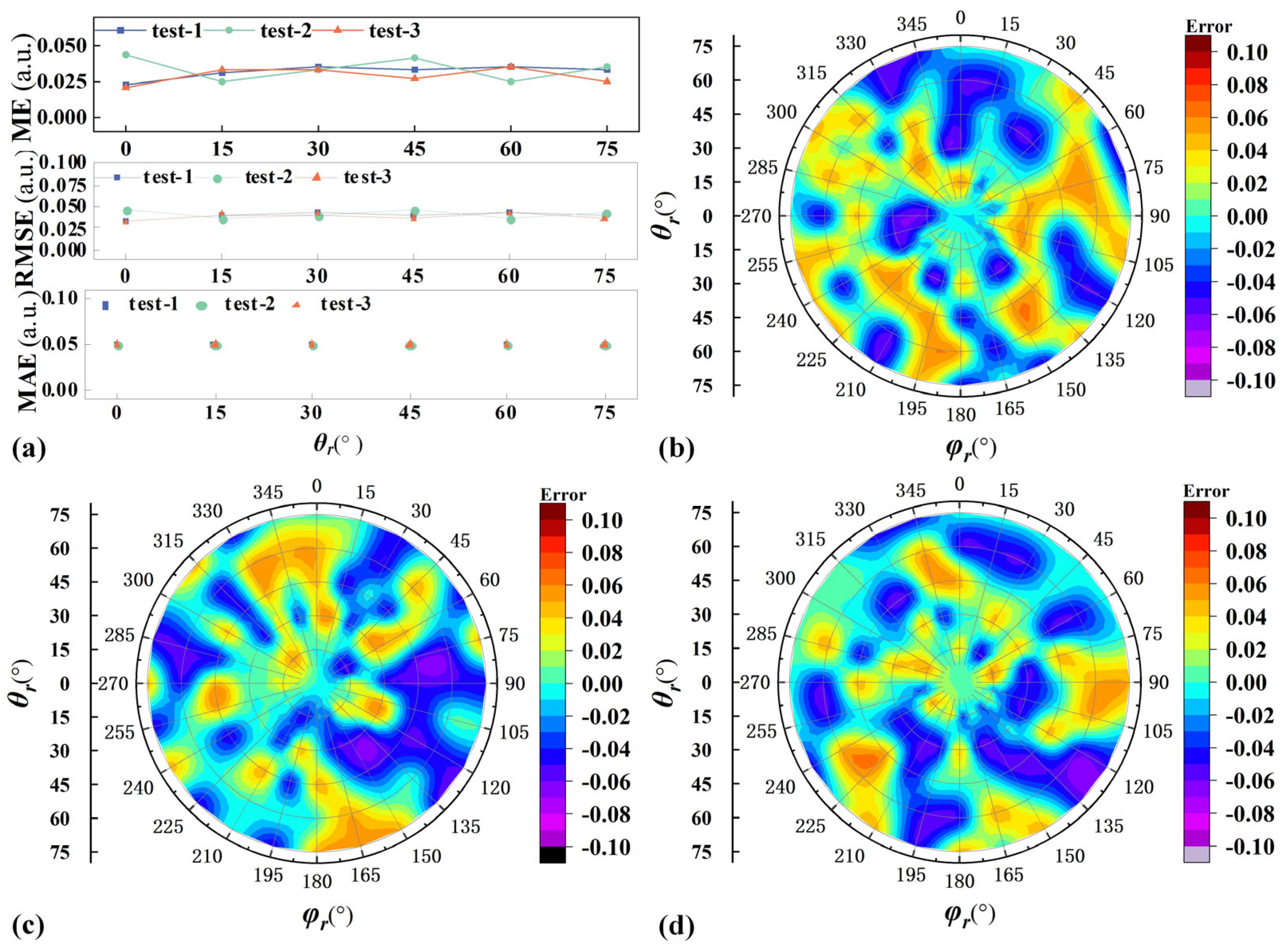

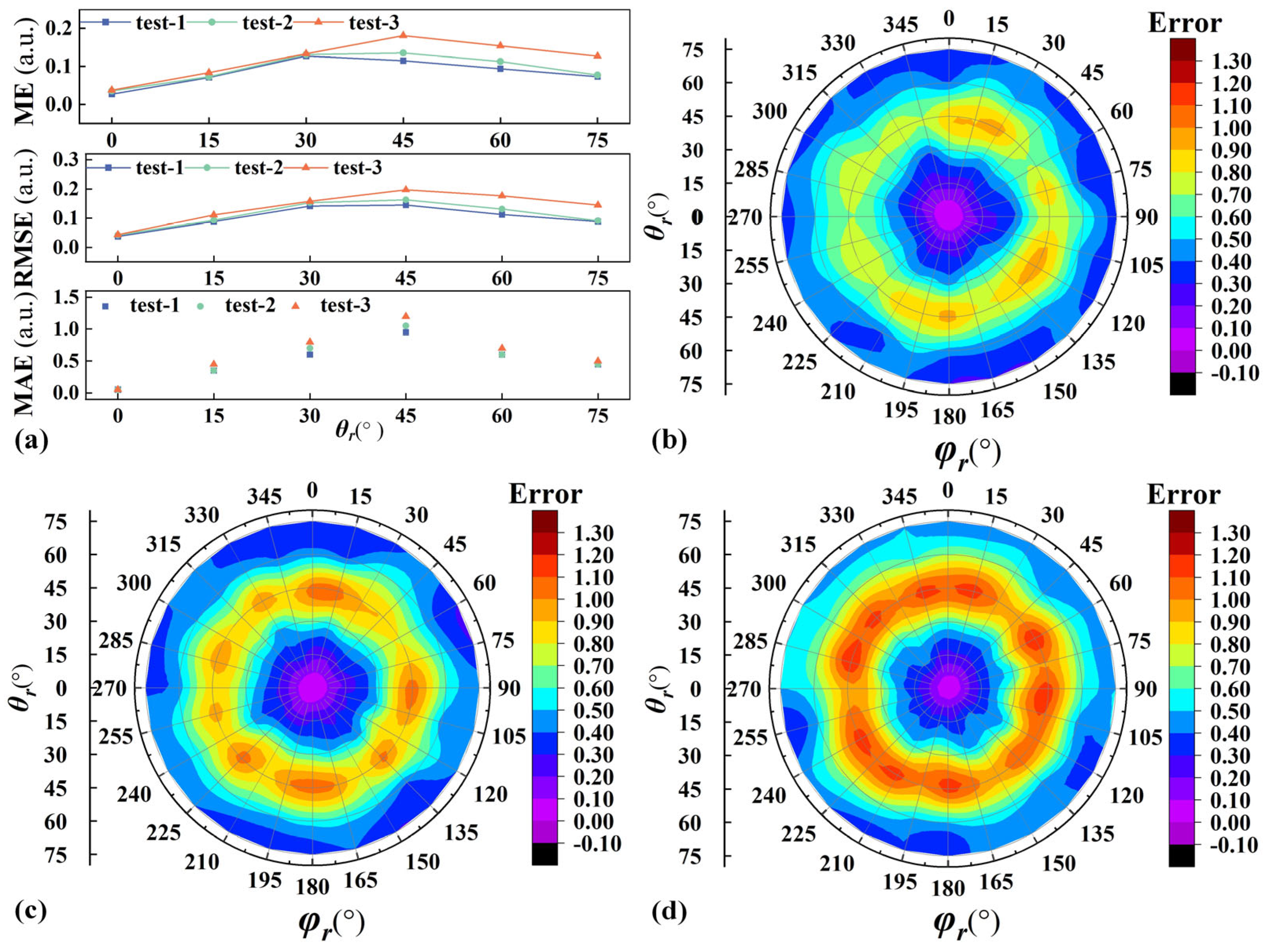

5.2. Impact Analysis of Angular Errors on Polarization Information

5.3. System Stability and Global Error Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nicodemus, F.E. Directional reflectance and emissivity of an opaque surface. Appl. Opt. 1965, 4, 767–775. [Google Scholar] [CrossRef]

