Research on the Application of Laser Ablation in the Rapid Detection of Ablation Resistance on the Surface of AgNi Contact Materials

Abstract

1. Introduction

2. Introduction to the Experiment

3. Analysis of Contact Ablation Resistance

3.1. Analysis of Ablation Resistance of Laser Test Contacts

3.1.1. Repeatability Verification

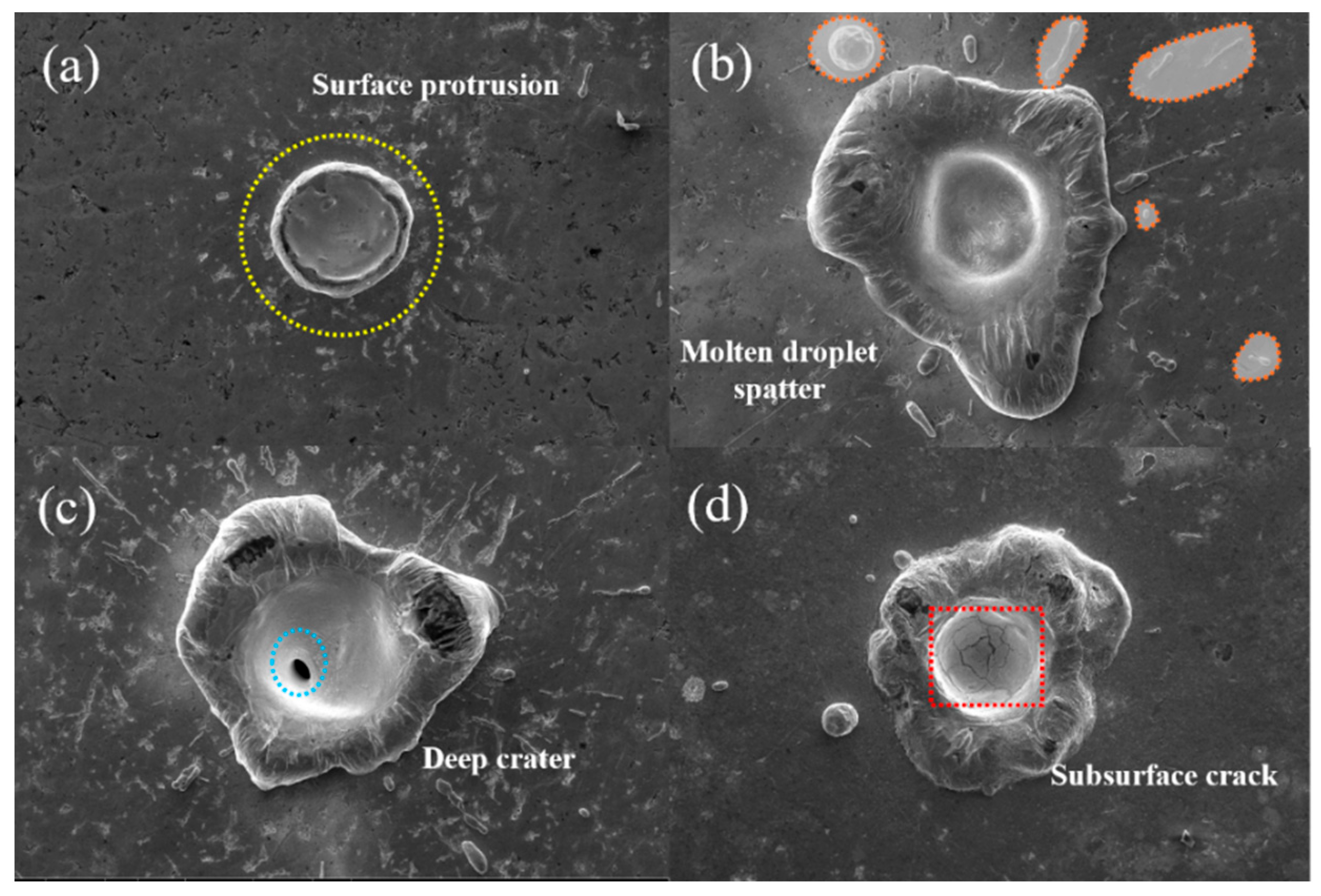

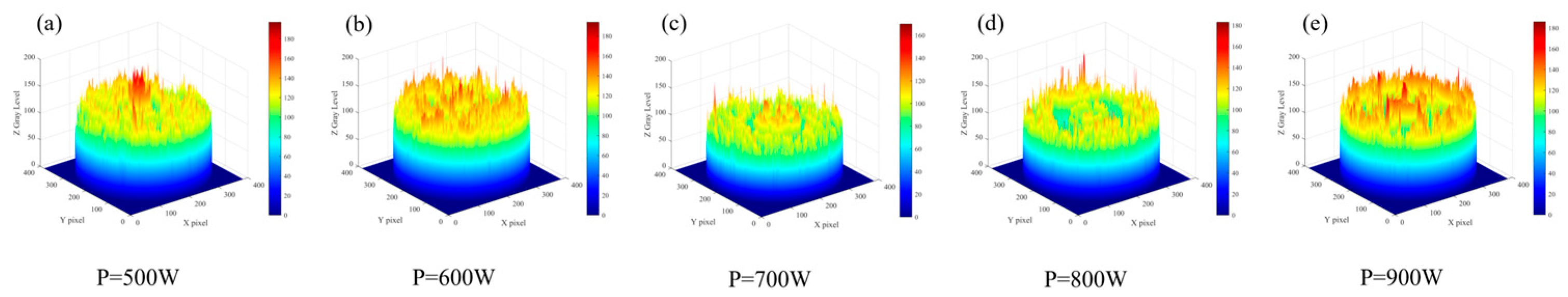

3.1.2. Surface Topography Characteristics of Laser Ablation Contacts

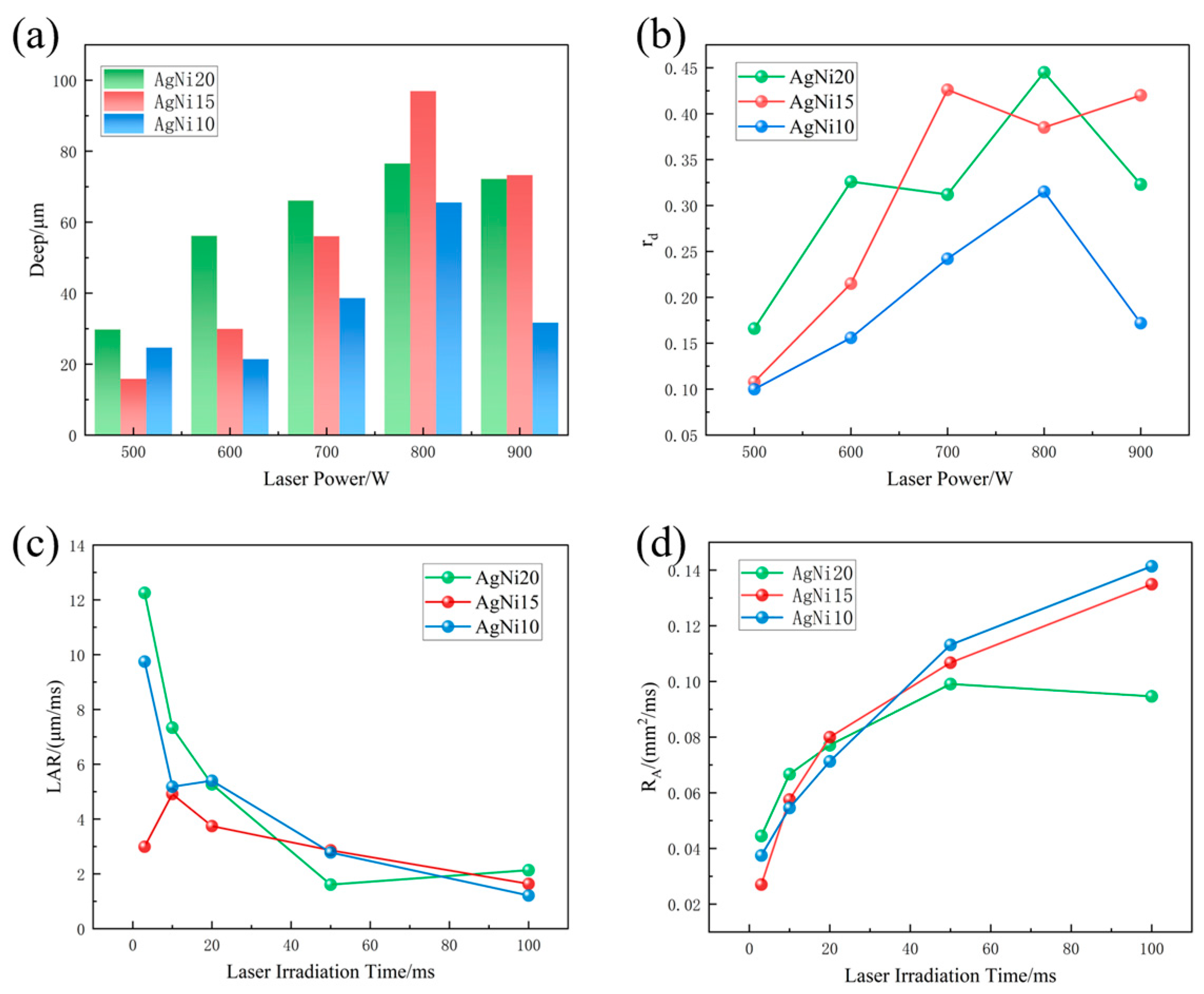

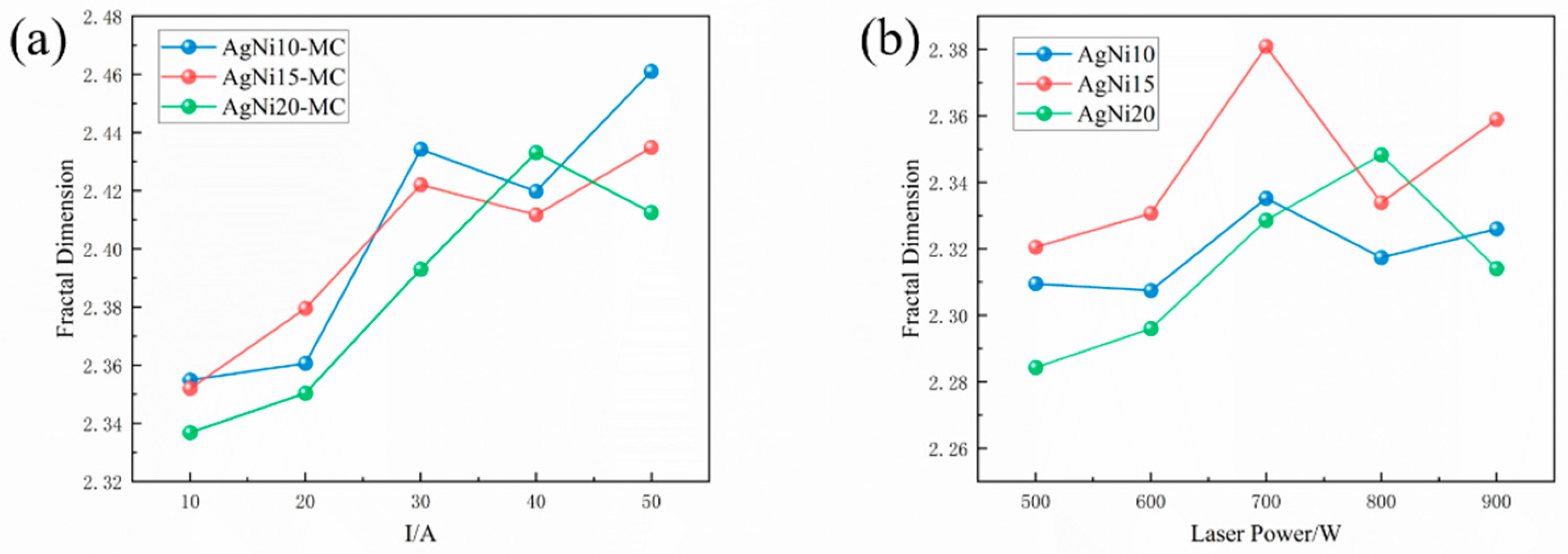

3.1.3. Analysis of Ablation Resistance

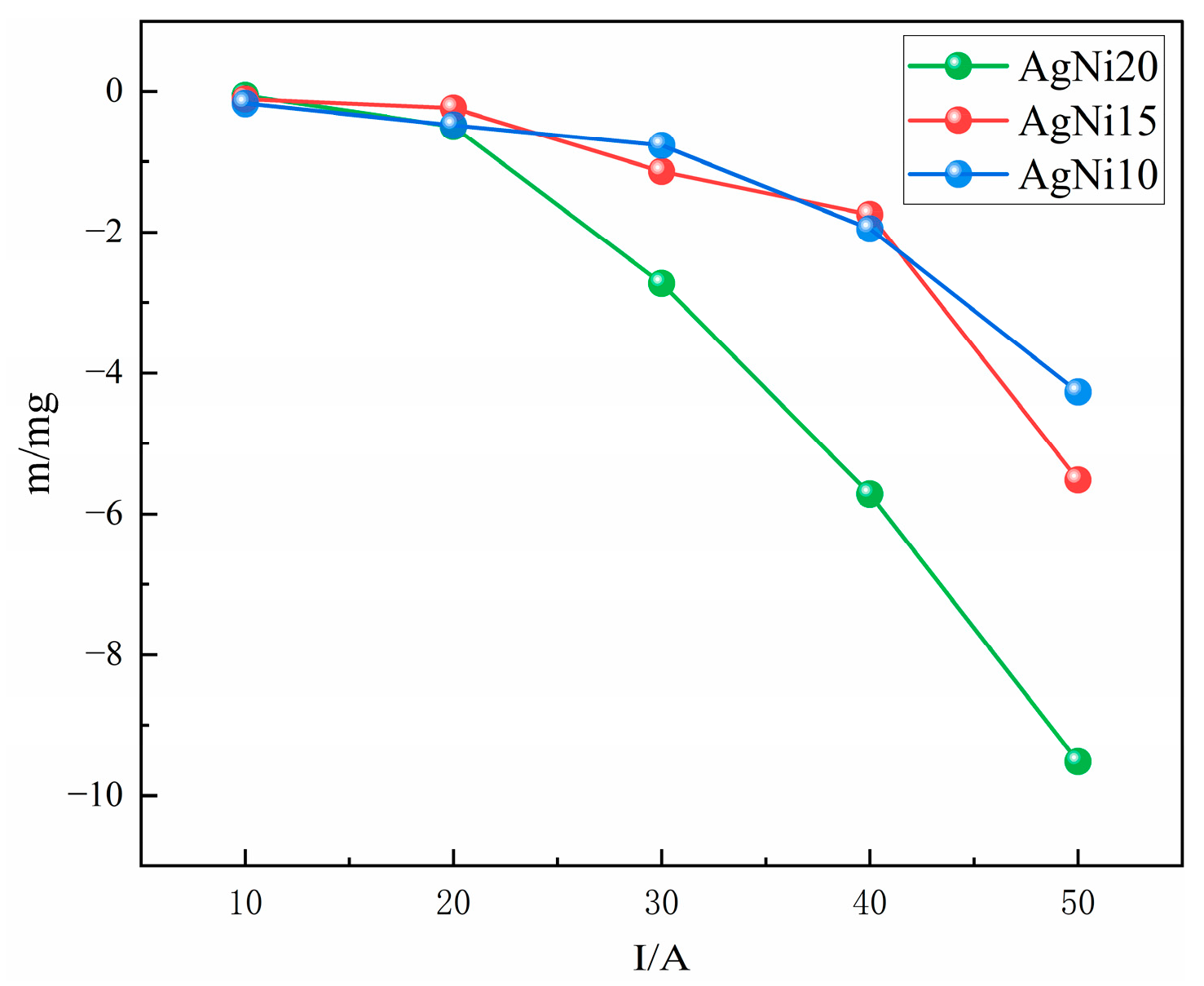

