1. Introduction

Road infrastructure is a cornerstone of economic development in Latin America, where more than 3.6 million kilometers of roads support nearly half of all interregional trade [

1]. Ecuador, with over 61,000 km, serves as a vital connector in regional mobility through its arterial and collector roads [

2]. However, Ecuador’s road density (239 km per 1000 km

2) remains well below the OECD average of 438 km [

3]. Persistent infrastructure quality issues contribute to elevated traffic fatality rates, with 18 deaths per 100,000 inhabitants, three times the OECD average [

4]. These figures highlight the urgent need to modernize road design practices to enhance safety, efficiency, and resilience in Ecuador’s transportation system.

Ecuador’s current geometric design guideline, the 2003 Manual de Carreteras [

5], has not been formally revised for two decades. Although a new version (NEVI-12) was proposed in 2013, it remains unimplemented [

6]. In contrast, several Latin American countries have adopted updated international guidelines, such as the 7th Edition of the AASHTO Green Book [

7], which incorporates parameters that reflect current traffic and vehicle trends. Continuous reliance on outdated standards in Ecuador risks design mismatches, higher project costs, and reduced safety. Revisiting and contextualizing design parameters is therefore both timely and essential for sustainable infrastructure planning [

8].

Two of the most critical parameters in geometric road design are the dimensions of the design vehicle and the height of the driver’s eye [

9]. These factors directly influence aspects such as turning radii, lane widening on curves, and sight distances, particularly on vertical alignments [

10]. When such parameters do not reflect the actual characteristics of the national vehicle fleet or the population’s anthropometry, they may result in inadequate infrastructure dimensions [

11,

12]. Such mismatches may lead to insufficient visibility, excessive excavation, or suboptimal clearance, affecting both road safety and construction efficiency [

13,

14]. Defining these values through empirical, context-specific data is essential.

Ecuador’s current standards assume a driver eye height of 1.15 m for light vehicles and 2.0 m for heavy vehicles [

5], which differ significantly from the AASHTO’s recommendations of 1.08 m and 2.4 m, respectively [

15]. Similarly, the assumed width and height of trucks in the Ecuadorian standard (2.60 m and 4.10 m) do not match the specifications of most locally used vehicles. These differences, though seemingly minor, can alter geometric configurations such as horizontal clearances or vertical profiles, which are vital for safety and constructability [

16]. These inconsistencies highlight the importance of recalibrating national standards using empirical, country-specific data [

12,

17].

To address this gap, this study highlights the need to update Ecuador’s road design parameters using a data-driven approach rooted in local realities. In recent years, the country’s vehicle fleet has evolved considerably, incorporating a wide variety of models with differing dimensions and configurations [

18]. Ecuador’s population also shows significant anthropometric diversity across its major ethnic groups, including Mestizo, Indigenous, Afro-Ecuadorian, Montubio, and White populations [

19]. These demographic and technological changes are not reflected in current standards, resulting in design mismatches that can compromise safety, increase construction costs, and reduce the effectiveness of road infrastructure. Therefore, there is a need for a methodology that can produce updated, locally calibrated values for critical geometric parameters.

The objective of this research is to propose a methodological framework for determining context-specific values for design vehicle dimensions and driver eye height in Ecuador’s road design standards. To achieve this, the study compiled a national database using 2023 vehicle registration records from INEC and supplemented it with technical specifications obtained from dealerships, manufacturers, and previous academic research. Vehicle dimensions, such as width, height, length, and overhangs, were recorded, while headlight and seat heights were estimated through AutoCAD-based scaling and field data collection. For driver eye height, anthropometric data disaggregated by sex and ethnicity were combined with seat height measurements to estimate the vertical distance from pavement to eye level. This methodological process allowed for derivation of updated design values grounded in the physical and demographic characteristics of Ecuador’s population and vehicle fleet.

The methodology presented in this study is distinct from previous efforts in Latin America, which have generally relied on international design standards or limited field samples and have not fully accounted for local anthropometric diversity or the evolving vehicle fleet. Unlike prior work, this research integrates national-level vehicle registration data with brand-specific technical specifications and employs a novel combination of CAD-based dimensional analysis and virtual anthropometric assignment. The methodological contribution lies in a replicable framework for estimating both vehicle dimensions and driver eye height through two complementary approaches: one based on percentile-based anthropometric data and another that simulates driver–vehicle combinations. This dual-method approach ensures robustness while addressing local variability, representing a significant improvement over earlier studies that failed to incorporate empirical diversity in population or fleet characteristics.

Furthermore, while this study focuses on baseline vehicle configurations as reported in manufacturers’ technical specifications, it is important to recognize that many modern vehicles—particularly in higher-end and heavy-duty segments—are equipped with dynamic adjustment systems. These include air- or hydraulically adjustable suspensions, as well as multi-range seat height adjustments, which can temporarily alter driver eye height and ground clearance. Such systems may influence visibility and clearance in real-world operations, but design standards typically rely on fixed, nominal values to ensure consistency and replicability. Incorporating empirical data into these baseline assumptions provides a solid reference point for both infrastructure design and potential integration into vehicle ergonomics and safety feature development.

2. Materials and Methods

2.1. Design

A comprehensive database of vehicles registered in Ecuador in 2023 was compiled using official aggregated records from the INEC [

20]. These records did not include detailed vehicle classifications; therefore, supplementary data were collected from vehicle dealerships, manufacturers, technical brochures, and previous academic studies to obtain precise specifications for both current and discontinued models.

Vehicle dimensions, including width, height, length, gross weight (kg), front overhang, and rear overhang, were collected. In some cases, vehicle profiles were digitized and scaled in AutoCAD to obtain precise measurements. Additional data, such as headlight heights (front and rear), were obtained using the same CAD scaling method, measuring from the ground to the headlight center.

