Vision-Based Closed-Loop Control of Pulsed MAG Welding Using Otsu-Segmented Arc Features

Abstract

1. Introduction

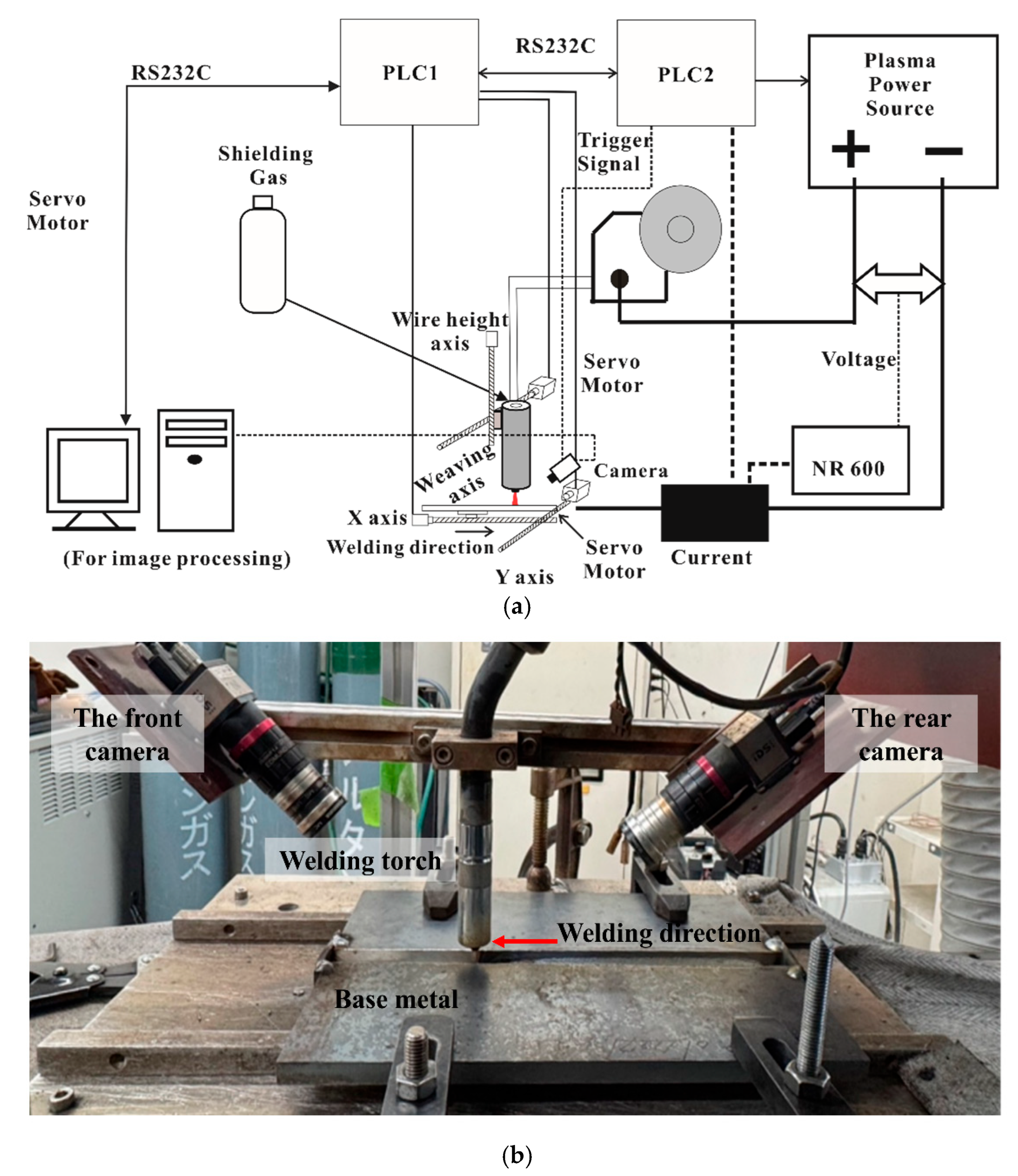

2. Designed Welding Control System and Utilized Materials

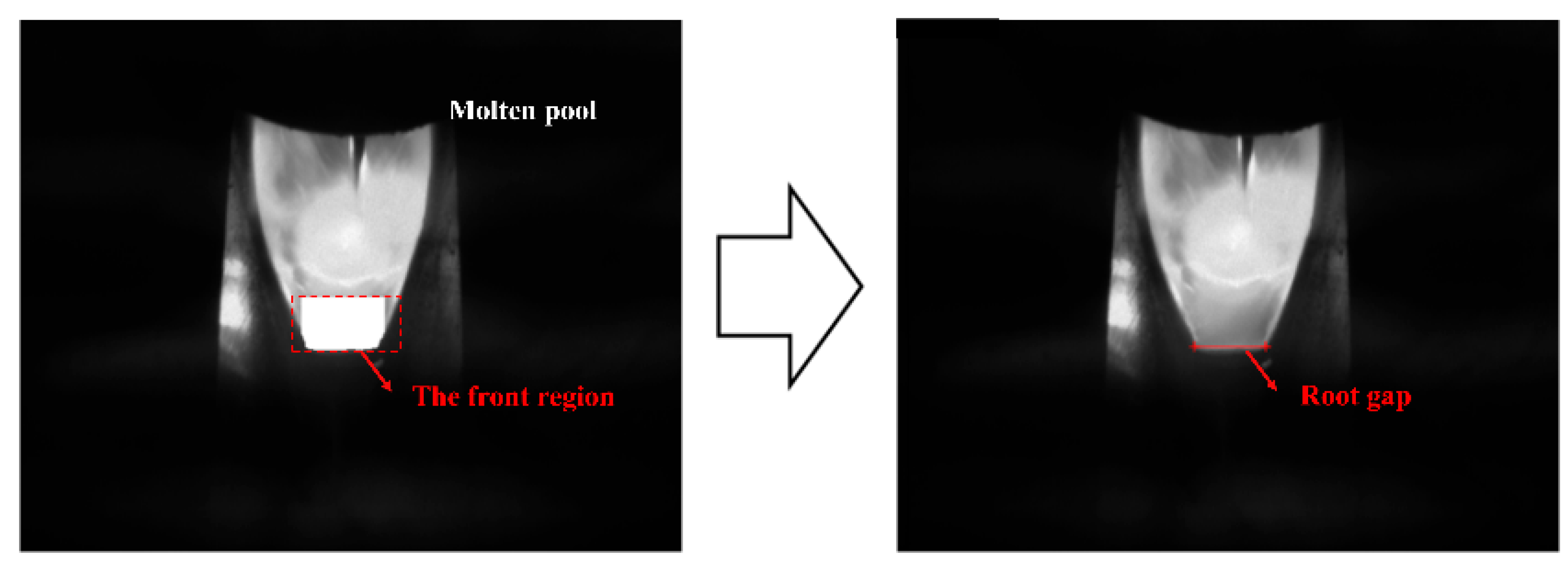

3. Molten Pool Observation and Image Processing for Arc Center Position

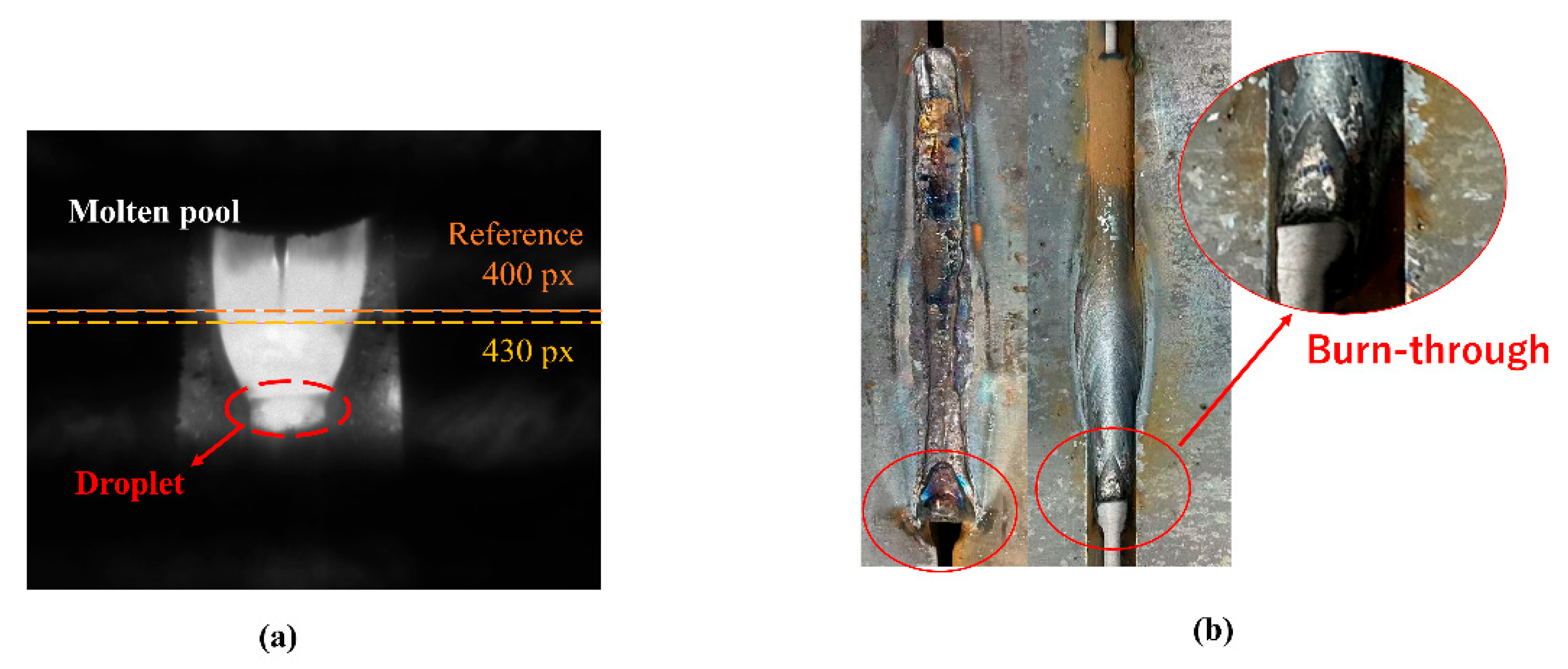

3.1. Basic Physical Phenomenon Analysis of the Molten Pool

3.2. Proposed Image Processing Method for Detecting the Arc’s Center Position

3.3. Proposed Control Method

4. Control-Oriented System Design and Experiment Validation

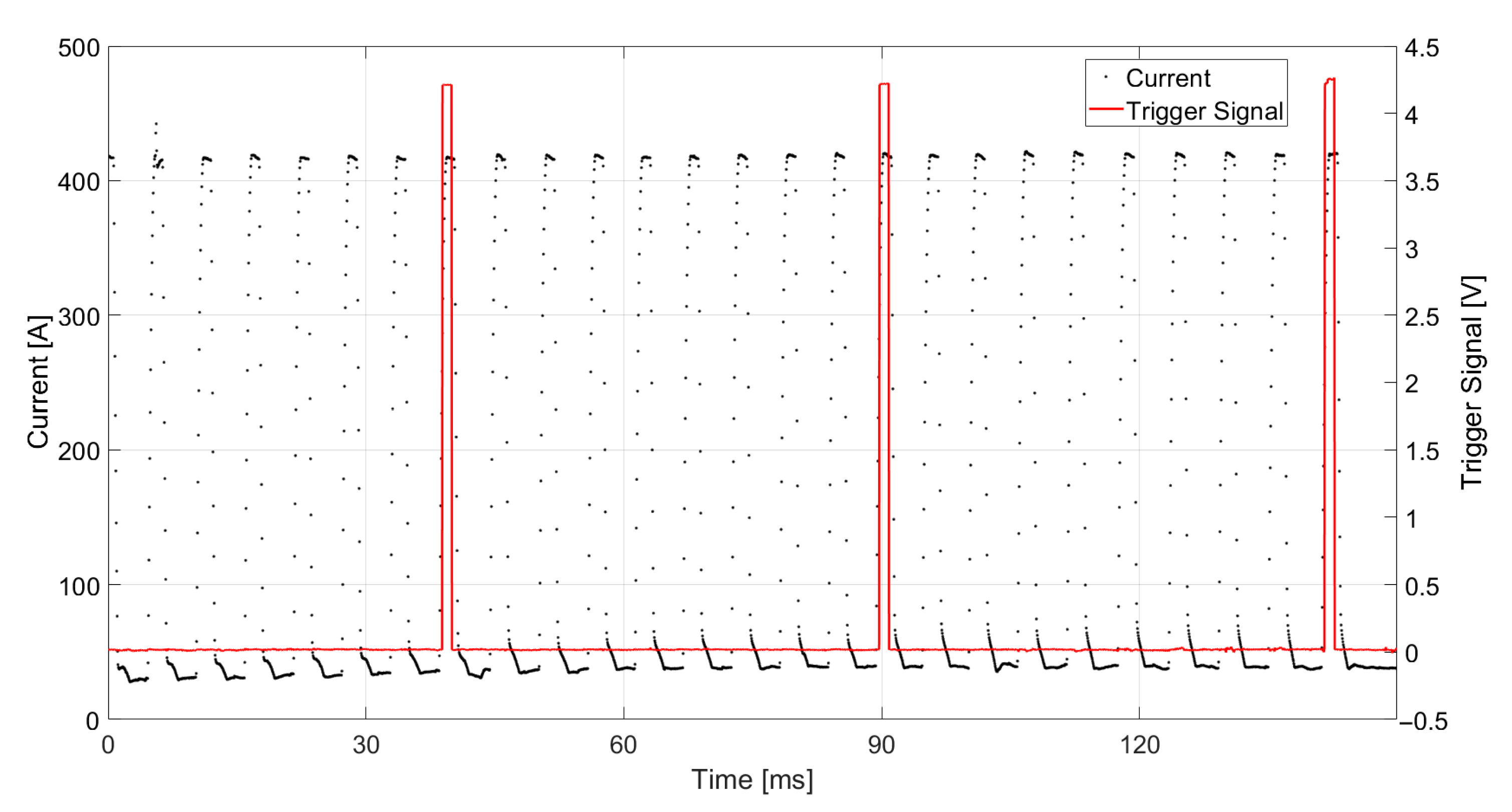

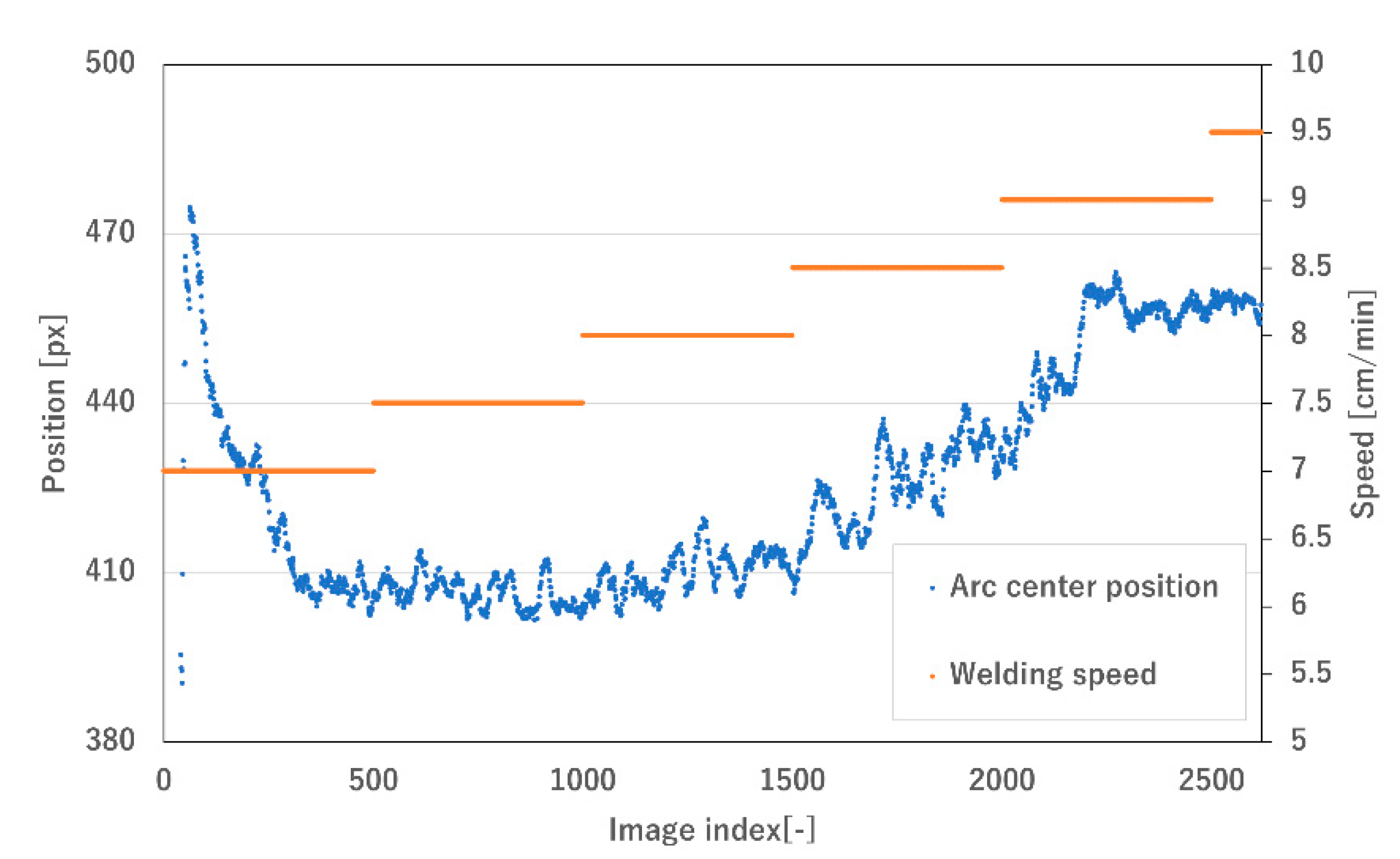