3.2. Results of Ablation Resistance of Contact Materials Under Actual Electrical Contact Test Conditions

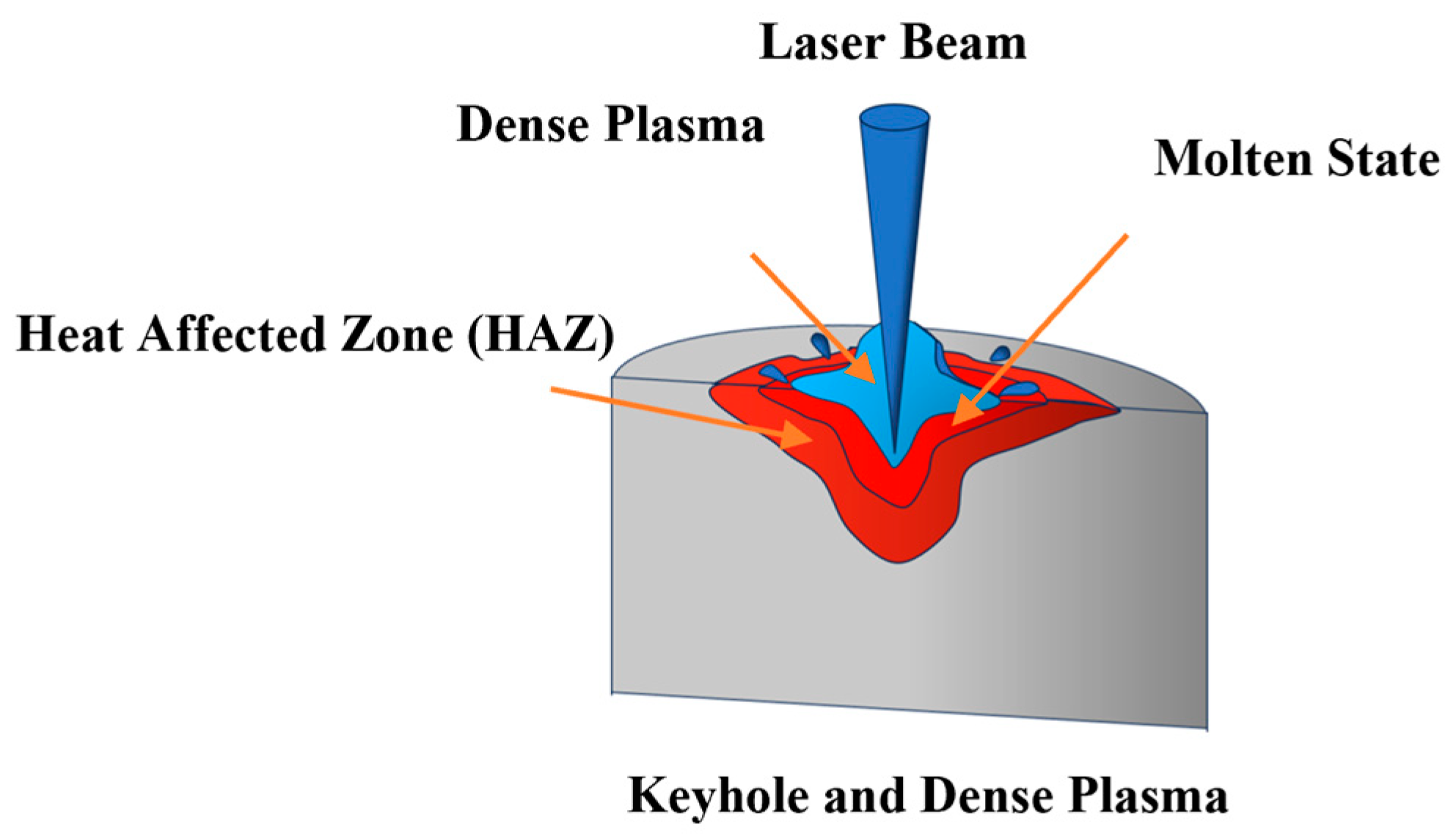

4. Analysis of Changes in Thermal Effects on the Surface of Contact Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, J.; Zhang, W.; Zhang, L.B.; He, Q.; Chen, W. Vibration Reliability Test Assessment of Electrical Connector Contacts. J. Mech. Eng. 2021, 57, 257–266. [Google Scholar]

- Yu, C.M.; Dong, W.J.; Lu, K.F.; Li, X.; Li, R.; Ge, Y. Analysis of flexibility requirements and key technologies for aerospace control systems. Aerosp. Control 2025, 43, 1–7. [Google Scholar]

- Zhang, P.; Guo, B.; Zhou, S.; Zhang, Z.; Li, W. Study on sliding wear characteristics of tungsten carbide particle reinforced copper matrix composites under electrical contact. Tribol. Trans. 2023, 66, 292–301. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, W.; Wen, S.; Liu, X. Three dimensional graphene/copper dual networks as composite conductors with enhanced current carrying capacity. ACS Appl. Nano Mater. 2024, 7, 8164–8174. [Google Scholar] [CrossRef]