- Guo, F.; Zhu, J.; Huang, L.; Li, H.; Deng, J.; Zhang, X.; Wang, K.; Liu, H.; Hou, X. A modified BRDF model based on Cauchy-Lorentz distribution theory for metal and coating materials. Photonics 2023, 10, 773. [Google Scholar] [CrossRef]

- Fankhauser, F.; Tyson, J.A.; Askari, J. Satellite optical brightness. Astron. J. 2023, 166, 59. [Google Scholar] [CrossRef]

- Gatebe, C.K.; King, M.D. Airborne spectral BRDF of various surface types (ocean, vegetation, snow, desert, wetlands, cloud decks, smoke layers) for remote sensing applications. Remote Sens. Environ. 2016, 179, 131–148. [Google Scholar] [CrossRef]

- Zhou, Y. An overview of BRDF models in computer graphics. Theor. Nat. Sci. 2023, 19, 205–210. [Google Scholar] [CrossRef]

- Kumar, H.; Ramkumar, J.; Venkatesh, K.S. Surface texture evaluation using 3D reconstruction from images by parametric anisotropic BRDF. Measurement 2018, 125, 612–633. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, S.; Li, Y.; Xu, Q.; Wang, L.; Gong, L. Study on the BRDF for the surfaces of typical metal materials. Coatings 2025, 15, 344. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, S.; Wang, Z. Establishment and verification of diffraction BRDF model for scratched material surface. Opt. Laser Eng. 2021, 142, 106597. [Google Scholar] [CrossRef]

- Taglione, C.; Mateo, C.; Stolz, C. Polarimetric imaging for robot perception: A review. Sensors 2024, 24, 4440. [Google Scholar] [CrossRef] [PubMed]

- Abbasi Habashi, S.; Koyuncu, M.; Alizadehsani, R. A survey of COVID-19 diagnosis using routine blood tests with the aid of artificial intelligence techniques. Diagnostics 2023, 13, 1749. [Google Scholar] [CrossRef]

- Torrance, K.E.; Sparrow, E.M. Theory for off-specular reflection from roughened surfaces. J. Opt. Soc. Am. 1967, 57, 1105–1114. [Google Scholar] [CrossRef]

- Miettinen, J.; Harkonen, A.K.; Piironen, T.H. Optical scattering measurement instrument for the design of machine vision illumination. In Optics, Illumination, and Image Sensing for Machine Vision VI; SPIE: Bellingham, WA, USA, 1992; Volume 1614, pp. 45–56. [Google Scholar] [CrossRef]

- Höpe, A.; Atamas, T.; Hünerhoff, D.; Schröder, S.; Schäfer, S. ARGon3: “3D Appearance Robot-Based Gonioreflectometer” at PTB. Rev. Sci. Instrum. 2012, 83, 045102. [Google Scholar] [CrossRef]

- Doctor, K.Z.; Bachmann, C.M.; Gray, D.J.; Montes, M.J.; Fusina, R.A. Wavelength dependence of the bidirectional reflectance distribution function (BRDF) of beach sands. Appl. Opt. 2015, 54, F243–F255. [Google Scholar] [CrossRef]

- Huang, B.; Peng, B.; Ren, Q.; Liao, S. Modeling and analysis of spectral polarization BRDF based on microfacet theory. J. Quant. Spectrosc. Radiat. Transfer 2024, 313, 108830. [Google Scholar] [CrossRef]

- Margall, F.; Lemineur, G.; Pacanowski, R.; Mavromatis, S.; Coiro, E.; Le Goff, A.; Ceolato, R. Supercontinuum laser-based gonio-scatterometer for in and out-of-plane spectral BRDF measurements. Opt. Express 2024, 32, 25581–25597. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, Y.; Liu, Z. High-precision BRDF measurement system in near infrared band. Acta Opt. Sin. 2022, 42, 1212002. [Google Scholar] [CrossRef]

- Dana, K.J. BRDF/BTF measurement device. In Proceedings of the Eighth IEEE International Conference on Computer Vision (ICCV 2001), Vancouver, BC, Canada, 7–14 July 2001; IEEE: Los Alamitos, CA, USA, 2001; Volume 2, pp. 460–466. [Google Scholar] [CrossRef]

