Review of Crack Depth Detection Technology for Engineering Structures: From Physical Principles to Artificial Intelligence

Abstract

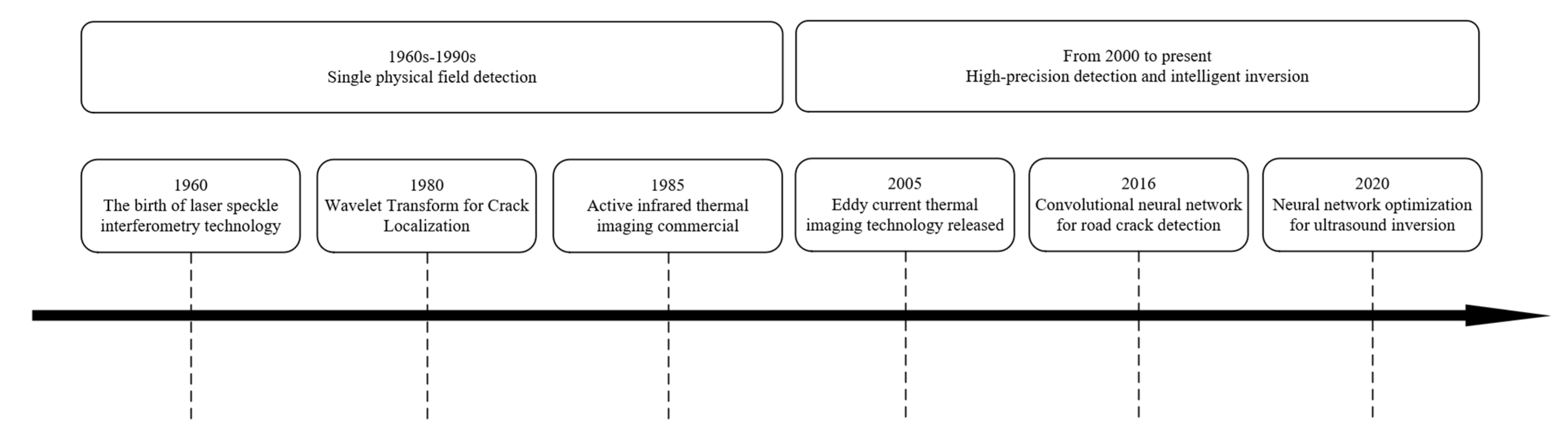

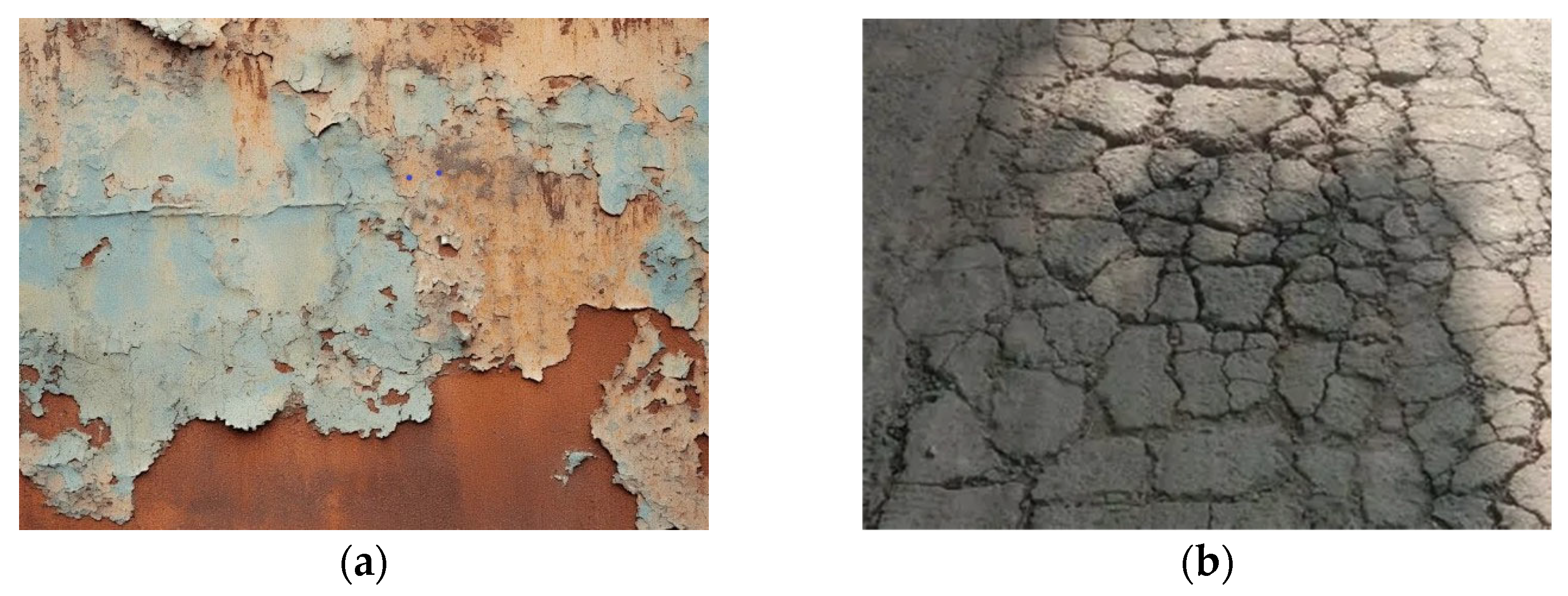

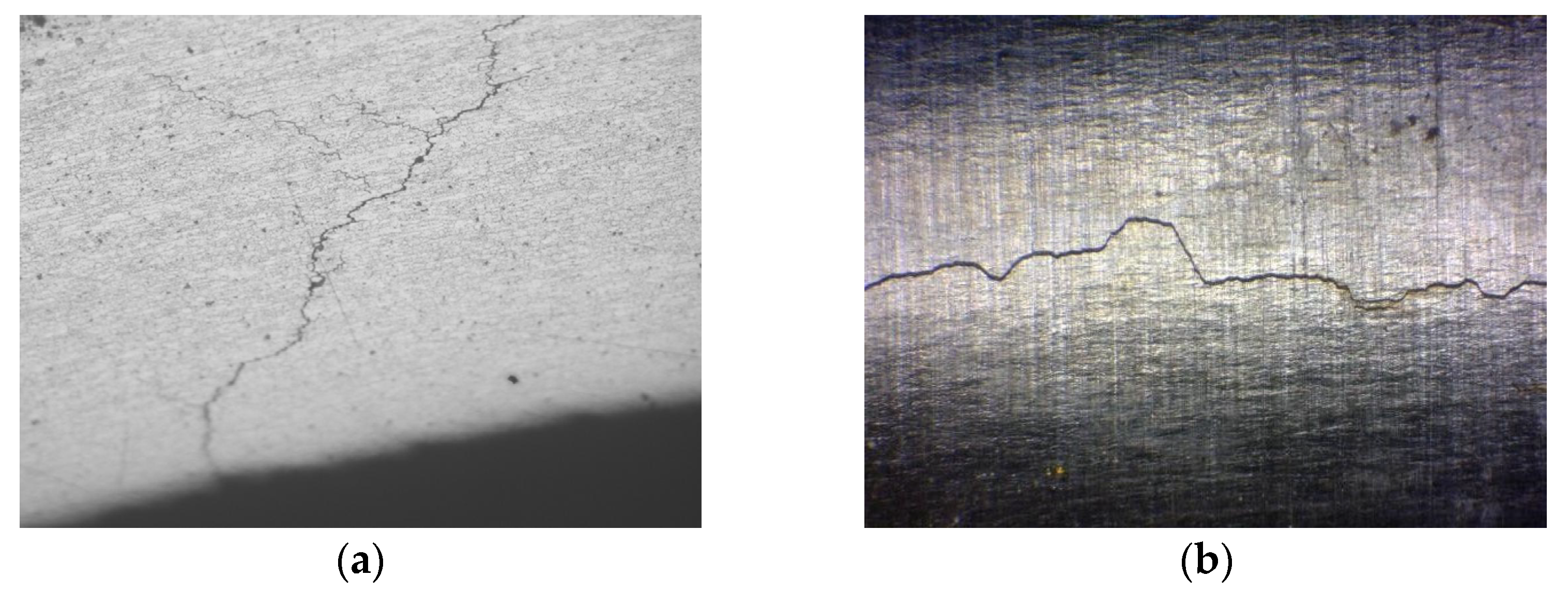

1. Introduction

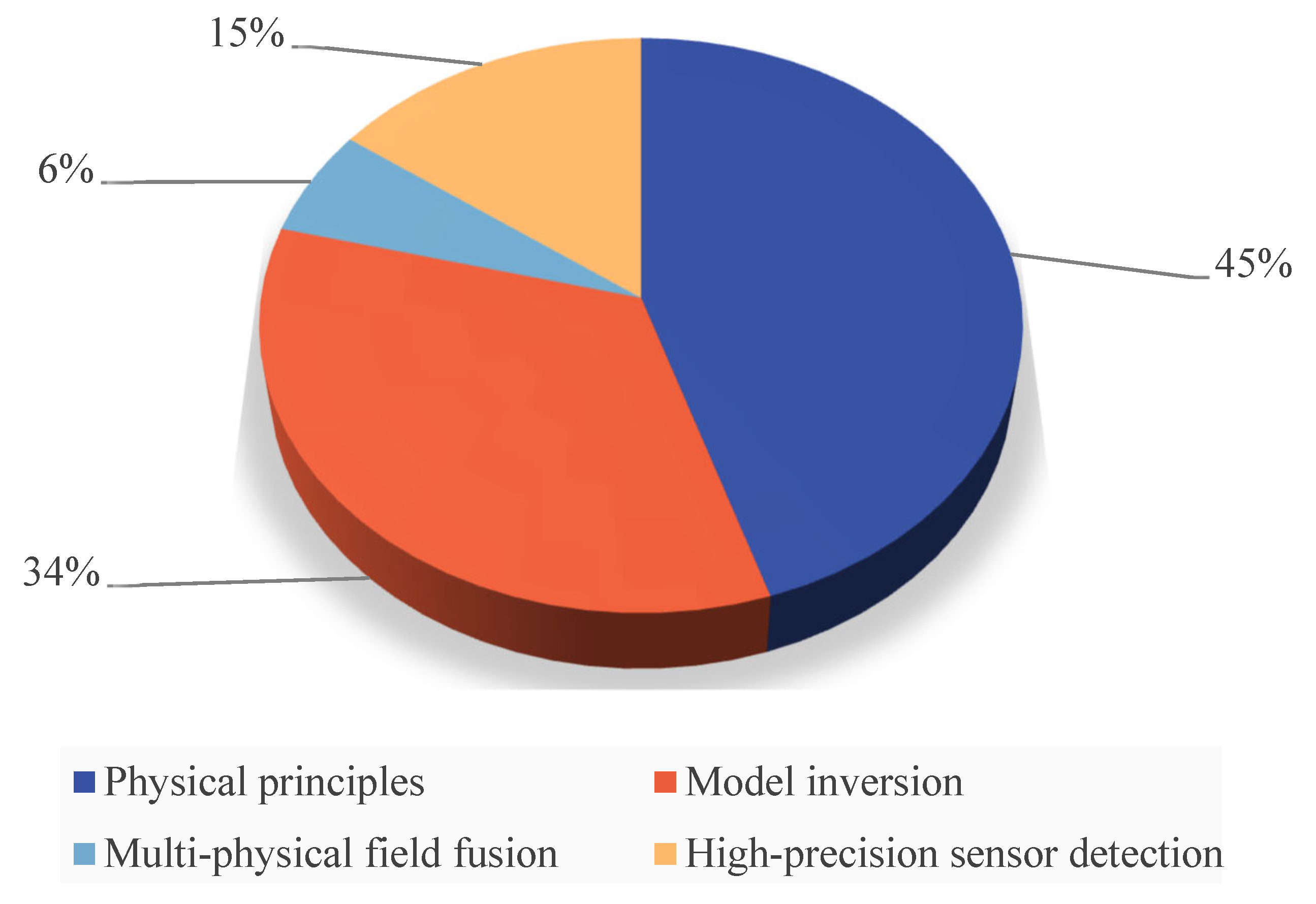

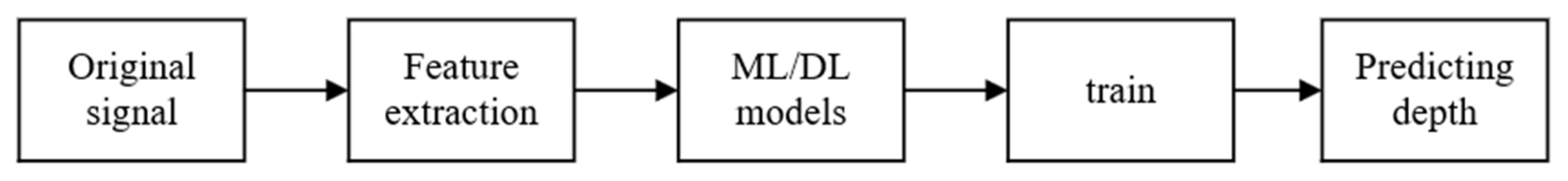

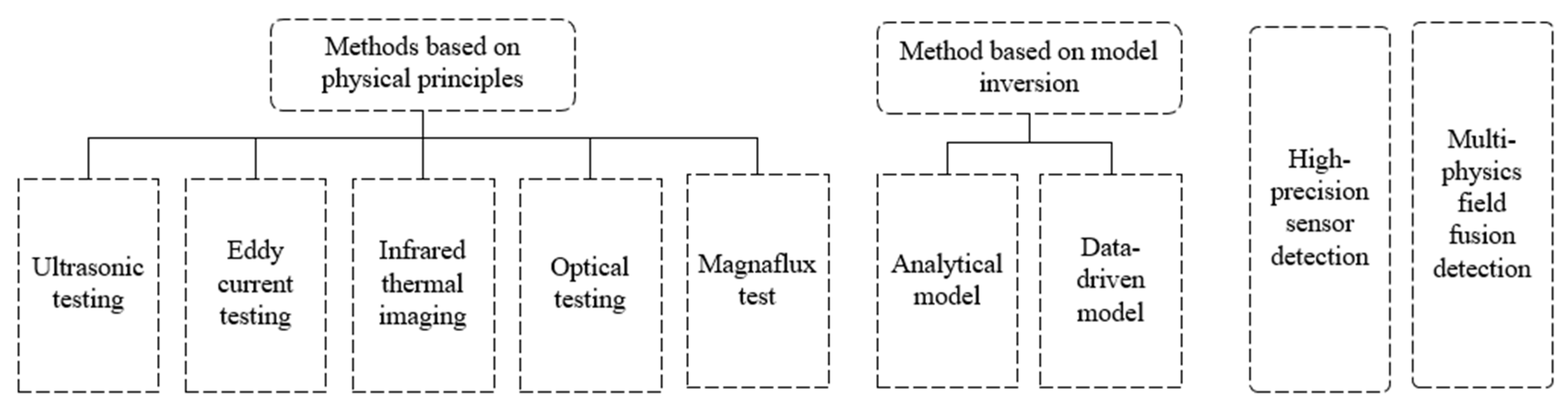

2. Classification and Review of Crack Depth Detection Technology