- Ma, G.; Wang, D.; Liu, Z.; Bi, S.; Zan, Y.; Xiao, B.; Ma, Z. Effect of hot pressing temperature on microstructure and tensile properties of SiC/Al-Zn-Mg-Cu composites. Acta Met. Metall. Sin. 2019, 55, 1319–1328. [Google Scholar]

- Zhai, G.F.; Cui, X.L.; Yang, W.Y. Review on the development of electromagnetic relay products and research technologies. Electr. Energy Manag. Technol. 2016, 2, 1–8. [Google Scholar]

- Volm, D.; Winkler, F. Development of a compact relay for high voltage switching of up to 1000V and 40A. In Proceedings of the 27th International Conference on Electrical Contacts ICEC 2014, Dresden, Germany, 22–26 June 2014; VDE: Frankfurt am Main, Germany, 2014; pp. 1–5. [Google Scholar]

- Wang, H.; Cai, Q.; Wang, J.; Zhang, Y.; Hu, D.; Wang, Y. First-principles and experimental investigations on physical properties and arc erosion behavior of metal-doped AgSnO2 electrical contact materials. Ceram. Int. 2023, 49, 26033–26048. [Google Scholar] [CrossRef]

- Fei, Y.; Wang, X.; Zhao, N.; Li, H.; Li, H.; Qiu, Y. Enhanced arc erosion and dynamic welding resistance of Ag-10 wt% Ni@ Gr contact material. Ceram. Int. 2024, 50, 21989–22000. [Google Scholar] [CrossRef]

- Gao, J.F.; He, S.; Xia, Y.; Ding, Y.; Wang, K.; Long, Y.; Ruan, W.; Duan, M.; Pang, Z. Research and application progress of silver-based contact materials for low-voltage electrical appliances. J. Funct. Mater. 2024, 55, 6053–6061. [Google Scholar]

- Yuan, X.; Fu, F.; He, R. Graphene-enhanced silver composites for electrical contacts: A review. J. Mater. Sci. 2024, 59, 3762–3779. [Google Scholar] [CrossRef]

- Huang, R.; Qiong, W.U.; Meng, Y. Influence of operation number on arc erosion behavior of Ag/Ni electrical contact materials. Trans. Nonferrous Met. Soc. China 2022, 32, 2681–2695. [Google Scholar] [CrossRef]

- Guo, Y. Progress in Cu_based Contact Materials of Low Voltage Apparatus. Electr. Eng. Mater. 2011, 3, 10–13. [Google Scholar]

- Sexton, L.; Lavin, S.; Byrne, G.; Kennedy, A. Laser cladding of aerospace materials. J. Mater. Process. Technol. 2002, 122, 63–68. [Google Scholar] [CrossRef]

- Mi, G.; Xiong, L.; Wang, C.; Hu, X.; Wei, Y. A thermal-metallurgical-mechanical model for laser welding Q235 steel. J. Mater. Process. Technol. 2016, 238, 39–48. [Google Scholar] [CrossRef]

- Shanmugarajan, B.; Sathiya, P.; Buvanashekaran, G. Mechanical and metallurgical properties of autogenous laser welded P92 material. J. Manuf. Process. 2016, 24, 11–18. [Google Scholar] [CrossRef]

- Ma, C.; Gu, D.; Dai, D.; Zhang, H.; Zhang, H.; Yang, J.; Guo, M.; Du, Y.; Gao, J. Microstructure evolution and high-temperature oxidation behaviour of selective laser melted TiC/TiAl composites. Surf. Coat. Technol. 2019, 375, 534–543. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Q.; Wang, J.; Guo, M.; Hou, H. Exploration of the influence mechanism of La doping on the arc erosion resistance of Ag/SnO2 contact materials by a laser-simulated arc. J. Mater. Eng. Perform. 2021, 30, 7577–7583. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Q.; Wang, J.; Hou, H. How Cu doping improves the interfacial wettability between Ag and SnO2 of Ag/SnO2 contact material. J. Alloys Compd. 2019, 792, 1248–1254. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, H.; Wang, J.; Fu, C.; Chang, Y. Effect of CuO additives on the formation of SnO2-rich layers in Ag-SnO2 materials. J. Alloys Compd. 2019, 770, 920–925. [Google Scholar] [CrossRef]