2.2. Data Vehicle Collection

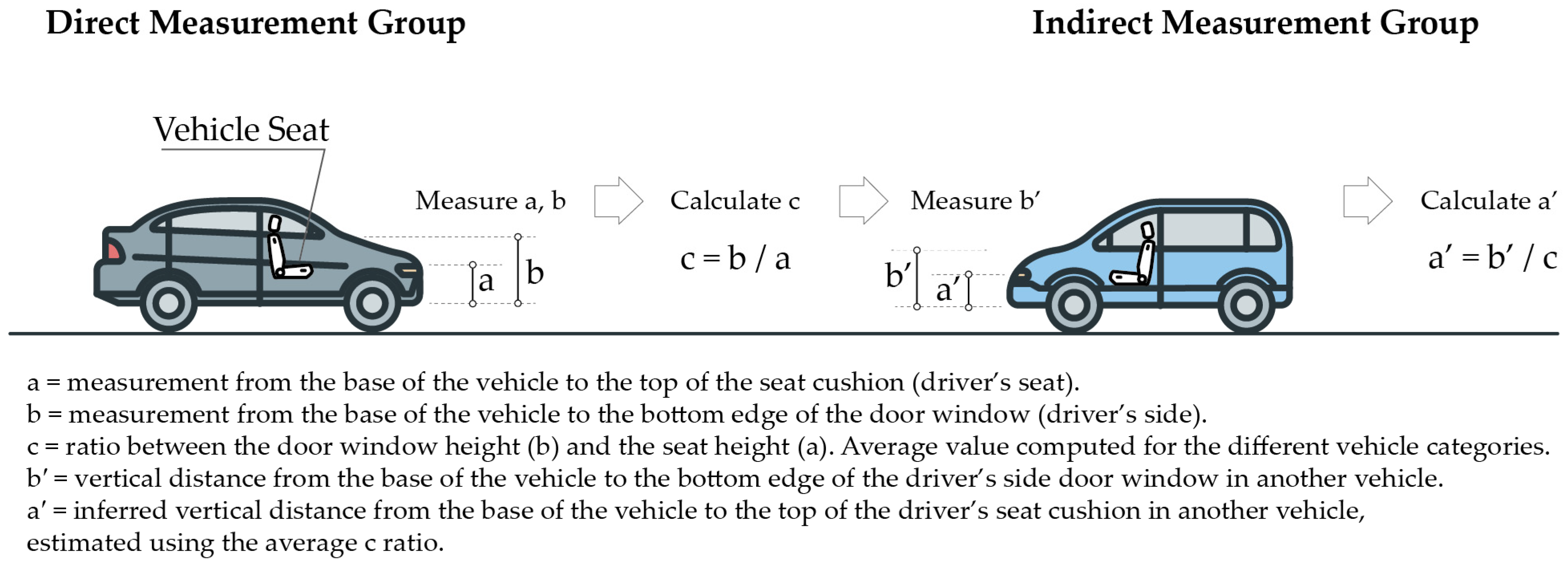

To estimate driver eye height, seat height data were initially obtained from direct measurements in technical manuals or during field visits to dealerships. When full technical specifications were unavailable, the height from the ground to the bottom edge of the door window was measured instead. A proportional relationship between door window height and seat height was then established for each vehicle category using a subset of vehicles with both measurements available. This ratio was used to infer seat height in a broader sample by simply measuring the door window height on site. Further details of this estimation process are shown in

Figure 1. Adding this estimated seat height and the vehicle’s ground clearance yielded the total distance from the pavement surface to the base of the driver’s seat.

The estimation of seated eye height for Ecuadorian drivers was performed using national anthropometric data. Height percentiles (5th, 10th, 25th, 50th, 75th, 90th, and 95th) for the five primary ethnic groups in Ecuador—Afro-Ecuadorian, Indigenous, Mestizo, White, and Montubio—were extracted from existing academic literature [

21]. This dataset, disaggregated by sex and presented in

Table 1, was collected between 2012 and 2013. The sample was robust, encompassing 19,949 households and 92,502 individuals, covering all household members aged 0 to 59 years.

Although the anthropometric data were collected between 2012 and 2013, they remain the most recent nationally representative dataset available for Ecuador, covering over 92,000 individuals. Height and body proportions, especially in adult populations, generally change slowly over time. In the absence of a newer survey with comparable scope and disaggregation by sex and ethnicity, these data remain a valid and robust foundation for estimating seated eye height. Additionally, using percentile values helps account for inter-individual variability and mitigates the potential impact of minor population changes over the past decade.

These seated heights reflect a relaxed posture similar to that of a typical driver. The relaxed seated height measurements were obtained from a previous study [

22], as detailed in

Table 2. That study included 768 individuals from the northern Ecuadorian provinces of Pichincha, Tungurahua, Imbabura, and Chimborazo. These relaxed seated height data served as a crucial baseline for comparison with measurements obtained through the procedure described later in this paper. As shown in

Table 2, not all ethnic groups listed in

Table 1 are represented. However, a comparison of their average heights suggests similarities between certain groups—Montubio and Mestizo, as well as Afro-Ecuadorian and White individuals. Therefore, it can be assumed that the relaxed seated height will be consistent across these specific ethnic groups.

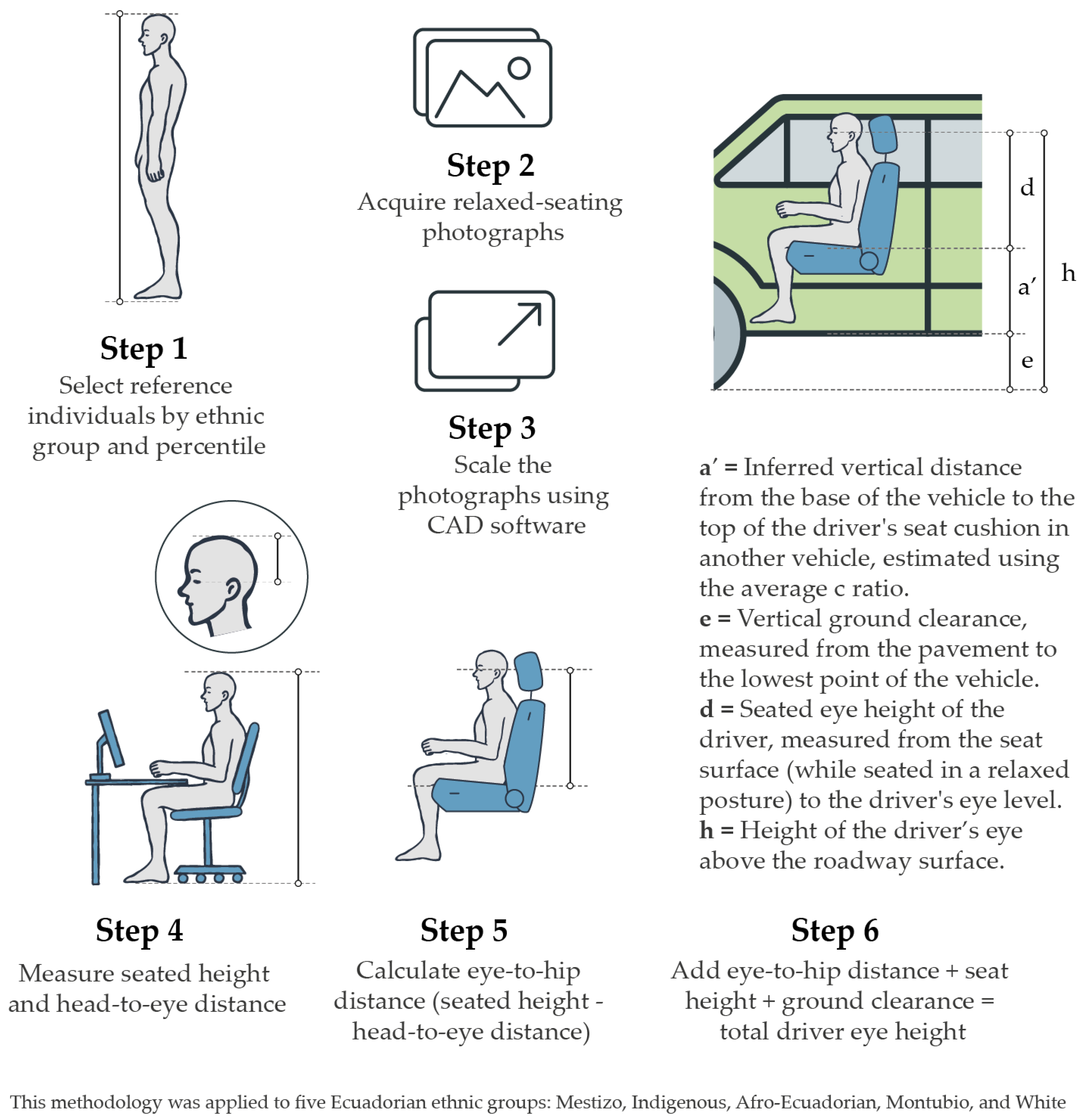

To estimate the vertical distance between a driver’s eyes and the top of the head, an essential component for calculating total eye height, the following procedure was applied:

2.2.1. Selection of Reference Individuals

For each sex-specific percentile within the five major Ecuadorian ethnic groups (Mestizo, Indigenous, Afro-Ecuadorian, Montubio, and White), a public figure whose standing stature matched the target height ± 1 cm was identified using reliable online sources (e.g., professional athletes, politicians). When no suitable public figure was found, volunteers matching the required stature were recruited on site.

2.2.2. Acquisition of Relaxed-Seating Images

Photographs of each reference individual in a relaxed seated posture—comparable to a typical driving position—were gathered from the web. If web images were unavailable, standardized photographs were taken of the field volunteers.

2.2.3. Image Scaling and Measurement

Each photograph was imported into CAD software V2025, scaled using the known standing stature, and measured to obtain

the seated height (distance from the ischial tuberosity to the vertex of the head),

the head-to-eye distance (vertical distance from the horizontal eye axis to the vertex).

2.2.4. Derivation of Eye-to-Hip Distance

The head-to-eye distance was subtracted from the seated height to yield the eye-to-hip (driver pelvis) distance for every percentile, sex, and ethnic group.

2.2.5. Computation of Driver Eye Height Above Pavement

For each vehicle, the eye-to-hip distance was added to the estimated seat height—which was either directly measured or inferred via the c ratio—and to the vehicle’s ground clearance. This sum represents the total driver eye height relative to the pavement. Additional methodological details and examples of the image-scaling process are provided in

Figure 2.

2.3. Database Development

All collected and calculated data were compiled into an Excel database to facilitate future updates and maintain national applicability. The dataset includes both the physical dimensions of vehicles and estimated driver eye heights. It is designed to be updated annually or periodically as new models and anthropometric trends emerge.

2.4. Database Analysis

The analytical phase of this study focused on quantifying deviations between Ecuador’s current road design parameters and the physical and anthropometric characteristics of its vehicle fleet and population. The data analysis was conducted in three main stages:

2.4.1. Descriptive Statistics and Percentile-Based Characterization

Vehicle dimensions were summarized using the 5th, 50th (median), and 95th percentile values for each category: passenger cars, SUVs, pickup trucks, and multiple classes of heavy vehicles. The 5th and 95th percentiles were chosen to simplify the presentation and highlight the most critical boundary conditions for geometric design, such as maximum vehicle widths or minimum ground clearances. These conditions directly influence turning radii, lane widening, and clearance requirements. While readers are encouraged to consult the full dataset (in the

Supplementary Materials) for further analysis, these specific percentiles emphasize the most critical design scenarios.

2.4.2. Comparative Analysis Against Design Standards

The percentile-based vehicle data were compared with the design parameters defined by Ecuador’s 2003 MOP standard and the AASHTO 2018 Green Book. Differences in dimensions—height, width, length, wheelbase, and gross weight—were quantified using mean squared error (MSE), mean absolute error (MAE), and maximum absolute error (MaxAE). This allowed for a systematic evaluation of how representative the current standards are relative to the operating fleet.

2.4.3. Estimation and Evaluation of Driver Eye Height

The primary objective of this study is to determine a representative driver eye height based on the anthropometric characteristics of Ecuador’s population, disaggregated by sex and ethnic group. This data-driven approach is designed to provide a locally grounded input for future geometric design, replacing imported assumptions with measurements relevant to our context. Once the eye height is established, the calculation of stopping sight distance (SSD) can proceed using the standard procedures outlined in AASHTO. Our contribution is not to change how SSD is computed but to improve the validity of the eye height input used in those established equations by aligning it with Ecuadorian population characteristics.

Two complementary methods were used to estimate the height of the driver’s eye above the pavement:

Method 1: Combined measured or inferred seat heights, ground clearance, and anthropometric eye-to-seat distances (disaggregated by sex and ethnic group) to estimate eye height using the 5th percentile for light vehicles and the 95th percentile for heavy vehicles.

Method 2: Applied a simulation approach in which anthropometric profiles were virtually assigned to the full fleet of recorded vehicles, enabling eye height distributions to be calculated across thousands of driver–vehicle combinations.

Results from both methods were analyzed and compared, with Method 1 offering a conservative, standardized estimate and Method 2 capturing greater variability and more closely simulating real-world diversity. Boxplots and summary statistics were generated to visualize eye-height distributions by vehicle type, sex, and ethnicity.

2.5. Ethical Considerations and Use of Generative AI

This study did not involve direct experimentation with human subjects. Most anthropometric data were derived from publicly available sources or through non-invasive field measurements of volunteers, respecting anonymity and informed consent. Therefore, ethics committee approval was not required.

3. Results

3.1. Fleet Composition by Vehicle Type and Brand Distribution

According to Ecuador’s National Transit Agency, 3,065,967 vehicles were registered in 2023 [