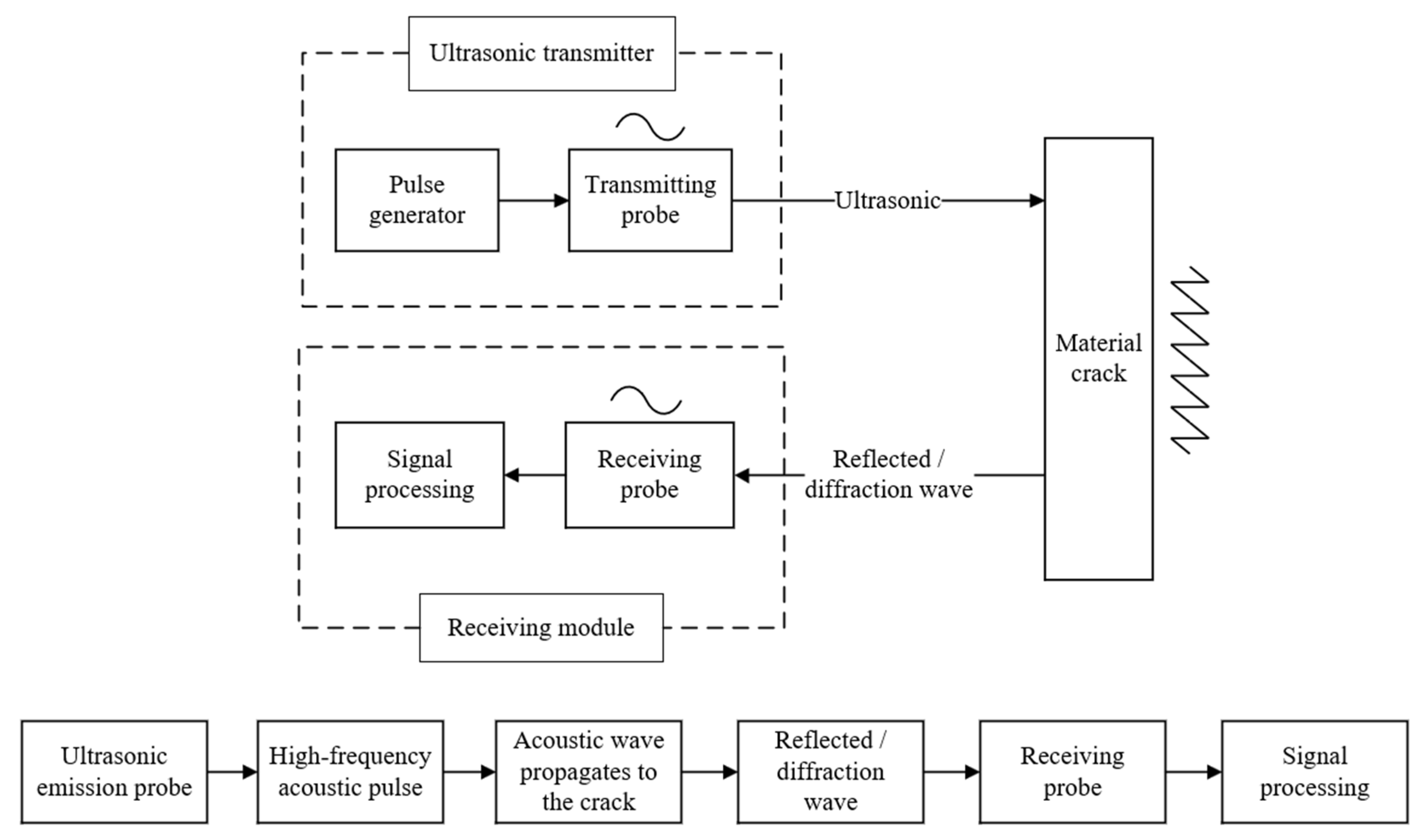

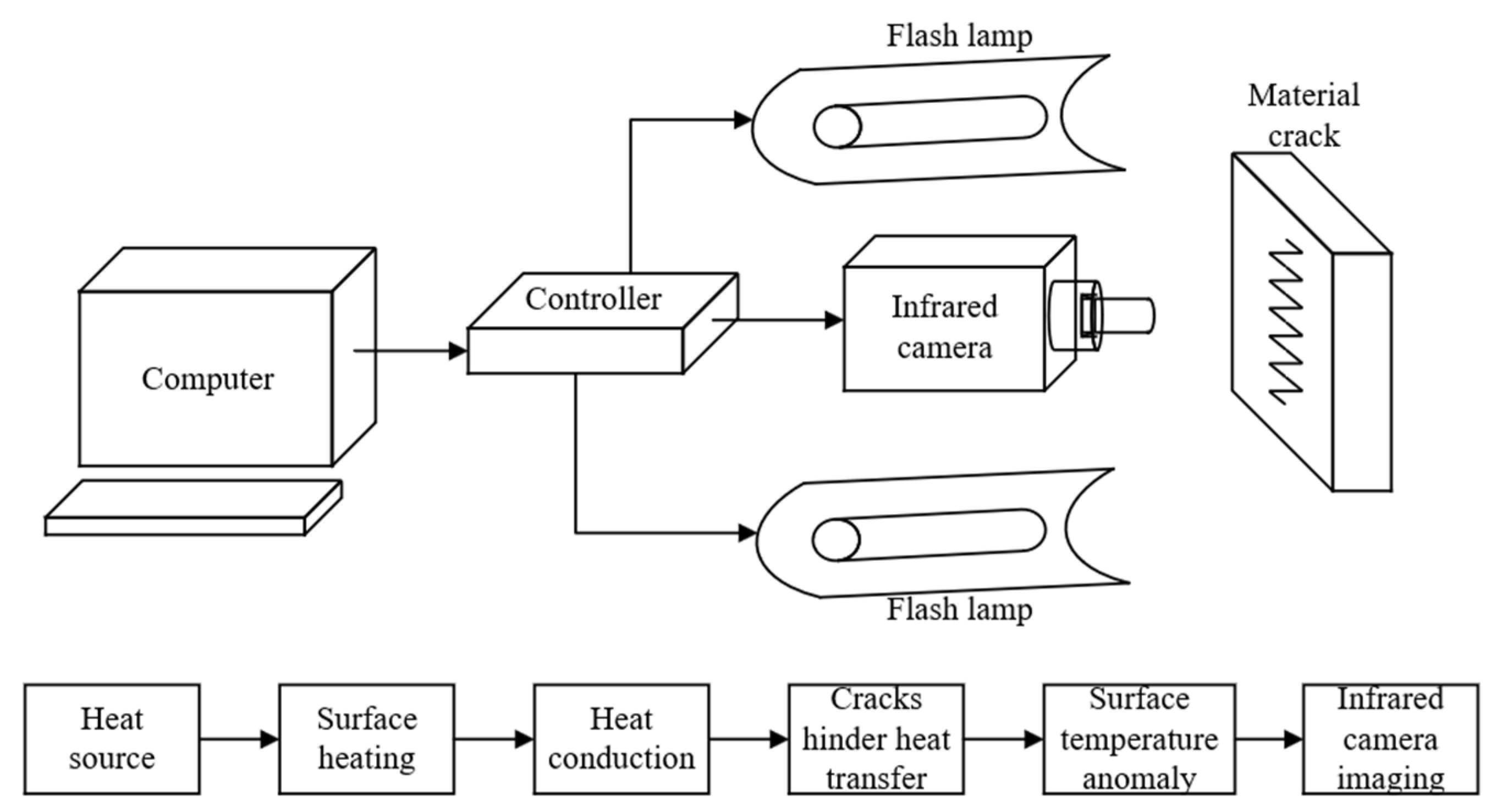

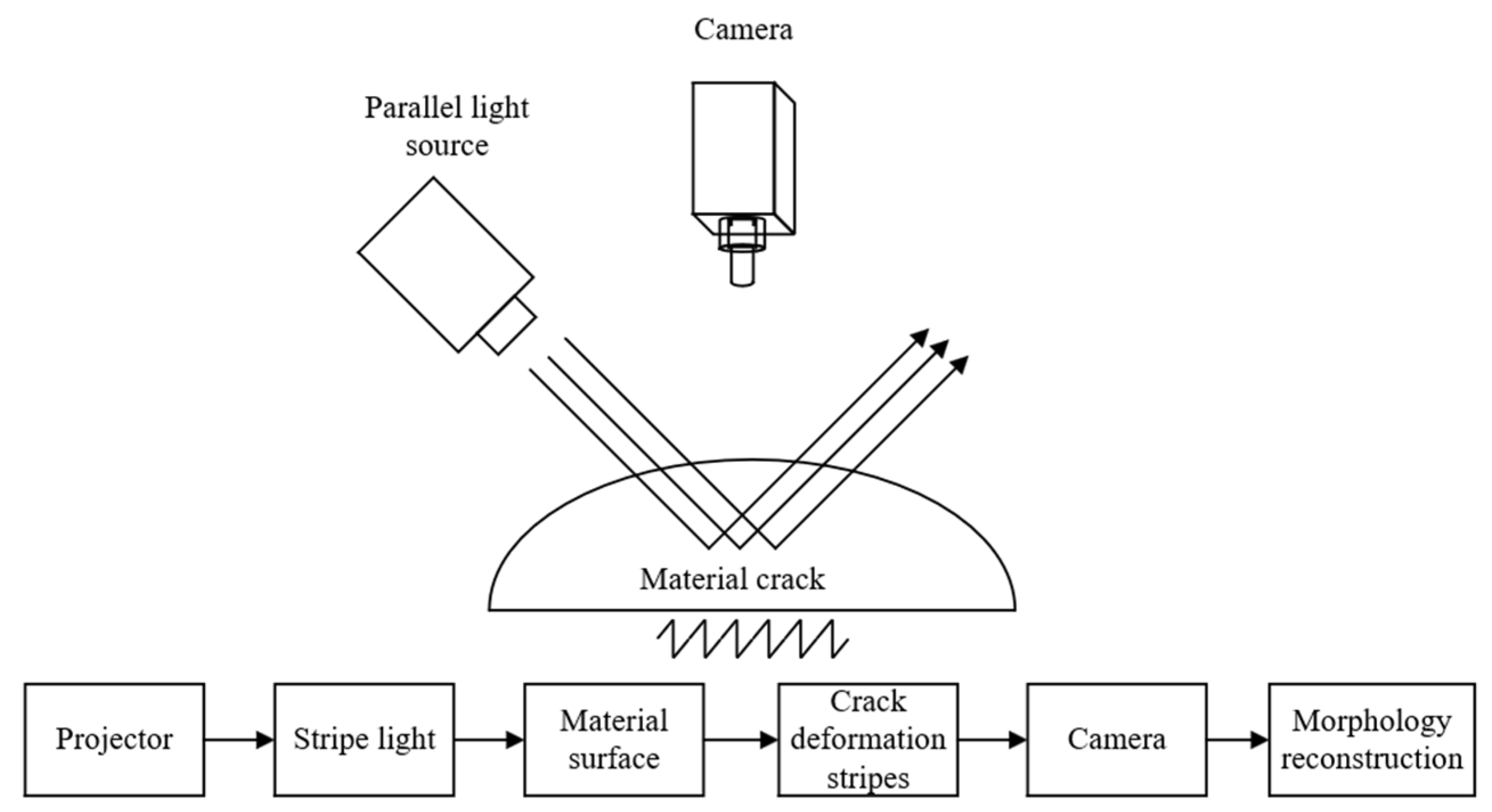

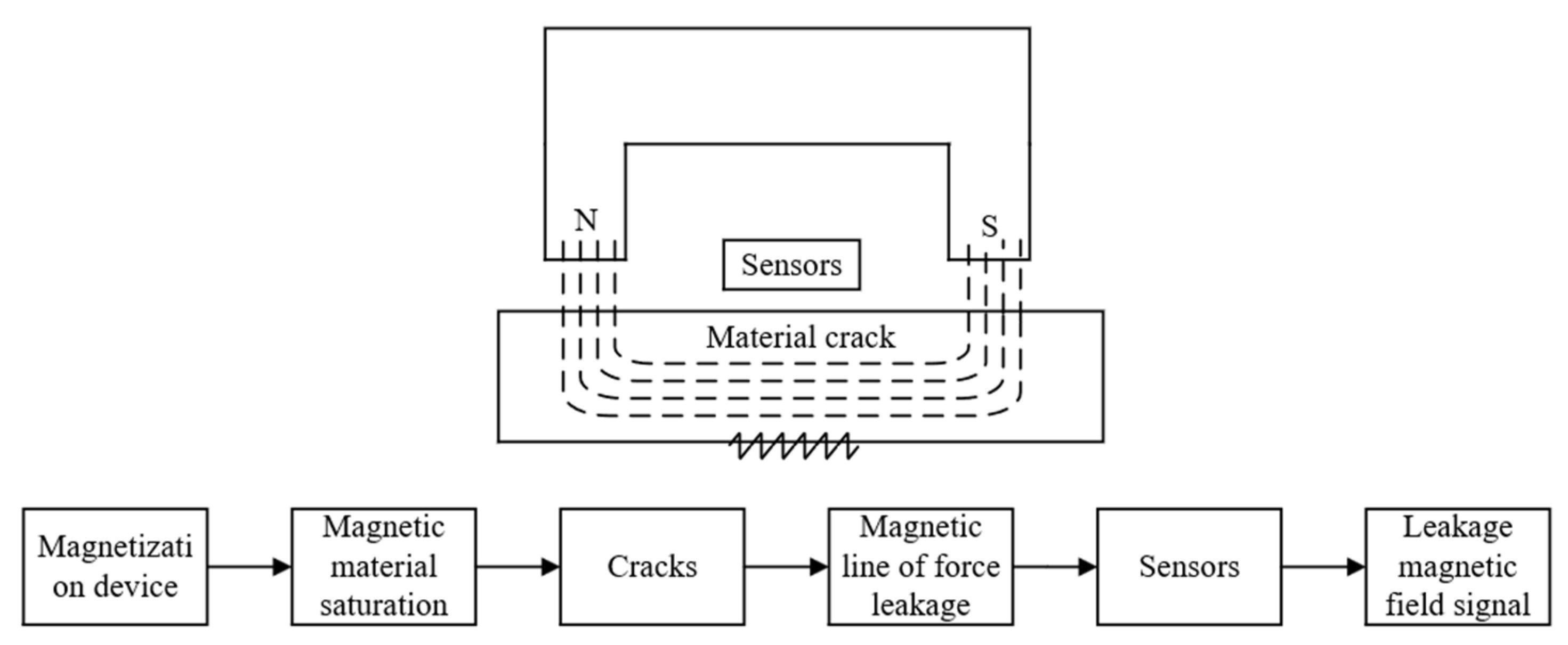

2.1. Detection Method Based on Physical Principle

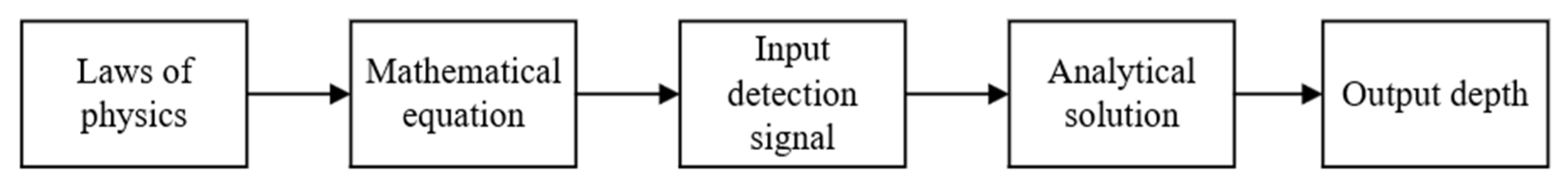

2.2. Model-Based Inversion Method

2.3. High-Precision Sensor Detection and Multi-Physics Field Fusion Detection

3. Technical Comparison and Key Challenges

3.1. Performance Index Comparison

3.2. Key Challenges