- Ren, J.; Zhao, J. Measurement of a bidirectional reflectance distribution and system achievement based on a hemi-parabolic mirror. Opt. Lett. 2010, 35, 1458–1460. [Google Scholar] [CrossRef]

- Ben-Ezra, M.; Wang, J.; Wilburn, B.; Nayar, S.K. An LED-only BRDF measurement device. In Proceedings of the 2008 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Anchorage, AK, USA, 23–28 June 2008; IEEE: New York, NY, USA, 2008; pp. 1–8. [Google Scholar] [CrossRef]

- Cao, H.; You, D.; Ji, D.; Gu, X.; Wen, J.; Wu, J.; Li, Y.; Cao, Y.; Cui, T.; Zhang, H. The method of multi-angle remote sensing observation based on unmanned aerial vehicles and the validation of BRDF. Remote Sens. 2023, 15, 5000. [Google Scholar] [CrossRef]

- Kim, M.; Jin, C.; Lee, S.; Kim, K.-M.; Lim, J.; Choi, C. Calibration of BRDF based on the field goniometer system using a UAV multispectral camera. Sensors 2022, 22, 7476. [Google Scholar] [CrossRef] [PubMed]

- Latini, D.; Petracca, I.; Schiavon, G.; Cisbani, A.; Loizzo, R.; d’Andrimont, R. UAV-based observations for surface BRDF characterization. In Proceedings of the 2021 IEEE International Geoscience and Remote Sensing Symposium (IGARSS), Brussels, Belgium, 11–16 July 2021; IEEE: New York, NY, USA, 2021; pp. 8193–8196. [Google Scholar] [CrossRef]

- Mazumder, N.; Deka, G.; Wu, W.W.; Kao, F.J.; Chiou, A. Polarization resolved second harmonic microscopy. Methods 2017, 128, 105–118. [Google Scholar] [CrossRef] [PubMed]

- Reztsov, T.V.; Chernykh, A.V.; Orlova, T.; Petrov, N.V. A dynamic analysis of toron formation in chiral nematic liquid crystals using a polarization holographic microscope. Polymers 2025, 17, 1849. [Google Scholar] [CrossRef]

- Bozhok, A.; Dellinger, J.; Takakura, Y.; Laude-Boulesteix, B.; Torcal-Milla, F.J.; Depeursinge, C. Fourier ptychographic microscopy and Mueller matrix microscopy: Differences and complementarity. In Proceedings of the Unconventional Optical Imaging II, Online Only, 20–23 April 2020; SPIE: Bellingham, WA, USA, 2020; Volume 11351, pp. 224–232. [Google Scholar] [CrossRef]

- Fu, Q.; Liu, X.; Yang, D.; Zhan, J.; Liu, Q.; Zhang, S.; Wang, F.; Duan, J.; Li, Y.; Jiang, H. Improvement of pBRDF model for target surface based on diffraction and transmission effects. Remote Sens. 2023, 15, 3481. [Google Scholar] [CrossRef]

- Chen, F.; Chen, G.; Zhang, Y. Analysis of scattering characteristics of coating materials through coupling of BRDF spectral polarization imaging with Torrance–Sparrow model. Optoelectron. Lett. 2025, 21, 271–277. [Google Scholar] [CrossRef]

- Butler, S.D.; Marciniak, A.M.A. Utilization and efficient computation of polarization factor Q for fast, accurate BRDF modeling. Opt. Express 2022, 30, 5803–5816. [Google Scholar] [CrossRef]

- Sui, C.; Tan, Y.; Zhang, Y. Fiber evidence identification based on spectral bidirectional reflectance distribution function. Acta Opt. Sin. 2021, 41, 0930001. [Google Scholar] [CrossRef]

- d’Eon, E.; Weidlich, A. VMF Diffuse: A unified rough diffuse BRDF. Comput. Graph. Forum 2024, 43, 15149. [Google Scholar] [CrossRef]