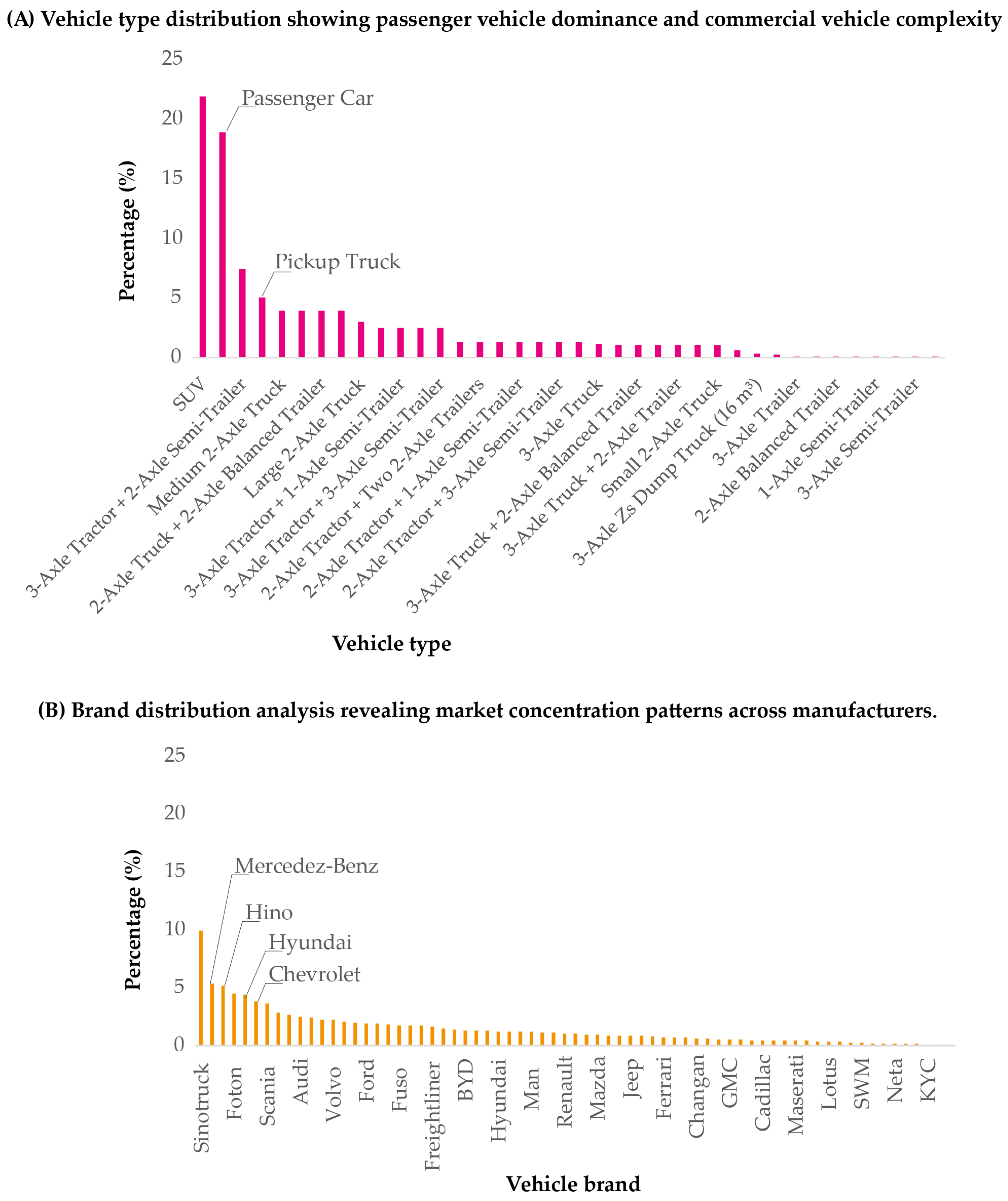

20]. Given the redundancy in make, model, and configuration within the national registry, random sampling would have led to over-representation of similar vehicles and required substantial resources. To ensure comprehensive coverage, this study adopted a brand-based sampling strategy informed by the INEC’s registry of vehicles by manufacturer. For each major brand, technical specifications of all available models—including current and discontinued ones—were collected from commercial dealerships and manufacturers. This approach resulted in a database covering 1170 distinct vehicle designs across 36 vehicle categories, representing 100% of the body style categories and most of the major design configurations present in Ecuador’s registered fleet. While this includes vehicles from most brands sold nationally, the coverage is defined here in terms of unique vehicle designs rather than total brand representation, thereby providing a clearer indication of the database’s comprehensiveness.

The sample demonstrated a pronounced preference for SUVs, which constitute the largest category at 21.88% (256 vehicles), followed by automobiles at 18.89% (221 vehicles). When combined with pickup trucks at 5.04% (59 vehicles), passenger vehicles collectively account for approximately 45.8% of the total sample. This distribution reflects contemporary transportation preferences that favor sport utility vehicles over traditional sedans, while simultaneously revealing the complex categorization of commercial vehicles, with heavy-duty trucks and tractor–trailers representing substantial fleet diversity across 30 distinct commercial vehicle classifications (

Figure 3a).

Complementing the vehicle type analysis, the brand distribution examination of 1162 vehicles with identifiable manufacturers revealed distinct market segmentation patterns that align with functional vehicle categories. The commercial vehicle segment demonstrates clear consolidation around established heavy-duty manufacturers, with Chinese brand Sinotruck achieving market leadership at 9.90% (115 vehicles), followed by European manufacturer Mercedes at 5.34% (62 vehicles) and Japanese manufacturer Hino at 5.16% (60 vehicles). Additional commercial vehicle representation includes Foton (4.48%, 52 vehicles), Hyundai (4.39%, 51 vehicles), and Scania (3.61%, 42 vehicles), indicating a strong preference for proven heavy-duty performance. Conversely, the passenger vehicle market exhibits greater brand diversification, with premium manufacturers such as BMW (2.67%, 31 vehicles), Audi (2.50%, 29 vehicles), and Chevrolet (2.41%, 28 vehicles) coexisting alongside mainstream brands including Toyota (2.24%, 26 vehicles), Nissan (2.07%, 24 vehicles), and Volkswagen (1.46%, 17 vehicles) (

Figure 3b).

3.2. Analysis of Light Vehicle Dimensions and Weights

For the purposes of this study, light vehicles were categorized into three main types: passenger cars, pickup trucks, and SUVs. The dataset included 221 passenger cars, 59 pickup trucks, and 256 SUVs. For each category, the 5th percentile, median, and 95th percentile values were calculated for key vehicle dimensions. The 5th and 95th percentiles were selected because they represent the most critical and potentially adverse conditions for geometric road design, unlike the first and third quartiles, which reflect more moderate scenarios.

Table 3 presents the descriptive statistics for several vehicle parameters, including height, width, length, ground clearance, overhangs, headlight heights, seat height, wheelbase (WB1), and gross weight.

Based on the standard deviation (SD) values in the “All Combined” column of the table, the dimensions with the greatest variability are Gross Weight (0.50 tons) and Length (0.45 m). This highlights the wide diversity in the sample, which includes everything from compact cars to large pickup trucks. Conversely, the least variable dimensions are Seat Height (0.04 m) and Ground Clearance (0.04 m), as indicated by their lowest standard deviations. This suggests that while vehicle size and weight vary dramatically across the fleet, these specific dimensions remain remarkably consistent.

To assess how these local vehicle dimensions compare with international standards, particularly those from AASHTO [

15], a selection of the most critical values from

Table 3 was compiled and contrasted with the AASHTO design vehicle parameters in

Table 4. The Ecuadorian MOP [

5] does not currently provide reference values for design vehicles.

The rear headlight height, selected as 0.75 m (5th percentile), is particularly relevant because AASHTO uses a reference object height of 0.60 m for calculating stopping sight distance. If Ecuador were to update its reference object height (currently 0.15 m, according to MOP standards) to 0.75 m, it would significantly reduce the available stopping sight distance, which could have implications for both new and existing roads.