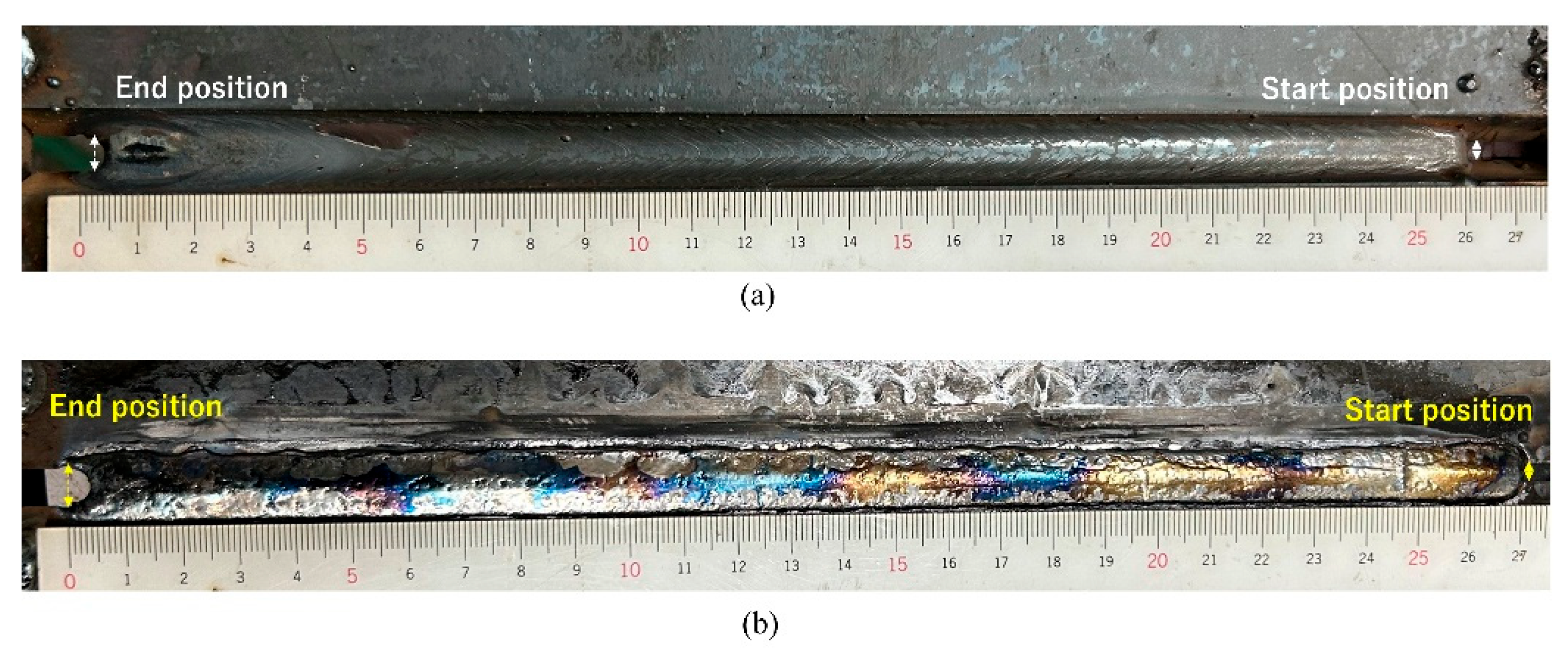

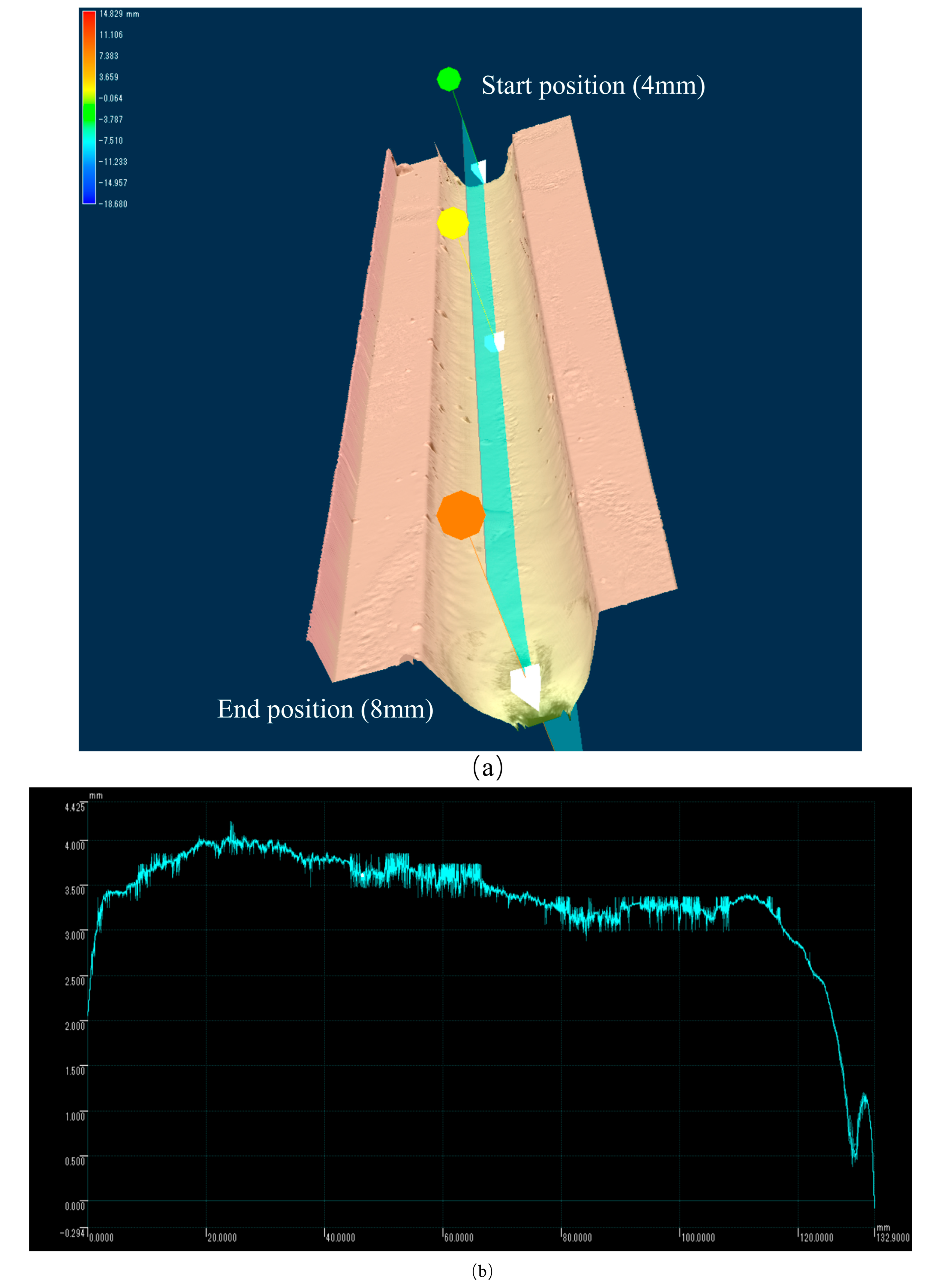

4.1. Fundamental Pulsed MAG Experiments

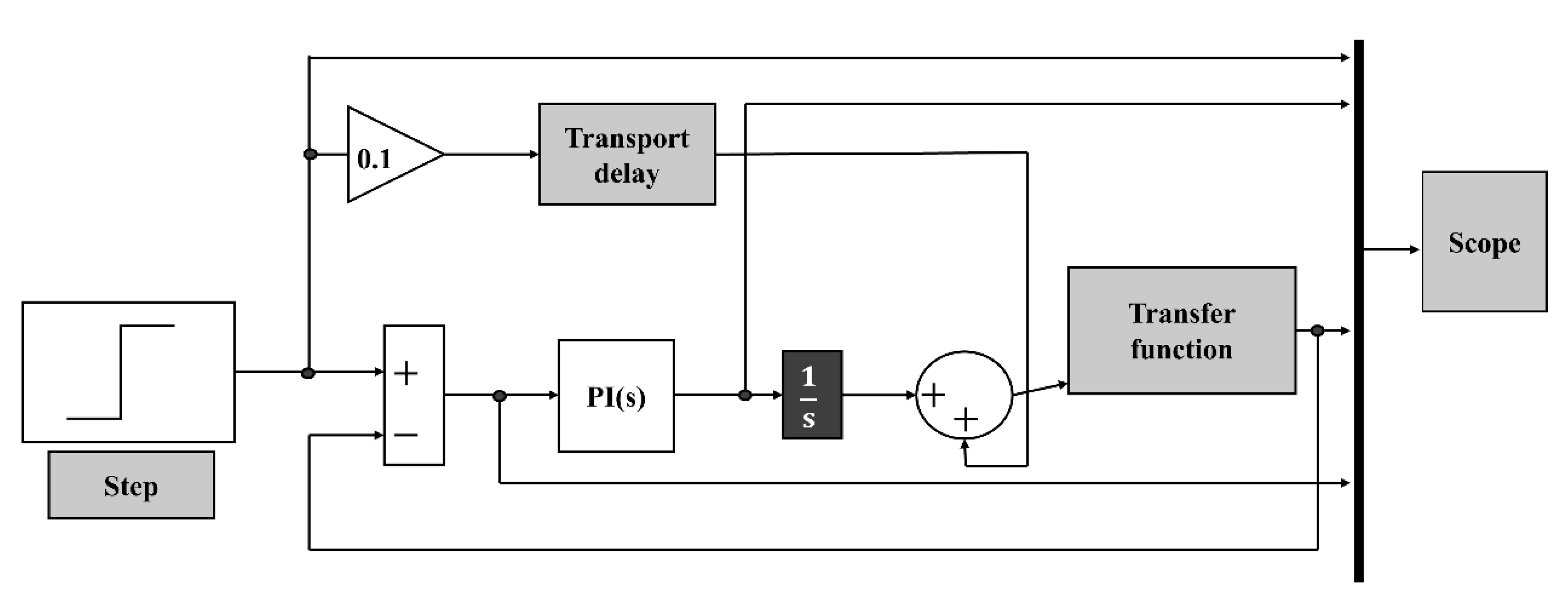

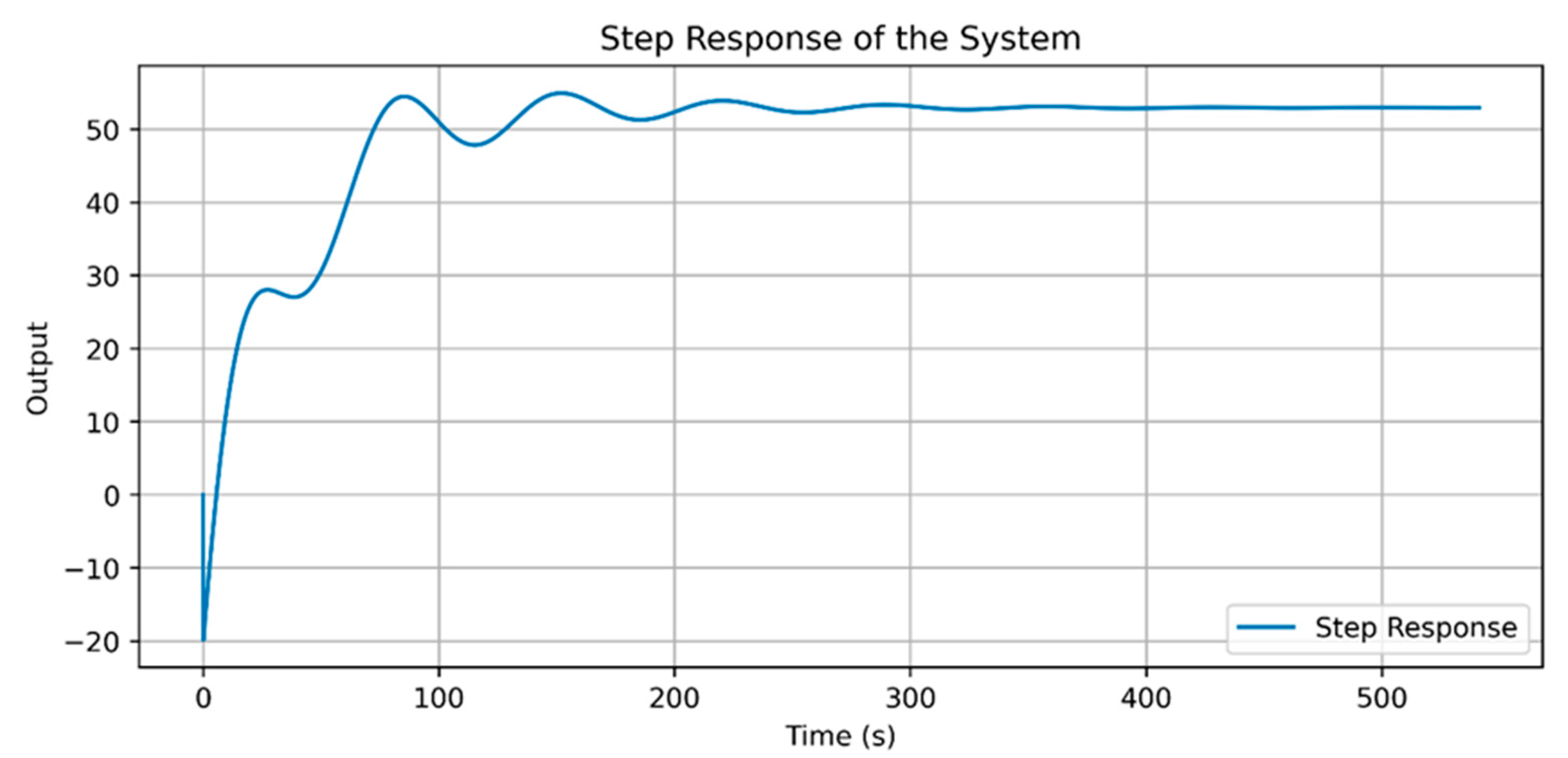

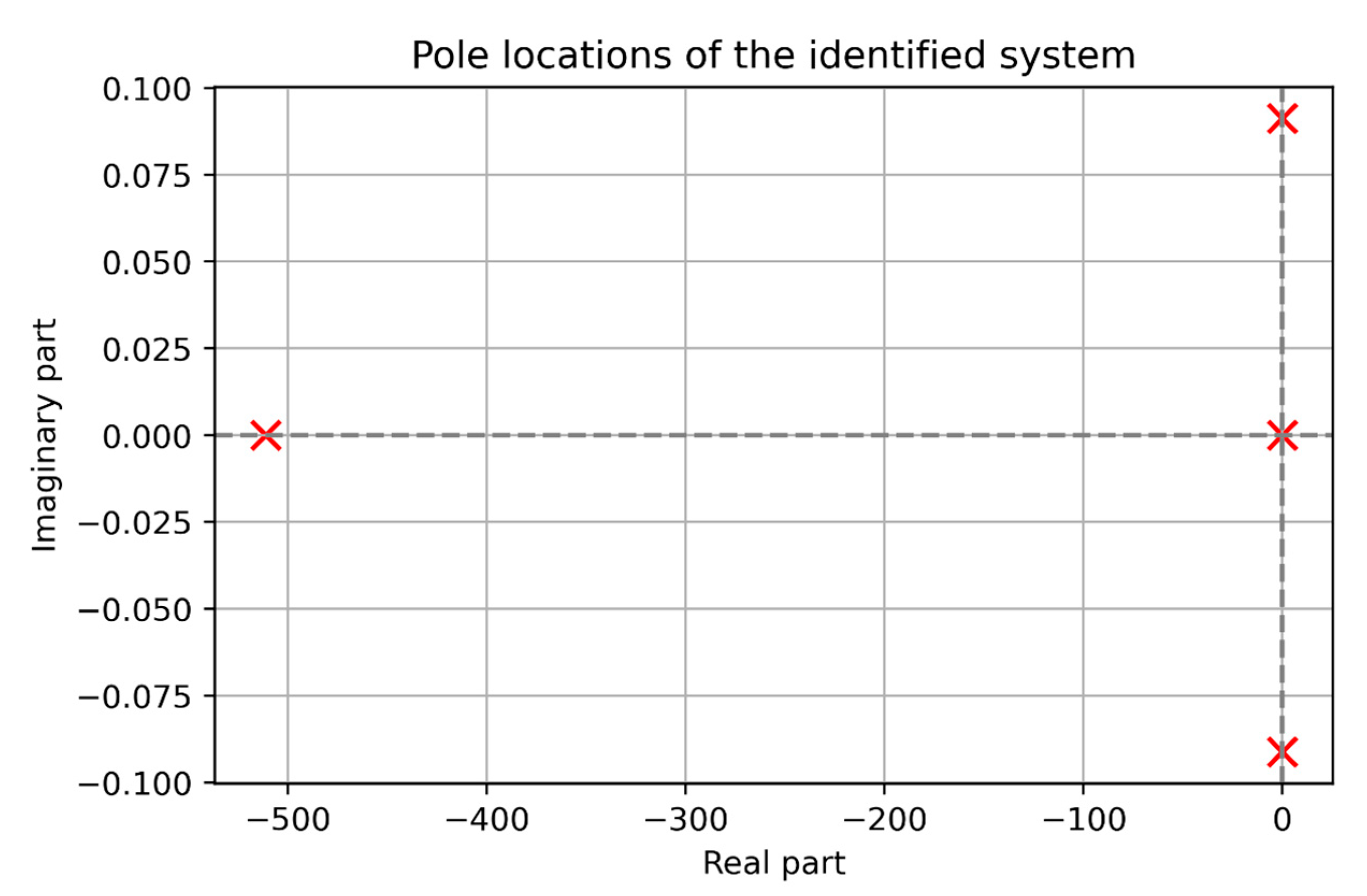

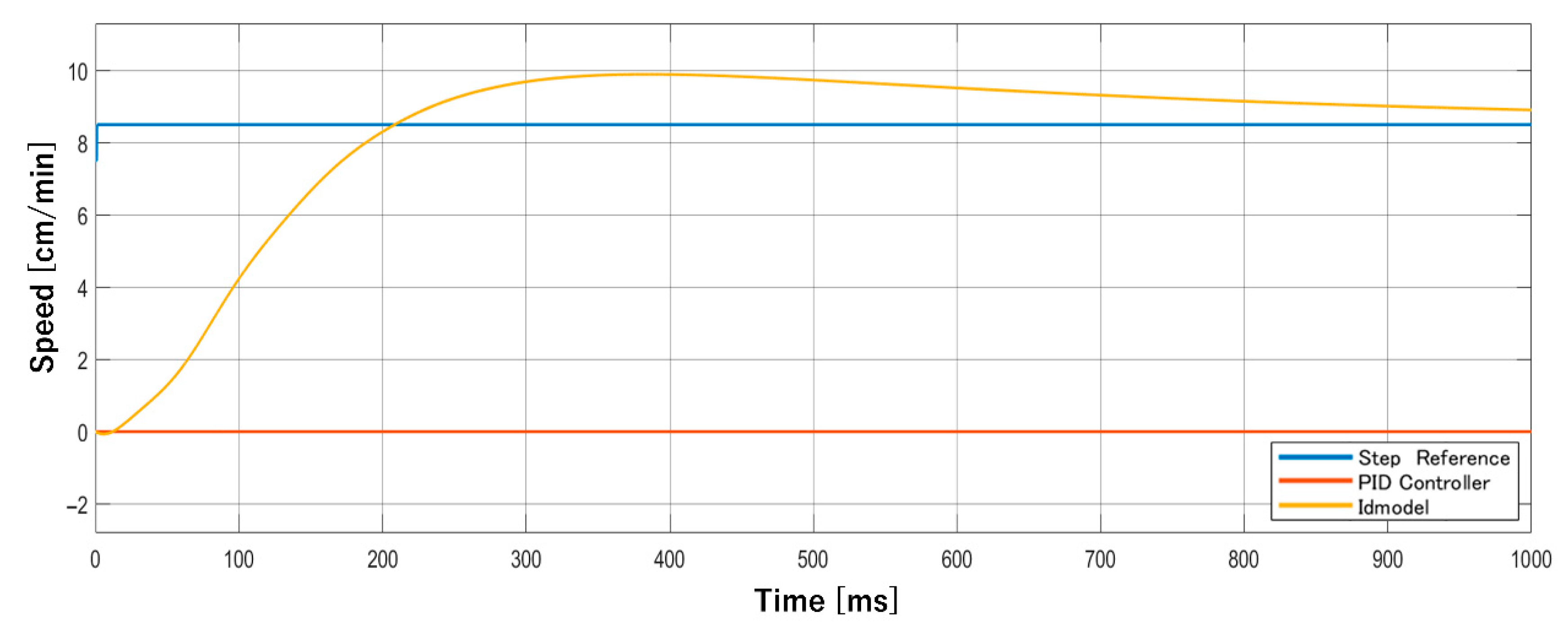

4.2. Proposed Control Experiment Simulation Based on PI Controller

4.3. Real-Time Welding Visual Feedback Control Experiments

5. Analysis of Control Experimental Results and Discussion

5.1. Bead Fluctuation Analysis After Visual Feedback Control Implementation