- Yang, S.; Su, H. Fast geometric sampling for Phong-like reflection. In Advances in Computer Graphics. CGI 2023, Lecture Notes in Computer Science; Sheng, B., Bi, L., Kim, J., Magnenat-Thalmann, N., Thalmann, D., Eds.; Springer: Cham, Switzerland, 2023; Volume 14496, pp. 211–222. [Google Scholar] [CrossRef]

- Badura, G.P.; Valenta, C.R.; Gunter, B. Convolutional neural networks for inference of space object attitude status. J. Astronaut. Sci. 2022, 69, 593–626. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Li, G.; Chen, D.; Wang, X. Degree of polarization model based on a modified three-component pBRDF. Appl. Opt. 2023, 62, 4777–4785. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Tian, Y.; Lei, S.; Li, Y.; Hua, X.; Guo, D.; Ji, C. A comprehensive correction method for radiation distortion of multi-strip airborne hyperspectral images. Remote Sens. 2023, 15, 1828. [Google Scholar] [CrossRef]

- Cao, Y.; Cao, Y.; Wu, Z.; Yang, K. A calculation method for the hyperspectral imaging of targets utilizing a ray-tracing algorithm. Remote Sens. 2024, 16, 1779. [Google Scholar] [CrossRef]

- Ye, Y.; Tan, Y.; Jin, G. Accurate measurement for damage evolution of ceramics caused by nanosecond laser pulses with polarization spectrum imaging. Opt. Express 2019, 27, 16360–16376. [Google Scholar] [CrossRef] [PubMed]

- Cristóbal, J.; Graham, P.; Prakash, A.; Buchhorn, M.; Gens, R.; Guldager, N.; Bertram, M. Airborne hyperspectral data acquisition and processing in the Arctic: A pilot study using the Hyspex imaging spectrometer for wetland mapping. Remote Sens. 2021, 13, 1178. [Google Scholar] [CrossRef]

- Wang, Y.; Su, Y.; Sun, X.; Hao, X.; Liu, Y.; Zhao, X.; Li, H.; Zhang, X.; Xu, J.; Tian, J. Principle and implementation of Stokes vector polarization imaging technology. Appl. Sci. 2022, 12, 6613. [Google Scholar] [CrossRef]

- Zhang, Z. Camera Calibration. In Computer Vision: A Reference Guide; Springer International Publishing: Cham, Switzerland, 2021; pp. 130–131. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Z.; Qiu, Z.; Sun, H.; Zhou, J.; Wang, J.; Chen, F.; Wu, H.; Qin, Z.; Wang, Z.; Zhong, J.; et al. Analysis of the Impact of Multi-Angle Polarization Bidirectional Reflectance Distribution Function Angle Errors on Polarimetric Parameter Fusion. Appl. Sci. 2025, 15, 9313. https://doi.org/10.3390/app15179313

Lv Z, Qiu Z, Sun H, Zhou J, Wang J, Chen F, Wu H, Qin Z, Wang Z, Zhong J, et al. Analysis of the Impact of Multi-Angle Polarization Bidirectional Reflectance Distribution Function Angle Errors on Polarimetric Parameter Fusion. Applied Sciences. 2025; 15(17):9313. https://doi.org/10.3390/app15179313

Chicago/Turabian StyleLv, Zhong, Zheng Qiu, Hengyi Sun, Jianwei Zhou, Jianbo Wang, Feng Chen, Haoyang Wu, Zhicheng Qin, Zhe Wang, Jingran Zhong, and et al. 2025. "Analysis of the Impact of Multi-Angle Polarization Bidirectional Reflectance Distribution Function Angle Errors on Polarimetric Parameter Fusion" Applied Sciences 15, no. 17: 9313. https://doi.org/10.3390/app15179313

APA StyleLv, Z., Qiu, Z., Sun, H., Zhou, J., Wang, J., Chen, F., Wu, H., Qin, Z., Wang, Z., Zhong, J., Tan, Y., & Zhang, Y. (2025). Analysis of the Impact of Multi-Angle Polarization Bidirectional Reflectance Distribution Function Angle Errors on Polarimetric Parameter Fusion. Applied Sciences, 15(17), 9313. https://doi.org/10.3390/app15179313