Other values such as gross weight (2.80 tons), seat height (0.23 m), and ground clearance (0.12 m) are also notable. Gross weight is particularly important for asset management, while seat height and ground clearance are directly related to driver eye height, which in turn affects visibility and road safety assessments.

Overall, the comparison shows that the AASHTO design vehicle tends to be larger and wider than the majority of vehicles sold in Ecuador. This suggests that applying AASHTO parameters in Ecuador may result in conservative designs. However, in some cases—such as vehicle height and front overhang—local vehicles exhibit higher values, which may require adjustments to calculations related to turning radii and shoulder widening.

3.3. Analysis of Heavy Vehicle Dimensions and Weights

To complement the analysis conducted for light vehicles, a similar percentile-based approach was applied to heavy vehicles, using the 5th percentile (P5), median (Med), and 95th percentile (P95) values. These percentiles help capture the variability and extremes in key dimensions that are critical for geometric road design. A wide range of heavy vehicle configurations was analyzed, including 2-axle and 3-axle rigid trucks, articulated tractor–trailer combinations, and dump trucks. The dataset encompasses typical vehicles found on Ecuadorian roads and includes both national configurations (MOP designations) and standard international counterparts (AASHTO classifications) (See

Table 5).

The comparison reveals significant dimensional variability across vehicle types. Vehicle height ranges from 2.32 m (small 2-axle trucks) to over 4.10 m for articulated vehicles and trailers, with the 95th percentile height reaching 4.10 m. This maximum height coincides with several articulated and semi-trailer configurations commonly operating in Ecuador, presenting critical implications for vertical clearance in infrastructure design. In terms of width, most vehicles conform to the international standard of 2.60 m, with very few exceptions falling below this value, suggesting limited variability and strong alignment with global norms.

Total vehicle length exhibits considerably broader dispersion. Small rigid trucks measure approximately 5.48 m, while the longest combinations—such as the 2-axle tractor with two 2-axle trailers—reach up to 36.35 m, surpassing the AASHTO WB-20D design vehicle by more than 1.35 m. This extreme length is representative of specific Ecuadorian configurations permitted under national regulations, and its inclusion underscores the need to reassess local geometric design parameters, especially for turning radii and intersection layout. Similarly, wheelbase dimensions (WB1–WB4) and overhangs show marked variation across configurations, reflecting differences in load distribution and maneuverability that directly affect horizontal alignment and turning paths.

Gross vehicle weight also displays a considerable range, from 5.10 tons in small 2-axle trucks to as much as 72 tons in 3-axle tractor–3-axle semi-trailer combinations. Notably, several Ecuadorian configurations exceed 60 tons, including 3-axle dump trucks and multi-trailer assemblies, surpassing many AASHTO design values. These findings suggest a mismatch between current design assumptions and actual operating conditions, potentially compromising the structural performance of pavements and bridges.

Overall, the data indicate that the Ecuadorian heavy vehicle fleet includes configurations that are significantly larger and heavier than those represented in standard AASHTO design.

Table 6 presents the discrepancies between observed dimensions of local vehicles and the corresponding design specifications from Ecuador’s MOP and AASHTO standards. The analysis uses three common error metrics: Mean Squared Error (MSE), Mean Absolute Error (MAE), and Maximum Absolute Error (MaxAE), applied across key vehicle characteristics such as overall height, width, length, and gross weight. For the AASHTO comparison, additional geometric elements, such as front and rear overhangs, wheelbase segments (WB1 and WB2), and kingpin-to-rear-tandem distance, were included.

The results indicate that the MOP standards show substantially higher dimensional mismatches, particularly in overall length, where the MaxAE reaches 36.35 m and the MSE is as high as 60.99. The gross weight comparison also reveals a substantial deviation from the MOP standard, with a MaxAE of 65.80 tons. In contrast, AASHTO demonstrates lower errors across most parameters, with maximum absolute deviations generally below 13 m for dimensional characteristics and under 13 tons for weight-related metrics. The relatively high MSE values for length and wheelbase elements in both standards suggest that local heavy vehicle configurations diverge significantly from standard assumptions, especially in longitudinal dimensions. These findings reinforce the need to recalibrate national design parameters based on updated empirical vehicle data.

3.4. Driver Eye-to-Hip Height by Ethnic Group and Sex

In

Appendix A,

Table A1 presents the calculated vertical distance from the driver’s eye level to the hip (i.e., the seat level) for five major ethnic groups in Ecuador, disaggregated by sex. This metric is essential for the accurate estimation of seated eye height, which influences visibility assessments and geometric road design. The data were derived using a combination of secondary and primary sources. For each ethnic group and percentile (5th, 10th, 25th, 50th, 75th, 90th, and 95th), individuals were selected based on their publicly declared standing height, ensuring that the selected individual’s height did not differ by more than 1 cm from the corresponding percentile of a national anthropometric study. Additionally, images showing a relaxed seated posture were used to estimate seated height, head-to-eye height, and the resulting eye-to-seat distance. When no suitable public figure was available, field measurements were conducted on volunteers.

For light vehicles, the most critical values for design purposes are those corresponding to the 5th percentile, as they represent the least favorable visibility conditions. Among all ethnic groups and sexes, the average eye-to-seat height at the 5th percentile was 66.2 cm, with a standard deviation of 6.2 cm. Within this group, the maximum recorded value was 68.2 cm, and the minimum was 52.2 cm.

In contrast, for heavy vehicles, the design-critical values correspond to the 95th percentile, which reflects the highest seated eye positions and thus the greatest visibility potential. In this case, the minimum eye-to-seat height was 63.5 cm, the maximum was 81.5 cm, and the mean was 72.5 cm, with a standard deviation of 7.3 cm.

3.5. Estimation of Driver Eye Height

The estimation of driver eye height can be approached in two ways. The first method involves summing the ground clearance, seat height, and the vertical distance from the driver’s eye to the seat, differentiated by ethnic group and sex. The second method consists of assigning seated eye heights based on the anthropometric data of each ethnic group to the range of vehicles included in the database. This allows for the calculation of representative values by vehicle type.

For the first approach,

Table 7 summarizes the relevant values, using the 5th percentile of ground clearance and seat height data for each vehicle type—representing the least favorable conditions. Among these, the passenger car is identified as the most critical case. For this vehicle, the resulting driver eye height is estimated at 0.87 m when using the minimum eye-to-seat height of 52.2 cm, 0.95 m when based on the average eye-to-seat height of 59.6 cm, and 1.03 m when using the maximum value of 68.2 cm.

Given these findings, it appears reasonable to adopt the average value of 0.95 m as a representative driver eye height for Ecuador. This value is lower than the value used by AASHTO (1.08 m) and significantly lower than the outdated value still used in Ecuador’s MOP standards (1.15 m).

For heavy vehicles, the estimation uses the 95th percentile values, representing the drivers with the highest seated eye positions—critical for maximum visibility assessments. The average driver eye height for heavy vehicles was found to be 1.70 m, which is 30 cm lower than the value used in the MOP standards and 70 cm lower than the AASHTO standard. These discrepancies highlight the importance of revisiting and possibly recalibrating design standards for sight distance, especially for local road conditions and fleet characteristics.