4. Future Research Directions

4.1. Multi-Physics Field Collaborative Detection and Data Fusion

4.2. Innovation in High-Precision and Multi-Dimensional Non-Destructive Testing Technology

4.3. Special Scenarios and New Materials

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, W.R.; Liu, Y.; Yuan, X.P.; Li, Q.T.; Zhou, G.J. Rail hidden damage detection based on the modal curvature differences method. Adv. Mech. Eng. 2024, 16, 16878132241279500. [Google Scholar] [CrossRef]

- Van’T Oever, J.; Thompson, D.; Gaastra, F.; Groendijk, H.A.; Offerhaus, H.L. Early interferometric detection of rolling contact fatigue induced micro-cracking in railheads. NDT E Int. 2017, 86, 14–19. [Google Scholar] [CrossRef]

- Pan, X.F.; Xiang, T.L.; He, Y.J.; Wu, J.B.; Xia, H.; Lei, T.; Wang, J. A Crack Detection Method for Aero-engine Blade Based on Air-Flow Thermography. J. Nondestruct. Eval. 2023, 42, 22. [Google Scholar] [CrossRef]

- Li, W.J.; Zhu, J.T.; Mu, K.C.; Yang, W.W.; Zhang, X.; Zhao, X.F. Experimental Investigation of Concrete Crack Depth Detection Using a Novel Piezoelectric Transducer and Improved AIC Algorithm. Buildings 2024, 14, 3939. [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhang, S.X.; Jia, Y.; Tang, L.; Tao, J.; Tian, H. Forward Simulation and Complex Signal Analysis of Concrete Crack Depth Detection Using Tracer Electromagnetic Method. Buildings 2024, 14, 2644. [Google Scholar] [CrossRef]