- Dong, B.W.; Wu, Z.P.; Jie, J.C.; Kang, H.J.; Li, T.J. Study on microstructure and anti-ablation mechanism of Cu-W alloy for electrical contacts. Copp. Eng. 2023, 4, 63–70. [Google Scholar]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Mohanty, A.; Mohanty, S.K.; Mohapatra, A.G. Real-time monitoring and fault detection in AI-enhanced wastewater treatment systems. In The AI Cleanse: Transforming Wastewater Treatment Through Artificial Intelligence: Harnessing Data-Driven Solutions; Springer: Berlin/Heidelberg, Germany, 2024; pp. 165–199. [Google Scholar]

- Haque, R.; Bajwa, A.; Siddiqui, N.A.; Ahmed, I. Predictive Maintenance in Industrial Automation: A Systematic Review of IOT Sensor Technologies and AI Algorithms. Am. J. Interdiscip. Stud. 2024, 5, 1–30. [Google Scholar] [CrossRef]

- Wang, H.; Wen, Q.L.; Huang, H.; Huang, G.; Jiang, F.; Lu, J.; Wu, X. Study on ablation characteristics and mechanism of CVD single crystal diamond processed by femtosecond laser. Acta Photonica Sin. 2023, 52, 51–65. [Google Scholar]

- Maddu, S.; Srivastava, T.; Katari, N.K.; Merugu, K.; Gundla, R.; Krishna Mohan, S. Studies on ablative performance of silicone low-density ablative material. Silicon 2023, 15, 3599–3608. [Google Scholar] [CrossRef]

- Tavares, A.; Di Lorenzo, E.; Cornelis, B.; Peeters, B.; Desmet, W.; Gryllias, K. Machine Learning approaches to damage detection in composite structures combining experimental and simulation domains. Mech. Syst. Signal Process. 2024, 215, 111412. [Google Scholar] [CrossRef]

- Versaci, M.; Laganà, F.; Morabito, F.C.; Palumbo, A.; Angiulli, G. Adaptation of an Eddy Current Model for Characterizing Subsurface Defects in CFRP Plates Using FEM Analysis Based on Energy Functional. Mathematics 2024, 12, 2854. [Google Scholar] [CrossRef]

- Sztankovics, I. Preliminary study on the function-defining 3D surface roughness parameters in tangential turning. Int. J. Integr. Eng. 2023, 15, 72–81. [Google Scholar] [CrossRef]

- Wang, C.; Yong, R.; Luo, Z.; Du, S.; Karakus, M.; Huang, C. A novel method for determining the three-dimensional roughness of rock joints based on profile slices. Rock. Mech. Rock. Eng. 2023, 56, 4303–4327. [Google Scholar] [CrossRef]

- Zhou, F.F.; Yin, N.; Wu, Z.S.; Song, S.Y.; Ju, P.F.; Zhang, Z.N. Research Progress on Electrical Contact Performance Based on Rough Surface Feature Analysis. China Surface Engineering. pp. 1–24. Available online: https://link.cnki.net/urlid/11.3905.tg.20250321.1101.004 (accessed on 11 August 2025).

- GB/T 33523.2-2017; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. China Standards Press: Beijing, China, 2017.

- Huang, J.; Zhou, Y.; Luo, Y. Representing topological self-similarity using fractal feature maps for accurate segmentation of tubular structures. In Proceedings of the European Conference on Computer Vision, Milan, Italy, 29 September–4 October 2024; Springer: Berlin/Heidelberg, Germany, 2024; pp. 143–160. [Google Scholar]

- Guida, G.; Viggiani, G.M.B.; Casini, F. Multi-scale morphological descriptors from the fractal analysis of particle contour. Acta Geotech. 2020, 15, 1067–1080. [Google Scholar] [CrossRef]

- Bian, L. Multiscale nature of spatial data in scaling up environmental models. In Scale in Remote Sensing and GIS; Routledge: Abingdon-on-Thames, UK, 2023; pp. 13–26. [Google Scholar]

- Rancu, A.; Chen, C.X.; Price, H.; Wax, A. Multiscale optical phase fluctuations link disorder strength and fractal dimension of cell structure. Biophys. J. 2023, 122, 1390–1399. [Google Scholar] [CrossRef]

- Maduabuchi, C. Thermo-mechanical optimization of thermoelectric generators using deep learning artificial intelligence algorithms fed with verified finite element simulation data. Appl. Energy 2022, 315, 118943. [Google Scholar] [CrossRef]