The second method for estimating driver eye height consists of virtually assigning the measured eye-to-seat heights—obtained for each ethnic group and sex—to the full range of vehicles included in the national fleet database. This method simulates a scenario in which representative drivers from each percentile group are “seated” in every vehicle in the dataset, allowing for a comprehensive assessment of eye height variability across both human and vehicle characteristics. For this approach, the 5th percentile eye-to-seat height was used for light vehicles, as it represents the most unfavorable visibility scenario. Conversely, the 95th percentile was applied to heavy vehicles, consistent with maximum visibility needs in freight and commercial vehicle operations.

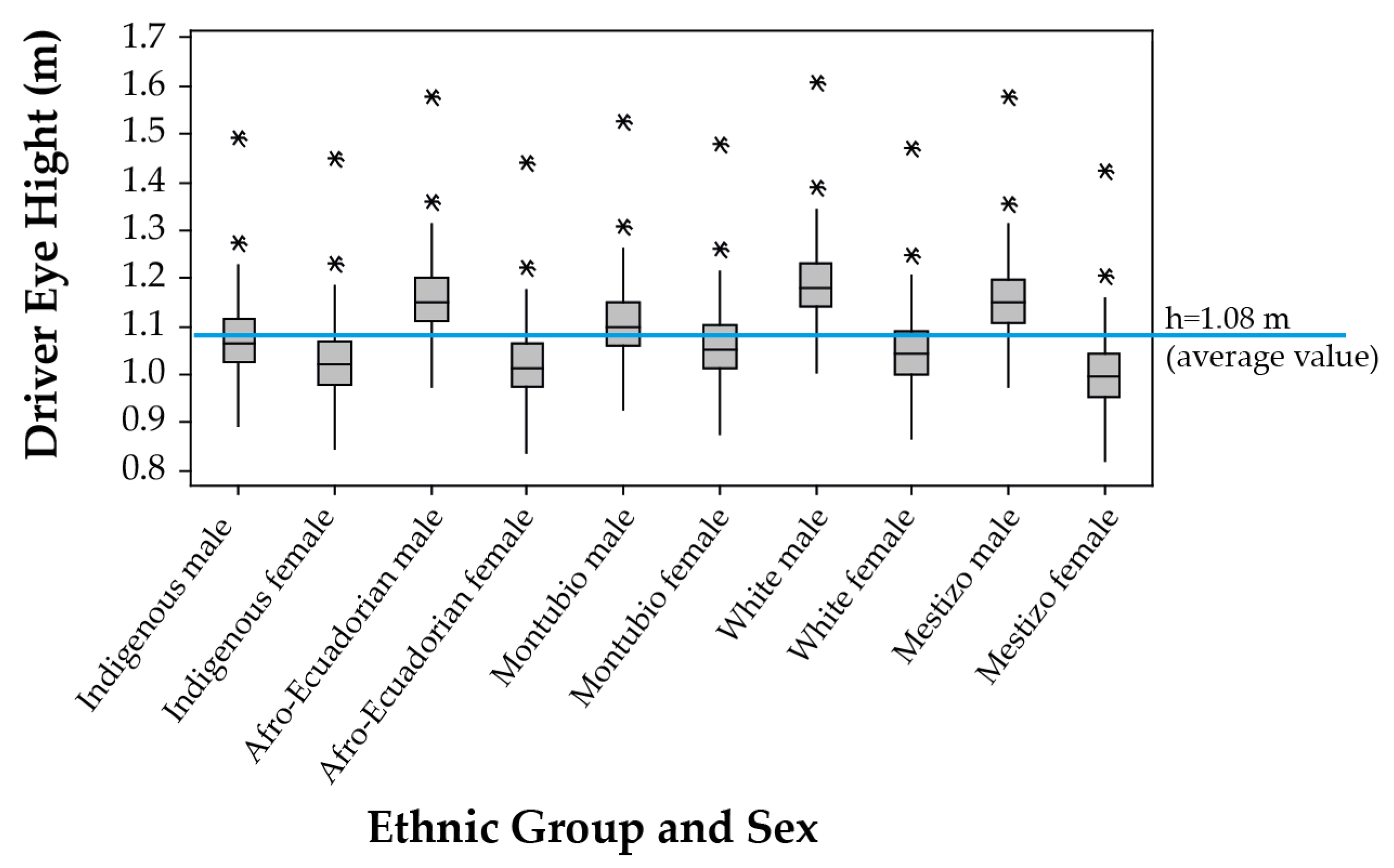

Figure 4 presents boxplots of the resulting driver eye heights for light vehicles, stratified by ethnic group and sex. The data shows a uniform standard deviation (SD) of around 0.07 m across all ethnic and gender groups, which indicates that the variability in driver eye height is consistent for all groups. However, the average eye height is consistently higher for male drivers than for female drivers. This is exemplified by the highest average being for White Men (1.18 m) and the lowest for Mestizo Women (1.00 m). In essence, while the spread of data is similar for everyone, the central values are distinctly different between the sexes. The average seated eye height for women is 1.02 m, while the combined average across all sexes and ethnicities is 1.08 m. Interestingly, this value matches the design eye height recommended by AASHTO and is slightly higher than the 0.95 m obtained using Method 1. This discrepancy is due to the fact that Method 1 uses representative values for seat height and ground clearance, thereby eliminating variability in vehicle design. In contrast, Method 2 preserves the full variability of the vehicle fleet and combines it with diverse anthropometric profiles—effectively increasing the number of permutations and potentially amplifying or attenuating the average values. Despite this, the result still falls below the outdated 1.15 m value currently used by Ecuador’s MOP.

A similar analysis was carried out for heavy vehicles using the 95th percentile eye-to-seat height for each ethnic group and sex. Due to the larger volume and greater diversity of the heavy vehicle fleet, only summary results are presented here.

The average driver eye height for trucks was found to be 1.34 m, with a high standard deviation of 0.19 m, a minimum of 0.63 m, and a maximum of 1.81 m. The large spread confirms the considerable variability in seat height and ground clearance within the heavy vehicle category. This also explains why Method 2 may be less reliable for estimating representative values in this category, especially when aiming for conservative design thresholds. Nonetheless, the maximum eye height of 1.81 m, obtained through this method, exceeds the previous values obtained via Method 1 and could serve as a useful reference for extreme-case visibility assessments.

3.6. Database Description

Each vehicle entry in the dataset includes up to 49 possible attributes, resulting in over 50,000 data points for the sample—excluding variables related to driver eye height. An Excel database was created and later uploaded to the

Supplementary Materials.