5.2. Experimental Observations and Practical Considerations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scotti, F.M.; Pudenz, M.; Perrin, S.; Siewert, E.; Bergmann, J.P. Heat input control in horizontal lap joint welding through active wire preheating in GMAW-P. Weld. World 2024, 68, 893–904. [Google Scholar] [CrossRef]

- Li, T.; Cao, Y.; Zhang, Y. Analysis of weld pool region constituents in GMAW for dynamic reconstruction through characteristic enhancement and LSTM U-Net networks. J. Manuf. Process. 2024, 127, 573–588. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Y. Control of DE-GMAW through human–robot collaboration. Weld. World 2025, 69, 1459–1468. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, C.; Pan, Z.; Wang, Z.; Liu, L.; Qi, X.; Mao, S.; Pan, J. Image Segmentation Approaches for Weld Pool Monitoring during Robotic Arc Welding. Appl. Sci. 2018, 8, 2445. [Google Scholar] [CrossRef]

- Montero Puñales, E.M.; Absi Alfaro, S.C. Stability on the GMAW Process. In Welding—Modern Topics; Kovacevic, R., Ed.; IntechOpen: London, UK, 2021; pp. 1–12. [Google Scholar]

- Ohara, T.; Kuroda, S.; Tanaka, M. A new approach to controlling metal transfer by dynamic modification in gas composition of arc atmosphere—Studies on pulsed gas MAG welding. Weld. World 2020, 64, 1185–1195. [Google Scholar] [CrossRef]

- Wang, B.; Hu, S.J.; Sun, L.; Freiheit, T. Intelligent welding system technologies: State-of-the-art review and perspectives. J. Manuf. Syst. 2020, 56, 373–391. [Google Scholar] [CrossRef]