- Kim, J.; Cho, Y.; Lee, J.; Kim, Y.H. Defect Detection and Characterization in Concrete Based on FEM and Ultrasonic Techniques. Materials 2022, 15, 8160. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Induction Thermography for Surface Crack Detection and Depth Determination. Appl. Sci. 2018, 8, 257. [Google Scholar] [CrossRef]

- Cho, Y.S.; Ahn, Y.S.; Park, S.K.; Kim, J.H. A study on the characteristics of surface wave induced by phased array Ut. Key Eng. Mater. 2004, 270–273, 264–270. [Google Scholar] [CrossRef]

- Chen, B.R.; Wang, C.Y.; Wang, W.; Wang, Y.; Lu, K.Q.; Ding, Y.P.; Chen, J.; Chen, Y.L.; Ju, B.F. Quantitative detection of lateral subsurface cracks based on laser-generated Rayleigh waves in the frequency domain. Appl. Phys. A 2024, 130, 245. [Google Scholar] [CrossRef]

- Rabe, U.; Pudovikov, S.; Herrmann, H.G.; Wiggenhauser, H.; Prabhakara, P.; Niederleithinger, E. Using the Corner Reflection for Depth Evaluation of Surface Breaking Cracks in Concrete by Ultrasound. J. Nondestruct. Eval. 2023, 42, 44. [Google Scholar] [CrossRef]

- Wang, Z.W.; Fei, Y.; Ye, P.X.; Qiu, F.S.; Tian, G.Y.; Woo, W.L. Crack characterization in ferromagnetic steels by pulsed eddy current technique based on GA-BP neural network model. J. Magn. Magn. Mater. 2020, 500, 166412. [Google Scholar] [CrossRef]

- Qiu, J.X.; Pei, C.X.; Liu, H.C.; Chen, Z.M. Quantitative evaluation of surface crack depth with laser spot thermography. Int. J. Fatigue 2017, 101, 80–85. [Google Scholar] [CrossRef]

- Liu, Z.P.; Yu, H.J.; Zhou, K.; Li, R.F.; Guo, Q. Influence of Volumetric Damage Parameters on Patch Antenna Sensor-Based Damage Detection of Metallic Structure. Sensors 2019, 19, 3232. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Liu, L.; Shi, Z.M.; Li, S.J.; Peng, M.; Wang, Y.; Liu, C.S. Fast concrete crack depth detection using low frequency ultrasound array SH waves data. J. Appl. Geophys. 2024, 230, 105530. [Google Scholar] [CrossRef]

- Gao, Y.X.; Cao, H.B.; Cai, W.W.; Zhou, G.X. Pixel-level road crack detection in UAV remote sensing images based on ARD-Unet. Measurement 2023, 219, 113252. [Google Scholar] [CrossRef]

- Mei, Q.P.; Gül, M. Multi-level feature fusion in densely connected deep-learning architecture and depth-first search for crack segmentation on images collected with smartphones. Struct. Health Monit. 2020, 19, 1726–1744. [Google Scholar] [CrossRef]

- Rao, K.B.; Reddy, D.M. Crack detection methodology in rotor bearing system by DWT based adaptive neuro-fuzzy inference systems. Appl. Acoust. 2022, 192, 108728. [Google Scholar] [CrossRef]

- Xue, X.F.; Wang, Y.Z.; Tian, P.Q.; Zhan, S.Z. Reliability Simulation Research for Nondestructive Ultrasonic Structure Testing Based on In Situ Influential Factors. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2020, 6, 04020027. [Google Scholar] [CrossRef]

- Yang, Z.W.; Yan, H.P.; Li, Y.; Kou, G.J.; Tian, G.; Zhang, W. A Novel Inclined Excitation Method for Crack Detection of Non-Ferromagnetic Materials Using Eddy Current Thermography. Strength Mater. 2019, 51, 558–568. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, Y.T.; Liu, B.W.; Tian, G.Y. Investigation on Velocity Effect in Pulsed Eddy Current Technique for Detection Cracks in Ferromagnetic Material. IEEE Trans. Magn. 2020, 56, 1–8. [Google Scholar] [CrossRef]

- Chen, X.; Ye, Z.; Xia, J.Y.; Wang, J.X.; Ji, B.H. Double-Probe Ultrasonic Detection Method for Cracks in Steel Structure. Appl. Sci. 2020, 10, 8436. [Google Scholar] [CrossRef]

- Yang, J.; Dong, L.H.; Wang, H.D.; Lin, E.; Zhai, S.C.; An, Z.H.; Guo, W.L.; Huang, Y.F. Numerical Stability of Quantitative Characterization of Surface Cracks Using Laser Lock-in Thermography. Int. J. Thermophys. 2022, 43, 132. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Detection and characterisation of short fatigue cracks by inductive thermography. Quant. Infr. Therm. J. 2022, 19, 239–260. [Google Scholar] [CrossRef]

- Liu, J.Q.; Zhang, Z.J.; Lin, Z.Y.; Chen, H.Z.; Yin, W.L. Characterization Method of Surface Crack Based on Laser Thermography. IEEE Access 2021, 9, 76395–76402. [Google Scholar] [CrossRef]

- Gui, R.; Xu, X.; Zhang, D.J.; Pu, F.L. Object-Based Crack Detection and Attribute Extraction from Laser-Scanning 3D Profile Data. IEEE Access 2019, 7, 172728–172743. [Google Scholar] [CrossRef]

- Yang, L.J.; Li, J.Y.; Zheng, W.X.; Liu, B. Simulation and Design of a Balanced-Field Electromagnetic Technique Sensor for Crack Detection in Long-Distance Oil and Gas Pipelines. Energies 2022, 15, 5274. [Google Scholar] [CrossRef]

- Wang, S.H.; Feng, B.; Qiu, G.Z.; Hu, Y.; Jiang, C.; Kang, Y.H. AC-MFL testing of orthogonal cracks detection of square billet based on the flexible-printed parallel cable magnetizer. Sens. Actuators A Phys. 2022, 347, 113897. [Google Scholar] [CrossRef]

- Liu, B.; Feng, G.; He, L.Y.; Luo, N.; Ren, J.; Yang, L.J. Quantitative Study of MMM Signal Features for Internal Weld Crack Detection in Long-Distance Oil and Gas Pipelines. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Okolo, C.K.; Meydan, T. Pulsed magnetic flux leakage method for hairline crack detection and characterization. AIP Adv. 2018, 8, 047207. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, C.L.; Zeng, H.M.; Wang, P. Rail crack detection and evaluation at high speed based on differential ECT system. Measurement 2020, 166, 108152. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, Y.T.; Wu, J.B.; Peng, J.P.; Jiang, C.; Fan, X.F.; Li, J. RCF crack direction assessment in moving ferromagnetic material by DC electromagnetic NDT technique. NDT E Int. 2023, 138, 102882. [Google Scholar] [CrossRef]