- Pratticò, D.; Laganà, F.; Oliva, G.; Fiorillo, A.S.; Pullano, S.A.; Calcagno, S.; De Carlo, D.; La Foresta, F. Integration of LSTM and U-Net models for monitoring electrical absorption with a system of sensors and electronic circuits. IEEE Trans. Instrum. Meas. 2025, 74, 2533311. [Google Scholar] [CrossRef]

| Test Sample | Specification Comparison | Test Conditions | Test Name | |

|---|---|---|---|---|

| Variable Power | Times Change | |||

| AgNi10/Cu AgNi15/Cu AgNi20/Cu |  | Laser Power/W | 500, 600, 700, 800, 900 | 600 |

| Action Time/ms | 3 | 3, 10, 20, 50, 100 | ||

| Diameter of light spot/mm | 0.195 | |||

| Contact Material | Average Diameter (μm) | (%) |

|---|---|---|

| AgNi10 | 81.00 | 3.78 |

| AgNi15 | 79.00 | 3.98 |

| AgNi20 | 84.00 | 2.56 |

| Test Conditions | Test Parameters |

|---|---|

| Test Voltage | AC 220 V |

| Test Current | 10 A, 20 A, 30 A, 40 A, 50 A |

| Movements’ Num. | 3000 times |

| Contact Pressure | 1.5 N |

| Test Method | Open & Close Experiment |

| Connection Time | 1 s |

| Breaking Distance | 2 mm |

| Test Sample | AgNi10 | AgNi15 | AgNi20 |

|---|---|---|---|

| r | 0.8467 | 0.7884 | 0.9201 |

| Comparison Dimension | Laser Ablation-Based Method | AI-Enhanced Embedded Monitoring |

|---|---|---|

| Main Stimulus Input | Pulsed laser (thermal excitation) | Electrical load (voltage/current) |

| Diagnostic Focus | Surface morphology evolution (cracks, roughness) | Electrical absorption dynamics |

| Output Parameters | Depth, ablation rate, fractal dimension, area | Impedance, signal waveform, transient voltage/current |

| Analysis Methodology | Statistical + morphology feature extraction | LSTM + U-Net deep learning pipeline |

| Instrumentation Required | Laser, SEM, profilometer, IR camera | Embedded sensors, ADCs, microcontrollers |

| Temporal Resolution | Post-process, quasi-static | Real-time |

| Main Application Scenario | Material screening under thermal load | Predictive maintenance, fault detection |

| Core Advantage | Controlled energy input, clear surface evolution | High sensitivity to electrical behavior |

| Integration Potential | Expandable to multi-modal sensor systems | Compatible with broader sensing ecosystems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, L.; Li, W.; Lu, M.; Jin, B.; Ji, Y.; Ma, R.; Miao, S.; Zhang, X.; Luo, T. Research on the Application of Laser Ablation in the Rapid Detection of Ablation Resistance on the Surface of AgNi Contact Materials. Appl. Sci. 2025, 15, 8961. https://doi.org/10.3390/app15168961

Wang Y, Liu L, Li W, Lu M, Jin B, Ji Y, Ma R, Miao S, Zhang X, Luo T. Research on the Application of Laser Ablation in the Rapid Detection of Ablation Resistance on the Surface of AgNi Contact Materials. Applied Sciences. 2025; 15(16):8961. https://doi.org/10.3390/app15168961

Chicago/Turabian StyleWang, Yun, Lintao Liu, Wenhua Li, Mingyu Lu, Bokai Jin, Yuxuan Ji, Rui Ma, Shuhua Miao, Xuanwei Zhang, and Tianai Luo. 2025. "Research on the Application of Laser Ablation in the Rapid Detection of Ablation Resistance on the Surface of AgNi Contact Materials" Applied Sciences 15, no. 16: 8961. https://doi.org/10.3390/app15168961

APA StyleWang, Y., Liu, L., Li, W., Lu, M., Jin, B., Ji, Y., Ma, R., Miao, S., Zhang, X., & Luo, T. (2025). Research on the Application of Laser Ablation in the Rapid Detection of Ablation Resistance on the Surface of AgNi Contact Materials. Applied Sciences, 15(16), 8961. https://doi.org/10.3390/app15168961