- Zhai, P.; Xue, S.; Wang, J.; Tao, Y.; Chen, T.; Ji, S. Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW. Metals 2020, 10, 611. [Google Scholar] [CrossRef]

- Rezende, R.F.; Arias, A.R.; Lima, E.J.; Coelho, F.G.F. Pulsed GMAW-Based WAAM–Influence of droplet detachment mode on the geometry and mechanical properties of 308 L stainless steel. J. Adv. Join. Process. 2025, 11, 100286. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K. Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. J. Mater. Eng. Perform. 2011, 20, 918–931. [Google Scholar] [CrossRef]

- Pan, Y.; Li, C.; Shi, Y.; Dai, Y.; Wang, W. Predictive analysis and feature extraction of weld penetration in P-GMAW based on interpretable deep learning. J. Manuf. Process. 2024, 124, 1506–1518. [Google Scholar] [CrossRef]

- Chen, T.; Xue, S.; Zhai, P.; Wang, B.; Long, W. Study on Penetration Sensing Method Based on Pool Oscillation and Arc Voltage during Pulsed GMAW. Appl. Sci. 2020, 10, 2735. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Song, H.S.; Saeed, G. Observation of a dynamic specular weld pool surface. Meas. Sci. Technol. 2006, 17, L9. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K. Monitoring of Weld Penetration Using Arc Acoustics. Mater. Manuf. Process. 2011, 26, 684–693. [Google Scholar] [CrossRef]

- Bai, P.; Wang, Z.; Hu, S.; Ma, S.; Liang, Y. Sensing of the weld penetration at the beginning of pulsed gas metal arc welding. J. Manuf. Process. 2017, 28, 343–350. [Google Scholar] [CrossRef]

- Yu, R.; Han, J.; Bai, L.; Zhao, Z. Identification of butt welded joint penetration based on infrared thermal imaging. J. Mater. Res. Technol. 2021, 12, 1486–1495. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, R.; Zhou, Q.; Chen, H.; Yuan, W.; Zhang, Y. Real-Time sensing of gas metal arc welding process—A literature review and analysis. J. Manuf. Process. 2021, 70, 452–469. [Google Scholar] [CrossRef]