- Zhao, S.X.; Sun, L.S.; Gao, J.Q.; Wang, J.Z.; Shen, Y. Uniaxial ACFM detection system for metal crack size estimation using magnetic signature waveform analysis. Measurement 2020, 164, 108090. [Google Scholar] [CrossRef]

- Gómez, M.J.; Castejón, C.; Corral, E.; García-Prada, J.C. Analysis of the influence of crack location for diagnosis in rotating shafts based on 3 x energy. Mech. Mach. Theory 2016, 103, 167–173. [Google Scholar] [CrossRef]

- Nguyen, K.V.; Nguyen, Q.V. Element stiffness index distribution method for multi-crack detection of a beam-like structure. Adv. Struct. Eng. 2016, 19, 1077–1091. [Google Scholar] [CrossRef]

- Zhu, L.F.; Ke, L.L.; Zhu, X.Q.; Xiang, Y.; Wang, Y.S. Crack identification of functionally graded beams using continuous wavelet transform. Compos. Struct. 2019, 210, 473–485. [Google Scholar] [CrossRef]

- Kharazan, M.; Irani, S.; Noorian, M.A.; Salimi, M.R. Effect of a breathing crack on the damping changes in nonlinear vibrations of a cracked beam: Experimental and theoretical investigations. J. Vib. Control 2021, 27, 2345–2353. [Google Scholar] [CrossRef]

- Wimarshana, B.; Goes, F.; Wu, N.; Wu, C. Experimental Study on Breathing Crack Detection and Evaluation Under Random Loading with Entropy. Trans. Can. Soc. Mech. Eng. 2017, 41, 669–680. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, Y.C.; Weng, X.X.; Liu, W.J. Curve-based crack detection using crack information gain. Struct. Control Health Monit. 2021, 28, e2764. [Google Scholar] [CrossRef]

- Jing, J.Y.; Yang, X.; Ding, L.; Wang, H.N.; Guan, J.C.; Hou, Y.; El-Badawy, S.M. Self-adaptive 2D-3D image fusion for automated pixel-level pavement crack detection. Automat. Constr. 2024, 168, 105756. [Google Scholar] [CrossRef]

- Cao, T.; Wang, Y.H.; Liu, S. Pavement Crack Detection Based on 3D Edge Representation and Data Communication with Digital Twins. IEEE Trans. Intell. Transp. Syst. 2023, 24, 7697–7706. [Google Scholar] [CrossRef]

- Wang, L.; Feng, Q.Q.; Yan, J. Pavement crack detection based on depth-supervision FRRN model. Meas. Control 2024, 58, 00202940241292189. [Google Scholar] [CrossRef]

- Sun, L.X.; Yang, Y.X.; Yang, Z.C.; Zhou, G.X.; Li, L.J. DUCTNet: An Effective Road Crack Segmentation Method in UAV Remote Sensing Images Under Complex Scenes. IEEE Trans. Intell. Transp. Syst. 2024, 25, 12682–12695. [Google Scholar] [CrossRef]

- Wang, C.; Liu, H.B.; An, X.Y.; Gong, Z.Q.; Deng, F. SwinCrack: Pavement crack detection using convolutional swin-transformer network. Digit. Signal Process. 2024, 145, 104297. [Google Scholar] [CrossRef]

- Saberironaghi, A.; Ren, J. DepthCrackNet: A Deep Learning Model for Automatic Pavement Crack Detection. J. Imaging 2024, 10, 100. [Google Scholar] [CrossRef] [PubMed]

- Guan, J.C.; Yang, X.; Ding, L.; Cheng, X.Y.; Lee, V.; Jin, C. Automated pixel-level pavement distress detection based on stereo vision and deep learning. Automat. Constr. 2021, 129, 103788. [Google Scholar] [CrossRef]

- Wang, C.Y.; Kong, Y.; Wang, W.; Chen, Z.F.; Chen, J.; Zhu, W.L.; Ju, B.F. Finite element analysis of laser-generated Rayleigh wave for sizing subsurface crack in frequency domain. Optik 2022, 260, 169145. [Google Scholar] [CrossRef]

- Tian, L.L.; Cheng, Y.H.; Yin, C.; Huang, X.G.; Zhang, B.; Bai, L.B. Data-Driven Method for the Measurement of Thickness/Depth Using Pulsed Eddy Current. Sensor. Mater. 2017, 29, 1325–1338. [Google Scholar]

- Wang, H.; Zhang, L.J.; Li, K.W.; Zhang, W.J.; Ma, Z.; Chen, X.H.; Ai, L.; Liu, D.H.; Yang, N.; Liu, S.B.; et al. Metal surface crack depth laser acoustic emission detection method based on multivariate feature adaptive extraction and cross-modal interaction fusion. Measurement 2025, 242, 116020. [Google Scholar] [CrossRef]

- Dong, X.J.; Zhang, C.S.; Wang, J.H.; Chen, Y.; Wang, D.W. Real-time detection of surface cracking defects for large-sized stamped parts. Comput. Ind. 2024, 159, 104105. [Google Scholar] [CrossRef]

- Li, K.S.; Ma, Z.Y.; Fu, P.; Krishnaswamy, S. Quantitative evaluation of surface crack depth with a scanning laser source based on particle swarm optimization-neural network. NDT E Int. 2018, 98, 208–214. [Google Scholar] [CrossRef]

- Tong, Z.F.; Xie, S.J.; Chen, H.E.; Qiu, J.X.; Cai, W.L.; Pei, C.X.; Chen, Z.M.; Uchimoto, T.; Takagi, T. Quantitative mapping of depth profile of fatigue cracks using eddy current pulsed thermography assisted by PCA and 2D wavelet transformation. Mech. Syst. Signal Process. 2022, 175, 109139. [Google Scholar] [CrossRef]

- Luo, M.T.; Zhong, S.C.; Huang, Y.; Zhang, Z.H.; Tu, W.L. Combined Terahertz Pulsed Imaging and Optical Coherence Tomography Detection Method for Multiple Defects in Thermal Barrier Coatings. Coatings 2024, 14, 380. [Google Scholar] [CrossRef]

- Qiu, Q.; Wu, J.B.; Chen, X.T.; Xia, H.; Zhang, M.C.; Zhu, J.Z. Tensile stress effect on crack depth quantification in ferromagnetic materials using ECPT. Measurement 2021, 182, 109740. [Google Scholar] [CrossRef]

- Ou, C.J.; Chen, Y.; Zhou, X.D.; Ma, B.; Chen, H.C.; Ou, C.T. Microwave resonance detection method for hidden crack depth in rock and cementitious mortar. Sci. Rep. 2025, 15, 5092. [Google Scholar] [CrossRef]