4. Discussion

The findings of this study highlight the urgent need to update Ecuador’s geometric design standards to better reflect the actual characteristics of its vehicle fleet and population. The estimated average eye height for drivers of light vehicles in Ecuador is 0.95 m, which is significantly lower than the values currently used in both the Ecuadorian Road Manual (1.15 m) [

5] and the AASHTO Green Book (1.08 m) [

7]. Neighboring countries report similarly lower values: Colombia adopts a height of 1.10 m [

23], and Peru uses 1.07 m [

24]. Although a 20 cm difference might appear minor, it has important implications for road safety—particularly in the calculation of stopping sight distances and the design of vertical curves. Overestimating driver eye height can result in road designs that fail to ensure adequate visibility for a significant segment of the population, especially women and members of shorter-statured ethnic groups. As a consequence, roads built under these assumptions may not provide sufficient sight distances for real-world drivers, potentially contributing to Ecuador’s high traffic fatality rate of 23.4 deaths per 100,000 people in 2021 [

25].

The increasing prevalence of adjustable suspension and seating systems in modern vehicles has important implications for the application of these findings. While our study establishes context-specific baseline values for Ecuador, manufacturers could integrate these results into vehicle ergonomic design to better accommodate regional anthropometric diversity. For example, default seat height presets or automated seat calibration could be configured to optimize sight distance for drivers from populations with shorter average eye heights, reducing reliance on manual adjustments. Similarly, dynamic suspension systems could be tuned to maintain optimal ground clearance and visibility profiles in varying road conditions, thereby improving both safety and comfort. These potential applications highlight the value of coupling infrastructure design data with adaptive vehicle technologies.

Similarly, the measured rear headlight height of 0.75 m (5th percentile) is significantly higher than the 0.60 m reference object height used by AASHTO for stopping sight distance calculations [

7]. In contrast, Ecuador currently uses a reference object height of just 0.15 m—the same value adopted by Colombia [

23] and Peru [

24]. If Ecuador were to adopt the more realistic 0.75 m value, the resulting reduction in calculated stopping sight distances would require more conservative vertical curve designs and could result in costly retrofits to existing infrastructure. However, Hauer has questioned the validity of the 0.15 m object height—commonly referred to as the “dead dog” object—arguing that it has no direct link to road safety but rather to earthworks and roadway maintenance considerations [

9]. In this context, it is essential to further investigate appropriate reference object heights, ideally not based on rear headlight height but rather aligned with elements more relevant to visual guidance, driver’s decision-making, and overall road safety performance.

A comparison with AASHTO design vehicles reveals that while international standards tend to be more conservative in terms of overall dimensions, local vehicle configurations—particularly in the heavy vehicle category—often exceed these assumptions. In Ecuador, articulated trucks can reach lengths of up to 36.60 m and gross vehicle weights of 72 tons, exceeding the specifications of standard AASHTO design vehicles. This discrepancy highlights a critical issue: the direct application of international design standards without local calibration may lead to infrastructure that is not adequately equipped to handle actual traffic conditions. As truck sizes and weights have increased, highway design criteria must evolve to ensure both safety and operational efficiency. Overweight trucks, especially those exceeding legal mass limits, contribute to increased risks of traffic accidents and accelerated deterioration of pavement structures [

26]. Truck characteristics—such as length, gross weight, axle load, and turning radius—are fundamental parameters in the geometric design of highways, influencing decisions related to turning paths, lane widths, stopping sight distance, and structural capacity.

Many geometric design policies are inherently based on vehicle characteristics, with trucks often serving as a key determinant in setting design values [

27]. Therefore, incorporating locally observed vehicle dimensions and weights into national design guidelines is essential to ensure roads can safely and efficiently accommodate the actual operating fleet, rather than relying solely on generalized international standards.

4.1. Anthropometric Diversity and Design Equity

The substantial variation in driver eye height across ethnic groups and genders—ranging from 52.2 cm to 81.5 cm in eye-to-seat distance—underscores the critical need to incorporate anthropometric diversity into infrastructure design. Female drivers consistently exhibit lower eye heights than their male counterparts, a difference that can have direct safety implications. Relying on a single, potentially male-biased eye height value may systematically disadvantage female drivers, particularly in scenarios requiring adequate stopping or intersection sight distance [

7].

Ecuador’s ethnically diverse population presents both challenges and opportunities for equitable design. Differences of up to 16 cm in average eye-to-seat height among ethnic groups indicate that fixed, one-size-fits-all standards may inadequately serve significant segments of the population. In this context, the use of percentile-based thresholds—such as the 5th percentile for light vehicle drivers to protect the most vulnerable users and the 95th percentile for commercial vehicle operators to ensure maximum forward visibility—offers a more inclusive approach to roadway safety and accessibility.

The disaggregated analysis by sex and ethnic group offers several advantages over the current SSD-based method for determining driver eye height. First, while AASHTO’s 1.08 m eye height is derived from North American anthropometric data and sight distance requirements, our methodology provides locally calibrated values that reflect the actual physical characteristics of Ecuadorian drivers, resulting in a more accurate 0.95 m estimate for light vehicles. Second, the disaggregation by ethnic groups reveals significant variability (eye-to-seat distances ranging from 52.2 cm to 81.5 cm) that generic international standards cannot capture, enabling more inclusive design that accommodates the full spectrum of the population. Third, unlike the AASHTO approach, which defines eye height based on stopping sight distance calculations, our empirical approach establishes eye height as an independent input parameter based on measured anthropometric data, allowing for more precise calibration of sight distance equations. This data-driven approach provides a robust empirical foundation that transportation authorities can use to develop locally appropriate sight distance standards, ensuring that geometric design serves the actual population rather than assuming conformity to international averages.

While our methodology produces empirically grounded baseline values for driver eye height, vehicle design processes should incorporate an additional safety margin to account for posture variation, seat wear, and potential driver movement during operation. For example, a manufacturer using our 0.95 m baseline for light vehicles might adopt a slightly lower reference (e.g., 0.93 m) to ensure adequate sight distance for nearly all drivers, including those who may not sit fully upright. This principle mirrors the conservative approach used in infrastructure design and ensures a robust alignment between vehicle ergonomics and road safety requirements.

Importantly, the study relied on driver-specific data rather than general population averages. This distinction is crucial, as the seating posture and body proportions of drivers may differ from those of the general public. The analysis incorporated anthropometric profiles across ethnic groups and sexes and matched them to representative vehicle types using a simulation approach. This enabled an assessment of ergonomic compatibility between Ecuadorian drivers and the most common vehicles in circulation. Although variability exists, the majority of sampled vehicles fall within an acceptable operational range for local drivers. However, current geometric design standards do not formally account for this alignment, underscoring the need to revise national parameters using local data.

These anthropometric disparities are shaped by a complex interplay of genetic, environmental, and socio-economic factors. Height, a polygenic trait with high heritability, varies significantly across ethnic groups and regions [

28]. For instance, genetic variance in height is greater in populations from North America and Australia than in those from East Asia, suggesting regional differences in genetic contribution to stature [

29].