- Mattera, G.; Polden, J.; Norrish, J. Monitoring the gas metal arc additive manufacturing process using unsupervised machine learning. Weld. World 2024, 68, 2853–2867. [Google Scholar] [CrossRef]

- Li, C.; Wang, J.; Dai, Y.; Shi, Y. Experimental validation of saliency maps for understanding deep neural networks for weld penetration prediction. J. Manuf. Process. 2023, 88, 22–33. [Google Scholar] [CrossRef]

- Chen, C.; Lv, N.; Chen, S. Welding penetration monitoring for pulsed GTAW using visual sensor based on AAM and random forests. J. Manuf. Process. 2021, 63, 152–162. [Google Scholar] [CrossRef]

- Wang, W.; Yamane, S.; Wang, Q.; Shan, L.; Zhang, X.; Wei, Z.; Yan, Y.; Song, Y.; Numazawa, H.; Lu, J.; et al. Visual sensing and quality control in plasma MIG welding. J. Manuf. Process. 2023, 86, 163–176. [Google Scholar] [CrossRef]

- Yang, W.; Xiao, Y.; Shen, H.; Wang, Z. Generalized weld bead region of interest localization and improved faster R-CNN for weld defect recognition. Measurement 2023, 222, 113619. [Google Scholar] [CrossRef]

- Dai, W.; Li, D.; Zheng, Y.; Wang, D.; Tang, D.; Wang, H.; Peng, Y. Online quality inspection of resistance spot welding for automotive production lines. J. Manuf. Syst. 2022, 63, 354–369. [Google Scholar] [CrossRef]

- Xia, L.; Zhou, J.; Xue, R.; Li, X.; Liu, H. Real-Time seam tracking during narrow gap GMAW process based on the wide dynamic vision sensing method. J. Manuf. Process. 2023, 101, 820–834. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Li, Y.; Wang, P. Weld penetration control using passive vision sensing and image processing. J. Manuf. Process. 2021, 64, 679–688. [Google Scholar]

- Biber, A.; Sharma, R.; Reisgen, U. Robotic welding system for adaptive process control in gas metal arc welding. Weld. World 2024, 68, 2311–2320. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Zhang, Z.; Yamane, S.; Wang, Q.; Shan, L.; Zheng, B.; Xia, Y.; Wang, D. Seam tracking and visual welding control in lap joint welding with Otsu’s thresholding and Gaussian line detection. Weld. World 2025, in press. [Google Scholar] [CrossRef]

- JIS G 3106:2017; Rolled Steels for Welded Structure. Japanese Standards Association: Tokyo, Japan, 2017.

- ISO 9692-1:2013; Welding and Allied Processes—Recommendations for Joint Preparation—Part 1: Manual Metal Arc Welding, Gas-Shielded Metal Arc Welding, Gas Welding and Beam Welding of Steels. International Organization for Standardization: Geneva, Switzerland, 2013.

- Ogata, K. Modern Control Engineering, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Hayter, A.J. Probability and Statistics for Engineers and Scientists, 4th ed.; Duxbury: Boston, MA, USA, 2012. [Google Scholar]

- ISO 5817:2014; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys—Quality Levels for Imperfections. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- Li, D.; Wang, M.; Wang, S.; Zhao, H. Research and development of weld tracking system based on laser vision. Meas. Control. 2022, 55, 1124–1133. [Google Scholar] [CrossRef]

- Seo, B.W.; Kim, D.Y.; Kim, C.; Kim, S.; Cho, Y.T. Development of seam tracking device in asynchronous tandem welding with arc sensing. Sci. Rep. 2022, 12, 18637. [Google Scholar] [CrossRef]

- Sharma, N.; Gupta, P.; Bansal, A.; Yadav, A.; Singh, H. Image processing-based seam tracking system for robotic welding applications. Sensors 2021, 21, 84. [Google Scholar]

| Element | C (max) | Mn (min) | P (max) | S (max) |

|---|---|---|---|---|

| Content | 0.23 | ≥2.5C | 0.035 | 0.035 |

| Element | C | Si | Mn | P | S | Ti |

|---|---|---|---|---|---|---|

| Content | 0.06 | 0.8 | 1.53 | 0.014 | 0.01 | 0.18 |

| Root Gap [mm] | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|

| Welding speed [cm/min] | 11.2 | 9.90 | 8.80 | 8.00 | 7.30 |

| Wire feeding speed [mm/s] | 97 | 97 | 97 | 97 | 97 |

| ) | ) | |

|---|---|---|

| Optimal value |

| 4 mm–5 mm | 5 mm–6 mm | 6 mm–7 mm | 7 mm–8 mm | Average | |

|---|---|---|---|---|---|

| Mean variance [mm2] | 0.01778 | 0.000426 | 0.008791 | 0.05165 | 0.01966 |

| Mean standard deviation [mm] | 0.0943 | 0.0146 | 0.0663 | 0.1607 | 0.0840 |

| Mean deviation [mm] | 0.0943 | 0.0146 | 0.0663 | 0.1607 | 0.0840 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Yamane, S.; Wang, W.; Tsumori, R.; Ochiai, K.; Lu, J.; Xia, Y. Vision-Based Closed-Loop Control of Pulsed MAG Welding Using Otsu-Segmented Arc Features. Appl. Sci. 2025, 15, 8950. https://doi.org/10.3390/app15168950

Luo Y, Yamane S, Wang W, Tsumori R, Ochiai K, Lu J, Xia Y. Vision-Based Closed-Loop Control of Pulsed MAG Welding Using Otsu-Segmented Arc Features. Applied Sciences. 2025; 15(16):8950. https://doi.org/10.3390/app15168950

Chicago/Turabian StyleLuo, Yuxi, Satoshi Yamane, Weixi Wang, Rei Tsumori, Kohei Ochiai, Jidong Lu, and Yuxiong Xia. 2025. "Vision-Based Closed-Loop Control of Pulsed MAG Welding Using Otsu-Segmented Arc Features" Applied Sciences 15, no. 16: 8950. https://doi.org/10.3390/app15168950

APA StyleLuo, Y., Yamane, S., Wang, W., Tsumori, R., Ochiai, K., Lu, J., & Xia, Y. (2025). Vision-Based Closed-Loop Control of Pulsed MAG Welding Using Otsu-Segmented Arc Features. Applied Sciences, 15(16), 8950. https://doi.org/10.3390/app15168950