- Du, G.F.; Huo, L.S.; Kong, Q.Z.; Song, G.B. Damage detection of pipeline multiple cracks using piezoceramic transducers. J. Vibroeng. 2016, 18, 2828–2838. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Z.B.; Yang, P.; Yang, L.S.; Hu, W.L.; Cao, J.; Chen, Z.Z.; Tian, G.Y. Quantitative Crack Depth Monitoring Based on Traveling Wave at Millimeter-Wave Frequency. IEEE Trans. Antennas Propag. 2022, 70, 8321–8329. [Google Scholar] [CrossRef]

- Xie, X.Y.; Dong, L.H.; Wang, H.D.; Di, Y.L.; Guo, W.L.; Wang, P.; Zhang, J. High-Sensitivity RFID Tag Sensor with Coupled Ring Resonators for Multiposition Crack Monitoring. IEEE Sens. J. 2024, 24, 37869–37878. [Google Scholar] [CrossRef]

- Gu, W.C.; Liu, X.Z.; Li, Z. Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging. Sustainability 2024, 16, 3731. [Google Scholar] [CrossRef]

- Pan, Z.H.; Guan, J.C.; Yang, X.; Fan, K.; Guo, N.Q.; Wang, X. One-stage 3D profile-based pavement crack detection and quantification. Automat. Constr. 2023, 153, 104946. [Google Scholar] [CrossRef]

- Mohamed, Y.S.; Shehata, H.M.; Abdellatif, M.; Awad, T.H. Steel crack depth estimation based on 2D images using artificial neural networks. Alex. Eng. J. 2019, 58, 1167–1174. [Google Scholar] [CrossRef]

- Long, Y.; Zhang, J.H.; Huang, S.L.; Peng, L.S.; Wang, W.Z.; Wang, S.; Zhao, W. A Novel Crack Quantification Method for Ultra-High-Definition Magnetic Flux Leakage Detection in Pipeline Inspection. IEEE Sens. J. 2022, 22, 16402–16413. [Google Scholar] [CrossRef]

- Lu, G.L.; He, X.H.; Wang, Q.; Shao, F.M.; Wang, J.K.; Zhao, X.K. MSCNet: A Framework with a Texture Enhancement Mechanism and Feature Aggregation for Crack Detection. IEEE Access 2022, 10, 26127–26139. [Google Scholar] [CrossRef]

- Pan, P.; Xu, Y.M.; Xing, C.; Chen, Y. Crack detection for nuclear containments based on multi-feature fused semantic segmentation. Constr. Build. Mater. 2022, 329, 127137. [Google Scholar] [CrossRef]

- Duan, Z.X.; Liu, J.H.; Ling, X.P.; Zhang, J.L.; Liu, Z.H. ERNet: A Rapid Road Crack Detection Method Using Low-Altitude UAV Remote Sensing Images. Remote Sens. 2024, 16, 1741. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Z.Y.; Liu, Z.Q.; Luo, N.; Xu, X.B. Research on internal detection technology for axial crack of long-distance oil and gas pipeline based on micromagnetic method. Struct. Health Monit. 2020, 19, 1123–1136. [Google Scholar] [CrossRef]

- Tabassum, N. Image-Based Crack Detection by Extracting Depth of the Crack Using Machine Learning. Master’s Thesis, University of South Carolina, Columbia, SC, USA, 2022; p. 83. [Google Scholar]

- Dahmene, F.; Yaacoubi, S.; El Mountassir, M.; Bouzenad, A.; Rabaey, P.; Masmoudi, M.; Nennig, P.; Dupuy, T.; Benlatreche, Y.; Taram, A. On the nondestructive testing and monitoring of cracks in resistance spot welds: Recent gained experience. Weld. World 2022, 66, 629–641. [Google Scholar] [CrossRef]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.I. Dramatically Enhanced Mechanosensitivity and Signal-to-Noise Ratio of Nanoscale Crack-Based Sensors: Effect of Crack Depth. Adv. Mater. 2016, 28, 8130–8137. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.J.; Kang, F.; Zhang, J.A. Monitoring depth and width of cracks in underwater concrete structures using embedded smart aggregates. Measurement 2022, 204, 112078. [Google Scholar] [CrossRef]

- Lu, X.C.; Li, W.L.; Sottos, N.R.; Moore, J.S. Autonomous Damage Detection in Multilayered Coatings via Integrated Aggregation-Induced Emission Luminogens. ACS Appl. Mater. Inter. 2018, 10, 40361–40365. [Google Scholar] [CrossRef]

| Methods | Precision (Crack Depth) | Applicable Materials | Detection Speed | Cost | Environmental Requirements |

|---|---|---|---|---|---|

| Ultrasonic testing | High, 0.1–1 mm [6] | Most solid materials | Slow (point-by-point scan) | Medium | Strict, smooth surface; needs a coupling agent [14] |

| Eddy current testing | Medium, 0.1–2 mm [53] | Conductive materials only | Fast (large area) | Low | Loose, non-contact detection [65] |

| Infrared thermal imaging method | Low, 1–3 mm [58] | Materials with good thermal conductivity | Fast (real-time imaging) | High | Strictly, active heating is required [7] |

| Optical detection | Medium, 0.1–0.5 mm [2] | Almost all surface-visible materials | Fast (large area) | Variable | Strictly, stable light conditions are required [59] |

| Magnetic detection | High, 0.1–1 mm [60] | Only ferromagnetic materials | Medium | Medium | Medium; avoid substantial magnetic interference [31] |

| Analytic model | Low [18] | \ | Slow (complex mathematical computation) | Low | Loose; not limited by the physical environment |

| Data-driven model | High [62] | \ | Medium (training time) | High | Medium; the data needs to cover different conditions [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, M.; Wang, S.; Guo, B.; Gu, W. Review of Crack Depth Detection Technology for Engineering Structures: From Physical Principles to Artificial Intelligence. Appl. Sci. 2025, 15, 9120. https://doi.org/10.3390/app15169120

Zhao M, Wang S, Guo B, Gu W. Review of Crack Depth Detection Technology for Engineering Structures: From Physical Principles to Artificial Intelligence. Applied Sciences. 2025; 15(16):9120. https://doi.org/10.3390/app15169120

Chicago/Turabian StyleZhao, Ming, Sen Wang, Baohua Guo, and Weifan Gu. 2025. "Review of Crack Depth Detection Technology for Engineering Structures: From Physical Principles to Artificial Intelligence" Applied Sciences 15, no. 16: 9120. https://doi.org/10.3390/app15169120

APA StyleZhao, M., Wang, S., Guo, B., & Gu, W. (2025). Review of Crack Depth Detection Technology for Engineering Structures: From Physical Principles to Artificial Intelligence. Applied Sciences, 15(16), 9120. https://doi.org/10.3390/app15169120