Environmental and socio-economic conditions further modulate these genetic potentials. In India, for example, gender-based nutritional disparities result in significantly lower average heights for women [

30], while in Russia, urban populations are generally taller than those in rural areas, reflecting disparities in living standards and access to resources [

31]. Globally, Northern European populations remain the tallest—with Dutch men averaging over 182.5 cm—while Guatemalan women are among the shortest, at approximately 140.3 cm [

32]. Although height has increased significantly in regions such as South Korea and Iran over the past century, countries in Sub-Saharan Africa have experienced little change [

32].

4.2. Technical and Economic Implications

The updated vehicle dimensions derived from this study have direct and significant implications for geometric design beyond sight distance alone. Observed variations in width, length, and wheelbase affect critical elements such as lane width, shoulder widening, turning radii, and intersection layout—particularly for large and articulated vehicles. For example, certain Ecuadorian configurations documented in this study (e.g., 3-axle tractor + 2-axle semi-trailer) reach up to 21.28 m in length and 4.10 m in height (

Table 5), requiring larger design envelopes than those provided by both the Ecuadorian MOP standard [

5] and the AASHTO WB-19 template [

15]. In mountainous and urban settings, this discrepancy can hinder maneuverability and compromise safety at tight intersections or sharp curves.

Equally important are the structural implications of increased gross vehicle weight (GVW). Several configurations exceed 60 tons, with some reaching up to 72 tons—values far beyond the assumptions used in legacy road designs. Overloaded vehicles accelerate pavement deterioration through repeated stress cycles, especially in flexible pavements with inadequate structural layers. The pavement damage caused by an axle increases with the fourth power of the axle load [

26]. This means that a 20% overload can double the damage compared to standard loading, and in extreme cases, a single overloaded vehicle can cause damage equivalent to several hundred standard axle repetitions. Similarly, a single pass of an 800-ton vehicle equates to the damage caused by 377 standard axles [

33].

Moreover, bridges and culverts designed under earlier standards may lack sufficient load-carrying capacity for these heavier configurations. Studies from Latin America have shown that overweight trucks are associated with increased accident rates, fatigue-induced structural failures, and reduced service life of critical bridge components [

34]. These issues are particularly acute in rural regions where design standards have not been updated for decades.

From an economic perspective, aligning geometric and structural design parameters with actual fleet characteristics may require upfront investments (e.g., wider lanes, reinforced pavements, and redesigned intersections). However, these costs can be offset by long-term savings due to improved durability, reduced accident rates, and lower maintenance needs. Some studies argue that higher-capacity vehicles may offer net benefits by reducing vehicle-kilometers traveled and increasing freight efficiency [

35], but this requires design adaptation to prevent accelerated infrastructure degradation.

Overall, the mismatch between observed vehicle characteristics and national design standards highlights the importance of periodic calibration. Continuing to rely on outdated vehicle assumptions risks underdesigning critical components, resulting in increased lifecycle costs, compromised safety, and operational inefficiencies. The empirical data presented in this study offer a foundation for updating both geometric and structural design guidelines in Ecuador and serve as a model for other Latin American countries facing similar challenges.

4.3. Methodological Contributions and Study Limitations

The proposed methodology demonstrates several strengths in addressing the challenge of updating design parameters in data-scarce environments. The combination of national registration data, manufacturer specifications, and CAD-based scaling provides a robust approach to vehicle characterization. The integration of anthropometric data across multiple ethnic groups represents a significant advancement in inclusive design methodology.

However, several limitations must be acknowledged. The study focuses on only two design parameters, while comprehensive geometric design requires calibration of numerous variables, including acceleration characteristics, braking performance, and driver behavior patterns. The anthropometric data, while comprehensive, date from 2012 to 2013 and may not reflect current population characteristics. Additionally, the methodology’s reliance on photographic analysis for anthropometric measurements introduces potential measurement errors that should be quantified in future studies. The database’s annual update capability addresses the dynamic nature of vehicle fleets, but the methodology’s effectiveness depends on consistent data collection and quality control. The scalability to other parameters and countries requires validation through implementation studies and performance monitoring.

4.4. Regional Context and Policy Implications

Ecuador’s experience reflects broader challenges facing Latin American countries in maintaining current infrastructure standards amid rapid technological and demographic changes. The 20-year gap since the last formal standard update illustrates the institutional challenges of maintaining responsive design guidelines. The proposed methodology offers a framework for addressing these challenges through systematic, data-driven approaches that can be adapted across the region. The database enables continuous updates rather than periodic major revisions. This approach could serve as a model for other countries facing similar challenges in maintaining up-to-date design standards with limited resources.

5. Conclusions

The findings of this study underscore the pressing need to revise Ecuador’s geometric design standards to more accurately reflect the physical characteristics of its vehicle fleet and the anthropometric diversity of its population. The estimated average driver eye height for light vehicles in Ecuador is approximately 0.95 m, which is notably lower than both the national standard of 1.15 m and the AASHTO reference of 1.08 m. For heavy vehicles, the average driver eye height was found to be 1.70 m, again significantly lower than the current assumptions of 2.0 m and 2.4 m in Ecuadorian and AASHTO guidelines, respectively. These discrepancies have direct implications for critical aspects of road safety, particularly sight distance calculations and the geometric configuration of vertical curves.

The analysis also reveals that while AASHTO design vehicles typically adopt conservative dimensions, several Ecuadorian vehicle configurations, especially among heavy vehicles, exceed these standards in terms of both length and gross weight. The presence of articulated trucks reaching lengths of up to 36.60 m and weights of nearly 110 tons illustrates the limitations of applying foreign design templates without local calibration. Such oversights can compromise operational efficiency and infrastructure durability, particularly in pavement design and intersection planning.

Equally important is the significant variation in eye height across different ethnic groups and genders in Ecuador. The observed range of eye-to-seat distance—from 52.2 cm to 81.5 cm—highlights the inadequacy of one-size-fits-all assumptions in roadway design. Incorporating percentile-based thresholds offers a more equitable and safety-conscious approach, ensuring that critical design elements accommodate both the most vulnerable users and those operating the largest vehicles.

Beyond technical implications, this study illustrates the economic and institutional consequences of outdated standards. Designs based on inaccurate assumptions may require costly retrofits or compromise safety outcomes, while proactive updates—though initially resource-intensive—can yield long-term savings and improved performance. The methodology developed herein, which integrates vehicle registration data, technical specifications, and population-specific anthropometry, provides a replicable and scalable framework for evidence-based updates to design standards. Its integration into a dynamic, interactive database also introduces an innovative approach to maintaining regulatory relevance over time.

Several research priorities emerge from this study. First, expansion of the methodology to additional design parameters—including vehicle performance characteristics, driver behavior patterns, and operational variables—would provide a more comprehensive foundation for standard updates. Second, longitudinal studies tracking changes in vehicle characteristics and anthropometric measures would enable more precise calibration of update frequencies and methodologies. Third, validation studies comparing safety outcomes on roads designed with updated versus traditional parameters would provide empirical evidence of the methodology’s effectiveness. Finally, regional collaboration in data collection and methodology development could enhance the efficiency and effectiveness of standard updates across Latin America.